Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

33results about How to "Transparency has no effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-performance quantum dot-polymer fluorescent nano composite material and preparation method thereof

InactiveCN101759946AImprove luminous performanceImprove mechanical propertiesLuminescent compositionsMolten stateFluorescence

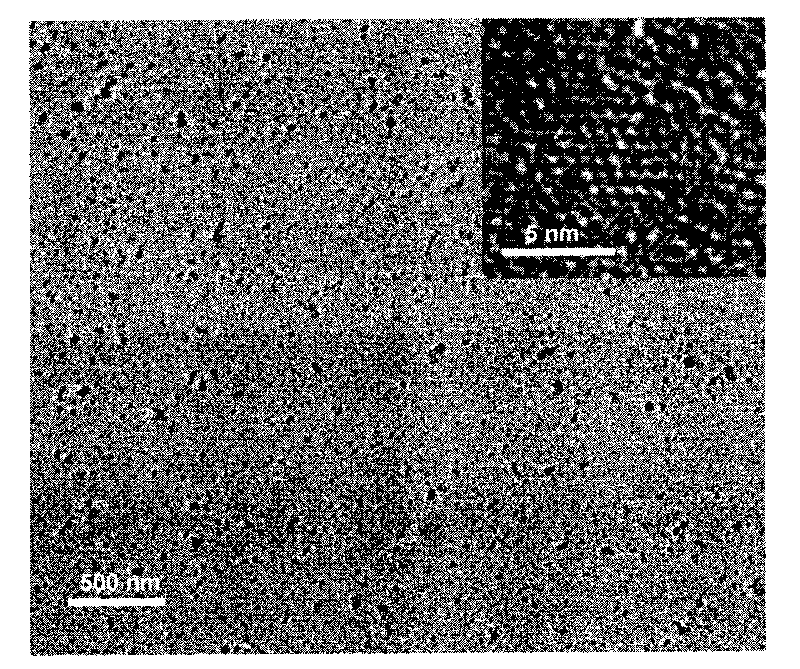

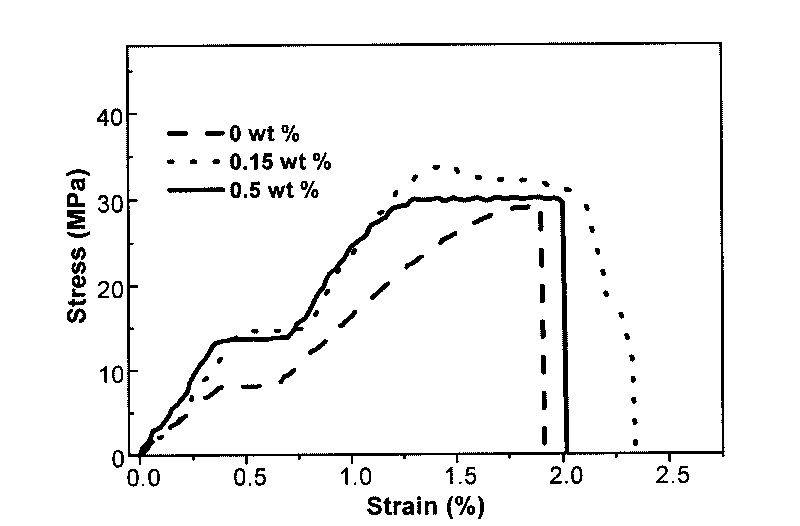

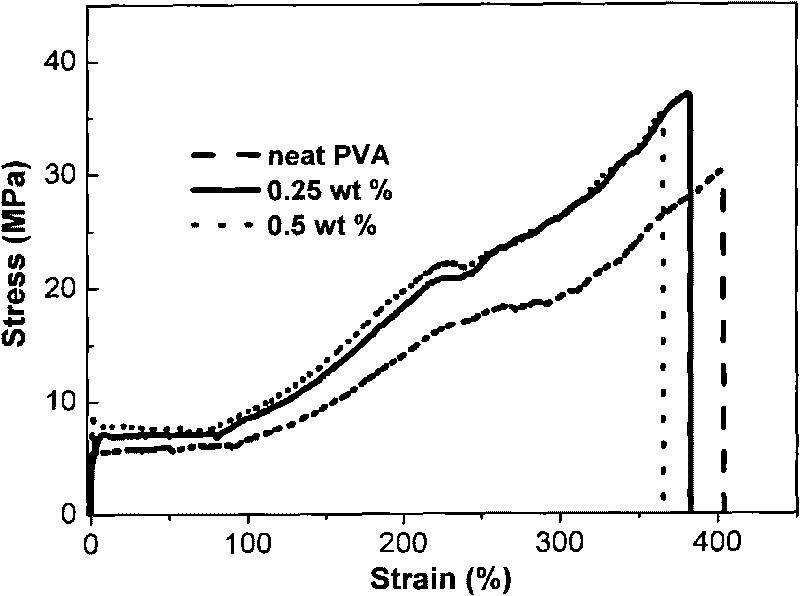

The invention discloses a high-performance quantum dot-polymer fluorescent nano composite material and a preparation method thereof. The high-performance quantum dot-polymer fluorescent nano composite material comprises polymer and quantum dot which has fluorescent property and is hybridized by silicon dioxide. The method comprises the following steps of: firstly, dissolving 1g of polymer by using a solvent or heating 1g of polymer into a molten state, then adding 0.0002-0.08g of quantum dot which has the particle diameter of 5-30 nanometers, is not modified or is modified by using silane coupling agent and is hybridized by the silicon dioxide and removing the solvent or cooling naturally after stirring for 2min-24hr to obtain the quantum dot-polymer nano composite material. The nano composite material has very strong photoinduced fluorescent property, and the mechanical property of the nano composite material is also enhanced greatly in comparison with that of a corresponding straight polymer. The high-performance quantum dot-polymer fluorescent nano composite material has simple preparation and is suitable for mass production. The invention has very good application prospect in the aspects of preparing an optical device and an optical material, replacing a traditional polymer material and the like.

Owner:ZHEJIANG UNIV

Water-resistant polyvinyl alcohol (PVA) film composition as well as fusion preparation method thereof

ActiveCN102234405ALower melt processing temperatureImprove plasticizing effectBlow moldingProcedure Agents

The invention discloses a water-resistant polyvinyl alcohol (PVA) film composition which comprises the following components in parts by weight: 100 parts of polyvinyl alcohol resin, 10-90 parts (preferably 20-50 parts) of compound plasticizing agent and 1-5 parts of processing agent, wherein the compound plasticizing agent is prepared from small molecular and high molecular plasticizing agents through compounding according to a certain proportion. The invention further discloses a preparation method of the composition. The film prepared by the method has good mechanical property, high transparency and high barrier property; the defects that PVA is easily degraded and smelled during a fusion process and PVA cannot be prepared by fusion are overcome; and the film is formed by a plurality ofmanners such as blow molding, curtain coasting, rolling and the like.

Owner:CHANGZHOU BAIJIA NIANDAI FILM TECH CO LTD

Antibacterial shading medical polyvinyl chloride plastic and preparation method thereof

The invention discloses antibacterial shading medical polyvinyl chloride plastic and a preparation method thereof. The antibacterial shading medical polyvinyl chloride plastic comprises, by weight, 100 parts of polyvinyl chloride, 5-90 parts of a plasticizer, 5-15 parts of an auxiliary plasticizer, 1-6 parts of a heat stabilizer, 0.1-3 parts of a ultraviolet light absorbent, 1-20 parts of a migration inhibitor, 0.1-10 parts of toner, 0.1-10 parts of titanium dioxide, 0.1-5 parts of an antibacterial material and 0.1-1 part of a lubricant. The migration inhibitor is beta-cyclodextrin. The antibacterial shading medical polyvinyl chloride plastic can effectively inhibit migration or decoloring of micromolecule substances such as a plasticizer and toner, can improve transfusion apparatus safety after disinfection, can guarantee patient usage safety, can thoroughly prevent light-avoiding agent migration and illumination-caused influence on a medical agent, does not influence drug use efficiency, has excellent dyeing resistance and anti-tarnishing performances in processing or use and does not influence PVC material transparency.

Owner:上海新上化高分子材料有限公司

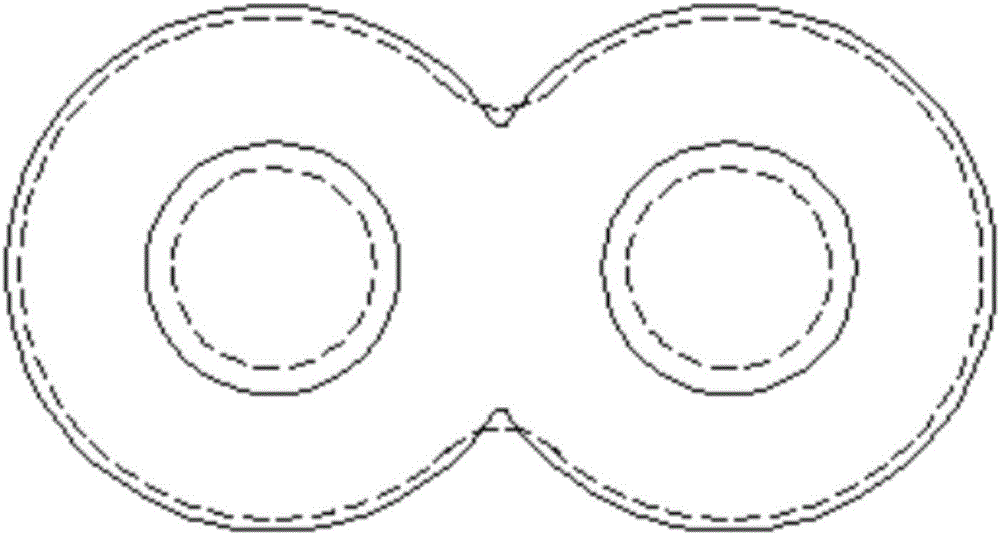

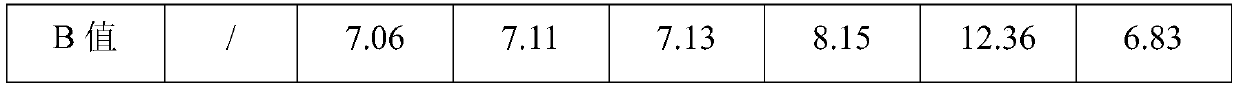

8-shaped hollow polyester fiber FDY (Fully Drawn Yarn) and preparation method thereof

ActiveCN106801265AReduce extrusion swelling effectImprove featuresMelt spinning methodsMonocomponent polyesters artificial filamentYarnFiber

The invention belongs to the polyester spinning field and relates to an 8-shaped hollow polyester fiber FDY (Fully Drawn Yarn) and a preparation method thereof. A spinning melt contains saturated fatty acid metal salt and modified polyester, wherein the mass ratio of saturated fatty acid metal salt to modified polyester is (0.0005-0.002) to 1; saturated fatty acid metal salt is fatty acid metal salt, the carbon atomic number is 12-22, the melting point is 100-180 DEG C, and the kinetic viscosity is less than or equal to 1Pa.s; a molecular chain of modified polyester comprises a terephthalic acid chain segment, a glycol chain segment and a rigid structure chain segment, and the molar ratio of the rigid structure chain segment to the terephthalic acid chain segment is (0.02-0.05) to 1; and the die swell ratio of the spinning melt is 1.23-1.33, and the after-filtration pressure during the spinning is 85-125kg / cm<2>. The prepared 8-shaped hollow polyester fiber FDY has relatively high degree of hollowness and relatively good shape-preserving effect.

