Freezing resistant type alkali-free accelerator, and preparation method and application thereof

A technology of quick-setting agent and anti-freezing type, applied in the field of anti-freezing alkali-free setting quick-setting agent and its preparation, can solve the problems of reducing the aqueous solution of alkali-free setting quick-setting agent, etc., so as to shorten the setting time, eliminate the retarding effect, prevent icing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

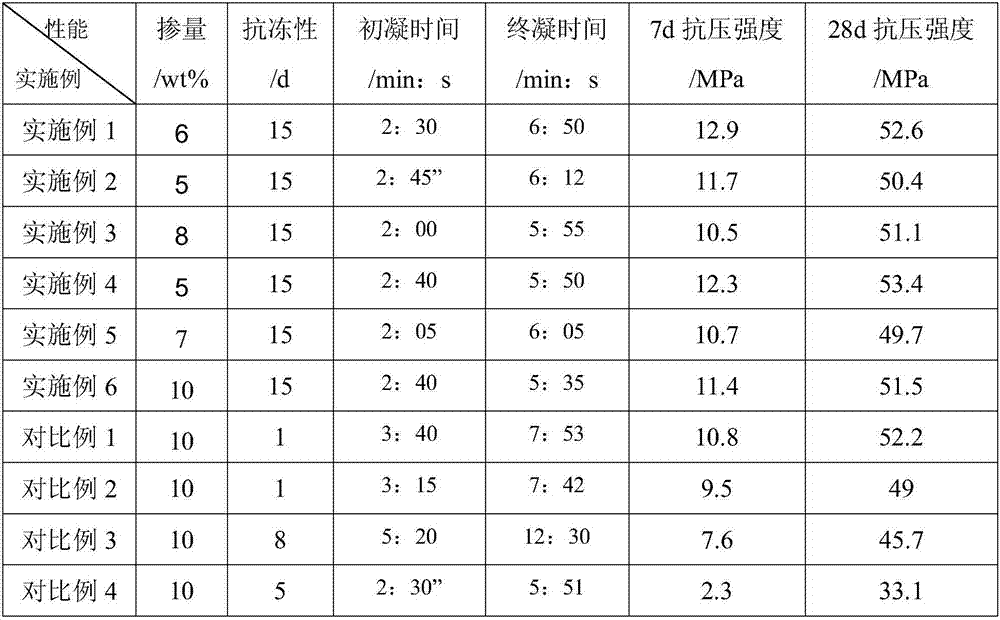

Examples

Embodiment 1

[0025] The preparation of antifreeze type alkali-free quick-setting agent comprises the following steps:

[0026] (1) Mix 58g of aluminum sulfate, 5g of diethanolamine, 0.5g of sodium fluoride and 36g of water, heat up to 60°C and react for 3 hours, then cool down to room temperature, add 0.5g of lactic acid and mix evenly to obtain the alkali-free accelerator;

[0027] (2) Mix 0.2g of soluble starch and 58.5g of water, heat up to 100°C to dissolve for 5 minutes, then cool down to room temperature, add 2.3g of N,N-dimethylglycine and 39g of trimethylglycine and mix evenly to obtain antifreeze;

[0028] (3) Add 1 g of antifreeze to 100 g of non-alkali quick-setting agent, and mix evenly to obtain an antifreeze type non-alkali quick-setting agent.

Embodiment 2

[0030] The preparation of antifreeze type alkali-free quick-setting agent comprises the following steps:

[0031] (1) Mix 40g of aluminum sulfate, 10g of triethanolamine, 3g of potassium fluoride and 44.5g of water, heat up to 90°C and react for 1 hour, then cool down to room temperature, add 2.5g of oxalic acid and mix evenly to obtain the alkali-free quick-setting agent;

[0032] (2) Mix 0.6g of soluble starch and 58.4g of water, heat up to 100°C to dissolve for 3 minutes, then cool down to room temperature, add 40g of trimethylglycine and 1g of N,N-diethylglycine and mix evenly to obtain antifreeze;

[0033] (3) Add 10 g of antifreeze into 100 g of non-alkali quick-setting agent, and mix evenly to obtain an antifreeze type non-alkali quick-setting agent.

Embodiment 3

[0035] The preparation of antifreeze type alkali-free quick-setting agent comprises the following steps:

[0036] (1) Mix 40g of aluminum sulfate, 7g of N,N-dimethylethanolamine, 1.5g of sodium fluoride and 50g of water, heat up to 70°C and react for 2 hours, then cool down to room temperature, add 1.5g of malic acid and mix well. Alkali-free accelerator;

[0037] (2) Mix 0.6g of soluble starch and 50g of water, heat up to 100°C to dissolve for 4 minutes, then cool down to room temperature, add 43g of trimethylglycine and 6.4g of N,N-diethylglycine and mix evenly to obtain antifreeze;

[0038] (3) Add 5 g of antifreeze to 100 g of non-alkali quick-setting agent, and mix evenly to obtain an antifreeze type non-alkali quick-setting agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com