Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

150results about How to "Simple casting process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Wax injection mold for investment casting of hollow turbine blades and method for rapidly manufacturing wax injection mold

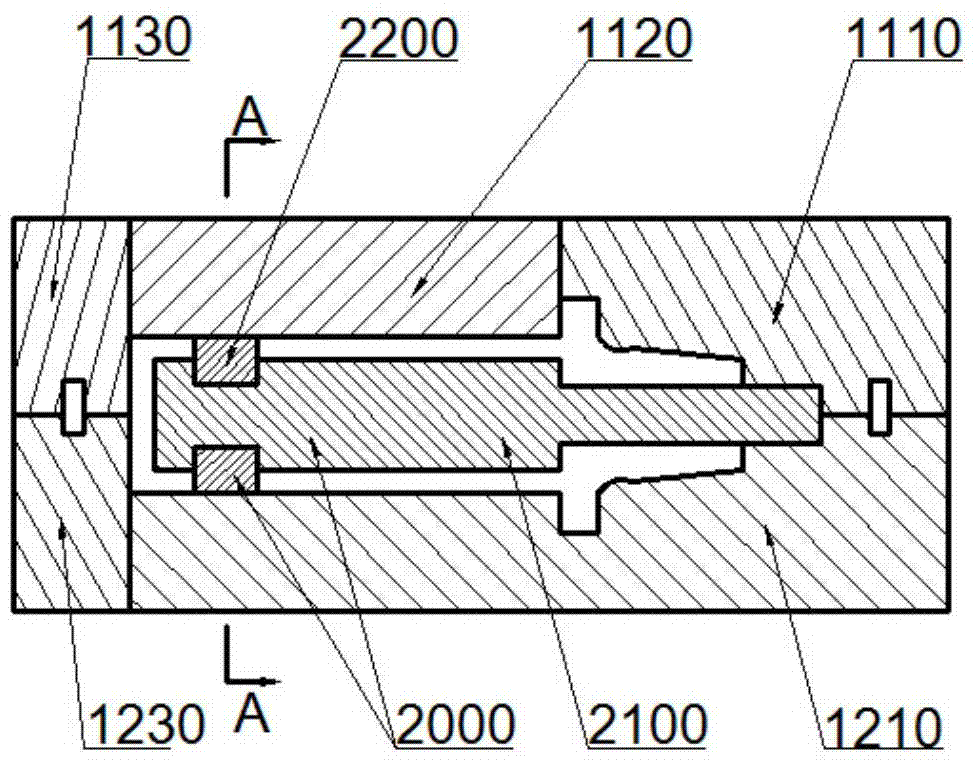

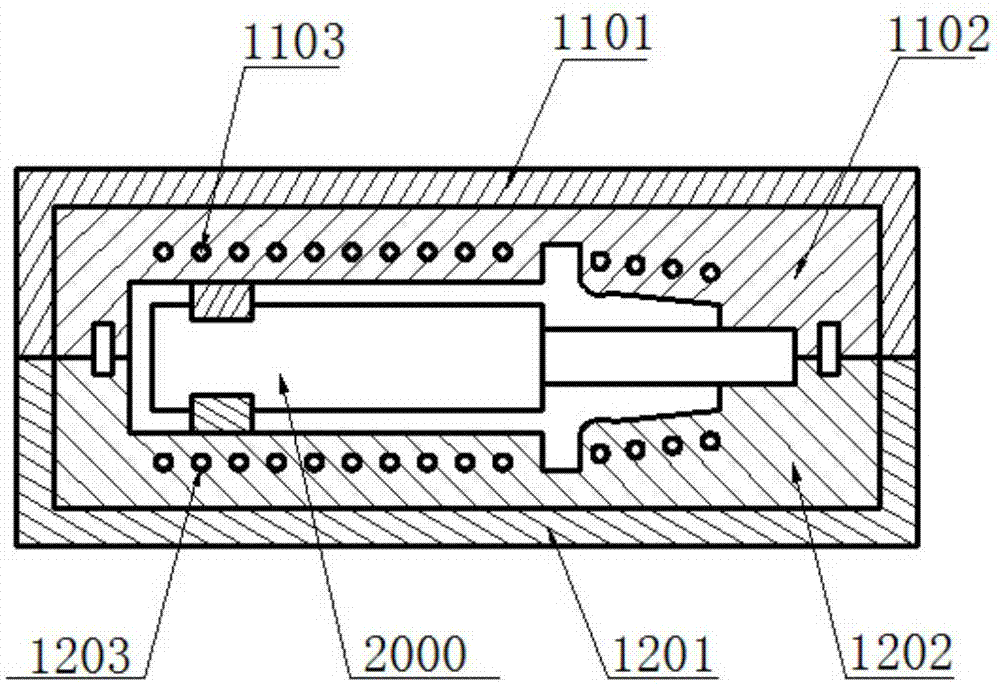

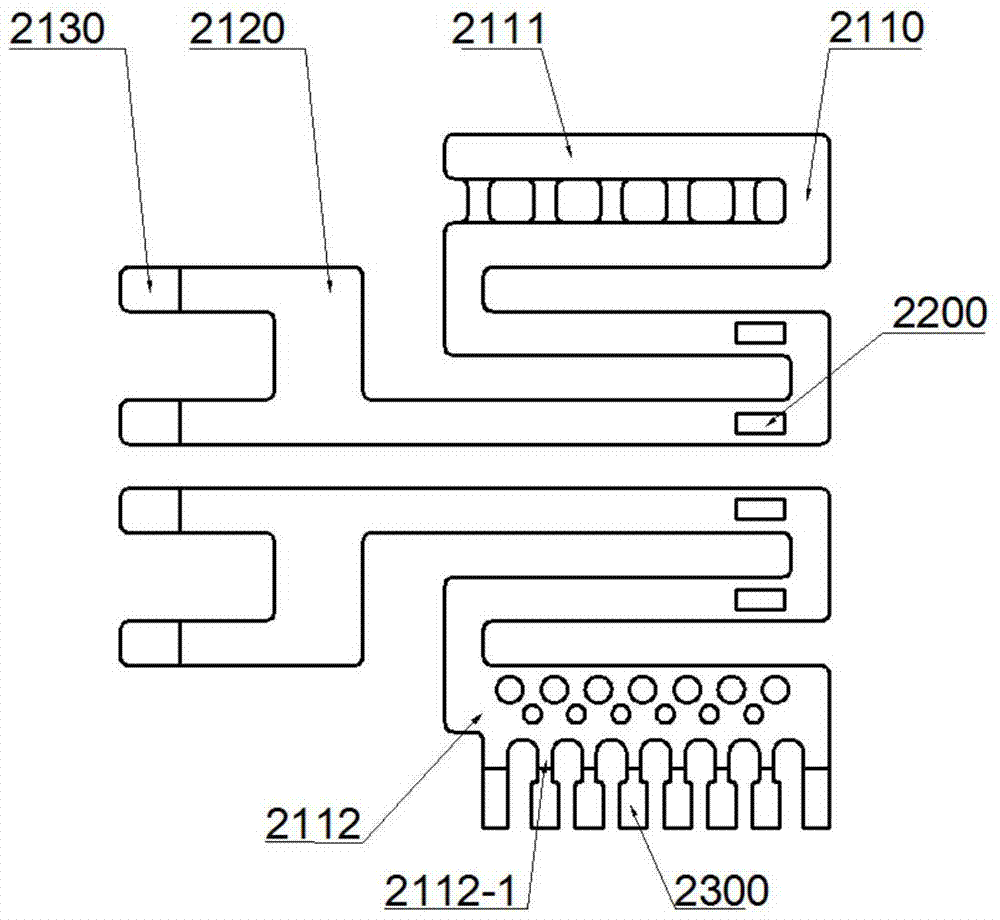

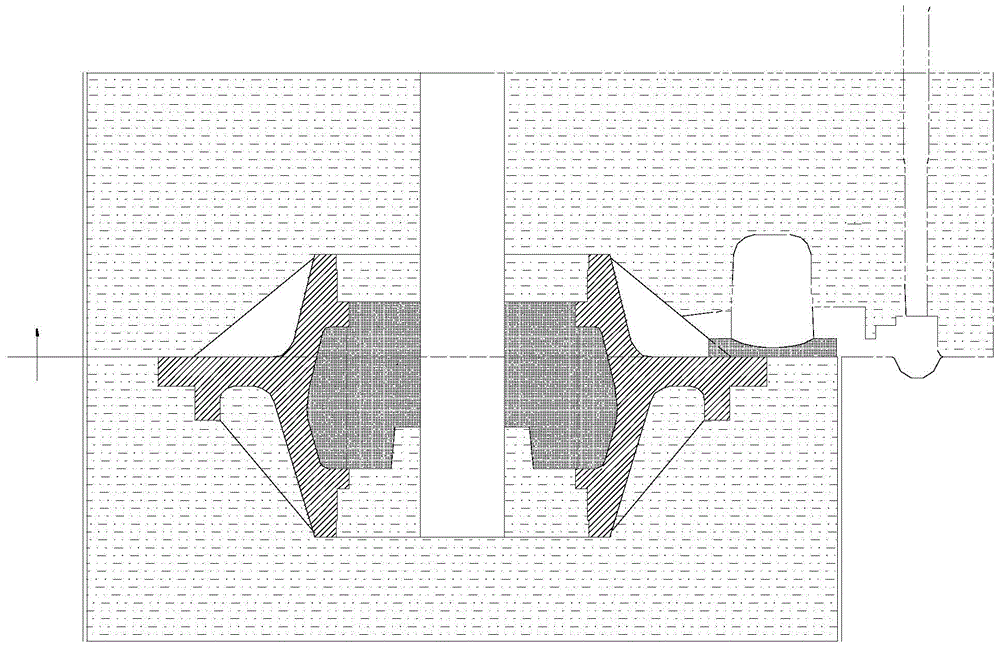

The invention discloses a wax injection mold for investment casting of hollow turbine blades and a method for rapidly and accurately manufacturing the wax injection mold. The mold consists of a cavity mold, a mold core and an accessory structure, wherein the cavity mold comprises an upper mold and a lower mold of a combined structure; each mold block forming the cavity mold consists of an external aluminum mold frame, an internal cast zinc alloy inlay and a conformal cooling copper pipe embedded into the inlay; a mold core positioning piece which can be decomposed at a high temperature is arranged on a longitudinal rib of the mold core; and water-soluble core blocks used for forming exhaust openings in the rear edges of the turbine blades are arranged on rear edge ribs of the mold core. The matching precision of the mold core positioning piece and the cavity mold is guaranteed by adopting a cavity mold interior running-in method, and the matching precision of the water-soluble core blocks and the cavity mold is guaranteed by adopting a cavity mold interior adhesion method. The wax injection mold disclosed by the invention is low in manufacturing cost and short in period, and the high wax pattern precision and core positioning precision can be obtained.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Aluminum alloy and aluminum alloy extruded profile machining method

The invention discloses aluminum alloy and an aluminum alloy extruded profile machining method. The aluminum alloy comprises, by weight, 0.6-1.4% of Si, 0.7-1.3% of Mg, 0.1-1% of Cu, 0.1-1% of Mn, 0.01-0.15% of Ti, 0-0.2% of Zr, 0-0.5% of Cr, 0-0.4% of Fe, 0-0.25% of Zn and the balance Al. The aluminum alloy also meets the requirements that the weight percentage range of Mg+Si+Cu is 1.4-3.7%, themole ratio of Mg to Si is 0.7-1.5, and the weight percentage range of Mn+Cr+Zr is 0.1-1.5%. The machining method comprises the steps that (1) a cast ingot of the alloy is subjected to homogenization treatment; (2) the cast ingot is extruded into aluminum profile; (3) extrusion production is conducted; (4) on-line quenching is conducted; (5) tension leveling is conducted; and (6) artificial aging is adopted. According to the aluminum alloy and the aluminum alloy extruded profile machining method, the technology is simple, and the production cost is low.

Owner:CHINALCO MATERIALS APPL RES INST CO LTD

Alloy austenitic-bainite ductile iron worm gear and preparation process thereof

ActiveCN101736190AEasy to controlImprove yieldPortable liftingGearing elementsAfter treatmentFerrosilicon

The invention relates to an alloy austenitic-bainite ductile iron worm gear and a preparation process thereof. The worm gear comprises the following components in percentage by weight: 3.5 to 3.9 percent of C, 2.3 to 2.9 percent of Si, less than or equal to 0.4 percent of Mn, less than or equal to 0.035 percent of P, less than or equal to 0.03 percent of S, 0.2 to 0.3 percent of Mo, 0.3 to 0.6 percent of Cu, 0.2 to 0.5 percent of Ni and the balance of iron. The preparation process comprises the following steps: smelting the components, taking a rare earth magnesium alloy as a spheroidizing agent and ferrosilicon as an inoculating agent, and casting a blank after treatment; roughly machining the blank of the worm gear, heating and isothermally quenching to obtain a proper amount of retained austenite; and finishing a gear to prepare the alloy austenitic-bainite ductile iron worm gear. The worm gear has the advantages to high fatigue resistance, high pitting resistance, lower density than steel, small deformation and the like, and is suitable for replacing a worm gear on a valve electric actuator made of a copper alloy or zinc base alloy (ZA27) so as to obviously reduce production cost.

Owner:YANGZHOU ELECTRIC POWER EQUIP MFG FACTORY CO LTD +2

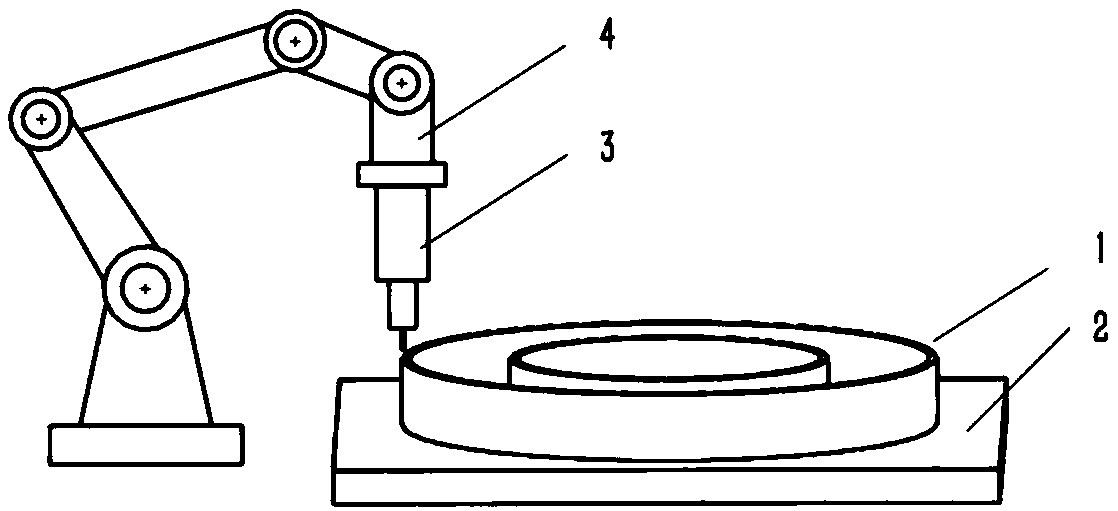

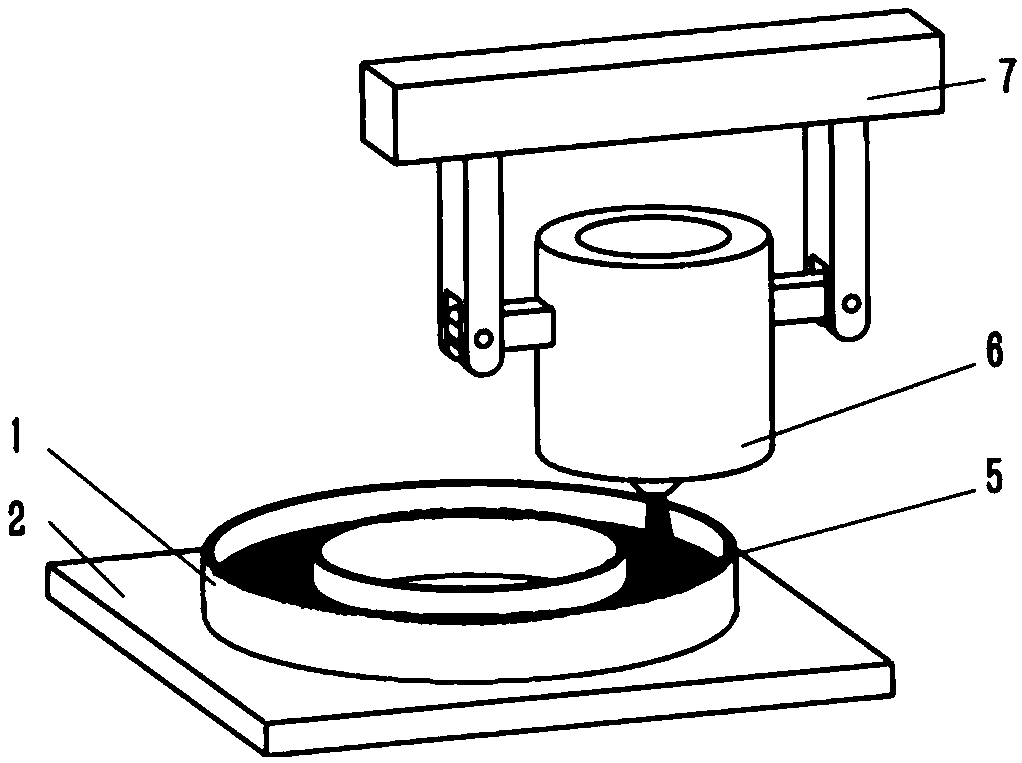

Additive manufacturing method and device for large metal part

ActiveCN109014200AImprove performanceSmall grain sizeAdditive manufacturing apparatusManufacturing technologyAdditive layer manufacturing

The invention belongs to the field of additive manufacturing, and specifically discloses an additive manufacturing method and device for a large metal part. Firstly, the additive manufacturing technology is used, slice processing is performed according to a data model of the part, then contour data of all layers are extracted, a deposition path of a contour is generated, a metal cavity having a certain thickness and depth is manufactured on a substrate, smelted metal is injected into the metal cavity, after the smelted metal is in the solidification or semi-solidification state, the part is rolled and processed, deposition of a new metal cavity in the part is continuously carried out, and the above steps are continuously executed until the overall part is completed. The additive manufacturing method and device solve the defects that a current large-scale metal part wholly adopts the additive manufacturing process so that the efficiency can be insufficient and cracking can be easy, thecasting process is adopted so that defects such as contraction and shrinkage can exist, the shortcoming that the process is complicated and the cycle is too long and the shortcoming that the forging process is adopted so that a forging press can have the tonnage limit and the cycle can be too long, and the high-performance metal parts can be quickly manufactured with low cost.

