Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

46results about How to "Simple industrial preparation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Transparent polylactic acid alloy material

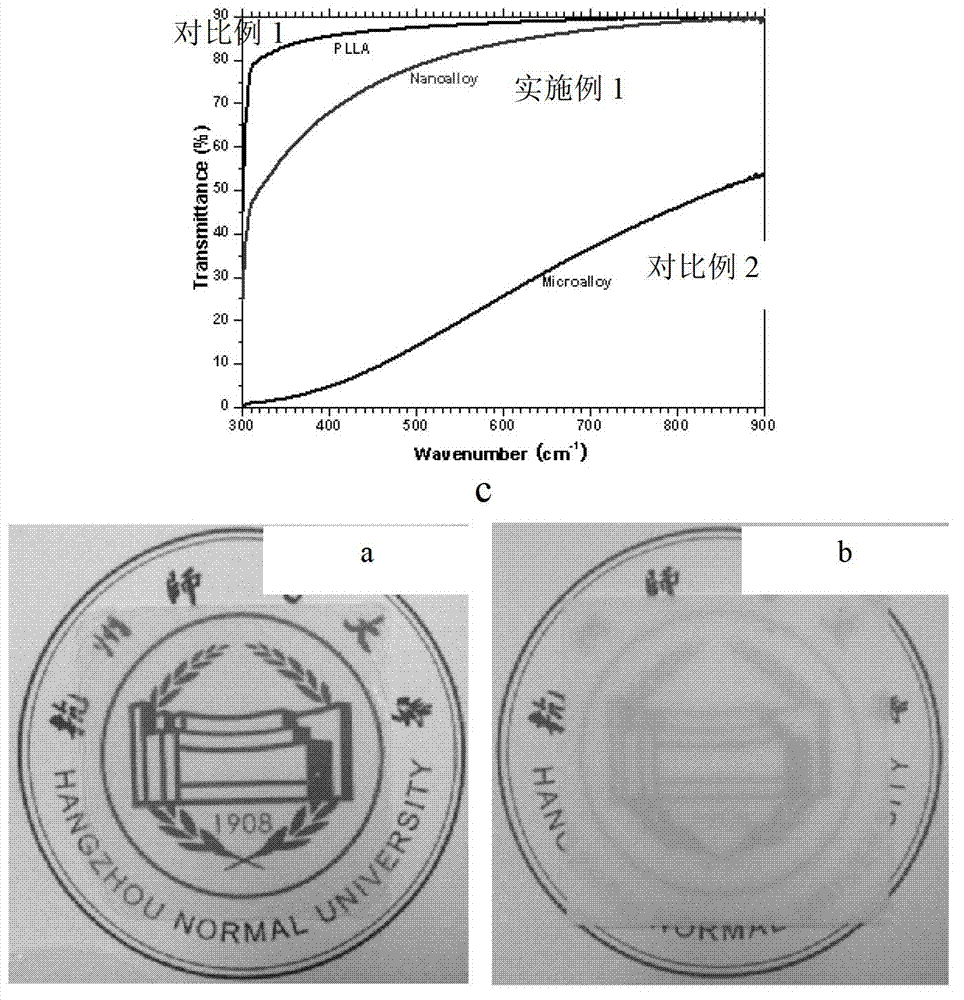

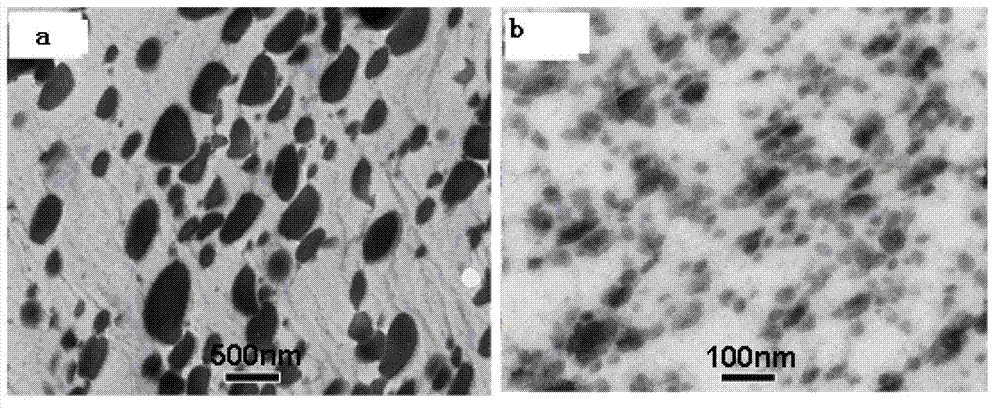

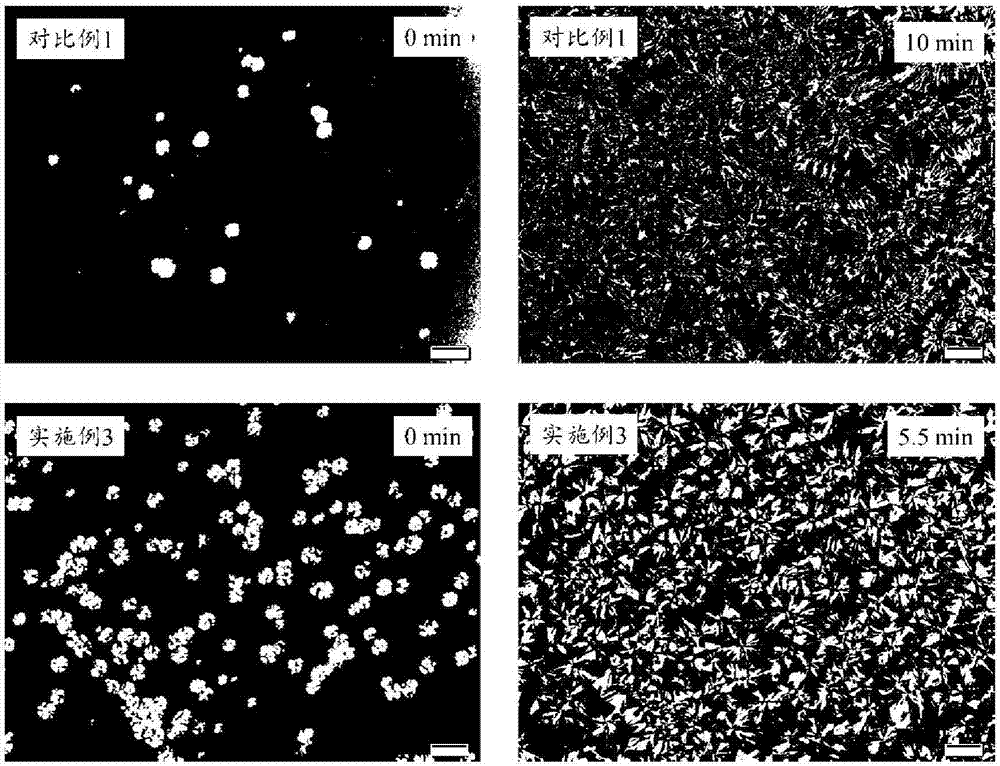

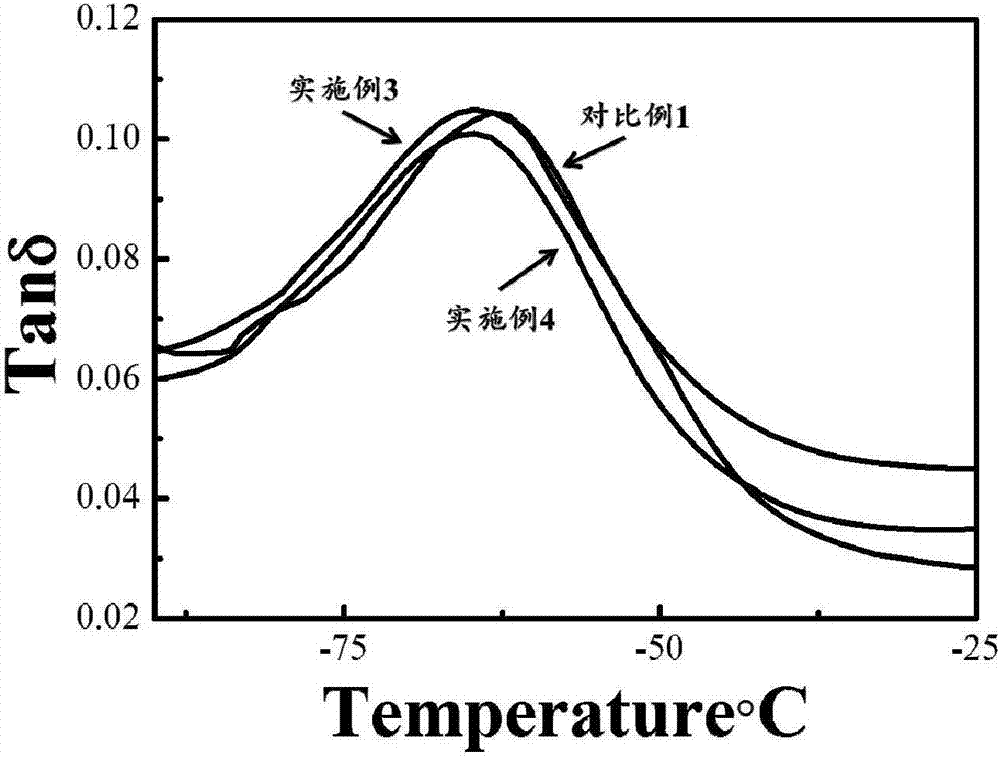

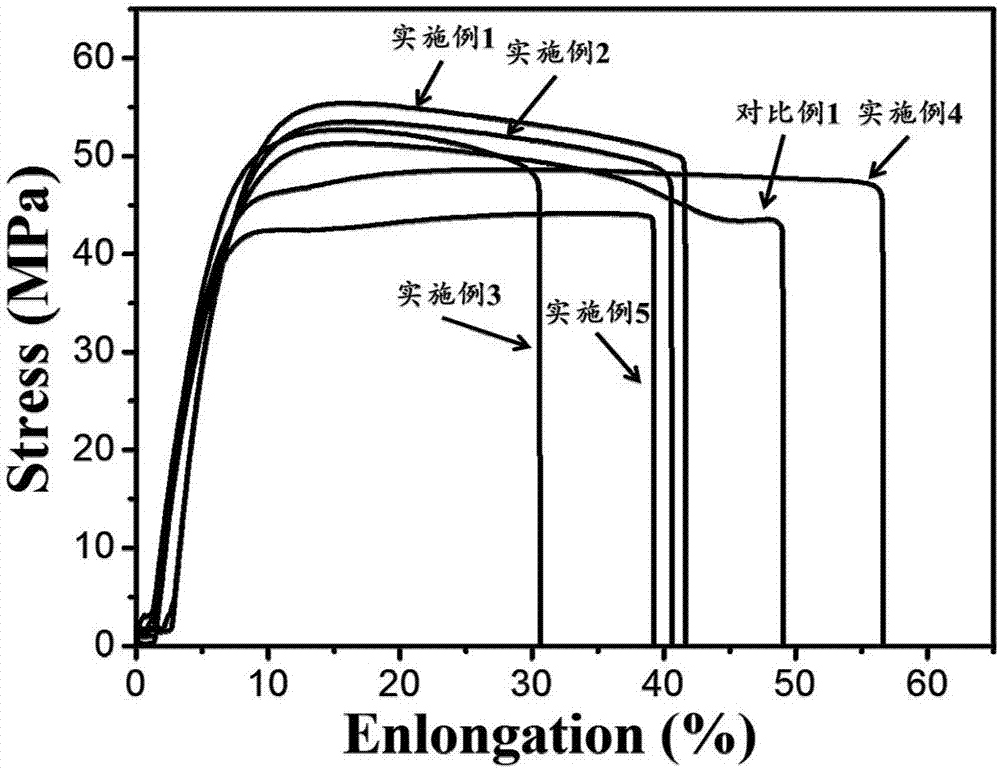

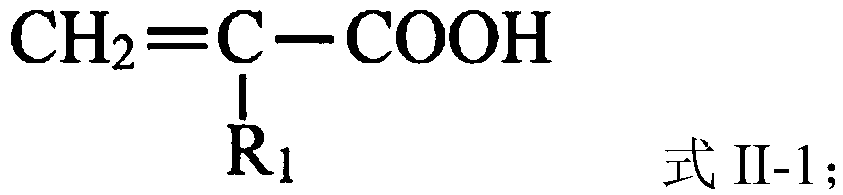

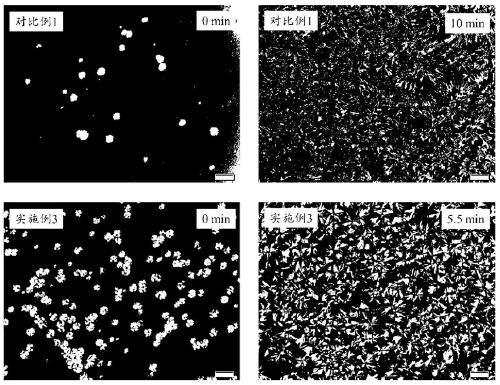

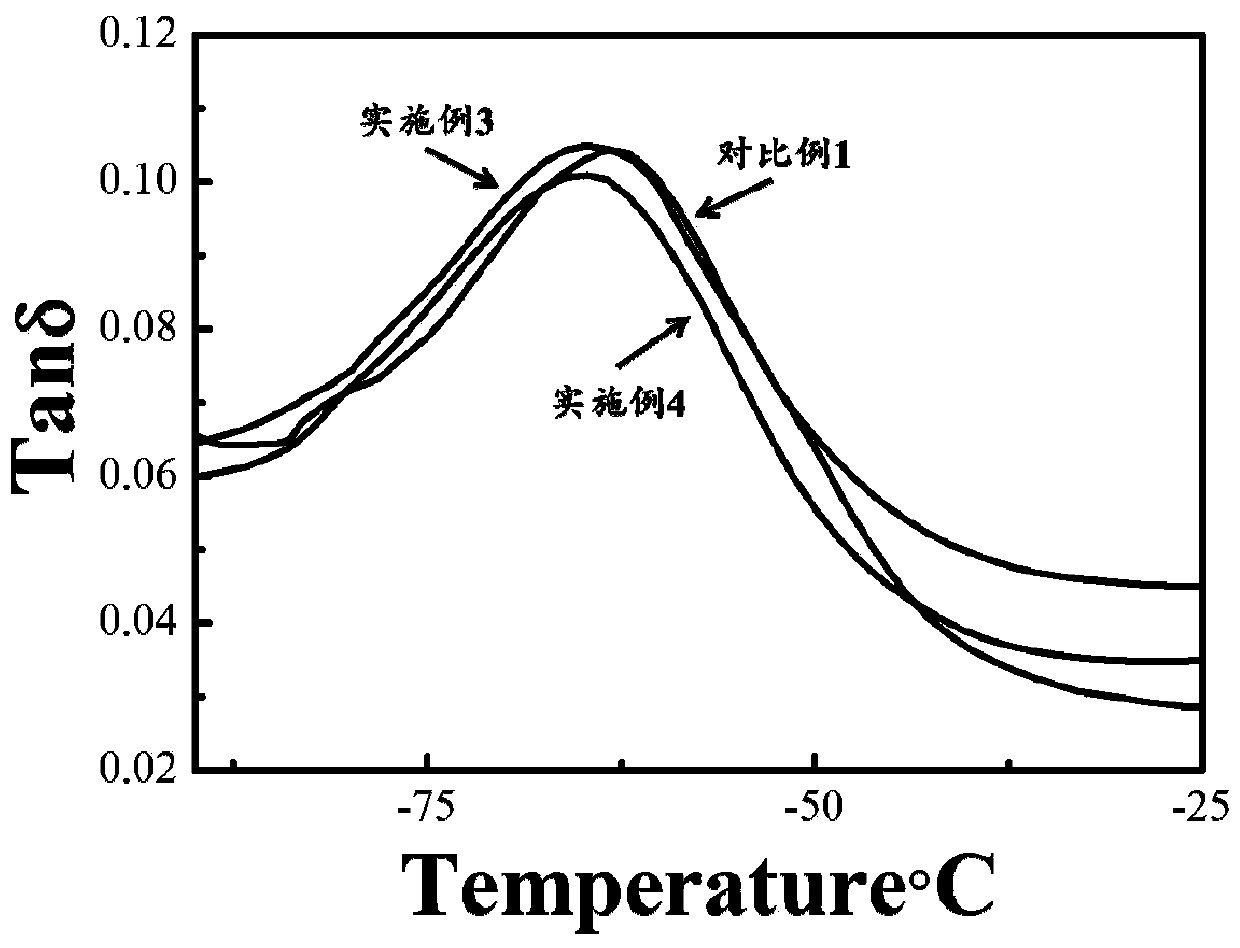

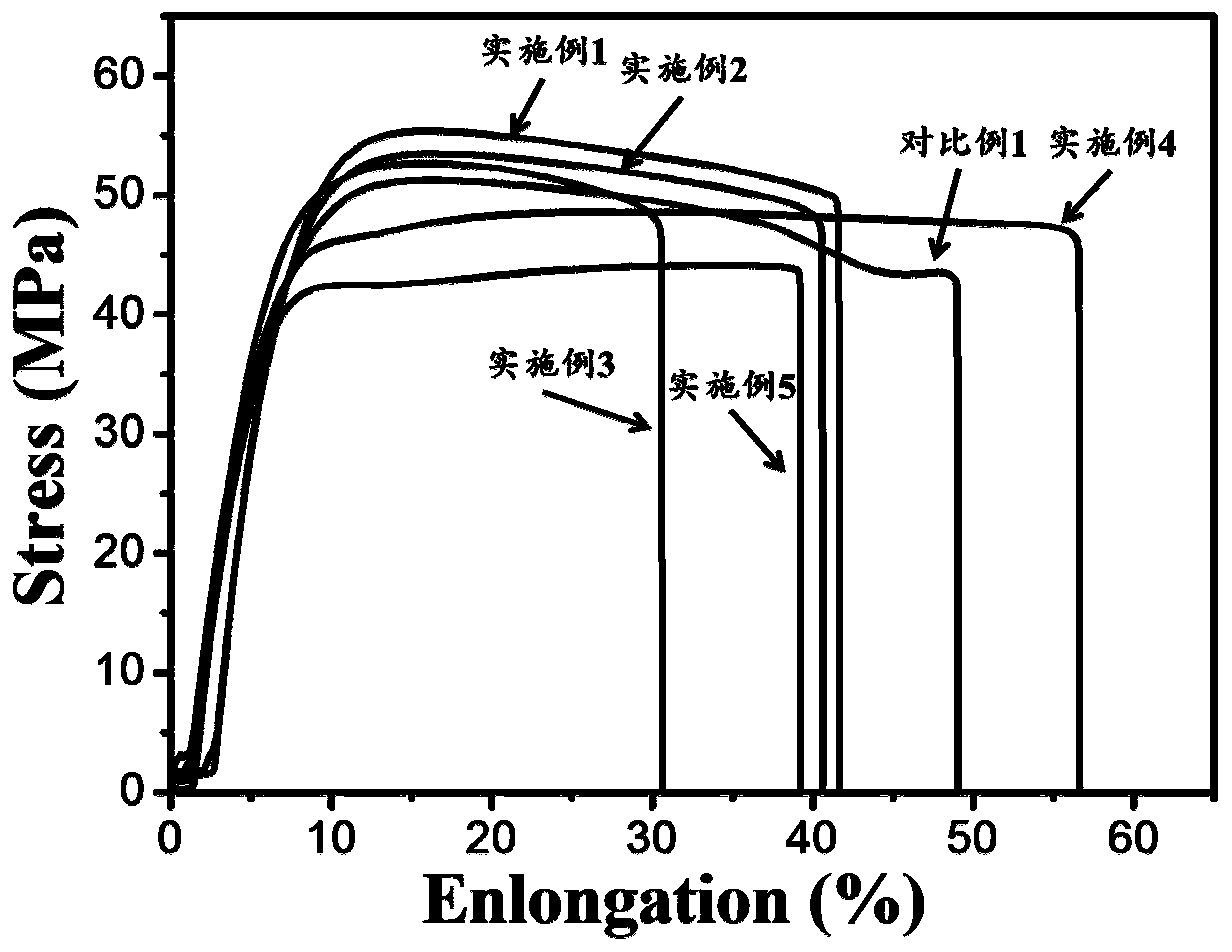

The invention discloses a transparent polylactic acid alloy material, which is prepared by polylactic acid and an elastomer by a melt mixing device through melt blending, based on the polylactic acid and the elastomer, the mass fraction of the polylactic acid accounts for 75-98% and the mass fraction of the elastomer accounts for 2-25%, and the elastomer is the elastomer containing maleic anhydride or an epoxy group. According to the invention, a certain amount of elastomer capable of being reacted with polylactic acid is added in the polylactic acid, the melt blending condition of the material is adjusted in a reasonable mode, all elastomer micro-areas are uniformly dispersed in the polylactic acid, and the disperse size is less than 100nm, thereby the transparent polylactic acid alloy material with substantially enhanced material shock resistance and fast crystallization speed of matrix polylactic acid can be obtained. A purpose that primary modification overcomes a plurality of polylactic acid application barriers can be realized. The transparent polylactic acid alloy material can be used in the industries of package, electron, building material, automobile and the like.

Owner:HANGZHOU NORMAL UNIVERSITY

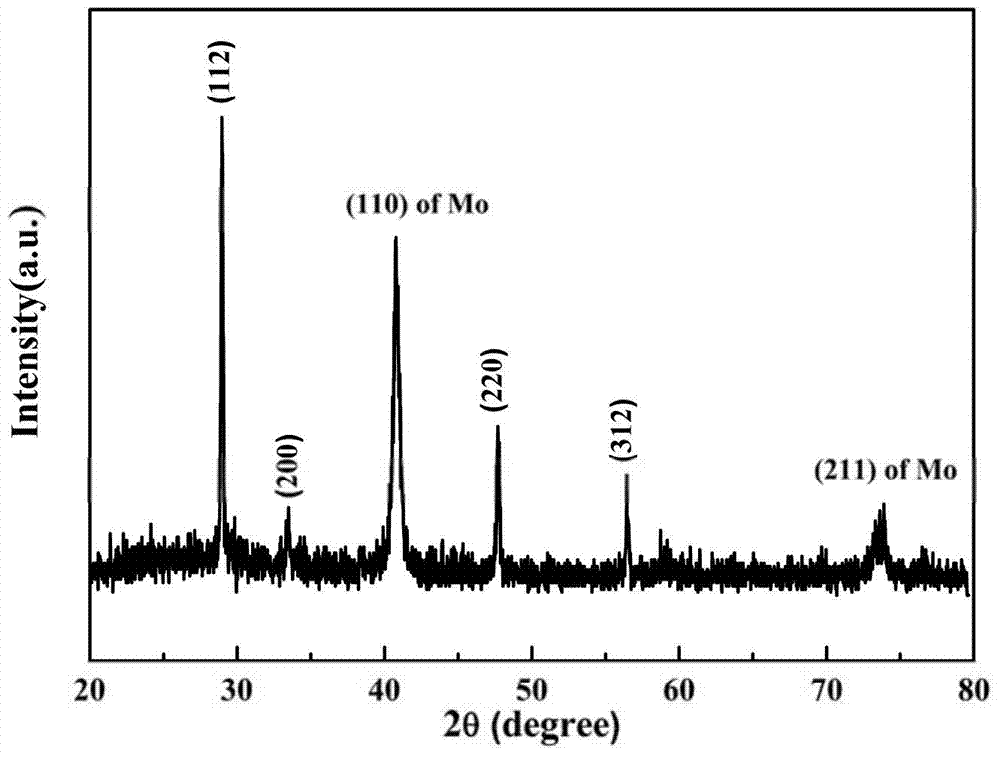

Copper-zinc-tin film material with controllable components, copper-zinc-tin sulfenyl solar battery and preparation method of the two

ActiveCN104120467AGuaranteed Simultaneous DepositionReduce uneven depositionCellsFinal product manufactureElectricityCopper

