Concrete admixture and a method for preparing the concrete admixture by calcining coal gangue

A technology for calcining coal gangue and concrete, which is applied in the directions of climate sustainability, sustainable waste treatment, solid waste management, etc., can solve the problems of low consumption, waste of resources, low utilization rate, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

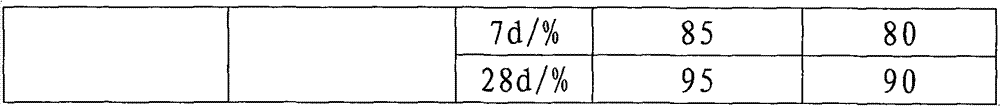

Embodiment 1

[0022] The equipment adopts GXDF-1 high-temperature flue gas fluidized furnace, and its commonly used coal-fired calorific value is about 5000kcal / kg. It was used for slag drying before, and then coal gangue was used as fuel, and coal gangue minerals were prepared while drying slag powder For composite materials, the calorific value of raw materials for configuration shall not be lower than 1600kcal / kg.

[0023] Take 80 parts of coal gangue with a calorific value of about 1300kcal / kg, 16 parts of secondary limestone powder, 2.5 parts of natural secondary gypsum and fluorite powder (CaF 2 content of more than 90%) 1.5 parts; the above materials are pulverized until the particle size is below 5mm and then uniformly mixed. Then it is mixed with standard coal with a calorific value of 6000kcal / kg at a ratio of 5:1, and the calorific value of the mixture is greater than 2000kcal / kg, which meets the calorific value requirements of fluidized fluidized furnace combustion. After mixin...

Embodiment 2

[0028] The equipment adopts the fluidized fluidized furnace provided by Hubei Huangshi Building Materials Equipment General Factory. Its common calorific value is about 5000kcal / kg high-calorific value coal. In order to reduce costs, low-calorific value coal gangue is used as fuel, and coal gangue mineral admixtures are produced at the same time. Raw materials prepared Calorific value not less than 1800kcal / kg.

[0029] Take 85 parts of coal gangue with a calorific value of about 1000kcal / kg, 12 parts of second-grade limestone powder, 2 parts of second-grade natural gypsum, and 1 part of fluorite; grind the above materials until the particle size is below 5mm and mix them uniformly to obtain raw material A. Raw material B selects standard coal with a calorific value of 6000kcal / kg.

[0030] Prepare raw material A and raw material B according to the mass ratio of 4:1, mix the raw materials evenly, place them in a fluidized furnace, control the temperature of the furnace at abou...

Embodiment 3

[0036] The equipment adopts ZDFR type high-temperature flue gas fluidized furnace, and its commonly used fuel is low calorific value coal (containing a large amount of coal gangue) of about 2000kcal / kg, and the calorific value of the raw materials configured for implementation is not less than 2000kcal / kg.

[0037] Preparation of raw material A: Take 70 parts of coal gangue, 25 parts of secondary limestone powder, 4 parts of secondary gypsum powder and 1 part of fluorite powder and mix them uniformly. Raw material B selects standard coal with a calorific value of 6000kcal / kg.

[0038] Prepare raw material A and raw material B according to the ratio of 8:1, mix the raw materials evenly, place them in a fluidized furnace, control the temperature of the furnace at about 900°C for calcination, adopt continuous calcination and intermittent slag removal, and slag discharge every 1-2 hours, naturally After cooling, the coal gangue mineral admixture is produced by grinding with a ball...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com