Owner:HUAZHONG UNIV OF SCI & TECH

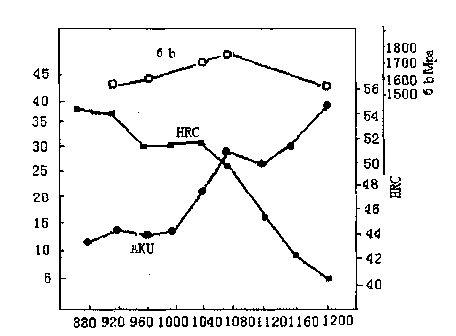

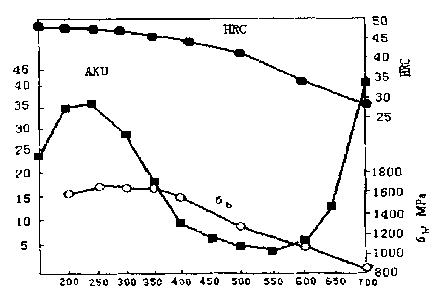

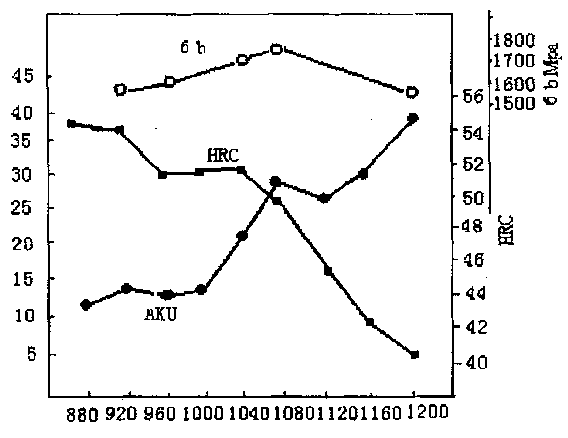

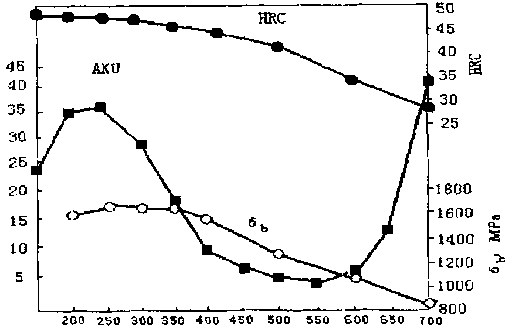

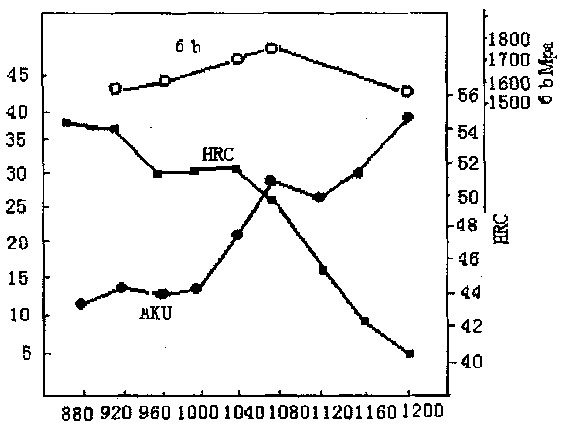

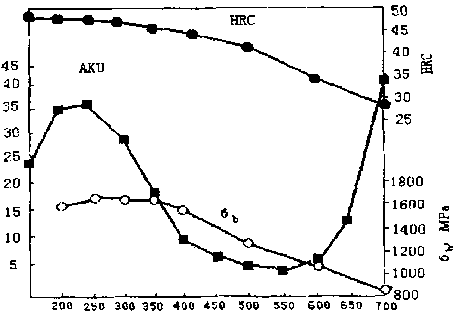

Method for preparing low alloy high wear resistant cast steel plate

The present invention relates to a method for preparing a low alloy high wear resistant cast steel plate. The cast steel plate includes the following components: 0.25-0.35 wt% of C, 0.9-1.6 wt% of Si, 0.3-1.8 wt % of Mn, 0.7-1.0 wt% of Cr, 0.15-0.3 wt% of Mo, 0.05-0.35 wt% of Ti, 0.01-0.05 wt% of Nb, 0.05-0.25 wt% of V, 0.01-0.1 wt% of RE, no more than 0.03 wt% of P and S, and the balance Fe. The components are melted and molded, and then a processed ingot is placed therein for heating. When the temperature reaches 1050-1070 DEG C, the heat preservation lasts. After the completion of heat preservation, the ingot is placed into a 240-245 DEG C salt bath furnace for heat preservation. The ingot is finally cooled by the air. The casting and heat treatment process of the present invention is relatively simple, easily controlled, and low in cost, and the produced material has good strength and toughness.

Owner:HAIAN COUNTY SHENLING ELECTRICAL APPLIANCE MFG

Automobile rear-bridge spiral conic gear of manganese-copper alloy autenite-bainite nodular iron and its preparing method

InactiveCN1936368AGuaranteed hardenabilityGuaranteed nodularityPortable liftingFurnace typesRoughcastCupola furnace

This invention relates to a MnCu alloy ADI car rear axle screw bevel gear and its preparation method, which takes ordinary pig iron as the raw material of said gear, applies a duplex method of cupola and electric cooker, takes rear earth, Mg and silicon iron alloy as the nodulizer to be processed then to slag and eliminate slag, gestates and casts the gear roughcast in two times, then finishes it after mechanical process, isothermal quenching and temper, in which, the composed weight percentage of said gear is: C 3.4-3.8%, Si 2.4-2.9%, Mn 0.4-1.0%, Cu 0.5-1.2%, P less than 0.06%, S less than 0.02% and the rest is iron.

Owner:WUHAN UNIV OF TECH +1

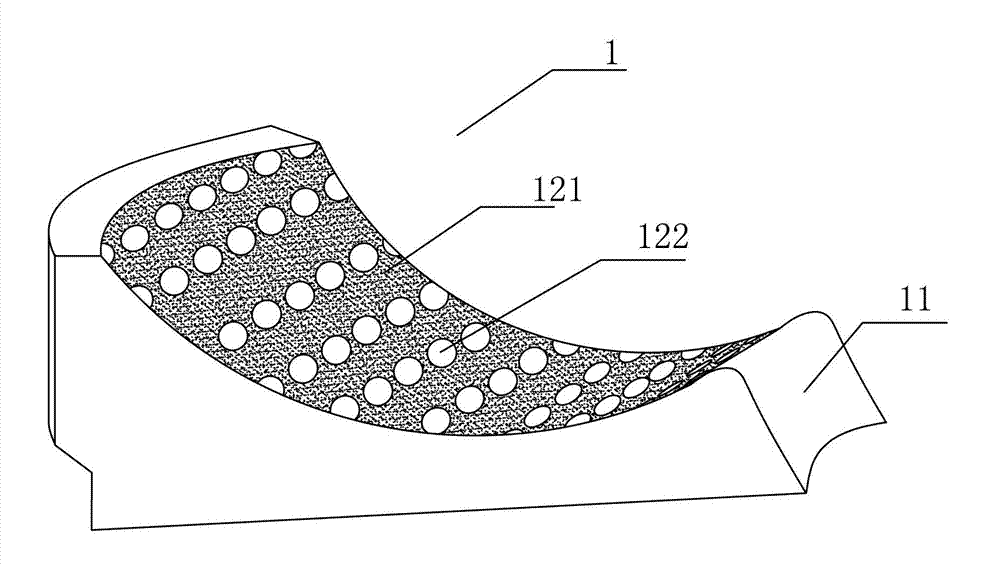

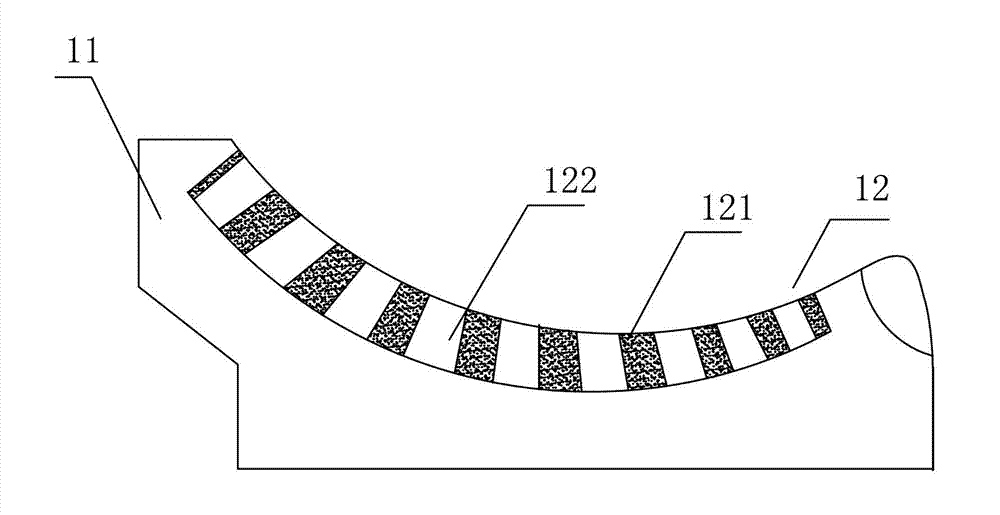

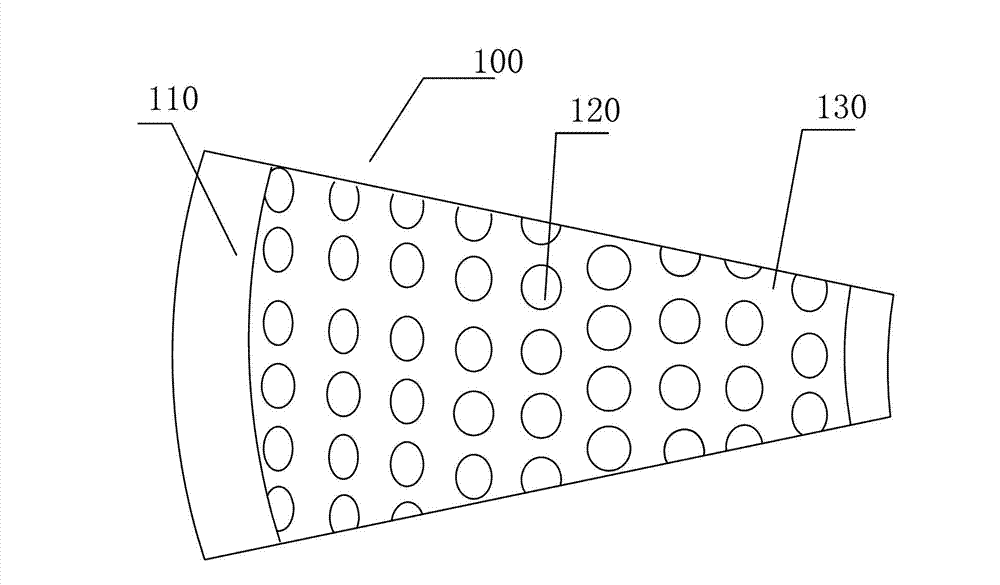

Lost foam casting type composite wear-resistant component and casting method thereof

ActiveCN103203428AAnti-wear self-protectionEvenly distributedFoundry mouldsFoundry coresWear resistantCasting types

The invention discloses a lost foam casting type composite wear-resistant component and a casting method of the lost foam casting type composite wear-resistant component. The wear-resistant component comprises a metallic substrate part and a working layer part, wherein the metallic substrate part is provided with concave part; the working layer part, the metallic substrate part are cast into a whole and the working layer part is filled into the concave part; reinforced particles are uniformly distributed on the working layer part; and the reinforced particles are wrapped with molten metal which flows around the reinforced particles during integrated casting and then is solidified, so as to be fixed on the working layer part. The composite wear-resistant component has wear-resistant and self-protective effects, and is capable of preventing possible cracks from expanding in a ceramic working layer; therefore, the wear resistance is improved, and the service life is prolonged. Compared with cast-in type reinforced particles, the reinforced particles disclosed by the invention have higher yield, are hardly influenced by the casting temperature and speed; simultaneously, the reinforced particles are distributed more uniform in the metal substrate; in addition, the casting method is simple to operate, short in production period and low in cost, and materials can be saved.

