Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

33 results about "Textile electrodes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

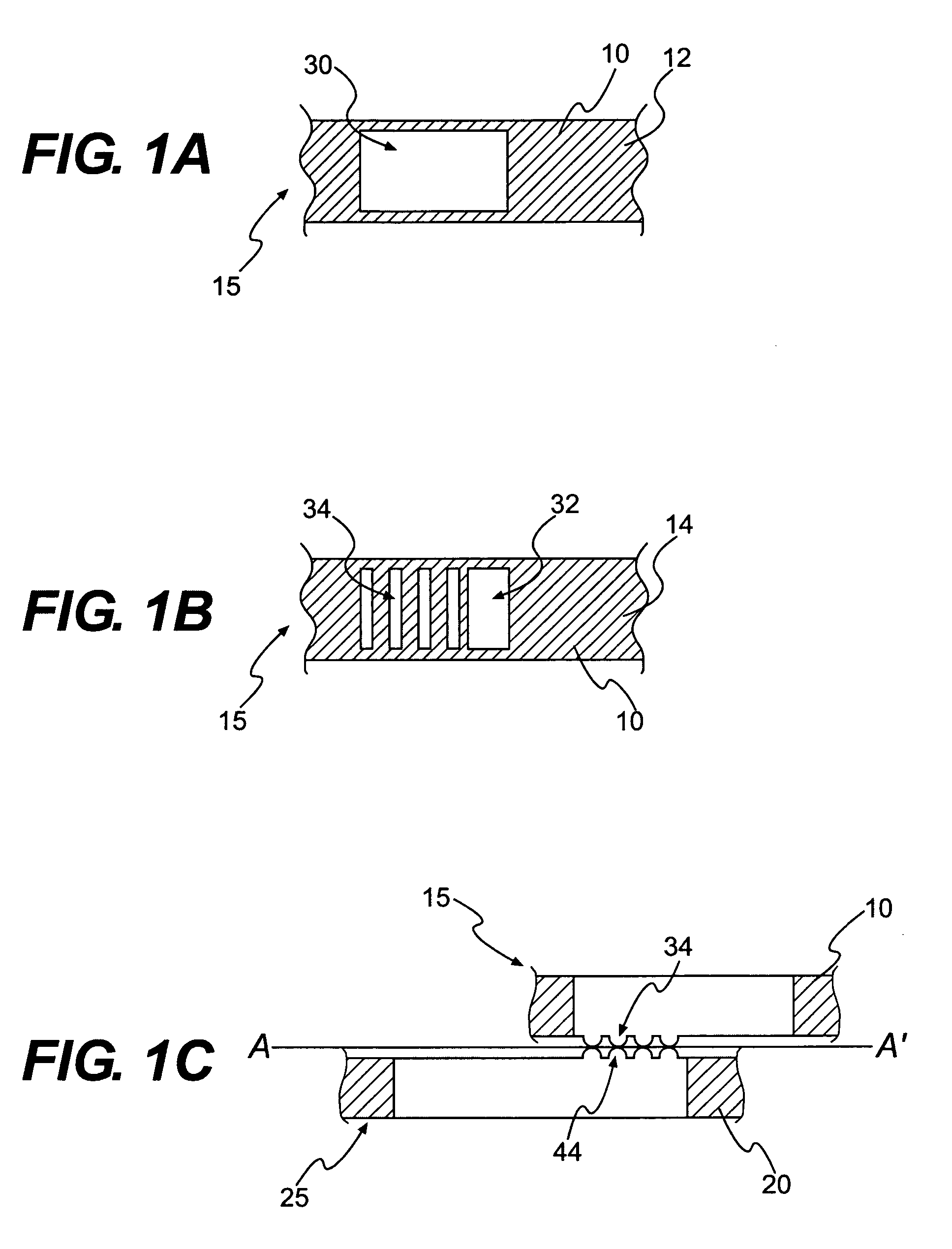

Textile-based electrode

Textile-based electrodes include a fabric portion having stretch-recovery non-conductive yarns and an electrically conductive region having stretch-recovery electrically conductive yarn filaments. The electrodes can further include float yarns and can be configured in a textured or ribbed construction. When incorporated into a garment, the electrodes can be used to monitor biophysical characteristics, such as the garment wearer's heart rate.