Owner:JIANGSU HENGKE ADVANCED MATERIALS CO LTD

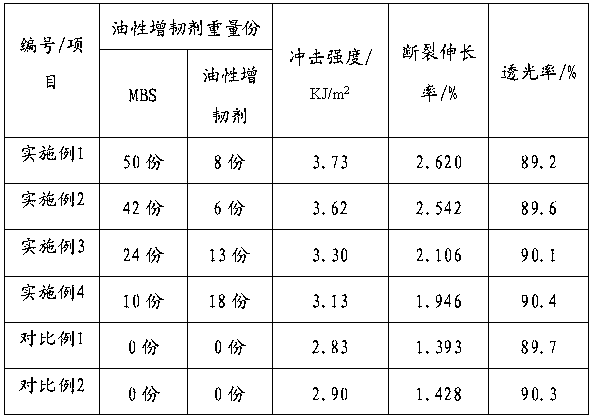

Preparation method of transparent toughened polystyrene functional color masterbatch

The invention discloses a preparation method of a transparent toughened polystyrene functional color masterbatch and belongs to the technical field of polymer material modification. The preparation method is characterized in that GPPS as a base resin raw material, MBS and an oily flexibilizer as main functional assistants, a transparent pigment, and various processing auxiliary agents are mixed uniformly; and the mixture is mixed by a double-screw extruder and then is cut into the transparent toughened polystyrene functional color masterbatches by a water loop heating granulator. Through mixing use of the transparent toughened polystyrene functional color masterbatches and the GPPS raw material, material toughness is improved; undesirable effects produced by stress cracking on a workpiece is improved obviously; and transparent color effects of the GPPS raw material are obtained. The transparent toughened polystyrene functional color masterbatch does not influence material transparency, has wide application prospects in fields of household electrical appliance, office supplies, electronic and electrical products and package, and is especially suitable for injection molding of transparent refrigerator drawers.

Owner:QINGDAO RICH PLASTIC NEW MATERIAL

PVC (polyvinyl chloride) diamante shower curtain and preparation method thereof

ActiveCN104194217AReduce forceLower glass transition temperatureFlat articlesPlasticizerPolyvinyl chloride

The invention relates to the technical field of plastic shower curtains and particularly relates to a PVC (polyvinyl chloride) diamante shower curtain and a preparation method thereof. The PVC diamante shower curtain comprises the following raw materials in parts by weight: 80-120 parts of PVC resin, 40-60 parts of a plasticizer, 5-10 parts of a thermal stabilizer, 0.05-0.5 part of a flame retardant, 0.1-0.2 part of an anti-ultraviolet agent and 0.01-0.02 part of phthalocyanine blue. The preparation method for the PVC diamante shower curtain comprises the following steps: preparing raw materials, stirring at a high speed, carrying out primary plastification, carrying out secondary plastification, filtering in a hierarchical manner, calendaring molding and cooling rolling. The shower curtain disclosed by the invention is flame-resistant, insulated, alkaline-resistant, acid-resistant, waterproof, corrosion-resistant, tensile-resistant, ageing-resistant, antistatic, clear in grain pattern, and good in 3D (three dimensional) steric effect. And the preparation method of the PVC diamante shower curtain is simple in process, convenient to operate and control, stable in quality, high in production efficiency and capable of being applied to large-scale industrial production.

Owner:DONGGUAN IUIU HOUSEHOLD PROD

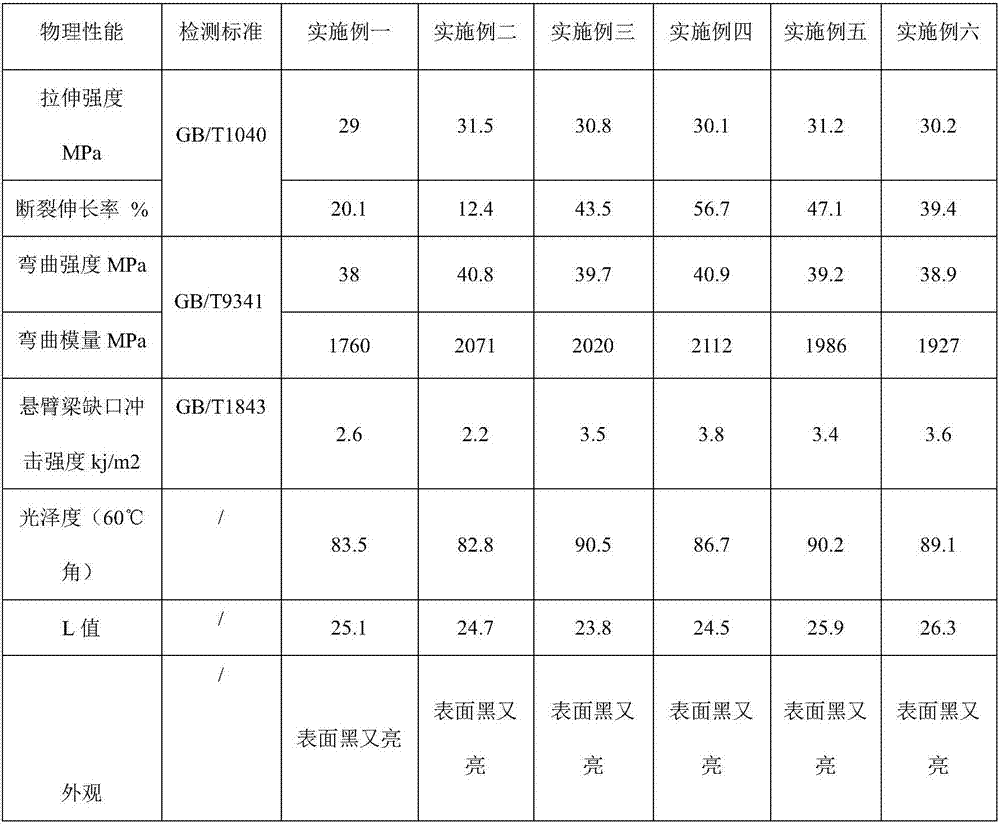

High light, high black and high impact polypropylene special material and preparation method thereof

The invention provides a high light, high black and high impact polypropylene special material and a preparation method thereof. The high light, high black and high impact polypropylene special material is composed of the following raw materials by weight: 80-90 parts of polypropylene resin, 10-20 parts of mineral filler, 0.1-0.5 part of a nucleating agent, 0.2-0.5 part of a dispersant, 0.2-0.4 part of an antioxidant, 1-4 parts of black masterbatch, and 0-1 part of other assistants. The high light, high black and high impact polypropylene special material provided by the invention adopts a special mixing process and preparation method, enhances the crystallinity of polypropylene material, and improves the dispersion of mineral filler. At the same time, because of high gloss, the composite material can replace ABS materials, reduce materials, and also meet the regulation (EC) No.1935 / 2004 of EU on food contact materials. The material can be used in kitchen appliance shells, endow the kitchen appliance surfaces with high gloss and high light, and improve the product appearances.

