Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32results about How to "Simple activation process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of nickel based metal load type catalyst

ActiveCN101455964AHigh catalytic activityImprove catalytic selectivityMetal/metal-oxides/metal-hydroxide catalystsActivation methodHydrogen atmosphere

The invention discloses a method for preparing nickel-base metal supported catalyst. The preparation method comprises the steps of reducing a nickel-base layered hydrotalcite precursor for 1 to 12 hours by use of hydrogen in hydrogen atmosphere at a temperature between 200 and 800 DEG C and directly generating the nickel-base metal supported catalyst. The composition of the nickel-base layered hydrotalcite precursor is Ni1-y-xMxAly(OH)2(CO3)y / 2+x(z-2) / 2.nH2O, wherein x is between 0 and 0.5; y is between 0.1 and 0.33; z is a valence of M; and the M is Fe, Co, Cu, Sn, Mg, Zn, La or Ce. As a direct H2 reduction-activation method leaves out the step of intermediate roasting, the method has the advantages of simplifying a catalyst- activating process and reducing energy consumption, and is an optimal option for preparing a metal supported catalyst by reducing and activating a catalyst precursor which contains a transitional metal catalyst prepared by a precipitation method.

Owner:ZHEJIANG UNIV OF TECH

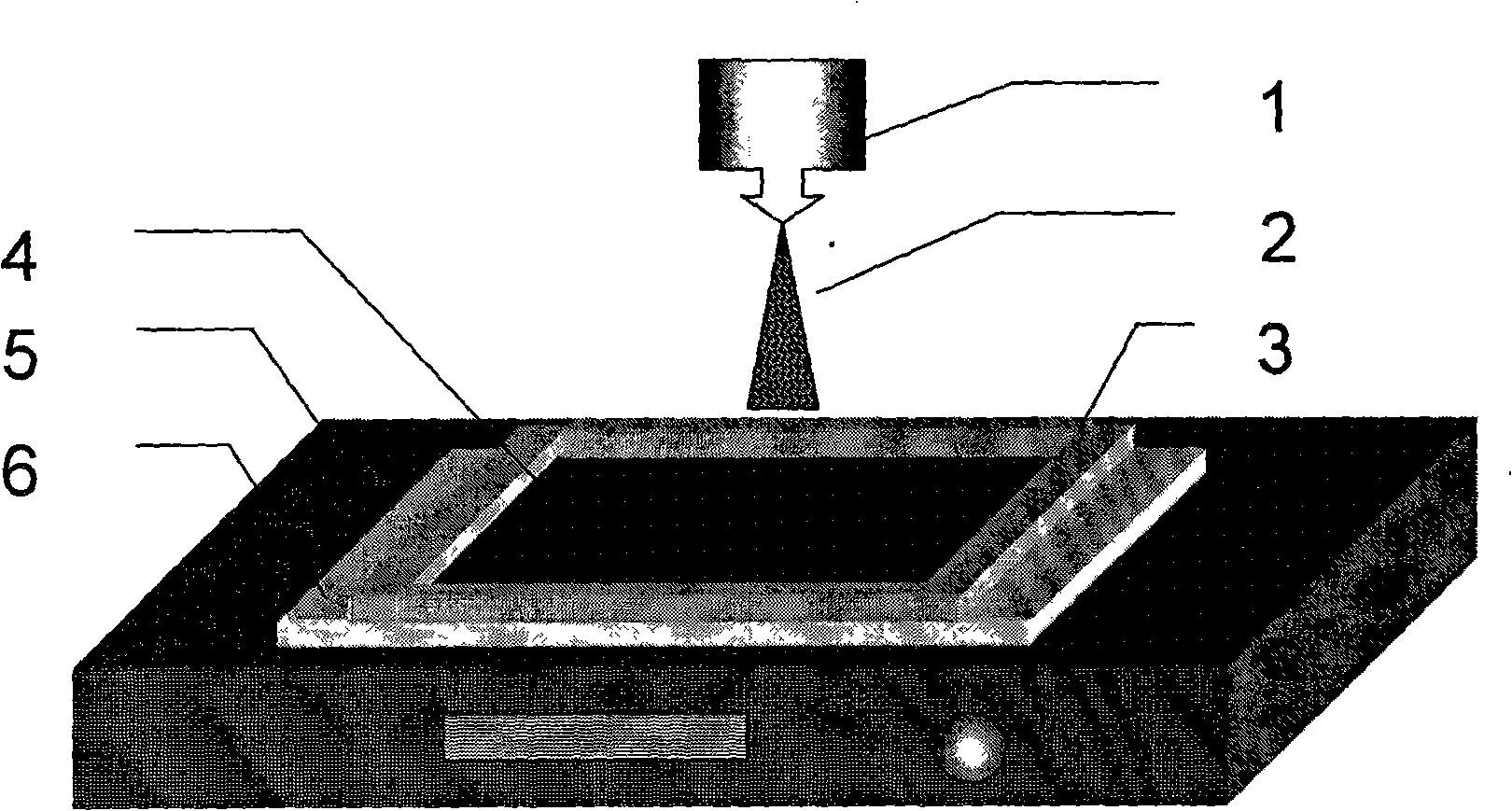

Preparation technique for membrane electrode of proton exchange film fuel cell

ActiveCN101276919AImprove solubilityNo pollution in the processFinal product manufactureCell electrodesState of artSpray coating

The invention relates to a technology that prepares a proton exchange membrane fuel cell electrode, comprising three parts of a pre-process of the proton exchange membrane, a preparation of a catalyst slurry and spray coating of a membrane electrode. The technology provided by the invention solves the problems that in prior art preparation process, the proton exchange membrane swells and rucks and the dosage of the catalyst is high and the preparation process is complicated. The prepared proton exchange resin has great elasticity and adhesive property, which is beneficial for improving adhesion of the catalyst layer and the proton exchange membrane and improves utilization ratio of the catalyst.

