Organic electroluminescence device manufacturing method, organic electroluminescence device and display device

An electroluminescence device and electroluminescence technology, which are applied to circuits, electrical components, electro-solid devices, etc., can solve problems such as low light extraction efficiency, and achieve the effects of enhancing light extraction rate, improving light extraction efficiency, and enhancing light extraction rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

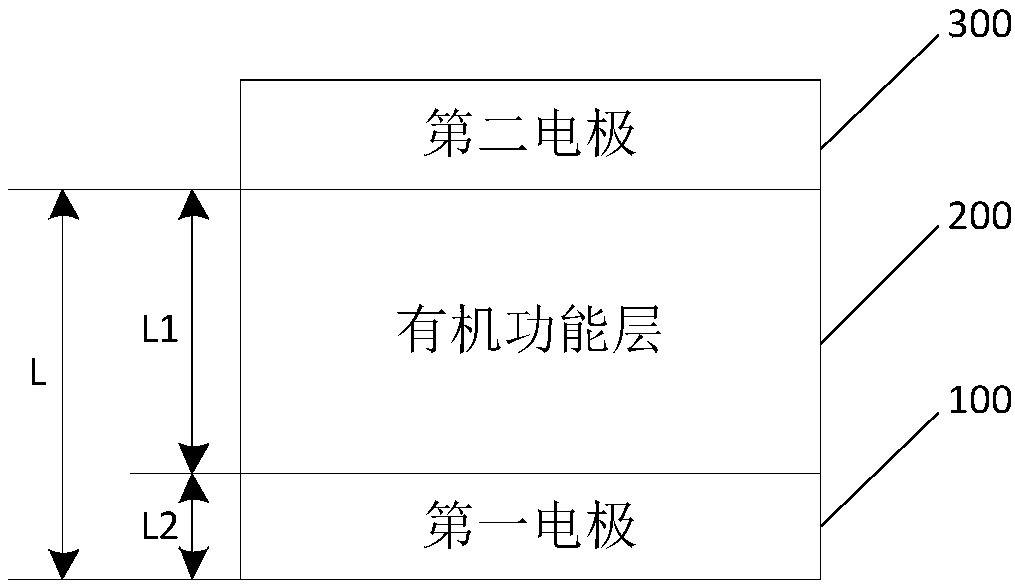

[0049] An embodiment of the present invention provides an organic electroluminescent device, such as figure 1 As shown, the first electrode 100 is a transparent anode, and the second electrode 300 is a metal cathode, that is, the organic electroluminescent device is a bottom-emitting device. The total microcavity length L of the organic light emitting diode in the bottom emitting organic electroluminescent device is the sum of the thickness L1 of the organic functional layer 200 and the thickness L2 of the first electrode 100 . In this embodiment, a white organic light emitting diode is used as an example for illustration. As an optional implementation manner, the organic light emitting diode can also be selected in other ways.

