Air cathode without metal catalyst and preparation method thereof

An air cathode and catalyst technology, applied in electrical components, battery electrodes, climate sustainability, etc., can solve the problems of expensive metal platinum, complicated operation process, complicated preparation process, etc., achieve high oxygen reduction characteristics, and stable Oxygen reduction properties, the effect of simple activation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

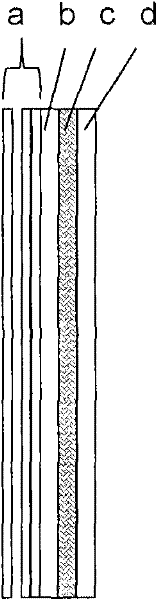

[0030] see figure 1 , in specific implementation, the cathode is composed of a multi-layer polytetrafluoroethylene layer a, a basic nano-carbon layer b, a current collector c, and a catalytic layer d. The negative electrode is prepared in the following steps: (1) the carbon powder of 20 nanometers and the 40%wt polytetrafluoroethylene emulsion (every gram of carbon powder adds 10ml) are mixed into a paste, and the mixture is coated on one side of the stainless steel net, Toner coating amount is 2mg / cm 2 , the coated stainless steel mesh was heated at 370 °C for 15 minutes, removed and cooled to room temperature. (2) Uniformly coat a layer of polytetrafluoroethylene emulsion on the surface of the carbon layer, and heat at 370° C. for 15 minutes. Repeat process (2) five times to form five polytetrafluoroethylene layers on the surface. (3) Activated carbon is ground into small particles, passed through a 500-mesh sieve, and the particles are less than 30uM, mixed with 1M KOH s...

specific Embodiment 2

[0033]The difference between this embodiment and specific example 1 is that the cathode diffusion layer is composed of two layers of nano-carbon basic layers and one layer of polytetrafluoroethylene coating. The dosage of 30%wt polytetrafluoroethylene emulsion is: add 50ml per gram of carbon powder. The carbon loading capacity of the nano-carbon layer is 8mg / cm 2 . The heat treatment temperature of the nano-carbon basic layer is 350° C. for 30 minutes; the heat treatment temperature of the polytetrafluoroethylene coating is 350° C. and the time is 15 minutes. Other structures and connection, operation are identical with specific embodiment 1.

specific Embodiment 3

[0034] The difference between this embodiment and specific example 1 is that the cathode diffusion layer is composed of 1 layer of nano-carbon basic layer and 4 layers of polytetrafluoroethylene coating, and the amount of 40%wt polytetrafluoroethylene emulsion is: add 20ml per gram of carbon powder. The carbon loading of the nano-carbon layer is 3mg / cm 2 . The heat treatment temperature of the nano-carbon basic layer is 360° C., and the time is 20 minutes; the heat treatment temperature of the polytetrafluoroethylene coating is 360° C., and the time is 5 minutes. Other structures and connection, operation are identical with specific embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com