Owner:辽宁沐与康中氢燃料电池有限公司

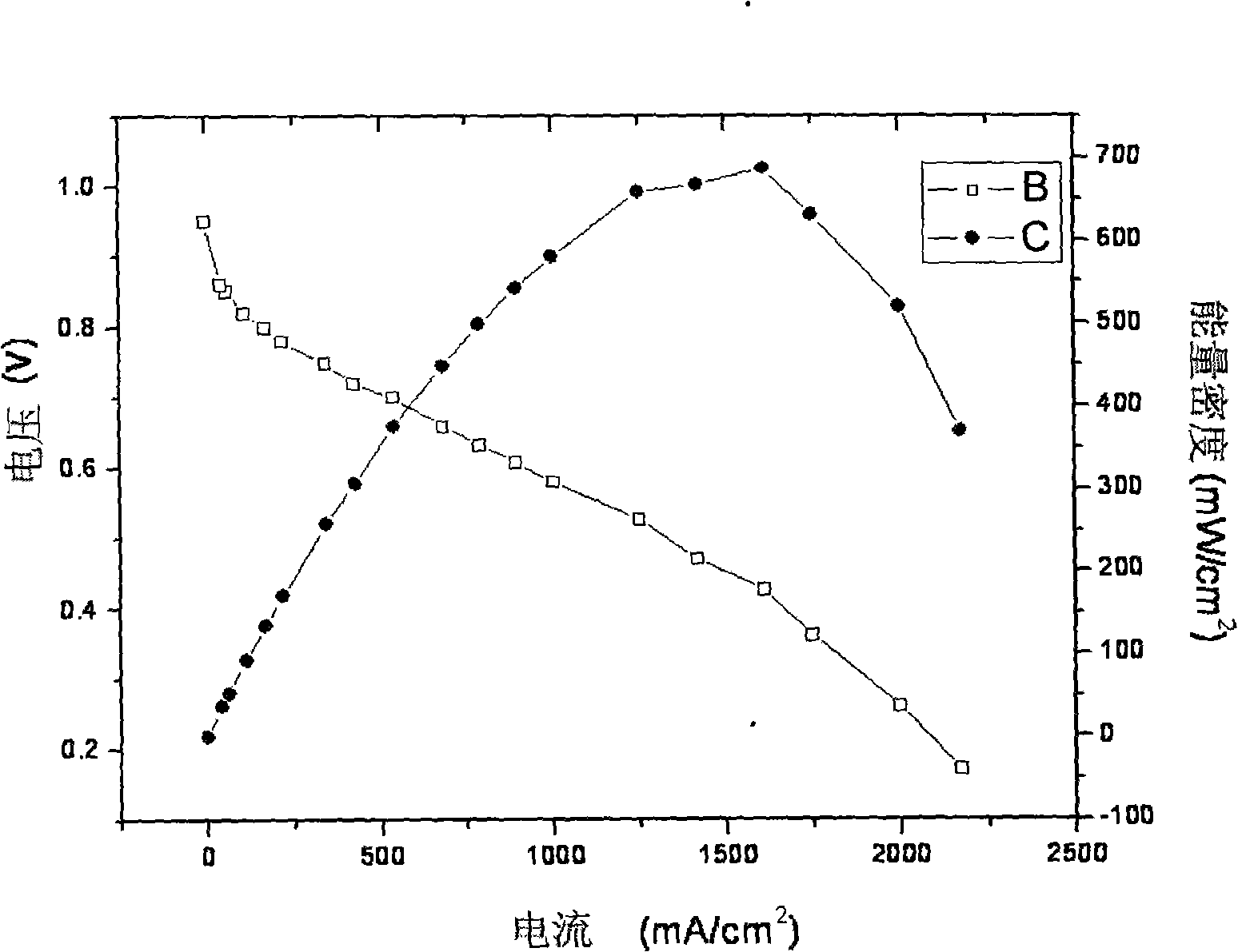

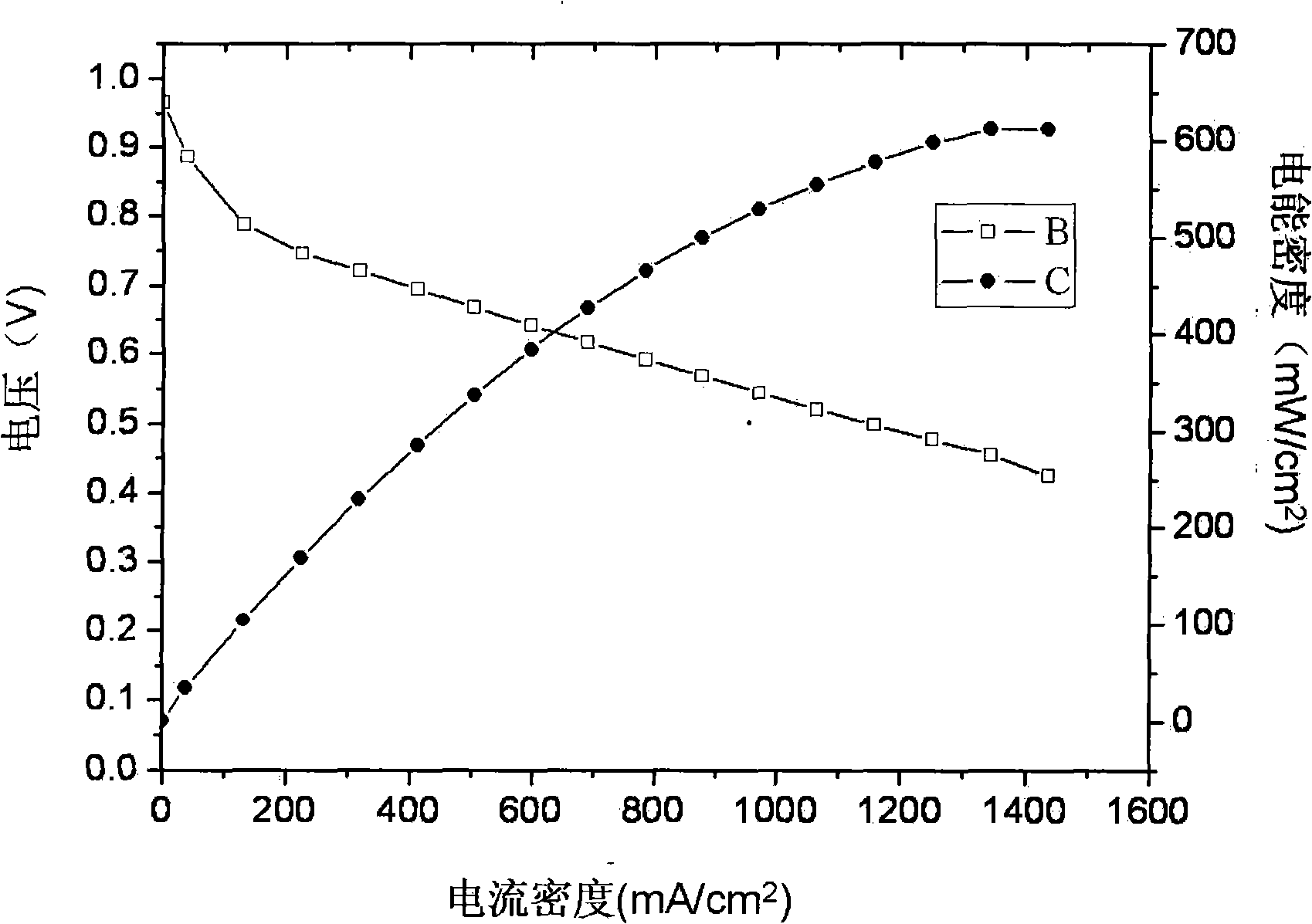

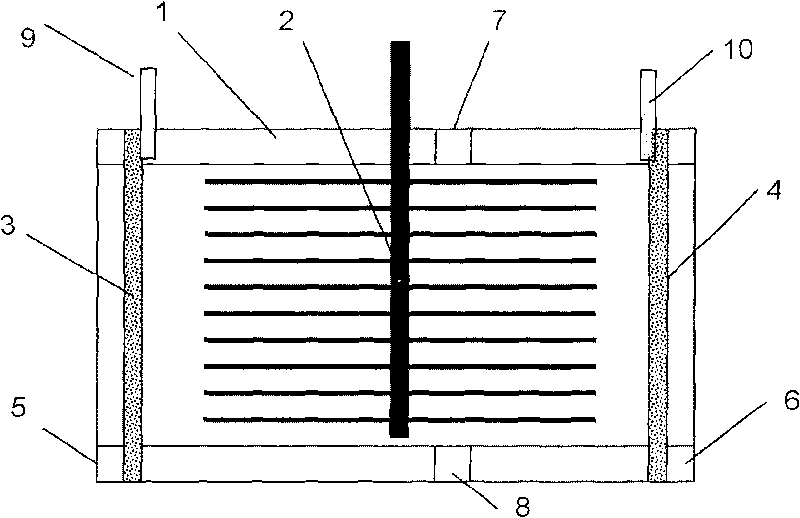

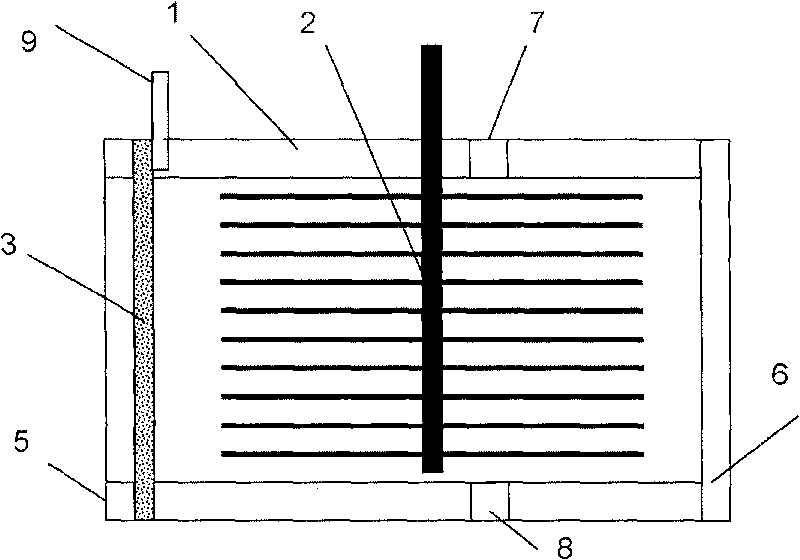

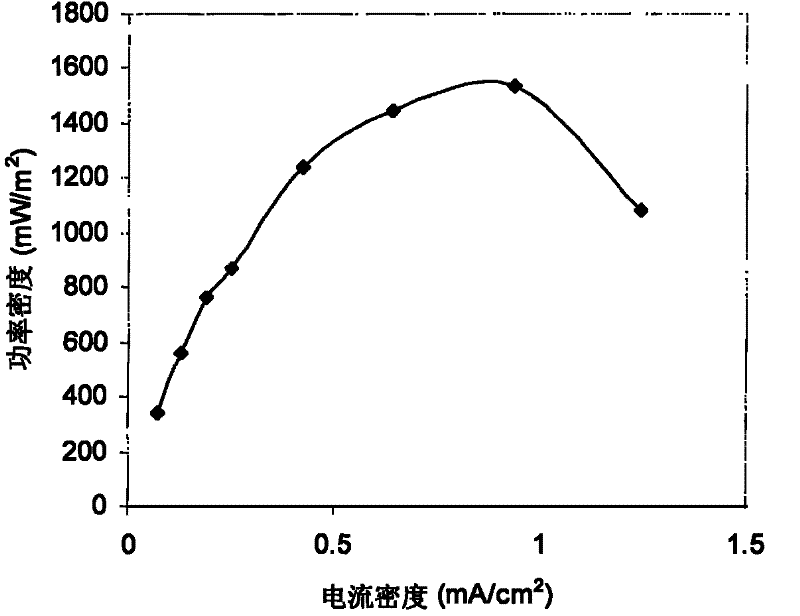

Single-chamber microbial fuel cell without metal catalyst

InactiveCN101702440AWide variety of sourcesLow priceCell electrodesBiochemical fuel cellsFiberEvaporation

The invention relates to a fuel cell and aims at providing a single-chamber microbial fuel cell without a metal catalyst. The cell comprises a cell shell, cathodes and an anode. Electrolyte is water which is filled in the cell shell and contains organic matters. The anode is a titanium core carbon fiber brush made by winding titanium wires and active carbon fibers; the cathodes are carbon cloths or stainless steel meshes with both sides respectively coated by diffusion layers and catalyst layers; and the diffusion layers are contacted with the air and the catalyst layers are contacted with the electrolyte. The cathodes of the invention are composed of multiple diffusion layers and catalyst layers, reduce loss of water due to evaporation and improve stability of the electrodes. One side of each cathode directly faces the air and oxygen is directly diffused to the catalytic surface of the cathode without additional air supply devices and driving force, thus greatly lowering the operation cost and improving the stability. The catalytic materials of the cathodes are active carbons featuring wide sources and low prices, without any metal catalyst, thus greatly reducing the constructive cost. The cell has the characteristics of simple structure, low cost and easy expansion.

