Preparation method of textile electrode material and textile electrode material

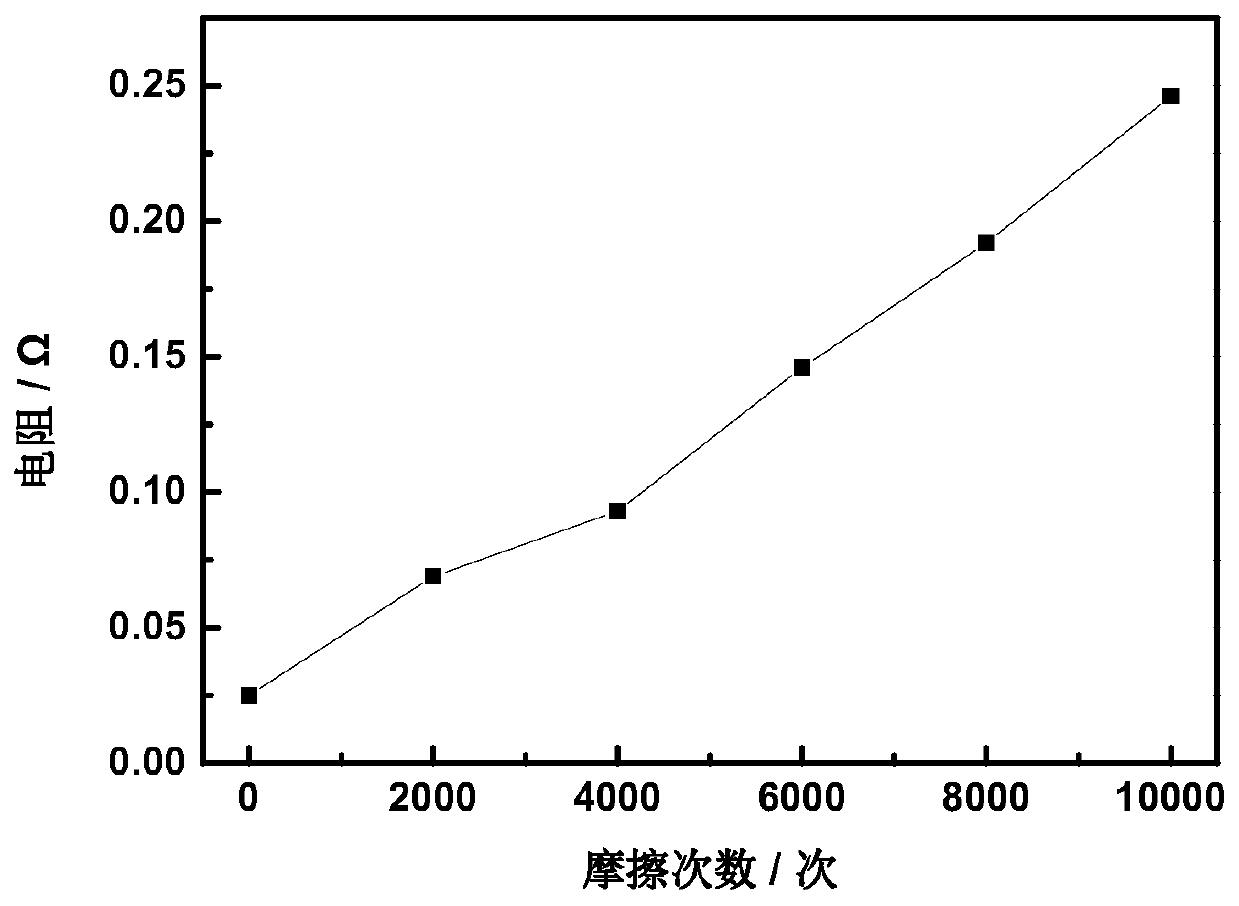

A technology of textile electrodes and fiber materials, which is applied in the field of preparation of textile electrode materials, can solve the problems of large electrode impedance, easy to fall off, and poor electrode durability, and achieve the effects of improving corrosion resistance, avoiding complex processes, and excellent interface properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