Owner:ADIDAS +1

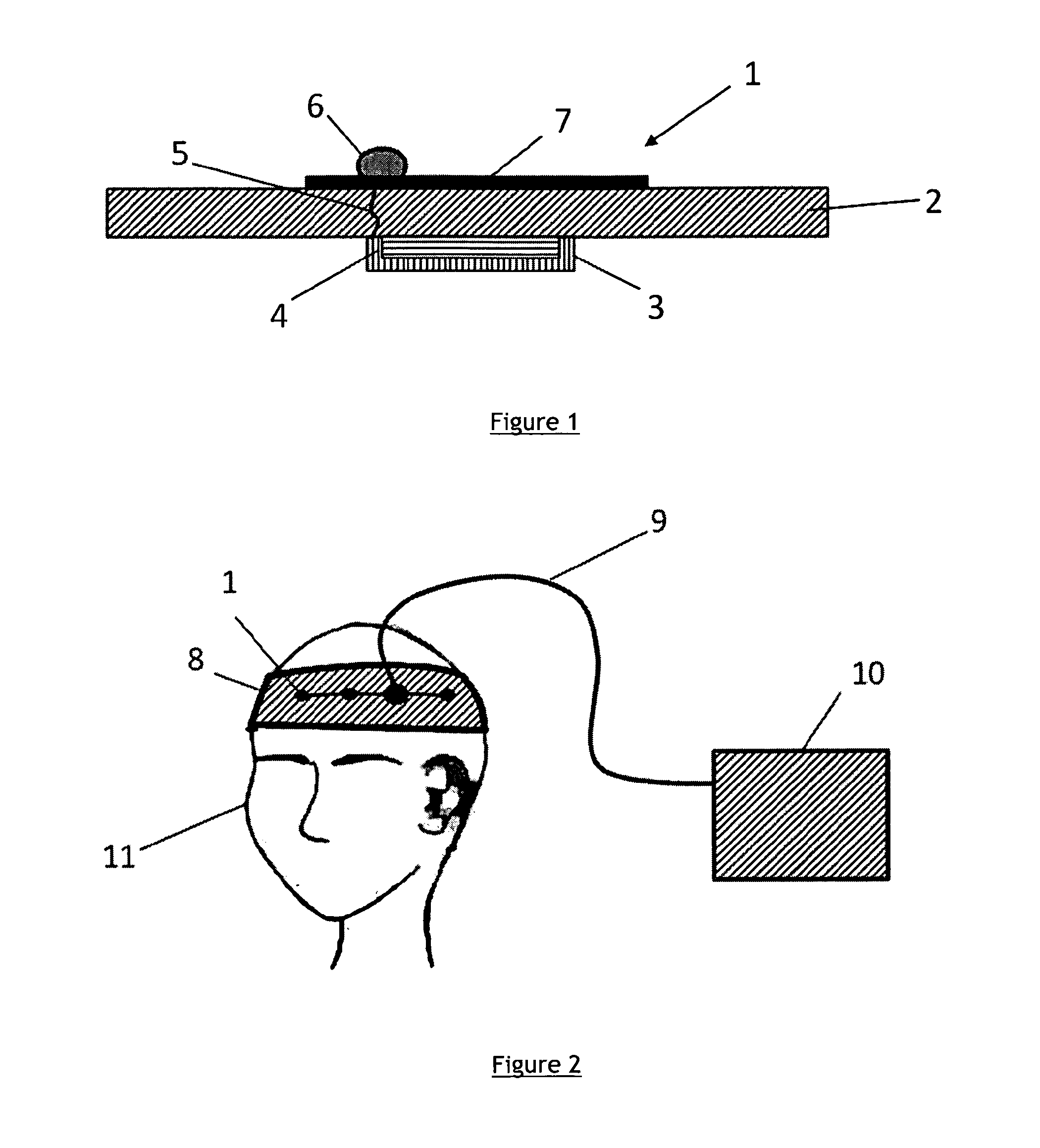

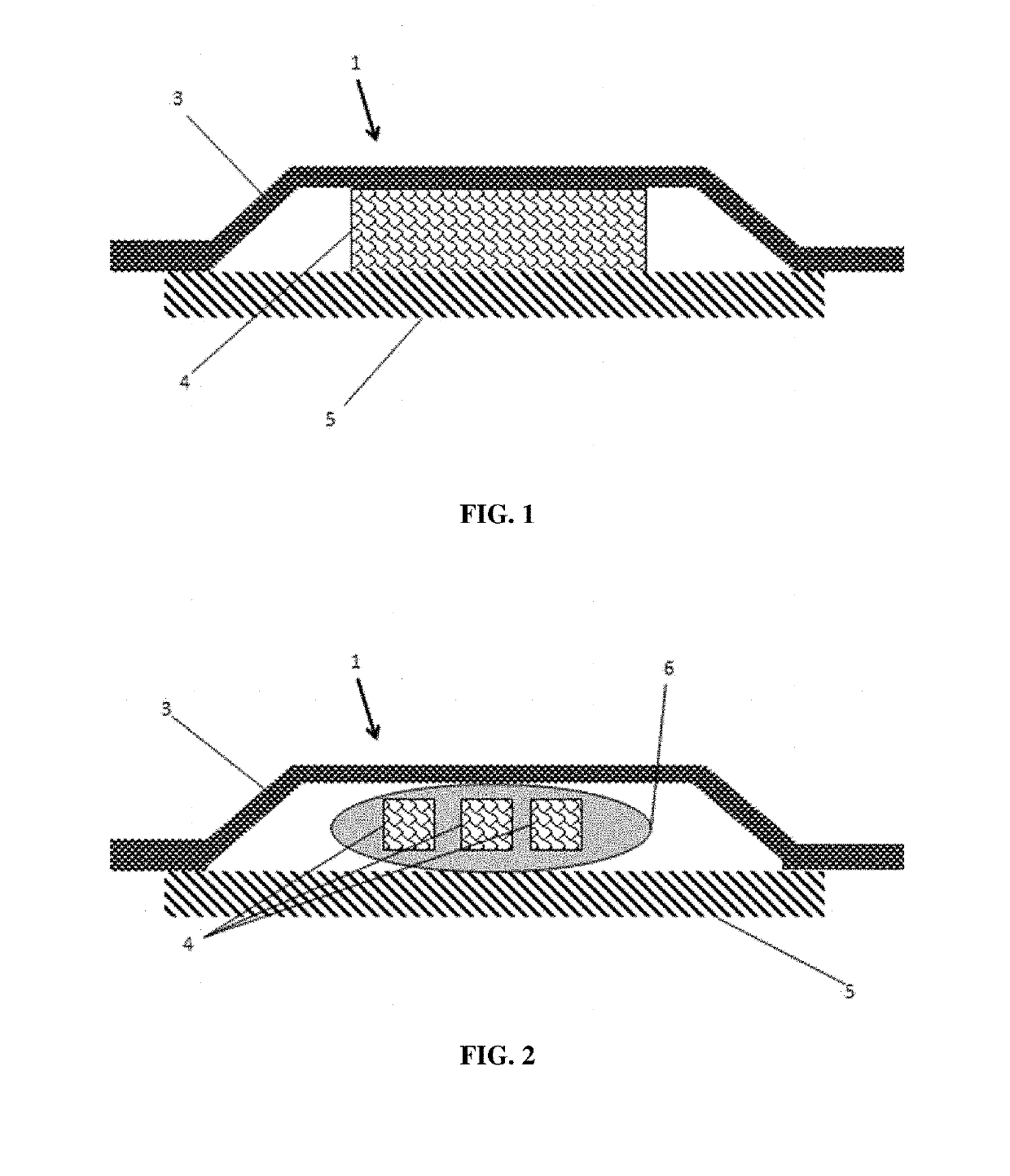

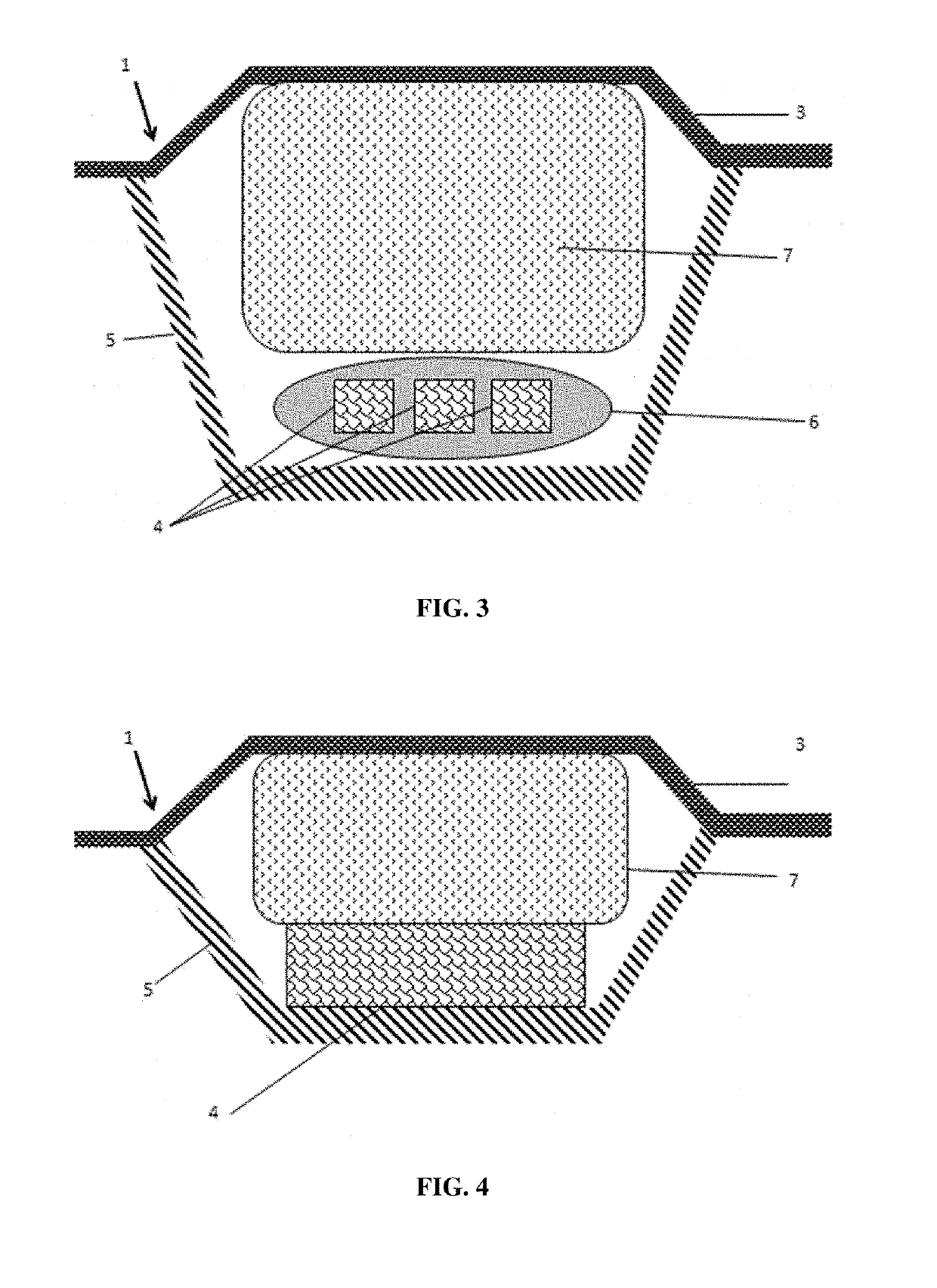

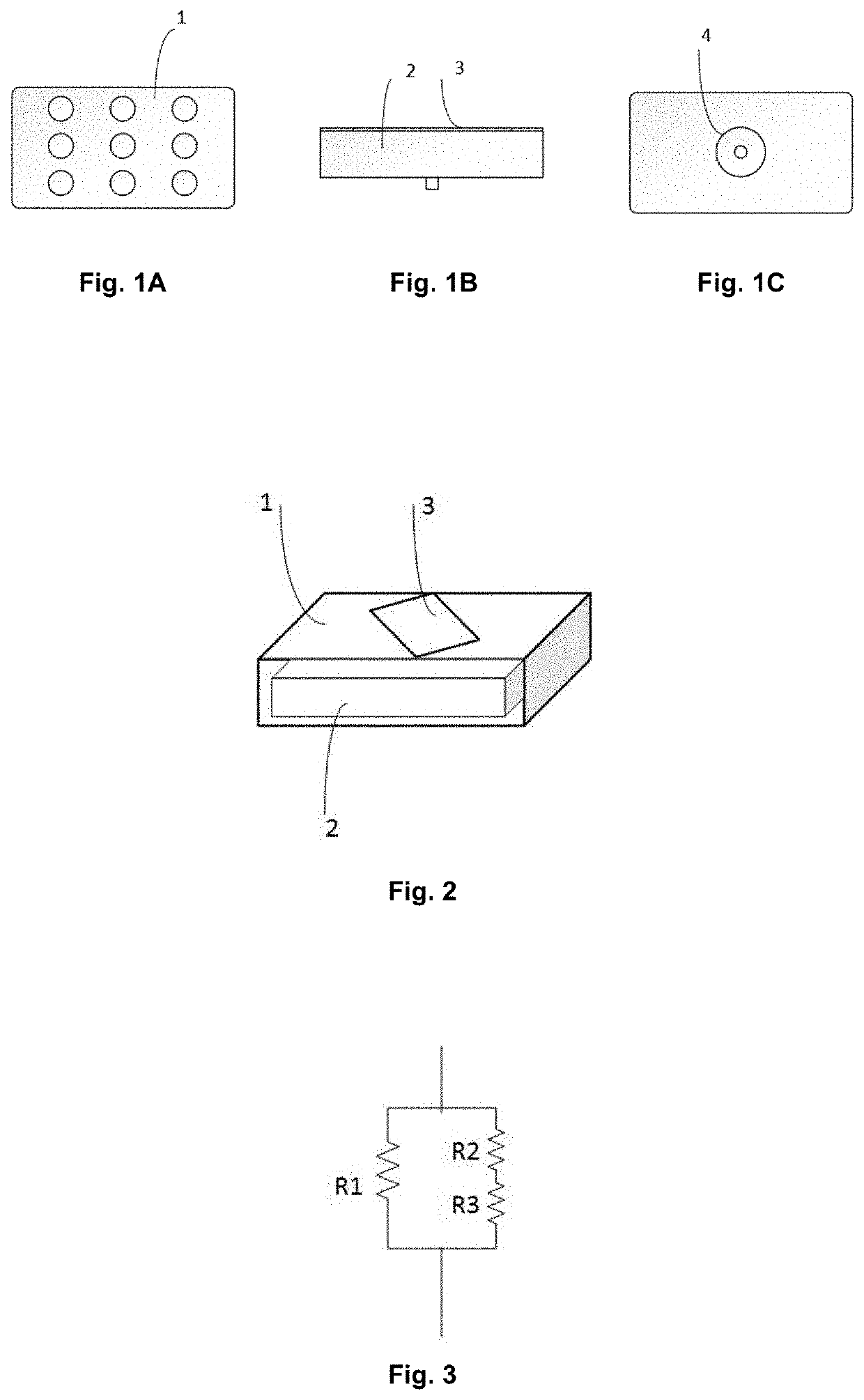

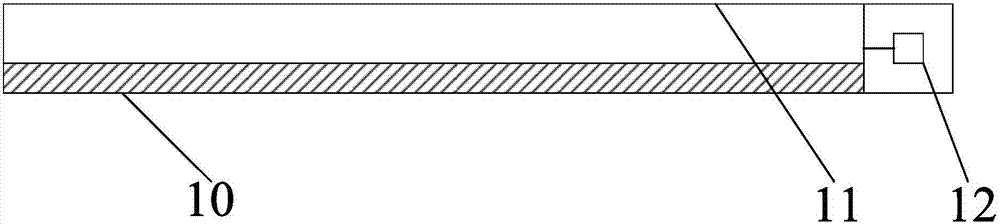

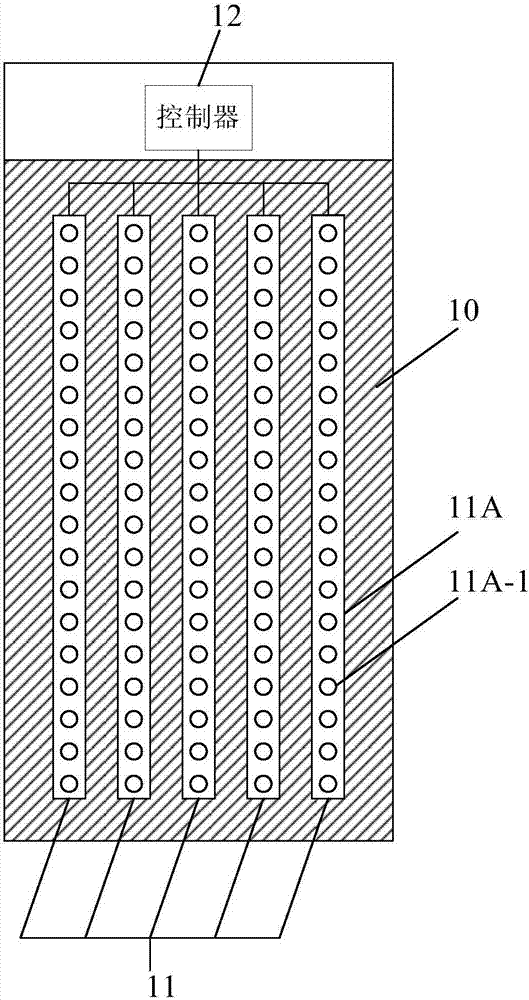

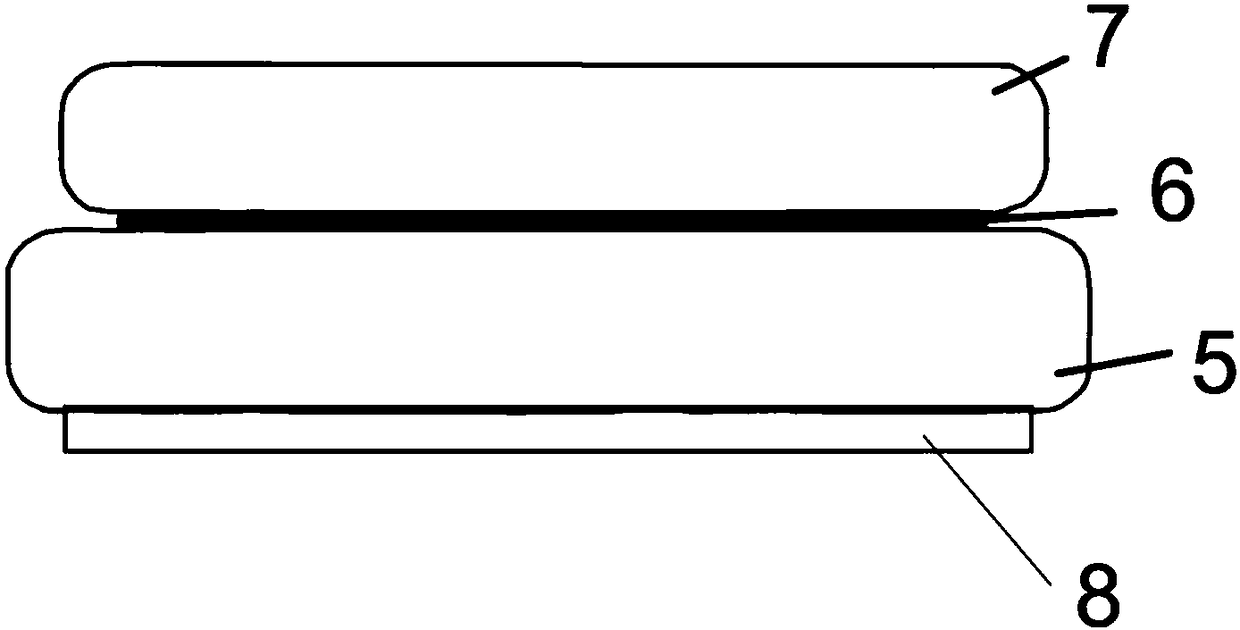

Textile Electrode

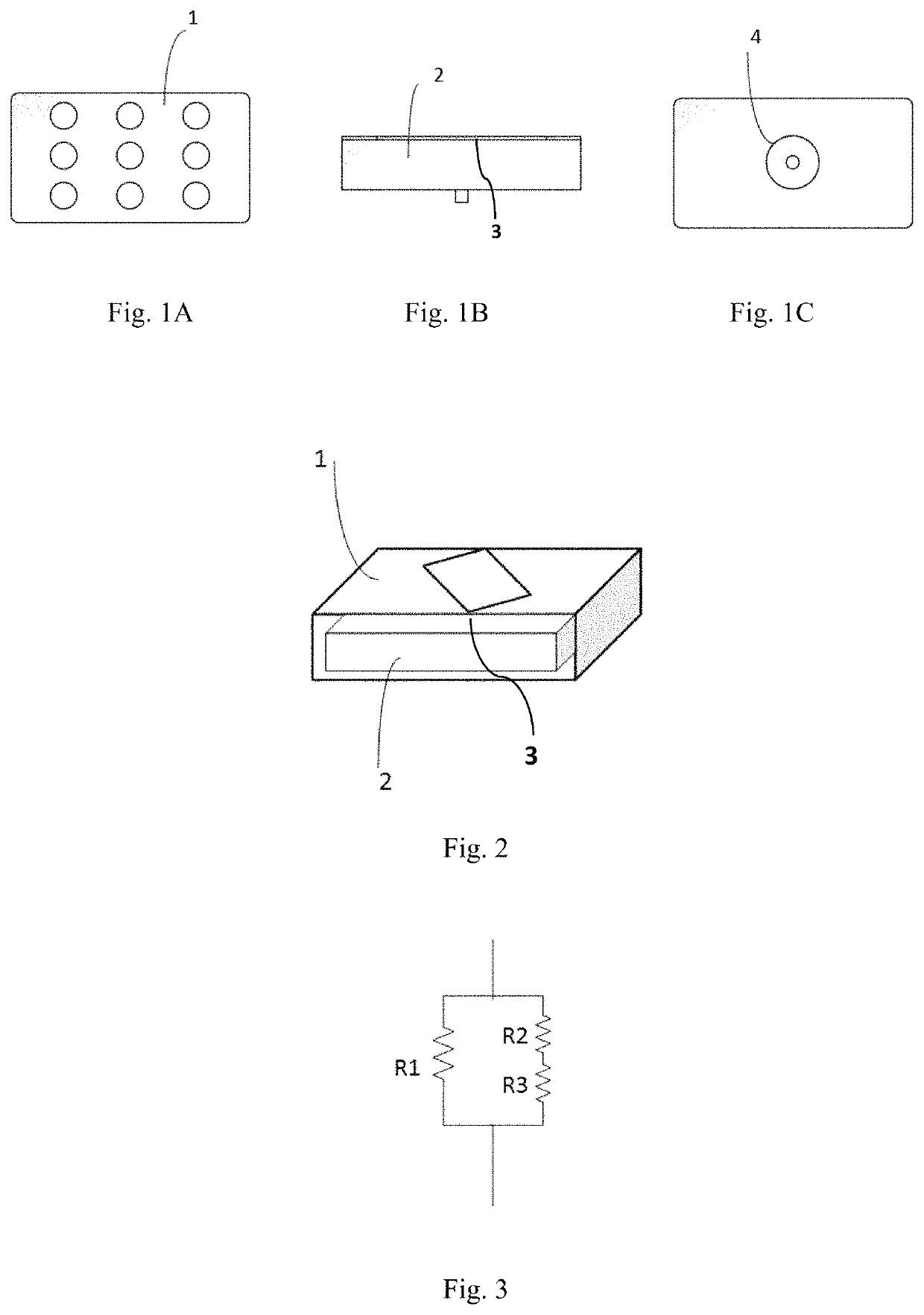

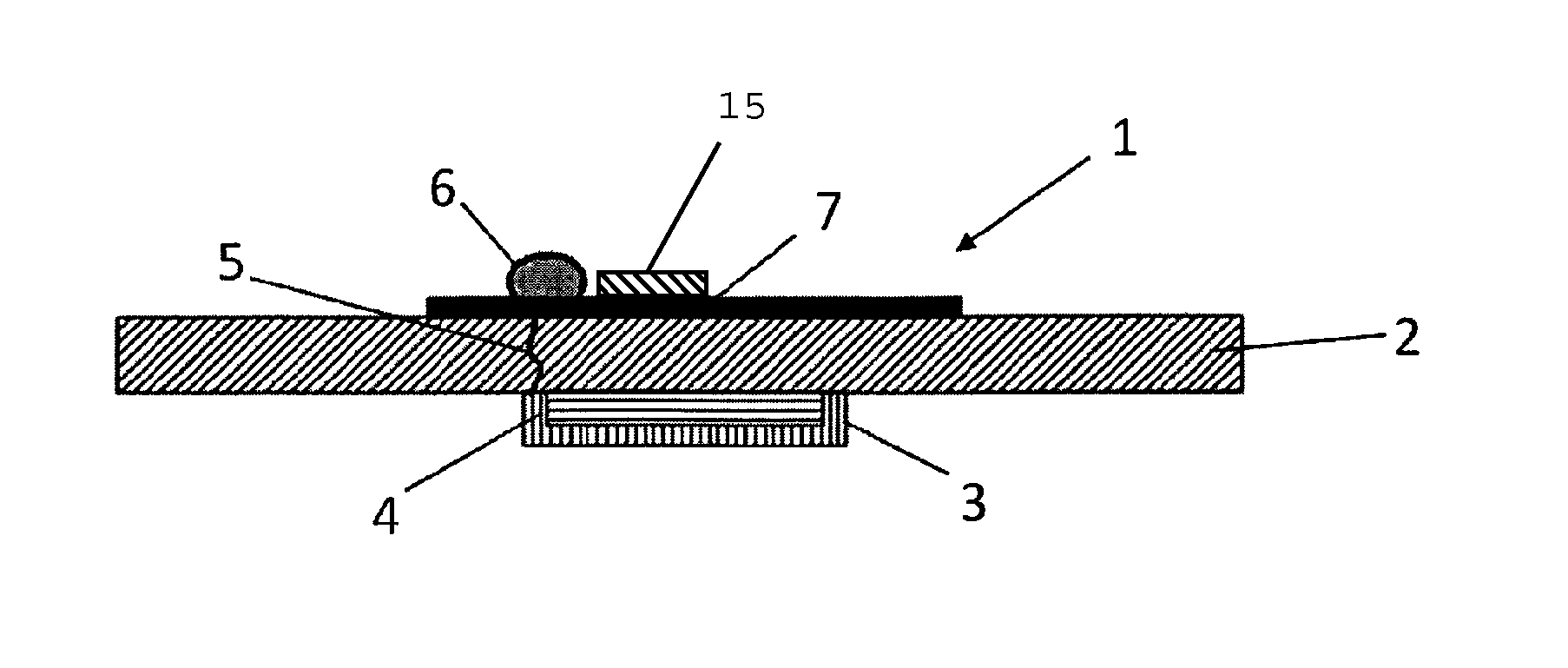

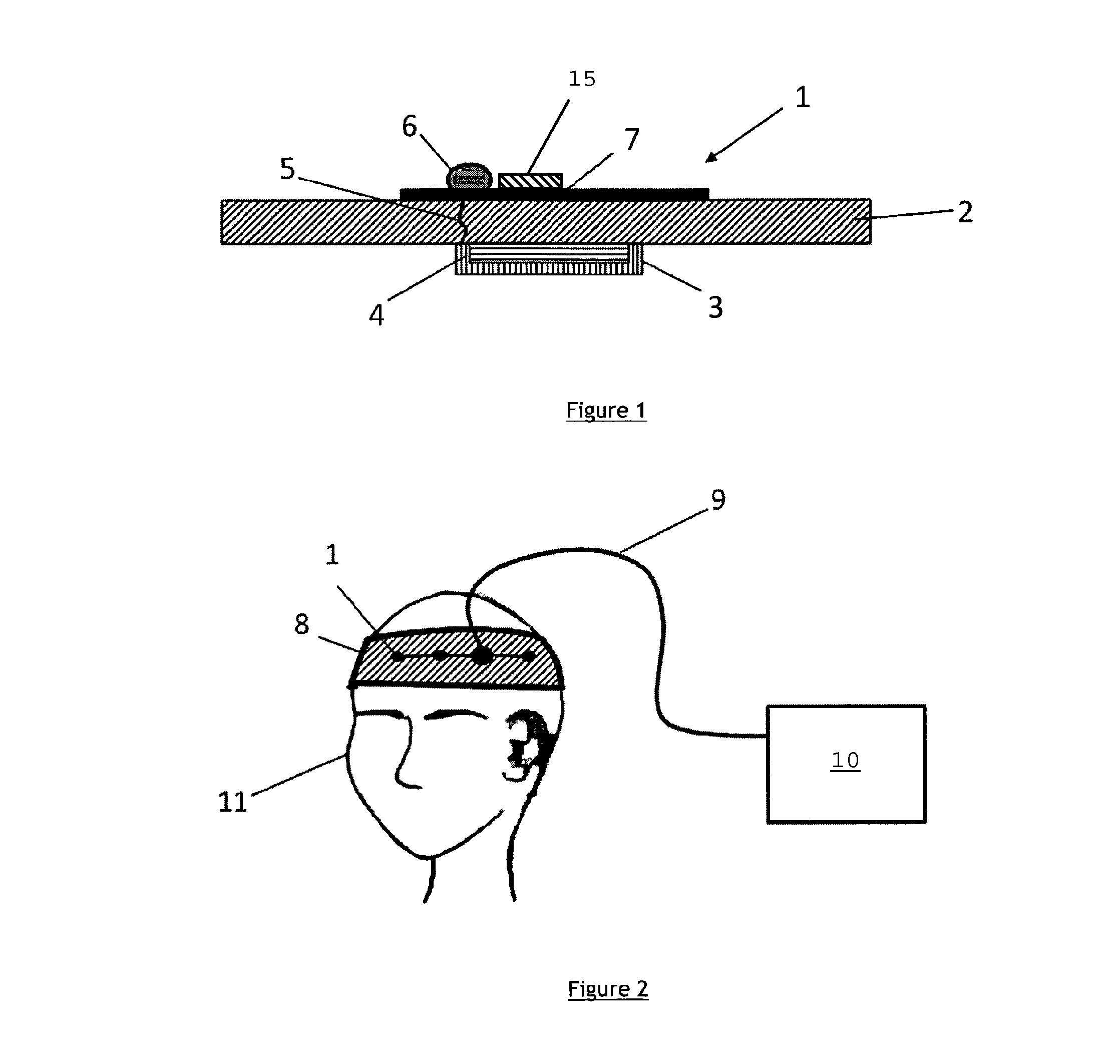

The present invention is related to a textile electrode (1) for measuring an electrical signal from a body part, said electrode comprising, successively from the side to be applied on the body part to the outside: a conductive textile contact (3) to be applied to said body part; a textile support (2) for supporting said textile contact (3); a vapour barrier sheet material (7) able to reduce, in use, evaporation of liquid from said textile electrode (1).

