Microstrip leaky wave antenna with metal round hole load introduced and control method thereof

A technology of leaky wave antenna and circular hole, which is applied in the direction of leaky waveguide antenna, radiation element structure, circuit, etc., can solve the problem of large size, achieve low production cost, reduce circuit layout area, and simple industrial production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described below in conjunction with the accompanying drawings.

[0047] The invention protects a microstrip leaky-wave antenna that introduces a metal hole load, which is composed of a signal line layer, a dielectric layer and a metal grounding plate arranged in sequence from top to bottom. The following are the manufacturing steps and control methods of specific embodiments of the invention :

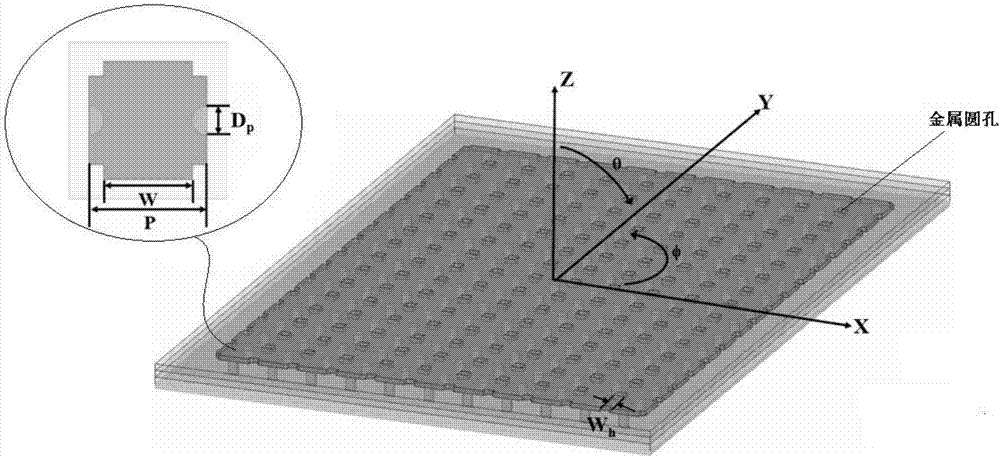

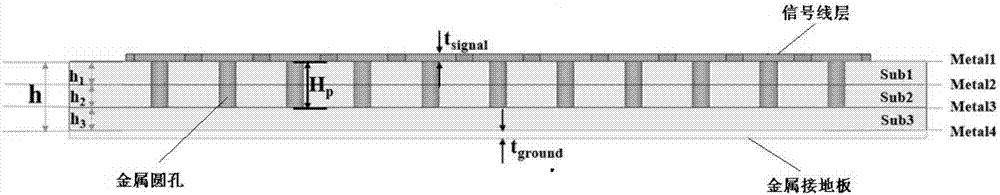

[0048] Step 1: The structure of the microstrip leaky wave antenna adopts four layers of metal and three layers of dielectric. The metal material is copper. The dielectric material parameters are: dielectric constant 4.7, loss tangent 0.008. The height of the metal layer is 16 μm, the height of the dielectric layer is h1=h2=h3=100 μm, h=h1+h2+h3=300 μm (see Picture 1-1 and 1-2 Shown), the above material parameters can be determined with the manufacturer:

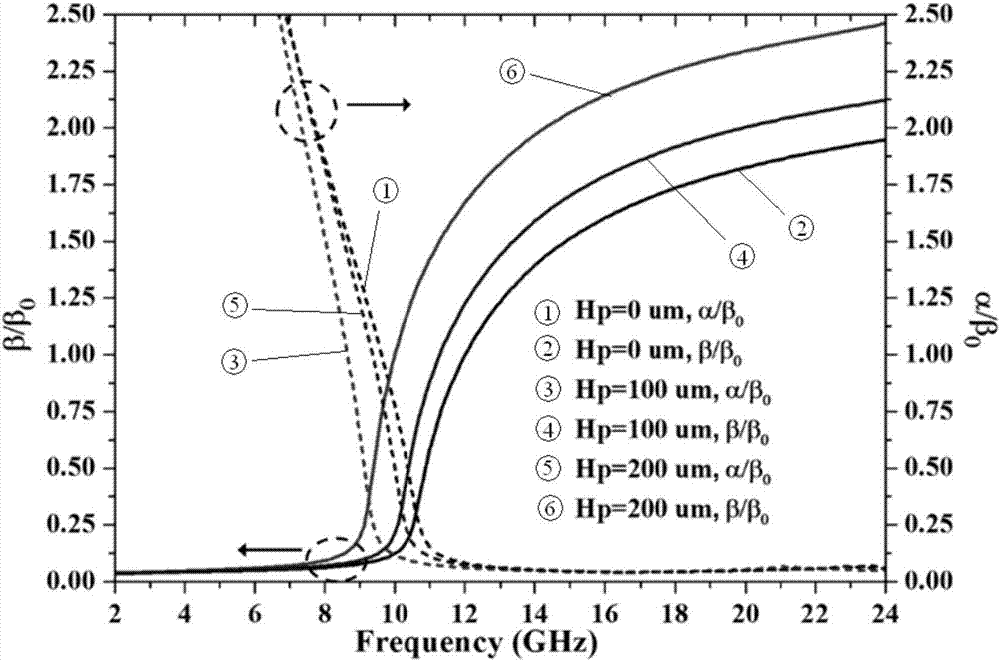

[0049] Step 2: Determine the structural parameters of the designed antenna according...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com