Curing-speed-adjustable two-component adhesive

A two-component adhesive, curing speed technology, applied in the direction of adhesives, non-polymer adhesive additives, adhesive additives, etc. The effect of improvement, adhesion performance improvement, and light transmittance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

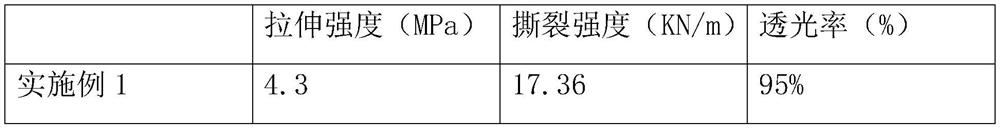

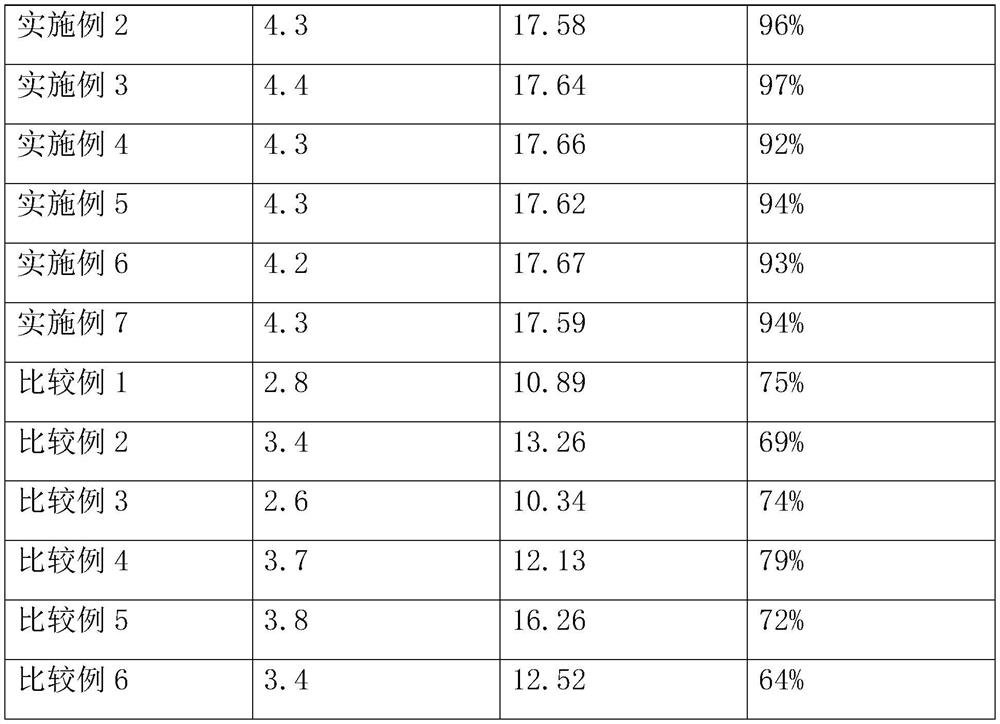

Examples

Embodiment 1

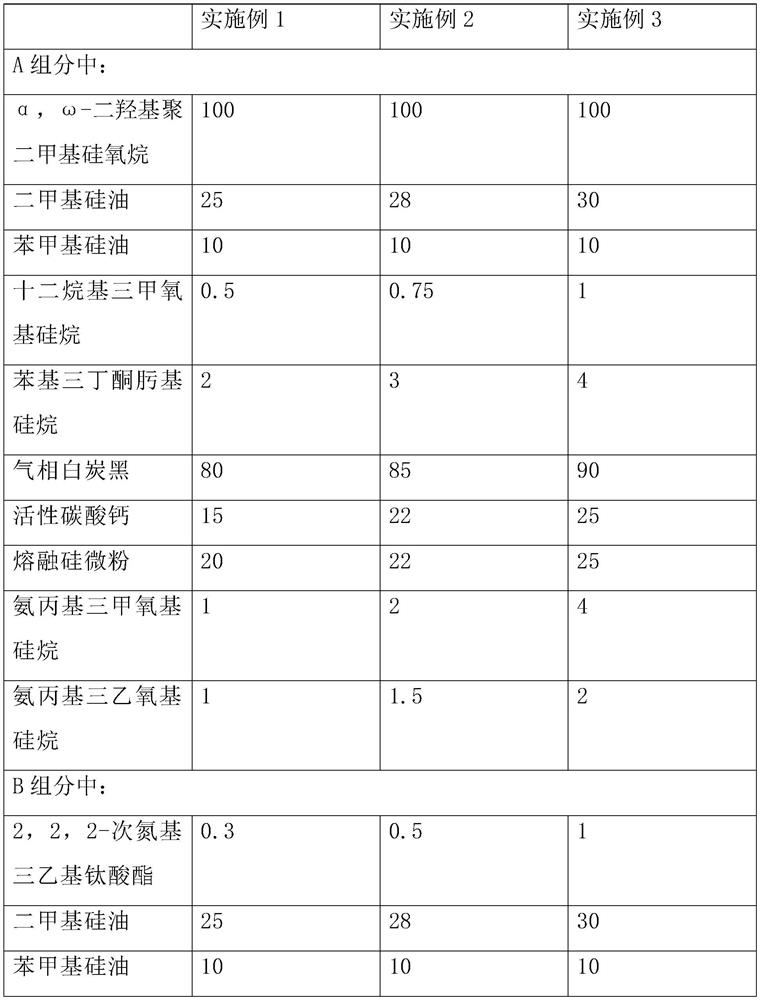

[0061] A two-component adhesive with adjustable curing speed, including A component and B component, wherein, A component

[0062] Including α, ω-dihydroxy polydimethylsiloxane, plasticizer, crosslinking agent, filler, coupling agent.

[0063] In component A, the plasticizer is a compound of dimethyl silicone oil and benzyl silicone oil;

[0064] The crosslinking agent is a compound of dodecyltrimethoxysilane and phenyltributanoximinosilane;

[0065] The filler is a compound of fumed white carbon black, activated calcium carbonate, and fused silica powder;

[0066] The coupling agent is a compound of aminopropyltrimethoxysilane and aminopropyltriethoxysilane.

[0067] The B component includes catalyst and plasticizer.

[0068] In component B, the catalyst is 2,2,2-nitrilotriethyl titanate;

[0069] The plasticizer is a compound of dimethyl silicone oil and benzyl silicone oil.

[0070] In Examples 1-3, the addition amount of each component is shown in Table 1 (in kg).

...

Embodiment 4

[0079] Compared with Example 3, the only difference is that the catalyst is butyl tin trichloride.

Embodiment 5

[0081] Compared with Example 3, the only difference is that the catalyst is n-octyltin.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com