Owner:ORINKO NEW MATERIAL CO LTD

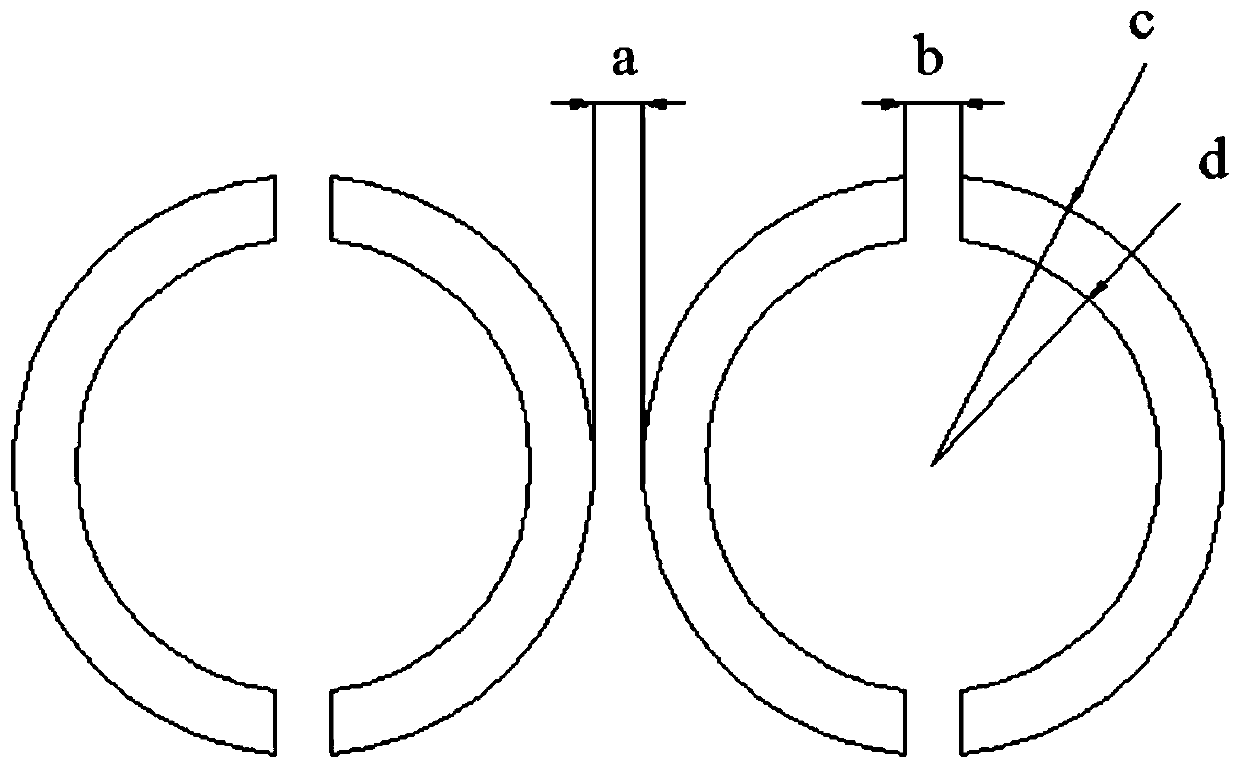

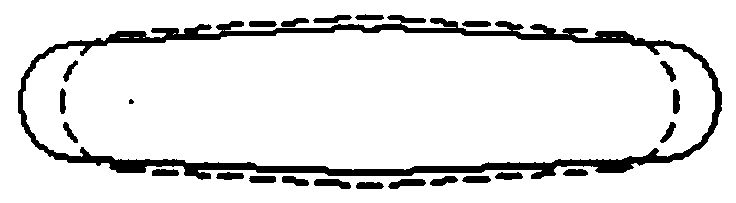

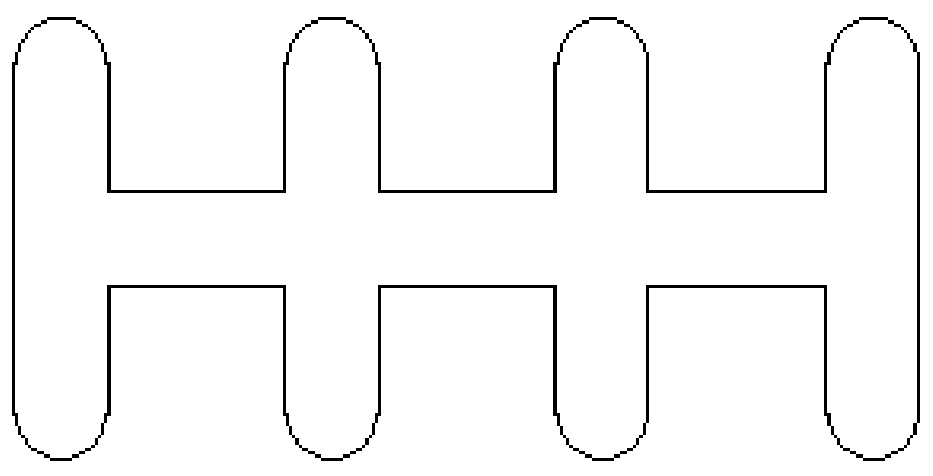

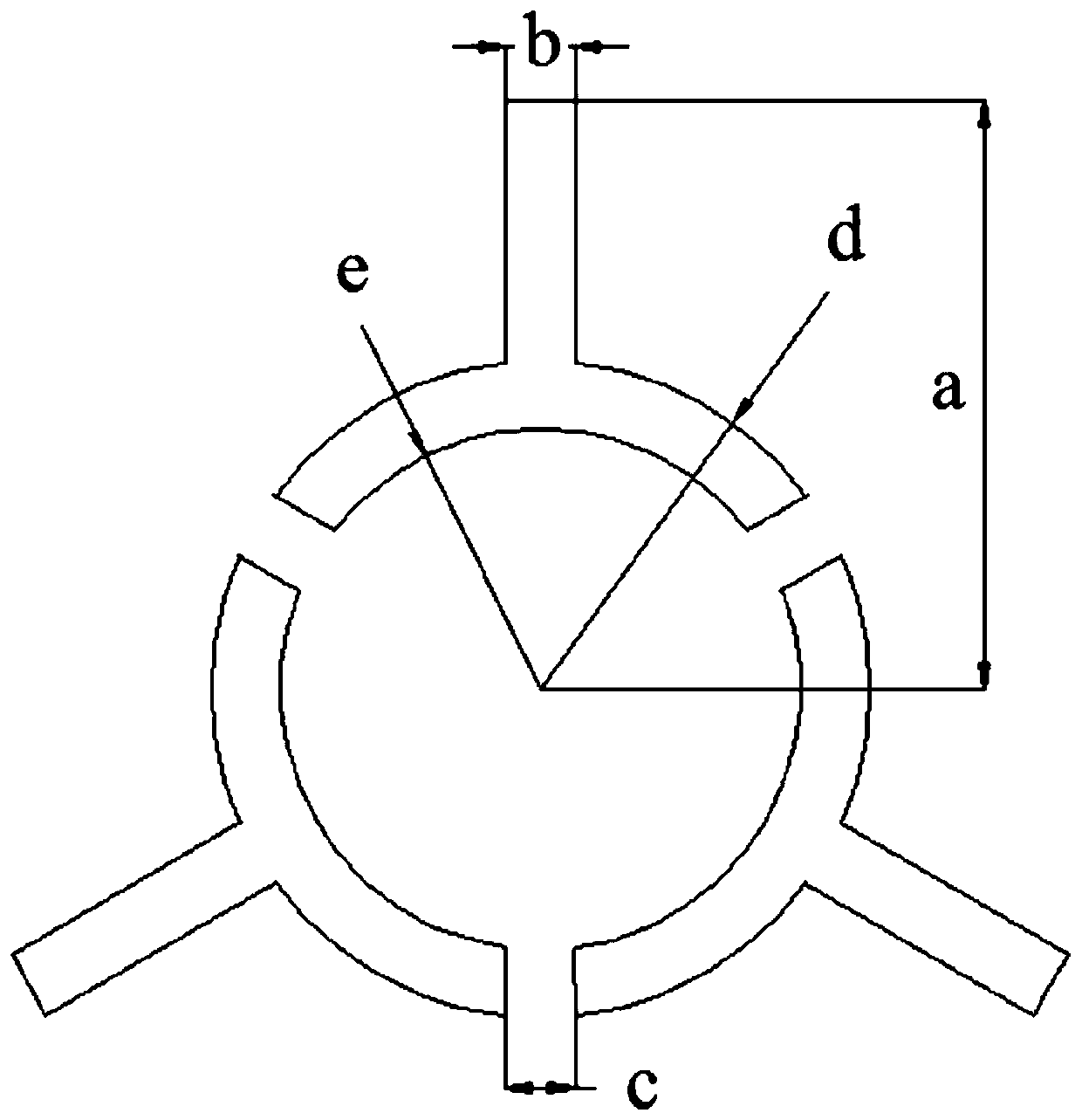

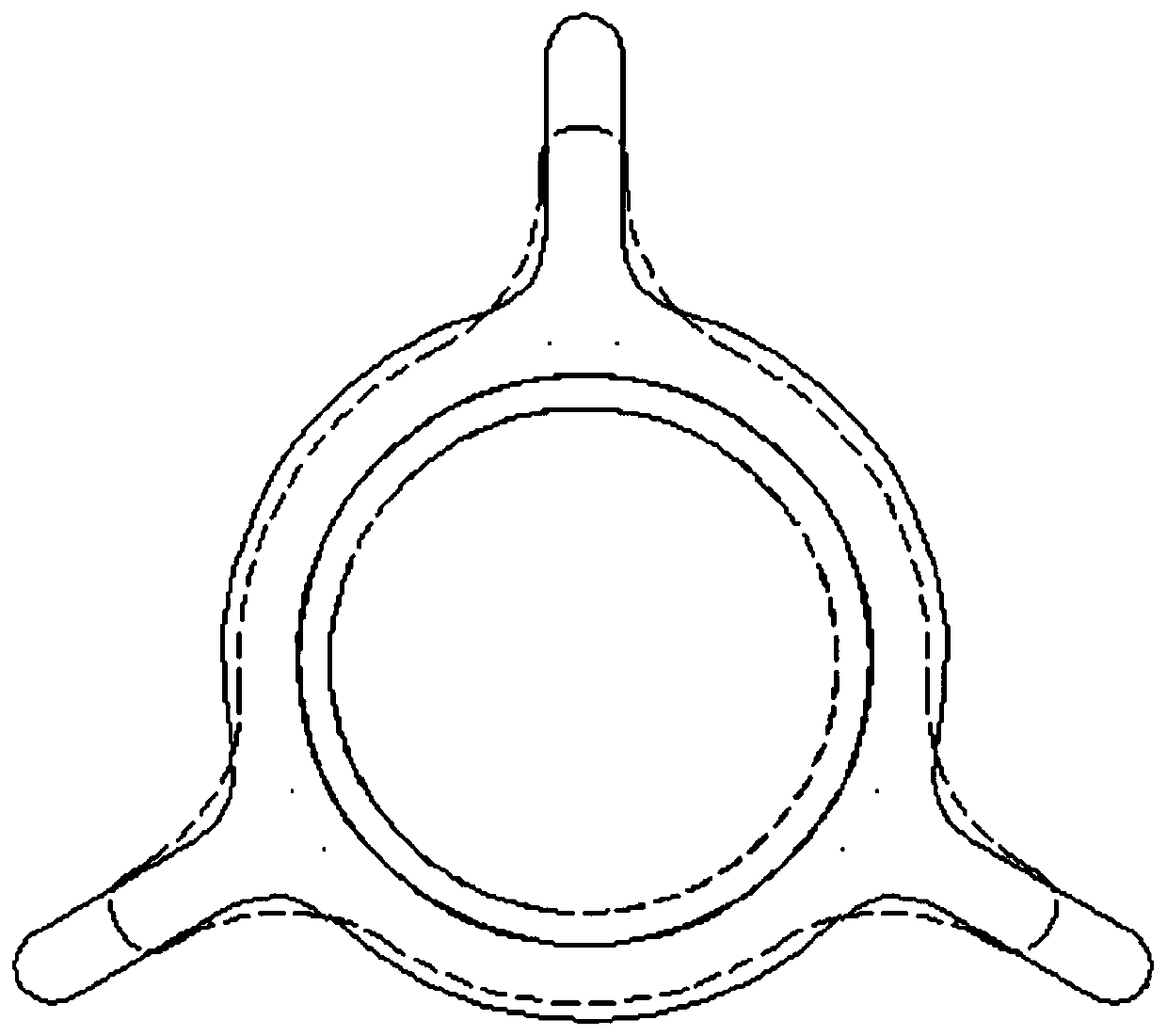

Multilobal hollow polyester fiber FDY (fully drawn yarn) and preparation method thereof

ActiveCN106835334AReduce extrusion swelling effectReduce surface tensionHollow filament manufactureMonocomponent polyesters artificial filamentFiberYarn

The invention belongs to the field of polyester spinning, and relates to a multilobal hollow polyester fiber FDY (fully drawn yarn) and a preparation method thereof. A spinning melt comprises a saturated fatty acid metal salt and modified polyester according to a mass ratio of (0.0005 to 0.002) to 1; the saturated fatty acid metal salt is a fatty acid metal salt with carbon atom number of 12 to 22, melting point of 100 to 180 DEG C, and dynamic viscosity less than or equal to 1Pa.s; a molecular chain of the modified polyester comprises a terephthalic acid chain segment, an ethylene glycol chain segment and a rigid structure chain segment, the molar ratio of the rigid structure chain segment to the terephthalic acid chain segment is (0.02 to 0.05) to 1, the extrusion swelling ratio of the spinning melt is 1.20 to 1.31, and the post-filtering pressure is 80 to 120kg / cm<2> during spinning. The prepared multilobal hollow polyester fiber FDY has higher hollow degree and a better shape preserving effect.