The invention discloses a preparation method of a copper-zinc-tin film material. The preparation method comprises the following steps: (1) the copper-zinc-tin film material comprises at least three main metal elements of copper, zinc and tin; electroplate liquid contains any two main metal elements; and additive solution contains a third main metal element; (2) at least one conducting electrode serves as a first electrode in the electroplate liquid; and a film substrate to be plated serves as a second electrode; (3) when electricity is conducted between the first electrode and the second electrode, and the speed is controlled to add the additive solution, that is, films containing three metals of copper, zinc and tin are synchronously deposited to obtain a substrate deposited with the copper-zinc-tin metal film on the surface; and the copper-zinc-tin film material is obtained. In the preparation method of a copper-zinc-tin sulfenyl solar battery, a cadmium sulfide buffer layer, a ZnO film and an ITO film or an AZO film are deposited on the copper-zinc-tin film material in sequence to obtain the copper-zinc-tin sulfenyl solar battery after the step (4).

Owner:SHAANXI NORMAL UNIV

Aliphatic polycarbonate alloy material

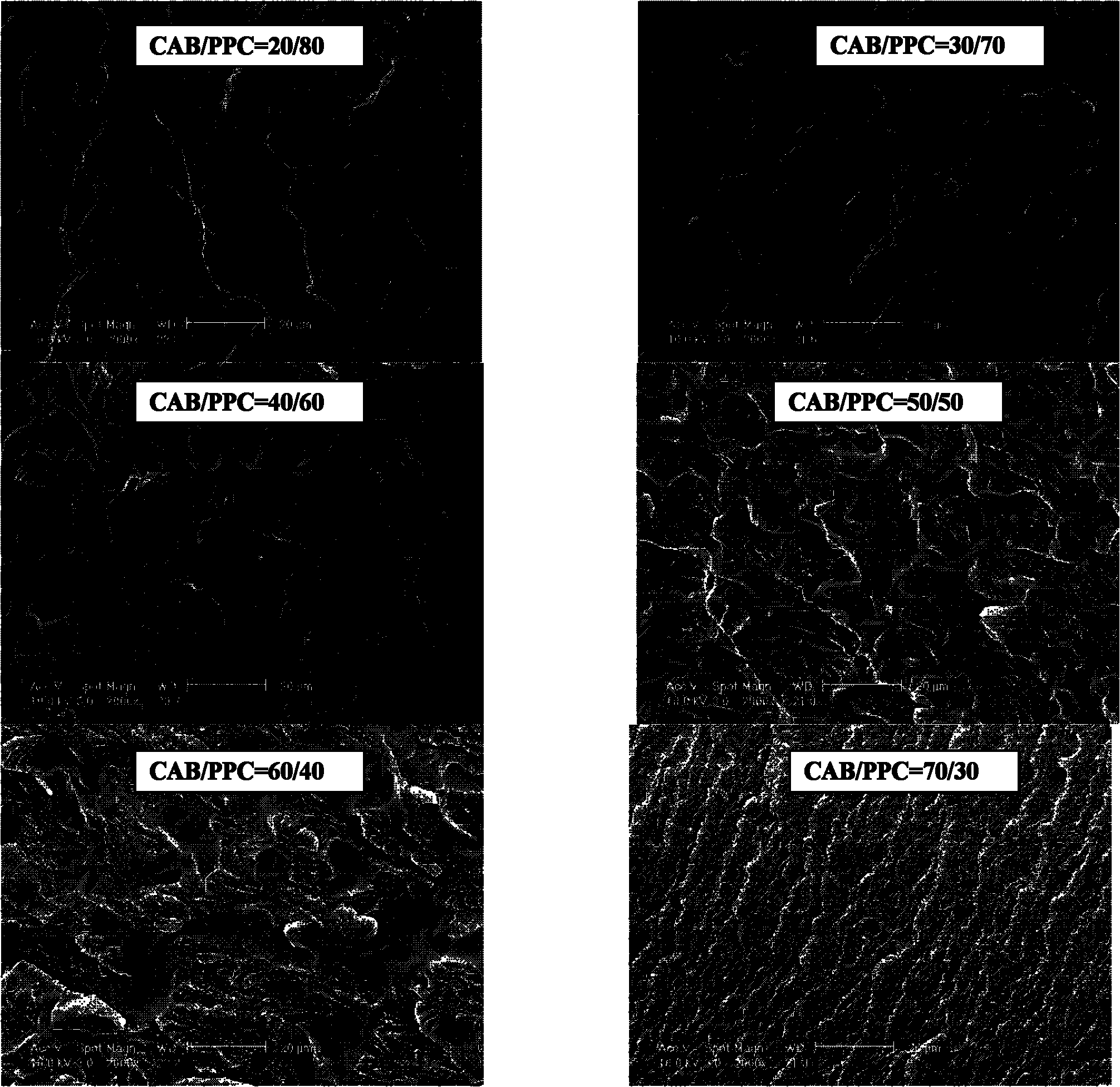

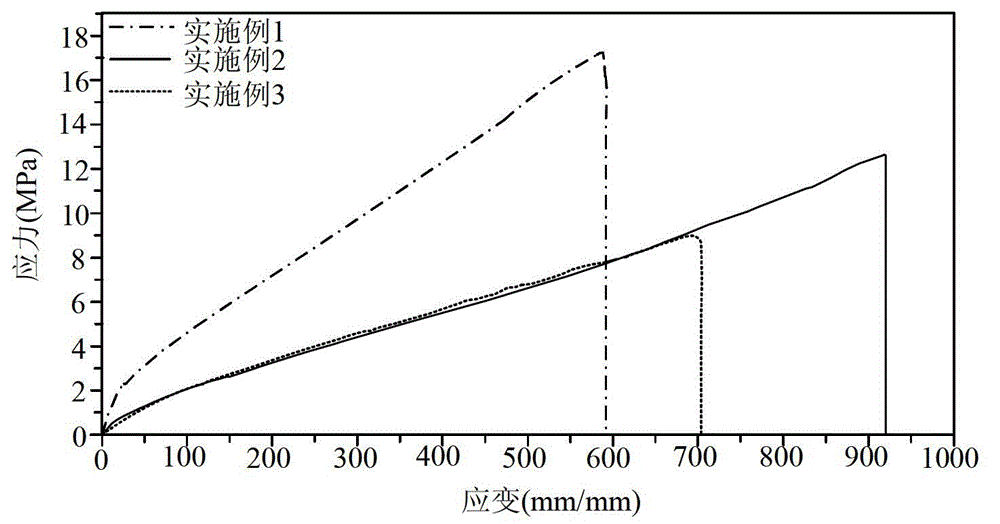

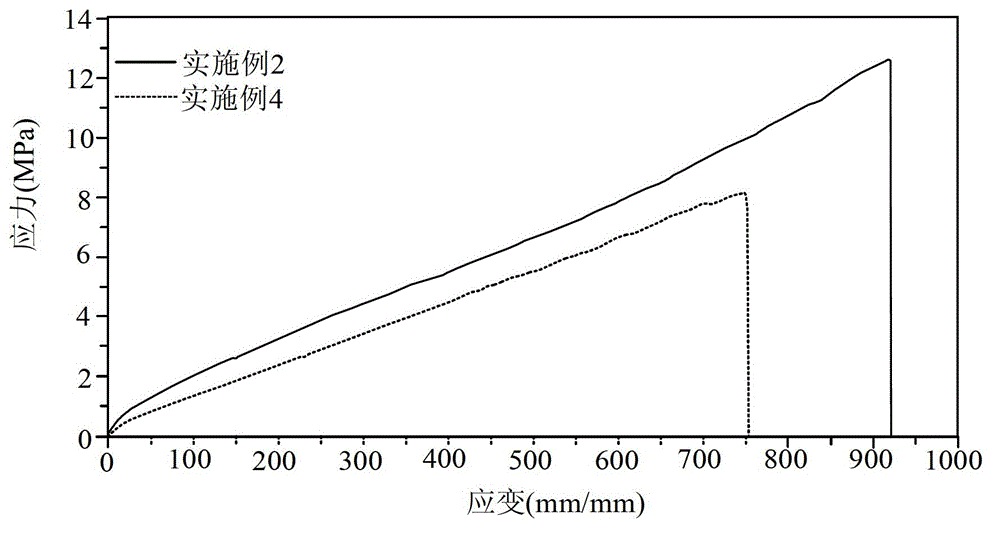

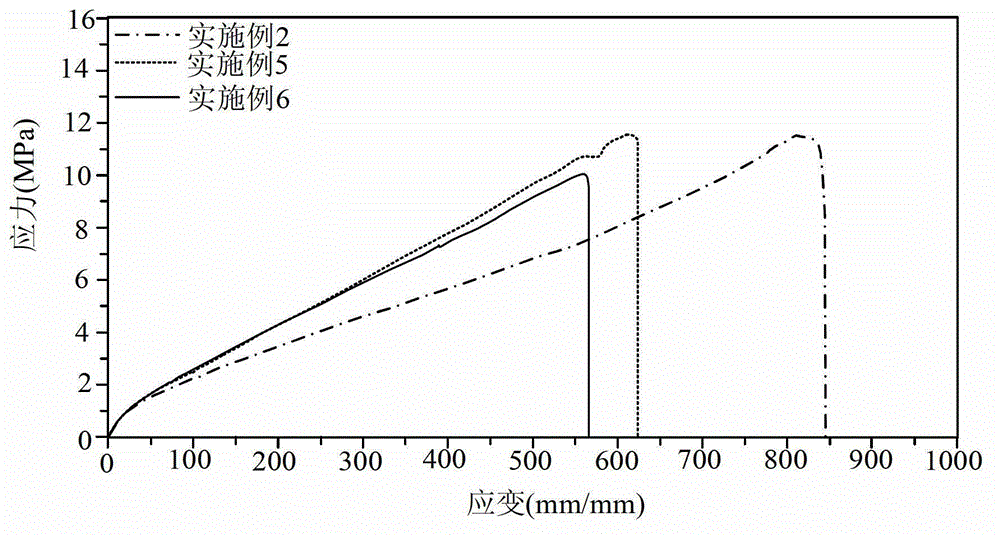

ActiveCN102153849ALow dependence on petrochemical resourcesReduce light transmittanceConjugated cellulose/protein artificial filamentsConjugated synthetic polymer artificial filamentsCelluloseAlloy

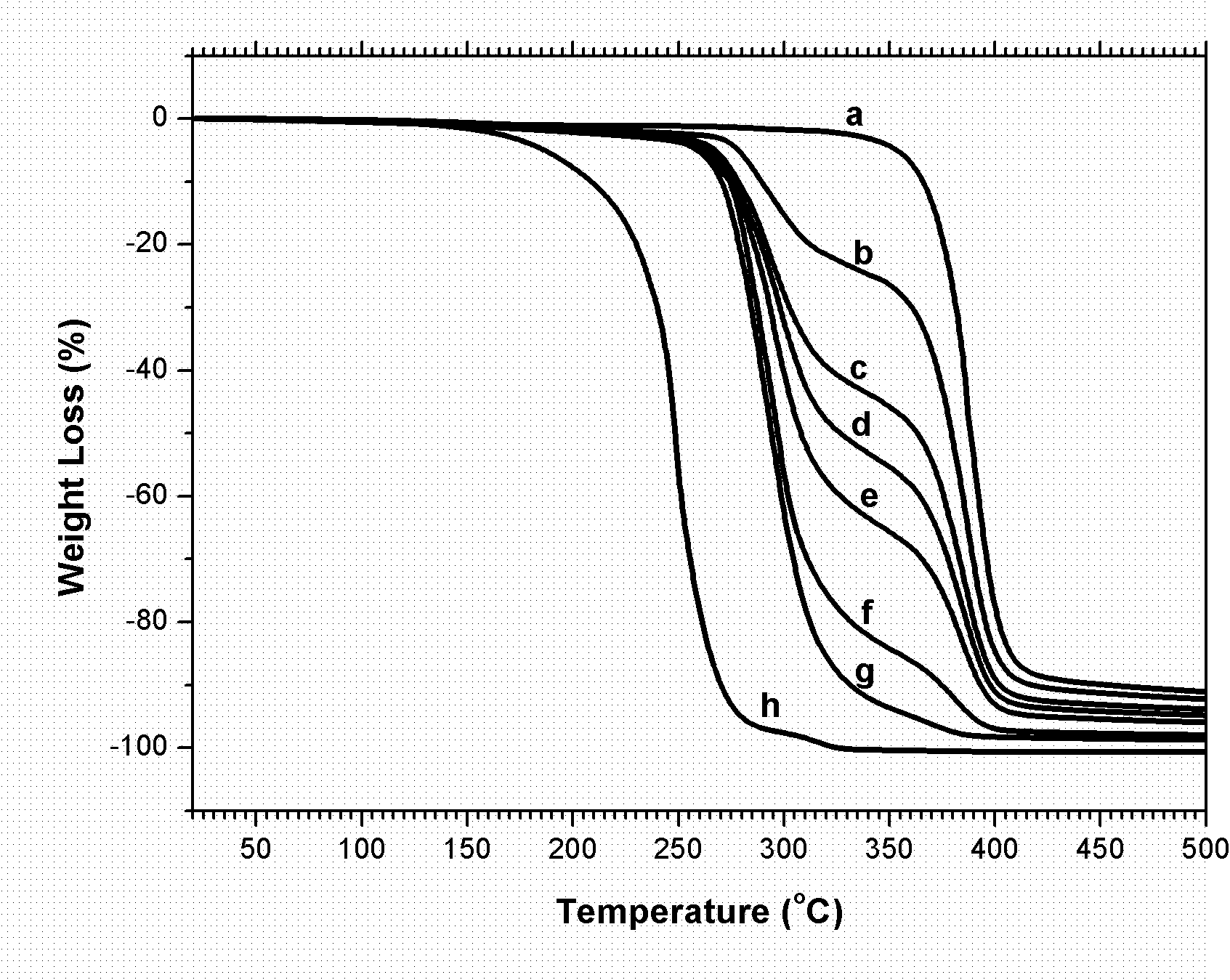

The invention discloses an aliphatic polycarbonate alloy material which is obtained by the following main steps: evenly mixing aliphatic polycarbonate and esterified cellulose, and then directly adding the mixture into a melting mixing device for melt blending. Based on the aliphatic polycarbonate and esterified cellulose, the mass fraction of the aliphatic polycarbonate is 5-95%, the mass fraction of the esterified cellulose is 5-95%, and the aliphatic polycarbonate is a copolymer of carbon dioxide and epoxide. By using the aliphatic polycarbonate alloy material, the mechanical property of the aliphatic polycarbonate material is greatly improved, the applicable temperature range of the aliphatic polycarbonate material is broadened, and the thermal degradation temperature of the aliphaticpolycarbonate material is improved.