Owner:BEIJING POWER EQUIP GRP

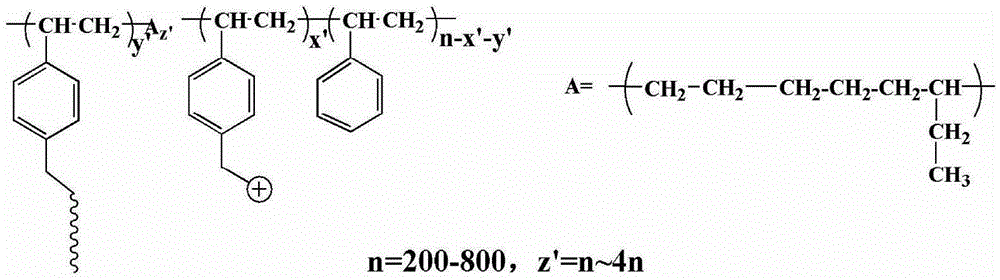

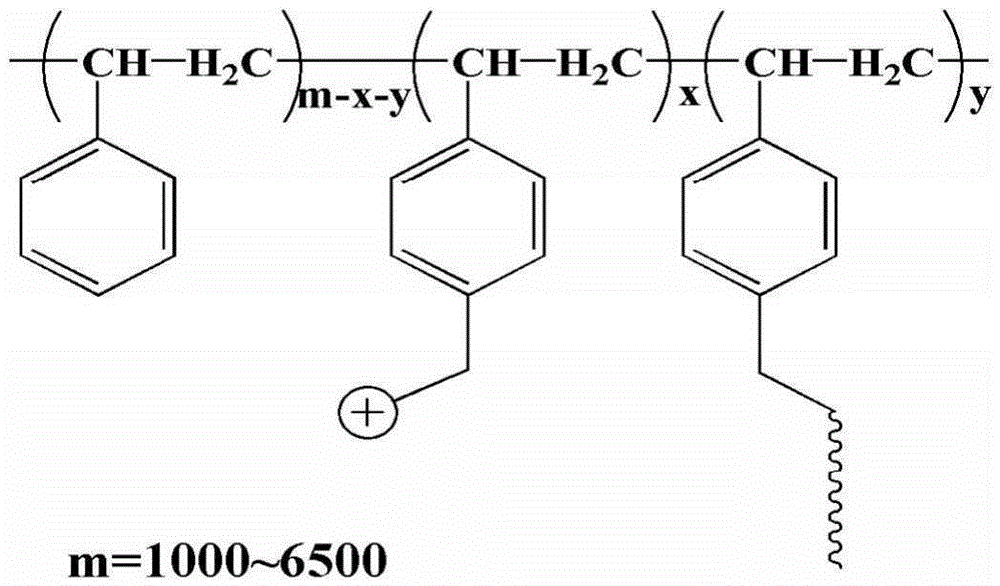

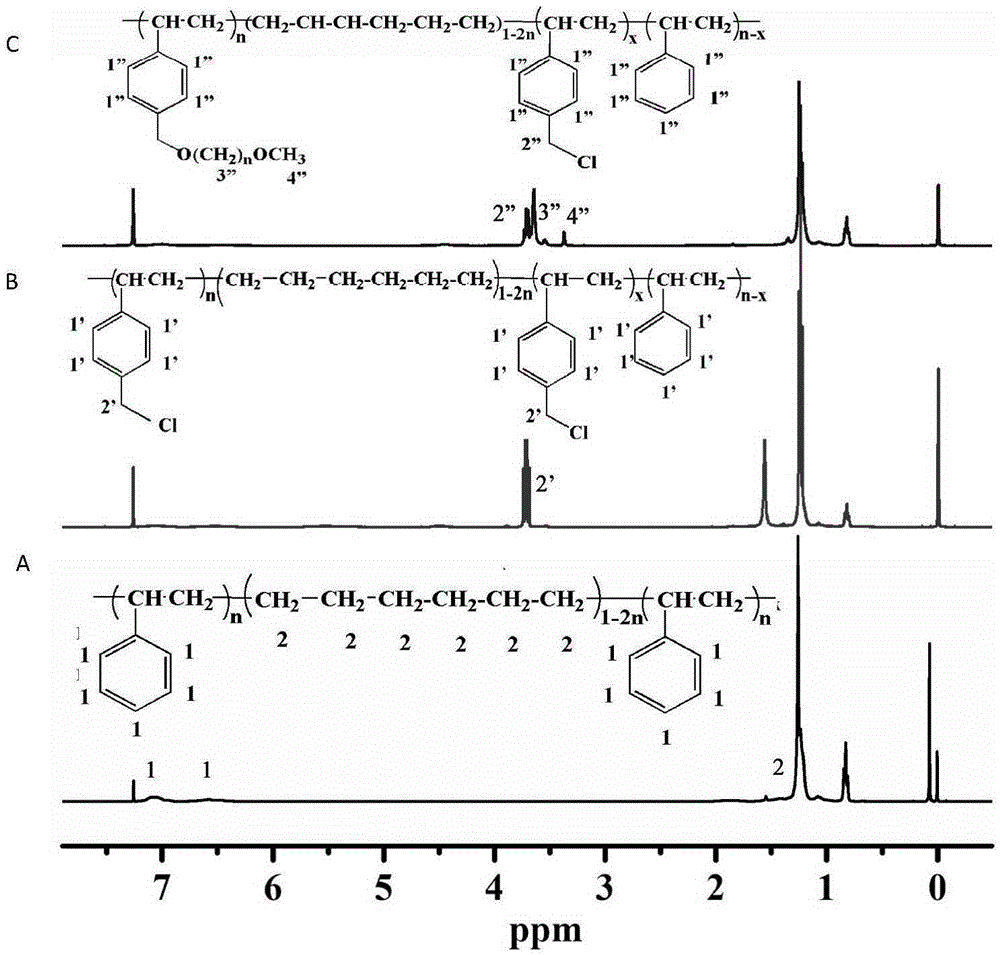

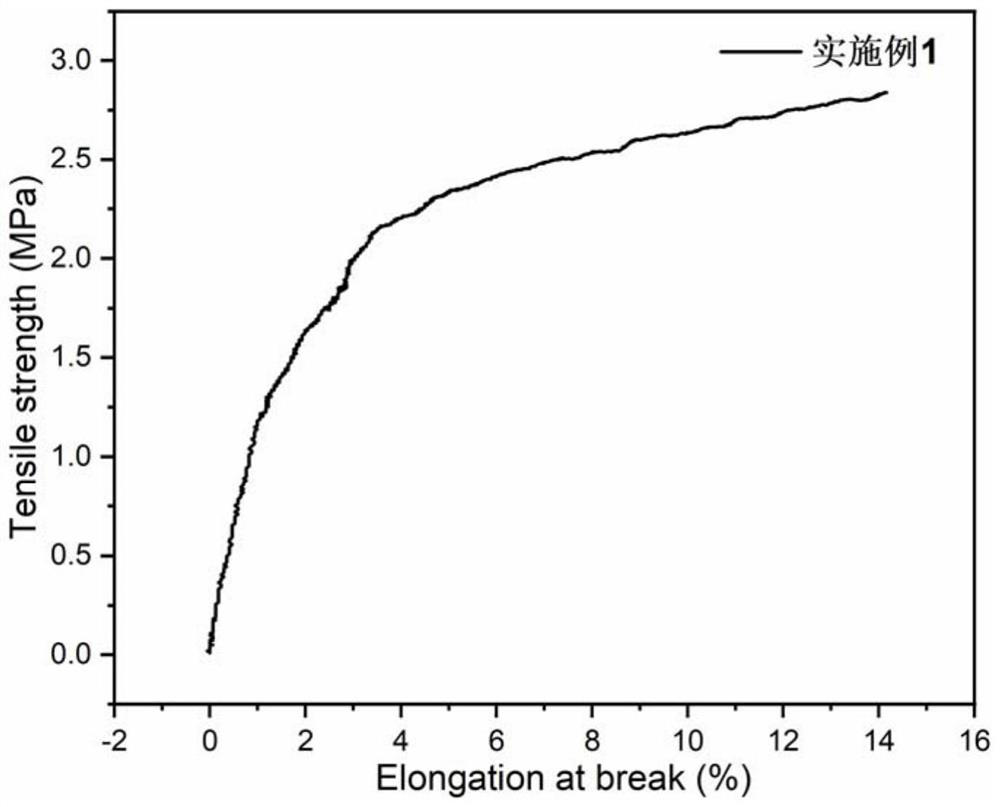

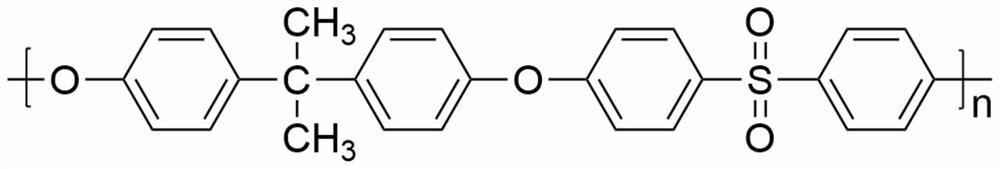

Alkaline anion exchange membrane and preparation method thereof

ActiveCN106883327ASimple casting processUniform surfaceIon-exchange membranesAlkaline anion exchange membrane

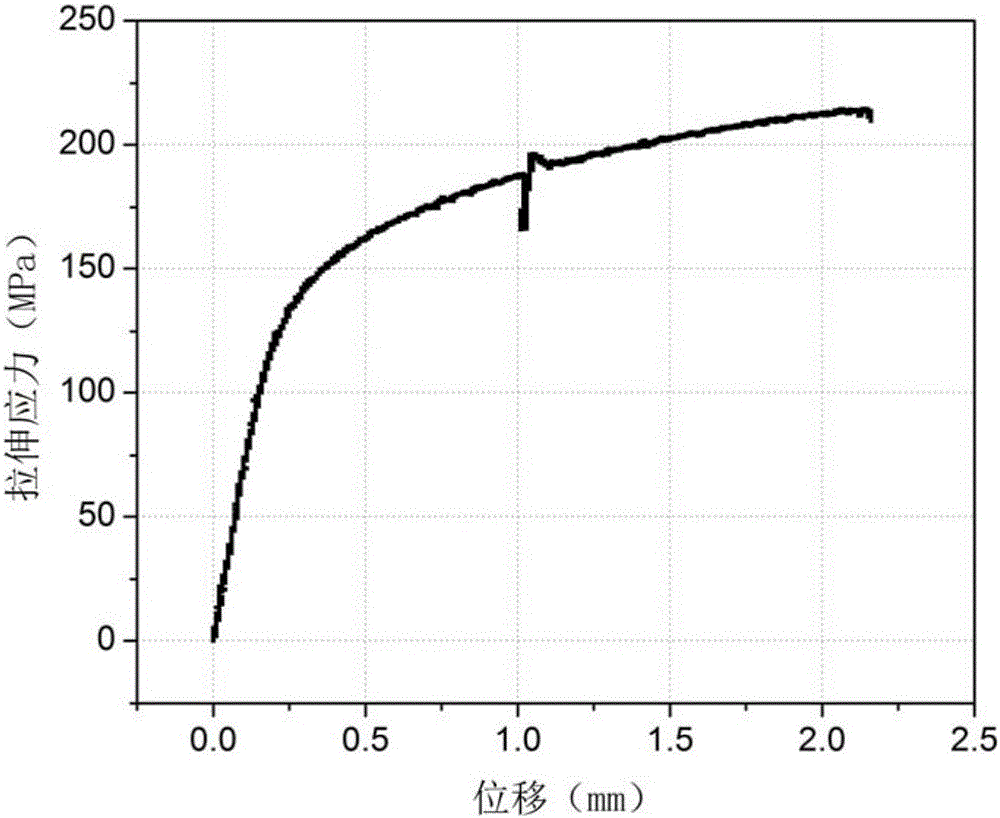

An alkaline anion exchange membrane comprises a polystyrene or poly(styrene-ethylene- butylene) segmented copolymer main chain; and the phenyl containing part of the polystyrene or poly(styrene-ethylene- butylene) segmented copolymer main chain is bonded with a cation functional group or a long hydrophobic side chain through methylene; wherein the molecular weight of polystyrene is greater than 100000, and the molecular weight of the poly(styrene-ethylene- butylene) segmented copolymer is greater than 40000. Compared with the prior art, the membrane casting technology is easy, large area membranes can be produced massively, the prepared alkaline anion exchange membrane with a long hydrophobic side chain has a uniform, smooth, and compact surface; the conductivity can reach 80 S / cm, the requirements of fuel cells on the conductivity of the alkaline anion exchange membrane can be met; the membrane also has good mechanical properties, the breaking elongation rate can reach 500%, the chemical stability is good, the stability time is longer than 3000 hours in a high temperature alkaline environment, the thermal stability is good, and the glass-transition temperature is higher than 180 DEG C.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Low-alloy high-wear-resistance cast steel

InactiveCN103060705AGood strength and toughnessSimple ingredientsProcess efficiency improvementAlloyHigh wear resistance

The invention relates to a low-alloy high-wear-resistance cast steel which comprises the following components: 0.25-0.35wt.% of C, 0.9-1.6wt.% of Si, 0.3-1.8wt.% of Mn, 0.7-1.0wt.% of Cr, 0.15-0.3wt.% of Mo, 0.05-0.35wt.% of Ti, 0.01-0.05wt.% of Nb, 0.05-0.25wt.% of V, 0.01-0.1wt.% of RE, at most 0.03wt.% of P and S, and the balance of Fe and inevitable impurities. The invention has the advantages of simple preparation process and favorable toughness compatibility.

Owner:张芝莲

Preparation method of low-alloy high-wear-resistance cast steel

The invention relates to a preparation method of low-alloy high-wear-resistance steel cast. The low-alloy high-wear-resistance steel cast comprises the following components: 0.25-0.35 wt.% of C, 0.9-1.6 wt.% of Si, 0.3-1.8 wt.% of Mn, 0.7-1.0 wt.% of Cr, 0.15-0.3wt.% of Mo, 0.05-0.35wt.% of Ti, 0.01-0.05 wt.% of Nb, 0.05-0.25 wt.% of V, 0.01-0.1 wt.% of RE, at most 0.03 wt.% of P and S, and the balance of Fe. The preparation method comprises the following steps: melting the components, casting to form, heating the treated casting, and keeping the temperature when the temperature reaches 1050-1070 DEG C; and after finishing keeping the temperature, putting the casting in a 240-245 DEG C salt bath furnace, keeping the temperature, discharging, and cooling in air. The casting and heat treatment technique is simple and easy to control and low in cost; and the prepared material has favorable toughness compatibility.

Owner:马丁青

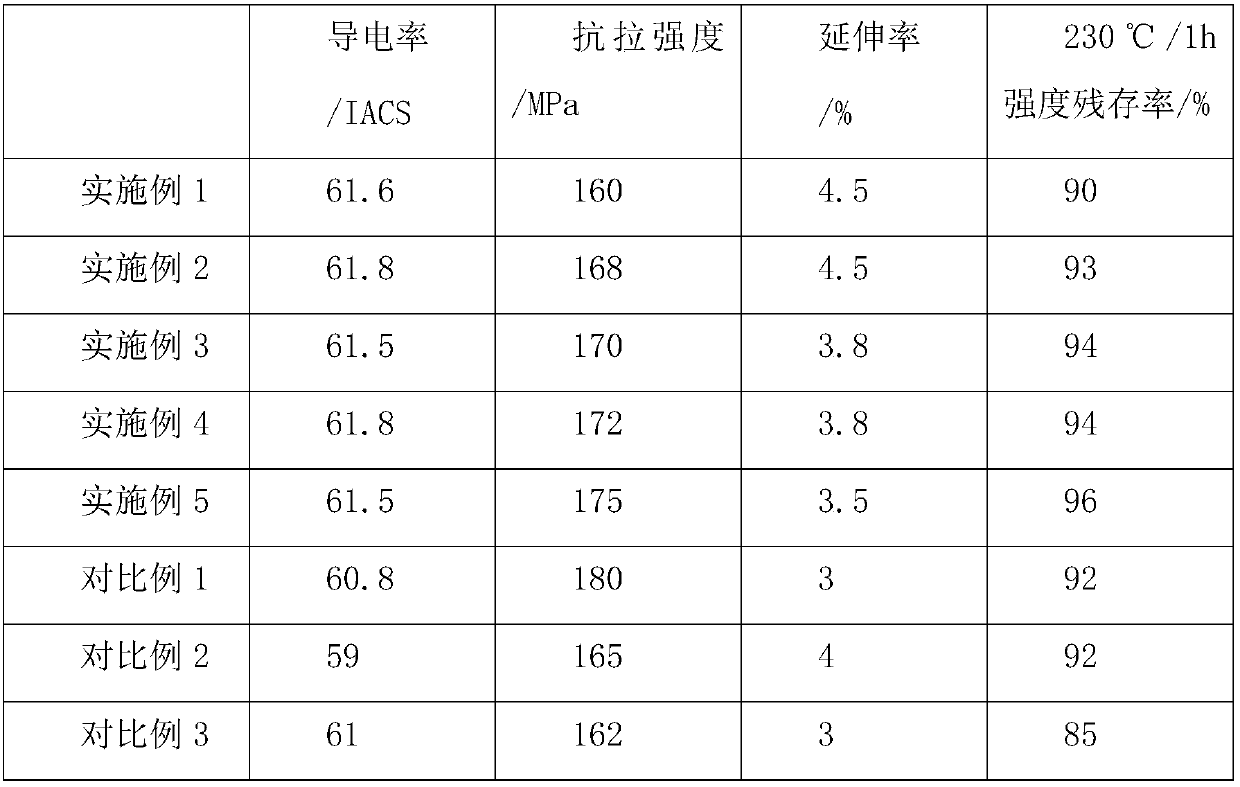

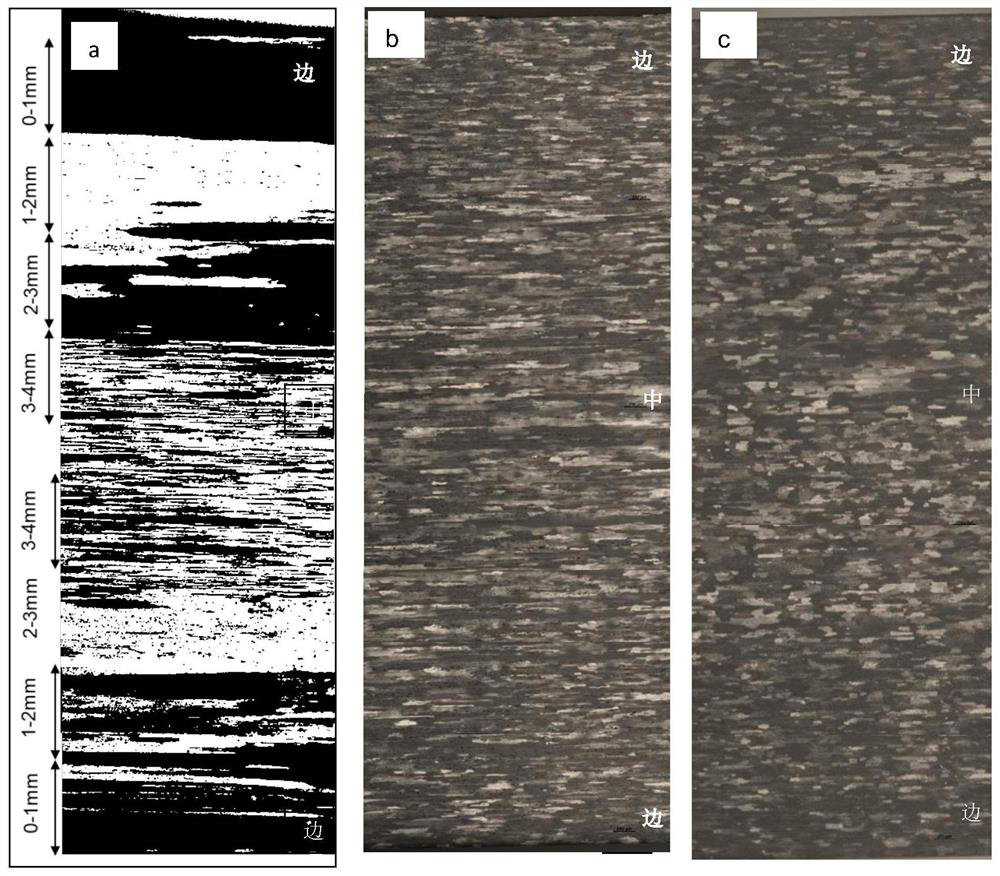

High-conductivity heat-resistant Al-Zr-Er alloy wire material and preparation method thereof

ActiveCN111349820ASolving ingredientsSolve the impurity contentConductive materialMetal/alloy conductorsRare-earth elementUltimate tensile strength

The invention provides a high-conductivity heat-resistant Al-Zr-Er alloy wire material. The alloy comprises the following components of, by mass, 0.02%-0.15% of Zr, 0.01%-0.2% of Er, 0.01%-0.04% of B,less than or equal to 0.20% of Fe, less than or equal to 0.05% of Si, less than or equal to 0.01% of (V+Ti+Cr+Mn) and the balance Al. According to the high-conductivity heat-resistant Al-Zr-Er alloywire material, the trace rare earth element Er is added while the element Zr is added into the alloy so as to modify the alloy and to optimize and adjust the content of the alloy elements, so that themechanical property of the alloy is guaranteed, and the electric conductivity is improved; and the electric conductivity of the prepared heat-resistant aluminum alloy monofilament material is largerthan or equal to 61.5% IACS, the tensile strength is larger than or equal to 160 MPa, the elongation rate is larger than 3.5%, the heat-resistant temperature is greater than or equal to 150 DEG C, andthe strength residual rate after heating at 230 DEG C for 1 hour is greater than 90%.

