Transparent double-component flame-retardant liquid silicone rubber perfusion material and preparation method thereof

A liquid silicone rubber, two-component technology, applied in the field of addition-type silicone rubber, can solve the problems of low tensile strength and tear strength of silicone rubber, unsuitable for electronic components, and ineffective flame retardancy, etc., to improve tensile strength Strength and tear strength, improvement of mechanical vibration resistance, improvement of hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

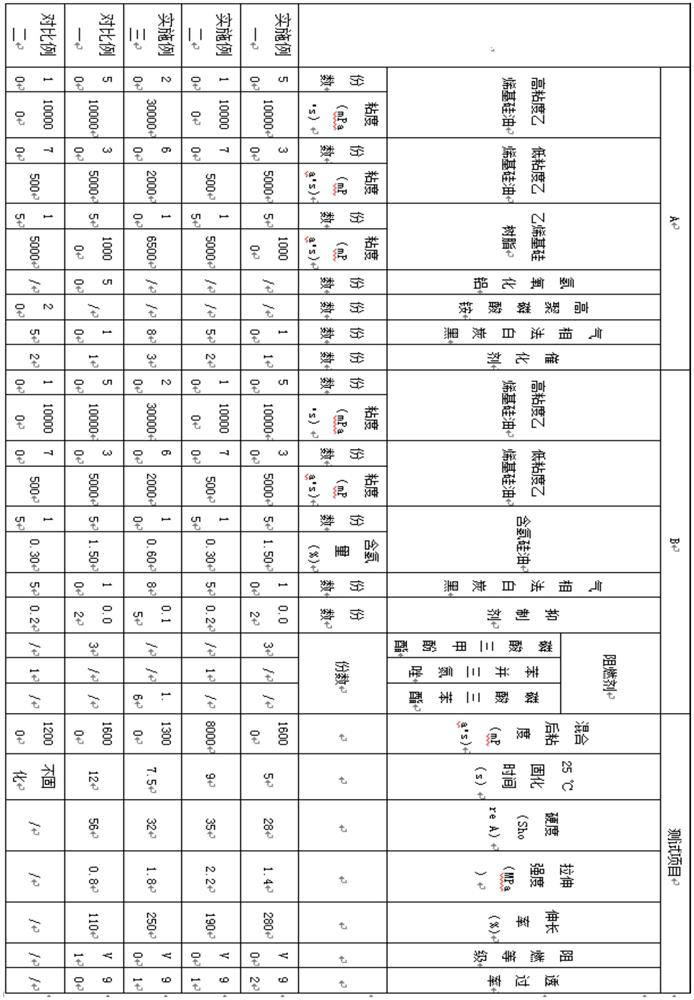

Embodiment 1

[0041] Example 1: first add 50 parts of 10000mPa·s high-viscosity vinyl silicone oil, 30 parts of 5000mPa·s low-viscosity vinyl silicone oil, and 10 parts of fumed silica into the double planetary stirring tank, stir and mix for 20min, and then add 5 parts of 10000mPa·s vinyl silicone resin and 1 part of platinum catalyst, stir and mix for 15min, and finally keep the vacuum degree in the stirring tank at -0.1MPa, remove air bubbles, and prepare A component; similarly, first mix 50 parts of 10000mPa s high-viscosity vinyl silicone oil, 30 parts of 5000mPa·s low-viscosity vinyl silicone oil, and 10 parts of fumed silica were stirred and mixed for 20 minutes to form a base material, and then 5 parts of hydrogen-containing silicone oil with a hydrogen content of 1.5%, 0.02 1 part of inhibitor and 3 parts of tricresyl phosphate, stirred and mixed for 15 minutes and kept the vacuum degree in the kettle at -0.1 MPa to remove air bubbles to obtain component B. Fill component A and com...

Embodiment 2

[0042] Example 2: first add 10 parts of 100000mPa·s high-viscosity vinyl silicone oil, 70 parts of 500mPa·s low-viscosity vinyl silicone oil, and 5 parts of fumed silica into the double planetary stirring tank, stir and mix for 20min, and then add 15 parts of 5000mPa·s vinyl silicone resin and 2 parts of platinum catalyst, stirred and mixed for 15 minutes, and finally kept the vacuum degree in the stirred tank at -0.1MPa, and removed air bubbles to prepare A component; s high-viscosity vinyl silicone oil, 70 parts of 500mPa·s low-viscosity vinyl silicone oil, and 5 parts of fumed silica were stirred and mixed for 20 minutes to form a base material, and then 15 parts of hydrogen-containing silicone oil with a hydrogen content of 0.3%, 0.2 1 part of inhibitor and 1 part of benzotriazole, stirred and mixed for 15 minutes and kept the vacuum degree in the kettle at -0.1MPa to remove air bubbles to obtain component B. Fill component A and component B into a two-component rubber tub...

Embodiment 3

[0043]Example 3: first add 20 parts of 30000mPa·s high-viscosity vinyl silicone oil, 60 parts of 2000mPa·s low-viscosity vinyl silicone oil, and 8 parts of fumed silica into the double planetary stirring tank, stir and mix for 20min, and then add Mix 10 parts of 6500mPa·s vinyl silicone resin and 3 parts of platinum catalyst for 15 minutes, and finally keep the vacuum degree in the stirred tank at -0.1MPa to remove air bubbles to obtain component A; similarly, first mix 20 parts of 30000mPa·s s high-viscosity vinyl silicone oil, 60 parts of 2000mPa·s low-viscosity vinyl silicone oil, and 8 parts of fumed silica were stirred and mixed for 20 minutes to form a base material, and then 10 parts of hydrogen-containing silicone oil with a hydrogen content of 0.6%, 0.15 parts Inhibitor and 1.6 parts of triphenyl phosphate, stir and mix for 15 minutes and keep the vacuum degree in the kettle at -0.1MPa to remove air bubbles, and obtain component B. Fill component A and component B int...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com