Owner:JIANGSU HENGKE ADVANCED MATERIALS CO LTD

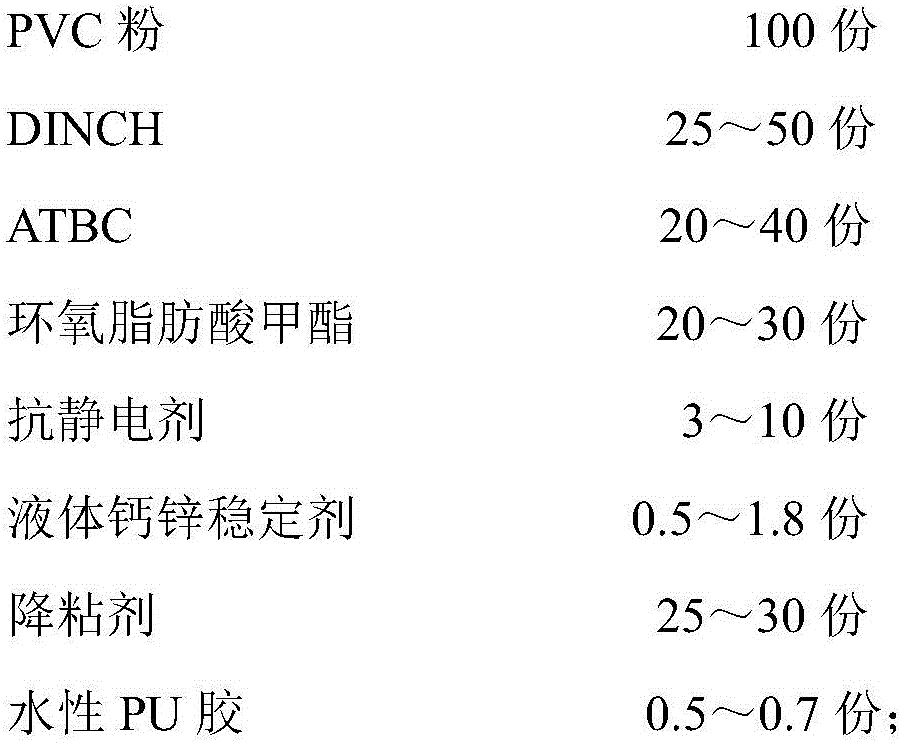

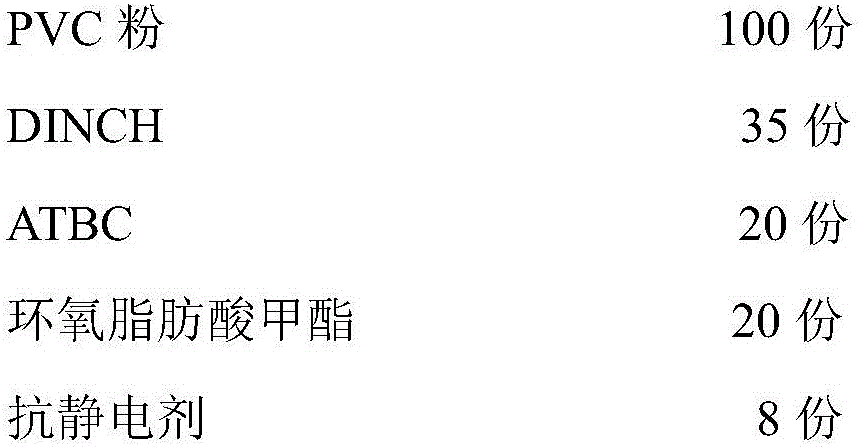

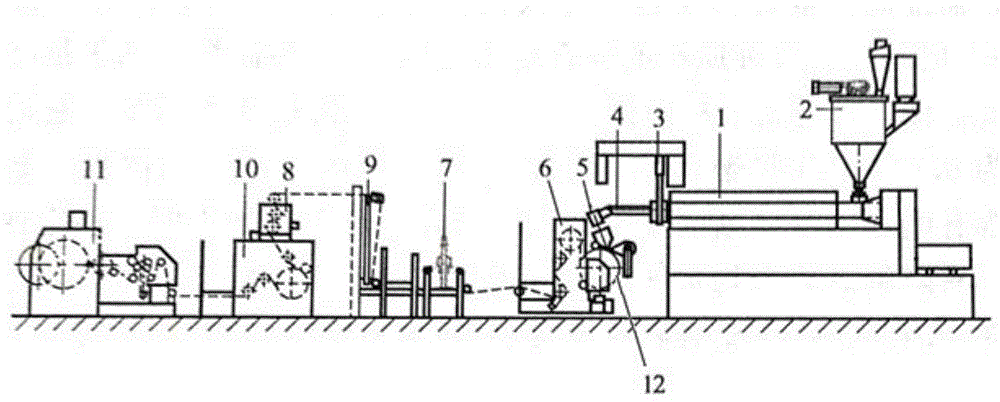

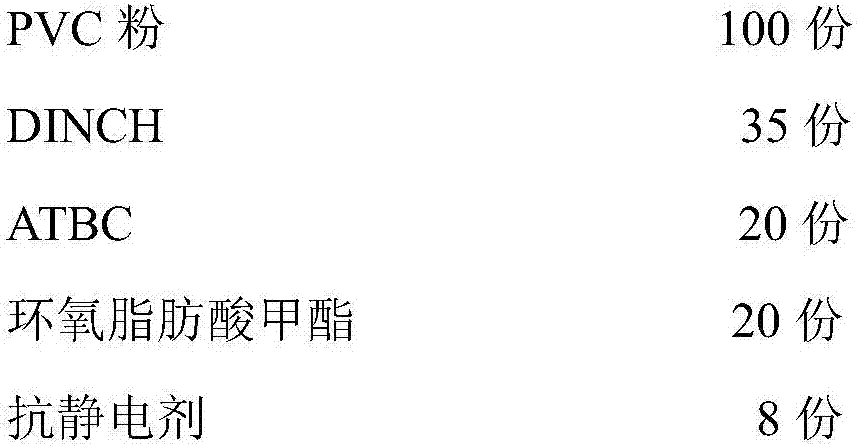

PVC (polyvinyl chloride) antistatic glove

The invention relates to a PVC (polyvinyl chloride) antistatic glove and belongs to the technical field of plastic gloves. The PVC antistatic glove is made from the following materials, by weight: 100 parts of PVC powder, 25-50 parts of DINCH, 20-40 parts of ATBC (acetyl tributyl citrate), 20-30 parts of epoxidized fatty acid methyl ester, 3-10 parts of an antistatic agent, 0.5-1.8 parts of liquid calcium-zinc stabilizer, 25-30 parts of a viscosity reducer, and 0.5-0.7 part of waterborne PU (polyurethane) rubber. The PVC antistatic glove is good in antistatic effect, durable, comfortable to wear and low in cost, the polymer antistatic agent that is used has excellent antistatic effect, is friendly to transparency of the glove and initial color performance of PVC and can also avoid the problems such as affected normal wearing due to glove adhesion caused by the adding of other antistatic agents to the formula, and a production process of the glove is simple and easy to perform.