Owner:CHINALCO MATERIALS APPL RES INST CO LTD +1

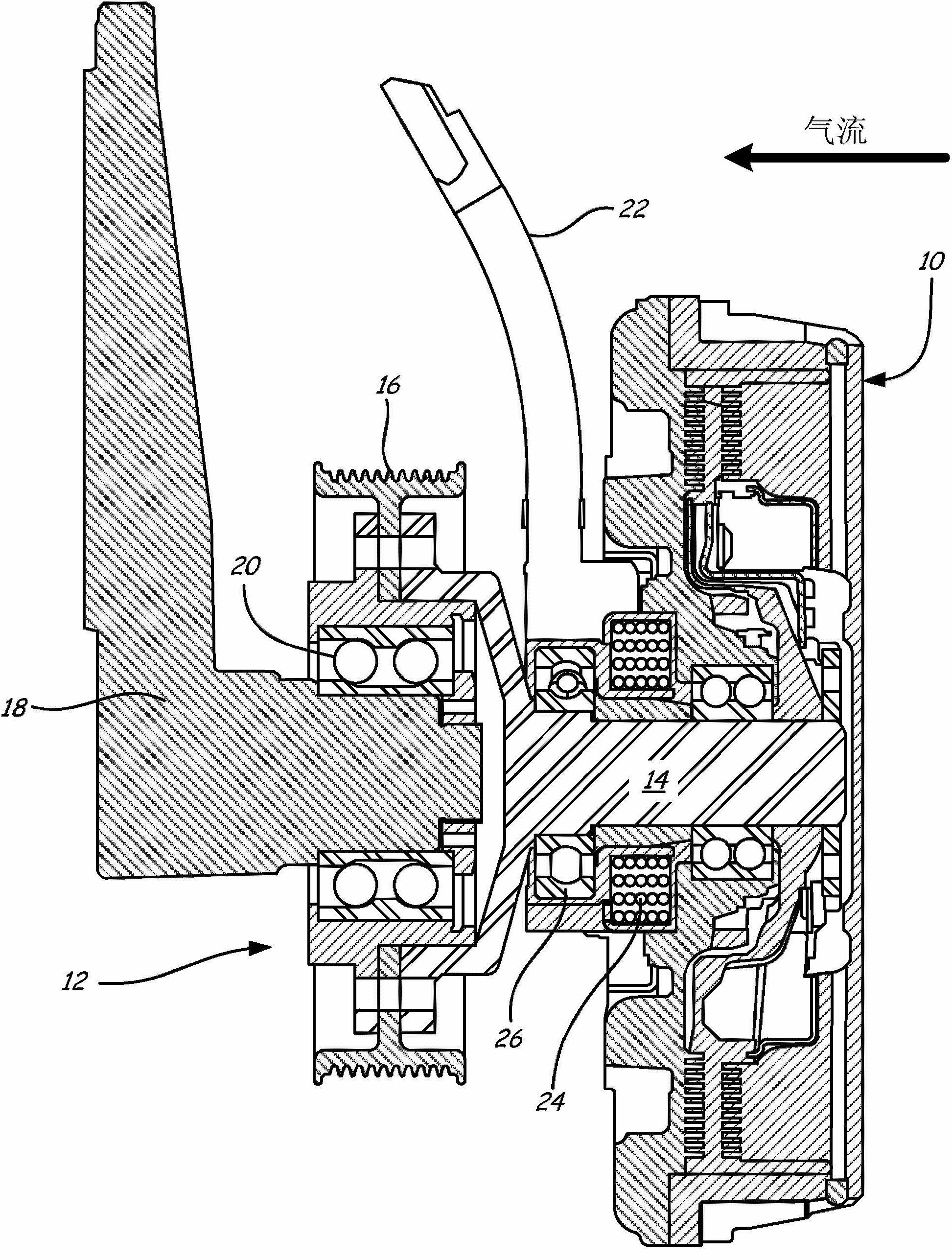

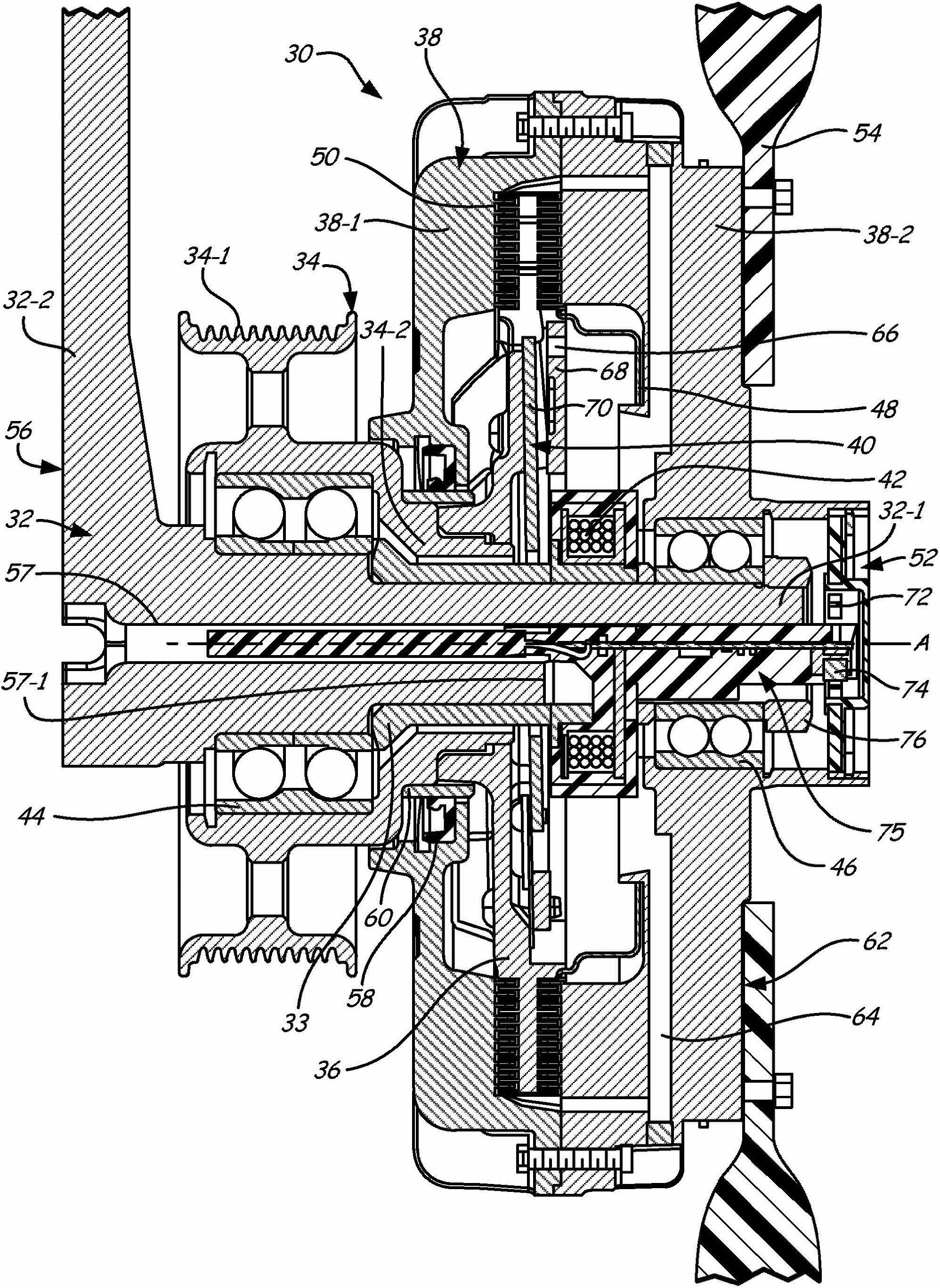

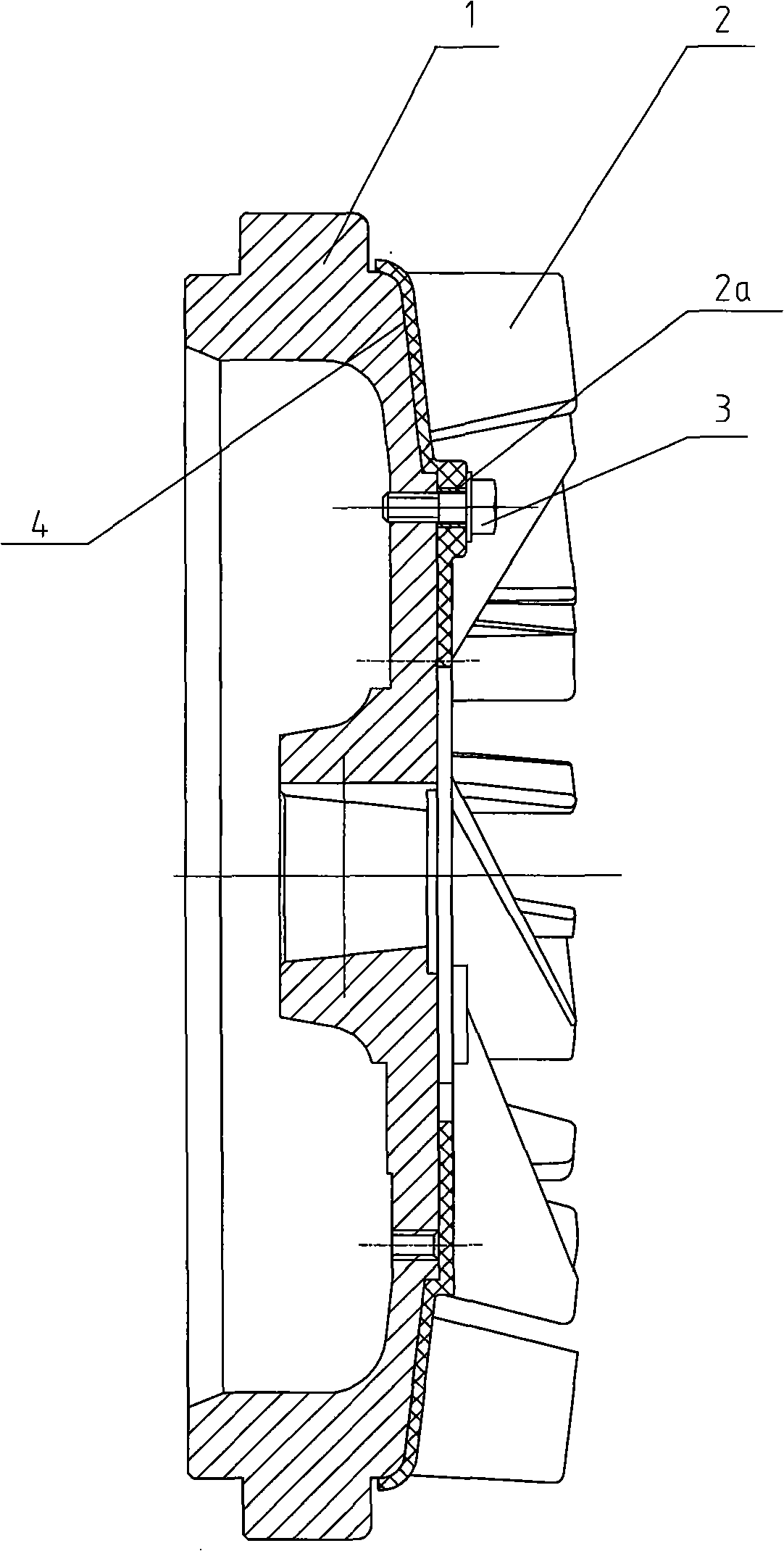

Integrated viscous clutch

InactiveCN102667213AIncrease the number of turnsLight in massFluid actuated clutchesCouplingsEngineeringClutch

A viscous clutch (30; 30') includes a stationary journal bracket (32; 32') defining a mounting shaft (32-1; 32-1'), an output member (34; 34') rotatably supported on the mounting shaft about an axis (A), an input member (34; 34') rotatably supported on the mounting shaft about the axis, and a working chamber (50; 50') defined between the input member and the output member to selectively transmit torque there between when a shear fluid is present. The mounting shaft extends axially through the viscous clutch from a front face (62; 62') of the viscous clutch to a rear face (56; 56') of the viscous clutch, with the rear face defining a mounting surface for mounting the viscous clutch at a mounting location. The front and rear faces are located at opposite sides of the viscous clutch and face in opposite directions.