Owner:ZHEJIANG UNIV

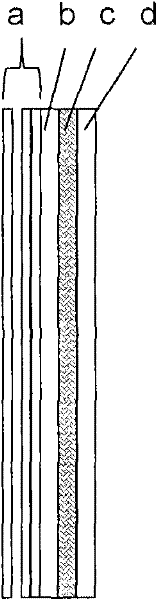

Air cathode without metal catalyst and preparation method thereof

InactiveCN101702435AWide variety of sourcesLow priceFinal product manufactureCell electrodesEvaporationEngineering

The invention relates to preparation of electrodes of fuel cells and aims at providing an air cathode without a metal catalyst and a preparation method thereof. The air cathode comprises a carbon cloth or a stainless steel mesh as a base material. Both sides of the base material are respectively coated by diffusion layers and catalyst layers, wherein the diffusion layers are contacted with the air and the catalyst layers are contacted with electrolyte. The cathode of the invention is composed of multiple diffusion layers and catalyst layers, reduces loss of water due to evaporation and improves stability of the electrodes. One side of the cathode directly faces the air and oxygen is directly diffused to the catalytic surface of the cathode without additional air supply devices and driving force, thus greatly lowering the operation cost of the cell and improving the stability. The catalytic materials of the cathodes are active carbons featuring wide sources and low prices, without any metal catalyst, thus greatly reducing the constructive cost. The air electrode has the characteristics of simple structure, low cost and easy expansion and can be used for producing microbial fuel cells with high properties and low costs and simultaneously purify waste water.

Owner:ZHEJIANG UNIV

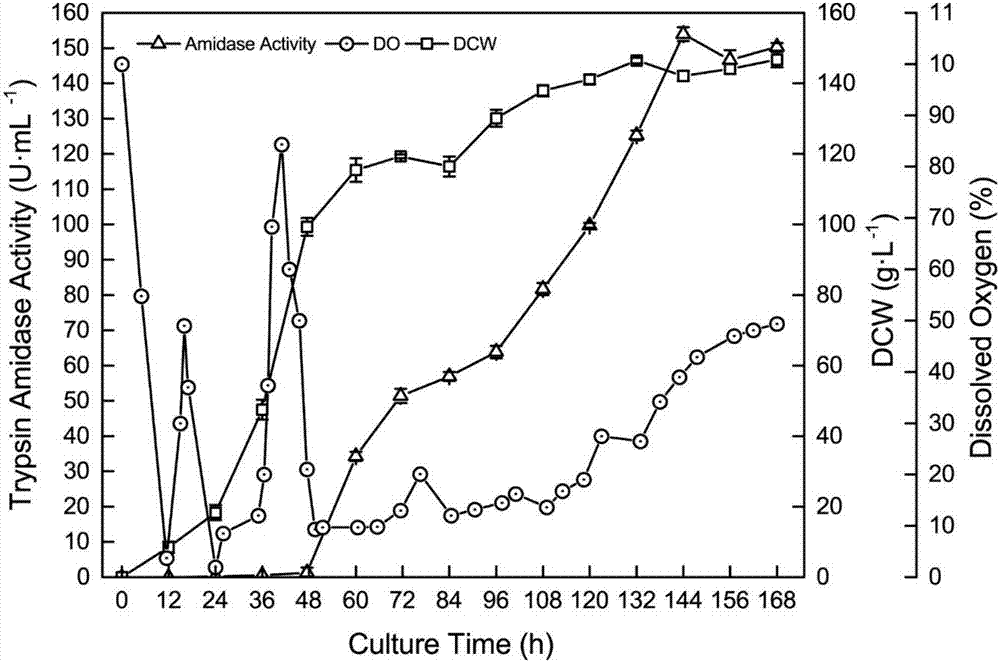

Method for improving trypsin activity through artificially-designed self-activated leading peptide sequence

ActiveCN106893700AIncrease enzyme activityIncrease productionPolypeptide with localisation/targeting motifFungiHeterologousPichia pastoris

The invention discloses a method for improving trypsin activity through an artificially-designed self-activated leading peptide sequence and belongs to the field of genetic engineering. Trypsin of an artificial self-activated leading peptide sequence TPAPPSDDLGTFDDDDK is fused at an expression N end of a pichia pastoris engineered strain constructed by the method. Trypsin activity (trypsin amidase activity) of the yeast engineered strain GS115-Sedeif reaches 156U.mL-1, and esterase activity is 15015.8U.mL-1 (BAEE serving as a substrate), which are 1.82 times and 3.29 times of strain trypsin activity before modification. By the method, the key problem of low trypsin heterogeneous expression is solved. By applying the recombinant strain to produce trypsin, the method has the advantages of high yield, simplified fermentation process and convenience in industrial application.

Owner:JIANGNAN UNIV

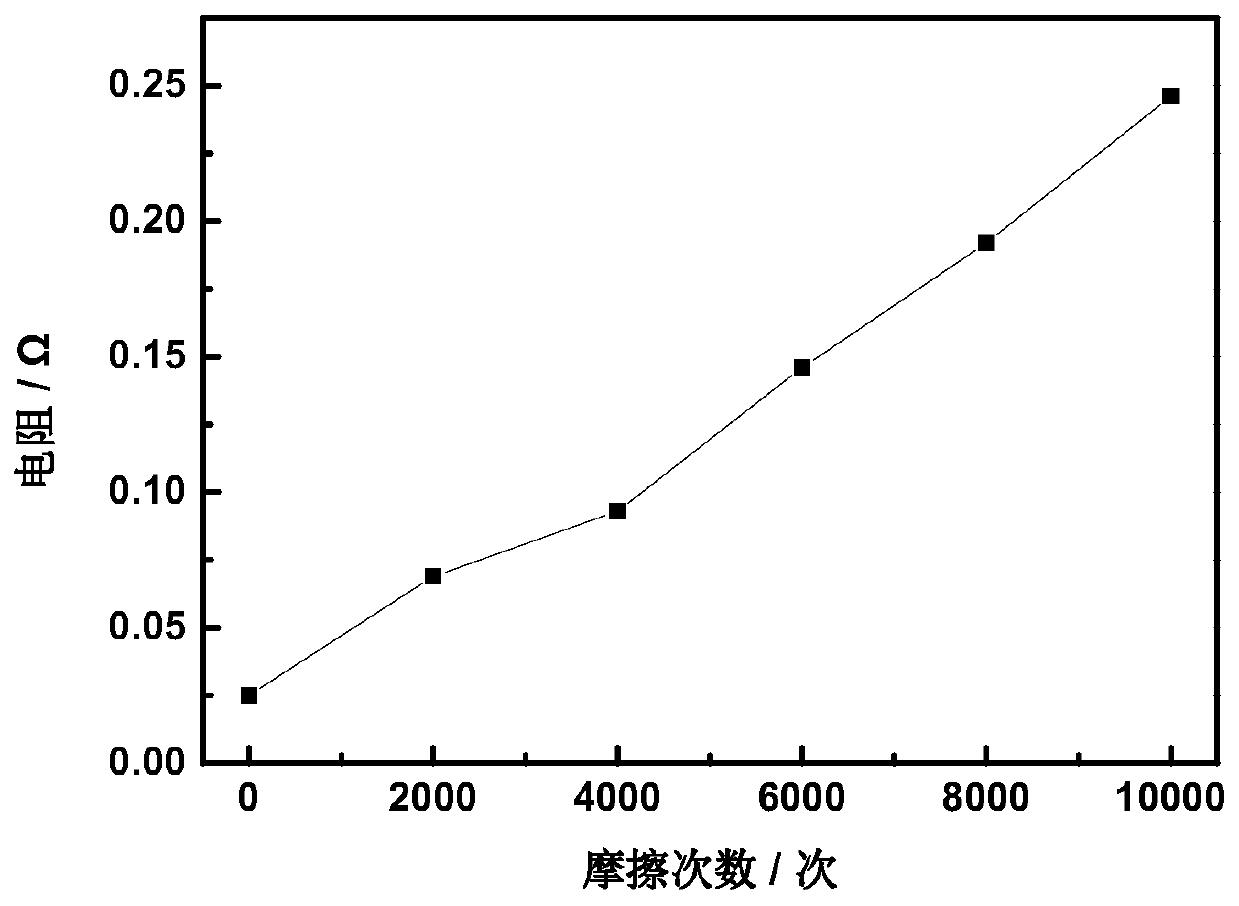

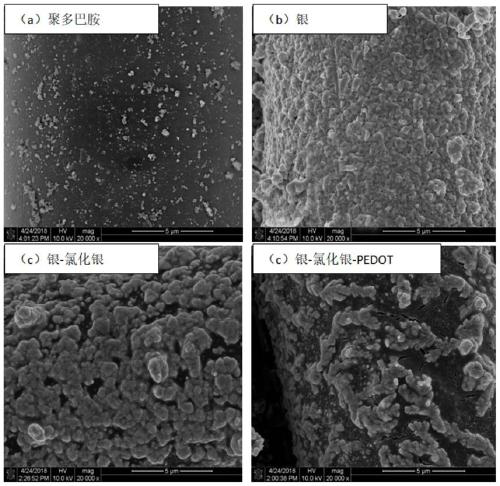

Preparation method of textile electrode material and textile electrode material

ActiveCN111395002AImprove conductivitySimplified coarseningLiquid/solution decomposition chemical coatingDiagnostic recording/measuringConductive polymer compositeSilver chloride

The invention discloses a preparation method of a textile electrode material and the textile electrode material. The preparation method comprises the steps that firstly, pretreated fabric is soaked ina dopamine hydrochloride solution, and polydopamine coated fabric is obtained; then, the polydopamine coated fabric is soaked in a silver-ammonia solution, a glucose solution is added after a certainperiod of time, and a silver-plated fabric is obtained; the silver-plated fabric is subjected to chlorination treatment in a sodium chloride solution through an electrochemical method, and a silver-silver chloride composite coating fabric is formed; finally, the silver-silver chloride composite coating fabric is modified in a conductive polymer monomer solution through an electrochemical method,and the silver-silver chloride-conductive polymer composite coating fabric is obtained. The surface specific resistance of the textile electrode material is 0.01-5 omega, the polarization impedance ina 0.9% sodium chloride solution is 10-1000 omega, the skin interface impedance is 1K omega-100M omega at 1Hz, and the phase angle variation within the frequency range of 0.5-50Hz is 0-30 degrees.

