Lignin-based carbon material, preparation method thereof and application thereof in chromium adsorption

A technology of lignin-based and carbon materials, applied in the field of lignin-based carbon materials and their preparation, can solve the problems of high energy consumption, difficult to operate, difficult to realize industrialization, etc., and achieves low activation temperature, good adsorption effect and simple process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

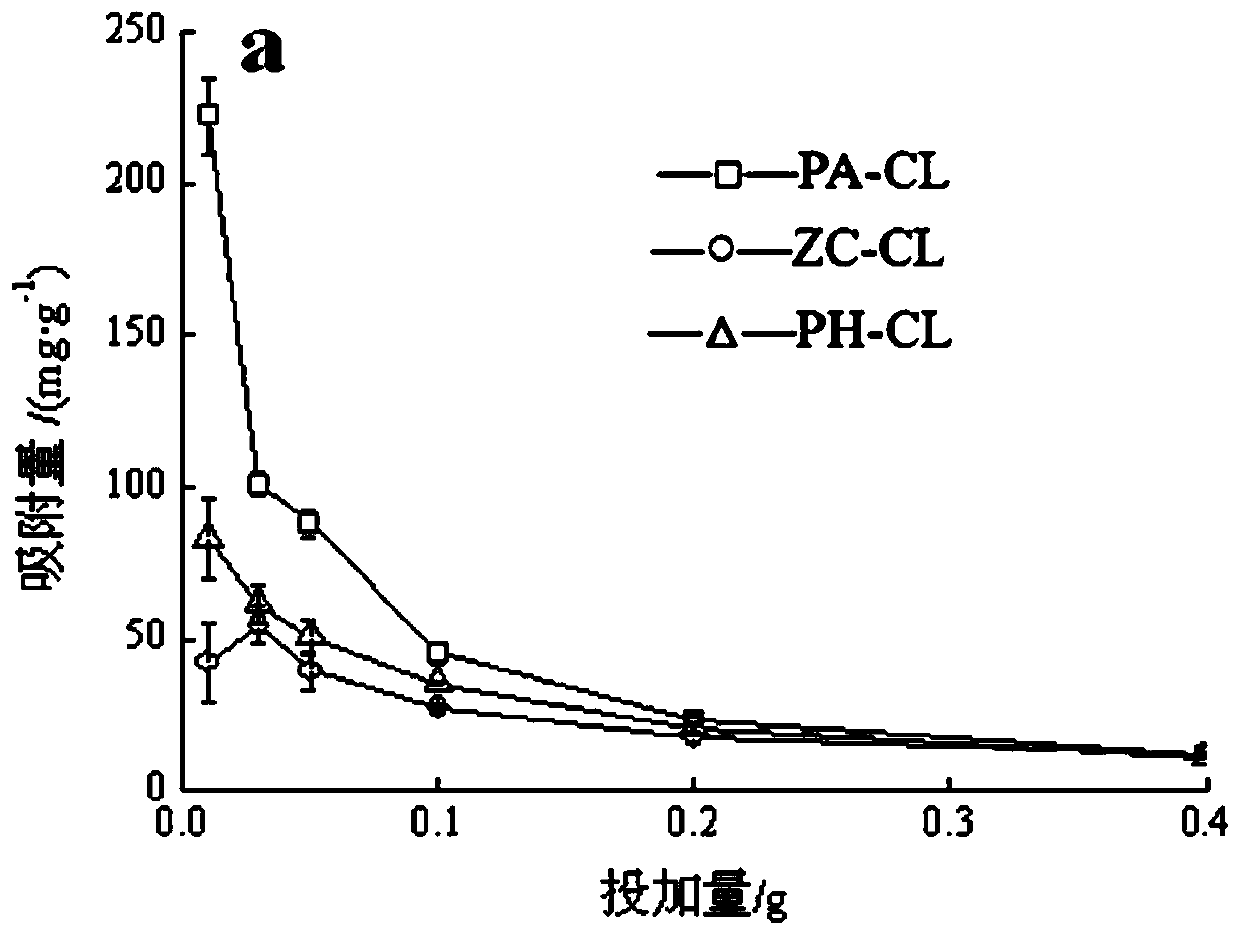

[0052] A preparation method for phosphoric acid-activated lignin-based carbon material (PA-CL), comprising the following steps:

[0053] Step 1, weigh 30g of dry lignin and place it in a 100mL reactor, add 90g of phosphoric acid (the impregnation ratio is 1:3) dropwise to the reactor at a rate of 60 drops / minute, stir evenly, then tighten the reactor, Put it in an oven at 140°C and react for 4 hours to obtain the reactant.

[0054] Step 2: Dry the reactant in an oven at 60°C for 5 hours, then put it into a crucible and put it in a muffle furnace, calcinate it at 400°C for 1 hour, wash it, and dry it again at 60°C for 5 hours to obtain phosphoric acid-activated lignin Carbon-based material (PA-CL), stored in a desiccator, for later use.

Embodiment 2

[0056] A preparation method of potassium hydroxide activated lignin-based carbon material (PH-CL), comprising the following steps:

[0057] Step 1, weigh 30g of lignin and put it in the reaction kettle, add 90g of potassium hydroxide solution with a mass fraction of 20%, make the impregnation ratio of the material 1:3, stir evenly, tighten the reaction kettle, and put it into an 80°C In the oven, react for 4h to obtain the reactant.

[0058] Step 2, slowly drop the reactant solution in the reactor into acidic water (pH value 2.0) twice the volume of the potassium hydroxide solution, so that the lignin precipitates out, and after filtering, put the precipitated lignin in an oven at 70°C Then put it into a crucible, place it in a muffle furnace at 800°C for 1h, wash it, and dry it at 65°C for 4h to obtain a potassium hydroxide (KOH)-activated lignin-based carbon material (PH-CL). Store in a desiccator for later use.

Embodiment 3

[0060] A preparation method for zinc chloride activated lignin-based carbon material, comprising the following steps:

[0061] Step 1, using ZnCl 2 Activation of industrial lignin, 30g lignin is placed in the reaction kettle, adding mass fraction is 40% ZnCl 2 Solution 90g, so that the material impregnation ratio is 1:3, after stirring evenly, place the reaction kettle in an oven at 120°C for 4 hours to react to obtain the reactant.

[0062] Step 2, drying the reactant at 70°C for 4h, calcining in a muffle furnace at 600°C for 1h, washing, and drying at 70°C for 4h to obtain ZnCl 2 The activated lignin-based carbon material (ZC-CL) was stored in a desiccator for future use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com