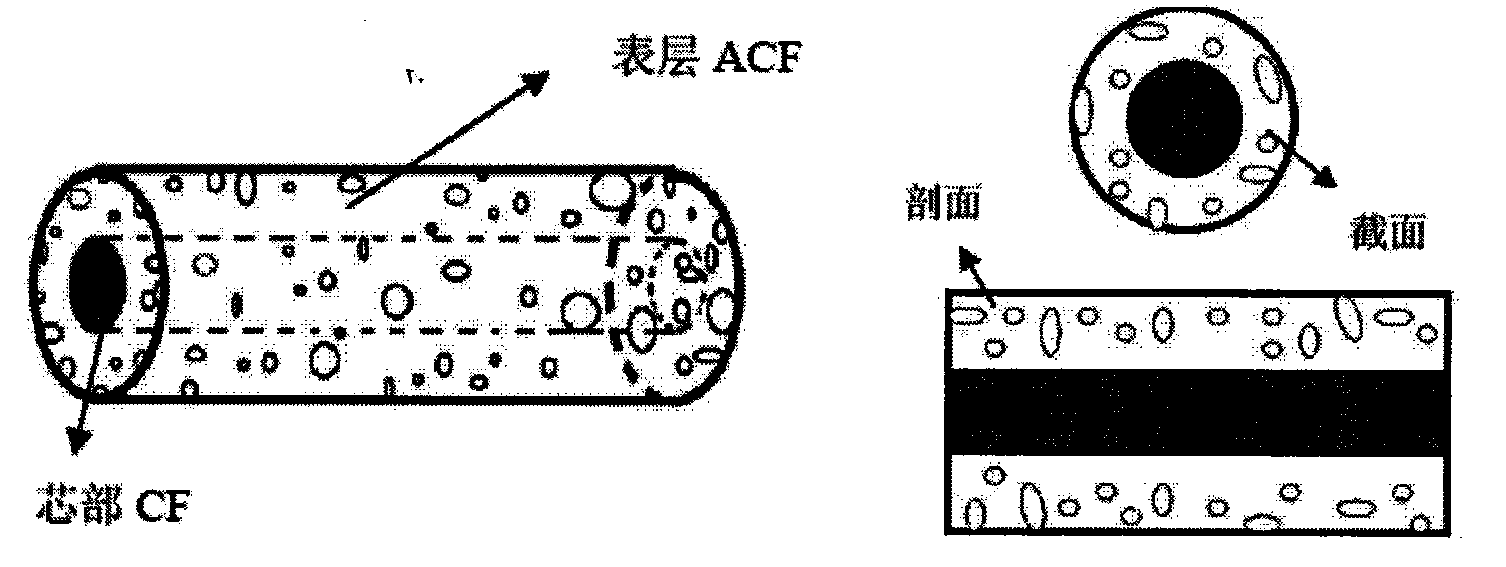

Porous activated carbon fiber adsorbing material of sheath-core composite structure and preparation thereof

A technology of porous activated carbon and adsorption materials, applied in the direction of alkali metal compounds, other chemical processes, alkali metal oxides/hydroxides, etc., can solve the problems affecting the range of use and service life of ACF, strength loss, etc., to achieve the benefit of load The effect of biological cells, prolonging the service life, and easy preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