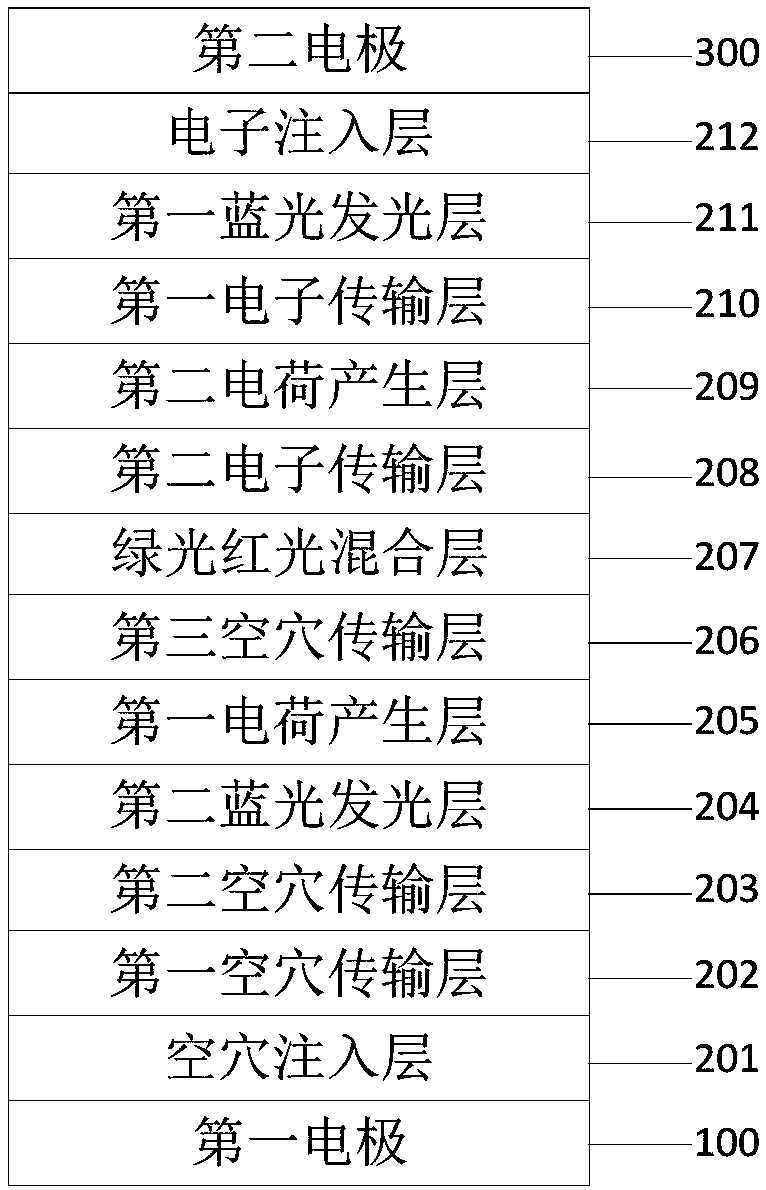

[0050] In the organic electroluminescence device of the embodiment of the present invention, the organic functional layer 200 includes three kinds of monochromatic light emitting layers, and the three kinds of monochromatic light are red light, green...

Embodiment approach

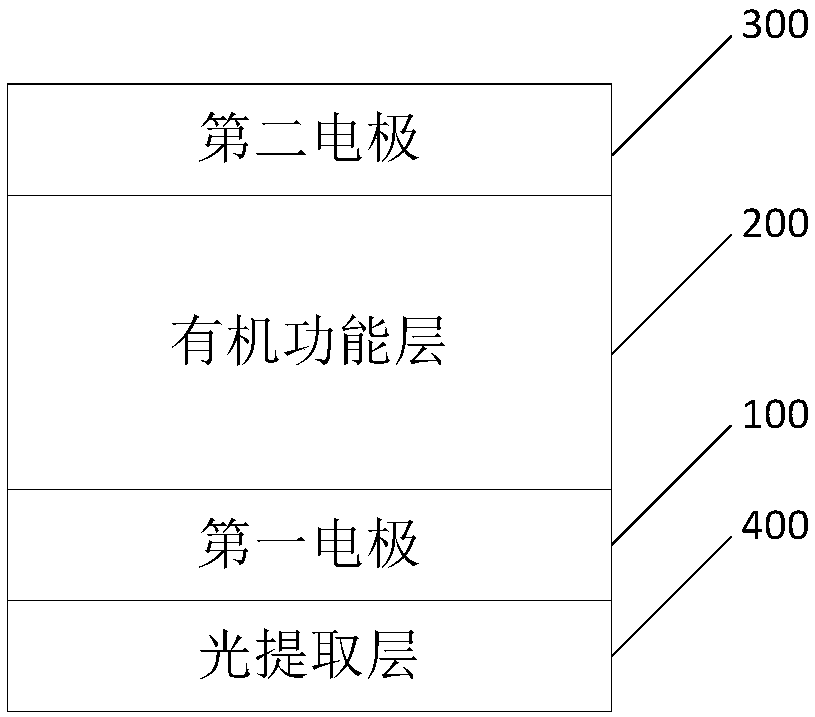

[0083] As another alternative embodiment of the present invention, when the organic electroluminescence device is a double-sided light-emitting device, during the manufacturing process, the thickness of the first electrode 100 and the second electrode 300 can be adjusted simultaneously to adjust the organic light emission. The purpose of diode microcavity length.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com