Sequential pressurization method after crystallization pressure keeping for metal mold low-pressure casting molding of aluminum alloy wheel

A technology of low-pressure casting and sequential pressurization, which is applied in the field of sequential pressurization after crystallization pressure holding for low-pressure casting of aluminum alloy wheel metal molds. It can solve the problems that it is difficult to achieve high crystallization boost pressure, and improve the effect of solidification and feeding. , Avoid overflow, improve tissue density and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

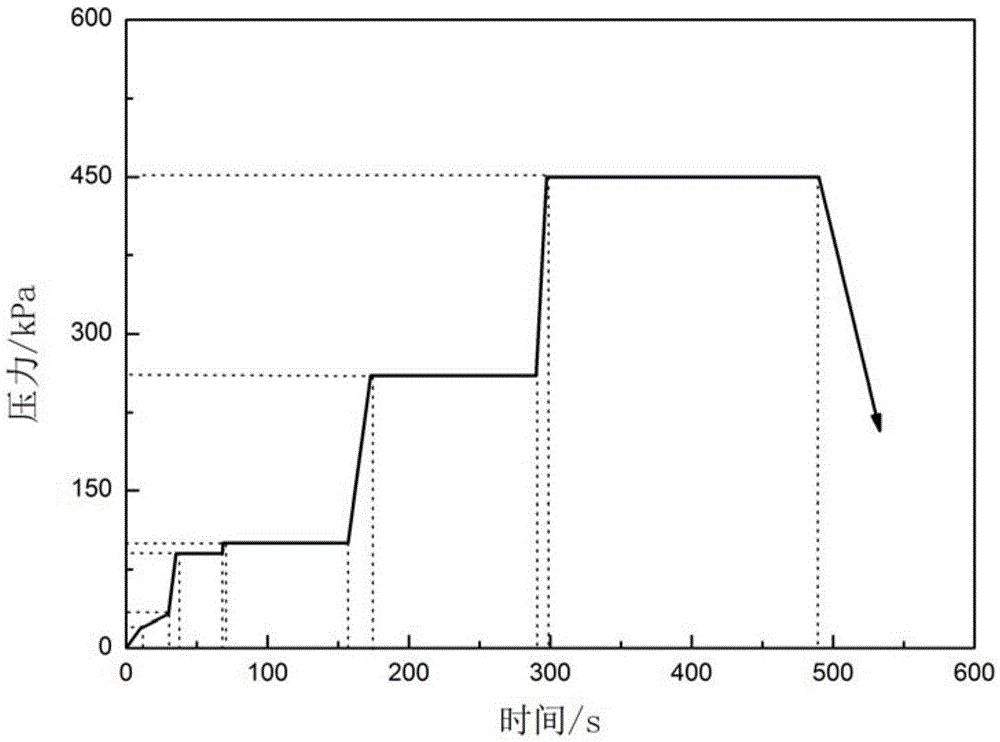

[0086] 26-inch, A356 alloy wheels. H13 steel mold, upper mold + lower mold + 4 side mold structure, directly exposed to the atmosphere. The pouring temperature is 710°C, the initial mold temperature is 400°C, and the cooling method is air cooling.

[0087] see Figure 2A As shown in the pressure-time curve diagram, the steps of preparing aluminum alloy wheels by adopting metal mold low-pressure casting molding, using crystallization and pressure-holding followed by sequential pressurization method are as follows:

[0088] Step 1, liquid ascending stage;

[0089] Under the conditions of the lifting pressure of 19kPa and the lifting speed of 1.9kPa / s, the aluminum liquid rises steadily along the rising pipe to the gate of the mold and flows into the mold;

[0090] Step 2, the filling stage;

[0091] Under the condition that the filling pressure is 32kPa and the filling speed is 0.65kPa / s, the molten aluminum is filled into the cavity from the gate until the cavity is complet...

Embodiment 2

[0111] 18-inch, A356 alloy wheels. H13 steel mold, upper mold + lower mold + 4 side mold structure, directly exposed to the atmosphere. The pouring temperature is 720°C, the initial mold temperature is 400°C, and the cooling method is wind-mist mixing cooling.

[0112] The steps of preparing aluminum alloy wheels by adopting metal mold low-pressure casting molding with crystallization and pressure-holding followed by sequential pressurization method are as follows:

[0113] Step 1, liquid ascending stage;

[0114] Under the conditions of the liquid lifting pressure of 21kPa and the liquid lifting speed of 1.8kPa / s, the aluminum liquid rises steadily along the liquid rising pipe to the gate of the mold and flows into the mold;

[0115] Step 2, the filling stage;

[0116] Under the condition that the filling pressure is 35kPa and the filling speed is 0.54kPa / s, the molten aluminum is filled into the cavity from the gate until the cavity is completely filled;

[0117] Step 3,...

Embodiment 3

[0135] 20 inches, A356 alloy cast spin wheels. H13 steel mold, upper mold + lower mold + 4 side mold structure, directly exposed to the atmosphere. The pouring temperature is 700°C, the initial mold temperature is 350°C, and the cooling method is wind-mist mixing cooling.

[0136] The steps of preparing aluminum alloy wheels by adopting metal mold low-pressure casting molding with crystallization and pressure-holding followed by sequential pressurization method are as follows:

[0137] Step 1, liquid ascending stage;

[0138] Under the conditions of the liquid lifting pressure of 18kPa and the liquid lifting speed of 2.0kPa / s, the aluminum liquid rises steadily along the liquid rising pipe to the gate of the mold and flows into the mold;

[0139] Step 2, the filling stage;

[0140] Under the conditions of the filling pressure of 30kPa and the filling speed of 0.98kPa / s, the molten aluminum is filled into the cavity from the gate until the cavity is completely filled;

[01...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com