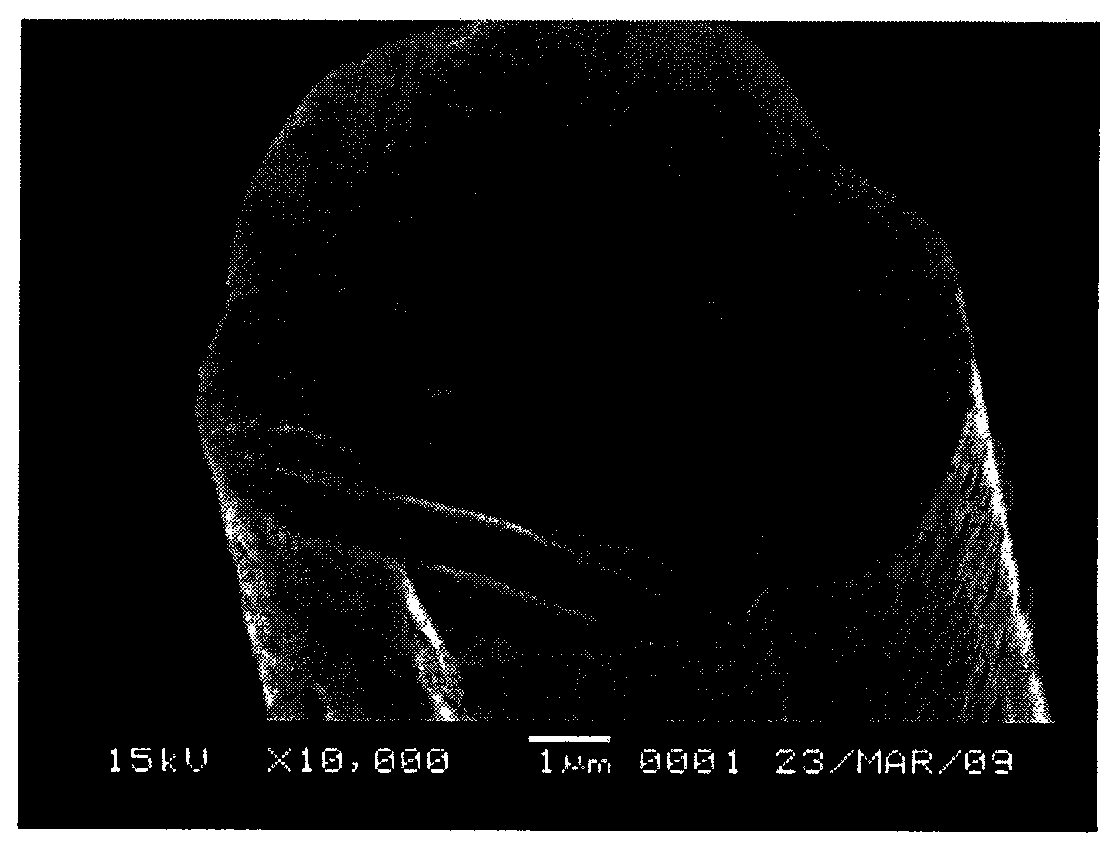

[0027] Viscose-based carbon fibers with a strength of 0.7GPa were placed in 0.1M Na 3 PO 4 The solution was left to stand for 3 hours, and then put into the activation furnace, and water vapor and N 2 , the temperature was raised to 1000°C at a rate of 20°C / min, and water vapor was passed through for constant temperature activation for 0.5 hours. After cooling down to 200°C, the inert gas and water vapor were turned off to prepare a porous activated carbon fiber adsorption material.

[0028] image 3 It is the electron microscope photo of the adsorption material of this embodiment, the pore size on the surface is 50nm2 / g.

Embodiment 2

[0030] Put viscose-based carbon fibers with a strength of 0.7GPa in 0.2M NaH 2 PO 4 Stand in the solution for 2 hours, then put it into the activation furnace, pass water vapor and N 2 , the temperature was raised to 1000°C at a rate of 10°C / min, and water vapor was passed through for constant temperature activation treatment for 1 hour. After cooling down to 200°C, the inert gas and water vapor were turned off to prepare a porous activated carbon fiber adsorption material.

[0031] Figure 4 It is the electron microscope photo of the adsorption material of this embodiment, the pore diameter on the surface is 100nm2 / g.

Embodiment 3

[0033] Viscose-based carbon fibers with a strength of 0.7GPa were placed in 0.1M Na 2 HPO 4 Stand in the solution for 4 hours, then put it into the activation furnace, pass water vapor and N 2 , the temperature was raised to 1000°C at a rate of 10°C / min, and water vapor was passed through for constant temperature activation for 0.5 hours. After cooling down to 200°C, the inert gas and water vapor were turned off to prepare a porous activated carbon fiber adsorption material.

[0034] Figure 5 It is the electron micrograph of the adsorption material of this embodiment, the pore diameter on the surface is 50nm2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com