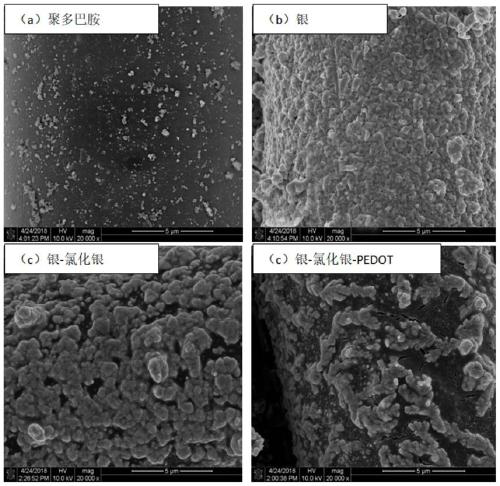

[0050] A kind of preparation method of textile electrode material, concrete steps are as follows:

[0051] (1) Cotton fiber fabric (fiber average diameter is 12um, average length is 32mm, tissue structure is plain weave fabric, unit area weight is 120g / m 2 ) after soaping treatment, soak in dopamine hydrochloride solution with a concentration of 50g / L and a pH value of 8.6 at room temperature, with a bath ratio of 1:40, and vibrate during the soaking process at a frequency of 45 times / min , the soaking time is 24h; and in the soaking process, 10% dopamine hydrochloride solution of the total volume of solid and liquid is added every 2h to obtain polydopamine-coated fabrics;

[0052] (2) Configure 25g / L silver nitrate solution, and add 2% dilute ammonia water drop by drop until the solution precipitates and becomes clear. Soak the polydopamine-coated fabric in the silver ammonia solution for 40min at room temperature. Vibrate at a frequency of 45 times / min, then add a glucose s...

Embodiment 2

[0057] A kind of preparation method of textile electrode material, concrete steps are as follows:

[0058] (1) the flax fiber fabric (the average fiber diameter is 14um, the average length is 22mm, the organizational structure is a plain weave fabric, and the weight per unit area is 160g / m 2 ) after soaping treatment, soak in dopamine hydrochloride solution with a concentration of 60g / L and a pH value of 8.5 at room temperature, and shake during the soaking process with a shaking frequency of 40 times / min and a bath ratio of 1:35 , the soaking time is 18h; and in the soaking process, 8% dopamine hydrochloride solution of the total volume of solid and liquid is added every 1.5h to obtain polydopamine-coated fabrics;

[0059] (2) Configure 20g / L silver nitrate solution, and add 2% dilute ammonia water drop by drop until the solution precipitates and becomes clear. Soak the polydopamine-coated fabric in the silver-ammonia solution at room temperature for 45 minutes. Vibrate at a...

Embodiment 3

[0064] A kind of preparation method of textile electrode material, concrete steps are as follows:

[0065] (1) Wool fiber fabric (the average fiber diameter is 20um, the average length is 55mm, the tissue structure is a plain weave fabric, and the weight per unit area is 180g / m 2 ) after washing with water, soak in dopamine hydrochloride solution with a concentration of 70g / L and a pH value of 8.0 at room temperature. The time is 15 hours; and 6% dopamine hydrochloride solution of the total volume of solid and liquid is added every 1 hour during the soaking process to obtain polydopamine-coated fabrics;

[0066] (2) Configure 24g / L silver nitrate solution, and add 2.5% dilute ammonia water drop by drop until the solution precipitates and becomes clear. Soak the polydopamine-coated fabric in the silver-ammonia solution at room temperature for 35 minutes. Vibrate at a frequency of 35 times / min, then add a glucose solution with a concentration of 49g / L, and keep shaking for 95 m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

| impedance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com