Owner:HORTON

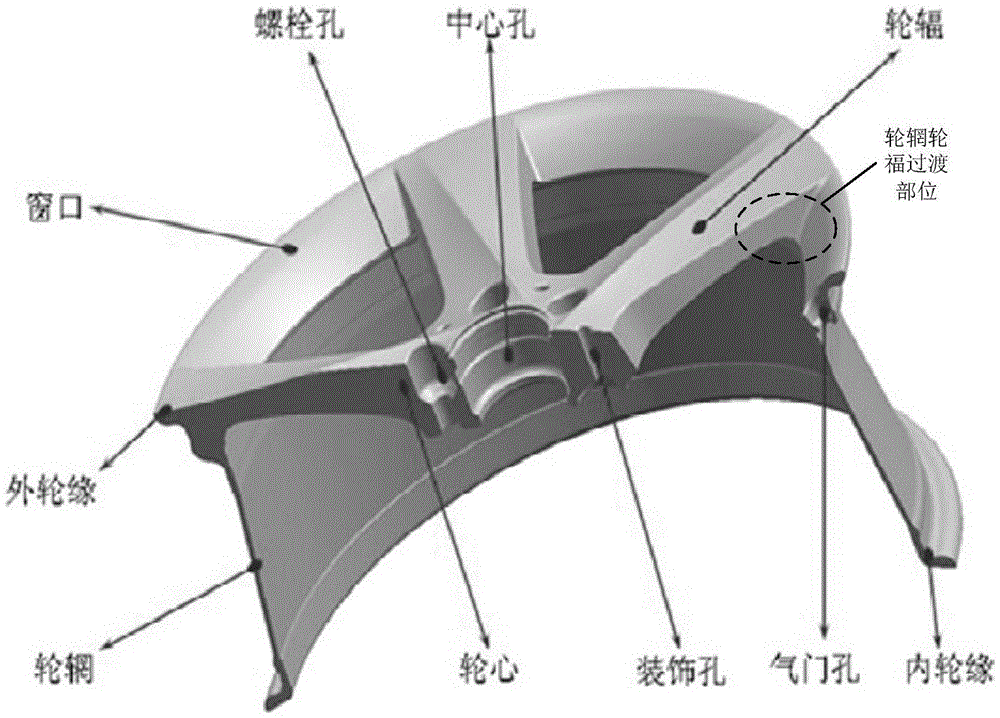

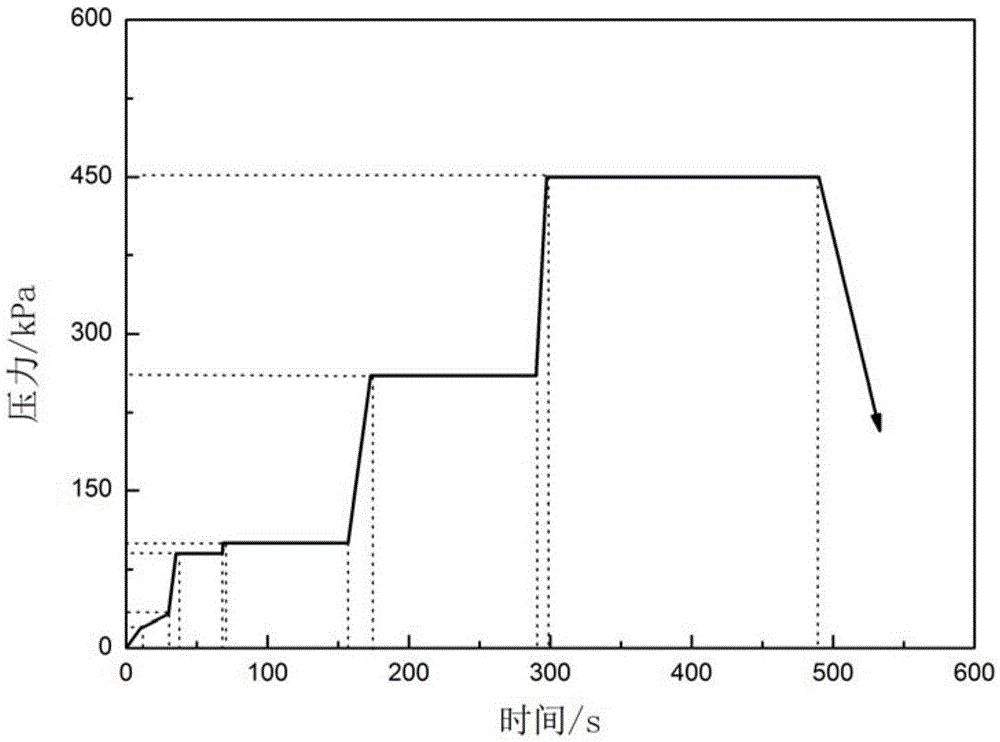

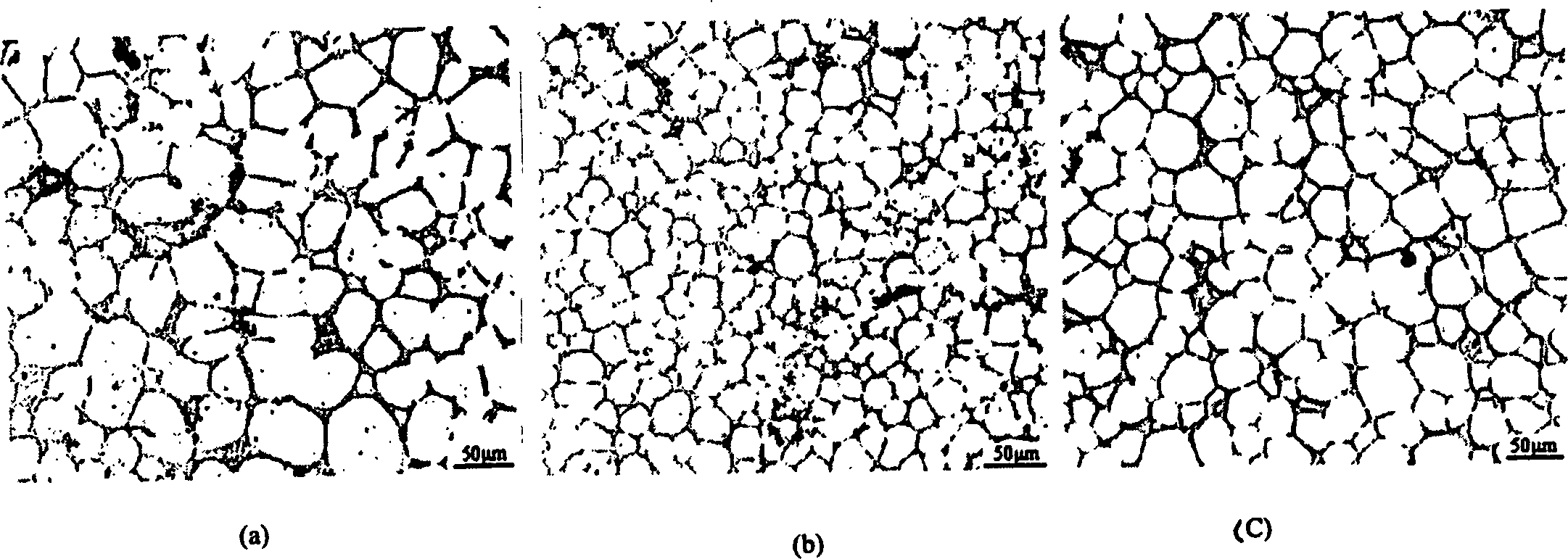

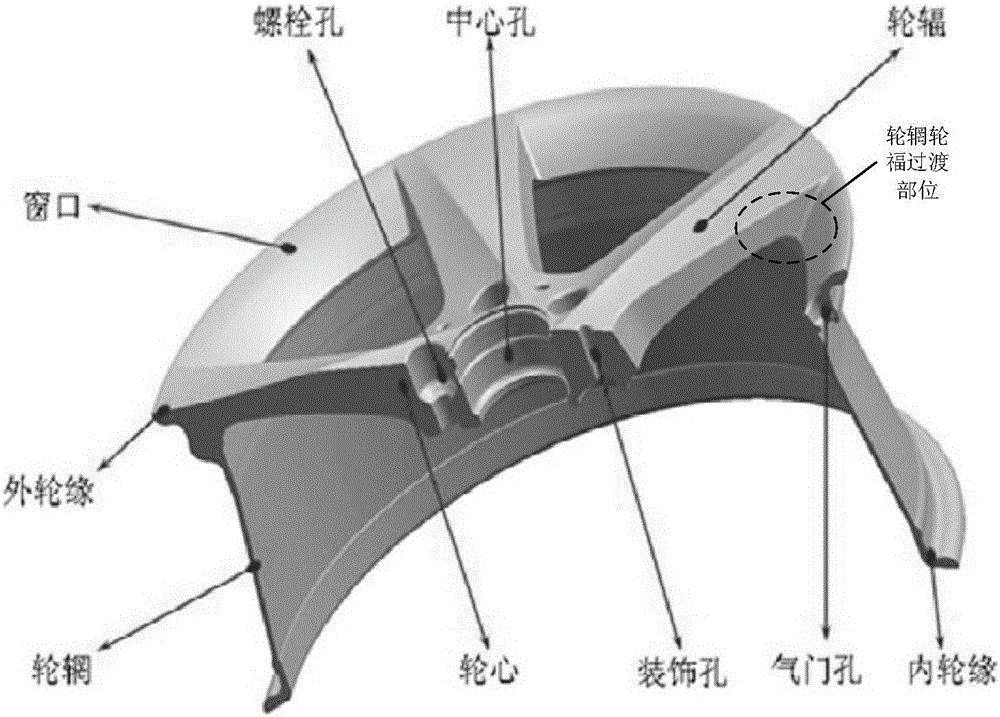

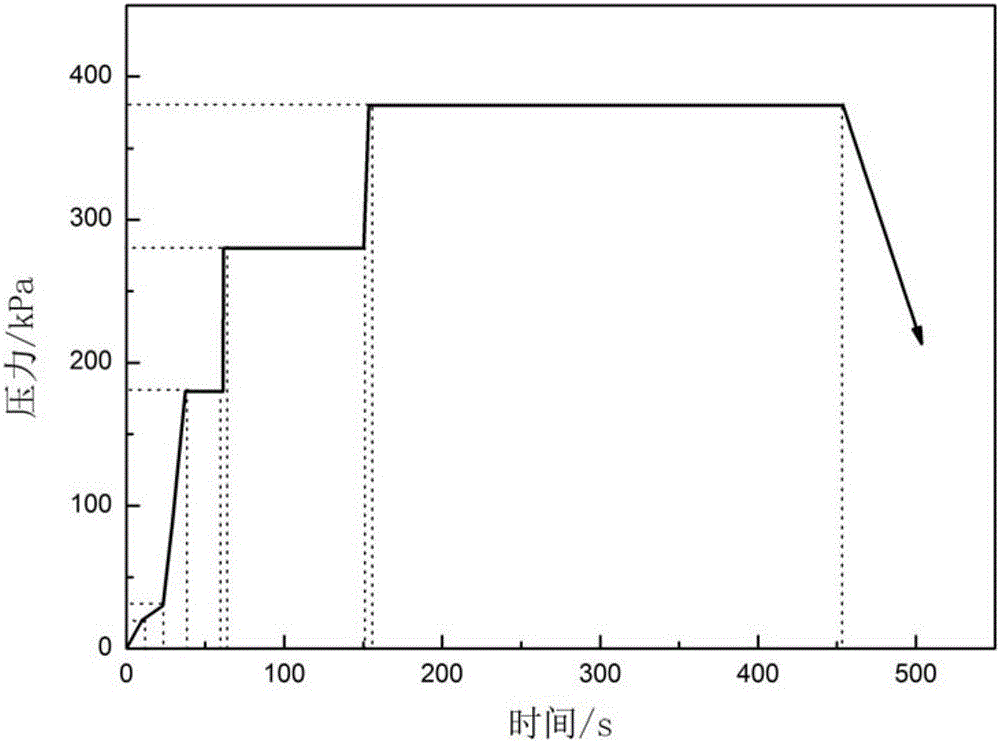

Sequential pressurization method after crystallization pressure keeping for metal mold low-pressure casting molding of aluminum alloy wheel

The invention discloses a sequential pressurization method after crystallization pressure keeping for metal mold low-pressure casting molding of an aluminum alloy wheel. The method continues a traditional low-pressure casting process of the aluminum alloy wheel in the phases of liquid rise, mold filling and crystallization pressurization; and the liquid rise pressure, the mold filling pressure and the crystallization pressurization pressure are controlled within 18-21 kPa, 30-35 kPa and 80-100 kPa. After the crystallization pressurization phase is performed, a sequential pressurization phase is added. After the completion of condensation of inner and outer rim parts is determined, the crystallization pressurization pressure is increased to 100-200 kPa; then, the crystallization pressure keeping pressure is sequentially adjusted according to the condensation time of rims, spoke and rims transition parts and wheel centers; and the minimum crystallization pressure keeping pressure can be increased to 310-1000 kPa. The method prominently improves the condensation feeding effect and the casting mechanical performance, prevents such defects as molten aluminum splashing and casting flanges and burrs, and prominently reduces the requirements on the mold structure and the casting mold clamping force.

Owner:北京航大新材科技有限公司

Non-chiller ductile iron non-riser casting technology

InactiveCN105750493ASimple structureSimple casting processFoundry mouldsFoundry coresDie castingOperability

The invention relates to a non-chiller ductile iron non-riser casting technology, which belongs to the technical field of ductile iron non-riser casting, and aims to solve the technical problems that the existing ductile iron castings are serious in shrinkage hole and shrinkage porosity defects, high in rejection rate, serious in waste of means of production, and high in production cost. The non-chiller ductile iron non-riser casting technology comprises the following steps of preparing moulding sand; manufacturing a template and a core box tooling; inoculating molten iron; manufacturing a casting cavity and a sand core; setting a pouring system, setting a core and assembling the mould, wherein the casting cavity is a resinous sand mold, and the moulding sand is prepared from scrubbing silica sand of 30 to 50 meshes and furan resin according to the mass parts of 100: 1.5; the casting cavity is not provided with a riser; an inner pouring gate of an ingate uses a flat pouring gate; no chiller is arranged inside the casting cavity. The non-chiller ductile iron non-riser casting technology fully utilizes self-feeding ability of ductile iron, and has the advantages of simple shape and structure, low ductile iron casting shrinkage hole and shrinkage porosity defects, simple casting process, strong operability, and capability of being applied to casting large ductile iron castings.

Owner:阳泉市煜昌机械制造有限公司

High-color-changing-resistance golden copper alloy and preparation method

The invention discloses a high-color-changing-resistance golden copper alloy and a preparation method. The alloy comprises Zn, Al, Co, Ce, B and the balance Cu. The preparation process comprises the steps of casting, hot rolling, cold rolling, solution hardening, cold finish and rough rolling, cold finish rolling and finished product annealing. The golden degree of the produced alloy is high, thehot processing performance and the cold processing performance are both excellent, and resistance to deformation is small; and the alloy includes no precious metal elements, and cost is low. The components of the alloy are reasonable and simple, the golden degree of the alloy is improved through reasonable matching of cheap aluminum and zinc, the casting process is simple through the simple alloycomponents, through reasonable matching of cerium and boron, the processing property is improved, and color changing resistance is improved; and the binding energy of trace cobalt and the vacancy in the copper alloy is low, binding with the vacancy in the copper alloy can be achieved effectively, a Zn atom diffusion channel is blocked, and dezinc corrosion corrosion of the alloy is improved. The alloy is simple in production process, low in production cost, good in processing performance and good in golden degree and is suitable for industrial production.

Owner:CENT SOUTH UNIV +1

Method for preparing semisolid slurry for ultralow temperature casting magnesium alloy

The method for preparing semisolid slurry for magnesium alloy ultralow temp. casting includes the processes and steps of melting magnesium, adding compound fire-resisting elements, adding alloy elements, heat-insulating and standing still and semicontinuous casing. Said invention utilizes the addition of compound fire-resisting elements to implement magnesium alloy smelting free from covering agent, and utilizes the pouring process which is made under the condition of the temperature of liquid phase line or the temperature below liquid phase link at a certain cooling rate after properly standing still to implement that its interior has no dirt inclusion or porosity.

Owner:NORTHEASTERN UNIV

Crystallization pressure keeping and increasing method for low-pressure casting molding of aluminum alloy wheel metal mold

The invention discloses a crystallization pressure keeping and increasing method for low-pressure casting molding of an aluminum alloy wheel metal mold; the method continues a traditional aluminum alloy wheel low-pressure casting process in the liquid rising, mold filling and crystallization pressurization phase; and the liquid rising pressure, the mold filling pressure and the crystallization pressurization pressure are controlled at 18-21 kPa, 30-35 kPa and 80-100 kPa. A traditional crystallization pressurization phase is changed to a crystallization pressure keeping and increasing phase. After the crystallization pressurization phase, the crystallization pressure keeping pressure is continuously increased to 100-200 kPa; then, the crystallization pressure keeping pressure is adjusted according to the solidification time of inner and outer flanges, a rim, a spoke and rim transition part and a wheel center in sequence; and the maximum crystallization pressure keeping pressure can be increased to 310-1000 kPa. The method prominently improves the solidification feeding effect and the casting mechanical performance, prevents such defects as molten aluminum splashing and casting flange burrs, and prominently reduces the requirements on the mold structure and the casting mold clamping force.

