Polylactic acid/ polyamide 11 alloy material

A technology of alloy materials and polylactic acid, which is applied in the direction of conjugated synthetic polymer artificial filaments, fiber chemical characteristics, textiles and papermaking, etc., can solve the problems of unimproved mechanical properties of materials, large phase area size of prepared materials, and interface stickiness. Improve the mechanical properties of impact toughness, high modulus and tensile strength, and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-12

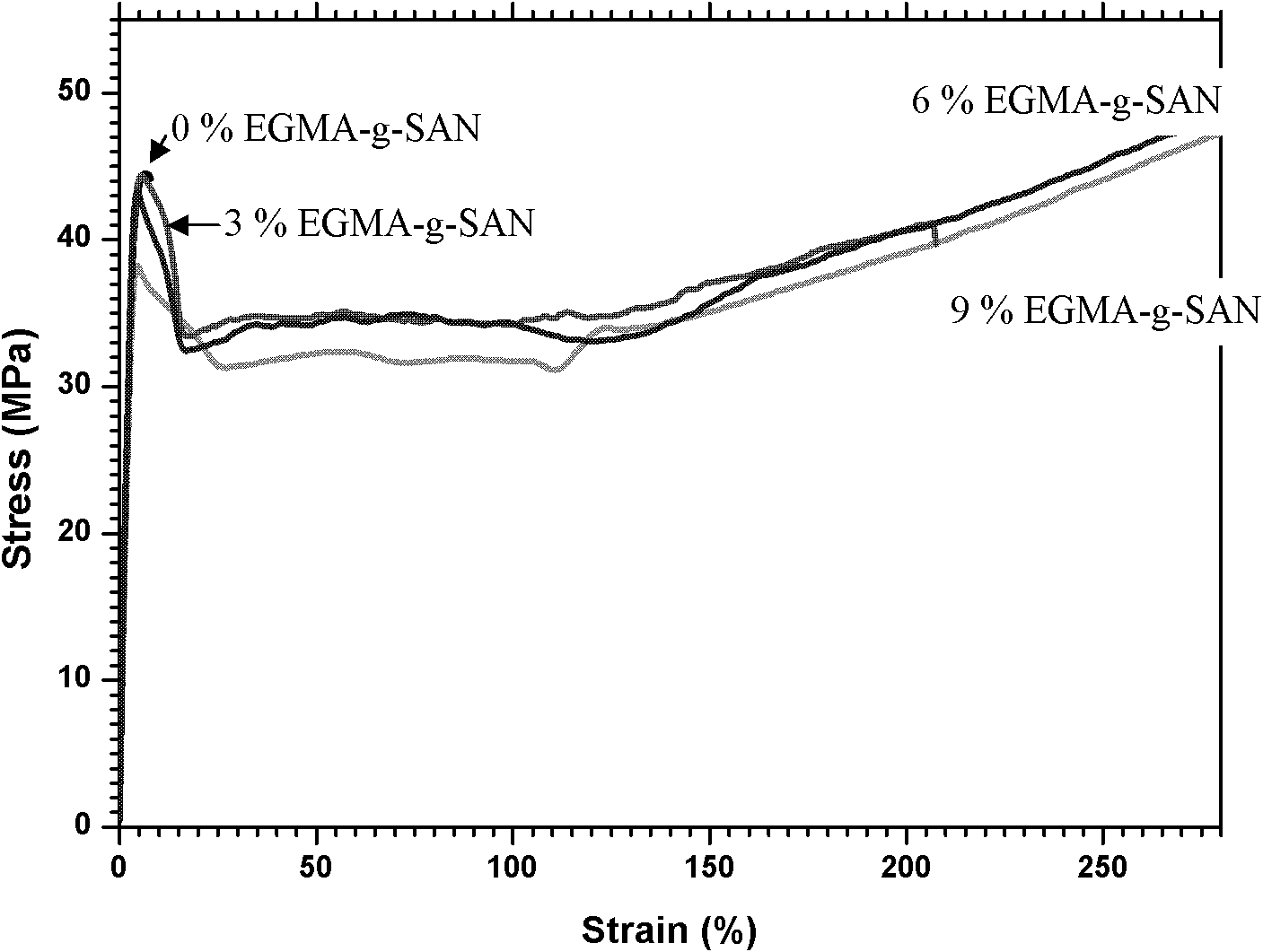

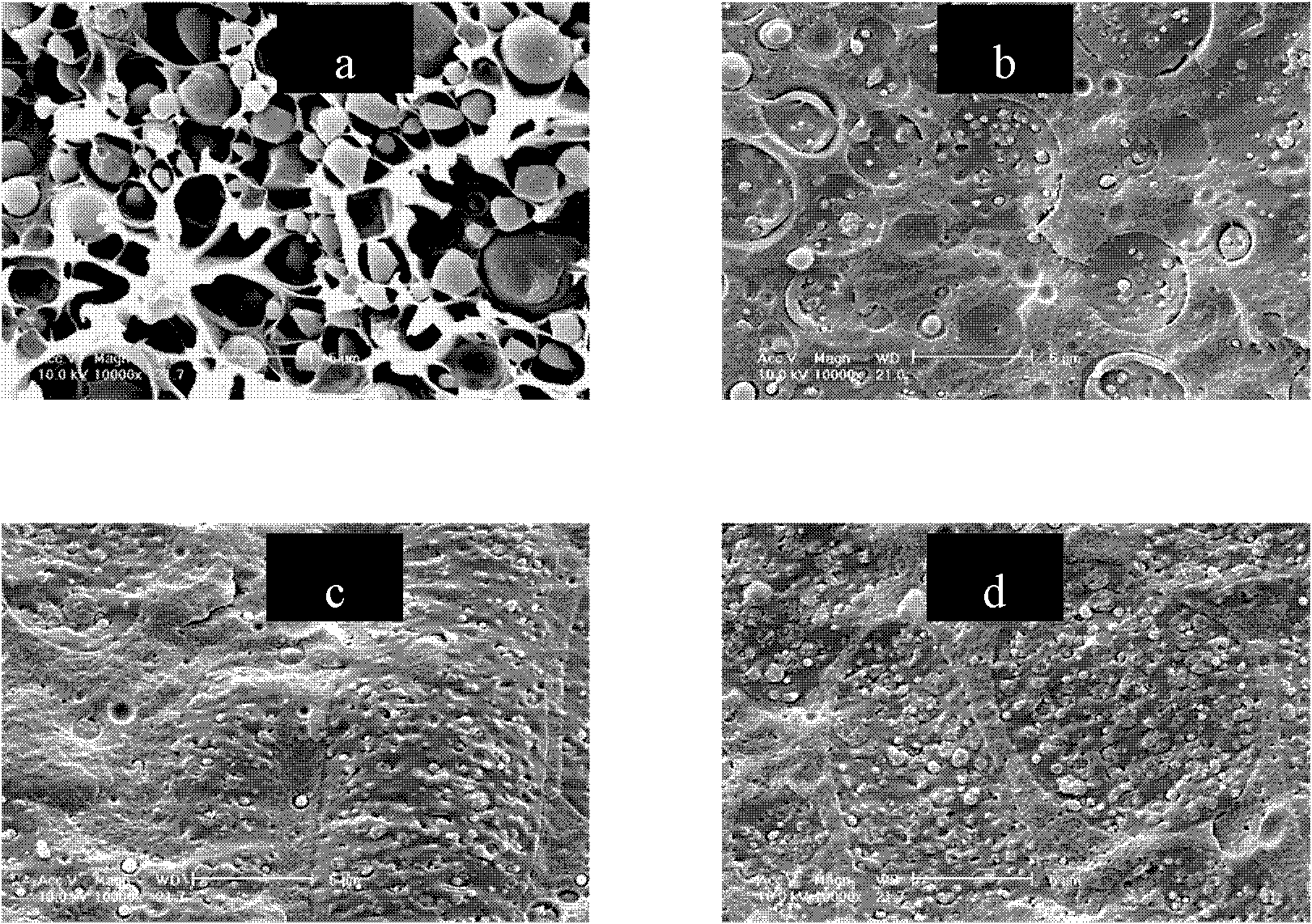

[0038] After polylactic acid (PLA), nylon 11 (PA11) and elastomer (EGMA-g-SAN) were dried in a vacuum oven at 80°C for 24 hours, the PLA / nylon 11 and elastomer were weighed according to the mass ratio in Table 1. After mixing and stirring at room temperature, add to the internal mixer, the temperature of the internal mixer is 200° C., the screw speed is set at 100 rpm, and the material is discharged after internal mixing for 5 minutes.

[0039] The above mixed samples were hot-pressed into a sheet with a thickness of 1mm in a hot press at 210°C, and a standard test sample was prepared with a standard dumbbell-shaped punching knife for performance testing. The results are shown in Table 1.