Owner:MINJIANG UNIV

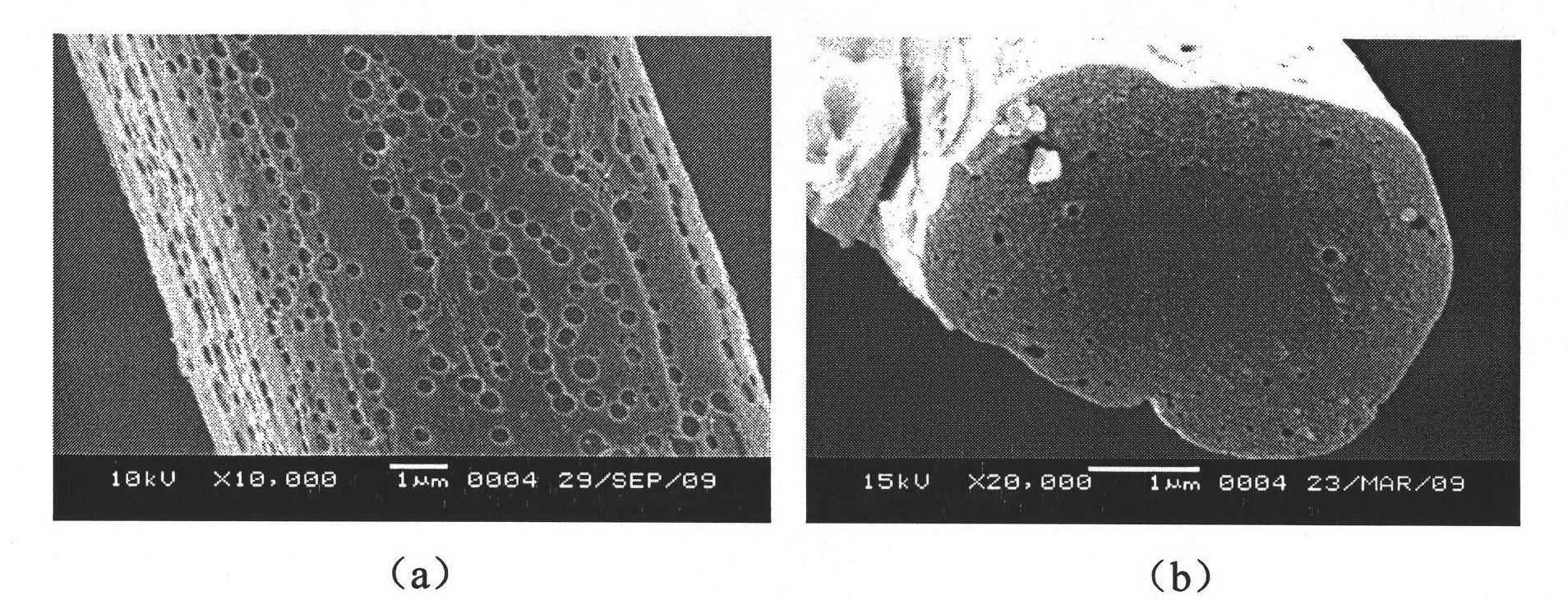

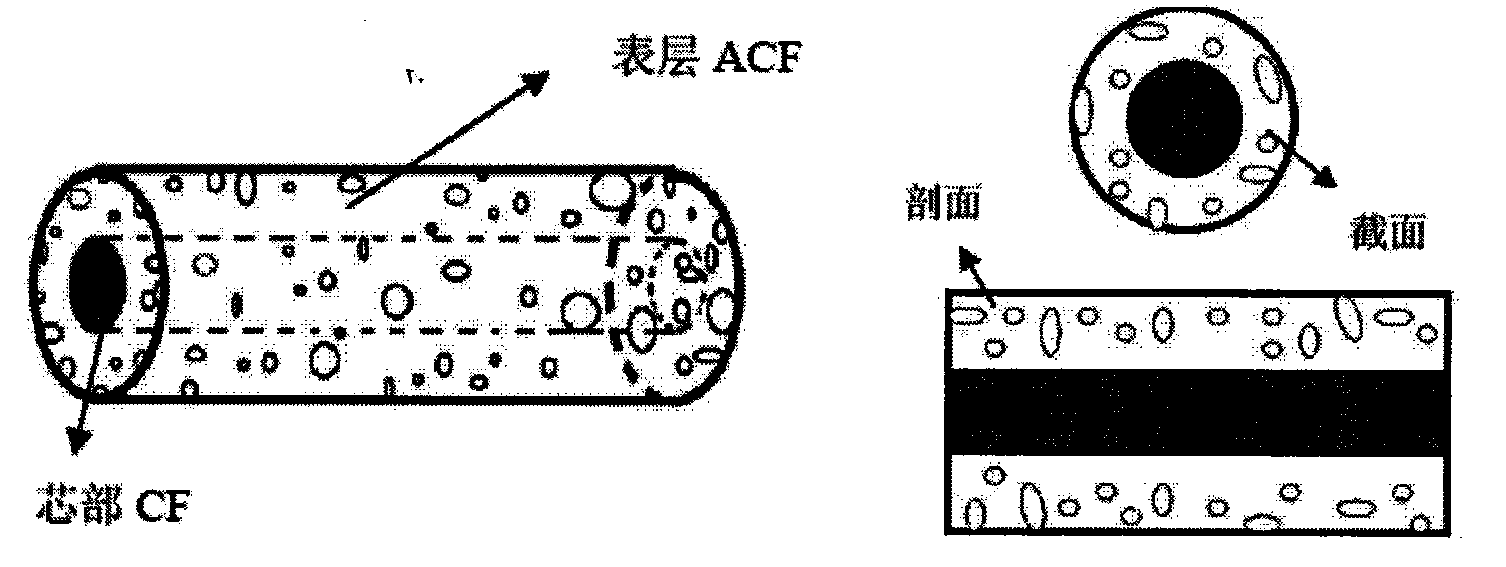

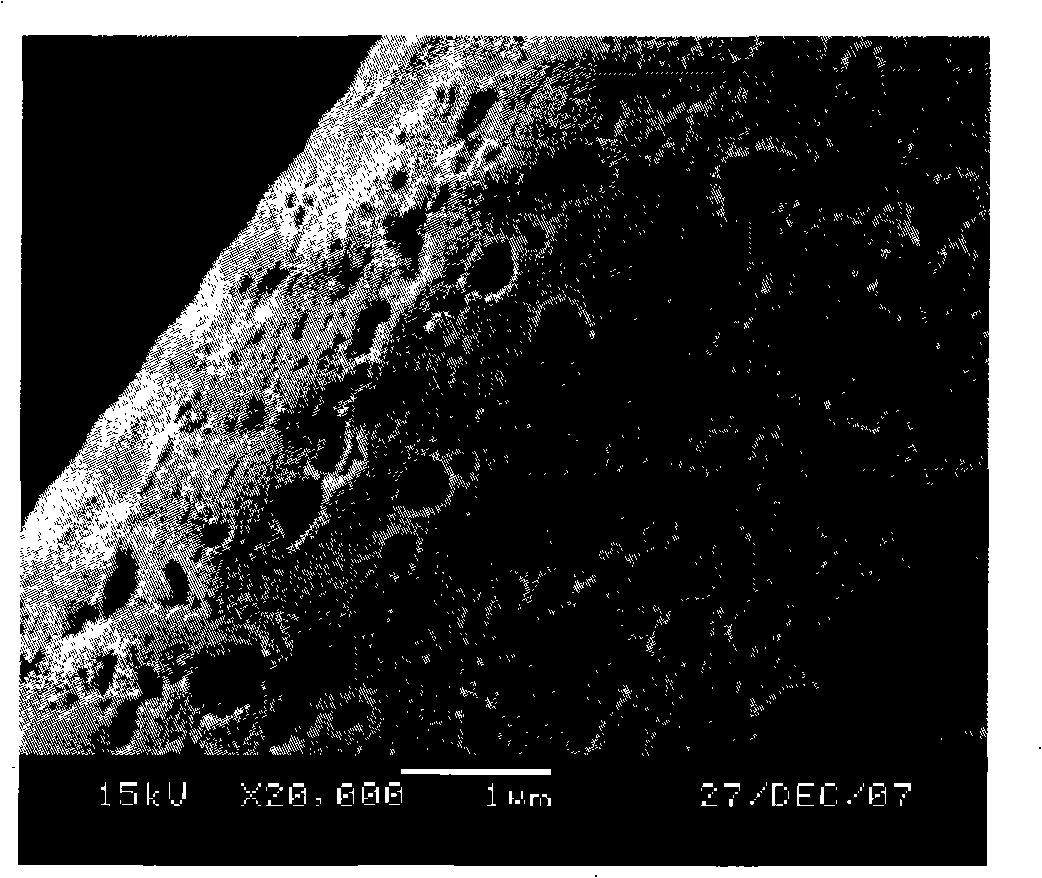

Porous activated carbon fiber adsorbing material of sheath-core composite structure and preparation thereof