Owner:南通九思医疗器械有限公司

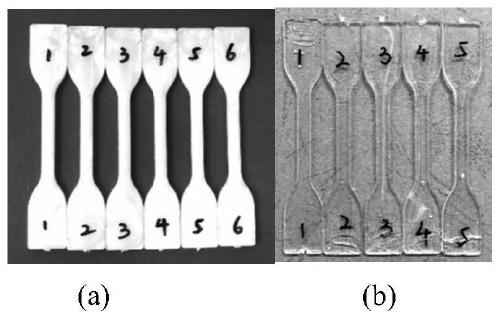

Oil resistance thermoplastic elastomer and preparing method thereof

The invention relates to an oil resistance thermoplastic elastomer and a preparing method thereof. Compatibility, processibility, mechanical property and oil resistivity of the existing commercial products are worse relatively. The oil resistance thermoplastic elastomer is a mixture of ethylene vinyl acetate cross-linking agent, ethylene-vinyl acetate (EVA), peroxide vulcanization agent, and addition agent. The method for preparing the oil resistance thermoplastic elastomer includes that firstly, the ethylene vinyl acetate EVM and the vulcanizing agent are commixed by weight 1000: 0.1to 5 at the temperature of 30-20 DEG C to obtain masterbatch. After the smashed masterbatch and the ethylene vinyl acetate EVA are mixed evenly, dynamic vulcanization is lasted for 1 minute to five minutes at the temperature of 0-250 DEG C, and the oil resistance thermoplastic elastomer is available. The elastomer has the advantages of being better in mechanical property, excellent in oil resistance property, simple in industrial device and recyclable in processing economy.

Owner:HANGZHOU NORMAL UNIVERSITY

Internally-plasticized antistatic polyformaldehyde material and preparation method thereof

The invention discloses an internally-plasticized antistatic polyformaldehyde material and a preparation method thereof. The polyformaldehyde material is a mixture of polyformaldehyde and ironic liquid. The preparation method comprises the following steps: respectively carrying out vacuum drying on polyformaldehyde and ironic liquid at 80-120 DEG C for 24-48 hours; adding the dried polyformaldehyde and ironic liquid into fusion mixing equipment in a mass ratio of 100 to (0.01-10), and carrying out fusion mixing at 170-200 DEG C, so as to obtain a mixture; and discharging the mixture out of the fusion mixing equipment, and cooling to the room temperature, so as to obtain the polyformaldehyde material. The polyformaldehyde material disclosed by the invention has excellent antistatic performance; by adding ironic liquid, the size of a spherocrystal of a polyformaldehyde matrix can be effectively reduced, so that a certain plasticization effect is achieved; and only common fusion mixing equipment is used in the preparation method, so that the industrial preparation is simple.

Owner:安徽贺赢新材料科技有限公司

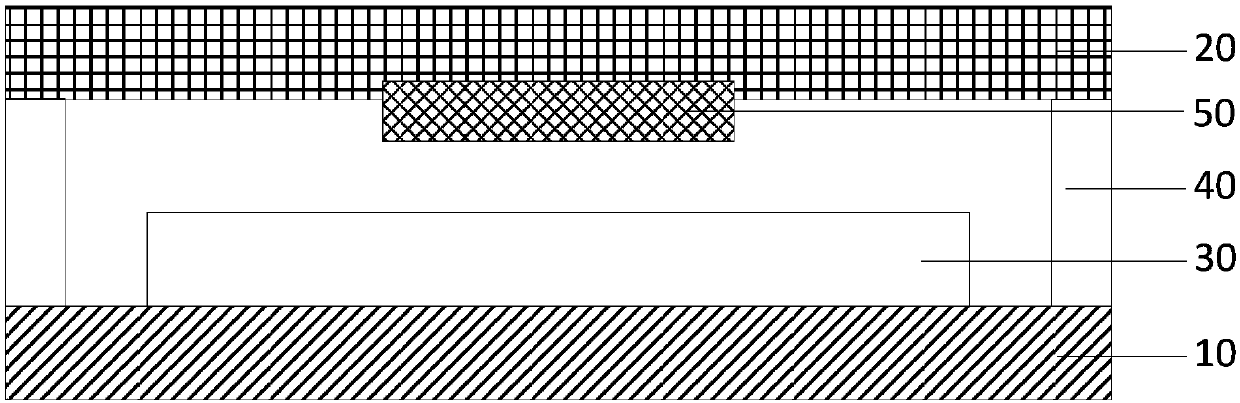

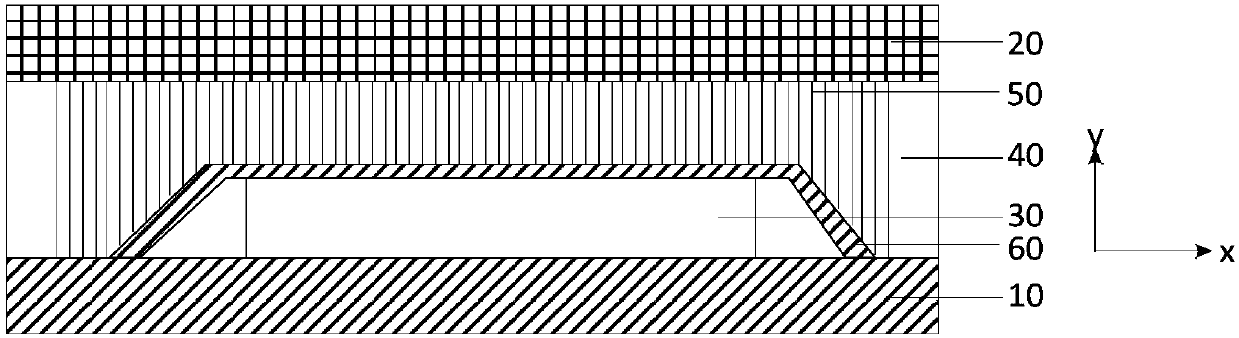

Packaging structure, preparation method of packaging structure and organic light-emitting display

PendingCN109994642AImprove water and oxygen barrier performancePlay a buffer roleSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringOrganic electroluminescence

The invention relates to the technical field of display, and discloses a packaging structure, a preparation method of the packaging structure and an organic light-emitting display. The packaging structure comprises a first substrate and a second substrate which are oppositely arranged, a to-be-packaged body formed between the first substrate and the second substrate, a packaging layer which is formed on the first substrate and continuously covers the exposed surface of the to-be-packaged body, and a drying agent layer which is clamped between the packaging layer and the second substrate, wherein the drying agent layer is a gel-state drying agent layer. According to the packaging structure, the gel-state drying agent layer is formed between the packaging layer and the second substrate by curing a liquid drying agent, and the thickness of the drying agent layer is not required, so that the water oxygen barrier capability of the packaging structure can be improved on the basis that the thickness of the packaging structure is not increased.

Owner:SUZHOU QUINGYUE OPTOELECTRONICS TECH CO LTD

Method for improving magnetic performance and corrosion resistance of cerium neodymium iron boron sintered magnet simultaneously

InactiveCN108183010ASimple industrial preparationImprove magnetic propertiesInductances/transformers/magnets manufactureMagnetic materialsCeriumPhase composition

The invention discloses a method for improving the magnetic performance and the corrosion resistance of a cerium neodymium iron boron sintered magnet simultaneously. The method is characterized in that a double-main-phase alloy technology is adopted, and a small amount of didymium hydride powder is added during powder mixing for crystal boundary structure reconstructing. Through the introduction of the didymium hydride powder, the distribution of the crystal boundary structure is changed, the phase composition of the crystal boundary structure is also changed, and therefore, the magnetic performance and the corrosion resistance of the cerium neodymium iron boron sintered magnet are improved simultaneously. The didymium hydride powder has the advantage of being easily prepared industrially,raw materials and equipment needed for the didymium hydride powder are didymium alloy used in industrial production of neodymium iron boron, a smelting and melt-spinning furnace, a hydrogen breakingfurnace and an airflow grinding pulverizer. By means of the method for improving the magnetic performance and the corrosion resistance of the cerium neodymium iron boron sintered magnet simultaneously, the advantages of the double-main-phase alloy technology and the crystal boundary structure reconstructing technology are integrated, the magnet cost is effectively lowered while the magnetic performance and the corrosion resistance are guaranteed, the application of cerium in a rail earth permanent magnetic material is further promoted, and the market space is wide.

Owner:ZHEJIANG UNIV

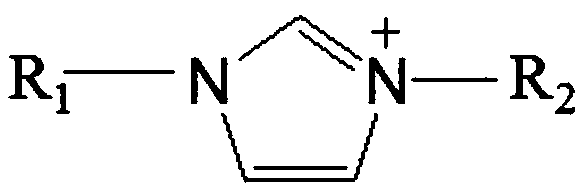

Permanent antibacterial polyether sulfone membrane material and preparation method thereof

The invention discloses a permanent antibacterial polyether sulfone membrane material and a preparation method thereof. According to the invention, through a Co-gamma radiation grafting chemical modification method, a unsaturated bond-containing ionic liquid connected by chemical bonds is uniformly distributed on the surface of polyethersulfone, wherein a mass ratio of the ionic liquid to the polyethersulfone is 2-11:100; according to the method, through radiation irradiation, the ionic liquid of the blended flat plate membrane is connected to the polymer through the chemical bond; and due togood compatibility between the polymer and the ionic liquid, the small molecules of the ionic liquid can fully contact the polymer during radiation irradiation, so that the small molecules of the ionic liquid are grafted to the PES molecular chain.

