Anti-ultraviolet polypropylene composition and polypropylene and polypropylene film prepared from composition

A technology of polypropylene film and polypropylene, which is applied in the field of plastic processing, can solve the problems of reduced UV shielding ability, limited improvement effect, and agglomeration of large particles, and achieves the effect of small particle size, narrow particle size distribution, and not easy to agglomerate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

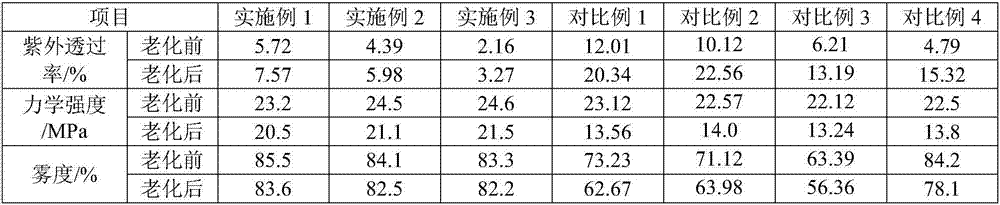

Examples

Embodiment 1

[0070] A kind of preparation method of anti-ultraviolet polypropylene film, the preparation method of described film comprises the steps:

[0071] (1) Surface modification of cerium oxide: the cerium oxide with an original particle size of 1 μm is pressed into a cylindrical shape with a tablet machine as a solid target; the surface modifier and ethanol are mixed according to the ratio of parts by mass of 1:10 as mobile liquid phase;

[0072] Immersing the solid target into the mobile liquid phase, the height of the part of the solid target immersed in the mobile liquid phase is 0.2mm, and the flow rate of the mobile liquid phase is 0.01ml / s;

[0073] Bombarding the surface of the solid target immersed in the continuous flow of the mobile liquid phase with a high-energy laser beam to obtain a suspension of the surface modifier grafted on the surface of cerium oxide, and the cerium oxide is decomposed into Nano size, modified cerium oxide particle size is D 50 = 80nm, while D ...

Embodiment 2

[0082] A kind of preparation method of anti-ultraviolet polypropylene film, the preparation method of described film comprises the steps:

[0083] (1) Surface modification of cerium oxide: the cerium oxide with an original particle size of 2 μm was pressed into a cylindrical shape with a tablet machine as a solid target; the surface modifier and ethanol were mixed according to the ratio of parts by mass of 1:10 as mobile liquid phase;

[0084] Immersing the solid target into the mobile liquid phase, the height of the part of the solid target immersed in the mobile liquid phase is 0.6mm, and the flow rate of the mobile liquid phase is 0.02ml / s;

[0085] Bombarding the surface of the solid target immersed in the continuous flow of the mobile liquid phase with a high-energy laser beam to obtain a suspension of the surface modifier grafted on the surface of cerium oxide, and the cerium oxide is decomposed into Nano size, modified cerium oxide particle size is D 50 = 100nm, while...

Embodiment 3

[0094] A kind of preparation method of anti-ultraviolet polypropylene film, the preparation method of described film comprises the steps:

[0095] (1) Surface modification of cerium oxide: cerium oxide with an original particle size of 3 μm is pressed into a cylindrical shape with a tablet machine as a solid target; the surface modifier and ethanol are mixed according to the ratio of parts by mass of 1:10 as mobile liquid phase;

[0096] Immersing the solid target into the mobile liquid phase, the height of the part of the solid target immersed in the mobile liquid phase is 1mm, and the flow rate of the mobile liquid phase is 0.04ml / s;

[0097] Bombarding the surface of the solid target immersed in the continuous flow of the mobile liquid phase with a high-energy laser beam to obtain a suspension of the surface modifier grafted on the surface of cerium oxide, and the cerium oxide is decomposed into Nano size, modified cerium oxide particle size is D 50 = 150nm, while D 97 =...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com