InactiveCN101844070AExtended service lifeConducive to loadOther chemical processesAlkali metal oxides/hydroxidesFiberCarbon fibers

The invention relates to a porous activated carbon fiber adsorbing material of a sheath-core composite structure and preparation thereof. The structure of the porous activated carbon fiber adsorbing material is as follows: a surface layer is made of macro-porous carbon fiber, and a core layer is made of non-porous carbon fiber; wherein the ratio of the cross-sectional area of the surface layer is controlled to be 10-40 percent, and the cross-section thereof is uniformly provided holes. The preparation comprises the following steps: (1) impregnating carbon fiber in aqueous solution of sodium salt for 2-4 hours, and then placing the carbon fiber in an activation furnace; (2) heating to 800-1100 DEG C under the protection of an inert gas, adding steam, and carrying out constant-temperature activation for 0.5-2 hour(s); and (3) reducing the temperature to be below 200 DEG C, and cutting off the inert gas and the steam, thereby preparing the porous activated carbon fiber adsorbing material. The strength of the adsorbing material provided by the invention is up to 0.3-0.6Gpa, and the surface layer thereof is of a porous structure, thereby not only prolonging the service life of the material, but also facilitating the loading of large-sized molecules such as biological cells and the like; and the preparation method can be controlled easily, the activation process is simple, and the invention is suitable for large-scale production.

Owner:DONGHUA UNIV

Chemical prepn process of composite hydroxyapatite/collagon layer on the surface of Ni-Ti alloy

The present invention belongs to the field of biological bone material preparing technology. The chemical preparation process of composite hydroxyapatite / collagen layer on the surface of Ni-Ti alloy includes the following steps: polishing, washing and drying the Ni-Ti alloy substrate and acid-alkali treatment; pre-calcifying of the substrate inside Na2HOP4 and Ca(OH)2 solution; and finally setting in simulating body fluid containing collagen to grow the composite hydroxyapatite / collagen layer. The process has the features of simple activating treatment and low acid-alkali treatment temperature. In the simulating body fluid containing collagen, hydroxyapatite and collagen are deposited simultaneously to form the composite hydroxyapatite / collagen layer with homogeneous surface and firm combination to the substrate. The present invention is suitable for implant with complicated shape.

Owner:TIANJIN UNIV

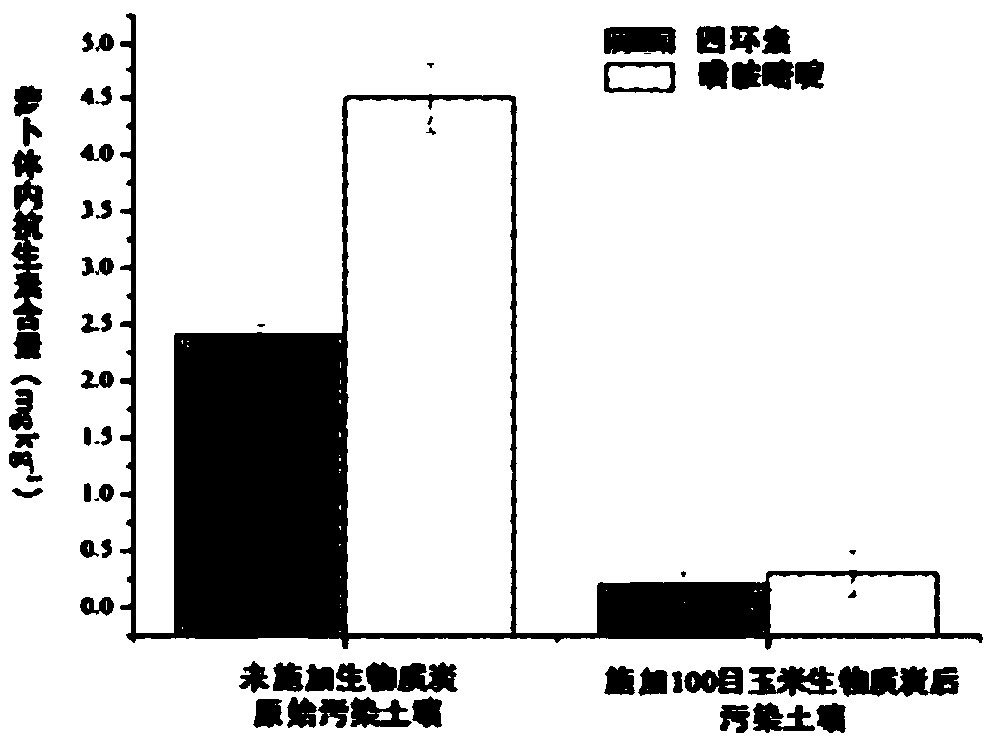

Method for stopping and controlling resistant pollutants in soil from migrating and gathering towards interiors of plant bodies through biomass charcoal, plant planting method and application

InactiveCN108812096ALow costSimple activation processGrowth substratesCulture mediaForest industryResistant genes

The invention provides a method for stopping and controlling resistant pollutants in soil from migrating and gathering towards the interiors of plant bodies through biomass charcoal, a plant plantingmethod and application and relates to the technical field of environmental engineering. According to the method, the biomass charcoal is mixed with soil, and then the field moisture capacity of the soil is adjusted, kept for 5-20 days and preferentially kept for 7-15 days; the resistant pollutants comprise antibiotics, resistant thalli and resistant genes. According to the method, the technical problem is solved that in the prior art, a method for effectively stopping and controlling the resistant pollutants in the soil from migrating and gathering towards the interiors of the plant bodies does not exist; the method for stopping and controlling the resistant pollutants from migrating and gathering is suitable for the soil polluted by various antibiotics, resistant thalli and resistant genes and has a good stopping and controlling effect. In addition, the invention further provides the corresponding plant planting method, and the method for stopping and controlling the resistant pollutants in the soil from migrating and gathering towards the interiors of the plant bodies through the biomass charcoal and the plant planting method can be applied in the fields of agriculture and forestry.

Owner:BEIJING GEOENVIRON ENG & TECH

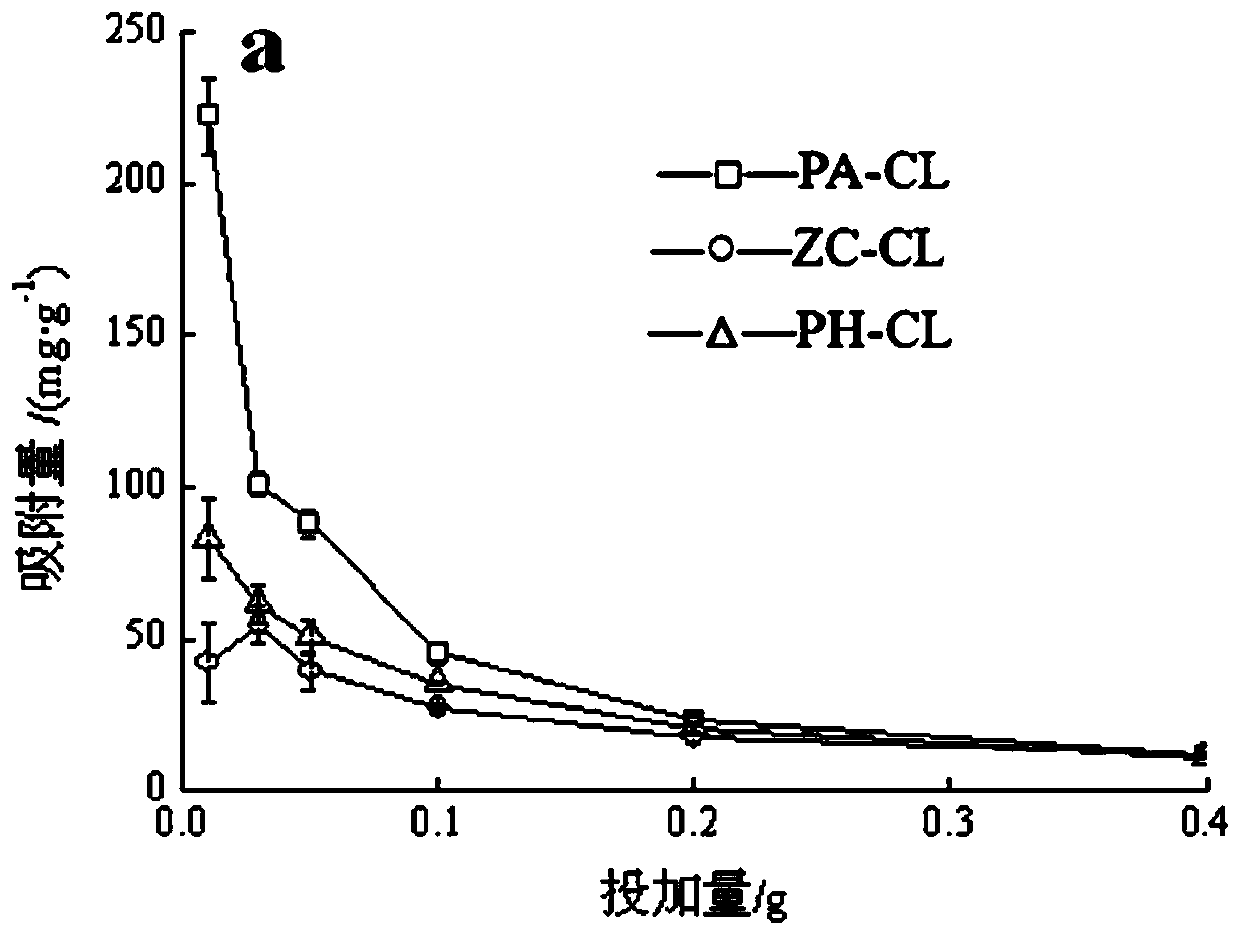

Lignin-based carbon material, preparation method thereof and application thereof in chromium adsorption