Owner:CECOTEPE ASBL

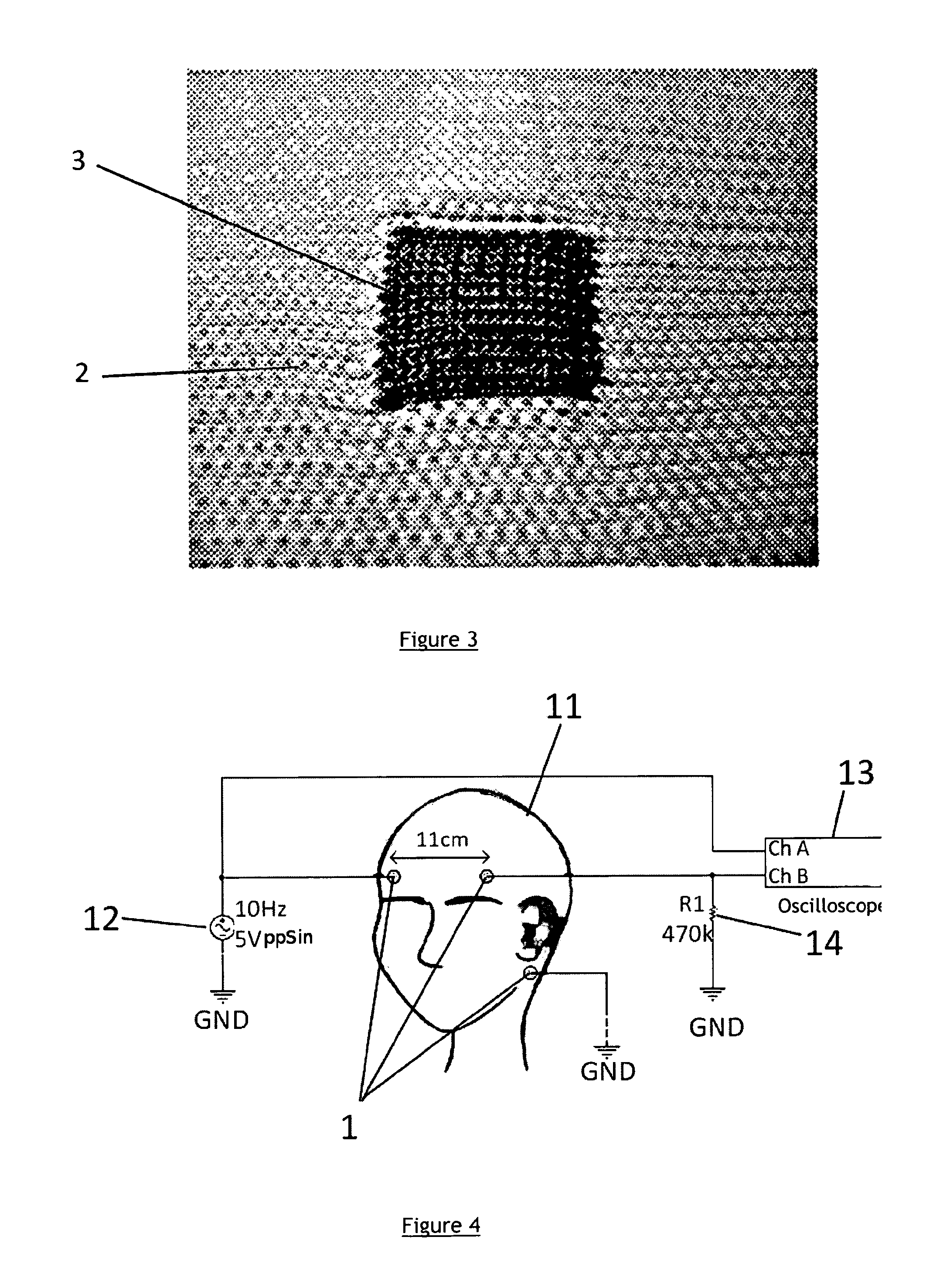

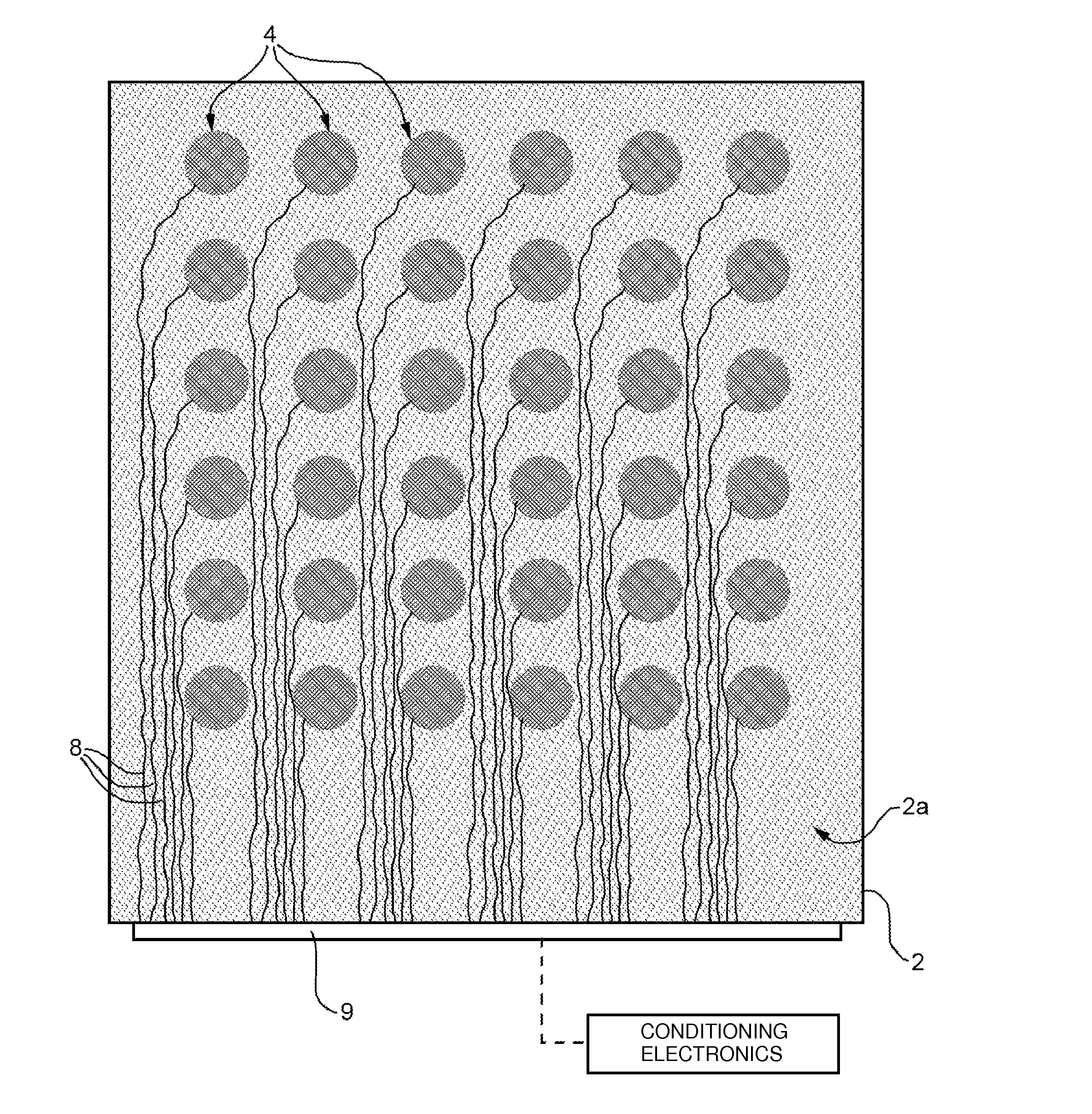

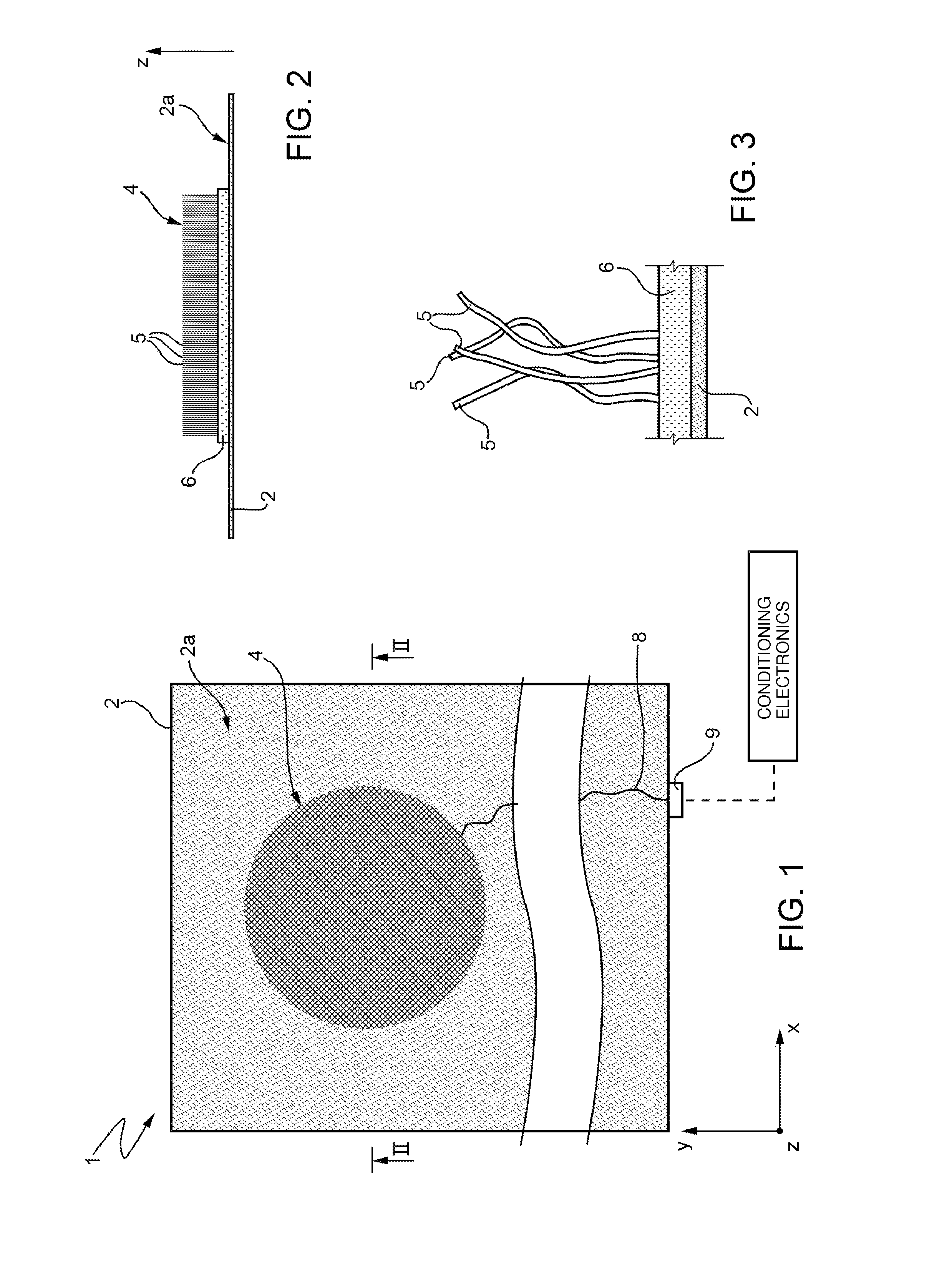

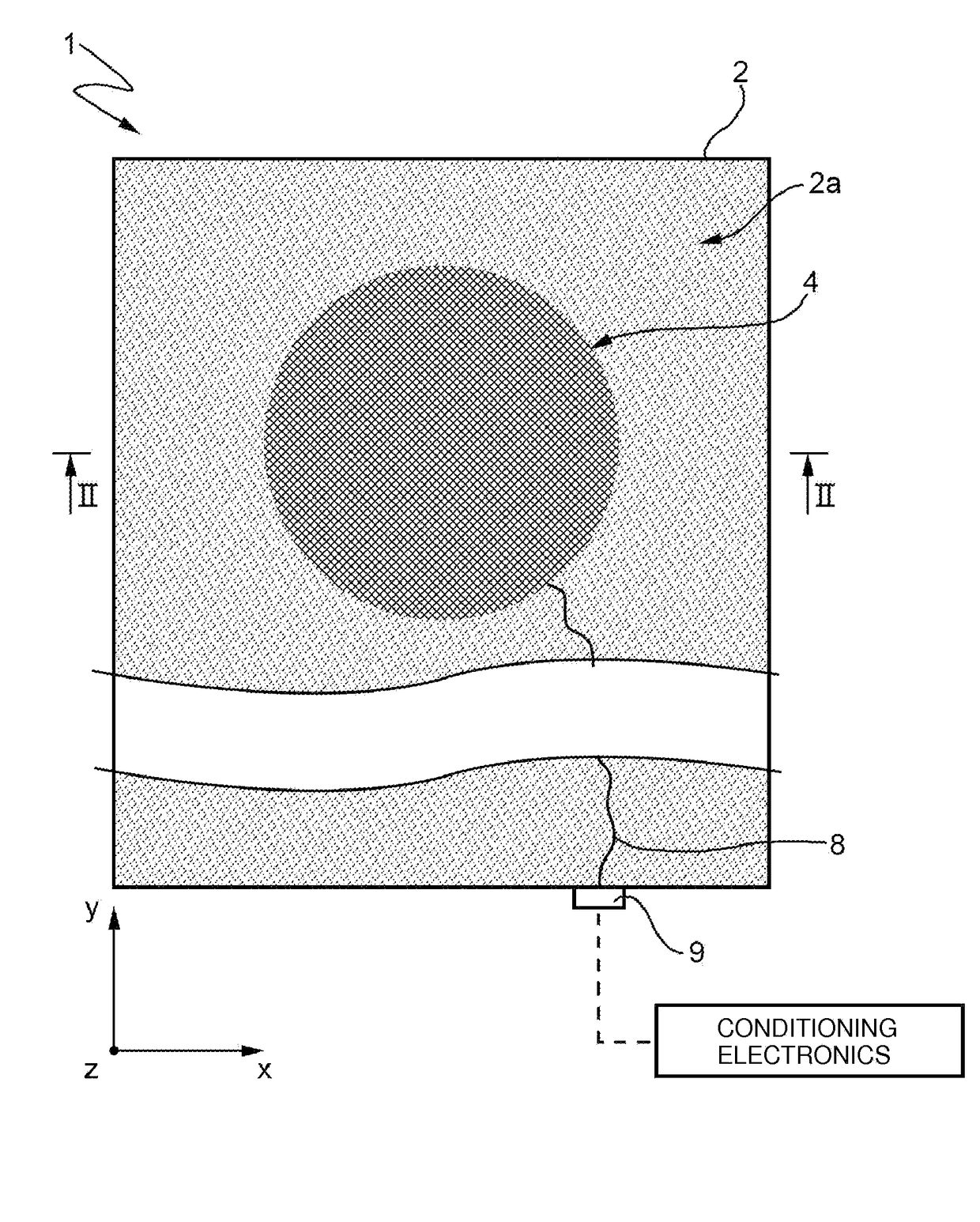

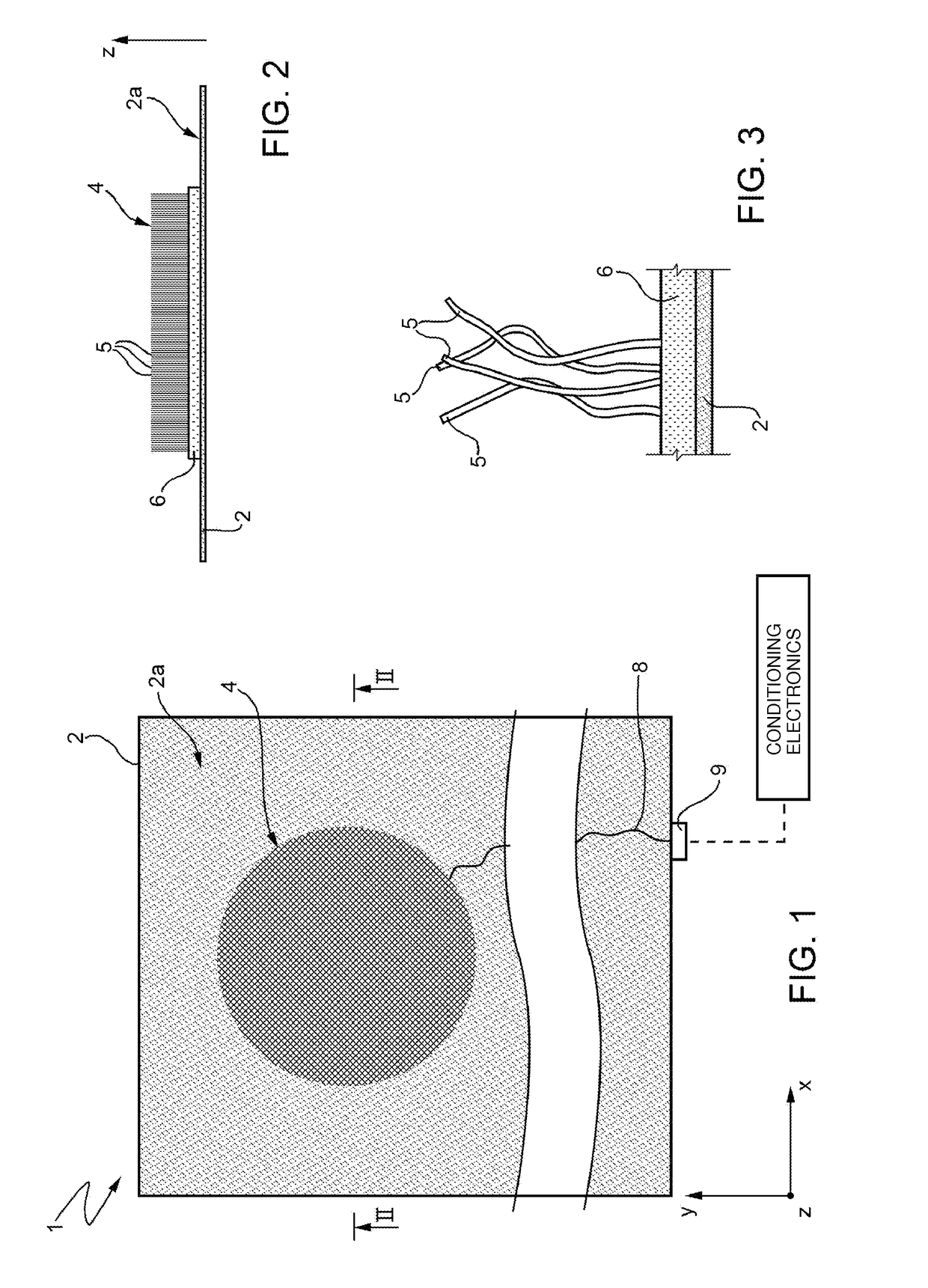

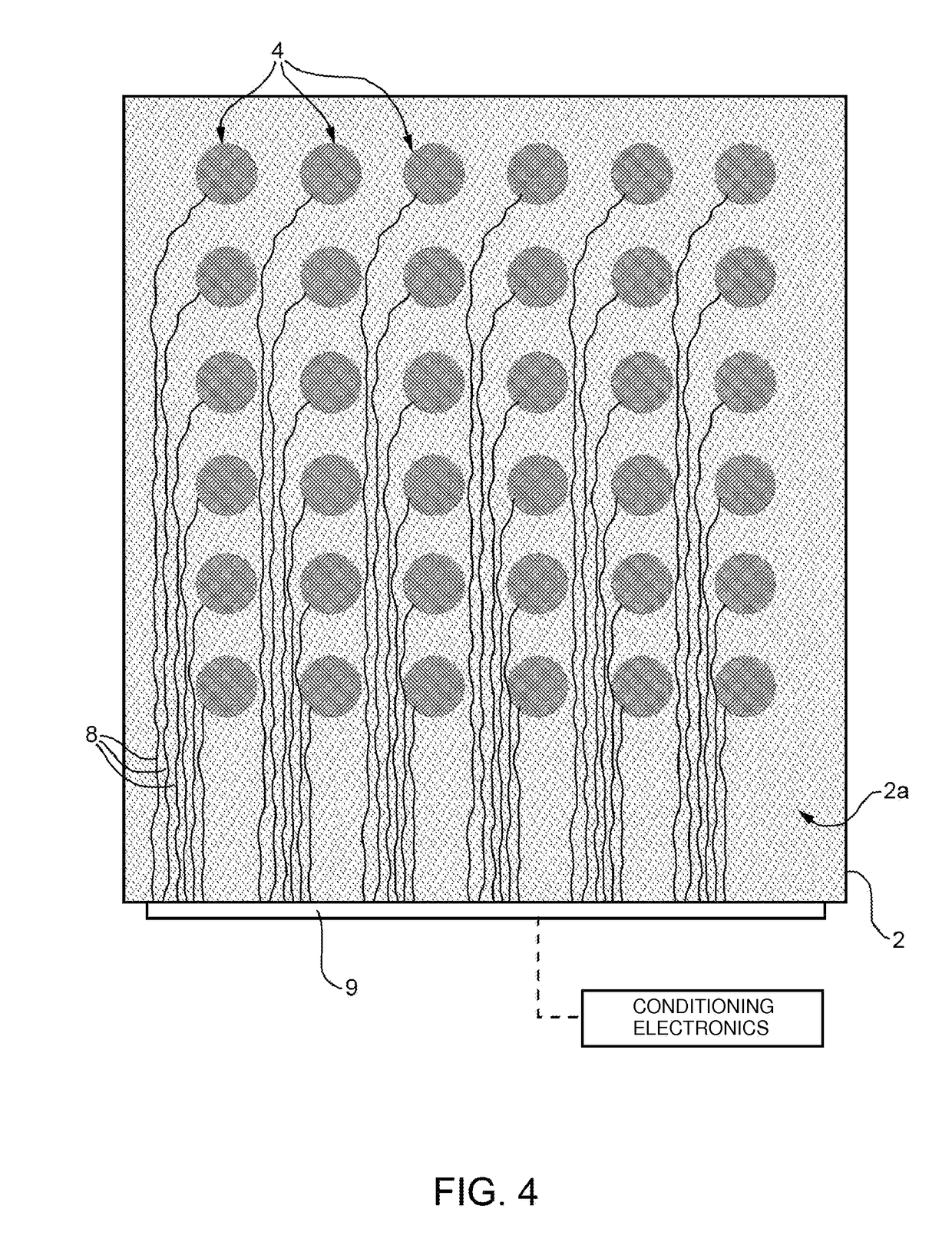

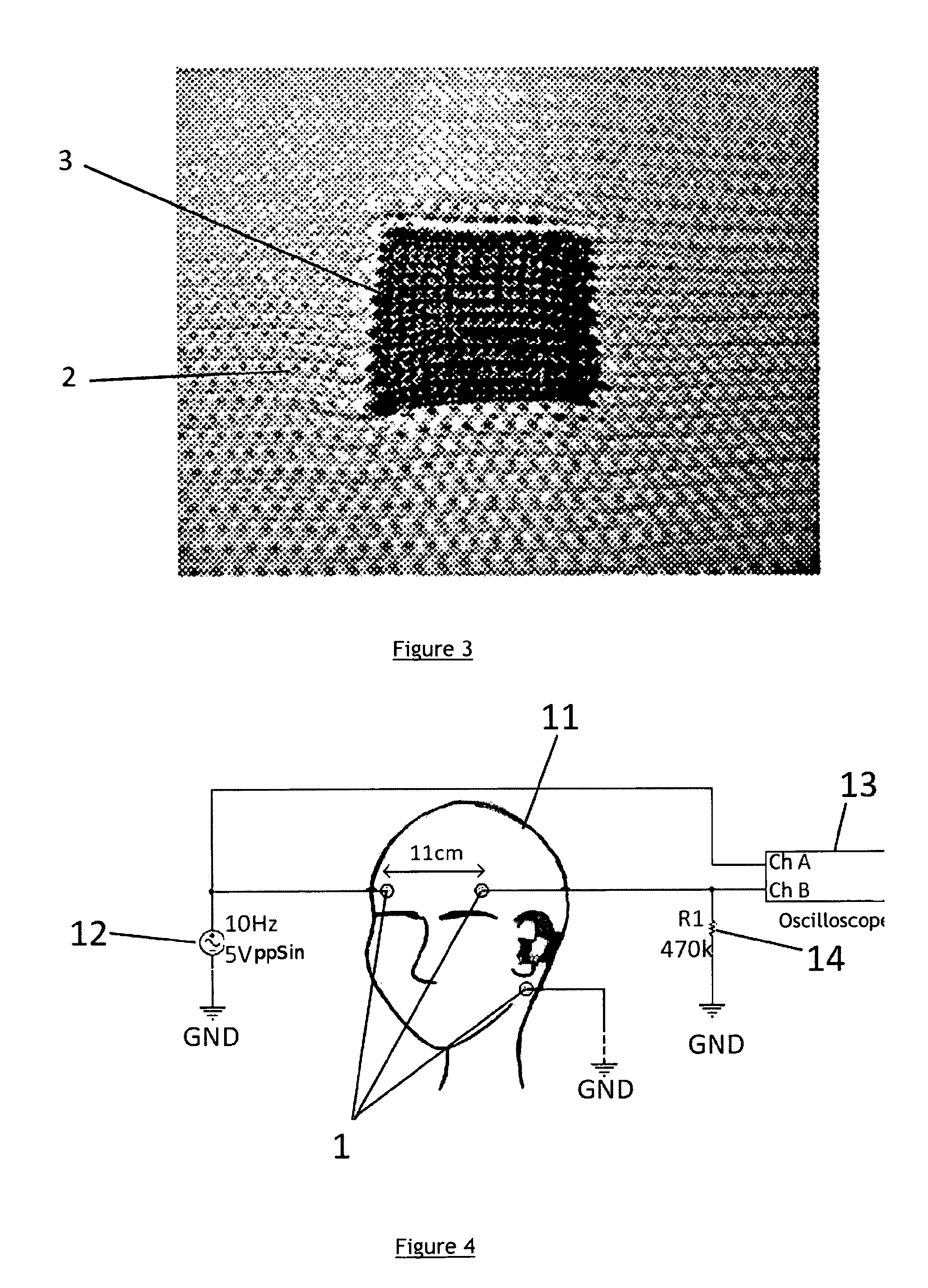

Textile electrode device for acquisition of electrophysiological signals from the skin and manufacturing process thereof

A textile electrode device, for detection of electrophysiological signals from the skin of a subject, having: a substrate designed to be positioned on the skin; at least a first detection electrode arranged on the substrate; and at least a first conducting element, carried by the substrate and electrically connected to the first detection electrode. The first detection electrode has a plurality of textile fibres, including conductive fibres and, optionally, fibres of a super-absorbent material, arranged in a direction substantially orthogonal to an upper surface of the substrate and reciprocally in contact with each other, so as to ensure uniform electrical contact over the entire first detection electrode. In particular, the first detection electrode is obtained by means of the flocking technique.