Owner:HANGZHOU NORMAL UNIVERSITY

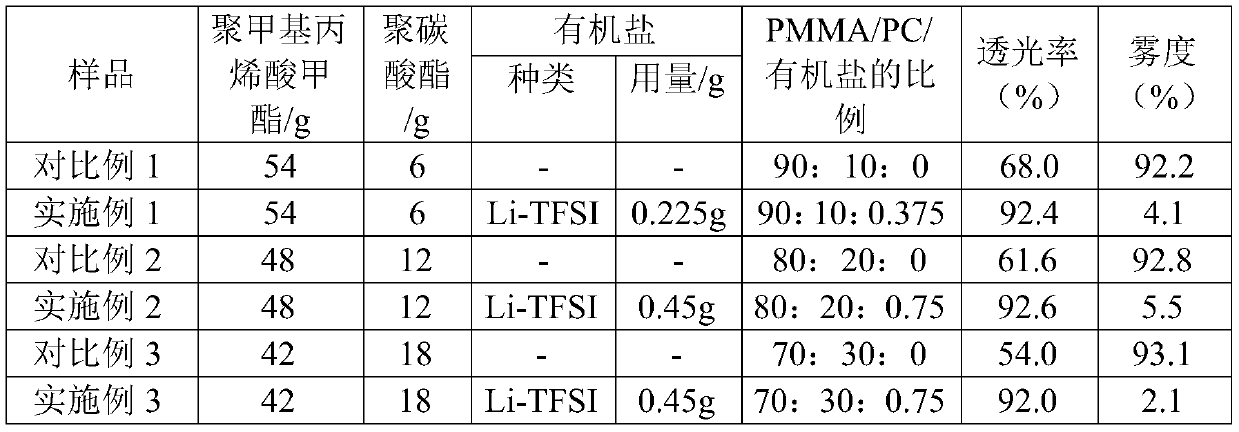

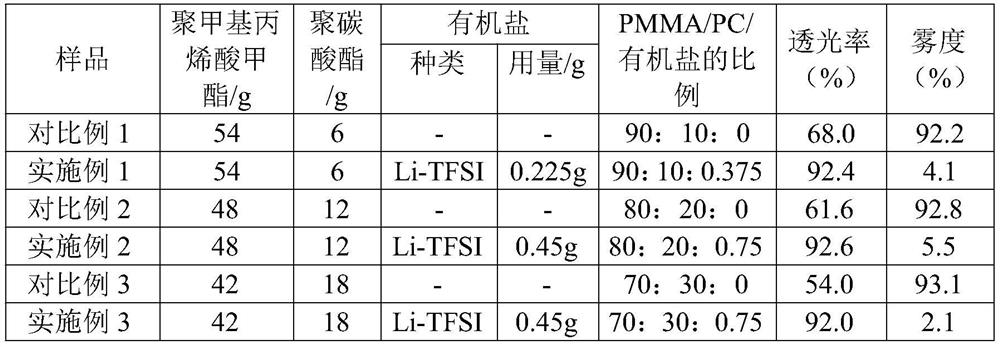

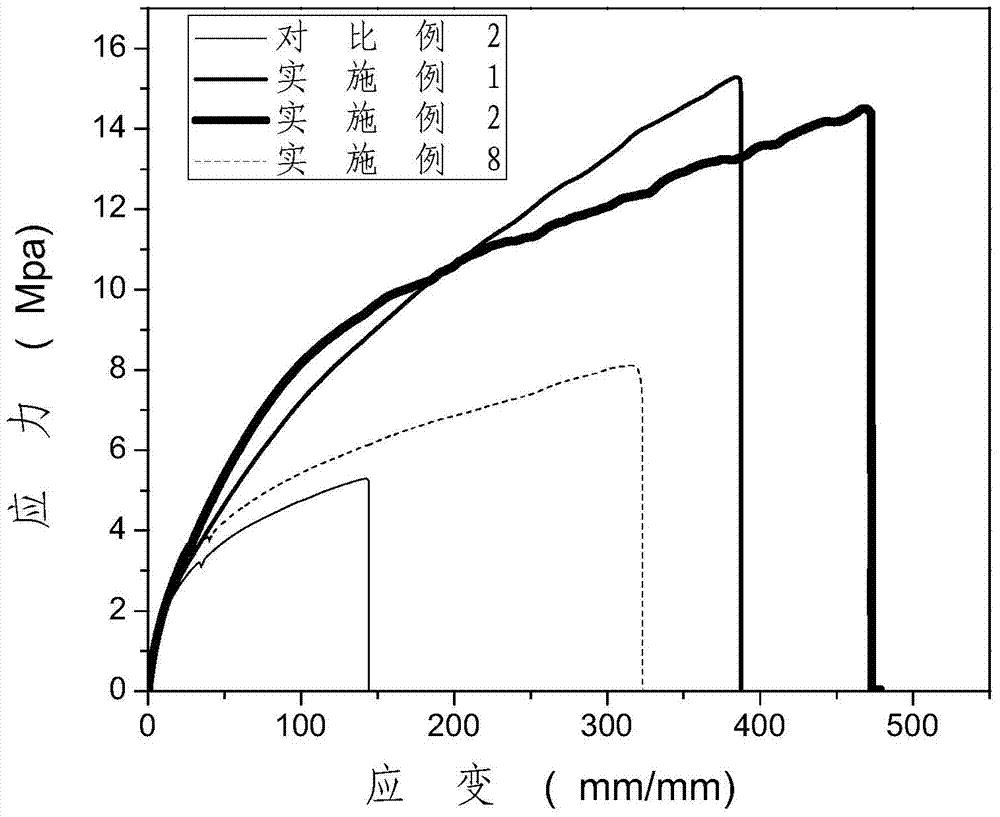

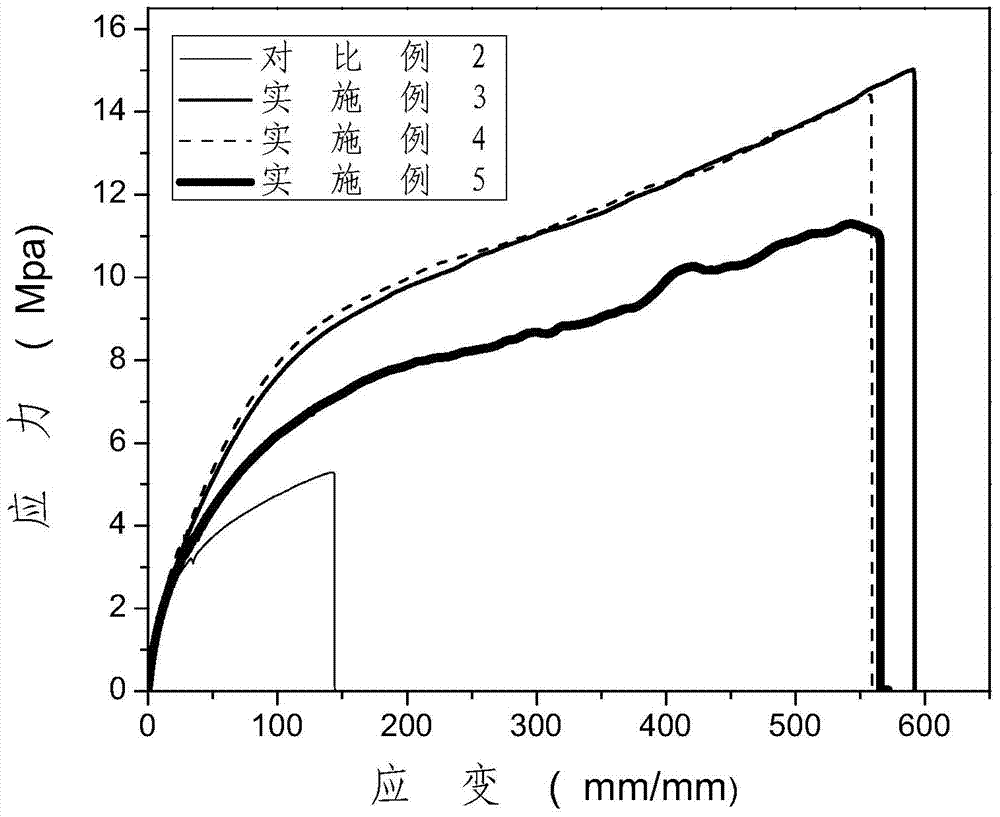

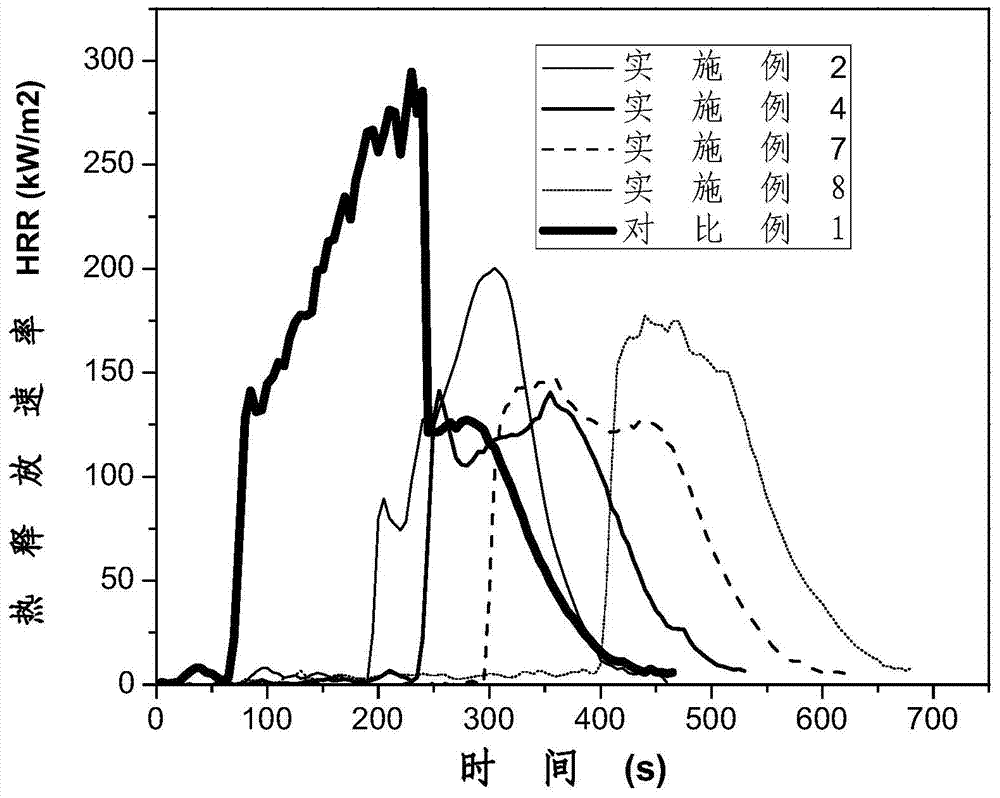

Optically transparent polymethyl methacrylate/polycarbonate composite and preparation method thereof

The invention discloses an optically transparent polymethyl methacrylate / polycarbonate composite and a preparation method thereof. The material is a blend of polymethyl methacrylate, polycarbonate andan organic salt with a metal as a cation, and the mass ratio is 60-90:40-10:0.2-3. By adding the organic salt with the metal as the cation, compatibility between the polymethyl methacrylate and the polycarbonate is greatly improved, light transmission performance of the material is greatly improved, light transmittance of the material is 90% or more, the haze is 10% or less, the refractive indexis 1.49 or more, and the material is optically transparent.

Owner:HANGZHOU NORMAL UNIVERSITY

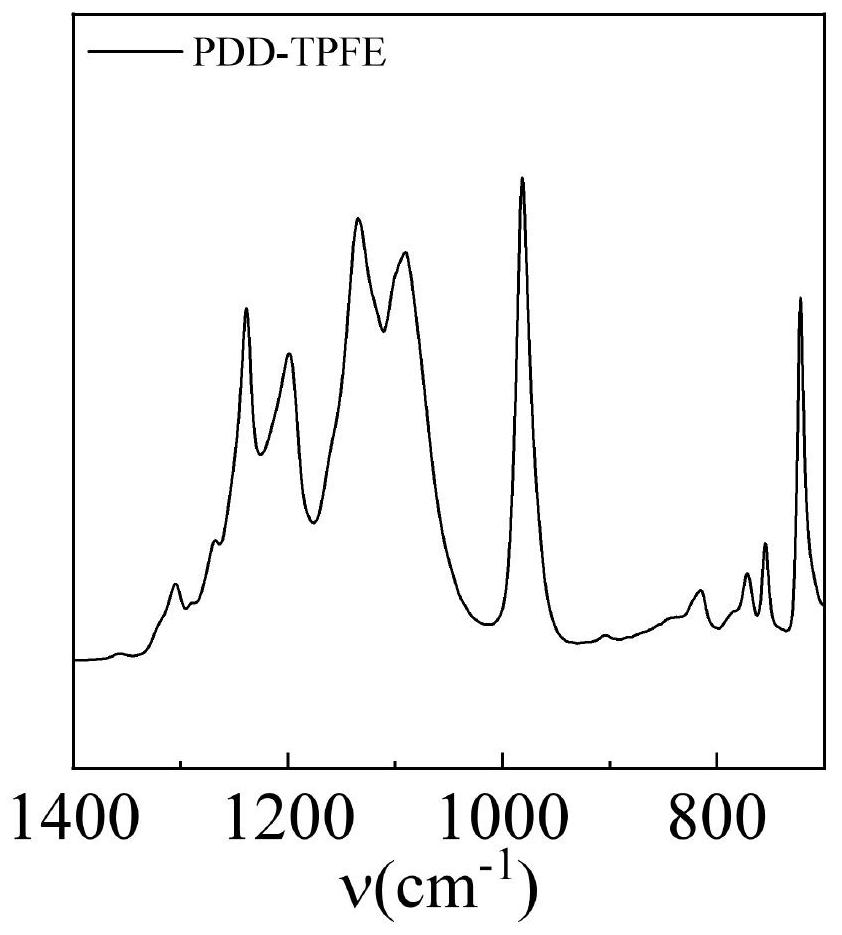

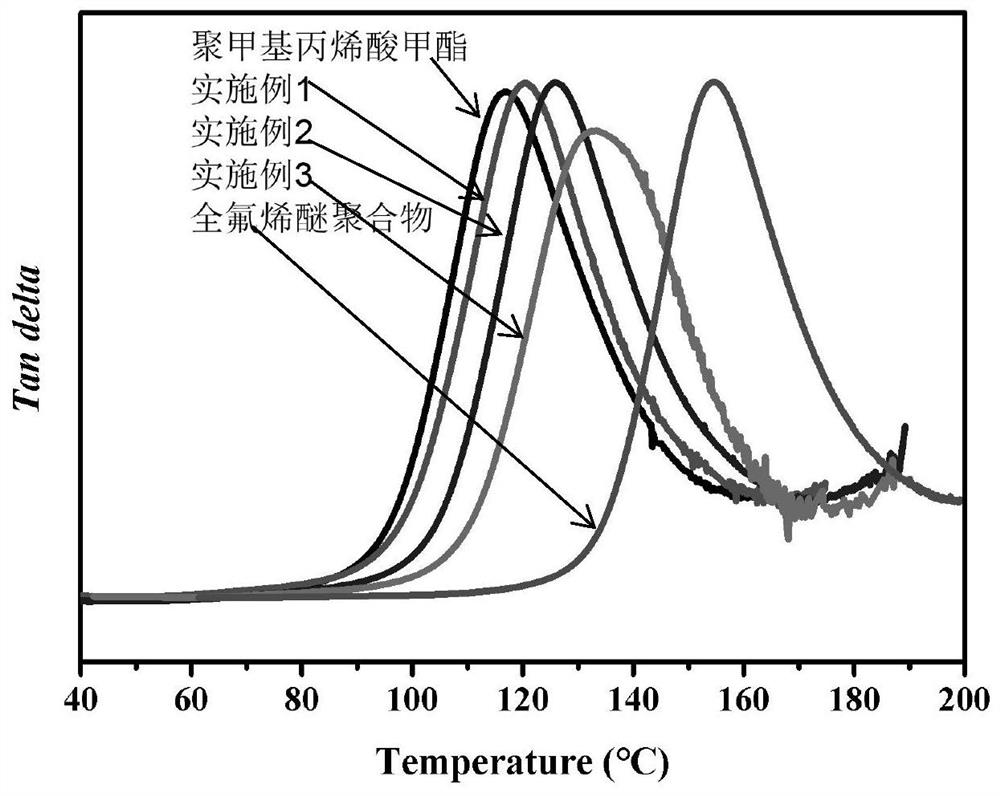

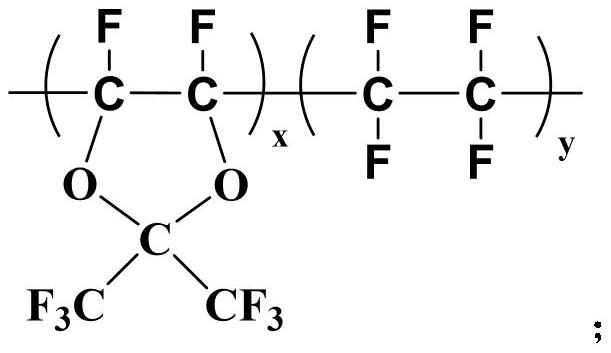

Low-refractive-index transparent material as well as preparation method and application thereof

ActiveCN112375173AHigh transparencyLow refractive indexCladded optical fibreOptical waveguide light guideAcrylic resinRefractive index

The invention discloses a low-refractive-index transparent material as well as a preparation method and application thereof. Although traditional plastic optical fibers are low in cost, the traditional plastic optical fibers have the defects of high optical loss, low temperature resistance and the like, in order to overcome the defects of the traditional plastic optical fibers, perfluororesin is adopted to replace the traditional plastic optical fibers, but the perfluororesin is complex in synthesis, high in manufacturing cost and high in cost performance. Therefore, a perfluoroalkene ether copolymer and an acrylic resin polymer are subjected to melt blending, and the low-refractive-index transparent material with higher economic benefits is prepared under the conditions that the transparency is not lost and the low refractive index is kept. The preparation method has the advantages that (1) the acrylate polymer is a common high polymer and is low in price; (2) only common melting andmixing equipment is needed for preparation, and the industrial preparation is simple; and (3) the material prepared by melt blending shows good transparency and extremely low refractive index.

Owner:HANGZHOU NORMAL UNIVERSITY

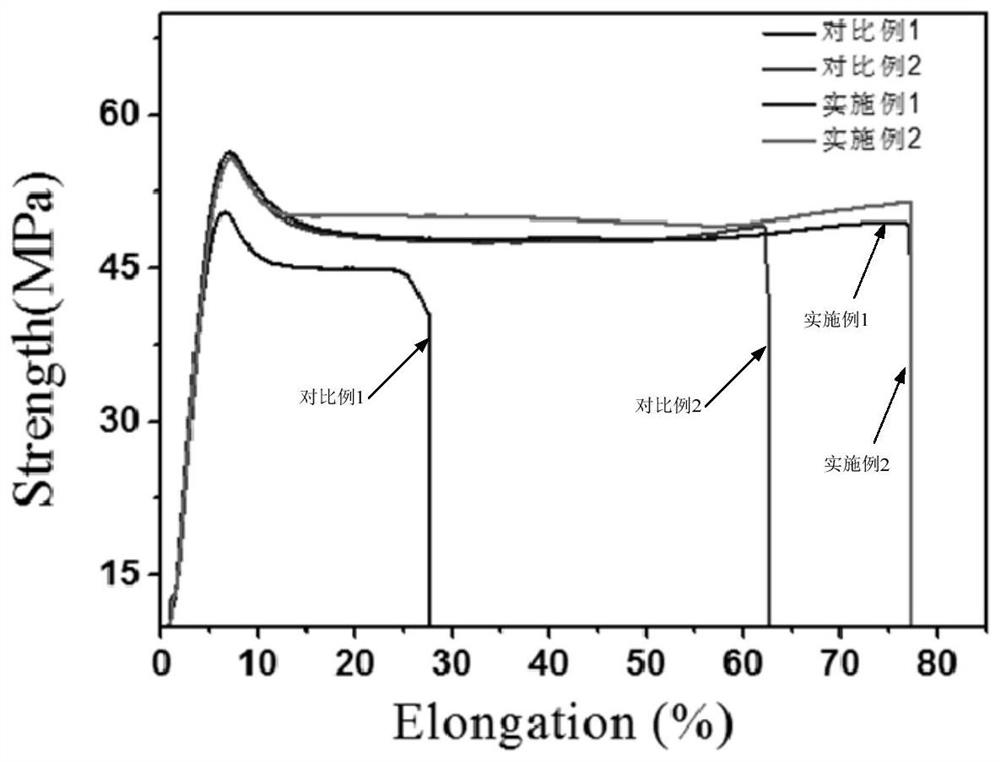

Preparation method of polylactic acid/polycaprolactone/polyformaldehyde blend

The invention relates to a preparation method of a polylactic acid / polycaprolactone / polyformaldehyde blend and belongs to the field of high polymer materials. The blend is prepared by mixing polylactic acid, polycaprolactone and polyformaldehyde. The polylactic acid used in the invention is bio-based polymer resin taking renewable biological resources as raw materials and has abundant raw materialsources, good biocompatibility and biodegradability and no pollution to the environment. The polycaprolactone is also biodegradable synthetic polymer resin, has good processing properties, and biocompatibility similar to that of the polylactic acid, and is widely applied to the aspects of medical fields, biodegradable packaging plastics and the like. Therefore, the prepared blending material belongs to an environment-friendly material. Meanwhile, according to the preparation method disclosed by the invention, by adding a small amount of polyformaldehyde, the tensile toughness of the polylactic acid / polycaprolactone blending material can be greatly improved.

Owner:HAINAN UNIVERSITY +1

Method for reutilizing solar cell backboard waste film and leftover material of solar cell backboard waste film

The invention discloses a method for reutilizing a solar cell backboard waste film and a leftover material of the solar cell backboard waste film. The method comprises the steps of adding the crushedsolar cell backboard waste film, an ethylene-vinyl acetate copolymer (EVA) and an efficient compatibilizer into melt blending equipment, and carrying out melt extrusion, so as to prepare a novel alloymaterial. According to the method, the industrial problems of manufacturer on solar cell backboards and upstream backboard films are solved, the solar cell backboard waste film waste in the solar cell industry is turned into weather, the circular reutilization of resources is truly realized, the non-renewable resources are saved, and the energy conservation and environmental protection purposes are achieved.