PendingCN110482547ASimple activation processLow activation temperatureCarbon compoundsOther chemical processesPhosphoric acidPotassium hydroxide

The invention discloses a lignin-based carbon material, a preparation method thereof and an application thereof in chromium adsorption. The lignin-based carbon material comprises a phosphoric acid activated lignin-based carbon material, a potassium hydroxide activated lignin-based carbon material or a zinc chloride activated lignin-based carbon material. The lignin-based carbon material takes theindustrial residue corncob lignin as a raw material, by respectively activating the phosphoric acid, potassium hydroxide and zinc chloride, the lignin-based carbon material (PA-CL, PH-CL and ZC-CL) isprepared, and the obtained lignin-based carbon material is good in Cr (VI) adsorption effect and high in removal efficiency. Especially the lignin-based carbon material PA-CL has the better effect, the Cr adsorption capacity can reach 108.4 mg / g, and the removal rate can reach 54.2%. The preparation method is simple and environment-friendly, is low in activation temperature, and can realize the resource and high-value utilization of the industrial lignin.

Owner:CHANGAN UNIV

Method for preparing conductive composite with attapulgite as substrate

The invention provides a method for preparing a conductive composite with attapulgite as a substrate. The method comprises steps as follows: activating attapulgite serving as the substrate, preparating a novel polyaniline conductive layer and compositng the substrate and the polyaniline conductive layer. The activation process is simple, the efficiency is high, and the cost is low; the prepared novel polyaniline conductive layer has excellent conductive performance, and the preparation cost is moderate; the adsorption effect of the attapulgite substrate and the novel polyaniline conductive layer is excellent, and the stability is high.

Owner:GUODIAN ENVIRONMENTAL PROTECTION RES INST CO LTD

Preparation technique for membrane electrode of proton exchange film fuel cell

ActiveCN100530797CImprove solubilityNo pollution in the processFinal product manufactureCell electrodesState of artSpray coating

The invention relates to a technology that prepares a proton exchange membrane fuel cell electrode, comprising three parts of a pre-process of the proton exchange membrane, a preparation of a catalyst slurry and spray coating of a membrane electrode. The technology provided by the invention solves the problems that in prior art preparation process, the proton exchange membrane swells and rucks and the dosage of the catalyst is high and the preparation process is complicated. The prepared proton exchange resin has great elasticity and adhesive property, which is beneficial for improving adhesion of the catalyst layer and the proton exchange membrane and improves utilization ratio of the catalyst.

Owner:辽宁沐与康中氢燃料电池有限公司

Porous activated carbon fiber adsorbing material of sheath-core composite structure and preparation thereof

InactiveCN101844070BExtended service lifeConducive to loadOther chemical processesAlkali metal oxides/hydroxidesFiberCarbon fibers

The invention relates to a porous activated carbon fiber adsorbing material of a sheath-core composite structure and preparation thereof. The structure of the porous activated carbon fiber adsorbing material is as follows: a surface layer is made of macro-porous carbon fiber, and a core layer is made of non-porous carbon fiber; wherein the ratio of the cross-sectional area of the surface layer is controlled to be 10-40 percent, and the cross-section thereof is uniformly provided holes. The preparation comprises the following steps: (1) impregnating carbon fiber in aqueous solution of sodium salt for 2-4 hours, and then placing the carbon fiber in an activation furnace; (2) heating to 800-1100 DEG C under the protection of an inert gas, adding steam, and carrying out constant-temperature activation for 0.5-2 hour(s); and (3) reducing the temperature to be below 200 DEG C, and cutting off the inert gas and the steam, thereby preparing the porous activated carbon fiber adsorbing material. The strength of the adsorbing material provided by the invention is up to 0.3-0.6Gpa, and the surface layer thereof is of a porous structure, thereby not only prolonging the service life of the material, but also facilitating the loading of large-sized molecules such as biological cells and the like; and the preparation method can be controlled easily, the activation process is simple, and the invention is suitable for large-scale production.

Owner:DONGHUA UNIV

Method for preparing biological activated carbon from tomato and eggplant straw mixture

InactiveCN110683539AImprove adsorption capacityLarge specific surface areaCarbon compoundsBiotechnologyBiological activated carbon

The invention belongs to the technical field of biological activated carbon preparation, and provides a method for preparing a biological activated carbon from a tomato and eggplant straw mixture. Themethod comprises the following steps: cleaning, pulverizing and mixing eggplant straw and tomato straw, soaking and activating with pyrophosphoric acid, carbonizing in a tubular furnace, recovering pyrophosphoric acid, rinsing, dehydrating, drying and pulverizing to obtain the biological activated carbon. The preparation process is simple, the production cost is low, the efficiency is high, and the prepared biological activated carbon is high in adsorption capacity and suitable for removing macromolecular harmful pollutants.

Owner:WEIFANG UNIV OF SCI & TECH

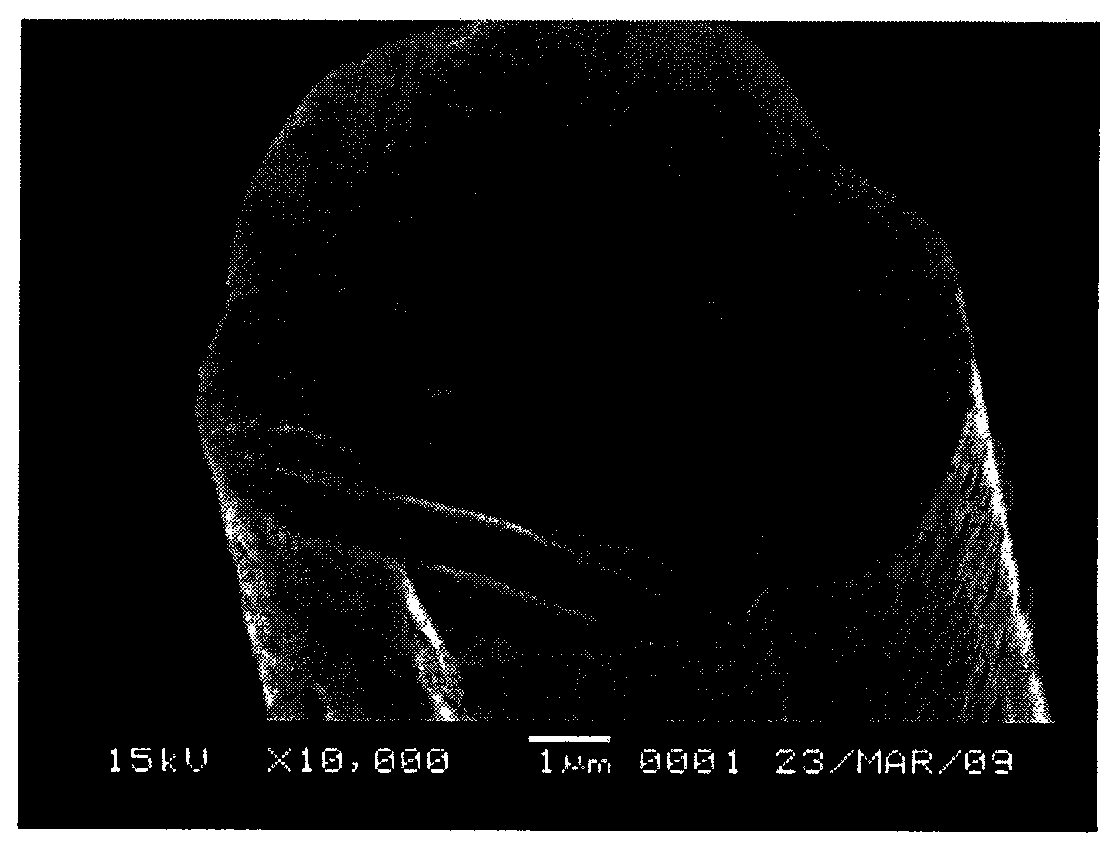

Preparation method of macropore activated carbon fiber with intensity more than 0.3GPa

InactiveCN101337176BHigh strengthSimple activation processOther chemical processesAlkali metal oxides/hydroxidesActivated carbonFiber

The invention provides a preparation method of a macropore activated carbon fiber, the strength of which is larger than 0.3 GPa. The preparation method comprises the following steps: a carbon fiber is soaked in mixed aqueous solution of sodium salt and acid for 12-24 hours, and dried under 100 DEG C after being taken out; then, the carbon fiber is put into an activation furnace, and heated to 800-1100 DEG C under the protection of inert gases; at the same time, vapour is introduced to activate the fiber for 0.5-1 hour. The strength of the obtained activated carbon fiber can reach 0.3-0.5 GPa,and the service life of the activated carbon fiber can be prolonged; the aperture of macropores on the surface of the obtained activated carbon fiber is 50-600 nm, thereby favoring the absorption of materials of large sizes. The preparation method directly utilizes the carbon fiber as the raw material, the activation process is simple, and the product strength is higher.