Owner:山东蓝帆新材料有限公司

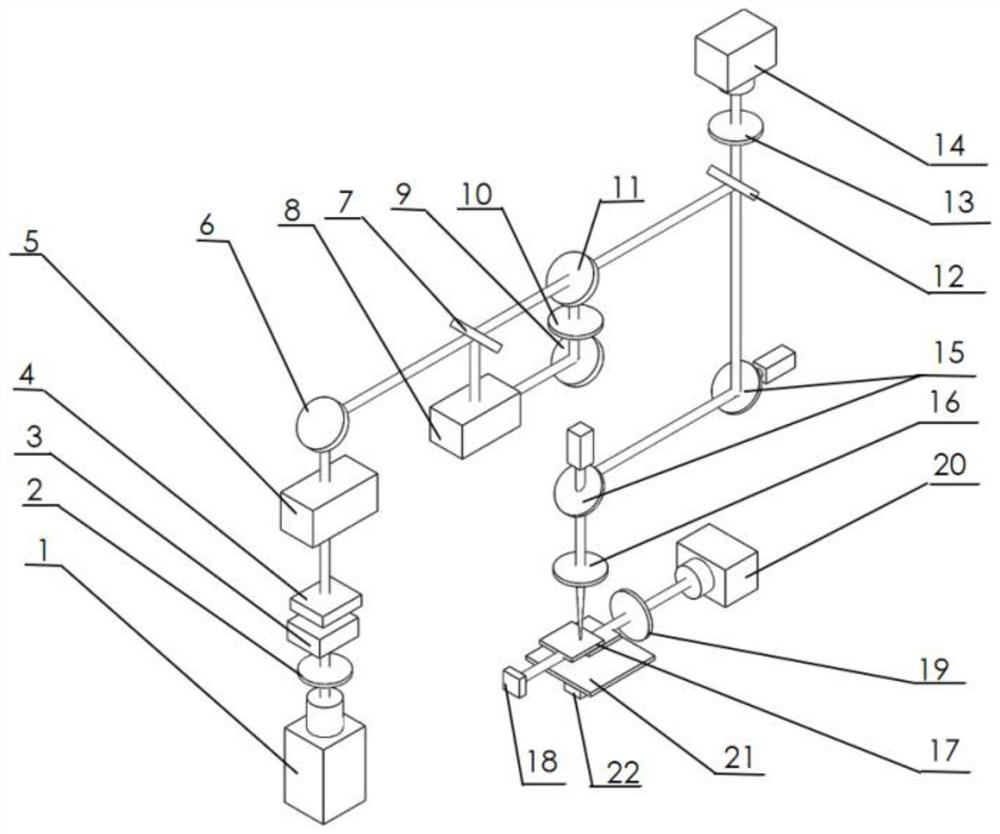

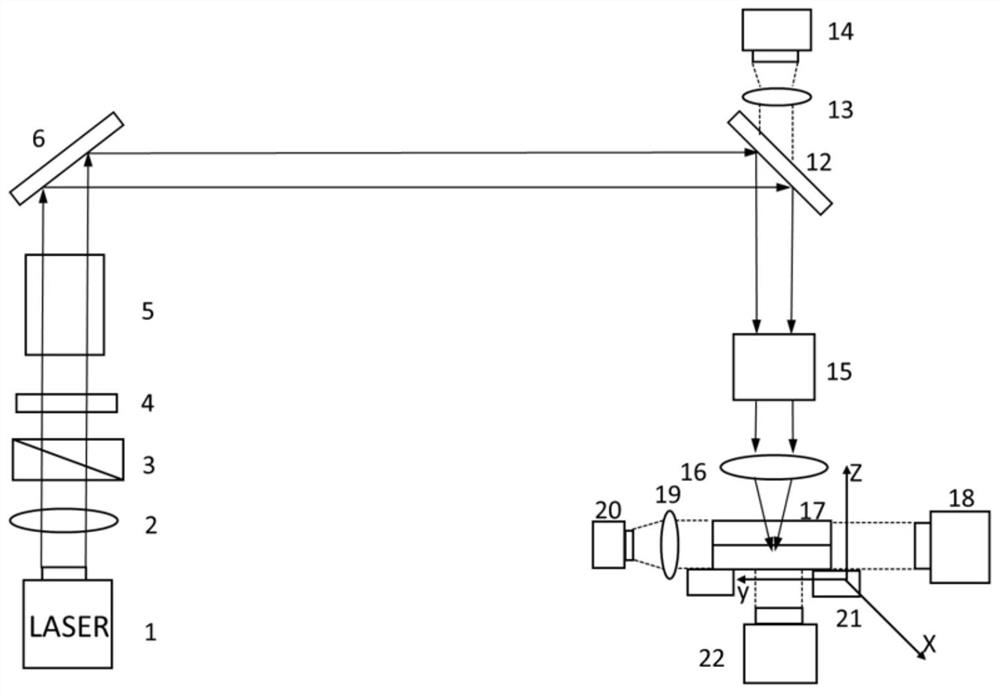

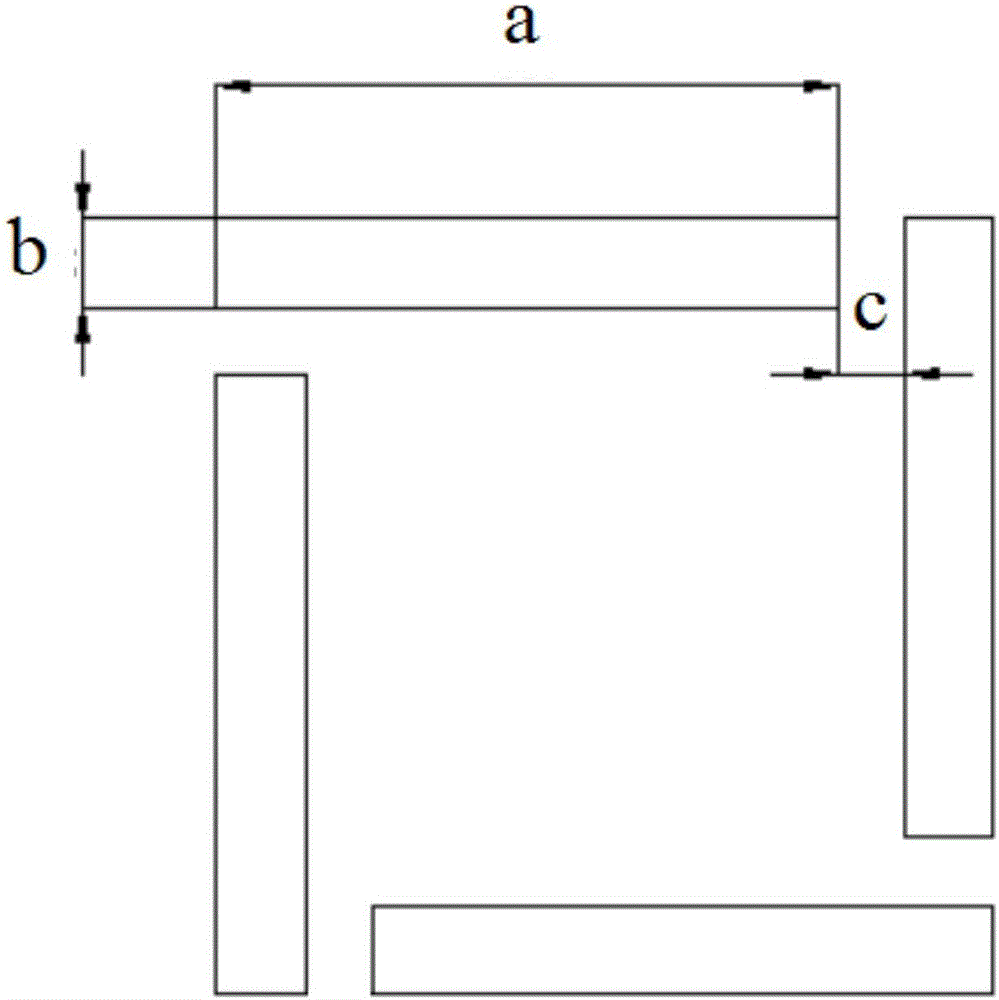

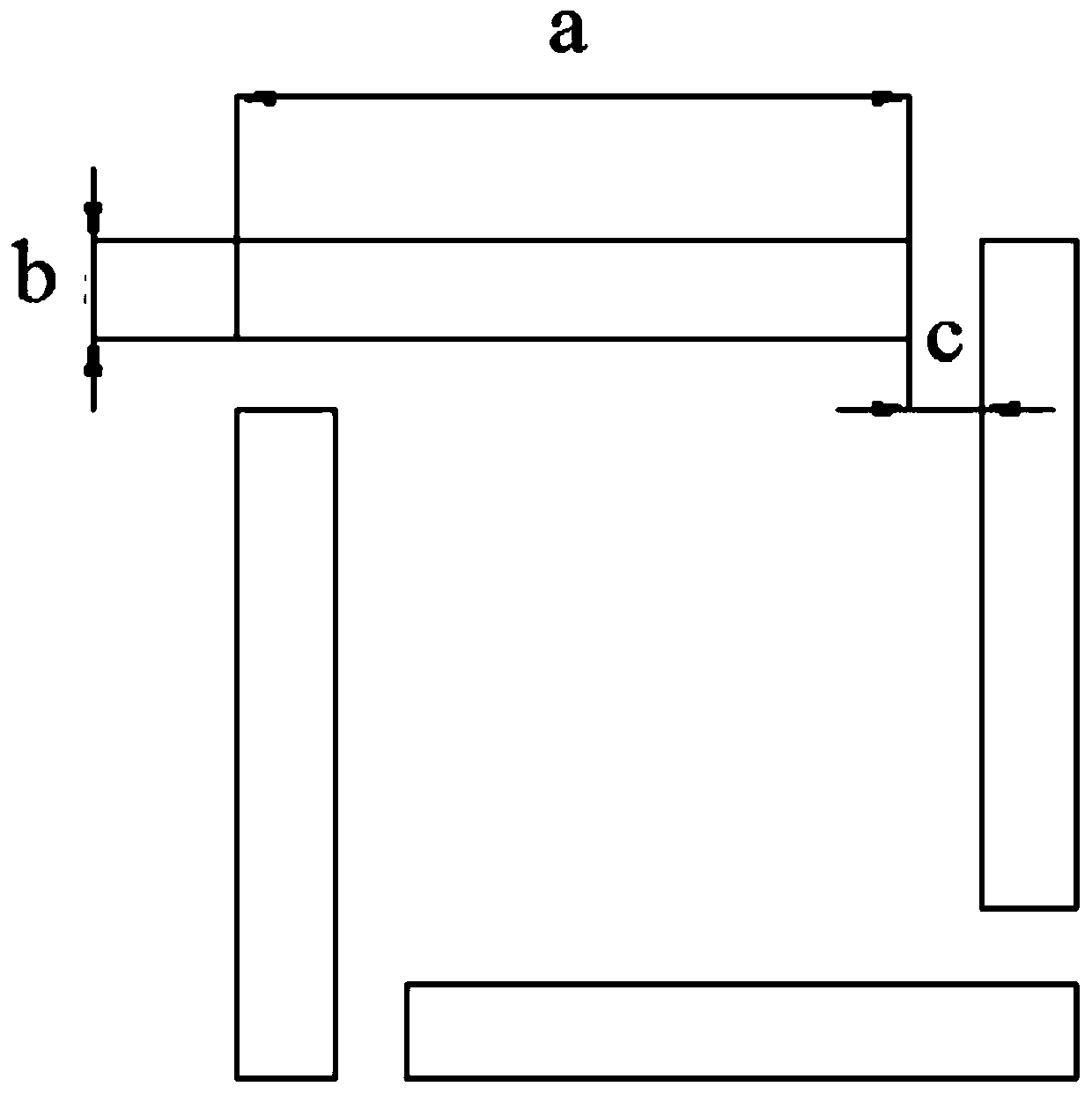

Double-light-path ultrafast laser welding device based on light beam shaping and machining method

InactiveCN113199143ASolving the challenge of non-optical contact solderingSolving Ultrafast Laser Welding ChallengesLaser beam welding apparatusFemto second laserPrism

The invention provides a double-light-path ultrafast laser welding device based on light beam shaping. The double-light-path ultrafast laser welding device comprises a femtosecond laser, a half-wave plate, a polarization splitting prism, an electric control shutter, a laser beam expander, a first holophote, a dichroscope, a galvanometer system, a field lens, a to-be-welded sample and an XYZ movable welding platform. Gaussian beams emitted by the femtosecond laser sequentially pass through the half-wave plate, the polarization splitting prism, the electric control shutter, the laser beam expander, the first holophote, the dichroscope, the galvanometer system and the field lens and then are gathered on a to-be-welded sample, and the to-be-welded sample is fixed on the XYZ movable welding platform to form a Gaussian light beam welding light path. A Bessel light beam conversion system is arranged between the first holophote and the dichroscope to form a Bessel light beam laser welding light path. The invention further provides a machining method using the device. According to the welding device, double-light-path welding of different laser beams is achieved, the welding device is suitable for non-optical contact welding and optical contact welding, the welding quality can be effectively improved, and the production cost can be effectively reduced.

Owner:GUANGXI UNIV

Fusion preparation method of polyvinyl alcohol film

InactiveCN101864132BLower melt processing temperatureSolving Melt Processing ProblemsFlat articlesPlasticizerPVA - Polyvinyl alcohol

The invention discloses a fusion preparation method of a polyvinyl alcohol film, which comprises the steps of mixing 100 parts by weight of polyvinyl alcohol, 10-45 parts by weight of small molecular plasticizer, 3-15 parts by weight of polymeric plasticizer, 1-5 parts by weight of processing agent, and 0.01-5 parts by weight of inorganic nanofiller, putting the components into a double-screw extruder, and fusing and plasticizing at the temperature of 140-250 DEG C and the screw rotate speed of 50-200rpm to directly extrude to form films or extrude to form films via fusing and plasticizing after pelleting. By choosing reasonable small molecular and polymeric compound plasticizers and inorganic nanofillers, the invention effectively reduces the fusing processing temperature of PVA, and solves the fusing processing problem of polyvinyl alcohol which has high molecular weight and high alcoholysis degree and is difficult to dissolve in water at normal temperature, and the obtained film has high transparency and good mechanical properties, is environmental-friendly, is non-toxic, and can be used for packaging a variety of products.

