A kind of optically transparent polymethyl methacrylate/polycarbonate compound and preparation method thereof

A polymethyl methacrylate, polycarbonate technology, applied in the field of polymethyl methacrylate/polycarbonate composite and its preparation, can solve the problem of lack of compatibility, PC and PMMA incompatibility, refractive index Differences and other issues, to achieve the effect of improving light transmission performance, improving transparency performance, and adding a small amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045]Step (1). Dry polymethyl methacrylate and polycarbonate in vacuum at 80-120°C for 24 hours respectively (Li-TFSI does not need to be dried);

[0046] Step (2). Add 54g of dried polymethyl methacrylate, 6g of dried polycarbonate and 0.225g of Li-TFSI into the internal mixer, melt and blend at 250°C at 50rpm / min Melt and knead for 10 minutes.

[0047] Step (3). The mixture is discharged from the melting and kneading equipment and lowered to normal temperature to obtain a polymethyl methacrylate / polycarbonate composite material.

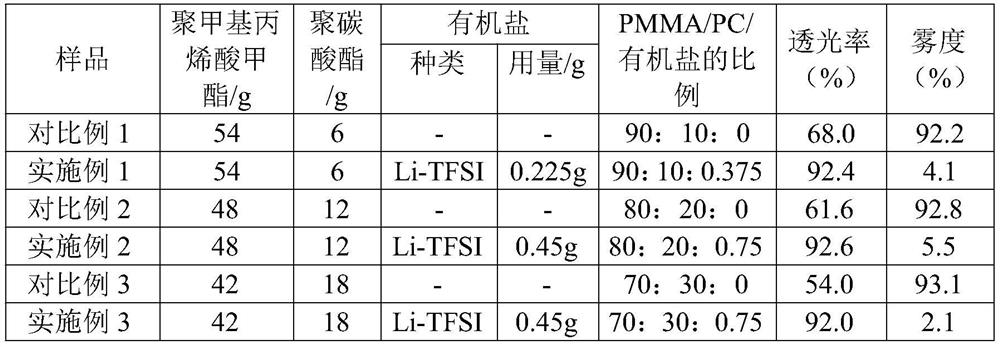

[0048] The mass ratio of polymethyl methacrylate, polycarbonate and Li-TFSI in the polymethyl methacrylate / polycarbonate composite material prepared in Example 1 was 90:10:0.375.

Embodiment 2

[0050] Step (1). Dry polymethyl methacrylate and polycarbonate in vacuum at 80-120°C for 24 hours respectively (Li-TFSI does not need to be dried);

[0051] Step (2). Add 48g of dried polymethyl methacrylate, 12g of dried polycarbonate and 0.45g of Li-TFSI into the internal mixer, melt and blend at 250°C, at 50rpm / min Melt and knead for 10 minutes.

[0052] Step (3). The mixture is discharged from the melting and kneading equipment and lowered to normal temperature to obtain a polymethyl methacrylate / polycarbonate composite material.

[0053] The mass ratio of polymethyl methacrylate, polycarbonate and Li-TFSI in the polymethyl methacrylate / polycarbonate composite material prepared in Example 2 was 80:20:0.75.

Embodiment 3

[0055] Step (1). Vacuum dry polycarbonate and polymethyl methacrylate at 80-120°C for 24 hours respectively (Li-TFSI does not need to be dried);

[0056] Step (2). Add 42g of dried polymethyl methacrylate, 18g of dried polycarbonate and 0.45gLi-TFSI into the internal mixer, and melt and blend at 230~260°C. The rotor speed is 45-75rpm, and the melt kneading is 10-25min.

[0057] Step (3). The blend is discharged from the internal mixer and lowered to normal temperature to obtain a compound with high light transmission.

[0058] The mass ratio of polymethyl methacrylate, polycarbonate and lithium salt in the polymer composite prepared in Example 3 was 70:30:0.75.

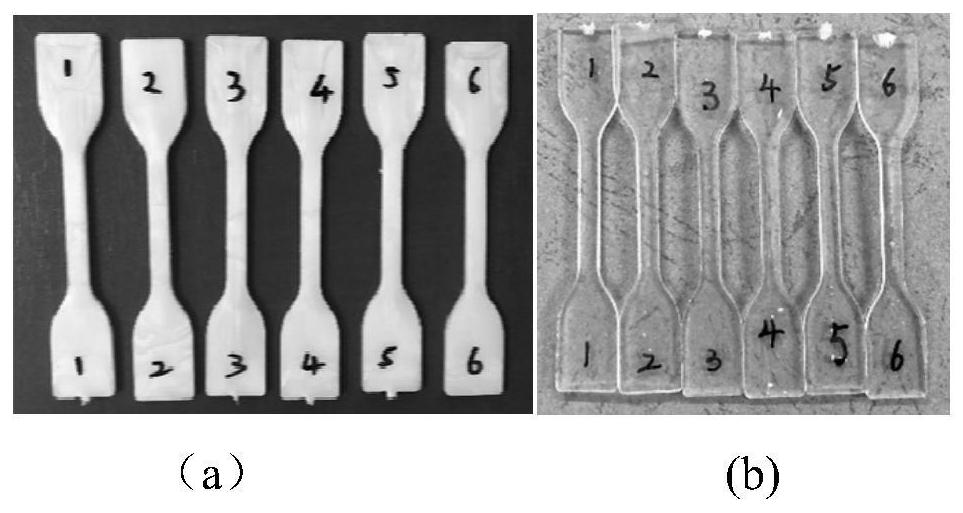

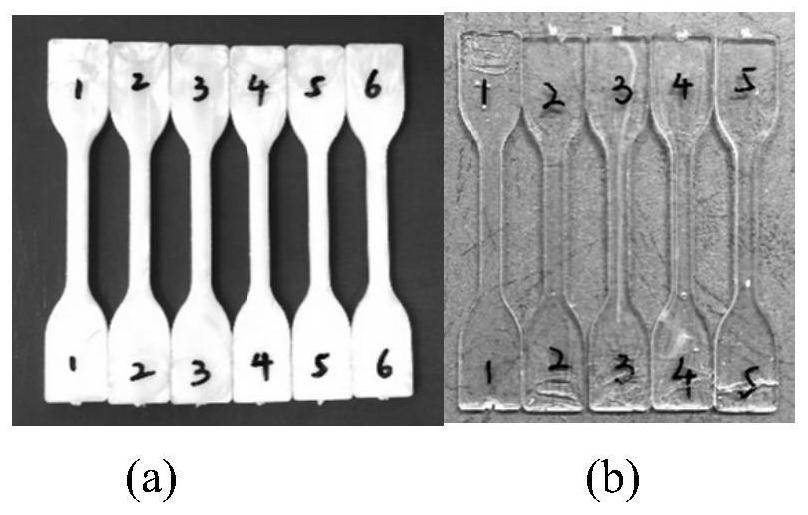

[0059] The materials prepared in Comparative Examples 1-3 and Examples 1-3 were subjected to a transmittance-haze test, and the test conditions were: the samples were pressed into 0.3 mm thin sheets.

[0060] The materials prepared in Comparative Examples 1-3 and Examples 1-3 were subjected to a refractive index tes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| haze | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com