Owner:POLITECNICO DI TORINO

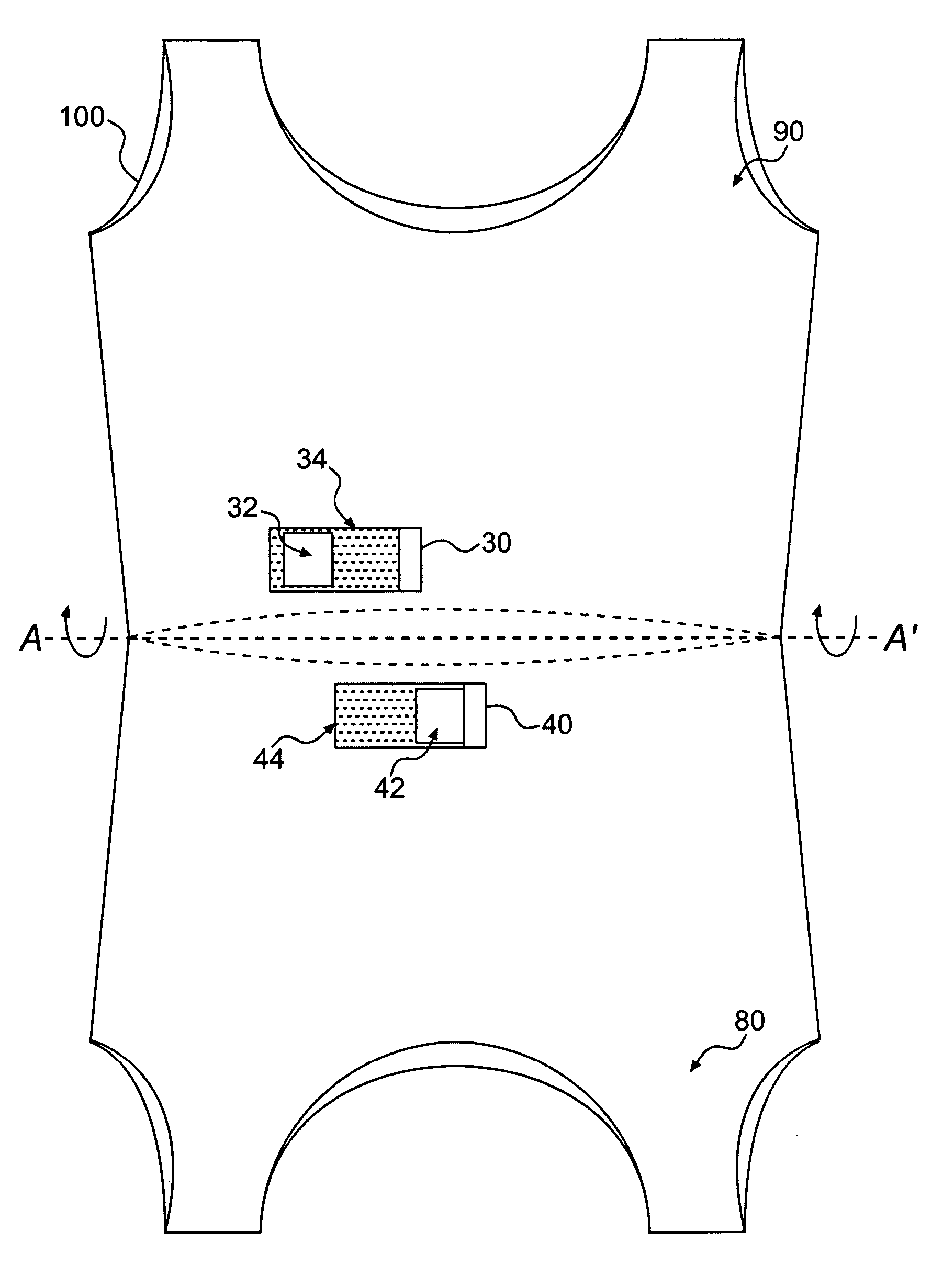

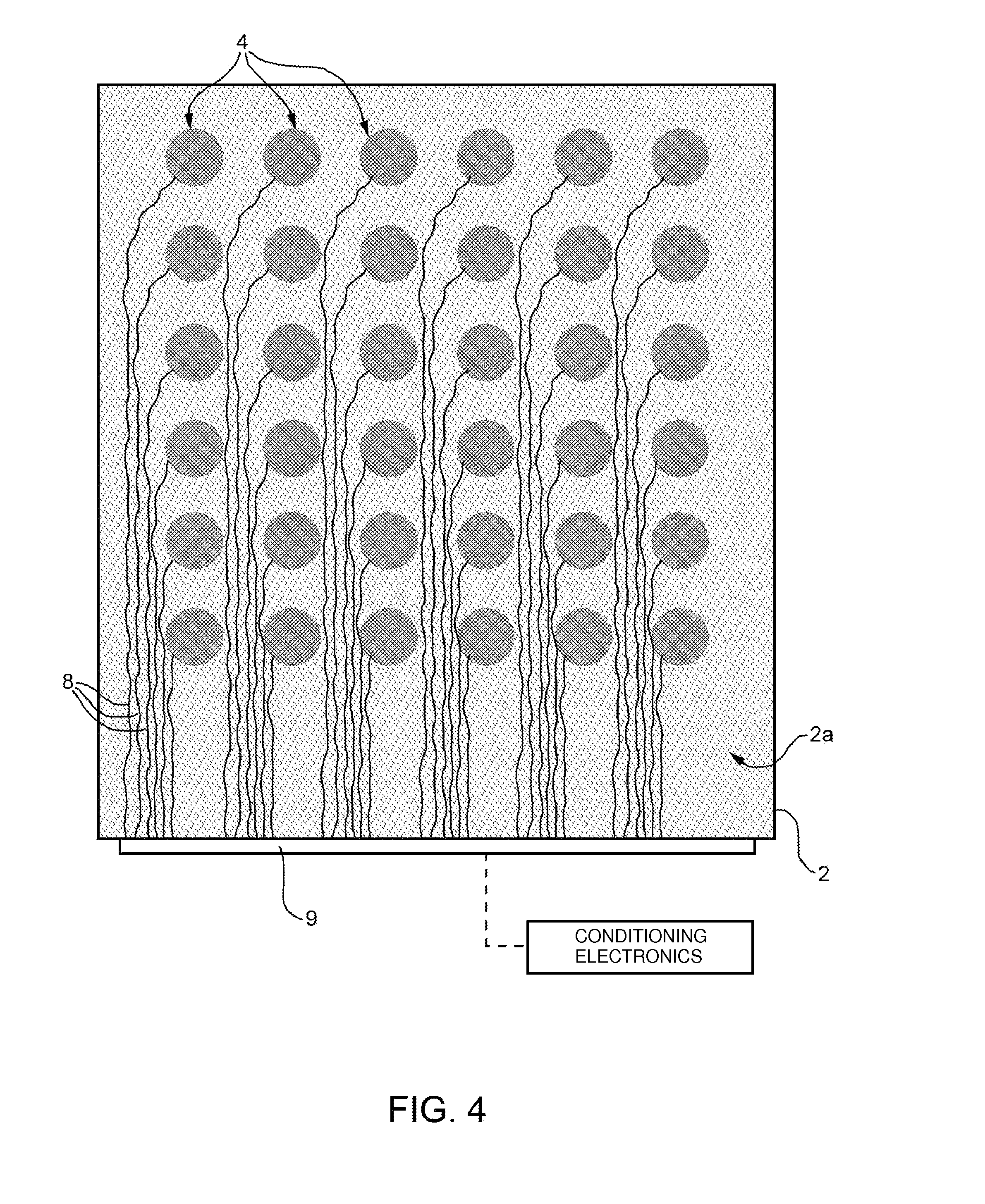

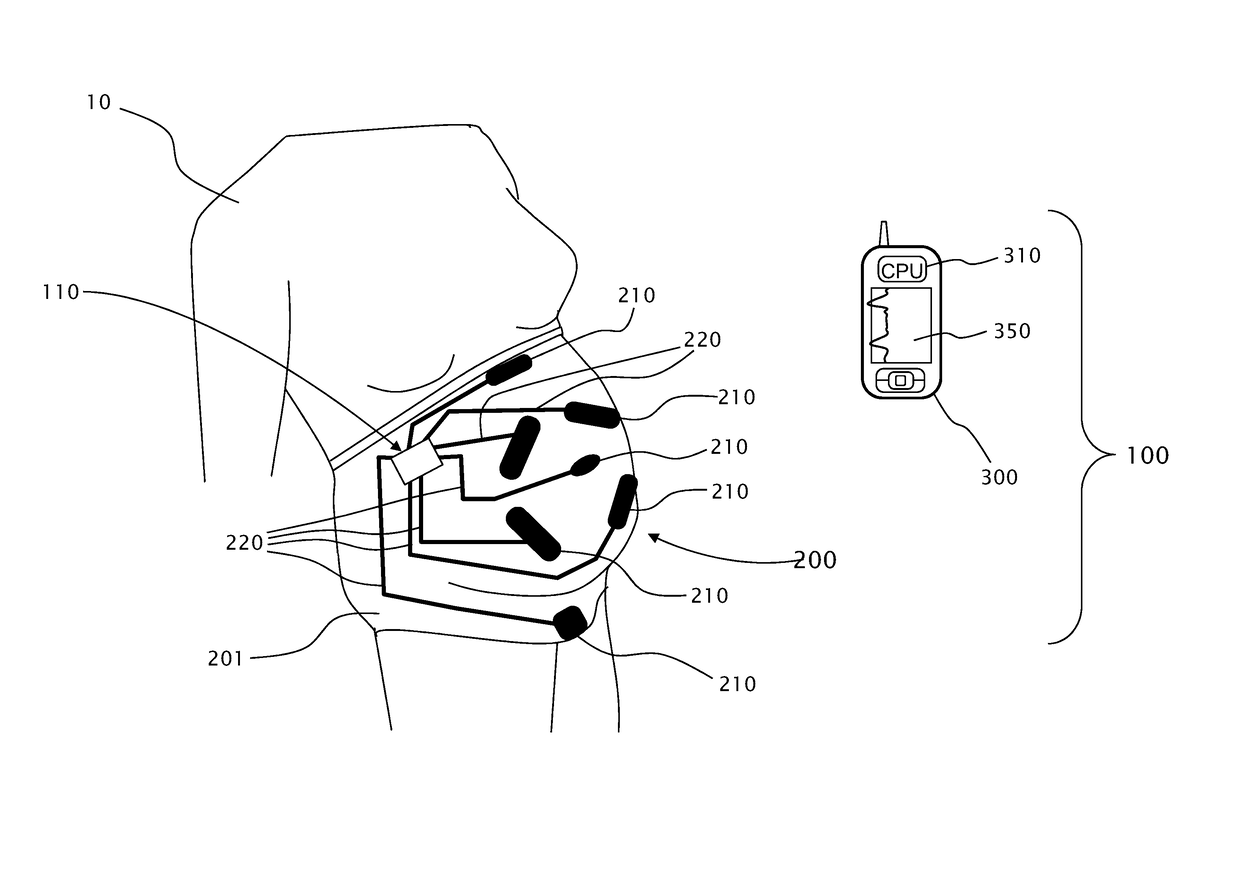

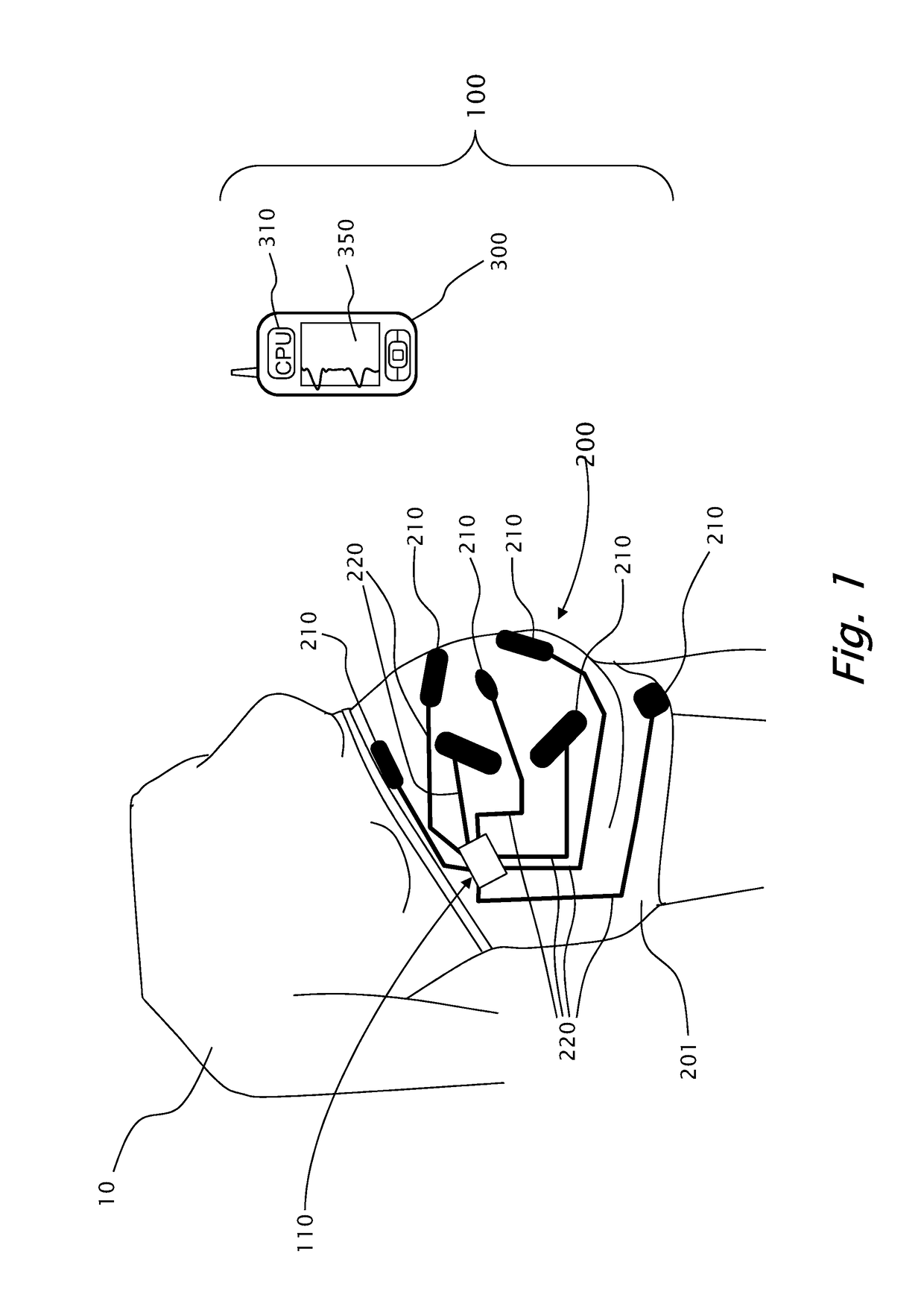

Wearable fetal monitoring system having textile electrodes

ActiveUS20160128594A1Increase the number ofElectrocardiographyElectromyographyElectricityConductive textile

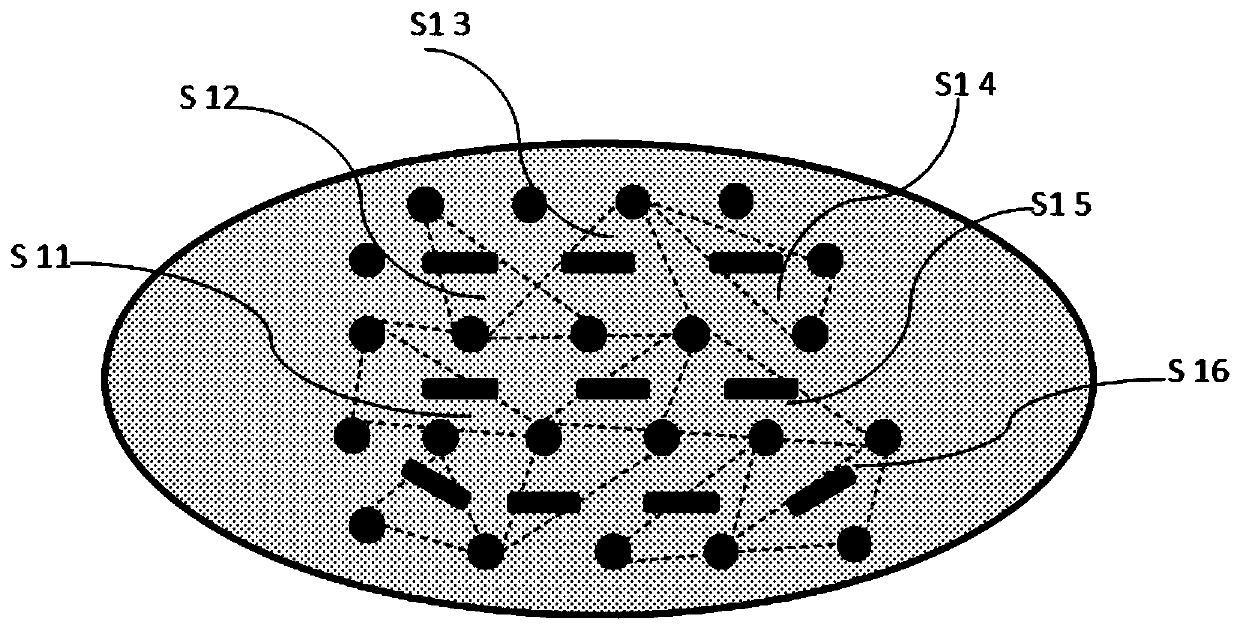

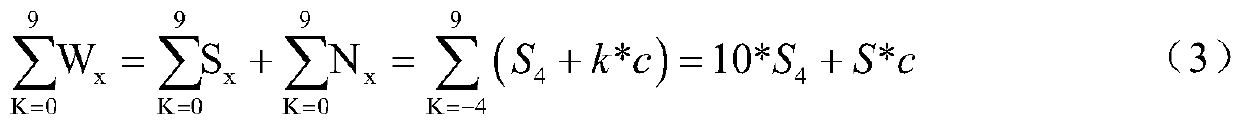

A seamless, smart fetal monitoring garment and methods of using thereof. The system includes a knitted or interwoven garment having a multiplicity of conductive textile electrodes for sensing maternal and fetal electrical vital signals. The maternal and fetal electrical vital signals are selected from a group including maternal heart rate, fetal heart rate and electromyogram (EMG) activities including uterine activities. The method includes wearing the garment, acquiring electrical mixed common, maternal and fetal vital signals from surface region of a pregnant woman, using the plurality of textile electrodes, optimally weighted summing-up the acquired signals, analyzing the summed-up signals to thereby extract the maternal signal and the fetal signal, including determining their heart rates, and including detecting health hazards and in some embodiments, including detecting a uterine contraction sequence suggesting the need to be hospitalized for birth giving.

Owner:AUTONETWORKS TECH LTD

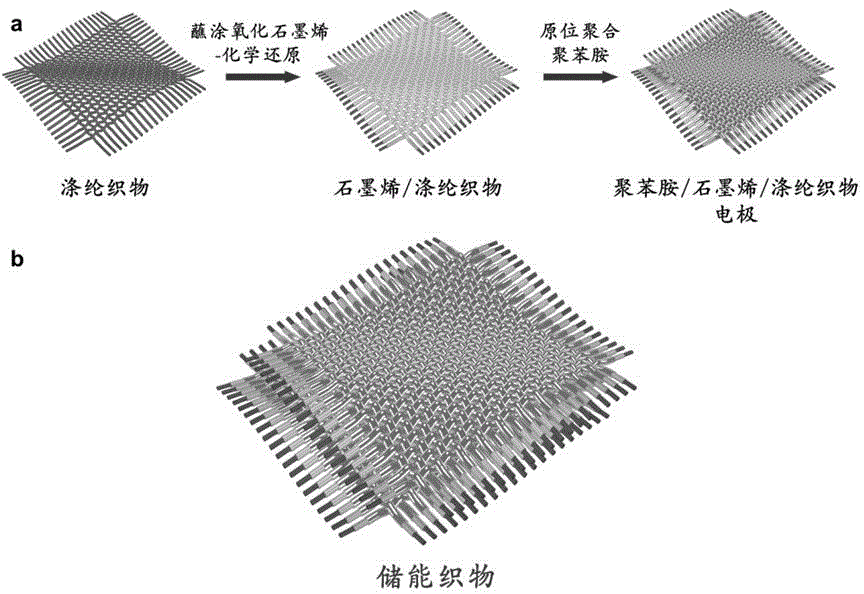

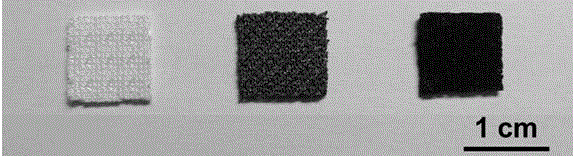

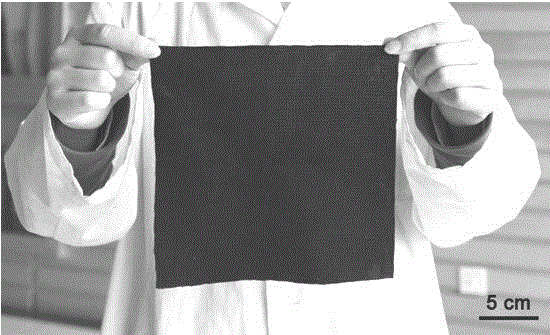

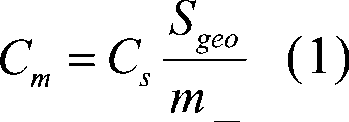

Fabric-like super capacitor based on graphene and polyaniline and preparation method thereof

ActiveCN104900422AImprove energy storage performanceGood dispersionHybrid capacitor electrodesHybrid/EDL manufacturePolyesterPolymer science

The present invention belongs to the field of fabric-like super capacitor technology and particularly relates to a fabric-like super capacitor based on graphene and polyaniline and a preparation method thereof. A polyester cloth is used as a substrate, through dipping oxide graphene chemical reduction, and in-situ polymerization method load polyaniline is used as a textile electrode. The area ratio capacity of the fabric-like super capacitor in 0.5mA / cm2 discharge current reaches 720mF / cm2. Through designing and building a flexible collector, a 20 cm2 large area fabric-like super capacitor discharges in 1mA current, a device total capacitor reaches 5000 mF, and the discharge capacity reaches 2500 mF in 10 mA current. According to the fabric-like super capacitor, the electrode material with a low use price such as graphene and polyaniline is used, the cost is low, the preparation is simple, the flexibility is excellent, due to a fabric-like shape characteristic, the capacitor can be integrated with clothing, and a wearable device can be powered at any time and any place.

Owner:FUDAN UNIV

Textile electrode and accumulator containing such an electrode

The invention relates to an electrode comprising (a) an electron collector containing one or more transition metals from the groups 4 to 12 of the Periodic Classification of the Elements, and (b) a material that is electrochemically active, present on the surface of the electron collector in the form of a nano-structured conversion layer containing nano-particles or agglomerates of said nano-particles, wherein the nano-particles have a mean diameter of between 1 and 1000 nm, preferably between 10 and 300 nm, wherein said electrochemically active material contains at least one compound of the transition metal or transition metals present in the electron collector, characterised by the fact that the electrode is a textile formed by metallic wires or fibres. The invention also relates to a half-accumulator and an accumulator containing such a textile electrode.

Owner:ELECTRICITE DE FRANCE

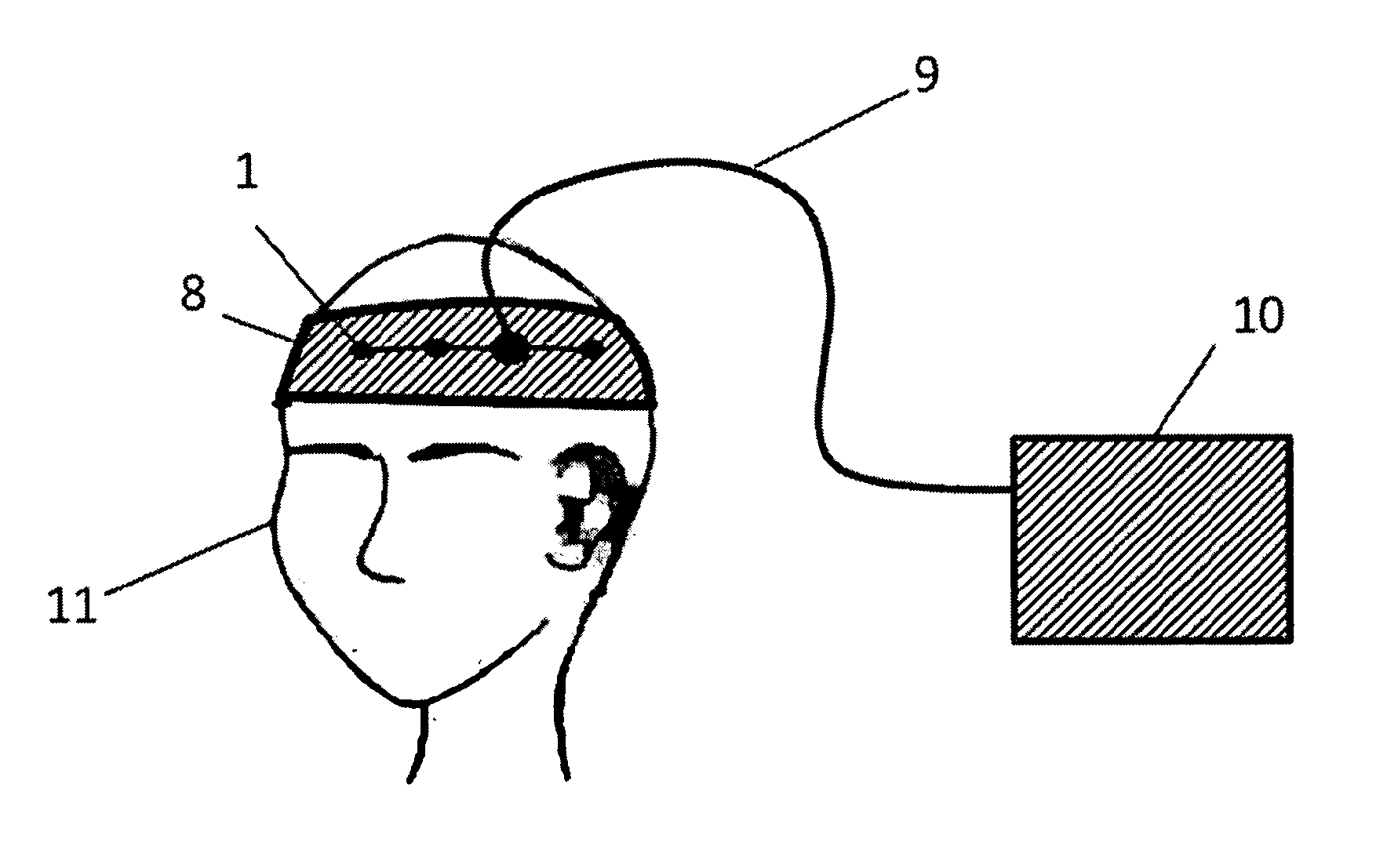

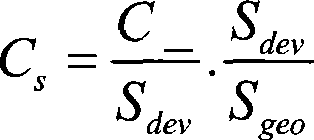

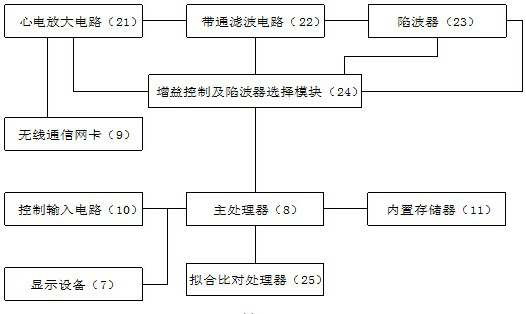

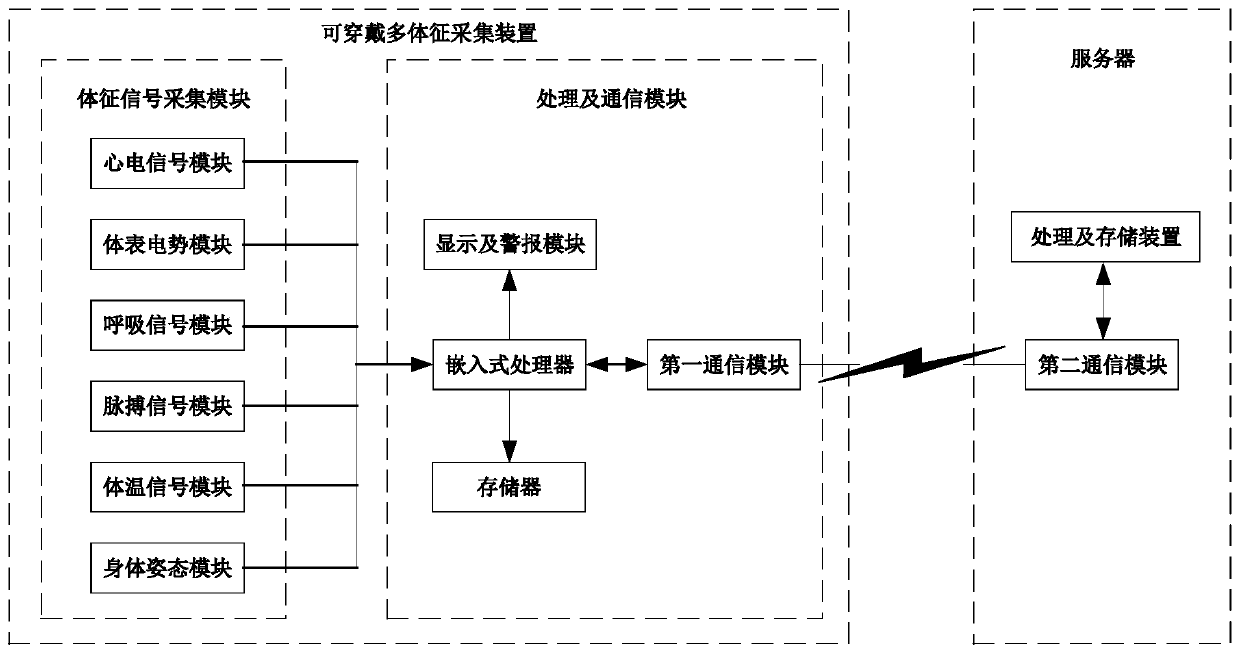

Wearable vital sign monitoring device and mental status monitoring method

ActiveCN107080527AReal-timeRealize early warningDiagnostic signal processingSensorsMental stateTextile sensors