Owner:SICHUAN UNIV

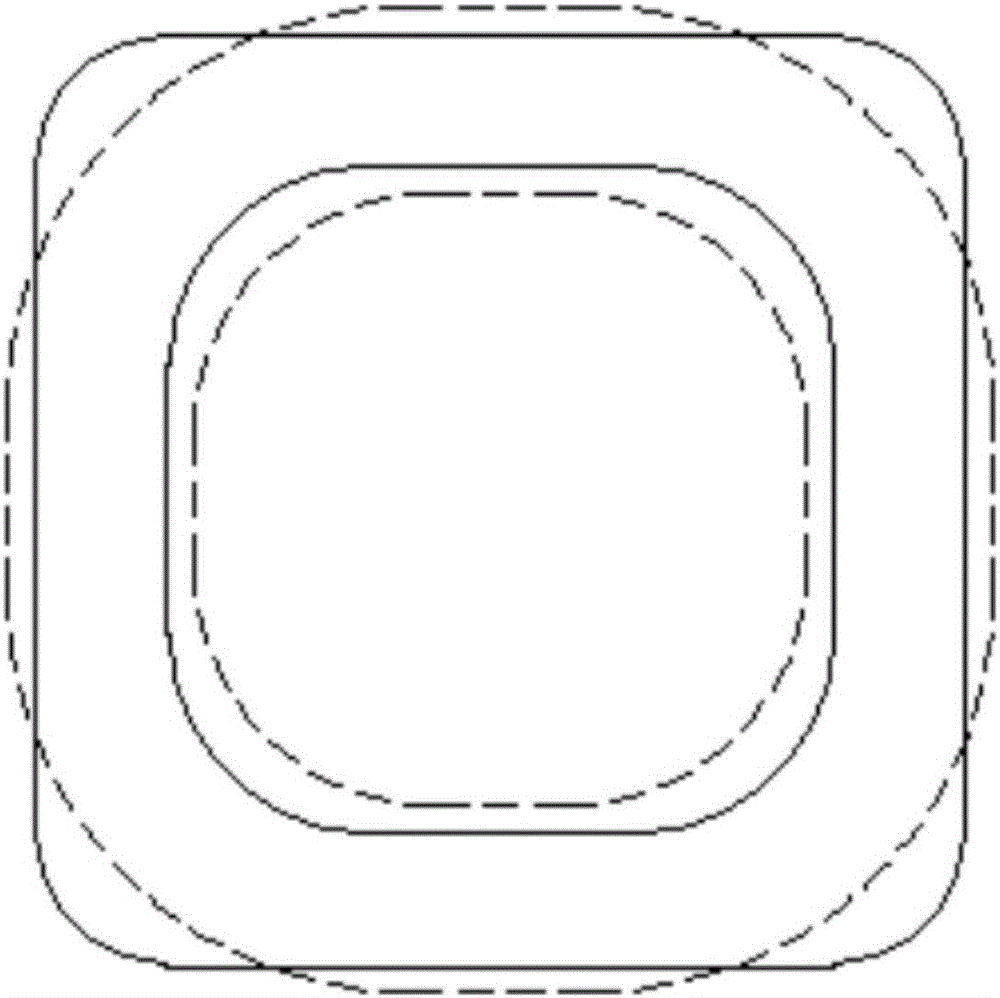

Square hollow polyester fiber FDY (Fully Drawn Yarn) and preparation method thereof

ActiveCN106835336AReduce extrusion swelling effectReduce surface tensionHollow filament manufactureFilament/thread formingChemistrySaturated fatty acid

The invention belongs to the field of polyester spinning, and relates to a square hollow polyester fiber FDY (Fully Drawn Yarn) and a preparation method thereof. A spinning melt contains a saturated fatty acid metal salt and modified polyester; the mass ratio of the saturated fatty acid metal salt to the modified polyester is (0.0005-0.002):1; the saturated fatty acid metal salt is a fatty acid metal salt of which the carbon atom number is 12-22, the melting point is 100-180 DEG C and the power viscosity is less than or equal to 1Pa*s; the molecular chain of the modified polyester comprises a terephthalic acid chain segment, a glycol chain segment and a rigid structure chain segment; the mole ratio of the rigid structure chain segment to the terephthalic acid chain segment is (0.02-0.05):1; the die swell ratio of the spinning melt is 1.21-1.32; the after-filtration pressure of the spinning melt in spinning is 82-123kg / cm<2>. The square hollow polyester fiber FDY provided by the invention is relatively high in hollowness degree and relatively good in conformal effect.

Owner:JIANGSU HENGKE ADVANCED MATERIALS CO LTD

Preparation of light-proof medical polyvinyl chloride plastics

The invention discloses preparation of light-proof medical polyvinyl chloride plastics. The antibacterial light-proof medical polyvinyl chloride plastics are prepared from the following components inparts by weight: 100 parts of polyvinyl chloride, 5 to 90 parts of plasticizer, 5 to 15 parts of auxiliary plasticizing agent, 1 to 6 parts of heat stabilizer, 0.1 to 3 parts of ultraviolet absorber,1 to 20 parts of migration inhibitor, 0.1 to 10 parts of toner, 0.1 to 10 parts of titanium dioxide, 0.1 to 5 parts of antibacterial material, 0.1 to 1 part of lubricant, and migration inhibitors aree-cyclodextrin. The preparation of the light-proof medical polyvinyl chloride plastics have the advantages that the migration or decoloration of small molecules such as plasticizers and toners can beeffectively inhibited, the safety of infusion devices after sterilization is enhanced, the safety of use of patients is ensured, and the migration of light-shielding agents and influence of illumination on a liquid medicine are fundamentally avoided, the use efficiency of the medicine is not affected, and has excellent resistance to dyeing and discoloration during processing or use, and transparency after adding a PVC (Polyvinyl chloride) material is not affected.

Owner:潜江市大虾风范水产品养殖有限公司

Preparation method of transparent toughened polystyrene functional color masterbatch

The invention discloses a preparation method of a transparent toughened polystyrene functional color masterbatch and belongs to the technical field of polymer material modification. The preparation method is characterized in that GPPS as a base resin raw material, MBS and an oily flexibilizer as main functional assistants, a transparent pigment, and various processing auxiliary agents are mixed uniformly; and the mixture is mixed by a double-screw extruder and then is cut into the transparent toughened polystyrene functional color masterbatches by a water loop heating granulator. Through mixing use of the transparent toughened polystyrene functional color masterbatches and the GPPS raw material, material toughness is improved; undesirable effects produced by stress cracking on a workpiece is improved obviously; and transparent color effects of the GPPS raw material are obtained. The transparent toughened polystyrene functional color masterbatch does not influence material transparency, has wide application prospects in fields of household electrical appliance, office supplies, electronic and electrical products and package, and is especially suitable for injection molding of transparent refrigerator drawers.

