Ultralow-temperature pouring sealant fireproof glass and preparation method thereof

A technology of fire-resistant glass and potting glue, which is applied in parallel glass structures, chemical instruments and methods, glass/slag layered products, etc., and can solve the problems of poor adhesion of fire-proof glass perfusion fluid, loss of visible light transmittance, and poor fireproof performance. Standards and other issues, to achieve good heat insulation, improve strength, good effect of low temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

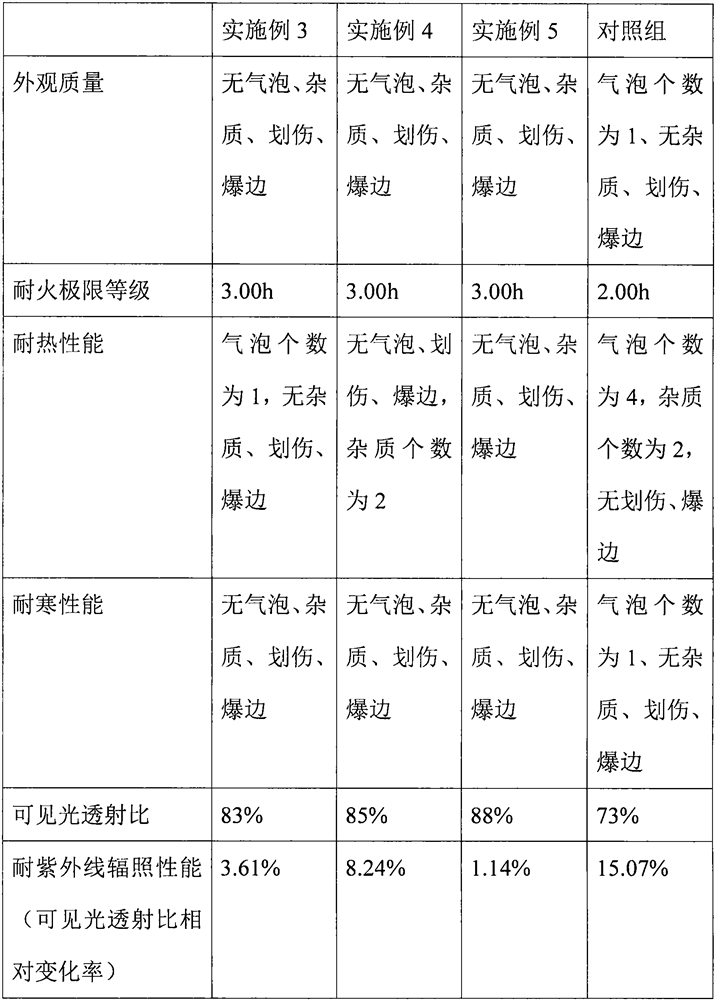

Examples

Embodiment 1

[0028] A fireproof glass with ultra-low temperature potting glue, comprising two layers of glass original sheets, flame-retardant adhesive strips and ultra-low temperature potting glue; the two layers of glass original sheets are sealed with the flame-retardant adhesive strips to form a glass cavity, The potting glue is potted in the glass cavity;

[0029] The raw materials of the ultra-low temperature potting glue include: 100 kg of silica sol solution with a mass fraction of 18% of silicon dioxide, 40 kg of γ-glycidoxypropylmethyldiethoxysilane, 5 kg of potassium hydroxide, and a particle size of 12kg of nano-hydrophilic particles of 10-100nm, 0.5kg of maltose, 3kg of potassium hydrogen phosphate, 0.3kg of sodium polyphosphate, 0.2kg of polyether modified silicone defoamer, 0.4kg of dipropylene glycol methyl ether, and 5kg of glycerin;

[0030] Nano-hydrophilic particles are nano-silica particles with sepiolite grafted on the surface and a particle size of 10-60nm. The speci...

Embodiment 2

[0033] A fireproof glass with ultra-low temperature potting glue, comprising two layers of glass original sheets, flame-retardant adhesive strips and ultra-low temperature potting glue; the two layers of glass original sheets are sealed with the flame-retardant adhesive strips to form a glass cavity, The potting glue is potted in the glass cavity;

[0034] The raw materials of the ultra-low temperature potting glue include: 100 kg of silica sol solution with a mass fraction of 25% of silicon dioxide, 20 kg of γ-glycidoxypropylmethyl diethoxysilane, 12 kg of potassium hydroxide, and a particle size of 4kg of nano-hydrophilic particles of 10-100nm, 3kg of fructose, 0.5kg of sodium dihydrogen phosphate, 0.3kg of sodium polyphosphate, 0.3kg of potassium polyphosphate, 0.1kg of polyether modified silicone defoamer, dipropylene glycol butyl Ether 0.4kg, dipropylene glycol methyl ether 0.8kg, glycerin 0.5kg;

[0035] Nano-hydrophilic particles are nano-silica particles with sepiolit...

Embodiment 3

[0038] A kind of fireproof glass with ultra-low temperature potting glue, comprising three-layer glass original sheet, flame-retardant rubber strip and ultra-low temperature potting glue; The potting glue is potted in the glass cavity;

[0039]The raw materials of the ultra-low temperature potting glue include: 100 kg of silica sol solution with a mass fraction of 20% of silica, 35 kg of foamed silicone rubber DC3-6548, 6 kg of potassium hydroxide, and nanometer hydrophilic particles with a particle size of 10-100 nm 10kg, sucrose 1kg, potassium hydrogen phosphate 1.5kg, sodium hydrogen phosphate 1kg, sodium polyphosphate 0.3kg, potassium polyphosphate 0.1kg, polyether modified silicone defoamer 0.17kg, dipropylene glycol butyl ether 0.5kg, glycerin 4kg;

[0040] Nano-hydrophilic particles are nano-silica particles with sepiolite grafted on the surface and a particle size of 10-60nm. The specific production process is as follows: 6kg sepiolite powder, 1.7kg cetyltrimethylammo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com