The invention provides a wearable vital sign monitoring device and a mental status monitoring method. The wearable vital sign monitoring device comprises two parts, namely a wearable multi-sign acquiring device and a server, wherein the wearable multi-sign acquiring device consists of a vital sign acquiring module and a processing and communicating module; acquisition of different physiological signals is realized by the vital sign acquiring module; the physiological signals are processed and integrated by an embedded lower-power-consumption processor, then are transmitted to a server side by the communicating module in a wireless mode and are stored and processed in the server; the mental status monitoring method provides a method for evaluating a mental status on the basis of sign signal data. According to the wearable vital sign monitoring device and the mental status monitoring method provided by the invention, by combining with a flexible processing technique and using a textile electrode, leads and various textile sensors embedded into clothes, lightness and comfortableness of the device are ensured while multiple physiological parameters are acquired; further analysis, exploitation and utilization of the acquired sign parameters are realized, and real-time judgment and early warning of a body and the mental status are realized.

Owner:SOUTHEAST UNIV

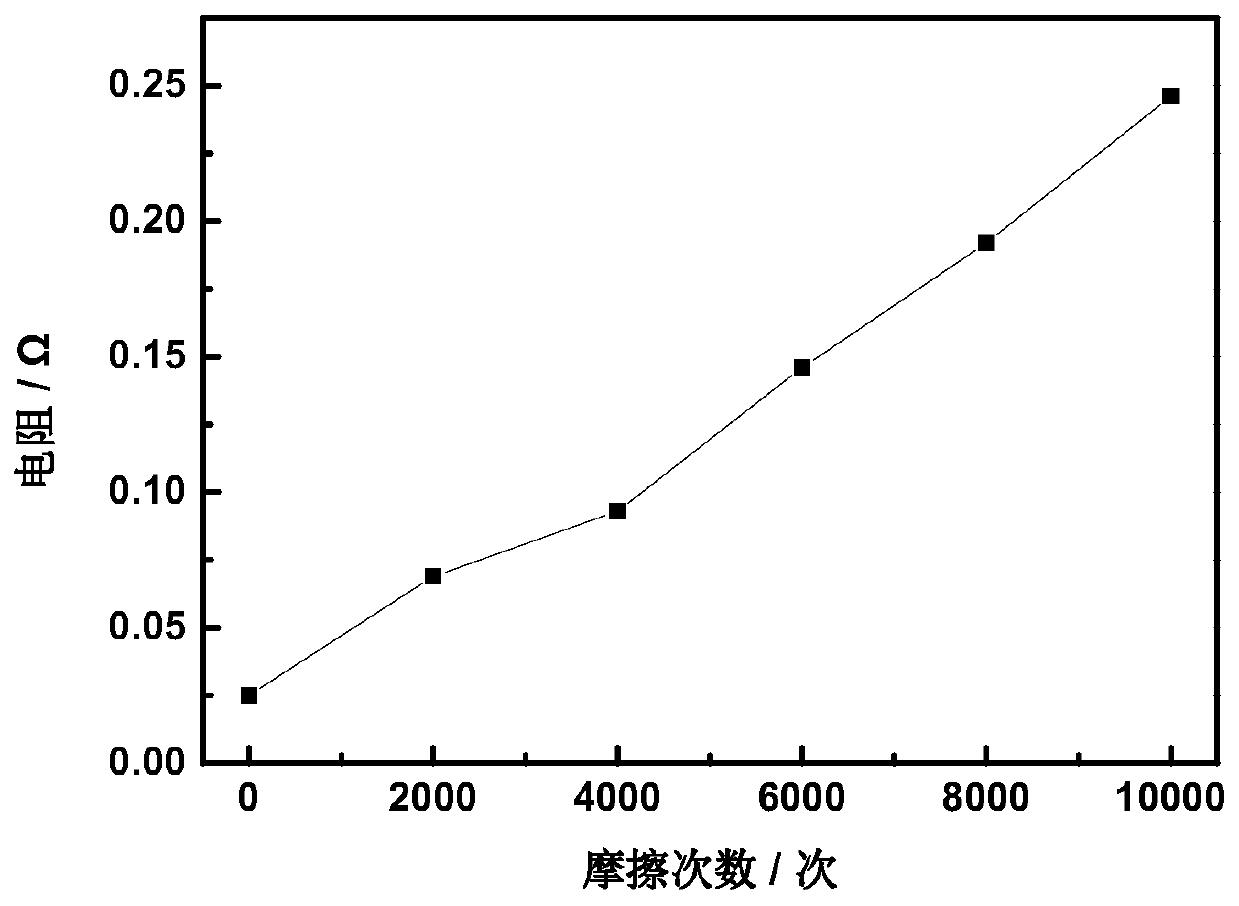

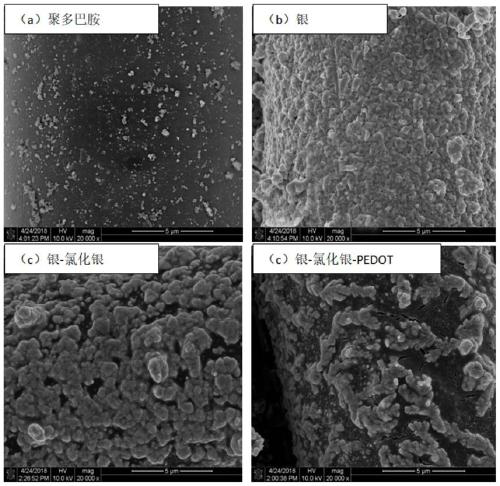

Preparation method of textile electrode material and textile electrode material

ActiveCN111395002AImprove conductivitySimplified coarseningLiquid/solution decomposition chemical coatingDiagnostic recording/measuringConductive polymer compositeSilver chloride

The invention discloses a preparation method of a textile electrode material and the textile electrode material. The preparation method comprises the steps that firstly, pretreated fabric is soaked ina dopamine hydrochloride solution, and polydopamine coated fabric is obtained; then, the polydopamine coated fabric is soaked in a silver-ammonia solution, a glucose solution is added after a certainperiod of time, and a silver-plated fabric is obtained; the silver-plated fabric is subjected to chlorination treatment in a sodium chloride solution through an electrochemical method, and a silver-silver chloride composite coating fabric is formed; finally, the silver-silver chloride composite coating fabric is modified in a conductive polymer monomer solution through an electrochemical method,and the silver-silver chloride-conductive polymer composite coating fabric is obtained. The surface specific resistance of the textile electrode material is 0.01-5 omega, the polarization impedance ina 0.9% sodium chloride solution is 10-1000 omega, the skin interface impedance is 1K omega-100M omega at 1Hz, and the phase angle variation within the frequency range of 0.5-50Hz is 0-30 degrees.

Owner:MINJIANG UNIV

Wearable fetal monitoring system having textile electrodes

A seamless, smart fetal monitoring garment and methods of using thereof. The system includes a knitted or interwoven garment having a multiplicity of conductive textile electrodes for sensing maternal and fetal electrical vital signals. The maternal and fetal electrical vital signals are selected from a group including maternal heart rate, fetal heart rate and electromyogram (EMG) activities including uterine activities. The method includes wearing the garment, acquiring electrical mixed common, maternal and fetal vital signals from surface region of a pregnant woman, using the plurality of textile electrodes, optimally weighted summing-up the acquired signals, analyzing the summed-up signals to thereby extract the maternal signal and the fetal signal, including determining their heart rates, and including detecting health hazards and in some embodiments, including detecting a uterine contraction sequence suggesting the need to be hospitalized for birth giving.

Owner:HEALTHWATCH LTD

Textile electrode device for acquisition of electrophysiological signals from the skin and manufacturing process thereof

A textile electrode device, for detection of electrophysiological signals from the skin of a subject, having: a substrate designed to be positioned on the skin; at least a first detection electrode arranged on the substrate; and at least a first conducting element, carried by the substrate and electrically connected to the first detection electrode. The first detection electrode has a plurality of textile fibres, including conductive fibres and, optionally, fibres of a super-absorbent material, arranged in a direction substantially orthogonal to an upper surface of the substrate and reciprocally in contact with each other, so as to ensure uniform electrical contact over the entire first detection electrode. In particular, the first detection electrode is obtained by means of the flocking technique.

Owner:POLITECNICO DI TORINO

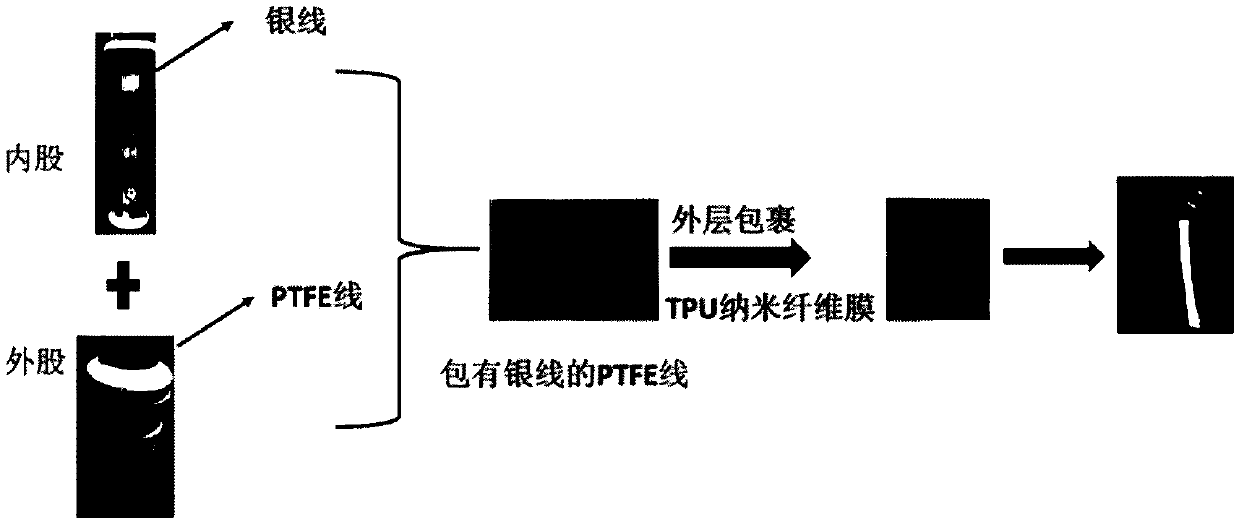

Nano fiber and textile electrode integrated wearable sensing member

InactiveCN109646012AEasy to stretchThe preparation process is matureDiagnostic recording/measuringSensorsYarnFiber

The invention discloses a preparation method of a nano fiber and textile electrode integrated wearable sensing member. The method comprises the steps that a coaxial textile electrode is prepared by taking a conductive silver wire as the axial center and winding the outer layer of the coaxial textile electrode with multiple strands of yarns with stronger electronegativity, the outer surface of thecoaxial textile is wrapped with a layer of electrostatic spinning nano fiber membrane with high tensile performance, and a high-tension energy-harvesting wearable sensing member with integrated nano fiber and textile electrode can be prepared. The wearable sensing member can be used for wearable electronic skin, when the electronic skin is externally stimulated, energy harvesting is achieved through triboelectrification for outputting a sensing signal, the preparation of the member is simple, and the wearable sensing member has a hope to achieve industrial development.

Owner:江苏国源环境科技有限公司

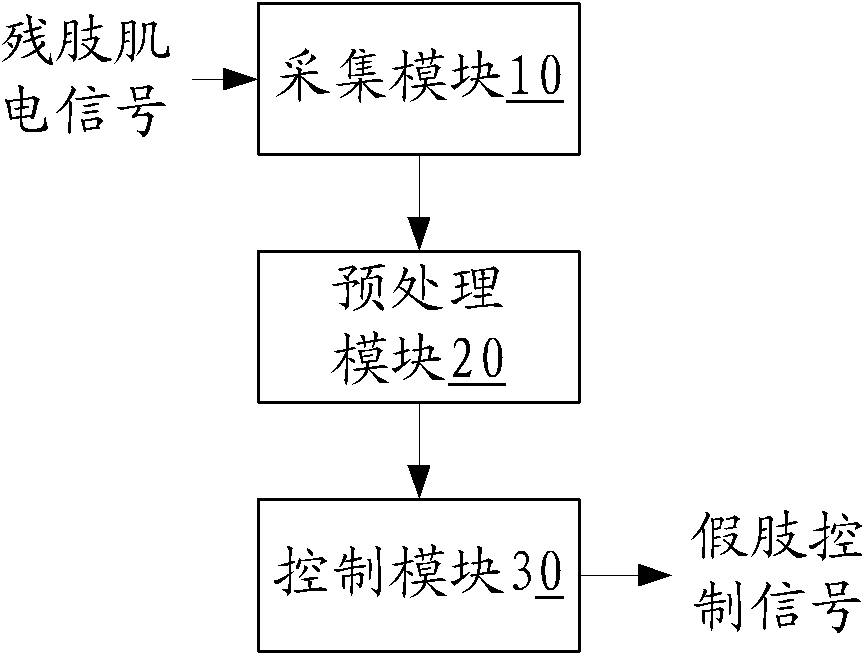

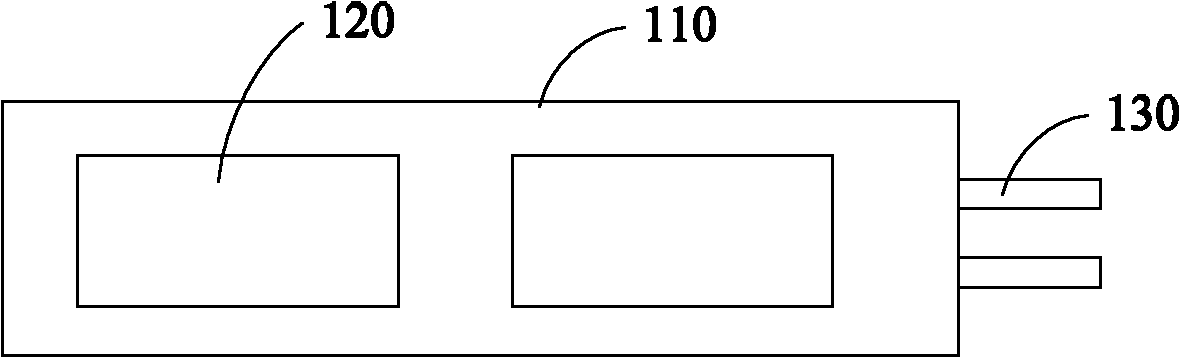

Myoelectric artificial limb control device

InactiveCN102028568AImprove conductivityGuaranteed breathableProsthesisRelative displacementPre treatment

The invention relates to a myoelectric artificial limb control device. The device comprises an acquisition module, a pre-processing module for pre-processing a myoelectric signal acquired by the acquisition module, and a control module for controlling an artificial limb based on the processed myoelectric signal, wherein the acquisition module comprises a textile electrode; and the textile electrode has high conductive property, and keeps properties such as permeability, flexibility, foldability and bonding and the like of the textile material. The textile electrode is convenient and comfortable, and can be easily attached to clothing and skin, so that motion artifacts cannot be generated due to relative displacement.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

Method for limiting elasticity of selected regions in knitted fabrics

ActiveUS9416470B2Maintaining dimensionElasticity of moreGarment special featuresElectrocardiographyConductive textileEngineering

A method for substantially reducing the elasticity of at least one selected textile region of a garment. The method includes producing the garment including a conductive textile electrode and rigidifying the at least one selected textile region. The rigidifying process includes applying rigidifying matter onto or into the at least one selected textile region. The at least one selected textile region is selected from the group consisting of a conductive textile electrode and a region of the garment situated between two adjacent textile electrodes. The invention further provides a garment having a tubular form, knitted by a seamless knitting machine with base-yarns. The garment includes at least one conductive textile electrode, composed of multiple knitted line segments, each knitted with a conductive yarn and a spandex yarn, wherein the spandex yarn and at least one base-yarn are knitted continuously.