Owner:QINGDAO RICH PLASTIC NEW MATERIAL

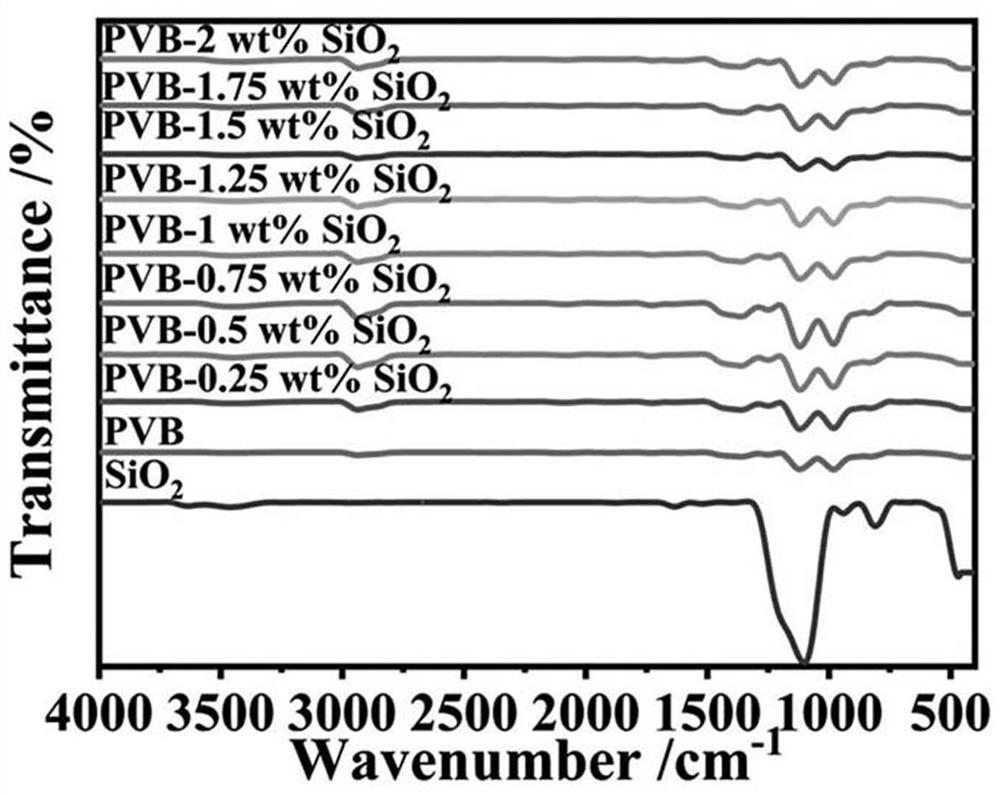

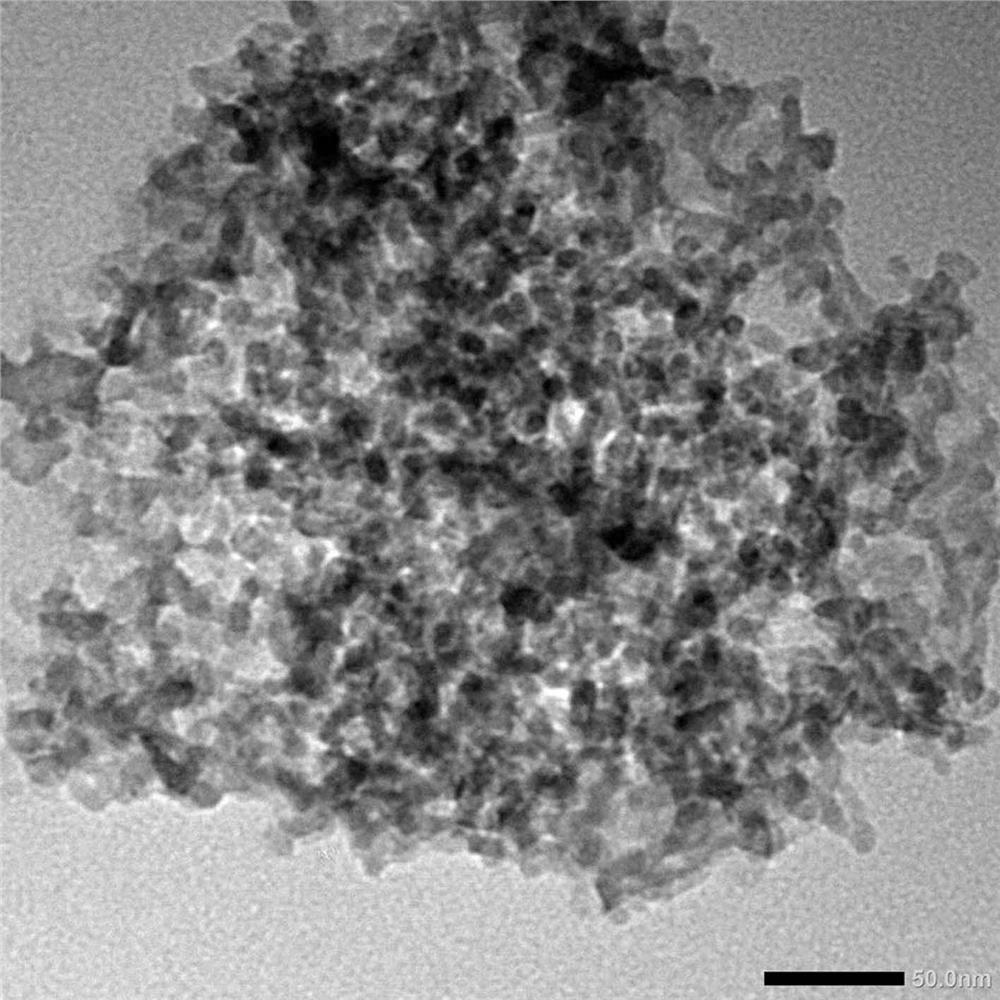

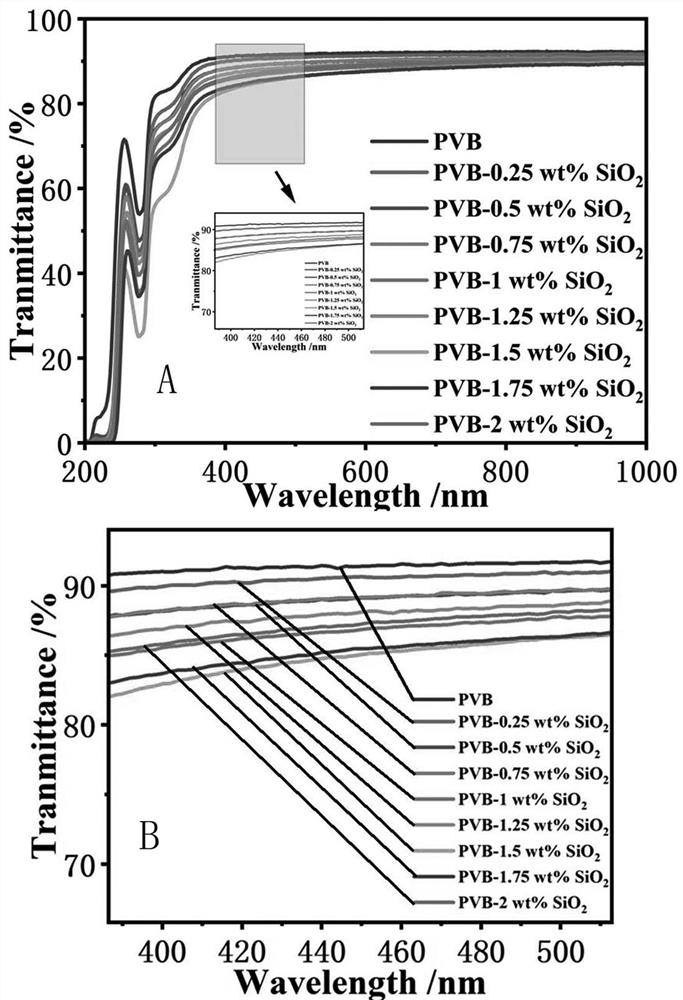

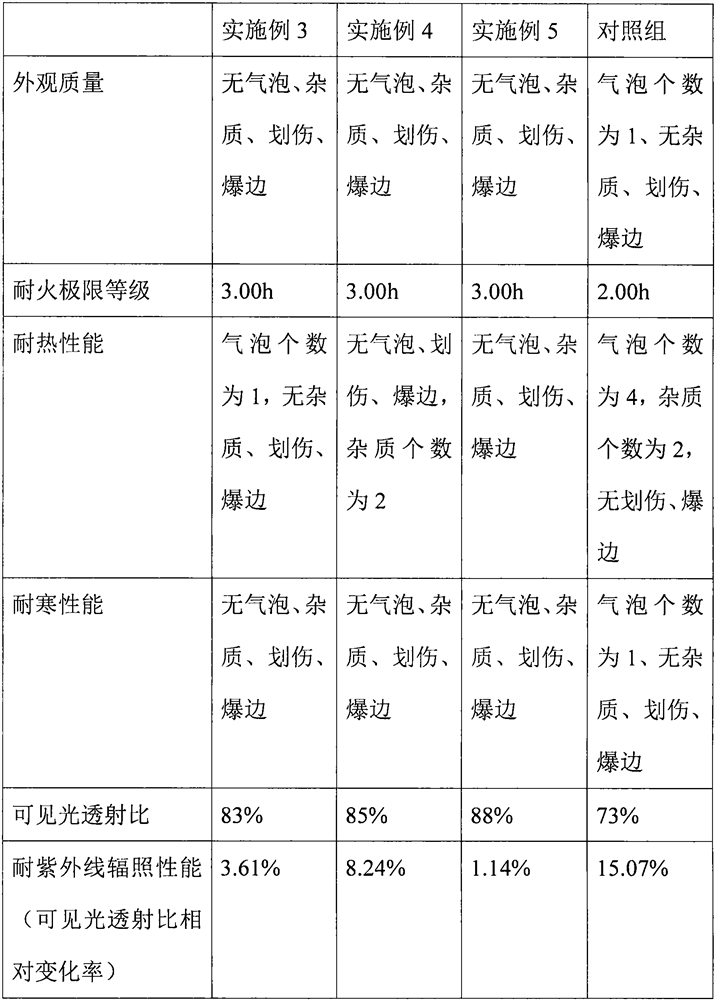

Nano silicon dioxide modified PVB material and preparation method thereof

The invention provides a nano silicon dioxide modified PVB material and a preparation method thereof. The nano silicon dioxide modified PVB material is prepared by the following steps: 1) weighing polyvinyl alcohol and deionized water, and dissolving an antioxidant under the action of mechanical stirring; 2) cooling, adding an emulsifier and nano silicon dioxide, emulsifying, adding n-butyraldehyde, continuously cooling, adding hydrochloric acid, keeping the temperature unchanged for 1-2 hours, heating to 70-75 DEG C at a constant speed, keeping the temperature for 1-2 hours, adding sodium hydroxide to adjust the pH value to be 4-4.5, keeping the temperature for 1-2 hours, washing, adding sodium hydroxide to the washed sample to adjust the pH value to be 13-14, magnetically stirring for 1-2 hours, washing with water to be neutral, and centrifugally drying; and 3) re-dissolving the dried sample in the ethanol solvent, stirring for 2-3 hours, and then pouring the mixture into a mold for drying. The method is an improvement on the PVB film of the middle layer of the automobile, so that the original glass interlayer has better strength, and the injury to personnel and articles when an impact accident occurs is effectively reduced.

Owner:ZHENGZHOU UNIV

Ultralow-temperature pouring sealant fireproof glass and preparation method thereof

ActiveCN113561584AStable gel systemLowering the freezing pointNon-macromolecular adhesive additivesClimate change adaptationDefoaming AgentsPotassium oxide

The invention discloses ultralow-temperature pouring sealant fireproof glass, which comprises a plurality of layers of raw glass sheets, flame-retardant adhesive tapes and ultralow-temperature pouring sealant, the peripheries of the multiple layers of raw glass sheets are sealed by flame-retardant adhesive tapes to form a glass containing cavity, and the ultralow-temperature pouring sealant is poured into the glass containing cavity; the ultralow-temperature pouring sealant is prepared from the following raw materials: a silica sol solution, organic silicon, potassium hydroxide, nano hydrophilic particles, a charring agent, a charring aid, a storage stabilizer, a defoaming agent, a plasticizer and glycerol. The invention discloses a preparation method of the ultra-low-temperature pouring sealant fireproof glass, which comprises the following steps: adding potassium hydroxide into a silica sol solution in a stirring state, adjusting the temperature to 60-80 DEG C for reaction, carrying out vacuum defoaming, then adding organic silicon for reaction, adding nano hydrophilic particles, a charring agent, a charring auxiliary agent, a storage stabilizer, a defoaming agent, a plasticizer and glycerol, uniformly stirring, filling the glass accommodating cavity, and curing to obtain the ultralow-temperature pouring sealant fireproof glass.

Owner:吉林省峰海工贸有限公司

Food-grade polypropylene material and preparation method thereof

The invention discloses a food-grade polypropylene material and a preparation method thereof. The food-grade polypropylene material is prepared from the following components in parts by weight: 98.6 to 99.2 parts of transparent polypropylene resin, 0.4 to 0.6 part of an antibacterial agent, 0.2 to 0.4 part of an antioxidant and 0.2 to 0.4 part of a lubricant, wherein the antibacterial agent is a silver-zinc composite antibacterial agent taking glass as a carrier. The food-grade polypropylene material can improve appearance degradation (yellowing) caused by a pure silver ion antibacterial agent, the refraction coefficient of the antibacterial agent used in the invention is equivalent to that of transparent PP, and the transparency of the transparent PP is not influenced basically.

Owner:ORINKO NEW MATERIAL CO LTD

A kind of 8-shaped hollow polyester fiber fdy yarn and preparation method thereof

ActiveCN106801265BReduce extrusion swelling effectImprove featuresMelt spinning methodsMonocomponent polyesters artificial filamentYarnFiber

The invention belongs to the polyester spinning field and relates to an 8-shaped hollow polyester fiber FDY (Fully Drawn Yarn) and a preparation method thereof. A spinning melt contains saturated fatty acid metal salt and modified polyester, wherein the mass ratio of saturated fatty acid metal salt to modified polyester is (0.0005-0.002) to 1; saturated fatty acid metal salt is fatty acid metal salt, the carbon atomic number is 12-22, the melting point is 100-180 DEG C, and the kinetic viscosity is less than or equal to 1Pa.s; a molecular chain of modified polyester comprises a terephthalic acid chain segment, a glycol chain segment and a rigid structure chain segment, and the molar ratio of the rigid structure chain segment to the terephthalic acid chain segment is (0.02-0.05) to 1; and the die swell ratio of the spinning melt is 1.23-1.33, and the after-filtration pressure during the spinning is 85-125kg / cm<2>. The prepared 8-shaped hollow polyester fiber FDY has relatively high degree of hollowness and relatively good shape-preserving effect.