Owner:杭州福禧新材料有限公司

Regeneration method of catalyst for preparation of unsaturated acid or unsaturated acid ester

ActiveCN108101770AHigh reactivitySimple industrial preparationMolecular sieve catalystsOrganic compound preparationChemistryOrganic chemistry

The invention relates to a regeneration method of a catalyst for preparation of unsaturated acid or unsaturated acid ester. The method comprises the step of regenerating the catalyst at a temperatureof 250-600 DEG C in an atmosphere containing hydrogen.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

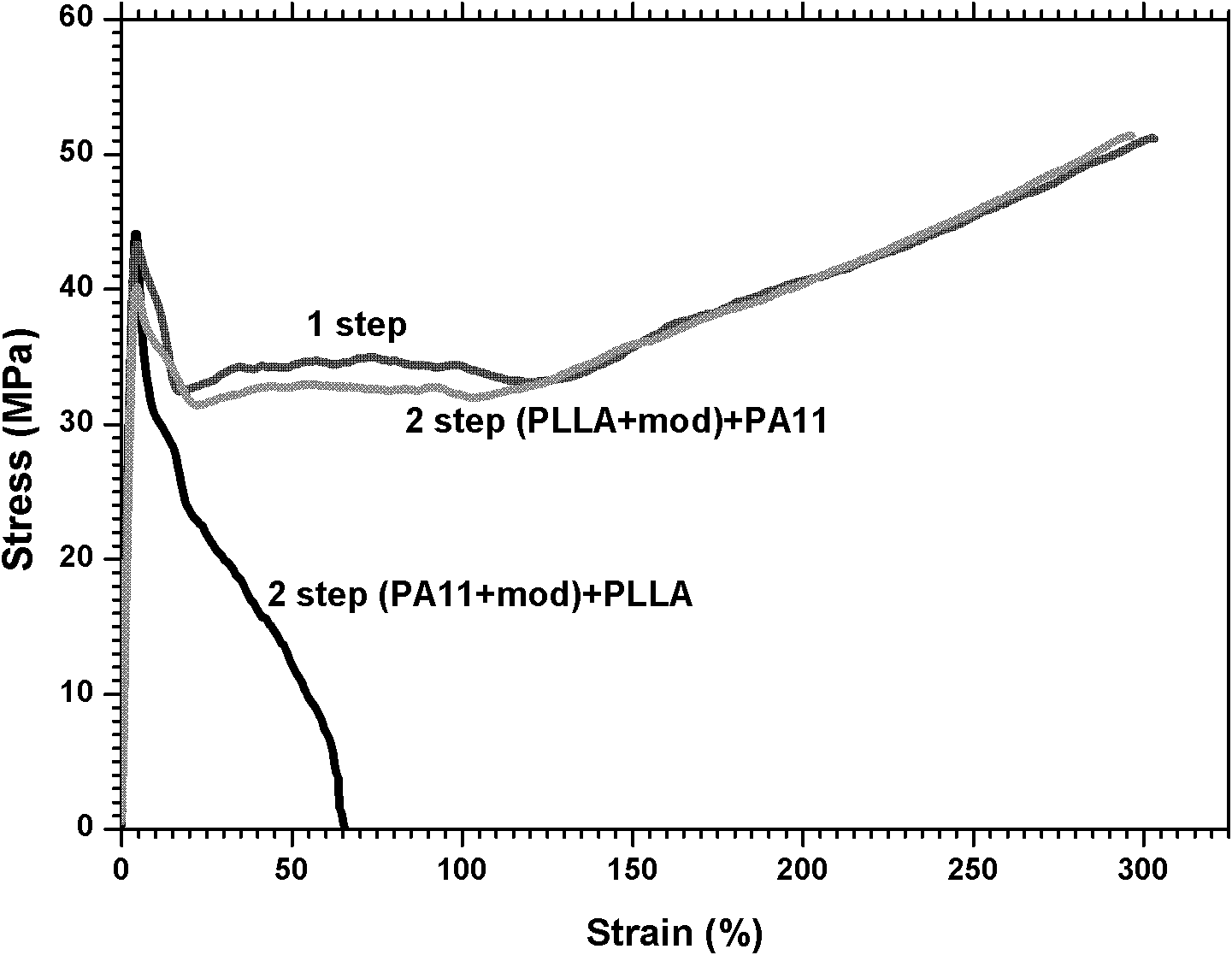

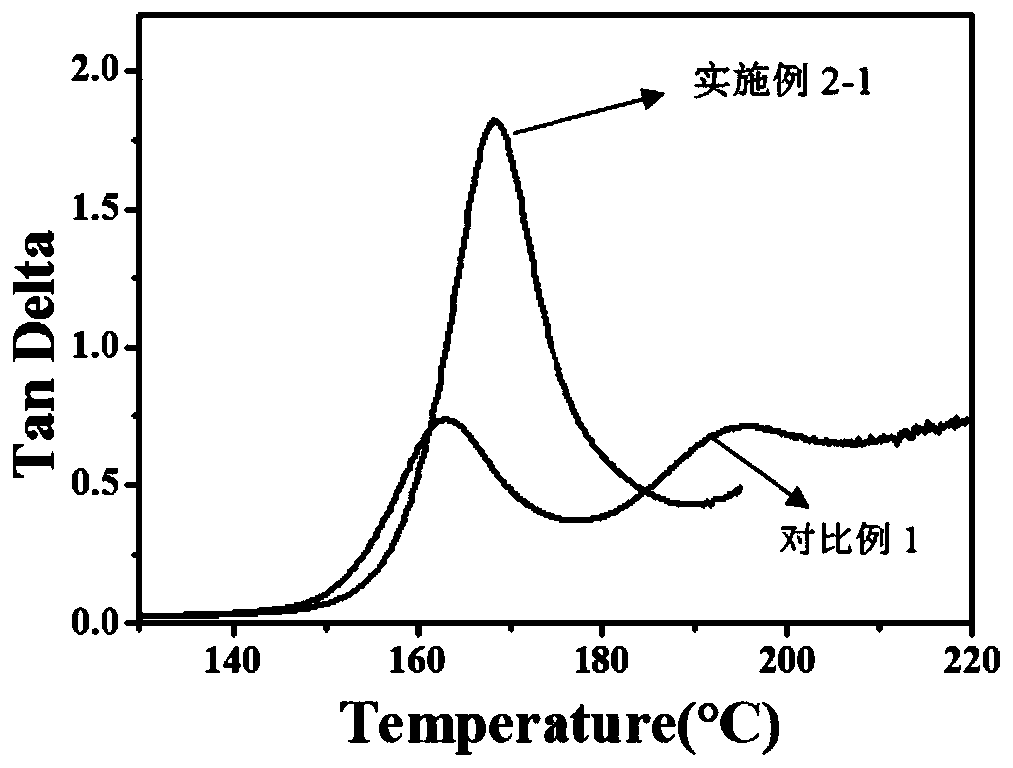

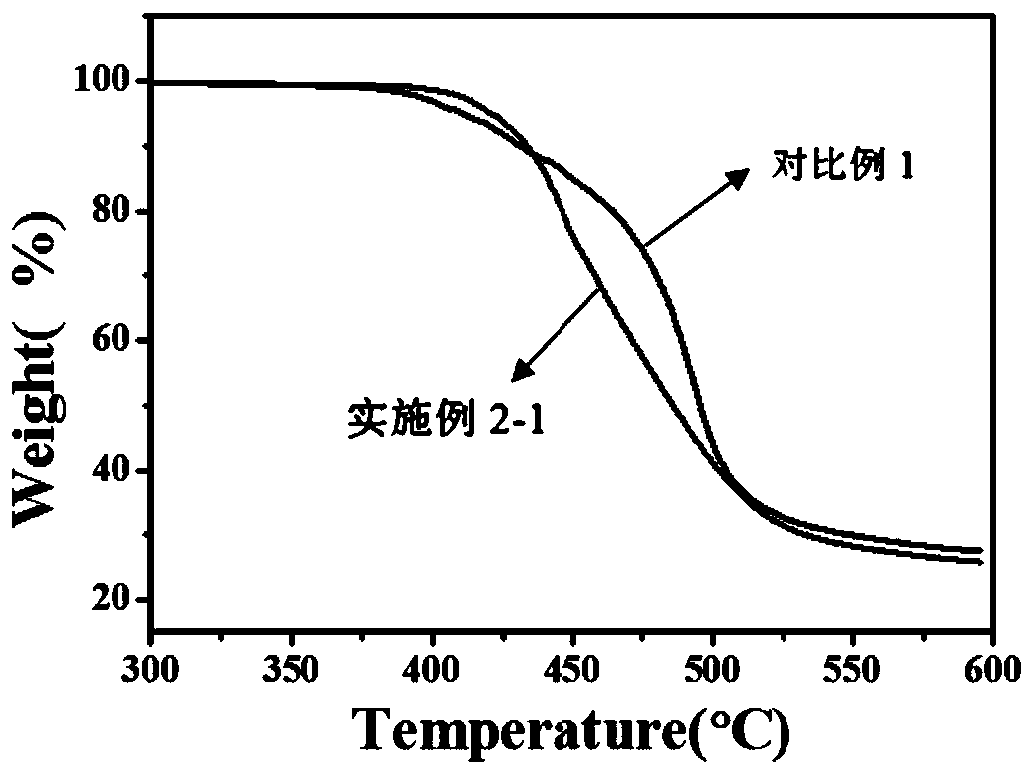

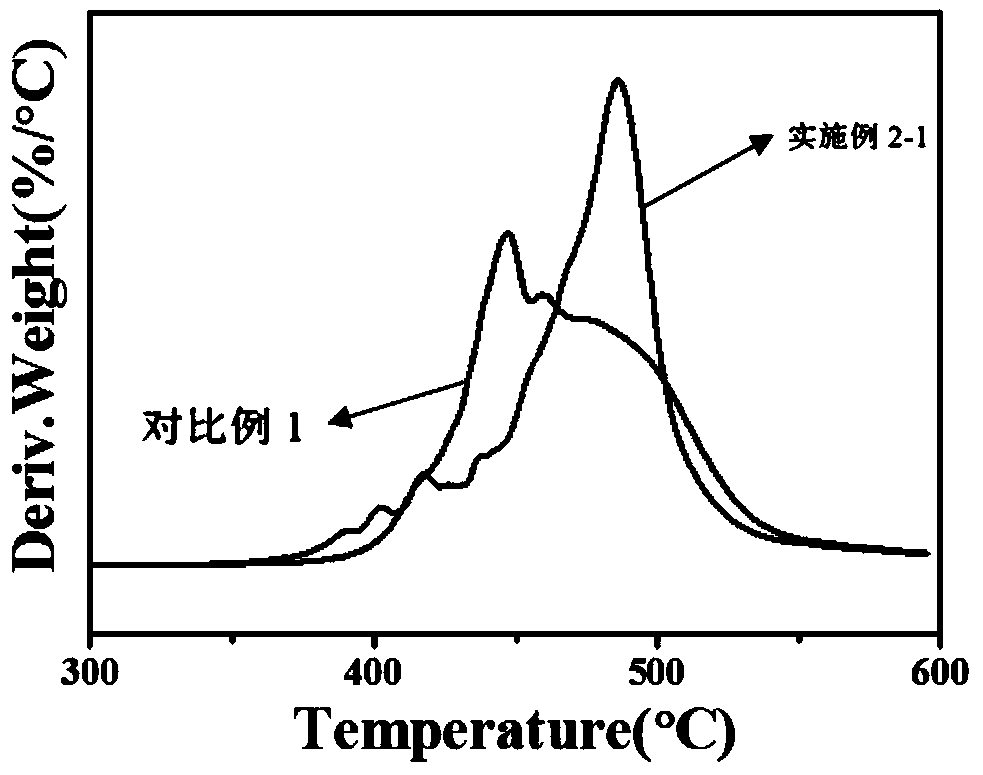

Polylactic acid/ polyamide 11 alloy material

ActiveCN102391628BLow dependence on petrochemical resourcesHigh hardnessConjugated synthetic polymer artificial filamentsArtifical filament manufactureElastomerPolyamide

The invention discloses a polylactic acid / polyamide 11 alloy material. The polylactic acid / polyamide 11 alloy material is mainly prepared by melting and blending polylactic acid, polyamide 11, and a third component by using melting and mixing equipment; based on the mass of the polylactic acid and the polyamide 11, the polylactic acid is 5 to 95 mass percent, and the polyamide 11 is 5 to 95 mass percent; and the third component is 0 to 15 percent based on the total mass of the polylactic acid and the polyamide 11, wherein 0 infinitely approaches 0 but is not 0; and the third component is an elastomer containing an epoxide group. The polylactic acid / polyamide 11 alloy material is high in hardness, modulus and tensile strength, the impact resistance is greatly improved and the polylactic acid / polyamide 11 alloy material meets the performance using requirements of a structural material.

Owner:南通九思医疗器械有限公司

Transparent heat-resistant polycarbonate material and preparation method thereof

The invention discloses a transparent heat-resistant polycarbonate material and a preparation method thereof. The polycarbonate material is a blend of polycarbonate, polyarylate and an organic salt. The preparation method comprises the following steps: subjecting the polycarbonate and the polyarylate to separate vacuum drying at 80-120 DEG C for 24-48 h; adding the dried polycarbonate, the dried polyarylate and the organic salt in a mass ratio of (60-90): (40-10): (0.3-3) into a melting and mixing apparatus for melting and mixing at 250-300 DEG C so as to obtain a mixture; discharging the mixture from the melting and mixing apparatus, and cooling the mixture to normal temperature so as to obtain the polycarbonate material. The polycarbonate material of the invention has excellent light transmittance and good heat resistance; and the preparation method thereof only needs the common melting and mixing apparatus, and is simple in industrial preparation of the material.

Owner:HANGZHOU NORMAL UNIVERSITY

A kind of transparent heat-resistant polycarbonate material and preparation method thereof

Owner:HANGZHOU NORMAL UNIVERSITY

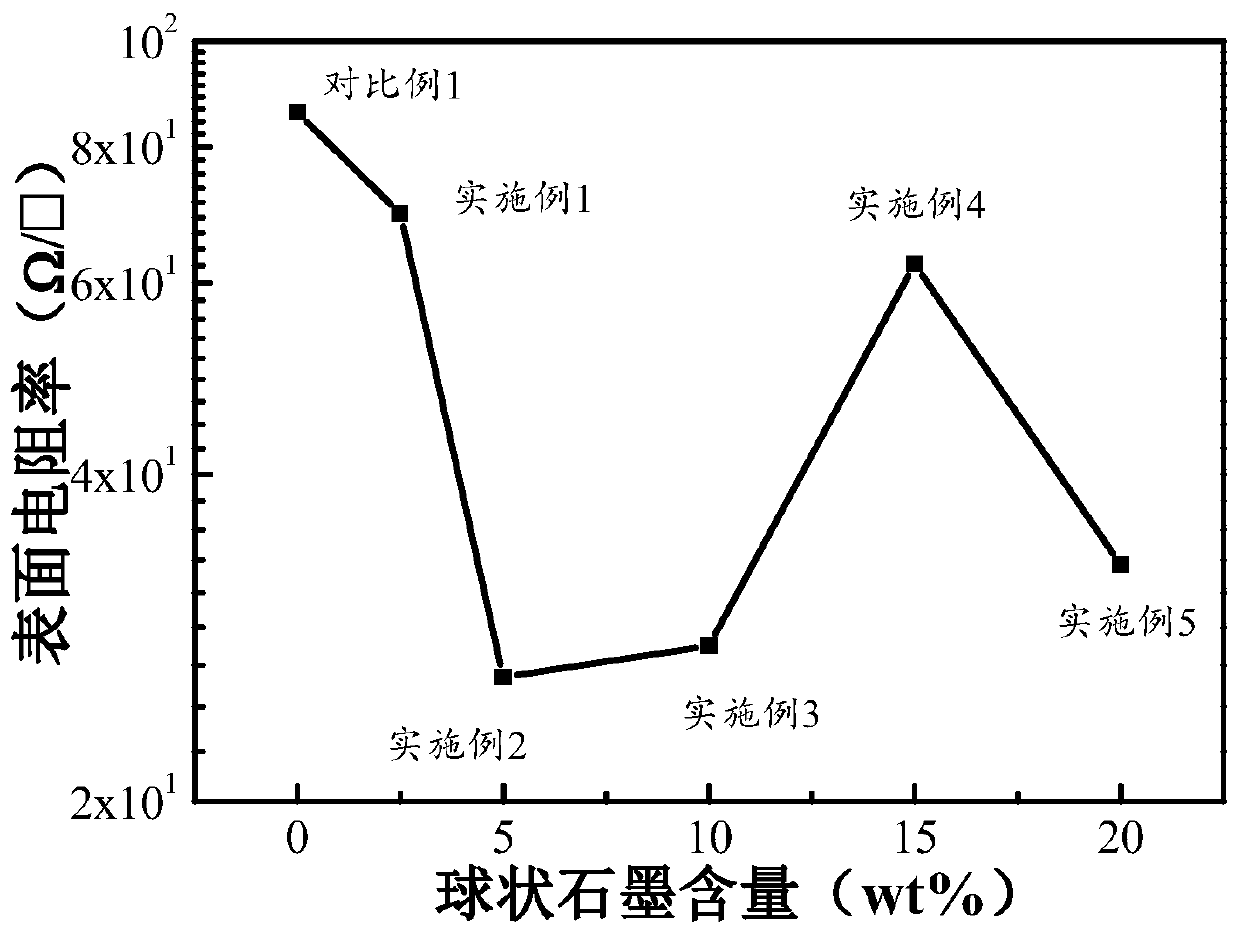

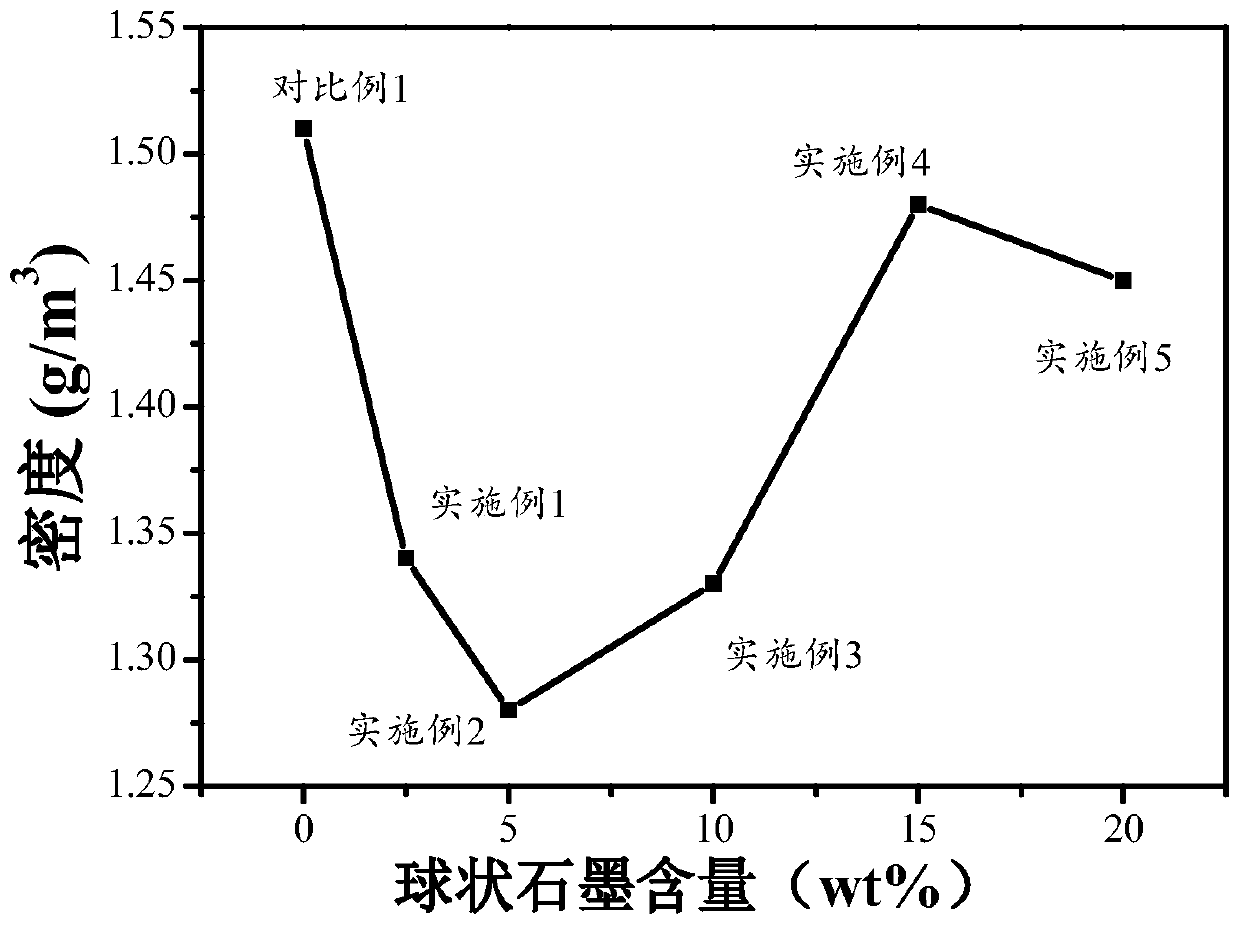

Polyphenylene sulfide composite material sheet with high vertical heat conductivity and preparation method thereof

InactiveCN110105760AExcellent vertical thermal conductivityReduced plane orientationHeat-exchange elementsPlane orientationMulti dimensional

The invention discloses a polyphenylene sulfide composite material sheet with high vertical heat conductivity and a preparation method thereof. A polyphenylene sulfide material is a blend of polyphenylene sulfide and a carbon filler. The carbon filler at least comprises a two-dimensional carbon structure and a zero-dimensional carbon structure. The preparation method comprises the steps that driedpolyphenylene sulfide and the carbon filler are added into a melting and mixing device to perform melting and mixing at the temperature of 290-310 DEG C to obtain a compound; the compound is discharged from the melting and mixing device and cooled to normal temperature to obtain the polyphenylene sulfide composite material; the composite material is pressed into the sheet with the thickness of 100-500 micron through a flat vulcanizing machine. The polyphenylene sulfide composite material sheet has excellent heat conduction performance in the vertical direction. Due to the addition of two-dimensional and zero-dimensional fillers, the plane orientation degree of a filler pile can be reduced, and a relatively perfect multi-dimensional packing network is formed. Moreover, the preparation method only needs to use the common melting and mixing device, and industrial preparation is simple.