Owner:HEALTHWATCH LTD

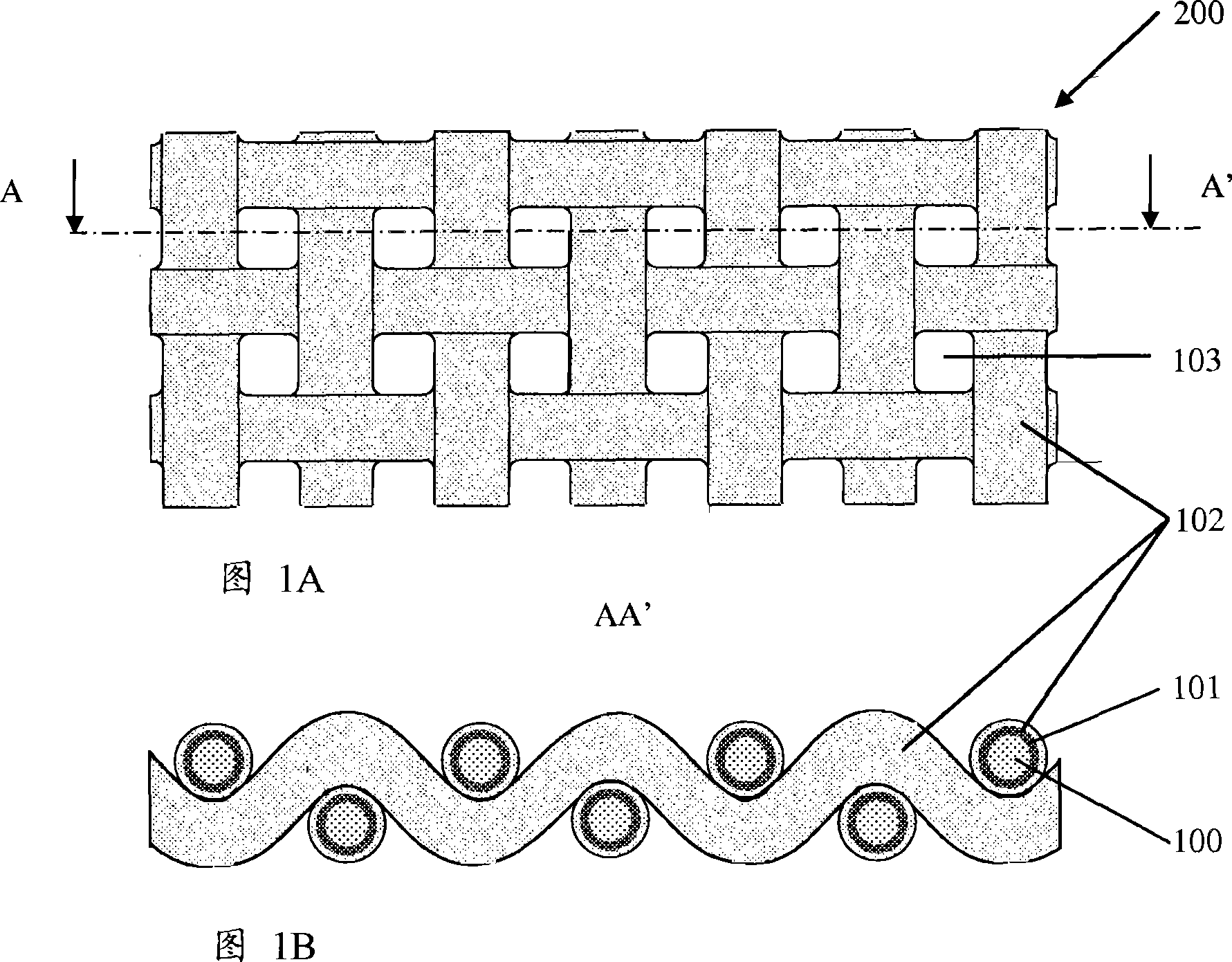

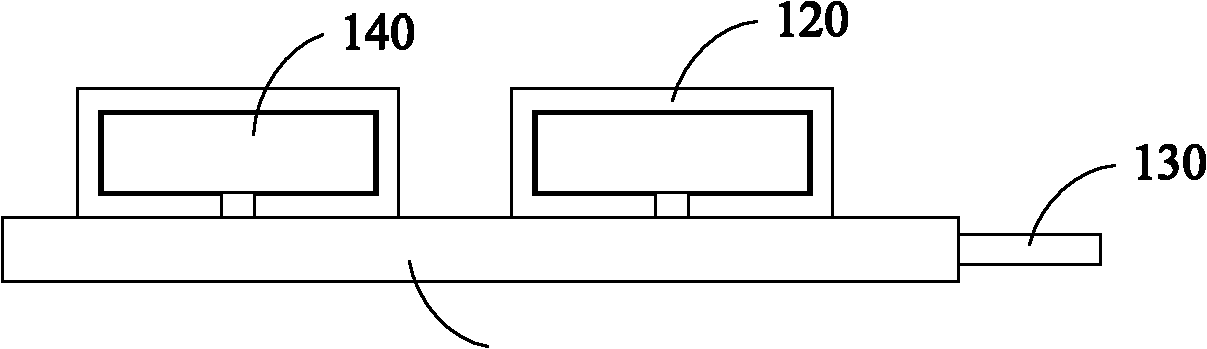

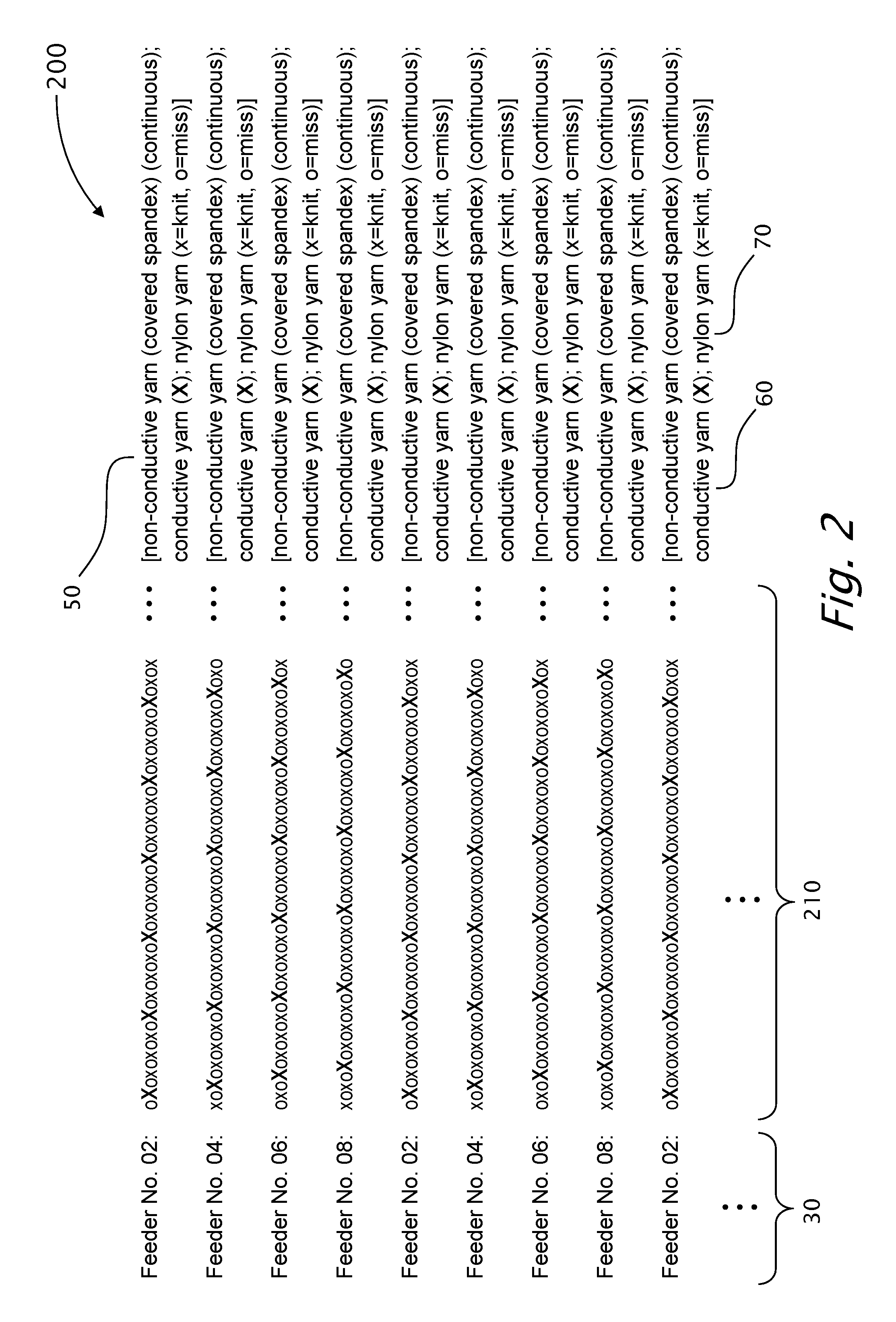

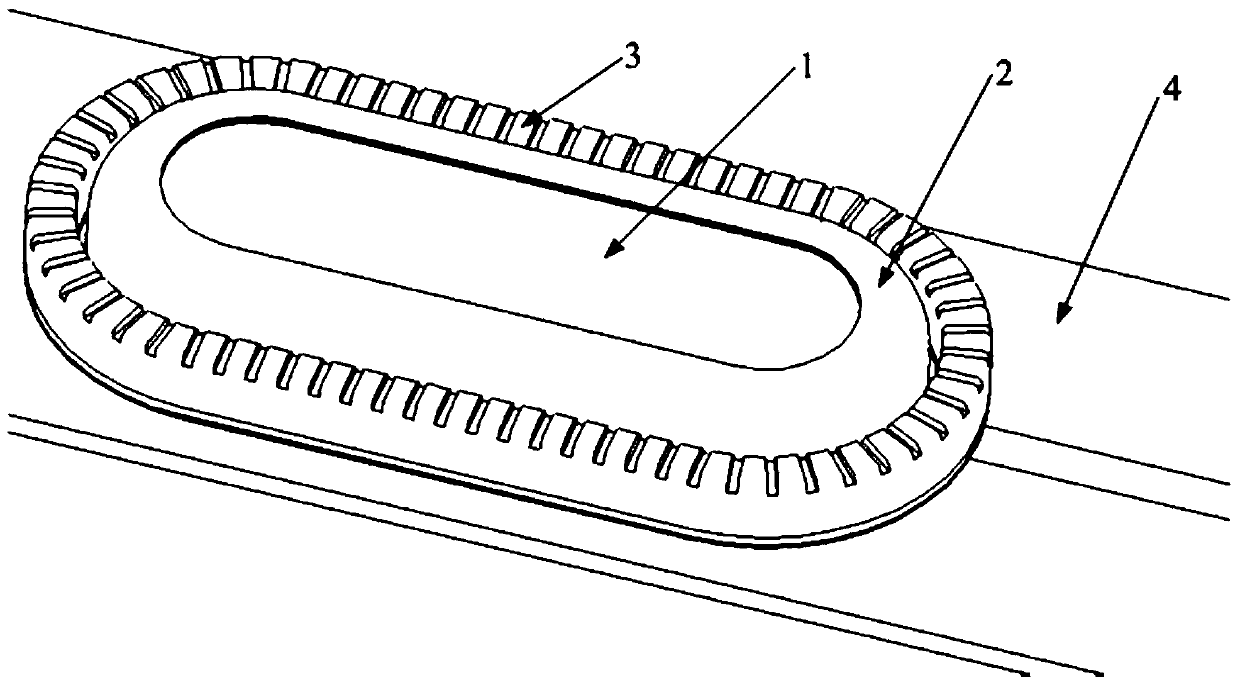

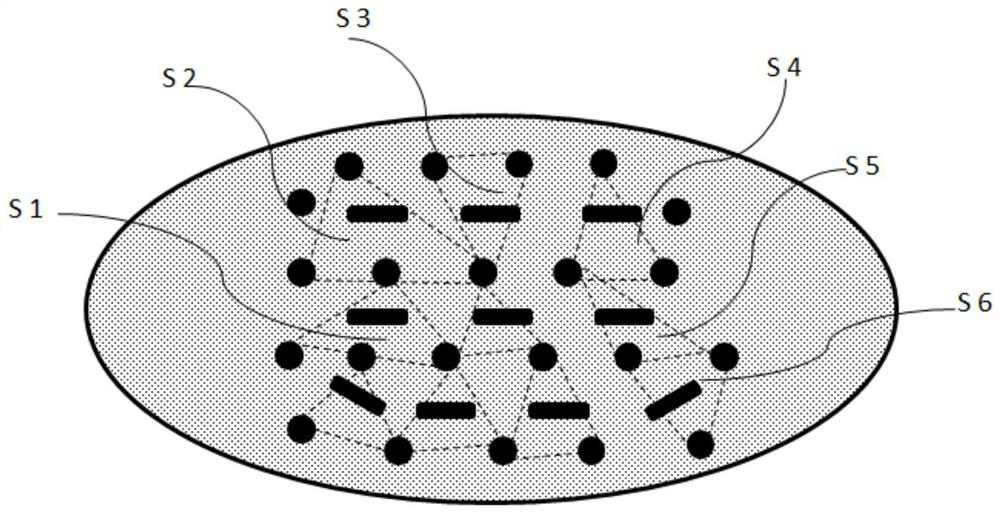

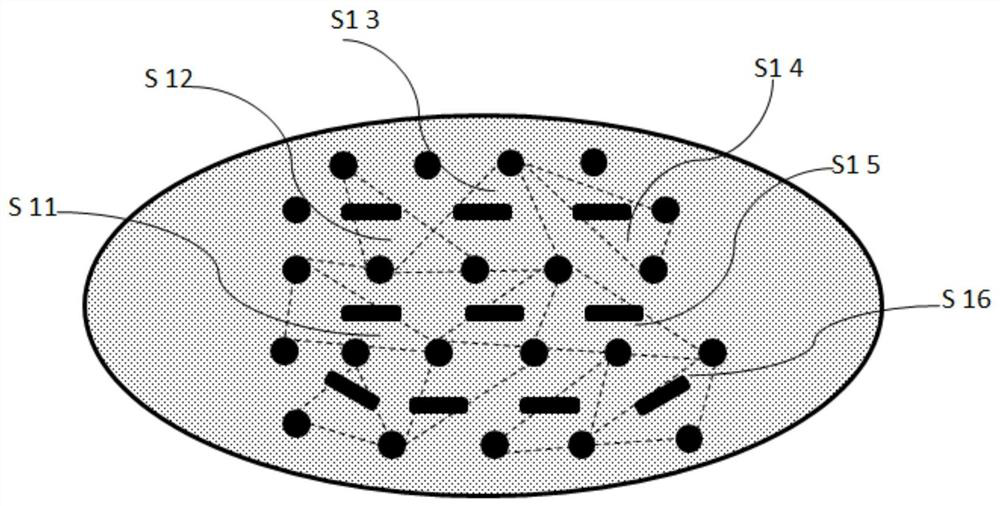

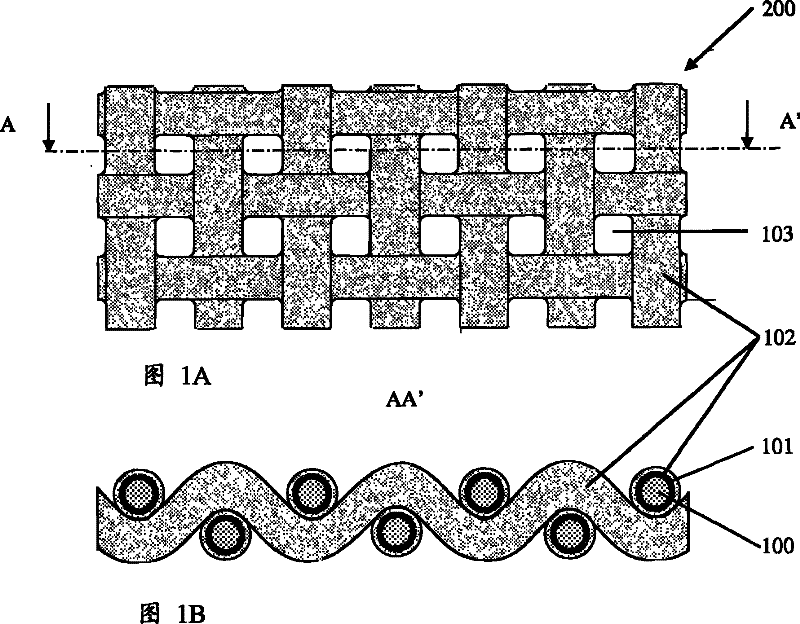

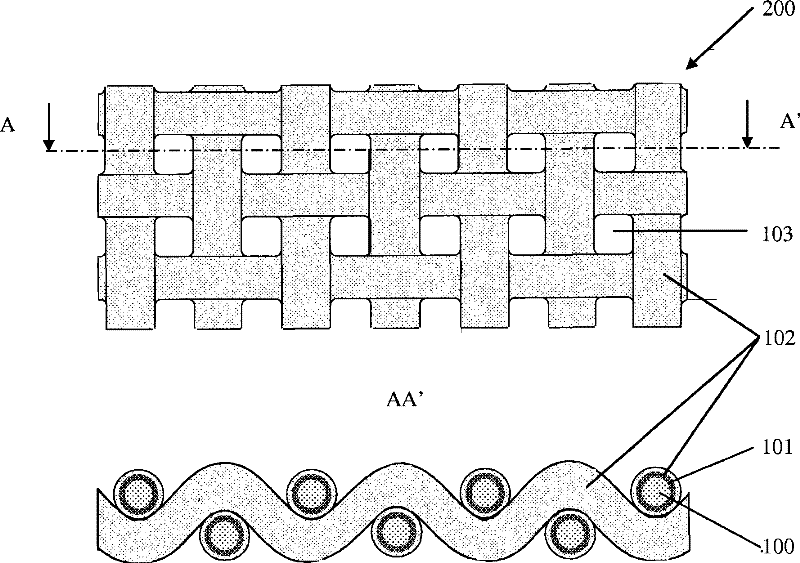

Float loop textile electrodes and methods of knitting thereof

InactiveCN104955346AIncrease pressureImprove tightnessElectrocardiographyWeft knittingConductive textileTextile electrodes

A method for knitting a garment having a tubular form, including knitting at least one conductive textile electrode on a machine having N participating feeders and M needles. The method includes the steps of continuously knitting the tubular form with one or more flexible non-conductive yarns, and knitting the electrode integrally within the tubular form, using a conductive yarn, in addition to the non-conductive yarns. The conductive yarn is knitted in a float-loop form by knitting a stitch and skipping over y needles, as follows: repeatably knitting a line segment Lk, using feeder Fi and starting at needle D1 and knitting line segment Lk+1, using the next feeder and start stitching the first float-loop at needle D1+s where 0<s<y. The tubular form has a preconfigured 10 knitting density, wherein the electrode has a knitting density that is higher than the preconfigured knitting density of the tubular form.