Owner:JIANGSU HENGKE ADVANCED MATERIALS CO LTD

AG (anti-glare) film and application thereof

InactiveCN109504218ATransparency has no effectNo chromatic aberrationReflecting/signal paintsLithiumOrganic solvent

The invention relates to an AG (anti-glare) film, which mainly comprises an organic solvent, PMMA (poly(methyl methacrylate)), a polyfluorosiloxane block-containing urethane-acrylate copolymer, Arabicgum, nanoscale silica sol, lithium silicate / sodium silicate / potassium silicate, a light stabilizer, an antioxidant, a flatting agent, an anti-blocking agent and a water-retaining agent. After the prepared liquid anti-glare film is sprayed on the surface of glass or tempered glass, the transparence of the glass and the tempered glass is not affected, and the aberration of light passing through theglass or the tempered glass cannot occur. After the anti-glare film is sprayed on the surface of the glass, an incandescent bulb is used for illumination for a long time, the temperature of the surface of the glass is increased after a period of time, and the AG (anti-glare) film sprayed on the surface of the glass does not fall off due to heating, and does not become yellow. After the anti-glarefilm is sprayed and the surface coated with the anti-glare film is irradiated by light, the light is diffusely scattered on the surface of the anti-glare film, so that the reflection phenomena are reduced, and therefore the phenomenon that a user cannot clearly see the screen is prevented.

Owner:太仓斯迪克新材料科技有限公司

Composite stabilizer for epoxy resin, and preparation method thereof

The invention concretely provides a special composite stabilizer capable of substantially improving the ageing resistance of epoxy resin and having no influences on the initial color of a product. The composite stabilizer comprises 45-75 mass% of a stabilizer a and 35-55 mass% of a stabilizer b. The preparation method comprises the following steps: weighing above two components in proportion, sequentially adding the two component substances into a mixing kettle, and carrying out normal stirring at a rotating speed of 40-180rpm through using an anchor or helix ribbon type stirrer for 0.2-1.0h to uniformly mix in order to obtain the composite stabilizer. The composite stabilizer added to the epoxy resin product can substantially improve the light stability, the thermal ageing resistance of the product, has no influences on the initial color of the product, greatly prolongs the service life of the product, and guarantees no change of the appearance (such as transparence and initial color) of the product.

Owner:SUNSHOW SPECIALTY CHEM CO LTD

A kind of flat polyester fiber fdy yarn and preparation method thereof

ActiveCN106835338BReduce bloatPromote crystallizationFilament forming substance formingArtificial thread manufacturing machinesPolyesterYarn

The invention relates to a flat polyester fiber FDY (Fully Drawn Yarn) and a preparation method thereof. The spinning melt comprises a saturated fatty acid metal salt and polyester, wherein a mass ratio of the saturated fatty acid metal salt to polyester is (0.0005-0.002):1; the filtered pressure during spinning is 84-126kg / cm<2>; a die-swell ratio of the spinning melt is 1.22-1.34; and the saturated fatty acid metal salt refers to a fatty acid metal salt with the carbon atom number of 12-22, the melting point of 100-180 DEG C and the dynamic viscosity of less than or equal to 1Pa.s. The saturated fatty acid metal salt is added into the spinning melt, and the filtered pressure and extrudate swelling during spinning can be effectively reduced, so that the product has an excellent shape preserving effect; meanwhile, the saturated fatty acid metal salt can serve as a nucleating agent, so that the fiber curing speed is increased, and the fiber shape preserving effect is improved. In addition, the fiber structure regularity is not greatly damaged by the saturated fatty acid metal salt, and excellent performances of the polyester fibers are maintained.

Owner:JIANGSU HENGKE ADVANCED MATERIALS CO LTD

A kind of transparent environment-friendly PVC modified material and preparation method thereof

Owner:广东祺龙科技有限公司

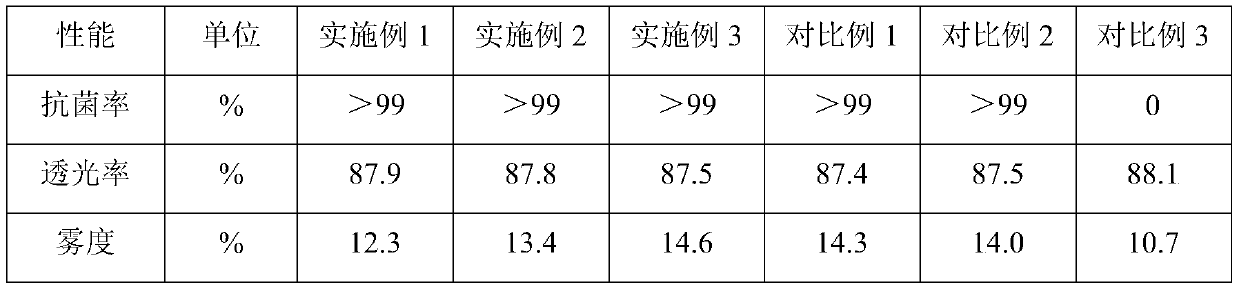

Antibacterial, mildewproof and deodorant composite film and preparation method thereof

The invention provides an antibacterial, mildew-proof and deodorizing composite film, which comprises a substrate, on which a layer of antibacterial film is compounded; the antibacterial film is composed of antibacterial agent and plastic, and the content of antibacterial agent is 0.1-10wt%; In parts by weight, the antibacterial agent consists of 1-10 parts of salicylanilide and 1-10 parts of imidazole. After the antimicrobial agent and plastic particles are evenly stirred, they are fed into a screw extruder and melted and extruded; the melt is cast into a film, and then hot pressed and pasted on the substrate to form a composite film. The composite membrane provided by the invention is safe and reliable, and the antibacterial agent can be used for acute oral LD 50 >10000mg / kg (rat); strong antibacterial properties, especially in high humidity environment; stable performance, very stable in acid-base solution and ultraviolet rays, non-corrosive container, slightly soluble in water, medicine Long-lasting effect; transparency has no effect.

Owner:杭州勤诚塑料包装材料有限公司

A Polyester Spinning Method for Reducing Extrusion Swelling Ratio

ActiveCN106835335BReduce bloatPromote crystallizationFilament forming substance formingArtificial thread manufacturing machinesPolyesterFiber

Owner:JIANGSU HENGKE ADVANCED MATERIALS CO LTD

pvc antistatic gloves

Owner:山东蓝帆新材料有限公司

A kind of diamond pattern PVC shower curtain and preparation method thereof

The present invention relates to the technical field of plastic shower curtains, in particular to a diamond pattern PVC shower curtain and a preparation method thereof. The diamond pattern PVC shower curtain comprises the following raw materials in parts by weight: 80-120 parts of PVC resin, 40-60 parts of plasticizer , 5-10 parts of heat stabilizer, 0.05-0.5 part of flame retardant, 0.1-0.2 part of anti-ultraviolet agent, 0.01-0.02 part of phthalocyanine blue; the preparation method includes raw material preparation, high-speed stirring, primary plasticization, secondary plasticization liquefaction, hierarchical filtration, calendering and cooling winding. The shower curtain of the present invention is flame-retardant, insulating, alkali-resistant, acid-resistant, waterproof, anti-corrosion, tensile-resistant, anti-aging, anti-static, has clear lines and patterns, and has good 3D three-dimensional effects. The preparation method of the invention has the advantages of simple process, convenient operation and control, stable quality, high production efficiency and large-scale industrial production.

Owner:DONGGUAN IUIU HOUSEHOLD PROD

Transparent acrylate structural adhesive and preparation method thereof

PendingCN113462296AGood transparencyGood stabilityOrganic non-macromolecular adhesiveModified epoxy resin adhesivesAdhesive cementPolymer chemistry

The invention discloses a transparent acrylate structural adhesive and a preparation method thereof, the transparent acrylate structural adhesive comprises a component A and a component B, and the volume ratio of the component A to the component B is 1: 1; wherein the component A comprises the following components in parts by weight: 30-60 parts of an acrylate monomer, 5-20 parts of a toughening agent, 1-8 parts of a stabilizer, 10-30 parts of a coupling agent and 0.5-5 parts of an accelerant; wherein the component B comprises the following components in parts by weight: 30-60 parts of an acrylate monomer, 20-50 parts of a plasticizer, 5-15 parts of an oxidizing agent and 0.5-1.0 part of a polymerization inhibitor. The invention relates to the technical field of adhesives, and particularly provides the transparent acrylate structural adhesive and the preparation method thereof.

Owner:南京博新新材料有限公司

A kind of ultra-fine denier polyester fiber fdy yarn and preparation method thereof

ActiveCN107245768BReduce bloatPromote crystallizationMelt spinning methodsMonocomponent polyesters artificial filamentPolyesterFiber

The present invention relates to an ultrafine denier polyester fiber FDY filament and a preparation method thereof, wherein a spinning melt comprises a saturated fatty acid metal salt and a polyester according to a mass ratio of the saturated fatty acid metal salt to the polyester of 0.0005-0.002:1, the post-filtration pressure during spinning is 125-155 kg / cm<2>, the extrusion expansion ratio of the spinning melt is 1.25-1.35, and the saturated fatty acid metal salt has the carbon atom number of 12-22, the melting point of 100-180 DEG C, and the dynamic viscosity of less than or equal to 1 Pa.s. According to the present invention, the saturated fatty acid metal salt is added to the spinning melt so as to provide the effect of the addition of the lubricant, such that the post-filtration pressure during the spinning is effectively reduced so as to effectively reduce the outlet expansion, and the product has the good shape retention effect; and the saturated fatty acid metal salt can be used as the nucleating agent to increase the fiber curing speed so as to further improve the fiber shape retention effect.

Owner:JIANGSU HENGKE ADVANCED MATERIALS CO LTD

A kind of multi-leaf hollow polyester fiber fdy yarn and preparation method thereof

ActiveCN106835334BReduce extrusion swelling effectReduce surface tensionHollow filament manufactureMonocomponent polyesters artificial filamentFiberYarn

The invention belongs to the field of polyester spinning, and relates to a multilobal hollow polyester fiber FDY (fully drawn yarn) and a preparation method thereof. A spinning melt comprises a saturated fatty acid metal salt and modified polyester according to a mass ratio of (0.0005 to 0.002) to 1; the saturated fatty acid metal salt is a fatty acid metal salt with carbon atom number of 12 to 22, melting point of 100 to 180 DEG C, and dynamic viscosity less than or equal to 1Pa.s; a molecular chain of the modified polyester comprises a terephthalic acid chain segment, an ethylene glycol chain segment and a rigid structure chain segment, the molar ratio of the rigid structure chain segment to the terephthalic acid chain segment is (0.02 to 0.05) to 1, the extrusion swelling ratio of the spinning melt is 1.20 to 1.31, and the post-filtering pressure is 80 to 120kg / cm<2> during spinning. The prepared multilobal hollow polyester fiber FDY has higher hollow degree and a better shape preserving effect.

Owner:JIANGSU HENGKE ADVANCED MATERIALS CO LTD

A kind of square hollow polyester fiber fdy yarn and preparation method thereof

ActiveCN106835336BReduce extrusion swelling effectReduce surface tensionHollow filament manufactureFilament/thread formingFiberYarn

Owner:JIANGSU HENGKE ADVANCED MATERIALS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com