Owner:DONGHUA UNIV

A preparation method of catalyst crystal and its application in catalytic degradation of organic wastewater

ActiveCN107115882BHigh activitySimple preparation processWater/sewage treatment by irradiationWater treatment compoundsOrganocatalysisCrystal

The invention belongs to the technical field of organic catalysis, and specifically relates to a preparation method of catalyst crystal and its use in catalytic degradation of organic wastewater, especially the catalytic degradation of 2,4-dichlorophenol. The present invention uses ammonium paramolybdate as the molybdenum source, melamine as the nitrogen source, iron thiocyanide as the sulfur source and iron source to modify titanium dioxide, and prepares brown catalyst crystals through in-situ reaction, which has a high specific surface area. And catalytic activity, the degradation rate of 2,4-dichlorophenol is as high as over 99%.

Owner:天津绿诺环保科技有限公司

Infrared window film getter and preparation method thereof

InactiveCN109980018AIncrease inspiratory capacityImprove reliabilityRadiation pyrometryFinal product manufactureHigh volume manufacturingInfrared window

The invention discloses an infrared window film getter. The infrared window film getter comprises a base layer, a Cr coating, a microstructure layer Cu, a zirconium-based getter and a nickel protective layer, wherein the Cr coating is plated on the surface of the base layer; the microstructure layer Cu is plated on the surface of the Cr coating and on the side, far away from the base layer, of theCr coating; the zirconium-based getter is plated on the surface of the microstructure layer Cu and on the side, far away from the Cr coating of the microstructure layer Cu; and the nickel protectivelayer is plated on the surface of the zirconium-based getter and on the side, far away from the microstructure layer, of the zirconium-based getter. The getter produced by the invention has large airsuction amount, high reliability and difficult particle generation, can be produced in a large scale, and has high process consistency and low cost, the getter is activated by vacuum heating, and theactivation process is simple and easy to operate.

Owner:合肥晶鼎光电科技有限公司

Air cathode without metal catalyst and preparation method thereof

InactiveCN101702435BWide variety of sourcesLow priceCell electrodesFinal product manufactureFuel cellsMetal catalyst

The invention relates to preparation of electrodes of fuel cells and aims at providing an air cathode without a metal catalyst and a preparation method thereof. The air cathode comprises a carbon cloth or a stainless steel mesh as a base material. Both sides of the base material are respectively coated by diffusion layers and catalyst layers, wherein the diffusion layers are contacted with the air and the catalyst layers are contacted with electrolyte. The cathode of the invention is composed of multiple diffusion layers and catalyst layers, reduces loss of water due to evaporation and improves stability of the electrodes. One side of the cathode directly faces the air and oxygen is directly diffused to the catalytic surface of the cathode without additional air supply devices and drivingforce, thus greatly lowering the operation cost of the cell and improving the stability. The catalytic materials of the cathodes are active carbons featuring wide sources and low prices, without any metal catalyst, thus greatly reducing the constructive cost. The air electrode has the characteristics of simple structure, low cost and easy expansion and can be used for producing microbial fuel cells with high properties and low costs and simultaneously purify waste water.

Owner:ZHEJIANG UNIV

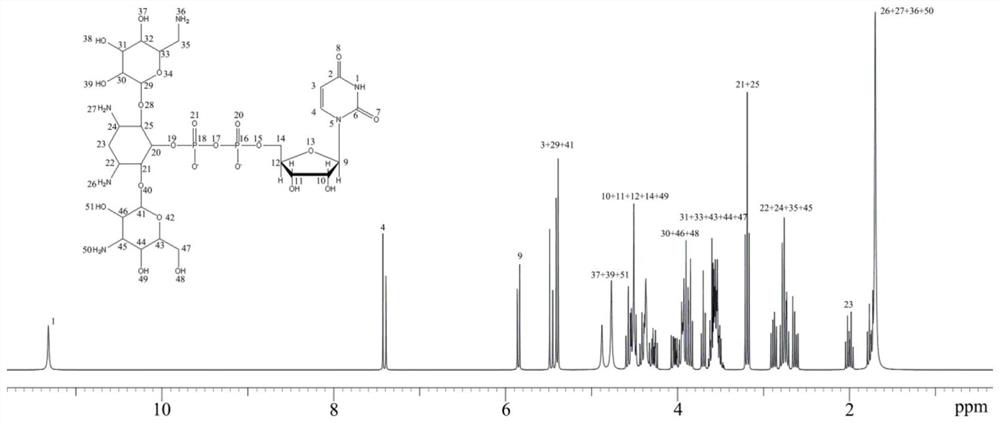

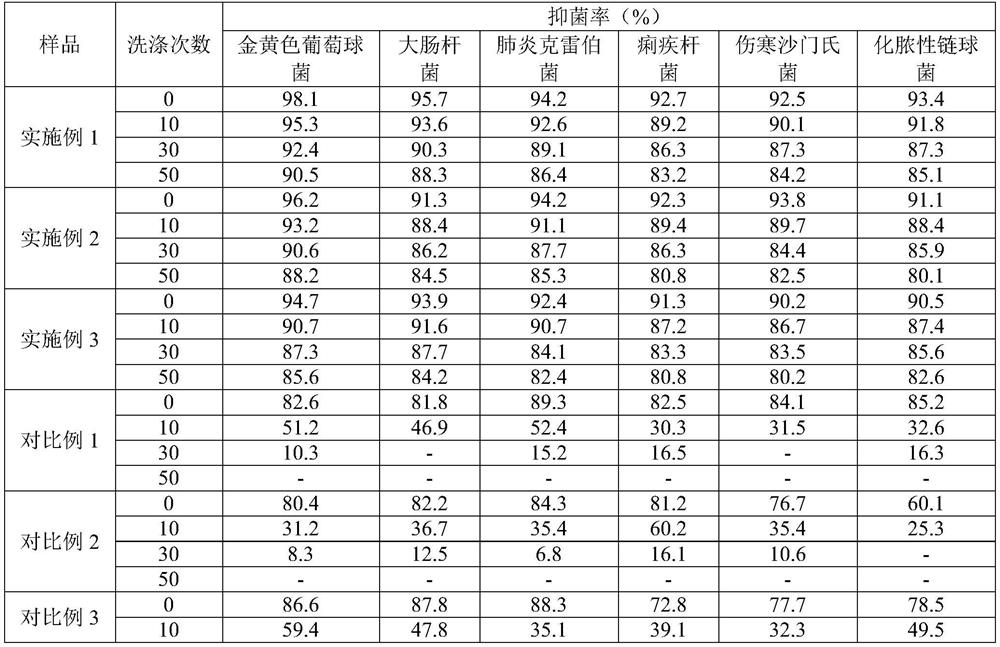

A kind of antibacterial cotton fabric and preparation method thereof

ActiveCN111172738BImprove bindingLow costPhysical treatmentBiochemical treatment with enzymes/microorganismsBiotechnologyKanamycin

The invention belongs to the technical field of textile fabric processing and discloses an antibacterial cotton fabric and a preparation method thereof. The preparation method specifically includes: (1) performing plasma treatment on cotton fabric; (2) mixing kanamycin, UMP, Saccharomyces cerevisiae extract, sugar, and potassium dihydrogen phosphate, adding them to water, and filtering after reaction to obtain an antibacterial finishing agent; (3) Apple seeds are pulverized, put into PBS buffer solution and fully stirred, filtered after leaching, and the filtrate is freeze-dried to obtain a glycosidase preparation; (4) The cotton fabric obtained through plasma treatment is immersed in an antibacterial finishing agent, And put into glucosidase preparation, fully impregnated; (5) wash and air-dry to make antibacterial cotton fabric. This antibacterial cotton fabric has long-lasting, broad-spectrum antimicrobial properties, is washable, and is non-toxic to humans and skin.

Owner:周大伟

Concrete admixture and a method for preparing the concrete admixture by calcining coal gangue

ActiveCN102167532BHigh strengthImprove impermeabilitySolid waste managementFluidized bedUltimate tensile strength

The invention relates to a concrete admixture, Which is made from a A component and a B component by steps of mixing, calcining and grinding; the A component includes following raw materials: coal gangue of 70 to 90 amounts by weight; limestone of 10 to 30 amounts by weight; gypsum of 2 to 5 amounts by weight; fluorite of 0.5 to 1.5 amounts by weight; The B component is standard coal; The calorific value of the mixed A and B components is more than 1600 kcal / kg. The invention also provides a method of preparing above mentioned concrete admixture by calcining coal gangue with a fluidized bed roaster, That is mixing the components well and sending into the fluidized bed roaster calcining for one to two hours at a temperature of 800 to 900 degrees, And then pulling out of the roaster for cooling, At last grinding into fine powder and screening to obtain products. The invention uses a simple technology, Increases utilization rate of coal gangue, Which is benefit for full use of the coal gangue, Being used as concrete admixture, With the advantages of more than 30% to 50% active amount, Low cost, Which can increasing intensity of concrete, Increasing impermeability and durability performance, And excellent performance.