Owner:HEALTHWATCH LTD

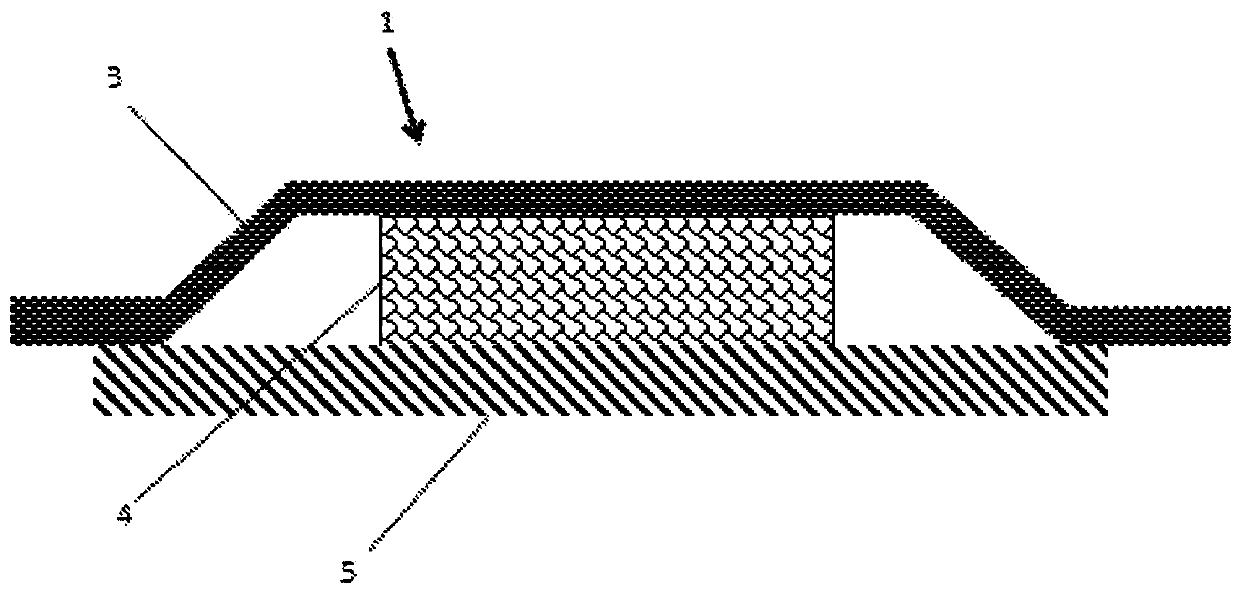

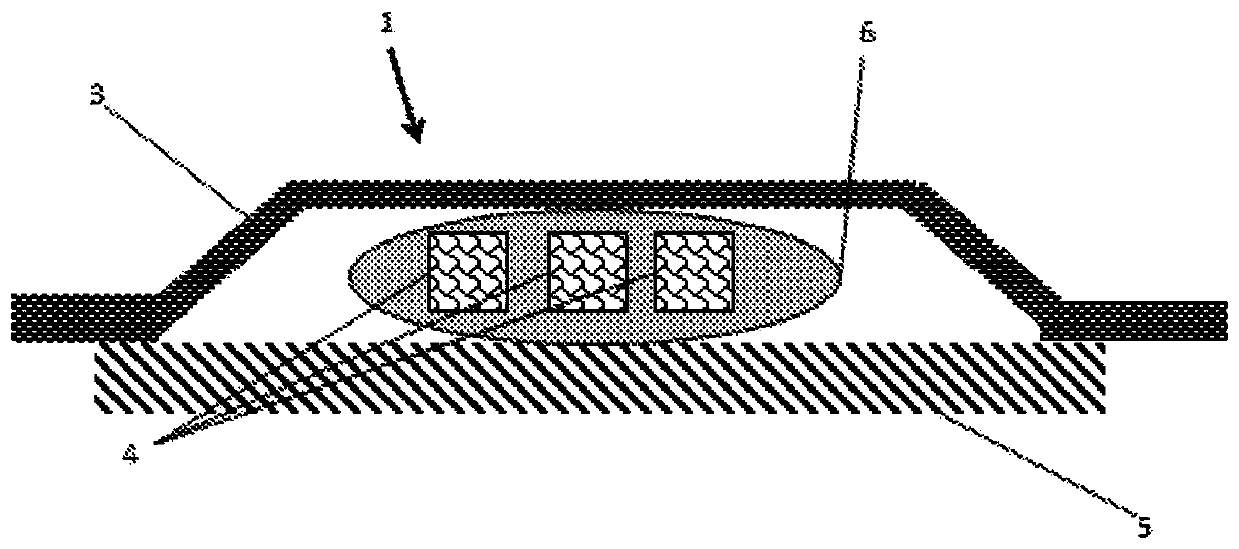

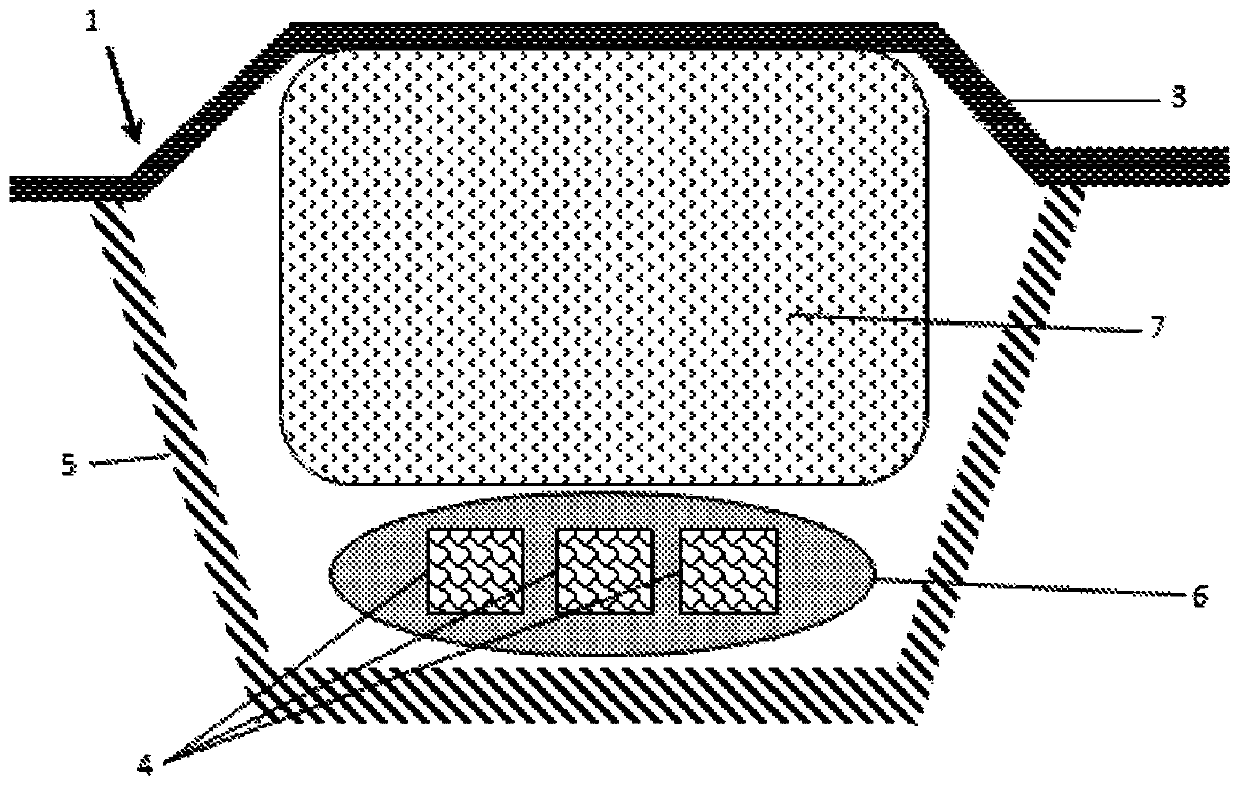

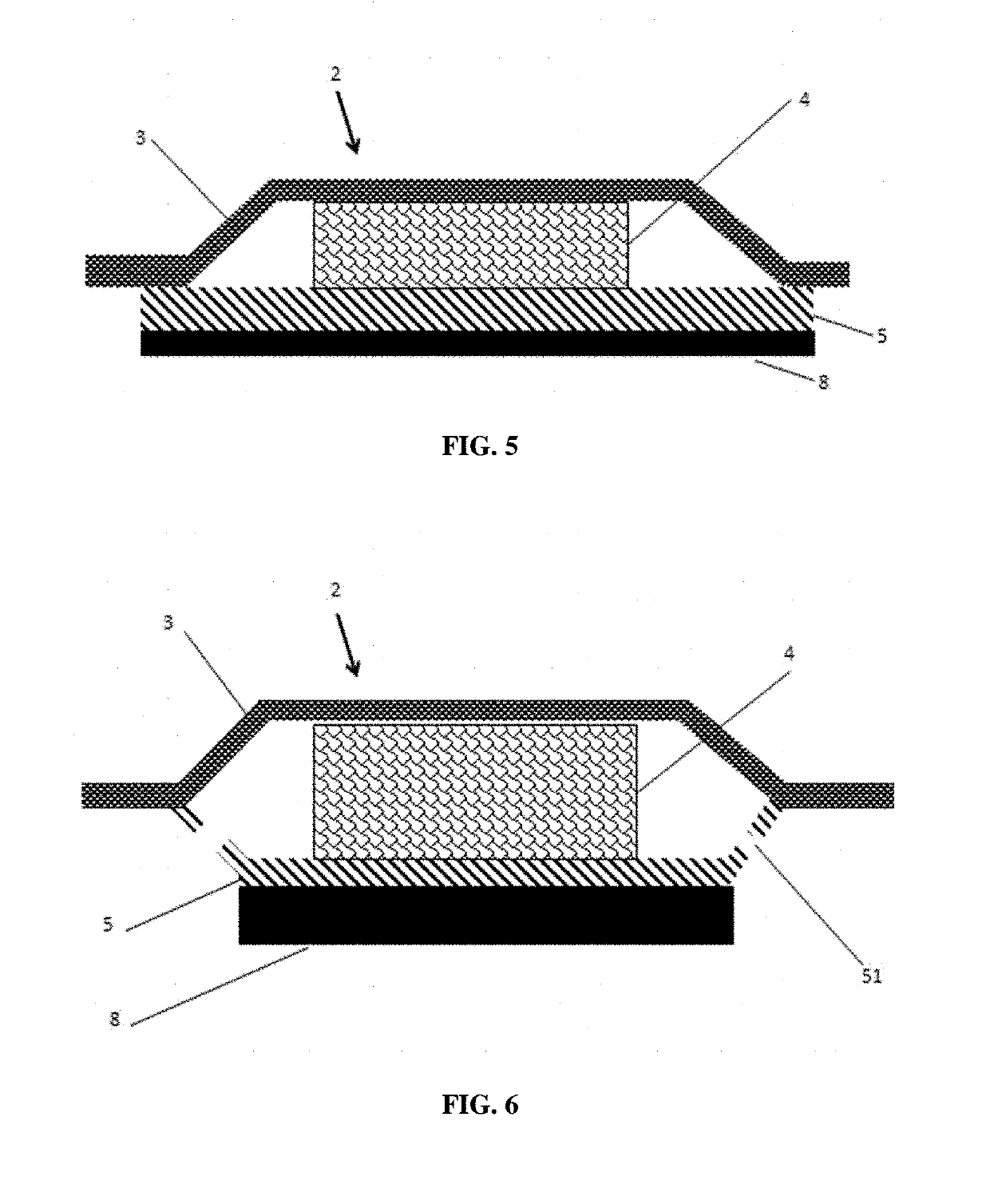

Device for humidification of textile electrode

The present invention relates to a device for humidification of a textile electrode (1) comprising a first layer (3); a second layer (5); and a material (4) capable of absorbing and retaining water; in which the material (4) capable of absorbing and retaining water is situated between the first layer (3) and the second layer (5); the first layer (3) is impermeable to water and to water vapour; andthe second layer (5) is permeable to water in a direction running from the outside towards the material capable of absorbing and retaining water, and impermeable to water and permeable to water vapour in the opposite direction. The present invention also relates to a system comprising such a humidification device.

Owner:波尓瑟兰尼提公司

Device for humidifying a textile electrode

This invention relates to a device for humidifying a textile electrode (1) comprising a first layer (3); a second layer (5); and a material capable of absorbing and retaining water (4); wherein the material capable of absorbing and retaining water (4) is located between the first layer (3) and the second layer (5); the first layer (3) is impermeable to liquid water and water vapour; and the second layer (5) is permeable to liquid water in a direction extending inwards towards the material capable of absorbing and retaining water, and is impermeable to liquid water and permeable to water vapour in the opposite direction thereto. This invention further relates to a system comprising such a humidification device.

Owner:BIOSERENITY

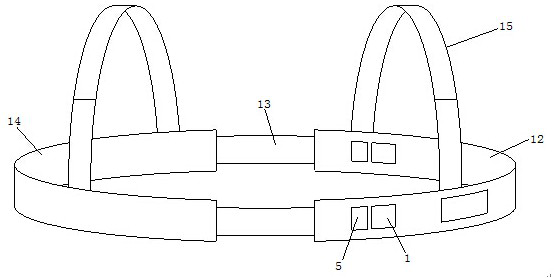

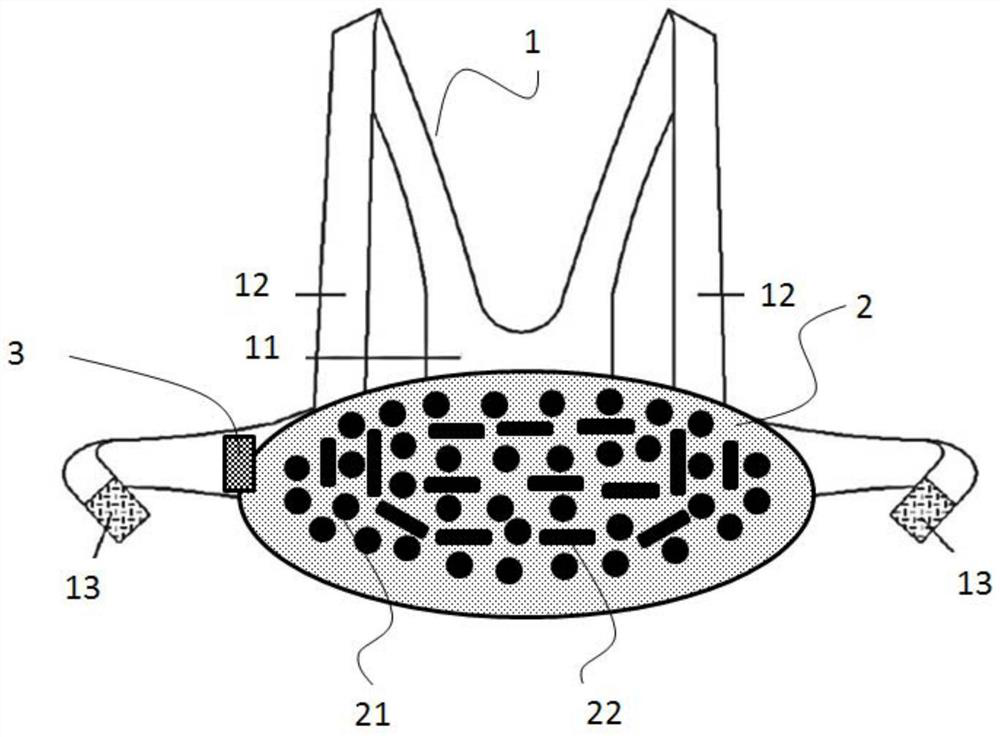

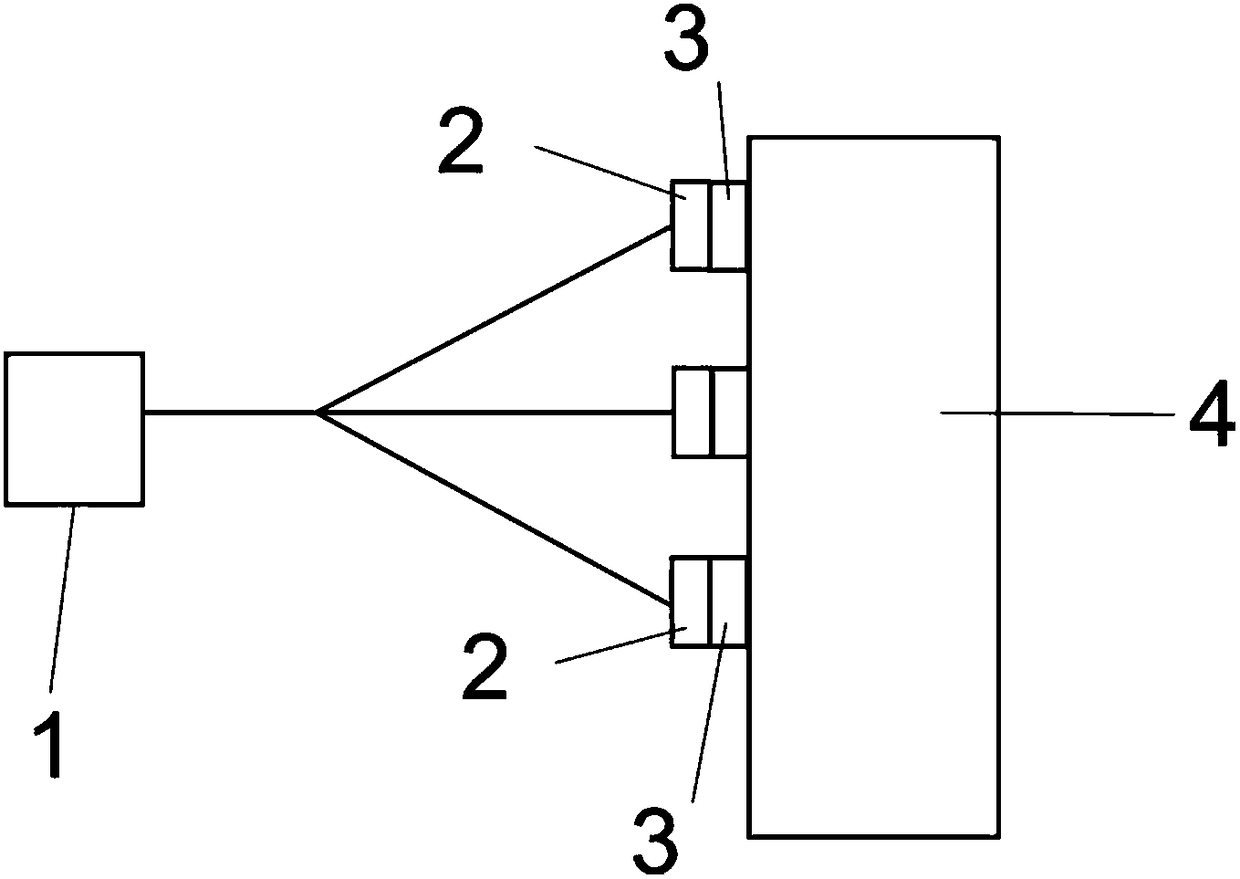

Independent wearable electrocardiogram data monitoring system and detection method thereof

InactiveCN111743532AImprove wearing comfortIncrease elasticityDiagnostic recording/measuringSensorsEcg signalWireless transmission

The invention discloses an independent wearable electrocardiogram data monitoring system. The device comprises a chest strap and hand rings, the chest strap comprises a fabric strap body, and an electrocardiosignal processing device and two textile electrodes (1) which are arranged on the fabric strap body, the two textile electrodes (1) are arranged on the fabric belt body and attached to the portion, close to the heart, of the chest of a patient and the portion, close to the heart, of the back of the patient respectively, and the output ends of the textile electrodes (1) are electrically connected with the signal input end of the electrocardiosignal processing device. A built-in monitoring chip (3), a wireless transmission circuit (4) and two analog-to-digital conversion circuits (2) arearranged in the electrocardiosignal processing device, and the output ends of the two textile electrodes (1) are electrically connected with the input ends of the two analog-to-digital conversion circuits (2) respectively. According to the technical scheme, the wearing comfort of the chest strap type electrocardiogram equipment is improved, a patient can be reminded whether wearing is correct ornot, and the electrocardiogram monitoring accuracy is improved.

Owner:CHENGDU ZHIA TECH CO LTD

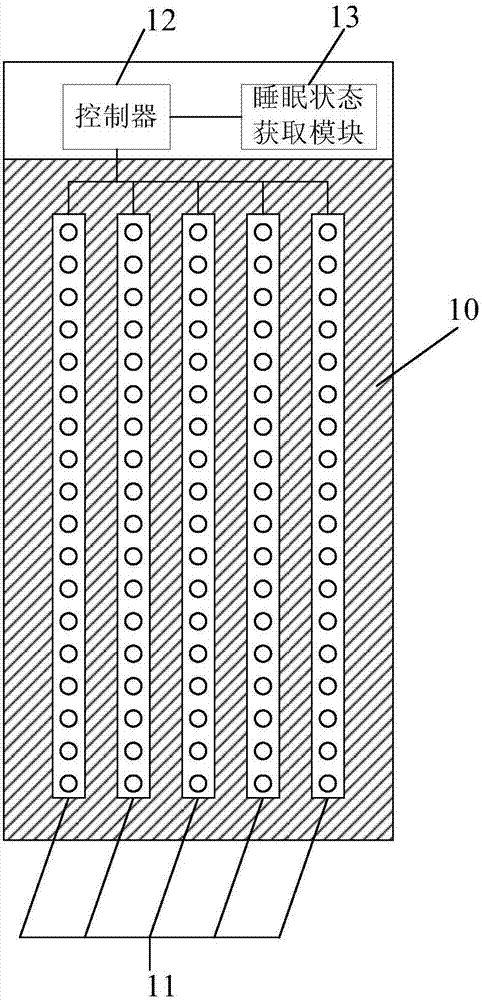

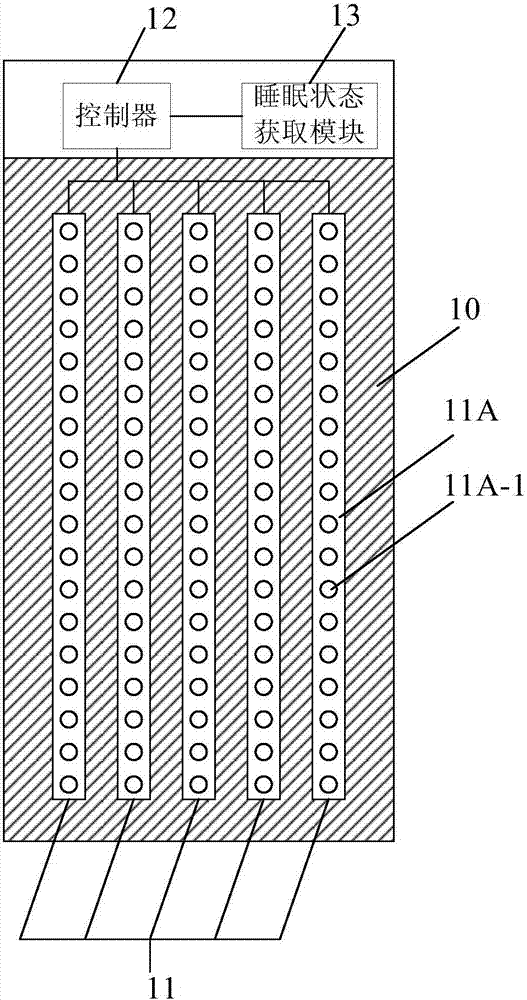

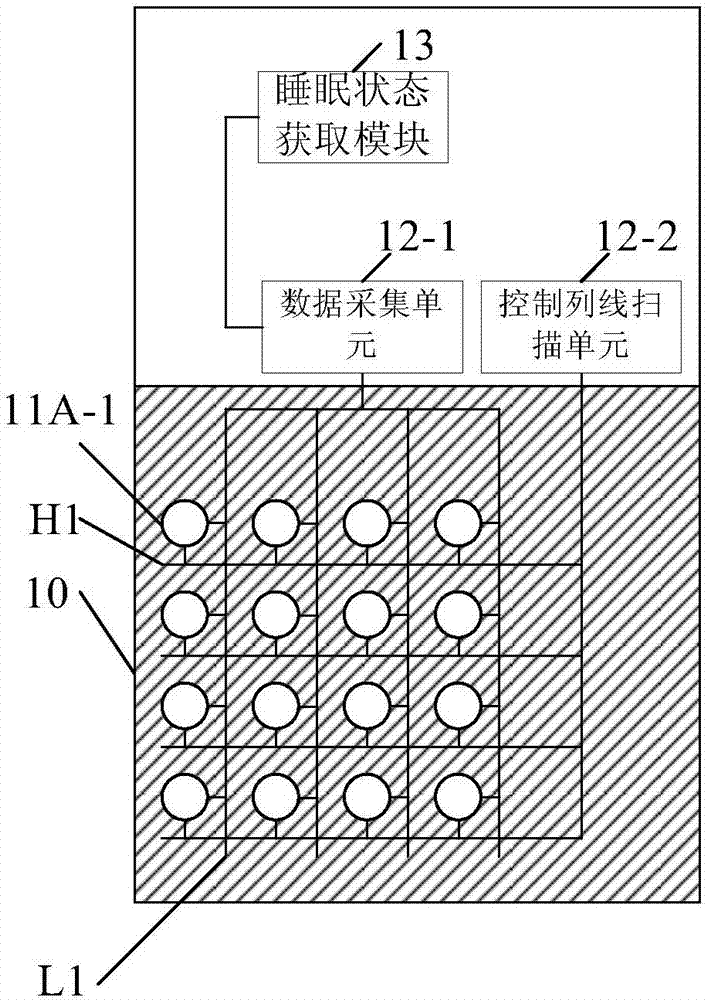

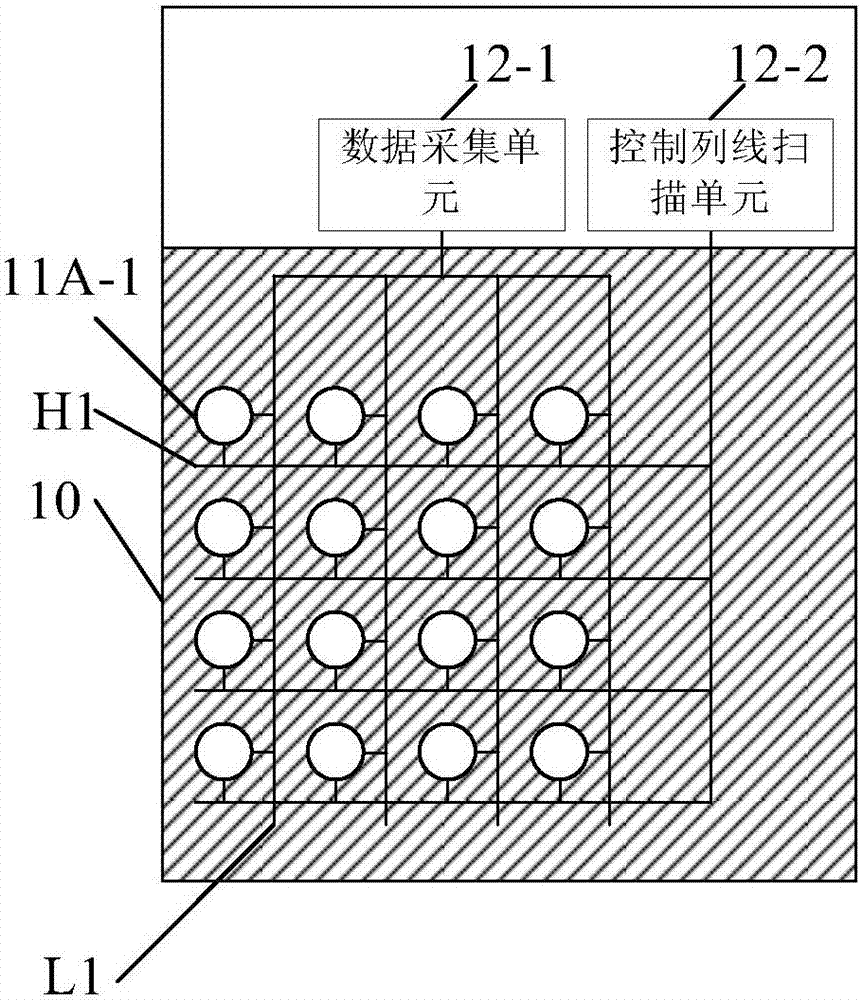

Intelligent mattress and control method

The invention provides an intelligent mattress and a control method. A controller obtains pressure data of a user through a flexible textile electrode module and obtains the sleeping state of the user through a sleeping state obtaining module according the pressure data of the user. Thus, information of the sleeping state is provided for the user. Therefore, the practicability of the intelligent mattress is improved.

