Non-asbestos alkaline electrolyzed water composite diaphragm and preparation method thereof

A technology of composite diaphragm and electrolysis of water, which is applied in the direction of diaphragm, electrolysis components, electrolysis process, etc., can solve the problems of poor hydrophilicity of polysulfone diaphragm, affect the flow of electrolyte, and reduce the performance of diaphragm, so as to improve hydrophilicity and reduce surface area. Resistance, the effect of improving the current efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

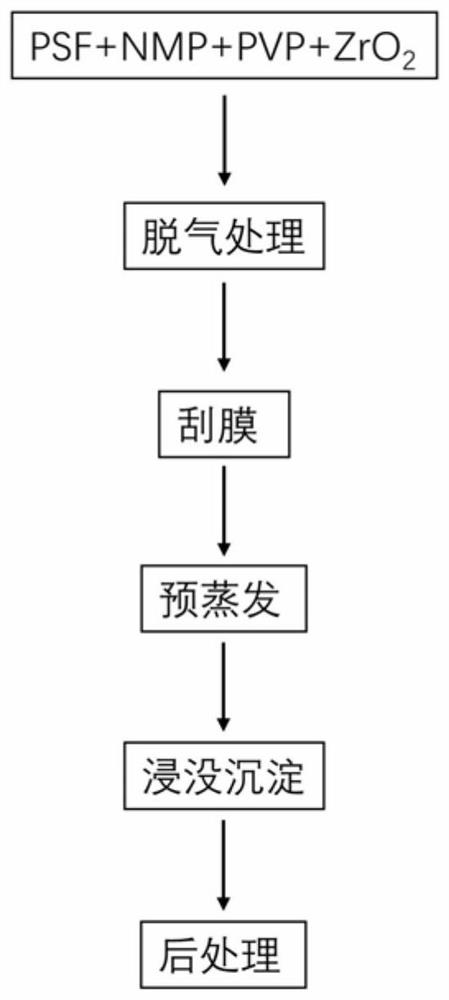

[0051] A preparation method of non-asbestos alkaline electrolyzed water composite diaphragm, the steps are as follows:

[0052] (1) Preparation of casting solution:

[0053] In the polysulfone polymer solution, add a polymer reinforcing agent, a pore-forming agent and a hydrophilic modifier, and after the reaction, perform degassing treatment to obtain a uniform milky white casting solution;

[0054] (2) Preparation of polysulfone / zirconia composite diaphragm:

[0055] Pour the film-casting solution obtained in step (1) directly onto the glass plate, adjust the distance between the scraper and the glass plate, scrape it with a film scraper to form a film, and pre-evaporate in the air for a period of time, then put it into a degasser at a certain temperature. In ionized water, the liquid film gradually coagulates, falls off the glass plate, and is taken out from the coagulation bath to obtain a polysulfone / zirconia composite diaphragm;

[0056] (3) Post-treatment of polysulfo...

Embodiment 1

[0059] A preparation method of non-asbestos alkaline electrolyzed water composite diaphragm, the steps are as follows:

[0060] (1) Preparation of casting solution:

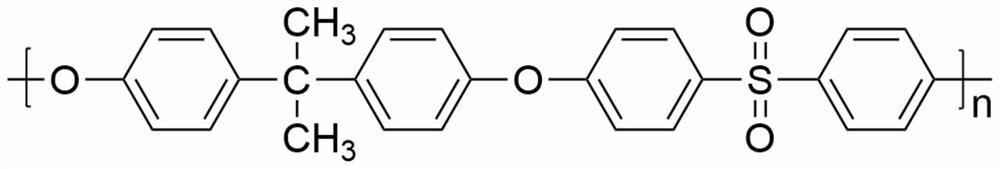

[0061] Place 3.0 g of polysulfone with a molecular weight of about 80,000 in a flask containing 11.0 g of commercially available N-methylpyrrolidone, stir at room temperature to dissolve it (rotating speed 350 r / min), and slowly add 0.5 g of hydrogenated nitrile rubber , 3.0g polyvinylpyrrolidone and 3.0g zirconium dioxide, continue stirring for 2 days to obtain a milky white casting solution, then reduce the stirring speed to 50r / min, continue stirring for 24h, and carry out degassing treatment;

[0062] (2) Preparation of polysulfone / zirconia composite diaphragm:

[0063] Adjust the distance between the scraper and the glass plate to 300 μm, pour an appropriate amount of the casting solution prepared in step (1) onto the front end of the glass plate, scrape it with a film scraper to form a film, stay in the ai...