Owner:北京航大新材科技有限公司

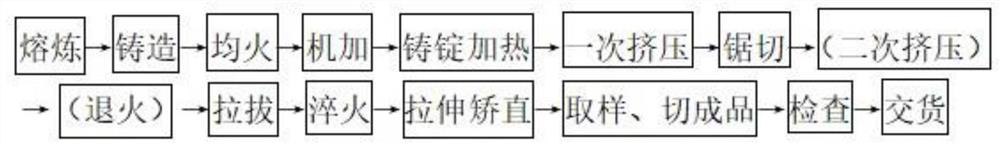

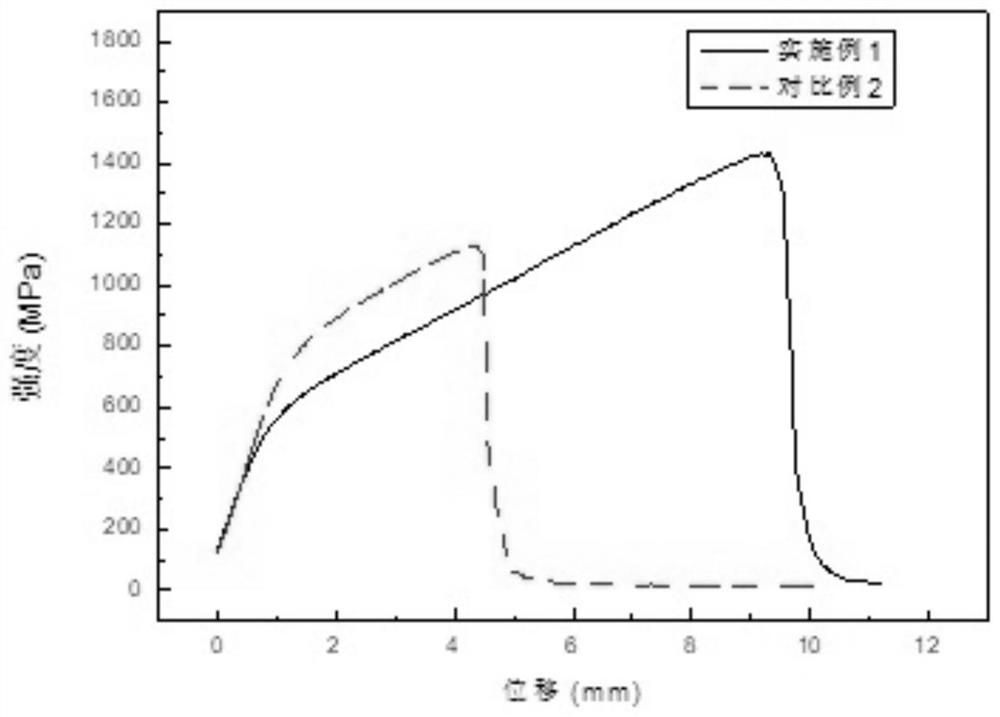

Processing method of 2xxx series aluminum alloy bars and wires for fasteners

ActiveCN113293273AExcellent formabilityExcellent matching plasticityFurnace typesHeat treatment furnacesWire rodTemperature control

The invention discloses a processing method of 2xxx series aluminum alloy bars and wires for fasteners, which comprises the following steps: adding an intermediate alloy into an aluminum ingot, smelting in a smelting furnace, and then carrying out semi-continuous casting to obtain an industrial cast ingot; carrying out homogenization treatment on the cast ingot added with the alloy, increasing the temperature of the cast ingot to 480-505 DEG C from the room temperature in a one-stage or multi-stage heating mode, and conducting out heat preservation for 10-60 h; extruding the obtained cast ingot into a bar, controlling the extrusion outlet speed of the profile to be 0.1-4 mm / s, and controlling the extrusion temperature to be 360-470 DEG C; carrying out annealing heat treatment on the extruded bar blank, the annealing process parameters are as follows: the temperature is 250-450 DEG C, the annealing time is 0.5-3 h, the bar blank is discharged from a furnace and cooled in air, and an annealed bar is obtained; carrying out cold drawing on the extruded bar or the extruded and annealed bar; carrying out solid solution quenching on the cold-drawn bars and wires; and pre-stretching the bars and the wires, and controlling the pre-stretching amount to be 0.1%-3%;.

Owner:CHINALCO MATERIALS APPL RES INST CO LTD

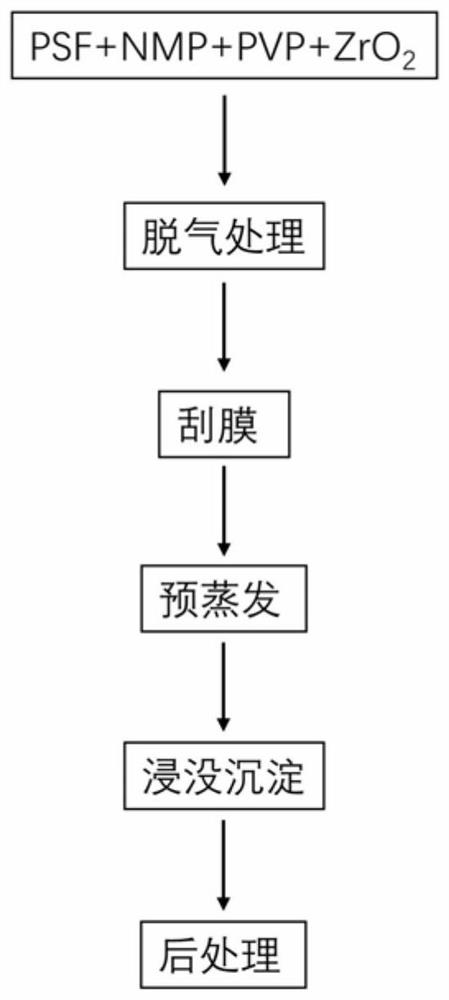

Non-asbestos alkaline electrolyzed water composite diaphragm and preparation method thereof

PendingCN114432905AImprove hydrophilicityReduce surface resistanceSemi-permeable membranesMembranesElectrolysed waterMaterials science

The invention relates to a non-asbestos alkaline electrolyzed water composite diaphragm and a preparation method thereof, and belongs to the technical field of electrolyzed water hydrogen production, and the preparation method comprises the following steps: (1) preparing a membrane casting solution; (2) preparation of a polysulfone / zirconium dioxide composite diaphragm; and (3) post-treatment of the polysulfone / zirconium dioxide composite diaphragm. The preparation method is efficient and convenient in reaction, and large-area preparation of the alkaline electrolyzed water diaphragm is facilitated. The reaction is efficient and convenient, and large-area preparation of the non-asbestos alkaline electrolyzed water composite diaphragm is easy; polysulfone resin with high alkali resistance and a high-molecular reinforcing agent are used as polymers; zirconium dioxide is used for carrying out hydrophilic modification on the polymer, and the addition of ZrO2 can improve the hydrophilicity of the polymer, so that the surface resistance is effectively reduced, and the current efficiency is improved. The alkaline composite diaphragm has good corrosion resistance, the alkali loss is 1.85%, and meanwhile, the prepared diaphragm shows good mechanical performance.

Owner:BEIJING UNIV OF CHEM TECH

Brake drum casting process

InactiveCN106001452AImprove molding qualityEasy to cleanFoundry mouldsFoundry coresNumerical controlRaw material

The invention relates to a brake drum casting process. The process includes the following steps that sand is mixed, specifically, the resin sand is used as the raw material, and a sand box is made after casting sand is prepared according to a ratio; dies are manufactured, specifically, the brake drum inner mold casting die and the brake drum outer mold casting die are manufactured according to the size and shape of a brake drum; smelting is conducted, specifically, raw materials are prepared according to a certain ratio and placed in an electric furnace to be smelted; pouring is conducted, specifically, molten iron obtained in the third step is poured into a sand mold inside a double-layer die; cooling is conducted to the normal temperature; a casting box is opened, a molded brake drum is taken out, shot blasting and polishing are carried out on the brake drum after the surface of the brake drum is cleaned, annealing is carried out after polishing, and surface strengthening is conducted; and machining is conducted, specifically, the brake drum is placed on a numerical control lathe to be machined, so that a finished product is obtained. The brake drum casting process has the advantages of being reasonable in procedure, capable of saving the raw materials and reducing the cost, simple in operation, stable in work, high in production efficiency, high in product percent of pass and good in molding quality.

