Antibacterial, mildewproof and deodorant composite film and preparation method thereof

An antibacterial, mildew-proof and composite membrane technology, applied in the field of composite membranes, can solve the problems of no antibacterial, deodorant, and mildew-proof, high cost, and achieve the effects of strong antibacterial properties, solving losses, and obvious effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] An antibacterial, mildew-proof and deodorizing composite film, comprising a base material, a layer of antibacterial film is compounded on the base material; the antibacterial film is composed of an antibacterial agent and plastic, the content of the antibacterial agent is 1wt%, and the antibacterial agent is made of water It is composed of 6 parts of salicylanilide and 4 parts of imidazole. Prepared according to the following steps:

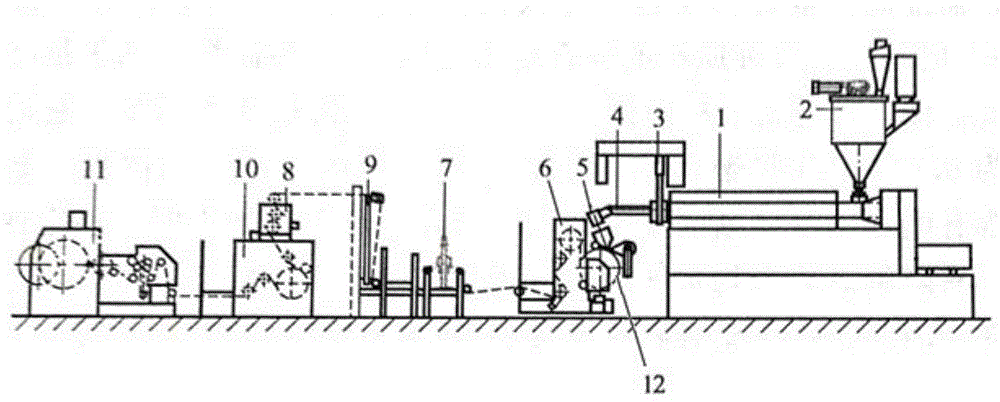

[0028] refer to figure 1 After stirring the antibacterial agent and plastic particles evenly, the suction machine sucks the material into the hopper 2, and then passes through the screw extruder 1, and the screw is extruded. In this process, the material is melted into a liquid by heating; Afterwards, these melts (melted liquid) are filtered through the filter screen 3 again, and flow out from the loose film mouth of the die head 5 through the melt pipe 4; On the base material, the melt is cast into a film, and the rubber rollers are ext...

Embodiment 2

[0030] The difference between this embodiment and Example 1 is that the composition of the antibacterial film is different, and the antibacterial film described in this embodiment is made up of antibacterial agent and plastics, and the content of antibacterial agent is 1wt%, and described antibacterial agent is composed of salicyloyl Composed of 4 parts of aniline and 6 parts of imidazole.

Embodiment 3

[0032] The difference between this embodiment and Example 1 is that the composition of the antibacterial film is different, and the antibacterial film described in this embodiment is made up of antibacterial agent and plastics, and the content of antibacterial agent is 1wt%, and described antibacterial agent is composed of salicyloyl Composed of 8 parts of aniline and 2 parts of imidazole.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com