Owner:CHINA UNIV OF MINING & TECH (BEIJING) +2

Regenerated adsorption material and preparation method thereof

ActiveCN111804273ALarge specific surface areaImprove adsorption capacityOther chemical processesWater contaminantsActivated sludgeCarbonization

Owner:HEFEI BAIHE ENVIRONMENTAL PROTECTION TECH CO LTD

A kind of hydrogen storage alloy with high hydrogen storage capacity and preparation method thereof

ActiveCN114107776BHigh hydrogen storage capacityEasy to storeHydrogenEnergy inputHydrogen pressureFe element

The invention relates to a hydrogen storage alloy with high hydrogen storage capacity and a preparation method thereof. The hydrogen storage alloy with high hydrogen storage capacity is AB 2 Type, the A side is composed of Ti and Zr elements, the B side is composed of Mn, Cr, Fe elements, and the general chemical formula is Ti a Zr 1‑a mn b Cr c Fe d , where, 0.55≤a≤0.78, 0.8≤b≤1.0, 0.7≤c≤0.85, 0≤d≤0.25, 1.7≤b+c+d≤2.0. The hydrogen storage alloy of the present invention has a high hydrogen storage capacity, and can reach a hydrogen storage capacity of 1.70wt% or more after being activated three times under the conditions of a temperature of 180°C and a hydrogen pressure of 1.25Mpa, and is used in the field of metal solid-state hydrogen storage. Better market prospects.

Owner:XTC HYDROGEN ENERGY SCI & TECH (XIAMEN) CO

A hydrogen isotope gas purification method

ActiveCN104128093BShort cycleReduce manufacturing costIsotope separationHydrogen isotopesPurification methodsProduct gas

The present invention provides a hydrogen isotope gas purification method, the purification method includes the following steps in turn: a. Leak rate inspection of the hydrogen isotope gas purification device, charging to 1.5MPa, and keeping the pressure for 60min; b. Pretreatment before purification ; c, purification treatment; d, post-processing. By adopting the purification method of the present invention, high-purity hydrogen isotope gas can be obtained.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

Preparation method of nickel based metal load type catalyst

ActiveCN101455964BHigh catalytic activityImprove catalytic selectivityMetal/metal-oxides/metal-hydroxide catalystsActivation methodHydrogen atmosphere

The invention discloses a method for preparing nickel-base metal supported catalyst. The preparation method comprises the steps of reducing a nickel-base layered hydrotalcite precursor for 1 to 12 hours by use of hydrogen in hydrogen atmosphere at a temperature between 200 and 800 DEG C and directly generating the nickel-base metal supported catalyst. The composition of the nickel-base layered hydrotalcite precursor is Ni1-y-xMxAly(OH)2(CO3)y / 2+x(z-2) / 2.nH2O, wherein x is between 0 and 0.5; y is between 0.1 and 0.33; z is a valence of M; and the M is Fe, Co, Cu, Sn, Mg, Zn, La or Ce. As a direct H2 reduction-activation method leaves out the step of intermediate roasting, the method has the advantages of simplifying a catalyst- activating process and reducing energy consumption, and is an optimal option for preparing a metal supported catalyst by reducing and activating a catalyst precursor which contains a transitional metal catalyst prepared by a precipitation method.

Owner:ZHEJIANG UNIV OF TECH

Method for modifying carbon fibers for paper-based friction material

The invention relates to a method for modifying carbon fibers for a paper-based friction material, and belongs to the technical field of preparation of paper-based friction materials. The method comprises the following operation steps of 1, adopting a carbon fiber pretreatment system; 2, implementing a carbon fiber pretreatment process; and 3, adopting a layer assembly deposition modification system of the carbon fibers, wherein the suspension liquid of the carbon fibers is used as a matrix for layer deposition modification, a multi-layer alternate deposition mode is adopted for layer deposition adsorption modification, and a modifier is divided into polymers with different anion and cation strengths; and 4, carrying out a layer assembly deposition modification process on the carbon fibers, and repeating the steps, modifying for 3-4 times, filtering and drying to obtain the modified carbon fiber. The obtained carbon fiber can be added as a component for the paper-based friction material. The method has the advantages of simple process and low energy consumption. The technical problems of dispersion, combination and the like of reinforced fibers in the preparation process of the paper-based friction material are solved. The method is suitable for modifying the carbon fibers in the large-scale production process of the paper-based friction material.

Owner:杭州萧山红旗摩擦材料有限公司

Using water as solvent hydrogenation to prepare the method for isooctyl p-dimethylaminobenzoate

ActiveCN111606817BSimple activation processEasy to operateOrganic compound preparationAmino-carboxyl compound preparationBenzoic acidPtru catalyst

The invention relates to the field of fine chemical industry, in particular to a method for preparing isooctyl p-dimethylaminobenzoate through hydrogenation using water as a solvent. The method for preparing isooctyl p-dimethylaminobenzoate by hydrogenation using water as a solvent in the present invention is characterized in that it comprises the following steps: (1) adding water, isooctyl p-nitrobenzoate and active nickel catalyst in proportion Reactor; (2) Heating to 100°C, introducing hydrogen gas, heat-retaining and pressure-retaining reaction until no hydrogen is absorbed; (3) cooling down, adding paraformaldehyde to the reactor, and then adding active nickel catalyst in proportion; (4) Heat until, feed in hydrogen, keep warm and pressurize until no hydrogen is absorbed; (5) Continue to keep warm and keep pressure for several hours, stop the reaction, and take samples for analysis; layer, the water layer is discharged into the sewage system, and the oil layer enters the distillation tower; (7) heat up, the distillation tower is rectified and purified until it meets the product specifications, and then it is packed in barrels.

Owner:浙江优创材料科技股份有限公司

A pretreatment method for preparing high specific surface hierarchical porous activated carbon from cotton straw

ActiveCN106809832BDeveloped specific surface areaWell-developed pore distributionCarbon compoundsComing outPretreatment method

The invention belongs to the field of activated carbon and particularly relates to a pretreatment method for preparing high-specific surface-area multi-hole activated carbon with cotton stalks. The pretreatment method includes: 1), smashing the cotton stalks into particles and screening to remove impurities; 2), rinsing materials prior to dehydrating; 3), adding the materials into an alkalescent solution for dump leaching, rubbing the materials mechanically to divide the same into threads, extruding excess fluid and performing dump leaching once more; 4), placing the materials into a closed pressure vessel, feeding high-pressure steam 1.0-2.5MPa in atmospheric pressure for 5-20 minutes, releasing the materials and the steam prior to releasing pressure to normal pressure and allowing the materials to come out; 5), rinsing with deionized water and performing dehydrating; 6), performing uniform drying. By the arrangement, natural microchannel structure of the cotton stalks can be effectively utilized and expanded, the specific surface area is increased, quality raw materials are provided for low-cost subsequent preparation of high-specific surface-area multi-hole activated carbon process, usage of activating agents in the subsequent process is low, and the pretreatment method is simple in activating process, high in sustainability and suitable for scale production.

Owner:新疆弘瑞达纤维有限公司

A kind of regeneration adsorption material and preparation method thereof

ActiveCN111804273BLarge specific surface areaImprove adsorption capacityOther chemical processesWater contaminantsActivated sludgeWater vapor

Owner:HEFEI BAIHE ENVIRONMENTAL PROTECTION TECH CO LTD

A kind of preparation method of iron-containing soil conditioner

ActiveCN110079326BPromote absorptionAvoid yellowingAgriculture tools and machinesOther chemical processesSoil scienceIron powder

The invention relates to a method for preparing an iron-containing soil conditioner, which comprises the steps of preparing ferrous ammonium citrate; the preparation step of ferrous ammonium citrate; Add iron powder to stir the reaction, cool down after the reaction, pass through ammonia gas to neutralize to pH 5.5-6.5, remove water, and obtain ferrous ammonium citrate. In the present invention, ferrous ammonium citrate is added to low-rank coal to make The water-insoluble humic acid in low-rank coal is activated into water-soluble humic acid. The activation process is simple, and the activation rate of humic acid can reach more than 50%. The iron element in the prepared iron-containing soil conditioner is divalent iron, which is easier Absorbed by crops, in addition, ammonium citrate, ammonium humate and the entire pH buffer system are conducive to the stability of ferrous ammonium citrate. Iron phenomenon, to avoid crop yellowing.

Owner:KINGENTA ECOLOGICAL ENG GRP +2

A method for removing wax before electroplating steel parts for pumps

ActiveCN107245741BSuppress generationImprove Wax Removal EfficiencyEnvironmental resistanceElectrolysis

The invention discloses a method for removing wax before electroplating steel parts for a pump. The method comprises the following operation steps that 3-5 steel parts are connected in parallel and then are placed in a phosphorus-free cleaning fluid as cathodes, a direct current is conducted, and the wax is removed through electrolysis. According to the method for removing the wax through the electrolysis, the wax removing efficiency is high, and the wax removing speed is high; the cleaning liquid does not contain phosphorus, so that no pollution is caused to the environment; the cleaning liquid is stable, and almost no foam is generated during electrolysis, so that the danger that explosion is caused due to the fact that the foam encounters electric sparks is avoided; and moreover, the cleaning fluid can be recycled, so that the production cost is reduced, and the environmental protection is facilitated.

Owner:ANHUI LUYUAN PUMP&VALVE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com