Oil resistance thermoplastic elastomer and preparing method thereof

A thermoplastic elastomer and oil-resistant technology, applied in the field of polymer materials, can solve the problems of poor oil resistance, etc., and achieve the effects of good processing performance, excellent oil resistance, and simple industrial preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Step (1). After mixing 50g EVM and 0.1g dicumyl peroxide DCP evenly, blending at 70°C to prepare the masterbatch;

[0051] Step (2). After the masterbatch is discharged, it is cooled to normal temperature and pulverized.

[0052] Step (3). Mix the pulverized masterbatch and 50g EVA evenly, and then add it to an internal mixer with a rotor speed of 80r / min at 160°C for dynamic vulcanization for 5 minutes, and discharge to obtain an oil-resistant thermoplastic elastomer.

[0053] The mass ratio of ethylene vinyl acetate cross-linked product, ethylene vinyl acetate EVA, and dicumyl peroxide DCP in the thermoplastic elastomer prepared in Example 1 was 50:50:0.1.

[0054] EVM is produced by LANXESS, the mass content of vinyl acetate in EVM is 50%, and the melt flow rate is 10g / min; the model of EVA is ELVAX750, the mass content of vinyl acetate in EVA is 9%, and the melt flow rate is 7g / min.

Embodiment 2

[0056] Step (1). After mixing 50g EVM and 0.1g dicumyl peroxide DCP evenly, blending at 70°C to prepare the masterbatch;

[0057] Step (2). After the masterbatch is discharged, it is cooled to normal temperature and pulverized.

[0058] Step (3). Mix the pulverized masterbatch and 50g EVA evenly, and then add it to an internal mixer with a rotor speed of 80r / min at 160°C for dynamic vulcanization for 5 minutes, and discharge to obtain an oil-resistant thermoplastic elastomer.

[0059] The mass ratio of ethylene vinyl acetate cross-linked product, ethylene vinyl acetate EVA, and dicumyl peroxide DCP in the thermoplastic elastomer prepared in Example 2 was 50:50:0.1.

[0060] EVM is produced by LANXESS, the mass content of vinyl acetate in EVM is 50%, and the melt flow rate is 10g / min; the model of EVA is ELVAX260, the mass content of vinyl acetate in EVA is 28%, and the melt flow rate is 6g / min.

Embodiment 3

[0062] Step (1). After mixing 50g EVM and 0.1g dicumyl peroxide DCP evenly, blending at 70°C to prepare the masterbatch;

[0063] Step (2). After the masterbatch is discharged, it is cooled to normal temperature and pulverized.

[0064] Step (3). Mix the pulverized masterbatch and 50g EVA evenly, and then add it to an internal mixer with a rotor speed of 80r / min at 160°C for dynamic vulcanization for 5 minutes, and discharge to obtain an oil-resistant thermoplastic elastomer.

[0065] The mass ratio of ethylene vinyl acetate cross-linked product, ethylene vinyl acetate EVA, and dicumyl peroxide DCP in the thermoplastic elastomer prepared in Example 3 was 50:50:0.1.

[0066] EVM is produced by LANXESS, the mass content of vinyl acetate in EVM is 50%, and the melt flow rate is 10g / min; the model of EVA is ELVAX40L-03, the mass content of vinyl acetate in EVA is 40%, and the melt flow rate The rate was 3 g / min.