Owner:JIANGSU NEW CARBON NEW MATERIAL TECH CO LTD

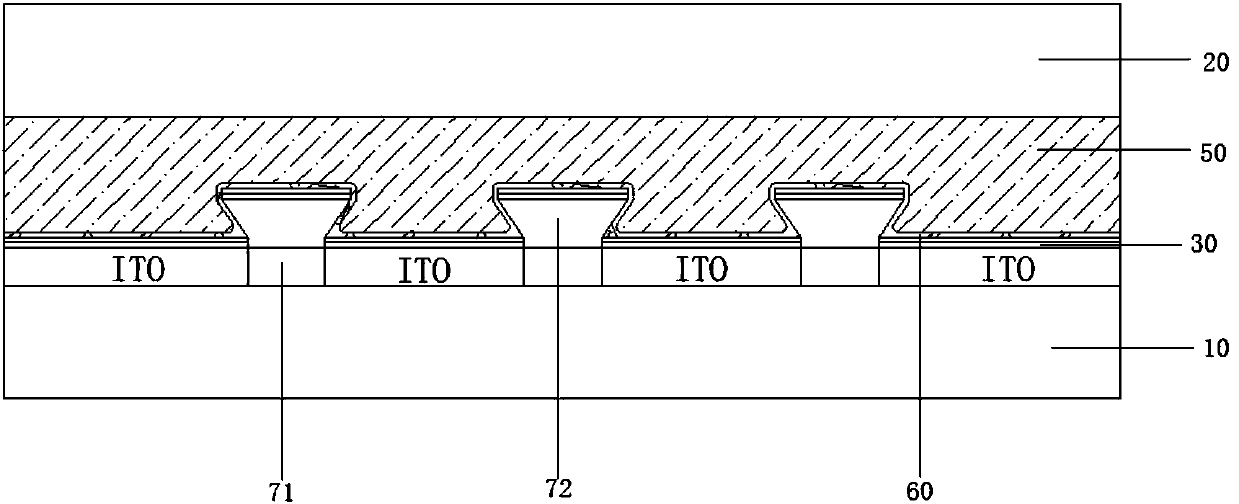

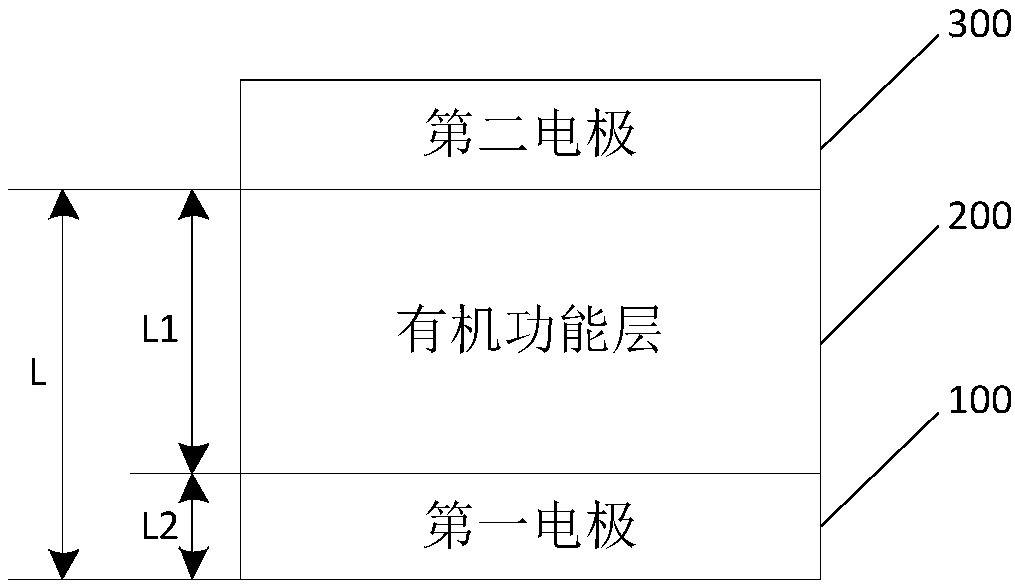

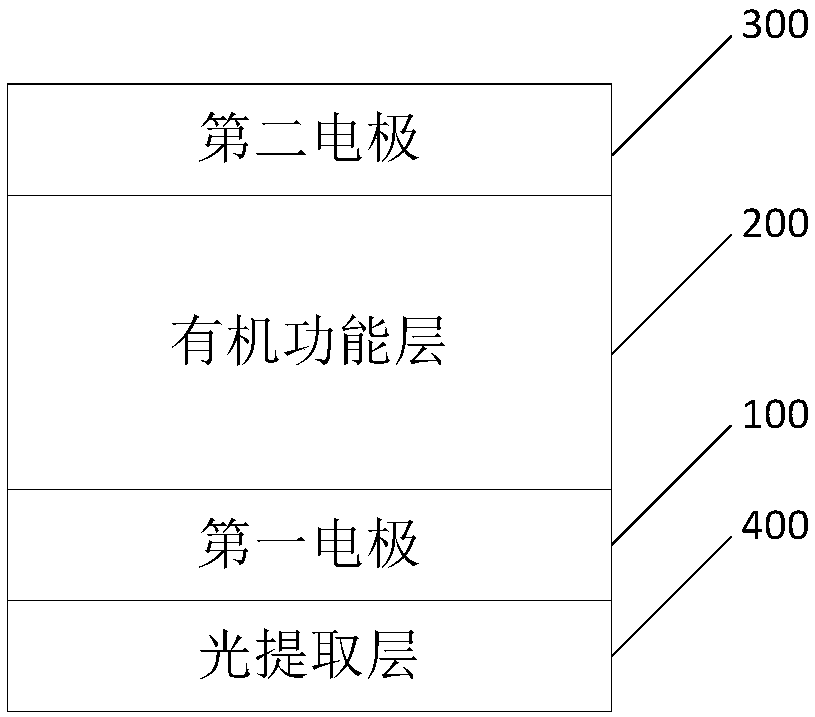

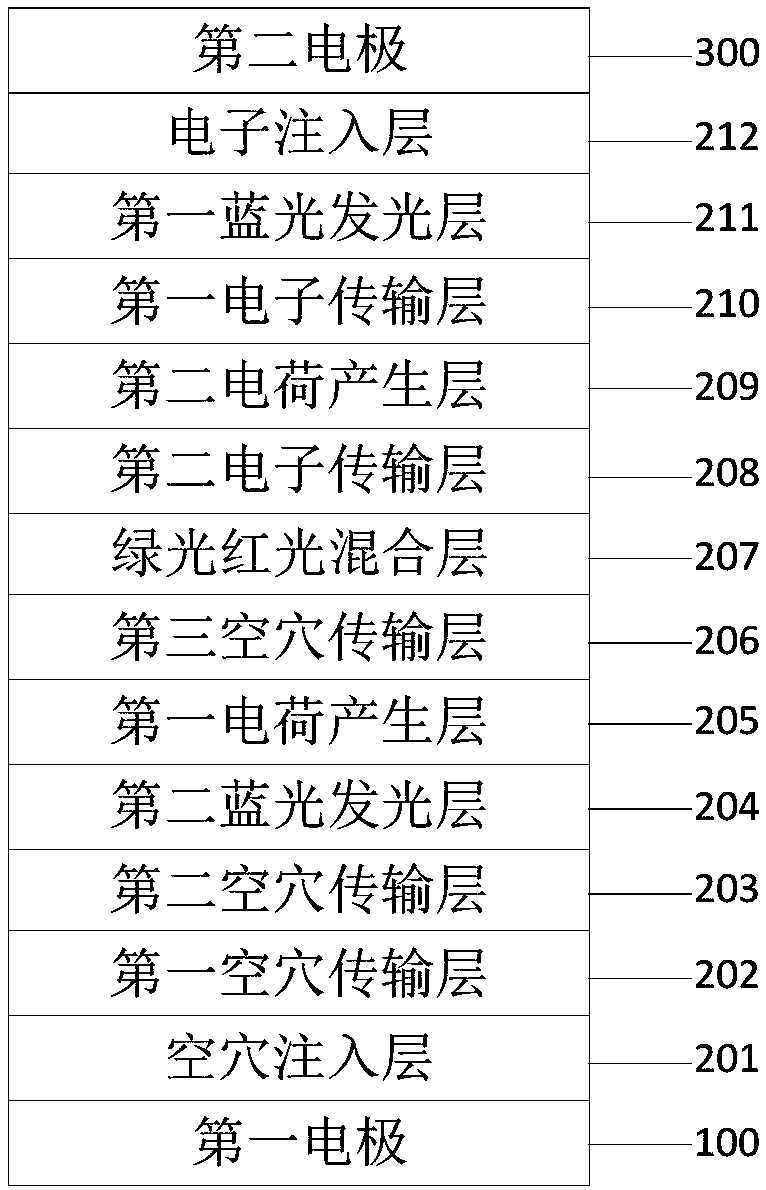

Organic electroluminescence device manufacturing method, organic electroluminescence device and display device

ActiveCN108417735AImprove light extraction efficiencyImprove light extraction rateSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceOrganic electroluminescence

The invention relates to the display technology field and provides an organic electroluminescence device manufacturing method, an organic electroluminescence device and a display device. The organic electroluminescence device manufacturing method contains a step of forming an organic light emitting diode and especially comprises the following steps of S1, forming a first electrode, an organic function layer and a second electrode which are stacked on a substrate, wherein the organic function layer includes at least one monochromatic light luminescent layer; and the first electrode and / or the second electrode are / is a light-emitting electrode; and S2, adjusting the thickness of the light-emitting electrode. By using the organic electroluminescence device manufactured by using the method ofthe invention, all monochromatic light generates uncorrelated optical resonance enhancement in the microcavity of the organic light emitting diode so that a purpose of enhancing the light extraction rate of all the monochromatic light is reached and then the luminous efficiency of the organic electroluminescence device is increased.