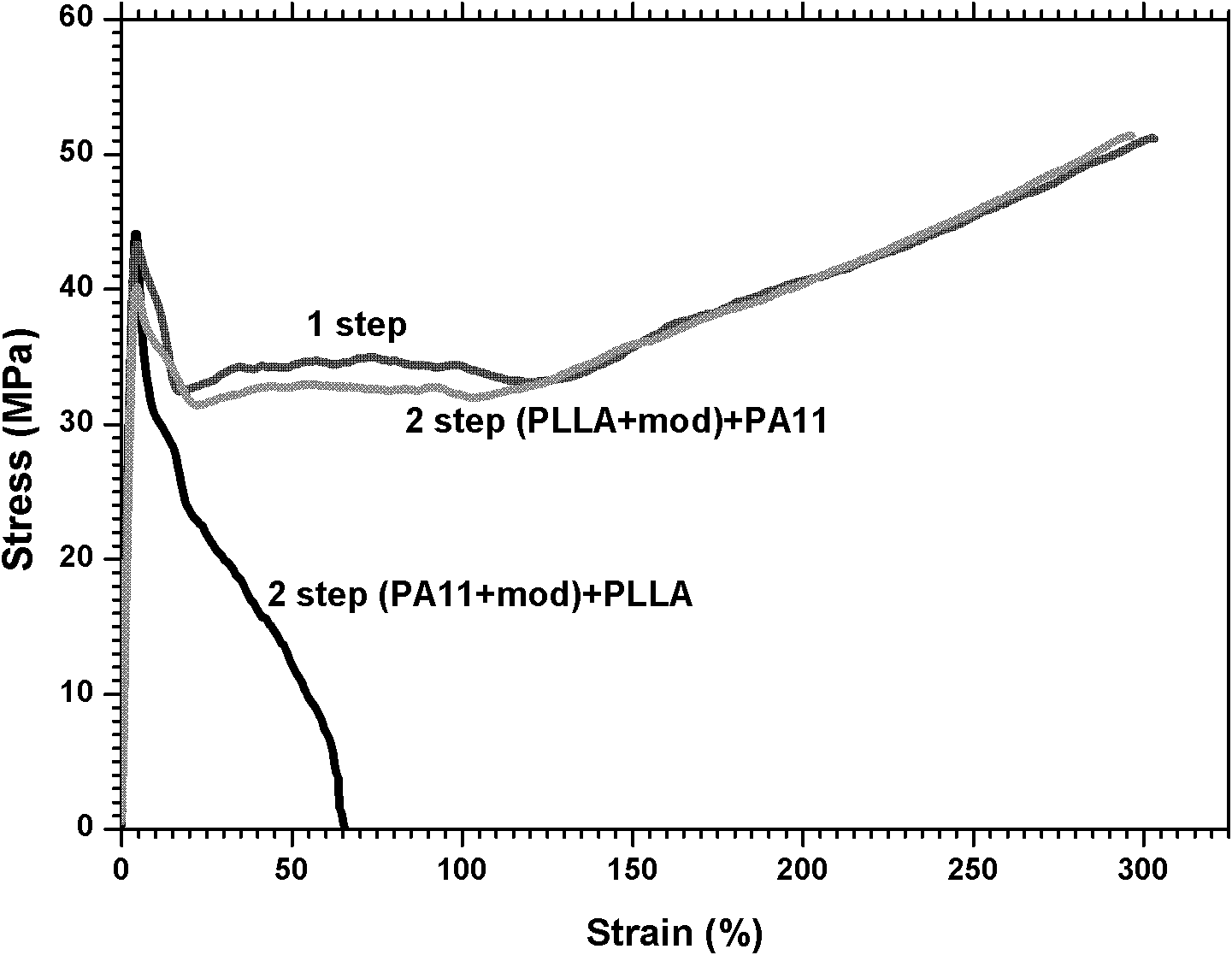

Embodiment 13

[0045] After polylactic acid (PLA), nylon 11 (PA11) and elastomer (EGMA-g-SAN) were dried in a vacuum oven at 80°C for 24 hours, the quantitative PLA and EGMA-g-SAN were first mixed and then added to the internal mixer , the temperature of the internal mixer is 200°C, the screw speed is set at 100rpm, and the material is discharged after internal mixing for 5 minutes. After pulverizing the sample, mix it with a certain amount of nylon 11, put it into an internal mixer, set the temperature of the internal mixer at 200°C, set the screw speed at 100 rpm, and discharge the material after internal mixing for 5 minutes. The mass ratio of the three raw materials used is PLA / nylon 11=55g / 45g, and EGMA-g-SAN is 6% of the total mass of PLA and nylon 11.

[0046] The above kneaded sample was hot-pressed into a sheet with a thickness of 1mm in a hot press at 210°C, and a standard test sample was prepared with a standard dumbbell-shaped punching knife for performance testing. The results a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com