Embodiment 2

[0068] A preparation method of non-asbestos alkaline electrolyzed water composite diaphragm, the steps are as follows:

[0069] (1) Preparation of casting solution:

[0070] Put 1.5g of polysulfone with a molecular weight of about 80,000 in a flask containing 11.0g of commercially available N-methylpyrrolidone, stir at room temperature to dissolve it (rotating speed 350r / min), slowly add 0.5g of SEBS rubber, 3.0g Polyvinylpyrrolidone and 4.5g zirconium dioxide were continued to stir for 2 days to obtain a milky white casting solution, then the stirring speed was reduced to 50r / min, and the stirring was continued for 24h to carry out degassing treatment;

[0071] (2) Preparation of polysulfone / zirconia composite diaphragm:

[0072] Adjust the distance between the scraper and the glass plate to 300 μm, pour an appropriate amount of the casting solution prepared in step (1) onto the front end of the glass plate, scrape it with a film scraper to form a film, stay in the air for 3...

PUM

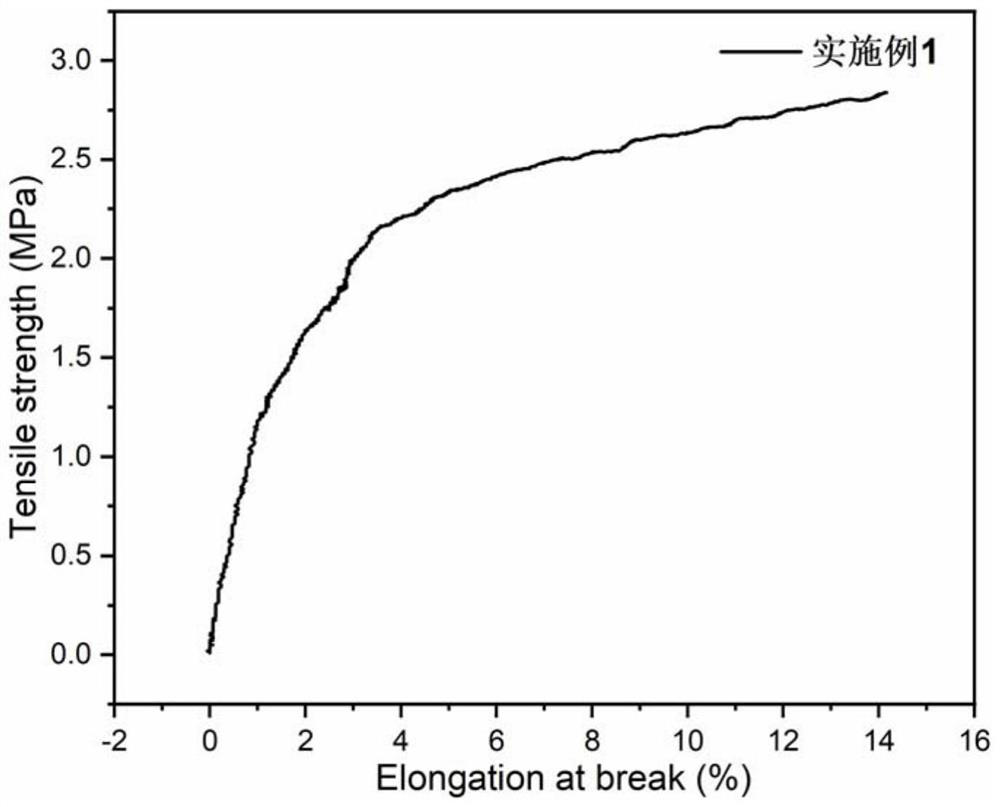

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com