Owner:KUNSHAN GO VISIONOX OPTO ELECTRONICS CO LTD

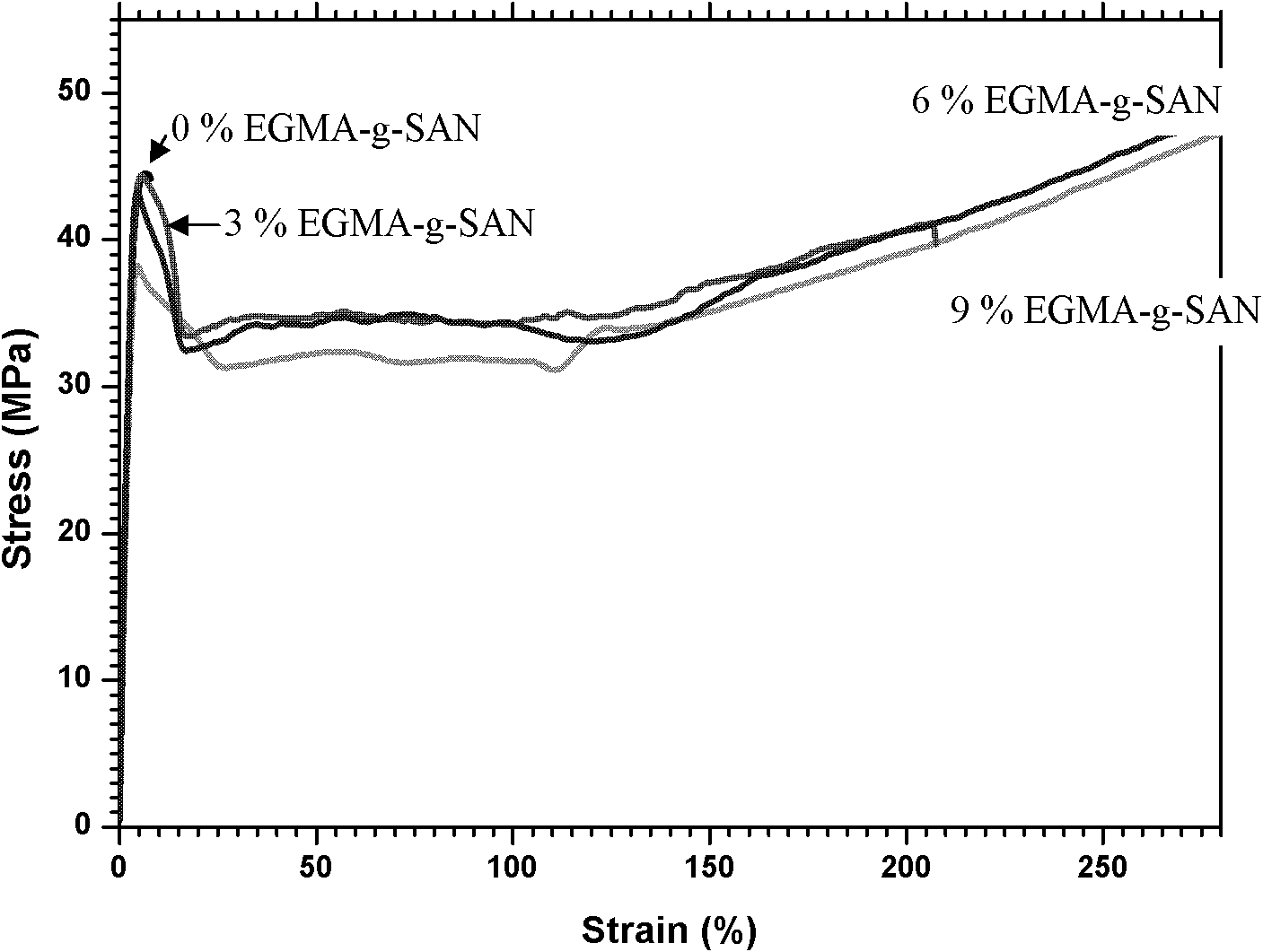

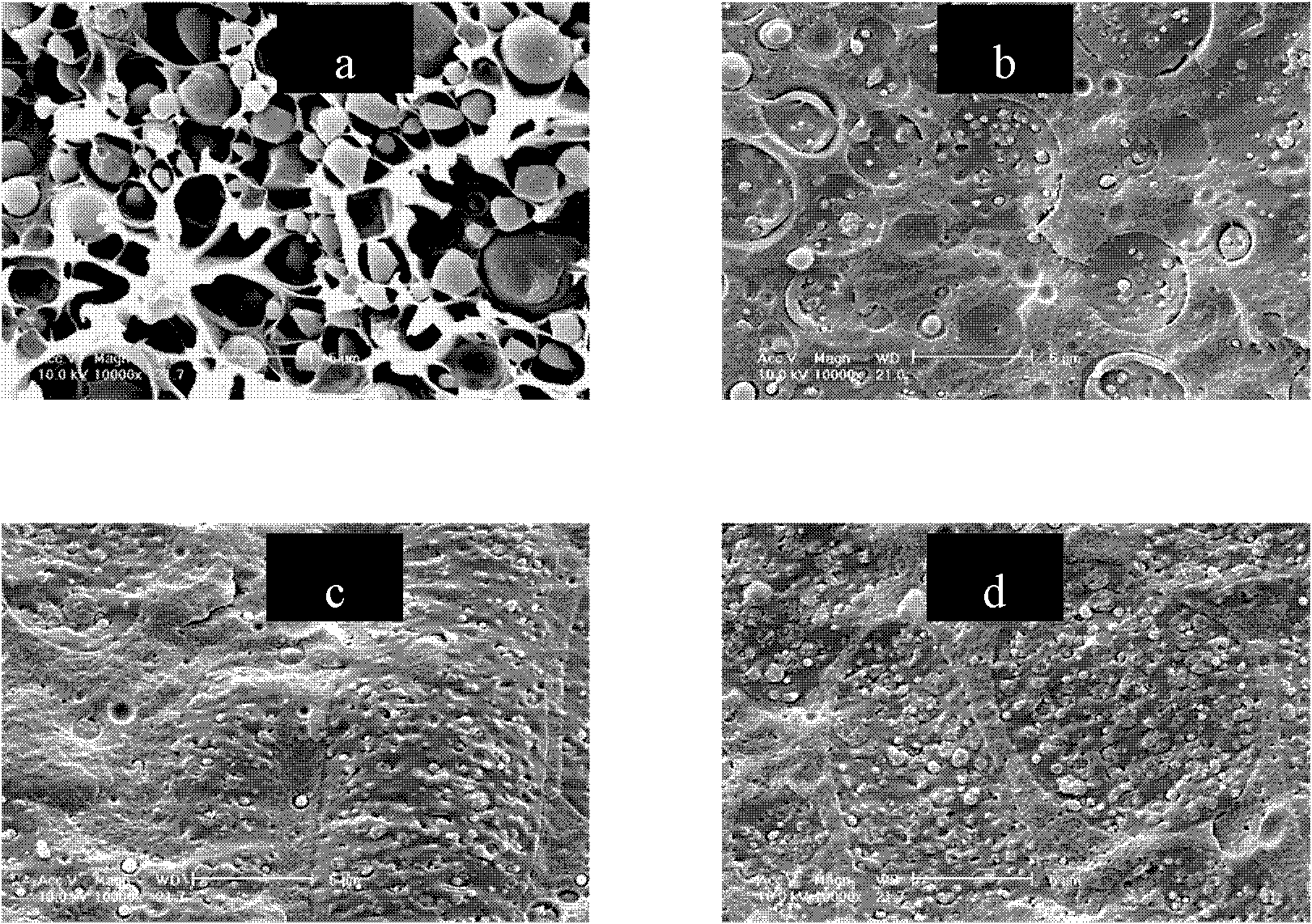

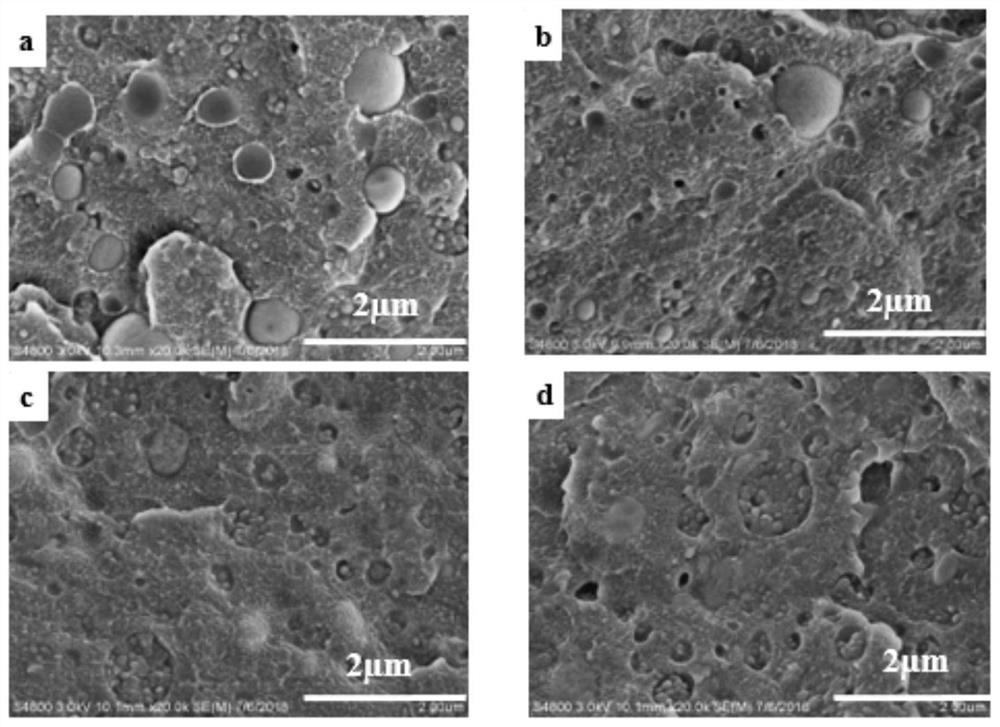

Preparation method and product of abs/pvdf alloy by self-assembly in situ

ActiveCN109135159BImprove mechanical propertiesGood solvent resistancePolymer scienceInterfacial adhesion

The invention discloses an in-situ self-assembly method for preparing ABS / PVDF alloy and a product thereof. Because the ABS and PVDF are completely incompatible systems of thermodynamics with poor interfacial adhesion force, so that the performance thereof is influenced, and the material has no practical value. In the invention, a graft polymer is generated in situ by using a melt blending method,and is applied to an ABS / PVDF system as a compatibilizer, so that the prepared compatibilizer can effectively compatibilize the ABS and the PVDF, enhance interfacial adhesion force, and improve the mechanical property of the ABS / PVDF alloy material. The in-situ self-assembly method for preparing ABS / PVDF alloy and product thereof has the advantages that: 1) the mechanical property of the alloy material added with the compatibilizer is greatly improved; 2) self-cleaning function through the addition of PVDF is achieved to solve the problem that the ABS is easy to get dirty and not resistant tooil; 3) the preparative equipment is a common melt blending equipment with simple industrial preparation, and easy achievement of the process.

Owner:HANGZHOU NORMAL UNIVERSITY

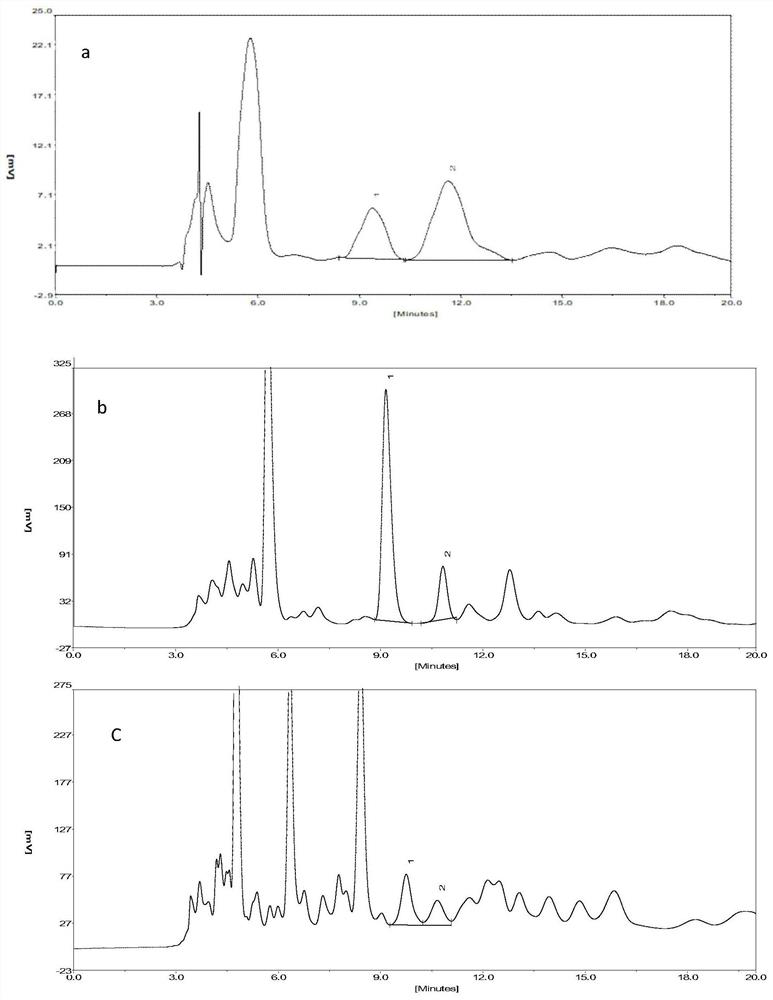

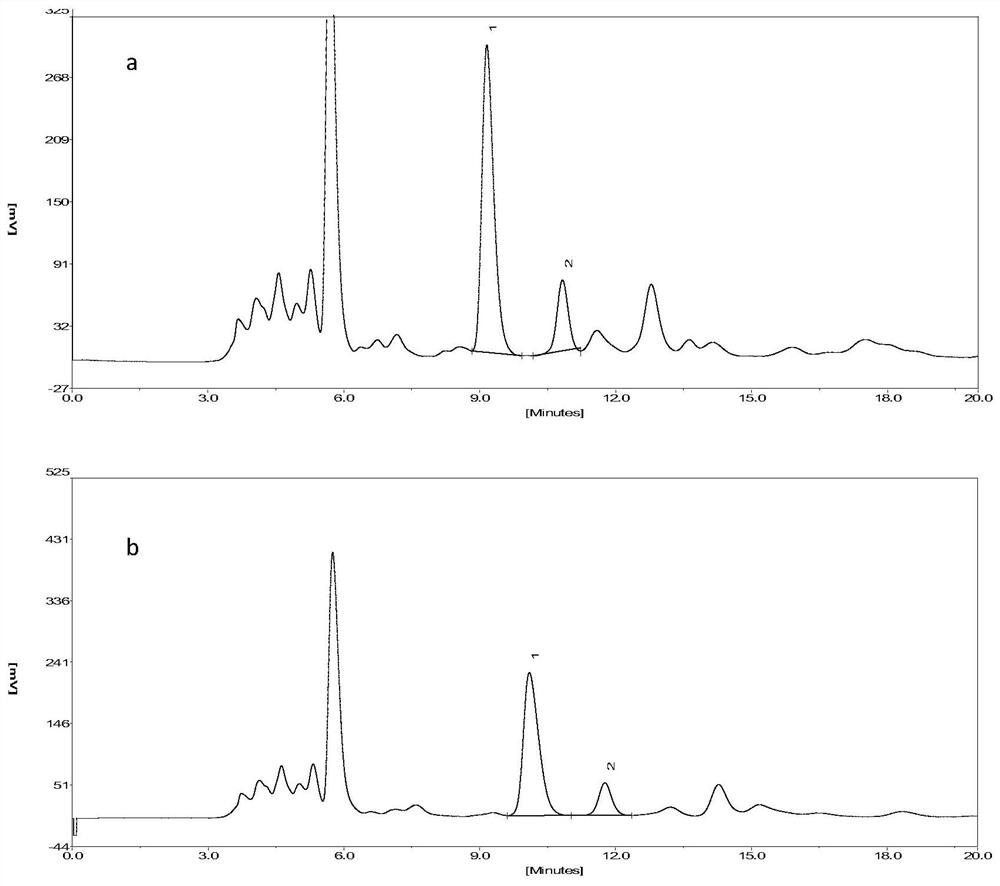

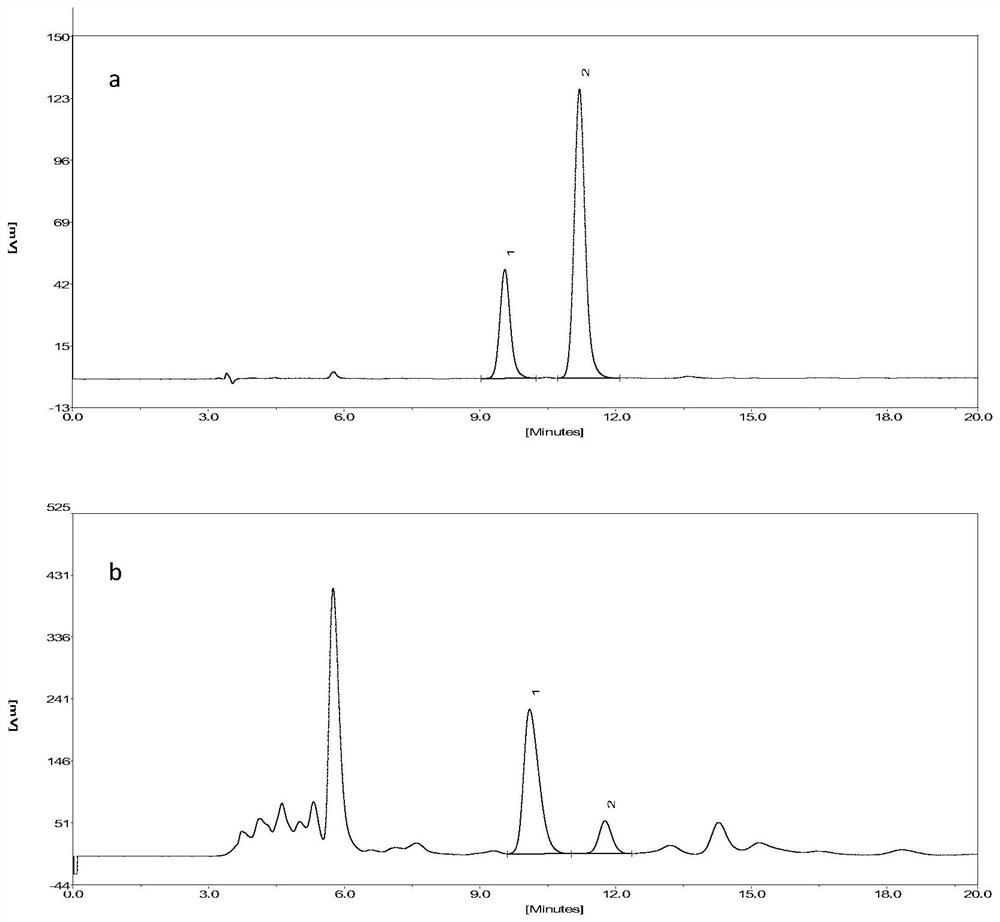

A deep eutectic solvent-water mixture for synchronously extracting salidroside and tyrosol in Rhodiola rosea and its preparation method and extraction method

ActiveCN108623642BEasily biodegradableGood environmental compatibilitySugar derivativesOrganic compound preparationTyrosolPropanoic acid

The invention discloses a deep eutectic solvent (DES)-water mixture used for simultaneous extraction of rhodioloside and 4-(2-hydroxyethyl)phenol from rhodiola root, and a preparation method and an extraction method thereof. The DES-water mixture is prepare through mixing of DES and deionized water, wherein the DES is prepared from glycol and acetylpropionic acid at a molar ratio of (1-3) : (3-1).The DES-water mixture is simple to prepare, is convenient for industrialized preparation, can be biologically degraded easily, is nontoxic, and is high in environment compatibility. The DES-water mixture is low in viscosity, and excellent in fluidity. The DES-water mixture can be used for simultaneous extraction of rhodioloside and 4-(2-hydroxyethyl)phenol from rhodiola root, increasing the extraction rate of rhodioloside and 4-(2-hydroxyethyl)phenol from rhodiola root; operation is safe; and no environment pollution or harm on human body is caused.

Owner:NANJING FORESTRY UNIV

Method for preparing low-grade unsaturated fatty acid ester

ActiveUS20200062686A1High reactivitySimple in industrial preparationMolecular sieve catalystsOrganic compound preparationMolecular sieveAldehyde

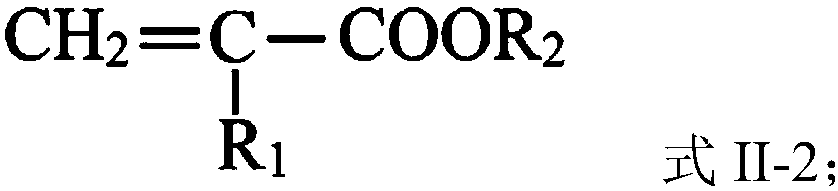

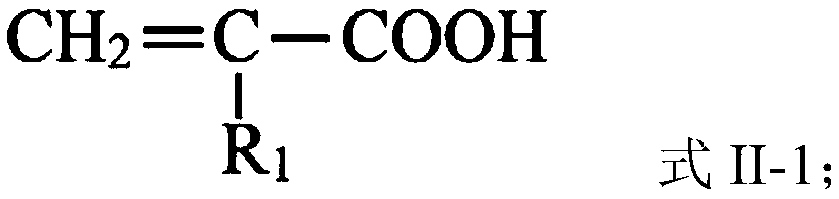

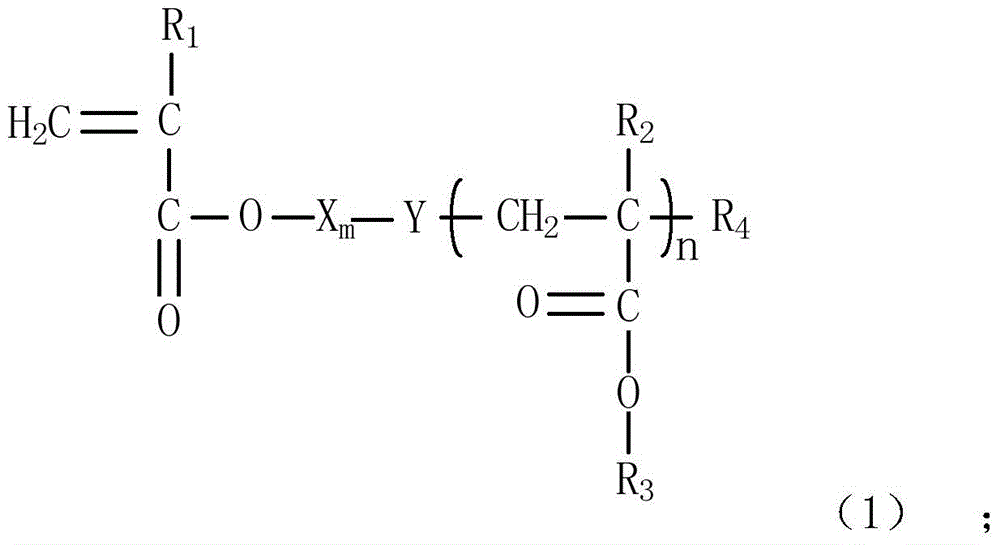

Provided is a method for preparing a lower unsaturated fatty acid ester, which comprises carrying out an aldol condensation reaction between dimethoxymethane (DMM) and a lower acid or ester with a molecular formula of R1—CH2—COO—R2 on an acidic molecular sieve catalyst in an inert atmosphere to obtain a lower unsaturated fatty acid or ester(CH2═C(R1)—COO—R2), wherein R1 and R2 are groups each independently selected from the group consisting of H- and C1-C4 saturated alkyl group.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Method for preparing low-grade unsaturated fatty acid ester

ActiveUS10919832B2Rich pore structureSimple preparation processMolecular sieve catalystsOrganic compound preparationMolecular sievePtru catalyst

Provided is a method for preparing a lower unsaturated fatty acid ester, which comprises carrying out an aldol condensation reaction between dimethoxymethane (DMM) and a lower acid or ester with a molecular formula of R1—CH2—COO—R2 on an acidic molecular sieve catalyst in an inert atmosphere to obtain a lower unsaturated fatty acid or ester(CH2═C(R1)—COO—R2), wherein R1 and R2 are groups each independently selected from the group consisting of H— and C1-C4 saturated alkyl group.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