Owner:娄土岭

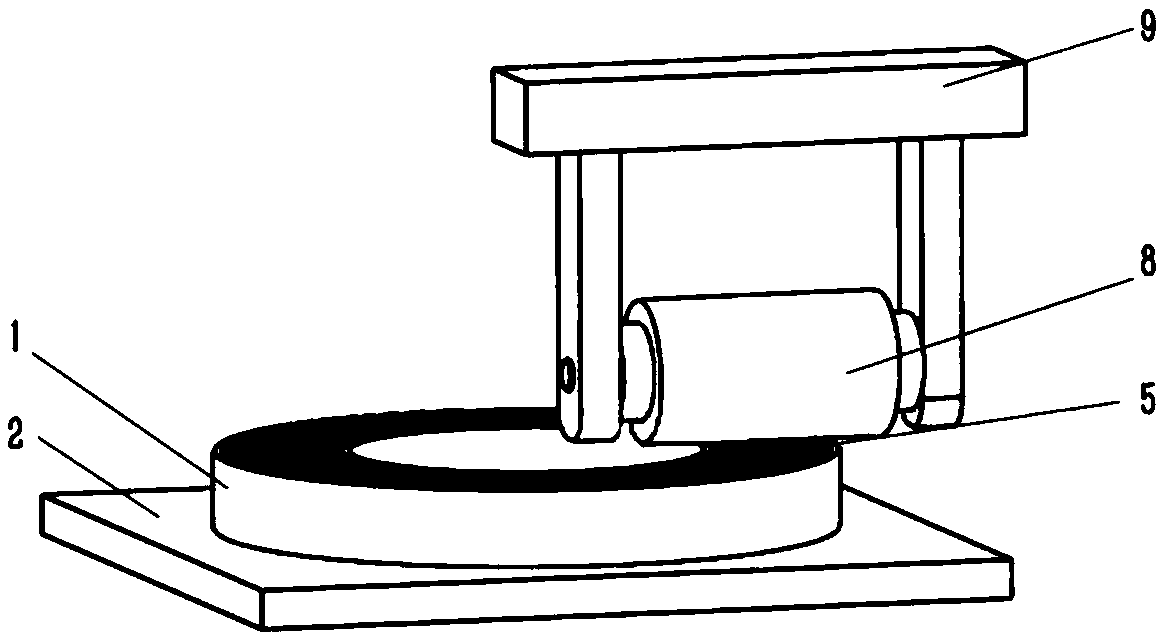

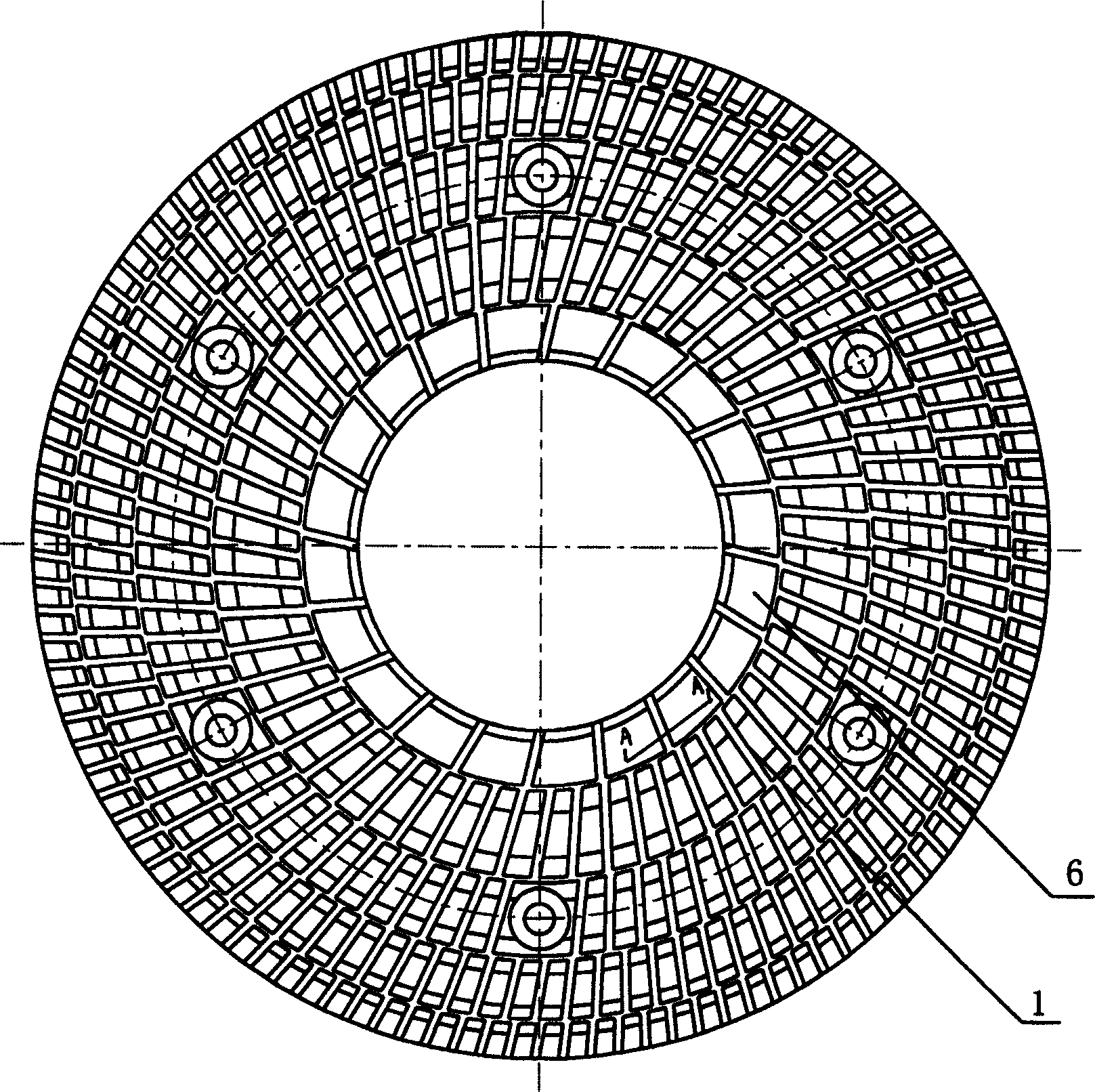

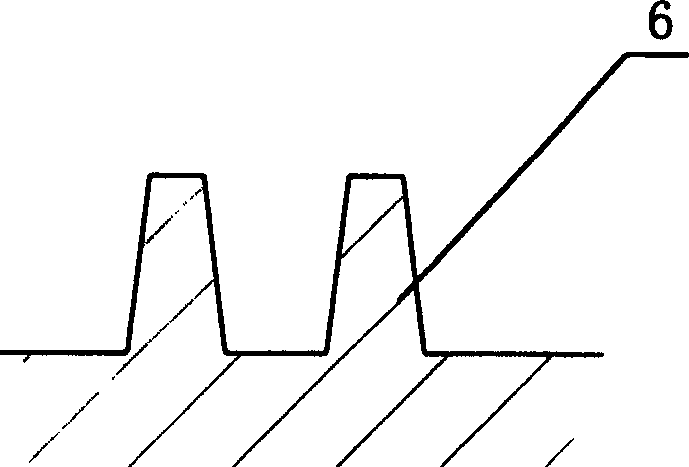

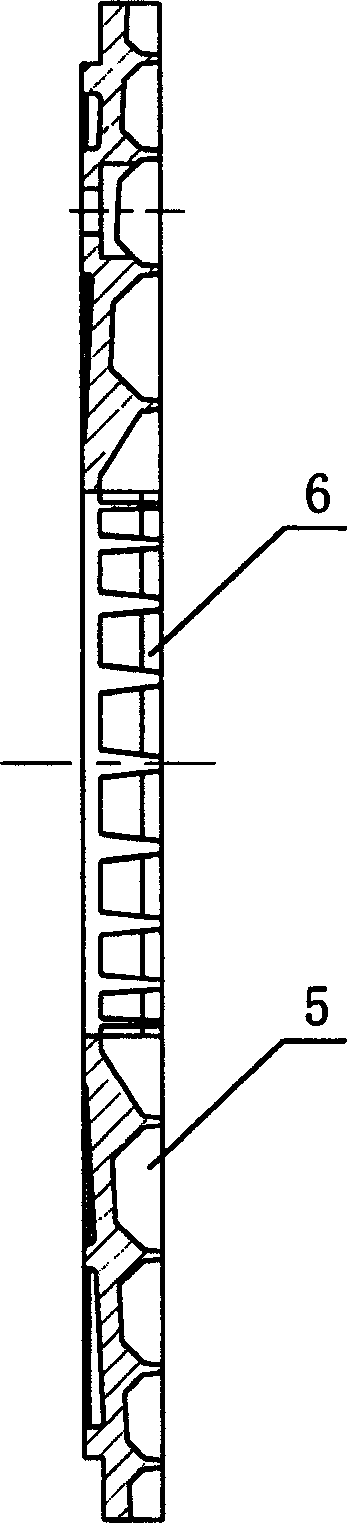

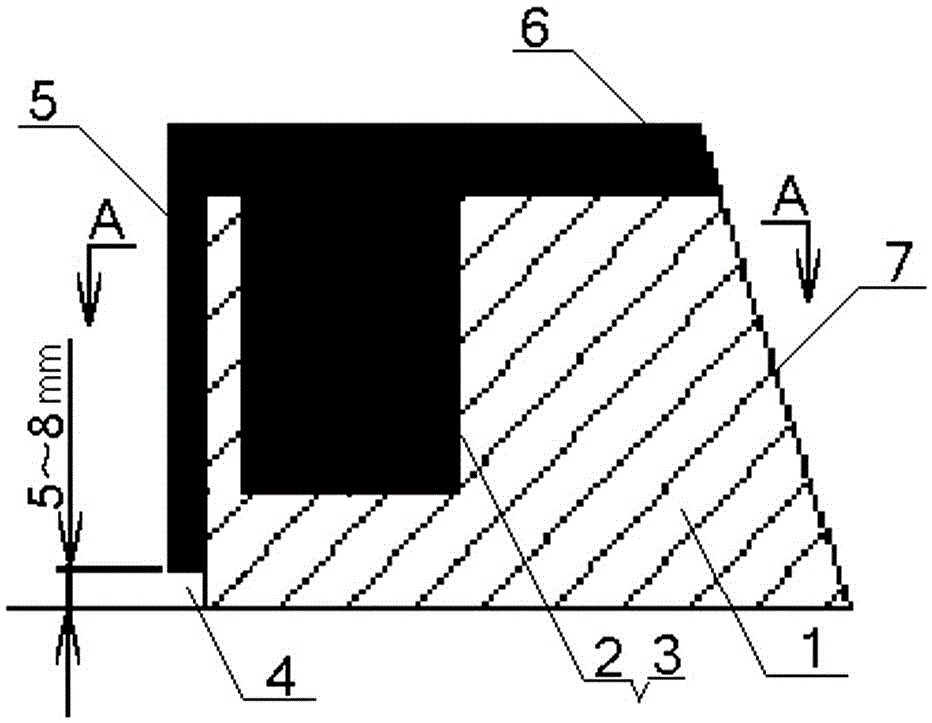

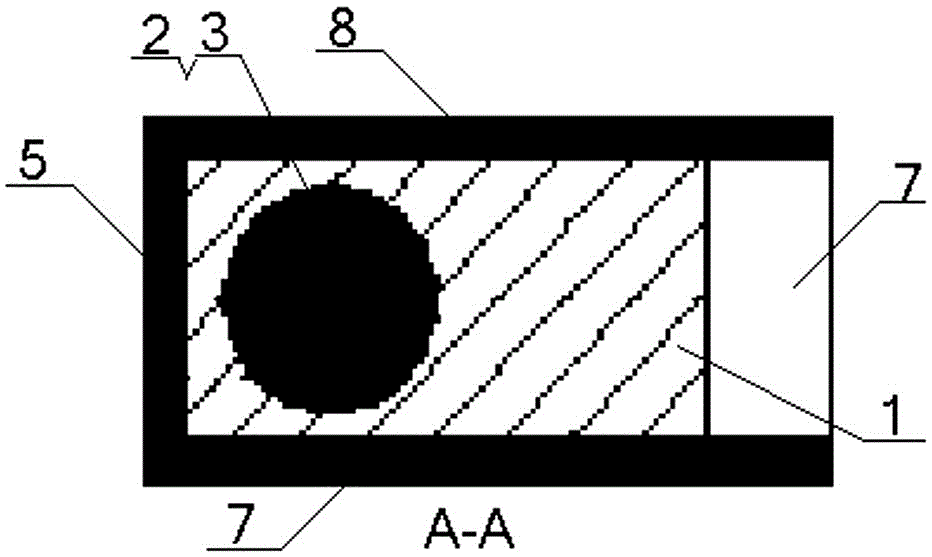

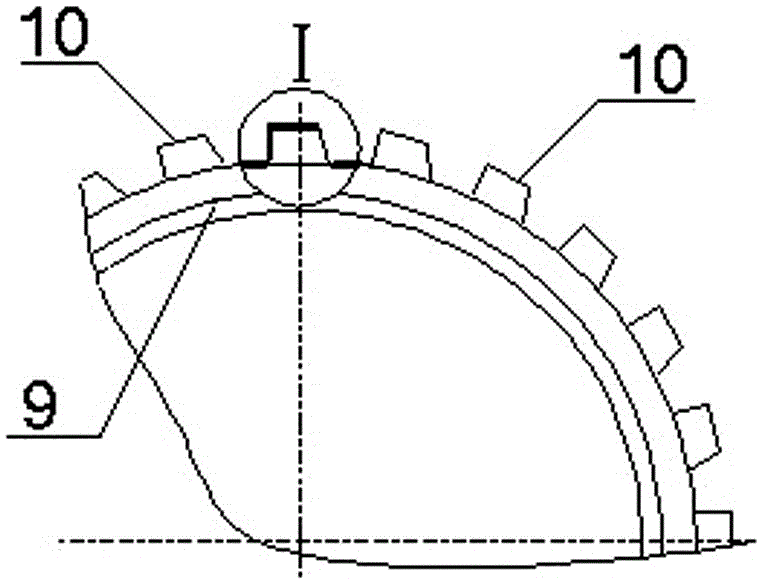

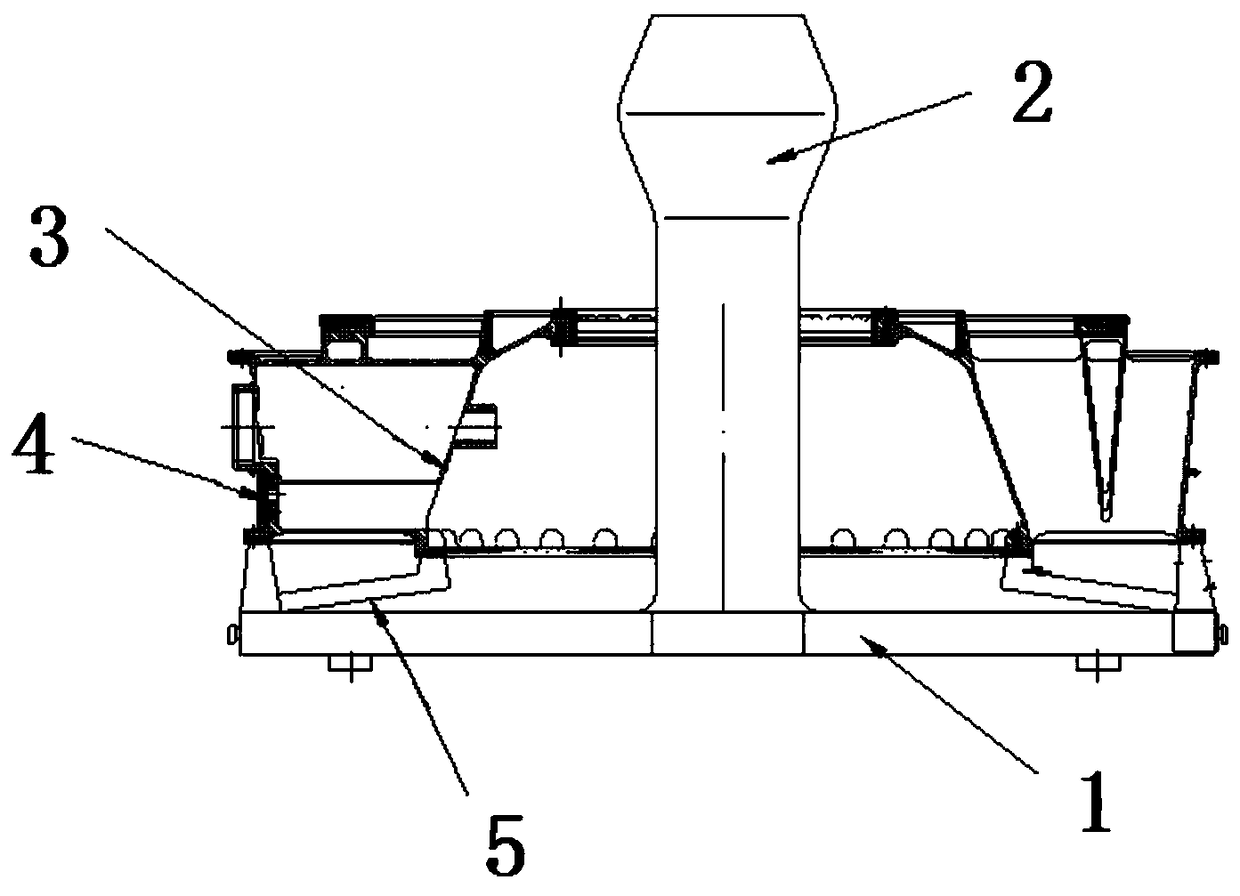

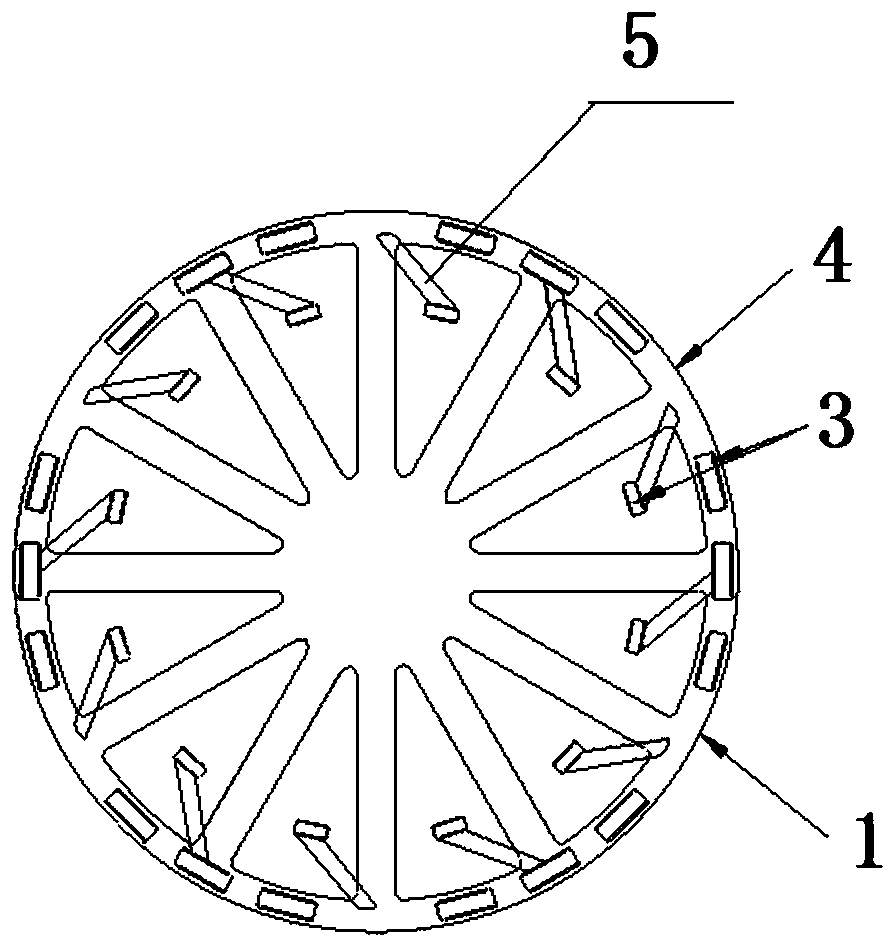

Millstone for refiner

InactiveCN1786336AExtended service lifeIncrease the amount of slurryPulp beating/refining methodsEngineeringEnergy consumption

The invention discloses paste mill millstone. It includes rolling millstone set on paste mill main shaft and fixed millstone set in shell body and cooperated with the rolling millstone. The rolling and fixed millstone are set concentric circle shield dam. One there and back shear zone is set between each two of the concentric circle shield dams. Each of the millstones is set more than four concentric circles there and back shear zones. The concentric circle there and back shear zone of the rolling and fixed millstone are alternated. Single shear zone is set between the neighbor concentric circle shield dams. Tooth space depth and single shear zone are both gradually diminished with the semi-diameter increasing. The bottom of tooth space of the first grinding teeth closed to circle center on rolling millstone is steep incline. Tooth shape is commutating tooth. The invention is used in paste mill millstone which can reduce energy consumption, and increase grinding pulp quality and yield but with simple structure.

Owner:CHANGSHA CC PAPER MACHINERY

Wear-resistant tooth roller of tooth roller crusher and production method of wear-resistant tooth roller

InactiveCN105057026AImprove wear resistanceExtended service lifeGrain treatmentsWear resistantHigh carbon

The invention discloses a wear-resistant tooth roller of a tooth roller crusher and a production method of the wear-resistant tooth roller. The wear-resistant tooth roller comprises a roller drum and roller teeth fixedly arranged on the outer surface of the roller drum. The wear-resistant tooth roller is characterized in that the roller teeth are fixedly connected with the outer surface of the roller drum in a welding way; counter bores are drilled in the top surfaces of the roller teeth, and a high-carbon and high-chromium wear-resistant welding wire is welded into the bores and fills the bores to form an impact-resistant column of the roller teeth; and a wear-resistant layer is overlaid on each of the outer surfaces of the roller teeth and the roller drum by using the high-carbon and high-chromium wear-resistant welding wire to form a wear-resistant tooth roller working surface capable of prolonging the service life of the tooth roller crusher. According to the method, the roller drum and the roller teeth are produced in different steps; then, the roller teeth with wear-resistant protective layers are fixedly connected with the outer surface of the roller drum in the welding way; and a wear-resistant protective layer is overlaid on the rest outer side surface of the roller drum, so that the wear resistance of the roller teeth is greatly improved, and the service life of each roller tooth is greatly prolonged. By using the method, worn and scrapped old tooth rollers can also be repaired and recycled, so that wastes are utilized, resources are saved, and the cost is reduced.

Owner:GUANGXI CHENMING MACHINERY REMFG TECH CO LTD

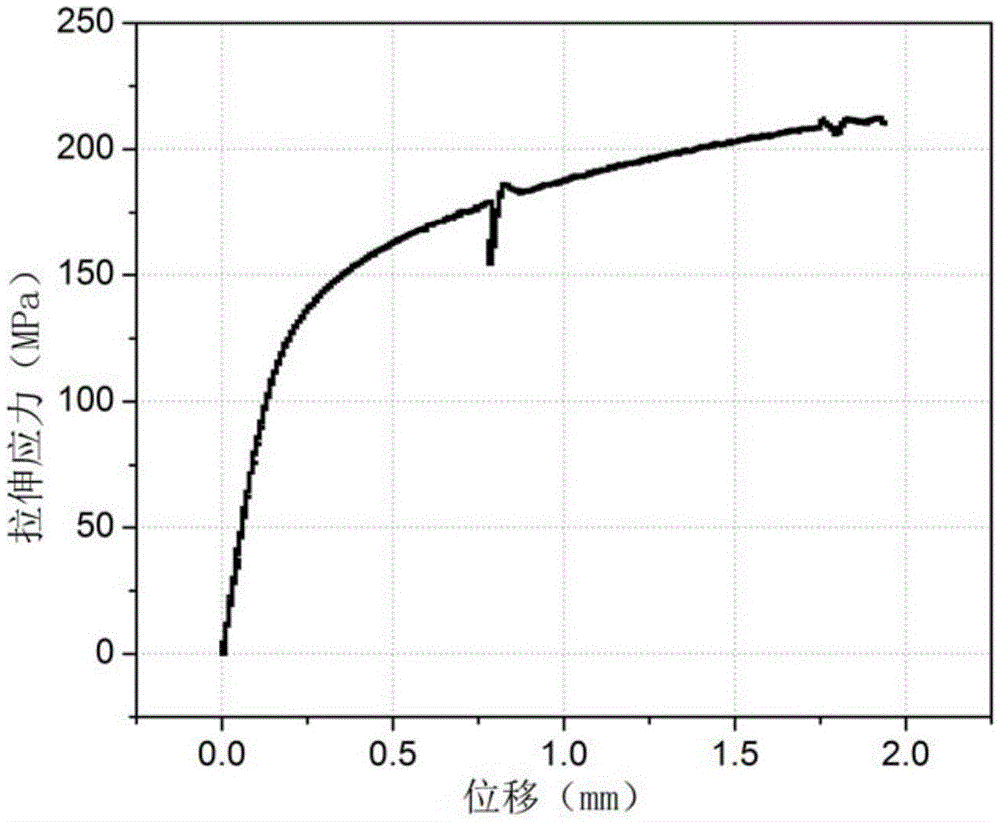

A preparing method of a Cu-containing low-alloy steel automobile wheel hub bearing unit

ActiveCN104087871ASimple casting processAvoid deformationFoundry mouldsFurnace typesTungstenAluminium

A preparing method of a Cu-containing low-alloy steel automobile wheel hub bearing unit is disclosed. The steel comprises following chemical components by weight: 0.24-0.33% of carbon, 2.25-3.32% of silicon, 0.23-0.40% of manganese, 0.002-0.003% of phosphor, 0.006-0.008% of sulfur, 0.12-0.22% of chromium, 0.06-0.08% of nickel, 0.003-0.009% of molybdenum, 0.087-0.098% of tungsten, 0.001-0.002% of titanium, 0.01-0.02% of aluminium, 0.0002-0.0003% of lead, 0.002-0.004% of strontium and 0.002-0.005% of copper, with the balance being iron. The method guarantees excellent characteristics comprising simple casting processes, difficult deformation and high heat conductivity of the alloy material, effectively reduces the cost of the alloy material at present of the automobile wheel hub bearing unit, and has good economic benefit.

