Nickel-based alloy and preparation method thereof

A technology of nickel-based alloys and alloys, applied in metal processing equipment, manufacturing tools, casting and molding equipment, etc., can solve the problems of small grain size, corrosion resistance and poor casting performance, achieve fine grain size, avoid Dendritic segregation, the effect of eliminating water vapor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

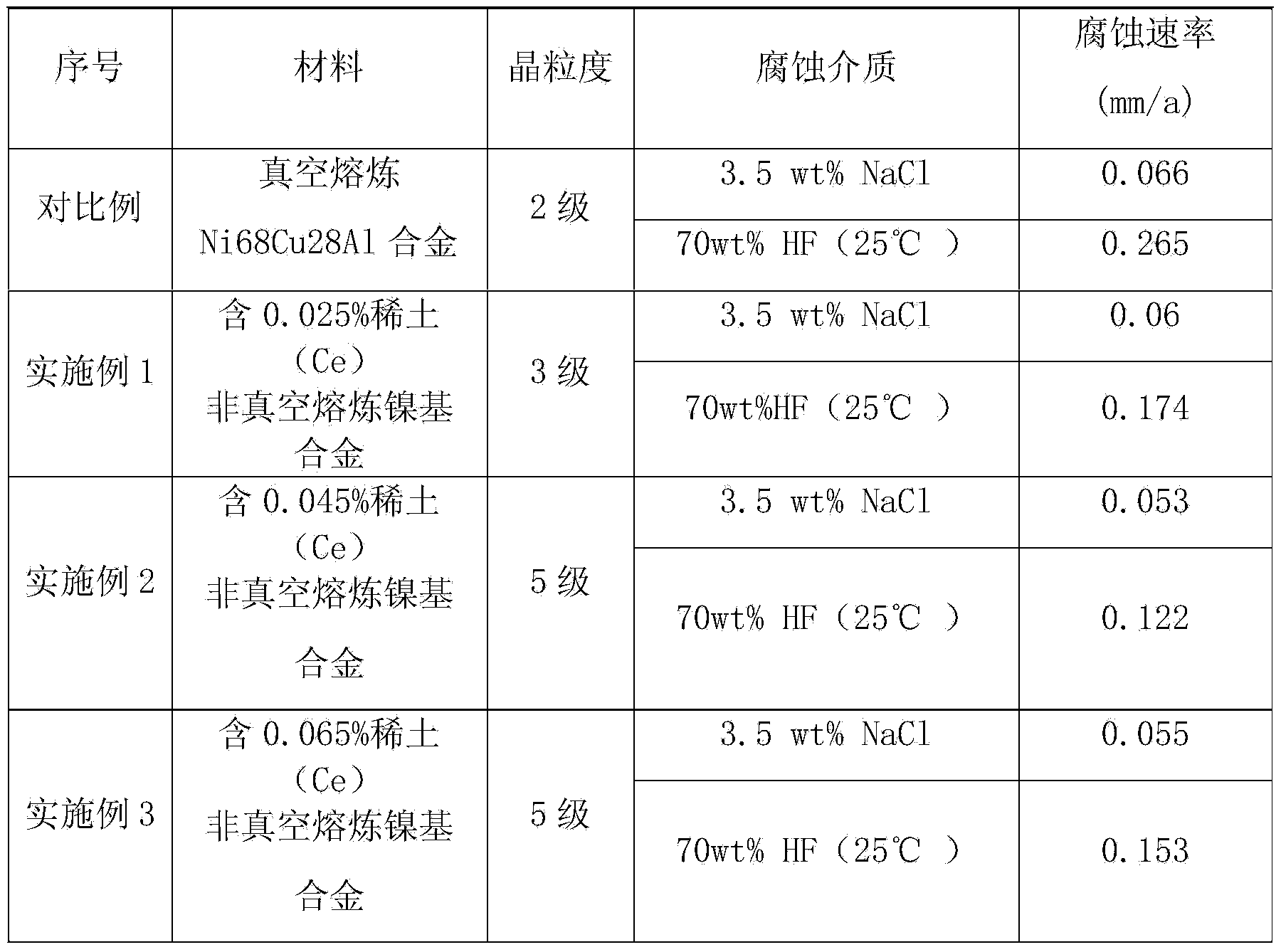

Embodiment 1

[0029] According to the mass percentage, respectively weigh Cu: 28%, Mn: 0.5%, Al: 2.5%, Ti: 0.5%, Ce: 0.025%, the balance is Ni and unavoidable impurity elements, and the sum of the mass percentages of each component is 100%. Melting is carried out in a medium frequency induction furnace under non-vacuum conditions (that is, normal atmospheric conditions) according to the above-mentioned composition ratios. The order of alloy addition is: Ni plate + Cu block + solvent (that is, glass) → add sponge Ti + Mn plate + Al wire after melting, thereby initially forming alloy liquid → add Ni-18Mg master alloy to the above alloy liquid → measure temperature out of the oven. The whole alloy melting time is controlled at 60min. When the ingredients are completely melted, by adding Ni-18Mg master alloy, the magnesium in it reacts with the oxygen in the alloy liquid to form solid-phase magnesium oxide slag, and the above alloy liquid is precipitated to control the oxygen content of the a...

Embodiment 2

[0031] According to the mass percentage, weigh Cu: 30%, Mn: 1.0%, Fe: 1.5%, Al: 2.8%, Ti: 0.75%, Ce: 0.045%, the balance is Ni and unavoidable impurity elements, each component The sum of the mass percentages is 100%. Melting is carried out in a medium frequency induction furnace under non-vacuum conditions (that is, normal atmospheric conditions) according to the above-mentioned composition ratios. The order of alloy addition is: Ni plate + Cu block + solvent (that is, glass) → adding sponge Ti + Mn plate + Al wire after melting, initially forming alloy liquid → adding Ni-18Mg master alloy → temperature measurement and release. The smelting time of the whole alloy is controlled at 75 minutes; when the ingredients are completely melted, add Ni-18Mg master alloy to make the magnesium in it react with the oxygen in the alloy liquid to form solid-phase magnesium oxide slag, and precipitate the above alloy liquid to control the oxygen content of the alloy liquid. If the content i...

Embodiment 3

[0033]According to the mass percentage, respectively weigh Cu: 35%, Mn: 1.5%, Fe: 2.5%, Al: 3.5%, Ti: 0.9%, Ce: 0.065%, the balance is Ni and unavoidable impurity elements, components The sum of the mass percentages is 100%. According to the above composition ratio, smelting is carried out in an intermediate frequency induction furnace under non-vacuum conditions (that is, normal atmospheric state), and the order of adding the alloy is: Ni plate + Cu block + solvent (that is, glass) → adding sponge Ti after melting + Mn plate + Al wire, alloy liquid is initially formed → Ni-18Mg master alloy is added to the alloy liquid → temperature measurement is released; the melting time of the whole alloy is controlled at 90min; when the ingredients are completely melted, Ni-18Mg master alloy is added, and finally magnesium and Oxygen reacts to generate solid-phase magnesium oxide slag, and the alloy liquid is discharged, thereby controlling the oxygen content of the alloy liquid to be be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com