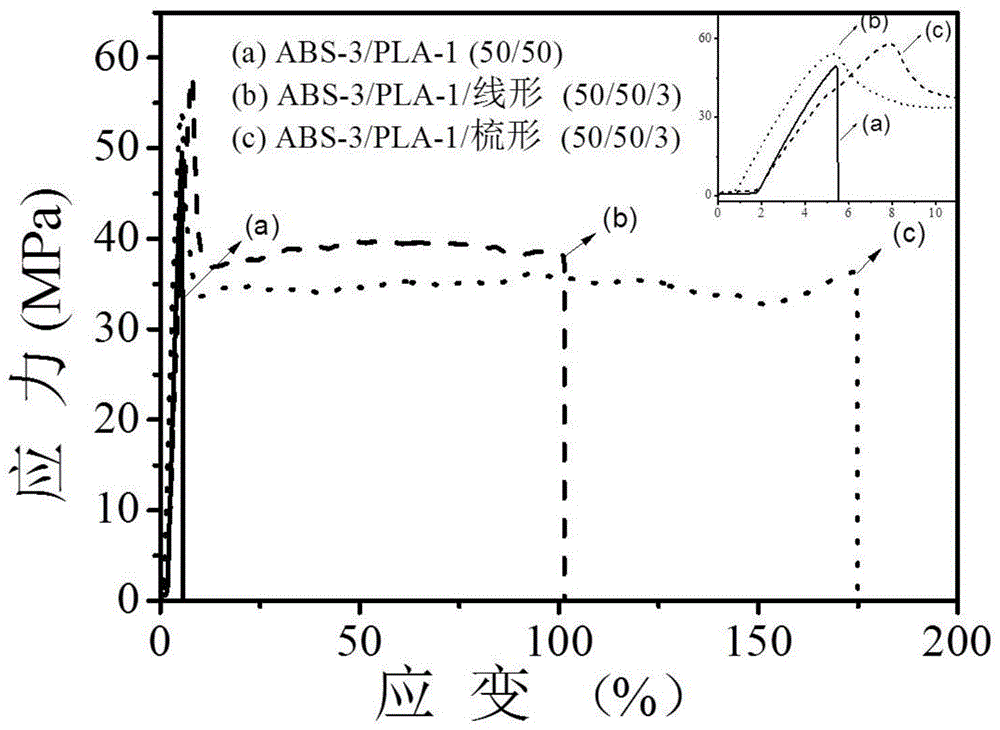

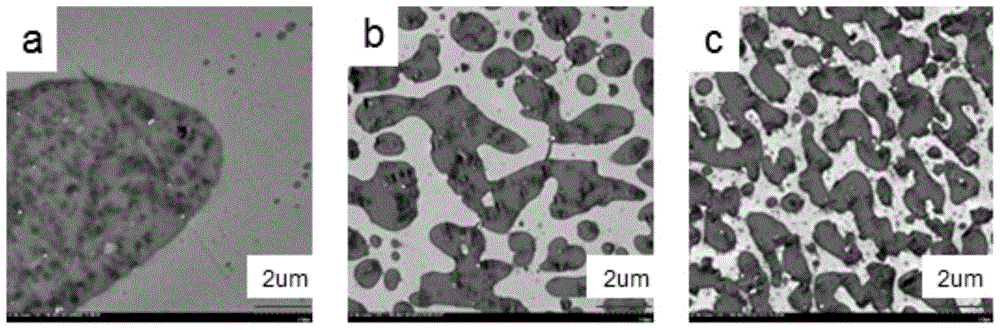

A kind of polylactic acid/abs alloy material and preparation method thereof

The invention discloses a PLA (polylactic acid) / ABS (acrylonitrile-butadiene-styrene copolymers) alloy material and a preparation method thereof. The PLA / ABS alloy material is a blend and the blend comprises PLA, ABS and a third component, wherein PLA accounts for 5-95% of total PLA and ABS by mass; ABS accounts for 95-5% of total PLA and ABS by mass; the third component accounts for 0.5-15% of total PLA and ABS by mass. The method comprises the following steps: mixing dried PLA, ABS and the third component uniformly and then adding the mixture to melt mixing equipment to undergo melt blending and blending the mixture at 180-220 DEG C for 5-10 minutes, thus obtaining a blend; then preparing the PLA / ABS alloy material through a forming process. The PLA / ABS alloy material and the preparation method have the advantages that the raw materials of PLA root in biomass, so that the PLA material has good biocompatibility and biodegradability; the prepared alloy material has high hardness, high modulus and tensile strength and high impact resistance.

Owner:HANGZHOU NORMAL UNIVERSITY

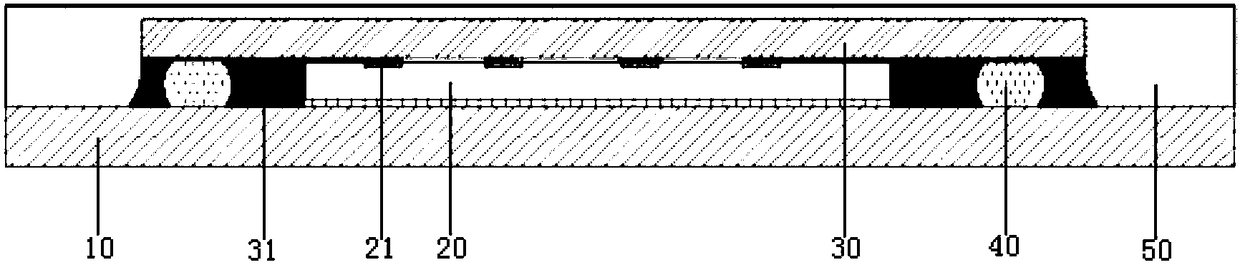

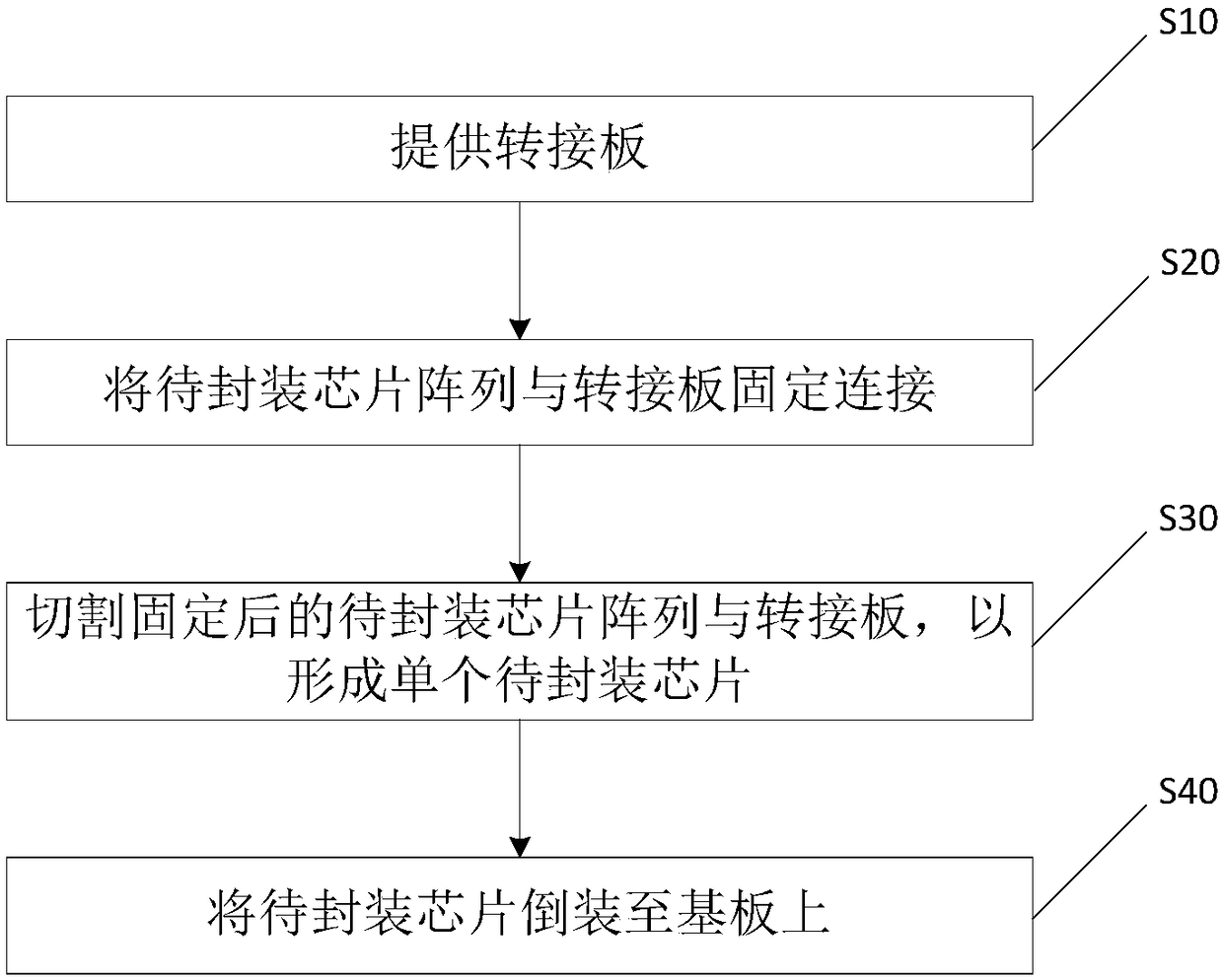

Chip package structure and chip package method

InactiveCN108389838APackage structure is simpleSimple industrial preparationSemiconductor/solid-state device detailsSolid-state devicesSemiconductor packageEngineering

The invention relates to the field of semiconductor package technology, and provides a chip package structure and a chip package method. The chip package structure comprises: a substrate; and a to-be-packaged chip and an adapter plate, which are arranged on the substrate in sequence, wherein a first surface of the to-be-packaged chip is electrically connected to the substrate, and a second surfaceopposite to the first surface is electrically connected to the adapter plate. By fitting the to-be-packaged chip on the adapter plate, that is, the to-be-packaged chip is arranged between the substrate and the adapter plate, the chip package can be implemented by using a standard upside-down assembly process, and the package structure is simple and easy to be industrially prepared; and the preparation efficiency is high, and the chip package structure is suitable for mass production.

Owner:NAT CENT FOR ADVANCED PACKAGING

A kind of internally plasticized antistatic polyoxymethylene material and preparation method thereof

The invention discloses an internally-plasticized antistatic polyformaldehyde material and a preparation method thereof. The polyformaldehyde material is a mixture of polyformaldehyde and ironic liquid. The preparation method comprises the following steps: respectively carrying out vacuum drying on polyformaldehyde and ironic liquid at 80-120 DEG C for 24-48 hours; adding the dried polyformaldehyde and ironic liquid into fusion mixing equipment in a mass ratio of 100 to (0.01-10), and carrying out fusion mixing at 170-200 DEG C, so as to obtain a mixture; and discharging the mixture out of the fusion mixing equipment, and cooling to the room temperature, so as to obtain the polyformaldehyde material. The polyformaldehyde material disclosed by the invention has excellent antistatic performance; by adding ironic liquid, the size of a spherocrystal of a polyformaldehyde matrix can be effectively reduced, so that a certain plasticization effect is achieved; and only common fusion mixing equipment is used in the preparation method, so that the industrial preparation is simple.

Owner:安徽贺赢新材料科技有限公司

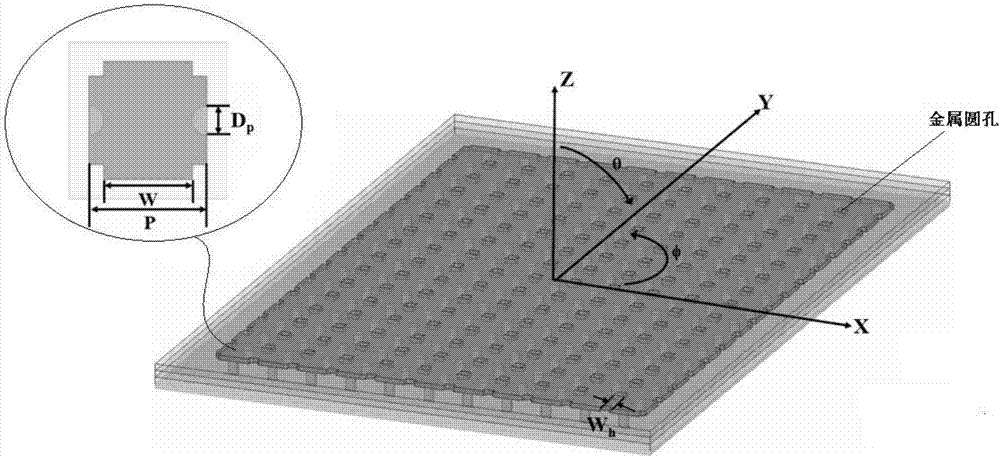

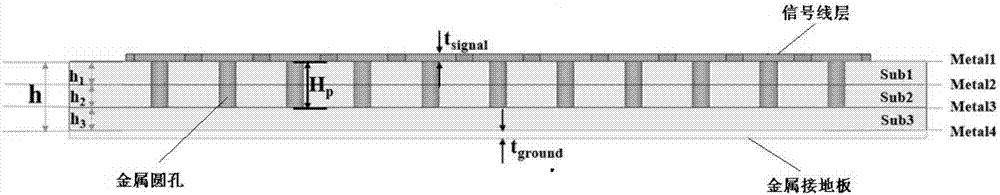

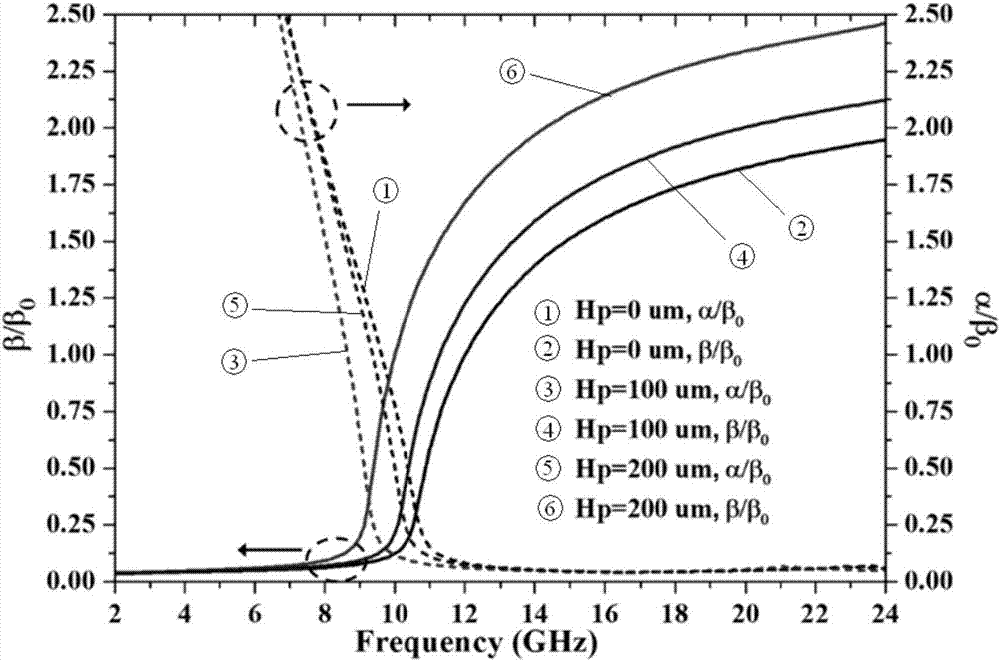

Microstrip leaky wave antenna with metal round hole load introduced and control method thereof

InactiveCN107069229AReduce layout areaReduce manufacturing costRadiating elements structural formsLeaky-waveguide antennasGround plateDielectric layer

The invention discloses a microstrip leaky wave antenna with metal round hole load introduced and a control method thereof. The antenna is provided with a signal line layer, at least two dielectric layers and a metal grounding plate sequentially from top to bottom, wherein metal round holes are equidistantly arranged in the signal line layer and the dielectric layers. Starting from the problem of narrowing the length of the microstrip leaky wave antenna in a cross section direction, the metal round holes are introduced to the traditional microstrip leaky wave antenna structure, the cut-off frequency of the microstrip leaky wave antenna in a first high order EH1 mode and leakage area frequency are controlled, the two frequencies both move to a low frequency, the length of the antenna in the cross section direction can be reduced by using the feature, the circuit layout area can be reduced, and the volume of a product is reduced.

Owner:TIANJIN UNIV

Complex catalyst for viscosity reduction of thick oil by hydrothermal catalytic cracking and preparation and application thereof

ActiveCN102019205BFully play the catalytic activityLow viscosityCatalytic crackingOrganic-compounds/hydrides/coordination-complexes catalystsEthylenediamineReduction rate

Owner:PETROCHINA CO LTD +1

A kind of optically transparent polymethyl methacrylate/polycarbonate compound and preparation method thereof

The invention discloses an optically transparent polymethyl methacrylate / polycarbonate composite and a preparation method thereof. The material of the invention is a blend of polymethyl methacrylate, polycarbonate and an organic salt whose cation is a metal. The mass ratio is 60-90:40-10:0.2-3. In the present invention, adding the metal organic salt as the cation greatly improves the compatibility between polymethyl methacrylate and polycarbonate, greatly improves the light transmittance of the material, and makes the light transmittance of the material greater than 90%. , the haze is less than 10%, the refractive index is greater than 1.49, and the material is optically transparent.

Owner:HANGZHOU NORMAL UNIVERSITY

A kind of ultra-soft halogen-free flame-retardant thermoplastic elastomer and preparation method thereof

ActiveCN103396640BImprove mechanical propertiesImprove flame retardant performanceElastomerVulcanization

Owner:HANGZHOU NORMAL UNIVERSITY

A kind of solar battery backboard waste film and its leftover material reutilization method

The invention discloses a method for reusing the waste film of a solar cell backboard and its leftover materials. In the method, the crushed solar cell backboard waste film, ethylene-vinyl acetate copolymer (EVA) and a high-efficiency compatibilizer are added into a melt blending device to melt and extrude to prepare a novel alloy material. The invention solves the industrial problems of the manufacturers of the solar battery backplane and its upstream backplane film, turns the waste of the waste film of the solar battery backplane in the solar battery industry into treasure, truly realizes the recycling and reuse of resources, and saves non-renewable resources, energy saving and environmental protection.

Owner:杭州福禧新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com