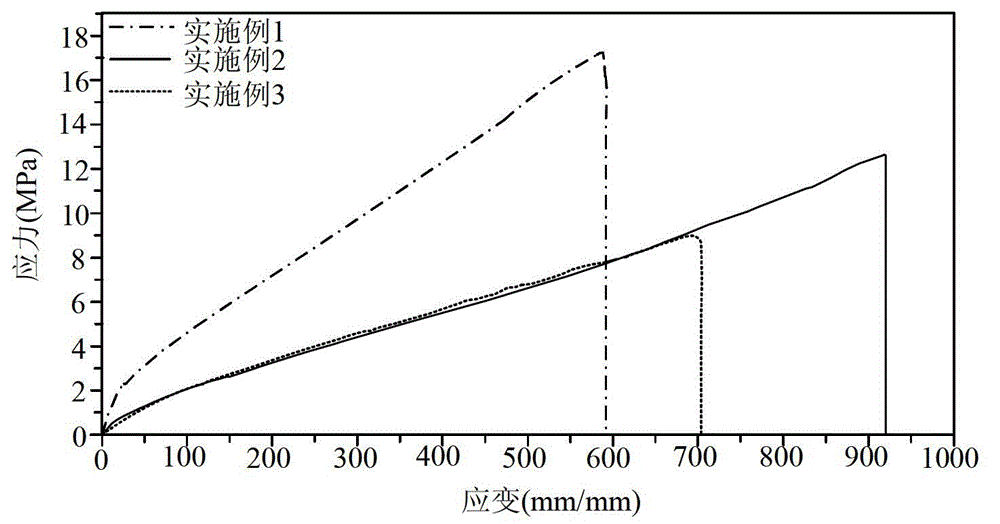

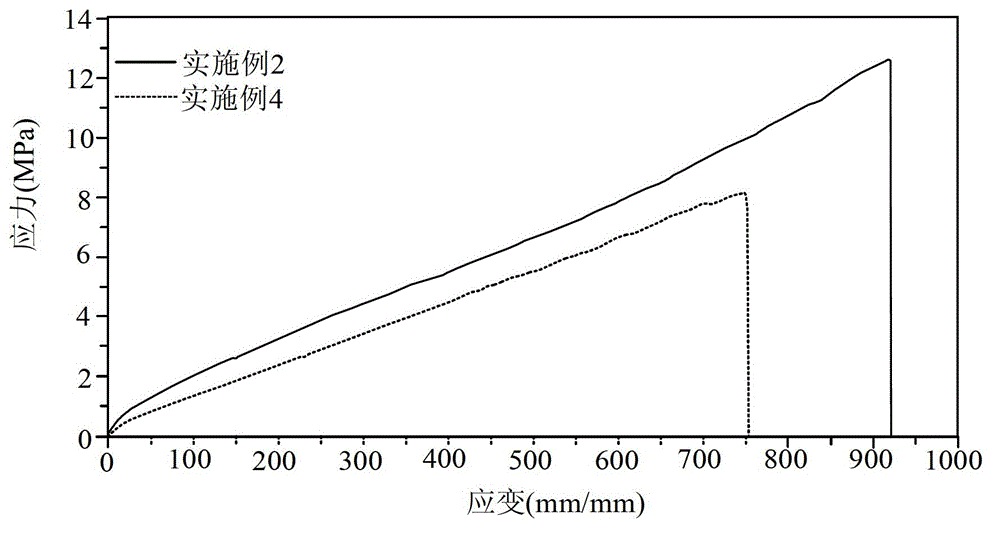

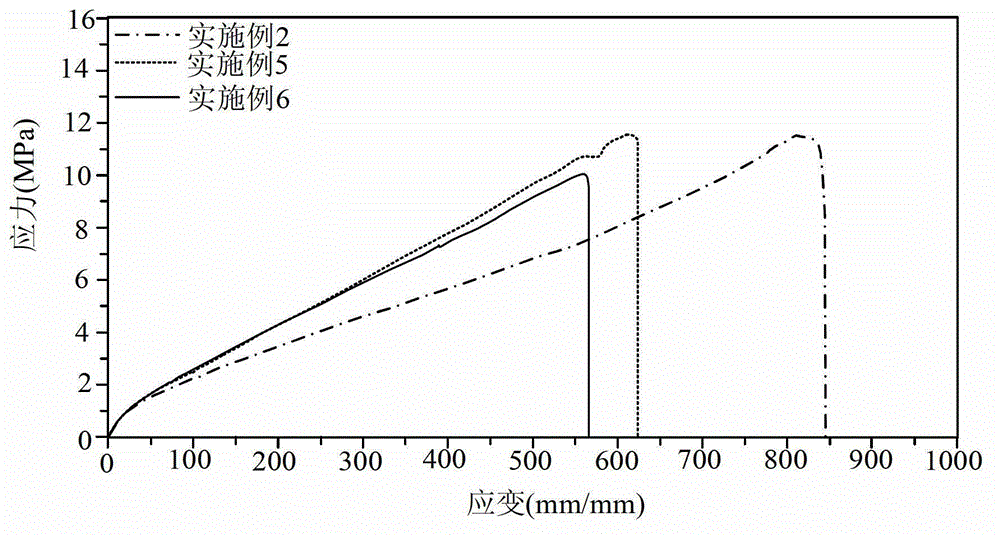

[0067] The elastomers obtained in Examples 1, 2, and 3 were hot-p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com