Owner:ANHUI JISITE INTELLIGENT EQUIP CO LTD

Runner device and mold filling method of centrifugal casting thin-wall cartridge receiver casting

The invention relates to a runner device and mold filling method of a centrifugal casting thin-wall cartridge receiver casting. The runner device comprises a disc-shaped transverse runner, a straightrunner vertically adheres to the transverse runner, and an annular inner runner and an annular outer runner further adhere to the transverse runner; the inner runner and the outer runner surround thearea beyond the straight runner; and the inner runner and the outer runner are connected through a plurality of lap joint runners. The mold filling method comprises the steps that after the runner device is prepared, molten metal is poured through the straight runner, the inner runner and the outer runner, so that the molten metal reaches the joint of the inner runner and the transverse runner atthe same time and is gathered. By means of the technical scheme, the cross section area of the lap joint runners is limited, so that the pressure head flowing through the molten metal is increased, and a foundation is laid for enabling the molten metal to reach the junction of the inner runner and the transverse runner at the same time and to be gathered, the purpose of avoiding cold separation defects of the casting is achieved, welding repairing and repairing processes for the casting in the later period are avoided, the casting technology is simplified, and the product quality is improved.

Owner:GUIZHOU ANJI AVIATION PRECISION CASTING

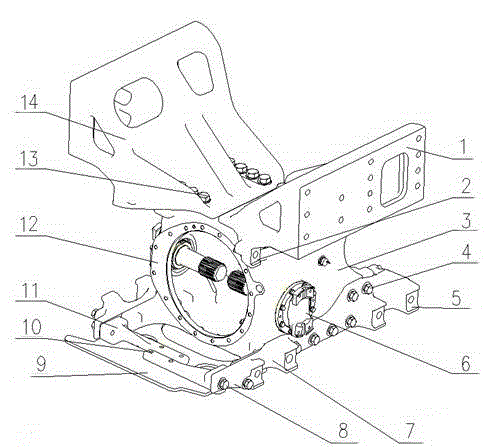

Independent suspension drive axle housing assembly for heavy-duty truck

InactiveCN102910034ASimple casting processReduce manufacturing difficultyAxle unitsVehicle frameReduction drive

The invention provides an independent suspension drive axle housing assembly for a heavy-duty truck. The independent suspension drive axle housing assembly comprises an axle housing and a semi-axis arranged on the axle housing, wherein the upper end of the axle housing is fixedly connected with two symmetrical upper brackets; a frame mounting end face and a suspension upper swing arm mounting end face are formed on the upper brackets; the lower end of the axle housing is fixedly connected with two symmetrical lower brackets; a suspension lower swing arm mounting end face is formed on the lower brackets; the suspension upper swing arm mounting end face corresponds to the suspension lower swing arm mounting end face; a protective plate bracket is fixedly connected between the ends of the two lower brackets; the lower end face of the protective plate bracket is fixedly connected with a protective plate; and a main reducer mounting end face is formed on the axle housing above the protective plate. By adoption of the structural form, the frame, the suspension and the main reducer are connected with the axle housing through split connecting pieces, so that the casting process of the axle housing is simplified under the condition that the connection strength is guaranteed, and the manufacturing difficulty of the axle housing is reduced.

Owner:SINO TRUK JINAN POWER

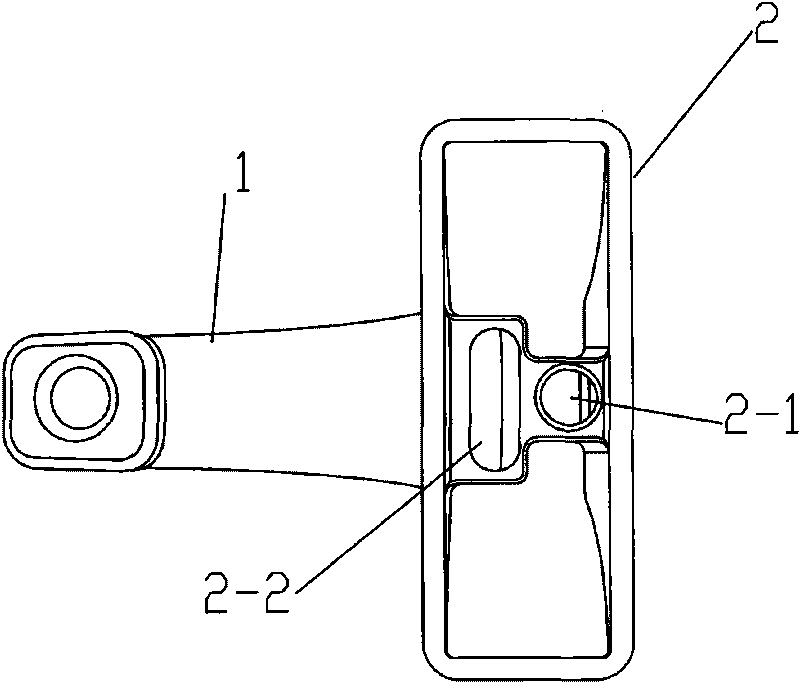

Composite flywheel with plastic blade of engine

InactiveCN101270794AReduce scrap rateSimple casting processFlywheelsMachines/enginesImpellerMiter joint

The invention relates to a sectional flywheel with a plastic fan blade for an engine, which is fixed on the front end of an engine crankshaft by a flywheel nut. The invention is characterized in that the invention includes a flywheel and a plastic fan blade which is tightly fixed on the screw hole of the flywheel by a bolt. A steel lining is arranged inside the screw hole of the plastic fan blade. The flywheel is provided with the locating spigot round of the fan blade. The flywheel has a miter joint with the two end planes of the fan blade. The invention changes the whole cast iron flywheel vane into the subassembly of cast iron flywheel and plastic fan blade. With the advantages of simple structure and low manufacture cost, the invention can prevent the vane damage in the casting and transportation process, effectively improving the economical efficiency of the engine and simplifying the casting technology of the flywheel. Reducing the defective index of the cast iron vane, the invention is also favorable for improving the fan efficiency.

Owner:WUXI KIPOR POWER CO LTD

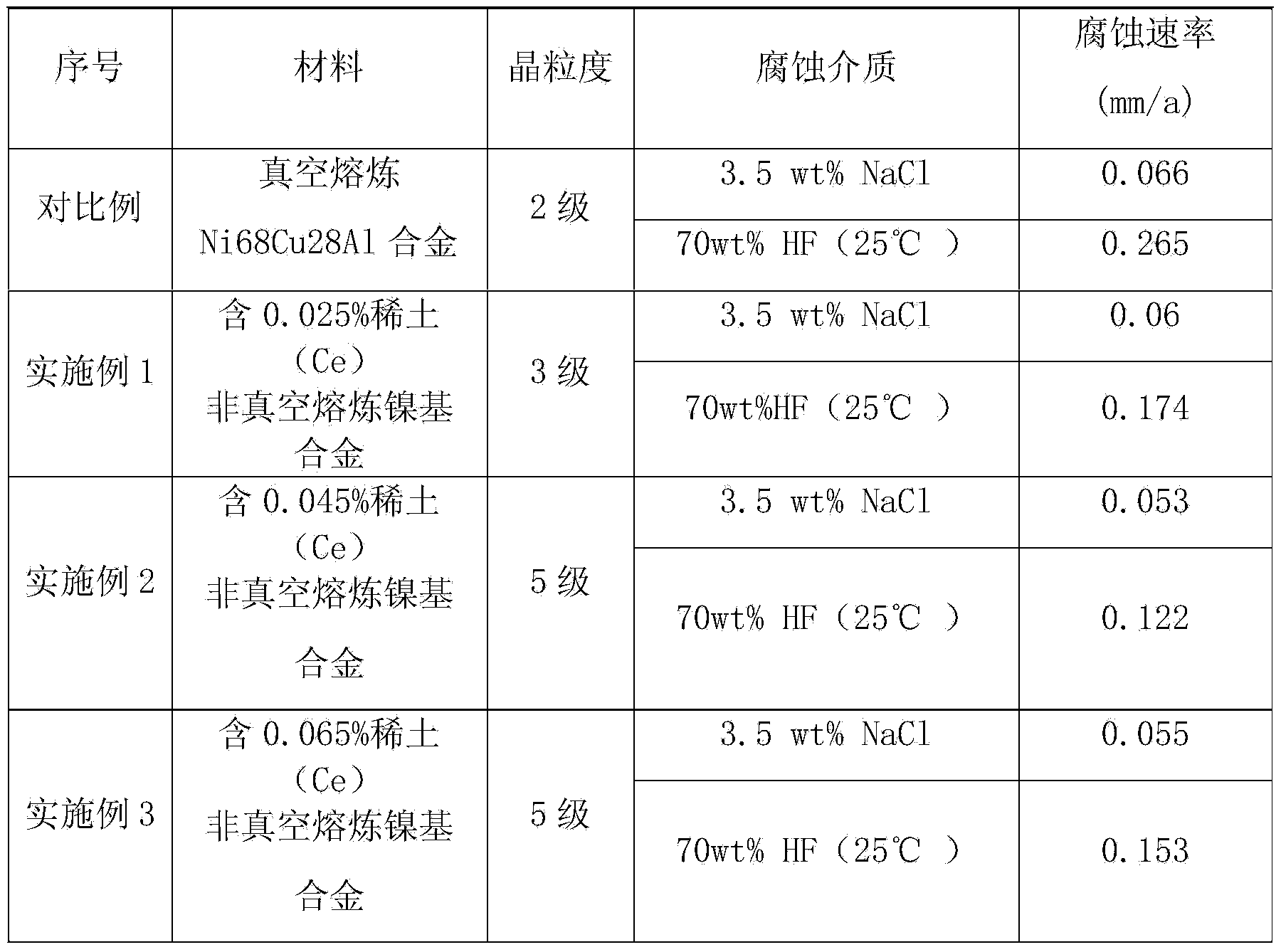

Nickel-based alloy and preparation method thereof

ActiveCN104388756AGood casting performanceImprove corrosion resistanceFoundry mouldsFoundry coresMaterials preparationRare earth

The invention belongs to the technical field of material preparation and in particular relates to a nickel-based alloy and a preparation method thereof. The nickel-based alloy comprises the following components in percentage by weight: 25-35% of Cu, 0.5-1.5% of Mn, 0-2.5% of Fe, 2.5-3.5% of Al, 0.5-0.9% of Ti, 0.025-0.065% of rare earth Ce and the balance of Ni and inevitable impurity elements, wherein the sum of the percents by weight of the components is 100%. The preparation method of the nickel-based alloy comprises the following steps: smelting the components, carrying out oxygen content treatment on an alloy liquid, carrying out modification treatment on the alloy liquid, and finally casting and cooling. The nickel-based alloy can have smaller grain size, corrosion resistance is stronger compared with that of the traditional casting nickel-based alloy, and the nickel-based alloy is also extremely simple and easy to prepare.

Owner:HEFEI UNIV OF TECH +1

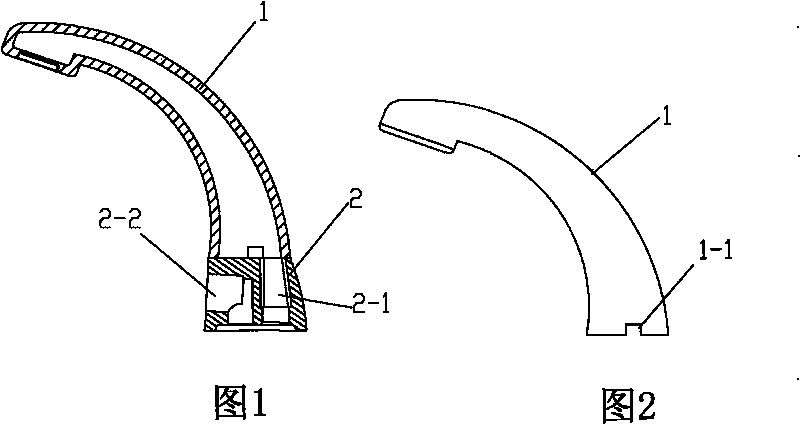

Stainless steel sensor faucet and production method thereof

InactiveCN101694248AGood for physical and mental healthReduce manufacturing costValve housingsPsychological healthCommunicating cavity

A stainless steel sensor faucet comprises a water outlet pipe and a base, wherein the water outlet pipe is in the shape of a bent pipe, the base is internally provided with a water communicating cavity and a mounting cavity used for arranging a sensor, the faucet is made of stainless steel material, and the water outlet pipe and the base have a split-type structure and are welded together. The stainless steel sensor faucet has the beneficial effects that: the sensor faucet is made of stainless steel material, not only has low production cost, but also is sanitary and environment-friendly, and is beneficial to the physical and psychological health of the populace. In addition, the stainless steel sensor faucet has simple casting technique, greatly saves labor force, improves the yield, reduces production cost, and is suitable for generalization.

Owner:林惠良

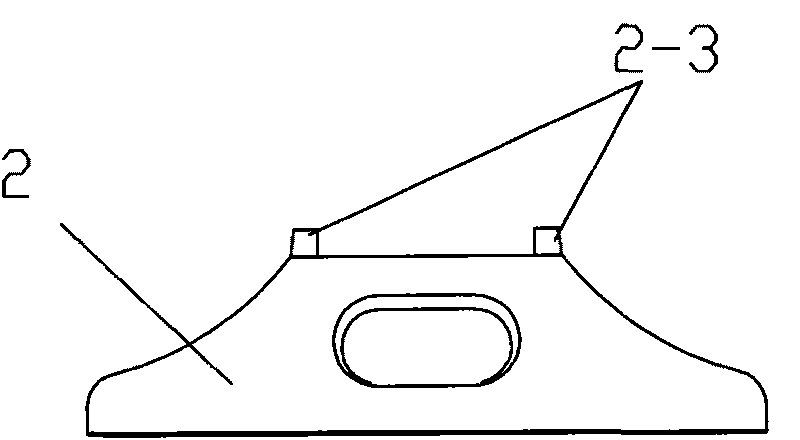

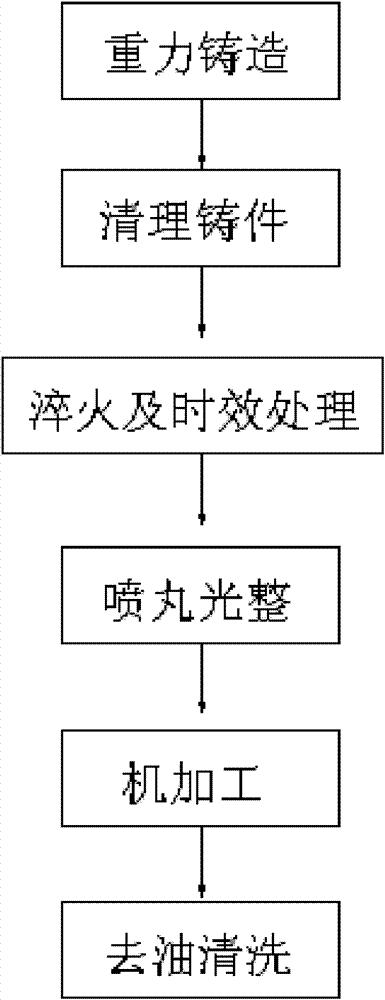

Gravity casting process of back cover board of turbosupercharger

InactiveCN102764876AImprove mechanical propertiesImprove machinabilityGas turbine plantsLiquid fuel feedersAlloySolid solution

The invention discloses a gravity casting process of a back cover board of a turbosupercharger. The gravity casting process comprises the following steps: casting an aluminum alloy raw material on a gravity casting machine at a casting temperature of 700-740 DEG C, cleaning overlaps, burr and pouring gates of a cast, heating the cast to 535-545 DEG C and thermally insulating for 2-3 hours to carry out solid solution aging, placing in water at 50-80 DEG C to quench manually, heating to 195-205 DEG C, thermally insulating for 2-3 hours, air-cooling, and carrying out blasting, finishing, machining and oil removal cleaning. The back cover board of the turbosupercharger produced by the casting process has the advantages of good mechanical property, good cutting and processing performance and mechanical property, simple casting process, convenience for operation and low production cost.

Owner:ENKEI ALUMINUM IND CHINA

High-strength powder metallurgical hub bearing unit

The invention discloses a high-strength powder metallurgical hub bearing unit. The high-strength powder metallurgical hub bearing unit is manufactured by the following steps: in part by weight, sequentially adding 20-25 parts of carbon fiber, 4-6 parts of antioxidant, 12-15 parts of glass fiber, 3-8 parts of zinc, 5-7 parts of magnesium and 8-15 parts of cobalt into a stirrer, stirring for 40-50 minutes to obtain an intermediate mixture, grinding the intermediate mixture into granules, and processing 20-30 parts of intermediate mixture, 10-20 parts of hard phase, 6-9 parts of bonding phase and 50-55 parts of alloy phase. The high-strength powder metallurgical hub bearing unit is simple in manufacturing process and has good properties of unlikeliness in deformation and good thermal conductivity; the cost of the alloy material of the current automobile hub bearing unit is effectively reduced, so that the high-strength powder metallurgical hub bearing unit is very high in economic benefit.

Owner:ANHUI JISITE INTELLIGENT EQUIP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com