Owner:尧乐网络科技(上海)有限公司

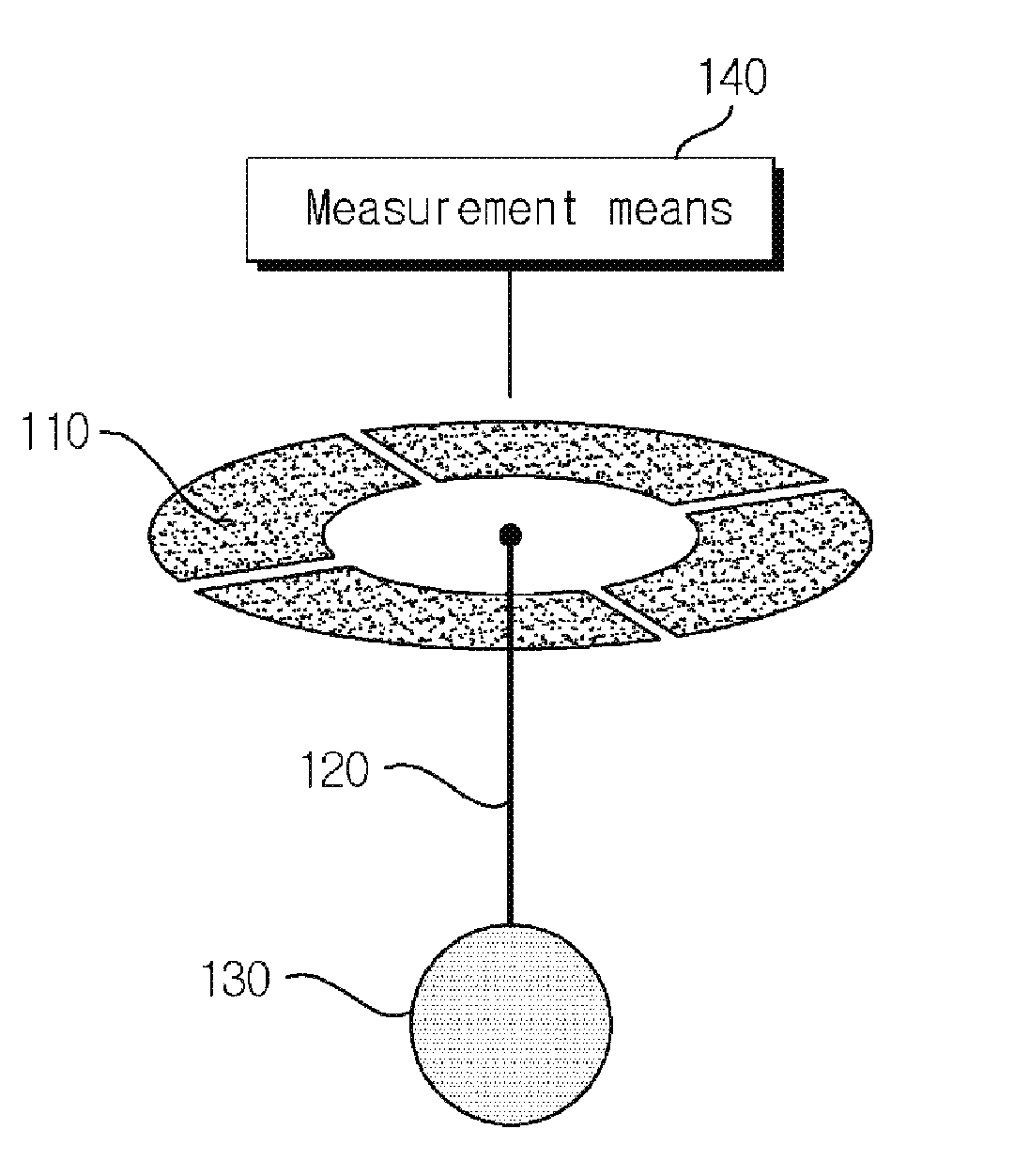

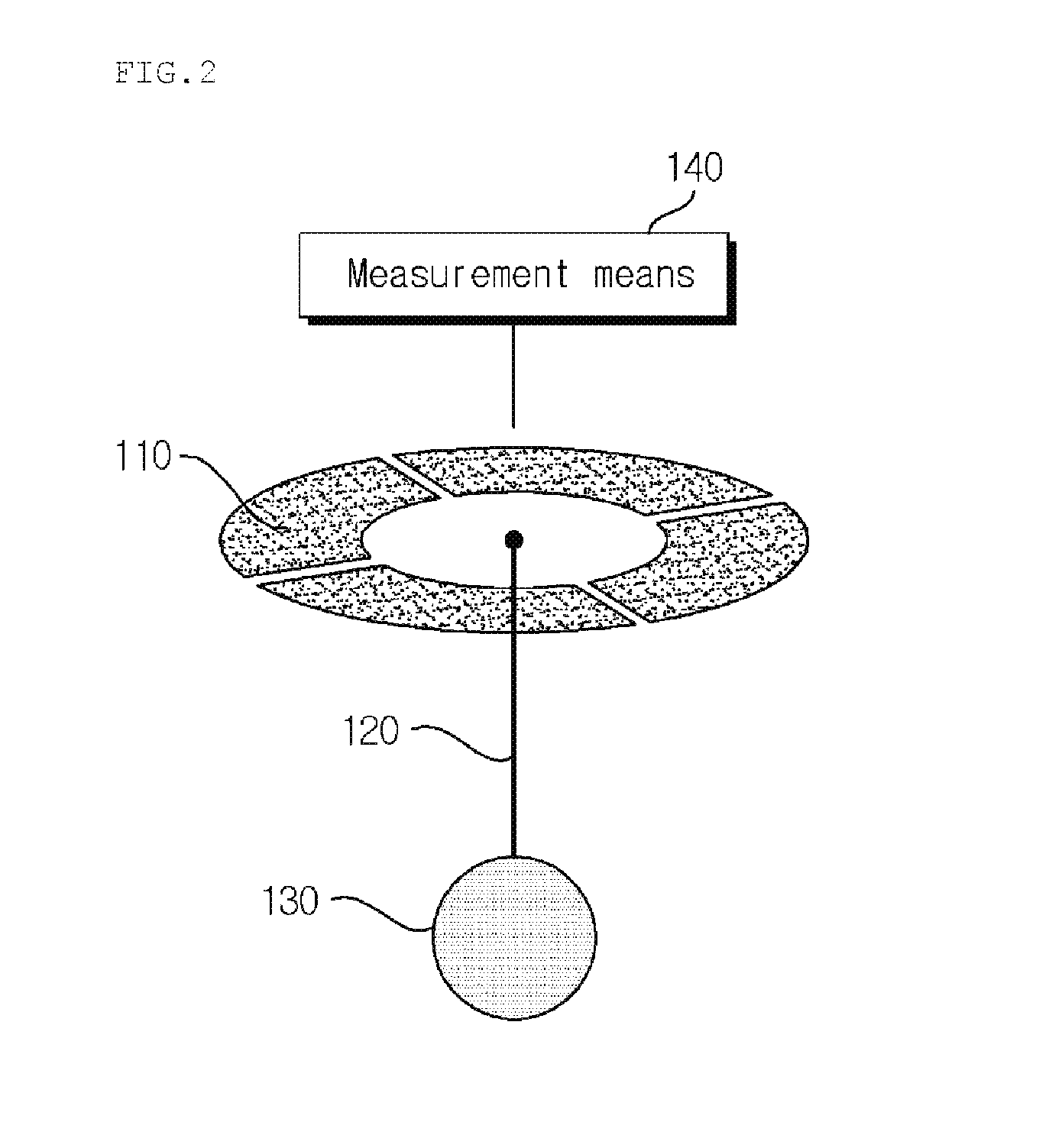

Sensor for measuring tilt angle based on electronic textile and method thereof

InactiveUS9316481B2Solid-state devicesSemiconductor/solid-state device manufacturingEngineeringTextile electrodes

Disclosed are a sensor for measuring a tilt angle based on electronic textile according to the present invention and a method thereof. A sensor for measuring a tilt angle based on electronic textile according to the present invention includes a plurality of textile electrodes disposed at predetermined uniform intervals on a textile surface; a textile conductive wire of which one end is connected to a center between the plurality of textile electrodes; and a metal bead connected to another end of the textile conductive wire to thereby be connected to the textile surface.

Owner:ELECTRONICS & TELECOMM RES INST

Manufacturing method of conductive cloth, textile electrodes and intelligent electrocardiograph coat

ActiveCN109717864AReduce porosityWon't moveHeating/cooling textile fabricsDiagnostic recording/measuringHeat deflection temperaturePorosity

The invention provides a manufacturing method of conductive cloth. The manufacturing method of the conductive cloth comprises the following steps: performing hot pressing on textile fabrics at hot deformation temperature so as to have fibers flattened as well as have the fibers bonded at cross-lap joints, thereby making bulges on the flattened textile fabrics planar; and then, plating a conductivelayer on surfaces of the flattened textile fabrics. Conductive cloth manufactured by the manufacturing method has a planar conductive layer on the surface; and thus, being applied for textile electrodes, effective contact area of the conductive cloth with the skin is greatly increased under the same pressure, thereby improving signal acquisition capability. At the same time, fibers at the cross-lap joints of the conductive cloth are bonded together, so that, dislocation between the conductive fibers of the conductive cloth is avoided so as to prevent introduction of noise; moreover, porosityof the conductive cloth is greatly reduced, so that, 'sweat perspiration' is appropriately facilitated, thereby further improving signal acquisition capability of the conductive cloth on dry skin surface. The invention further provides textile electrodes and an intelligent electrocardiograph coat.

Owner:LENOVO (BEIJING) CO LTD

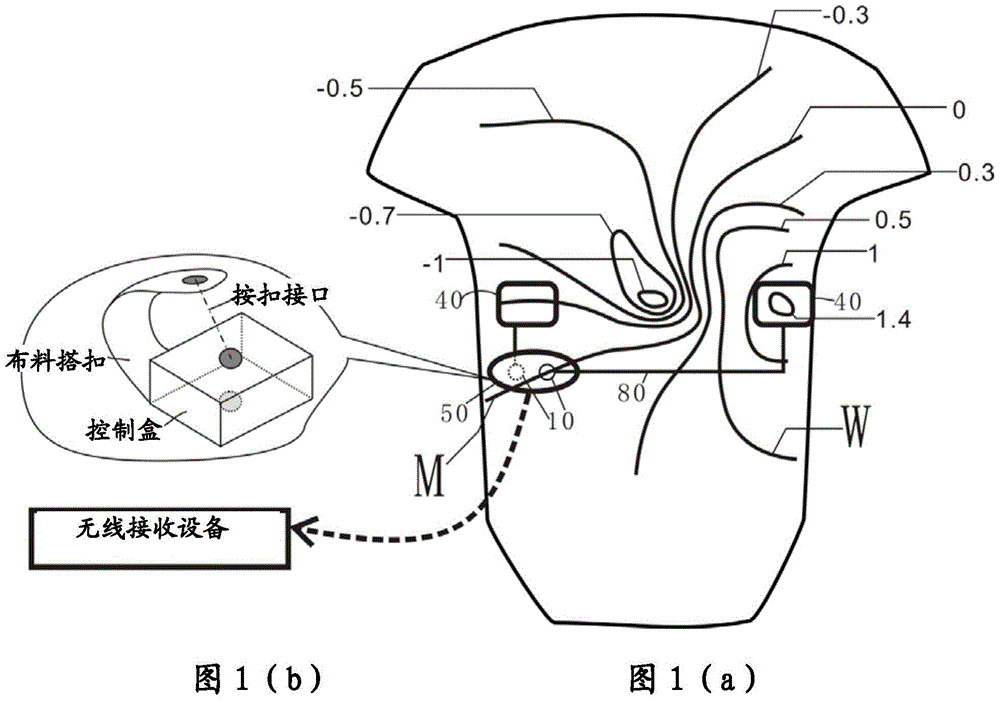

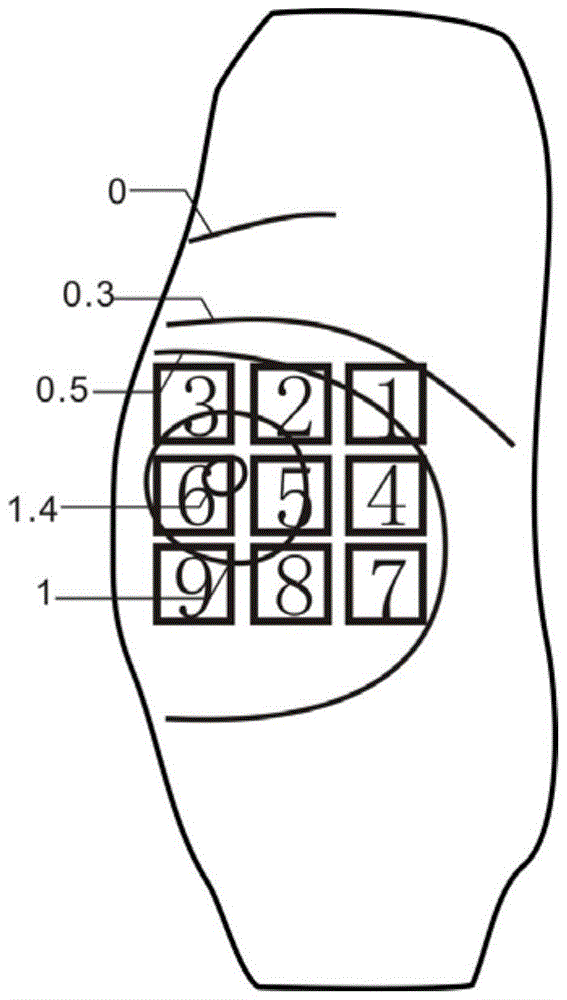

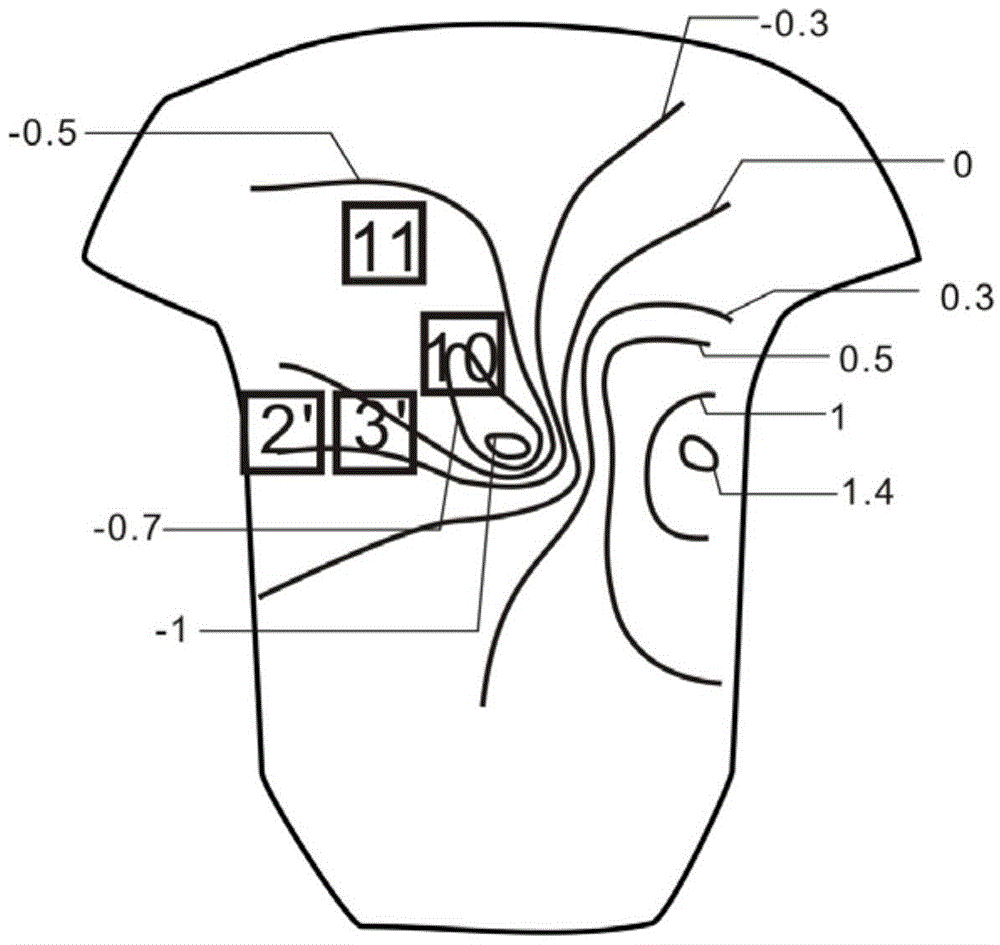

An article, method and system for detecting heartbeat or electrode contact

ActiveCN104302351BReduce motion disturbanceSolve the problem of not fitting with the bodyExternal electrodesCapacitanceEcg signal

Disclosed are an object, method, and system for detecting heartbeat or whether or not electrodes are in proper contact. The system is multiple textile electrodes that are arranged on a textile product, where an isopotential surface map of an electrocardiogram (ECG) is used, and where interference caused by movements of a human body is considered, and is arranged as a structure of separated electrodes. The system is capable of detecting heartbeat on the basis of the positions and areas of the electrodes, and of the arrangement of conductive cables, and is capable of selecting, according to changes in the state of the environment, dry cell powered- or capacitively coupled-electrodes to acquire an electrocardiography signal. The system is capable of detecting whether or not the electrodes are in proper contact with the human body by measuring noise, surface resistance, and muscular resistance, and is capable of inferring the posture and movements of the human body on the basis of the ECG signal and noise.

Owner:杨章民

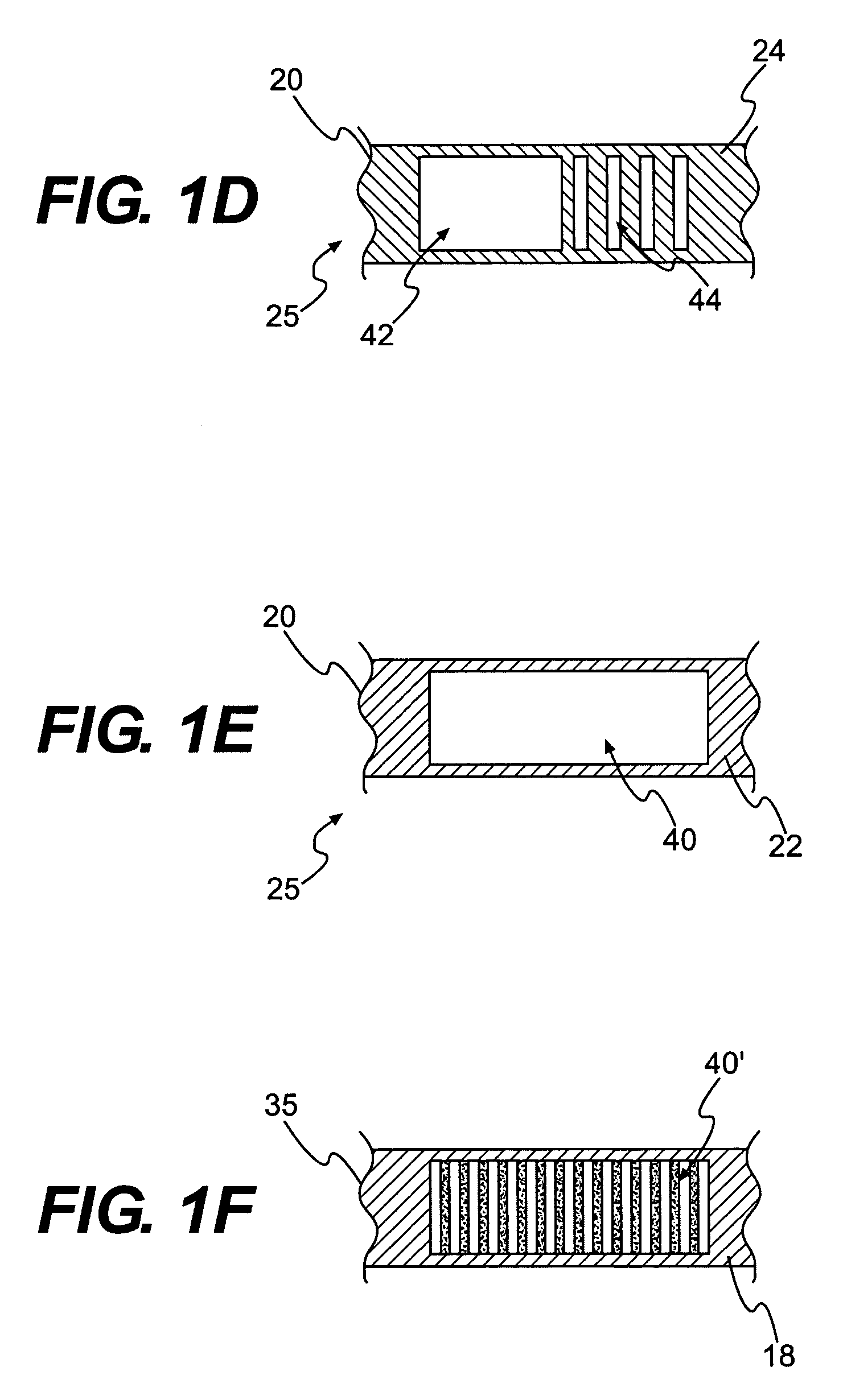

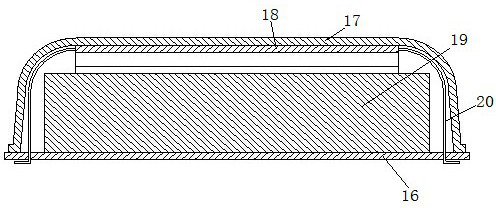

A Novel Sweat Absorbing Textile Electrode

ActiveUS20200046246A1Improve conductivityReduce contact resistanceElectroencephalographyMedical devicesElectrical connectionEngineering

A novel sweat absorbing textile electrode comprises a textile electrode body and an electrical coupling member, the textile electrode body comprising a conductive foam and a conductive fabric wrapped around the conductive foam, the electrical coupling member being fixed on the conductive fabric; wherein a through hole is provided on the conductive fabric on the side in contact with the human skin. The textile electrode has a light weight, small size and soft texture. It fits on the skin, has good air permeability, and is capable to absorb sweat, which can prevent short circuit between electrodes caused by sweat and be used for collecting bioelectrical signal when sweat comes out from human body. It may also be applied in bioelectrical signal monitoring in high temperature, high humidity environment, and during daily exercise.

Owner:SOUTH CHINA UNIV OF TECH

Intelligent yoga mat of distributed type flexible textile electrode and control method

InactiveCN107088289AImprove practicalityShock absorber matsProgramme control in sequence/logic controllersEngineeringPressure data

The invention provides a smart yoga mat with distributed flexible textile electrodes and a control method, wherein the flexible textile electrode array can convert the pressure of the user in the process of using the smart yoga mat into an electrical signal, and then the controller can obtain the pressure data of the user , so as to provide data reference for knowing the user's yoga fitness. Thereby improving the practicability of intelligent yoga mat.

Owner:尧乐网络科技(上海)有限公司

Sweat absorbing textile electrode

ActiveUS11191472B2Quickly and effectively absorbAvoiding short circuit between electrodes in areasMedical devicesDiagnostic recording/measuringHigh humidityHuman skin

Owner:SOUTH CHINA UNIV OF TECH

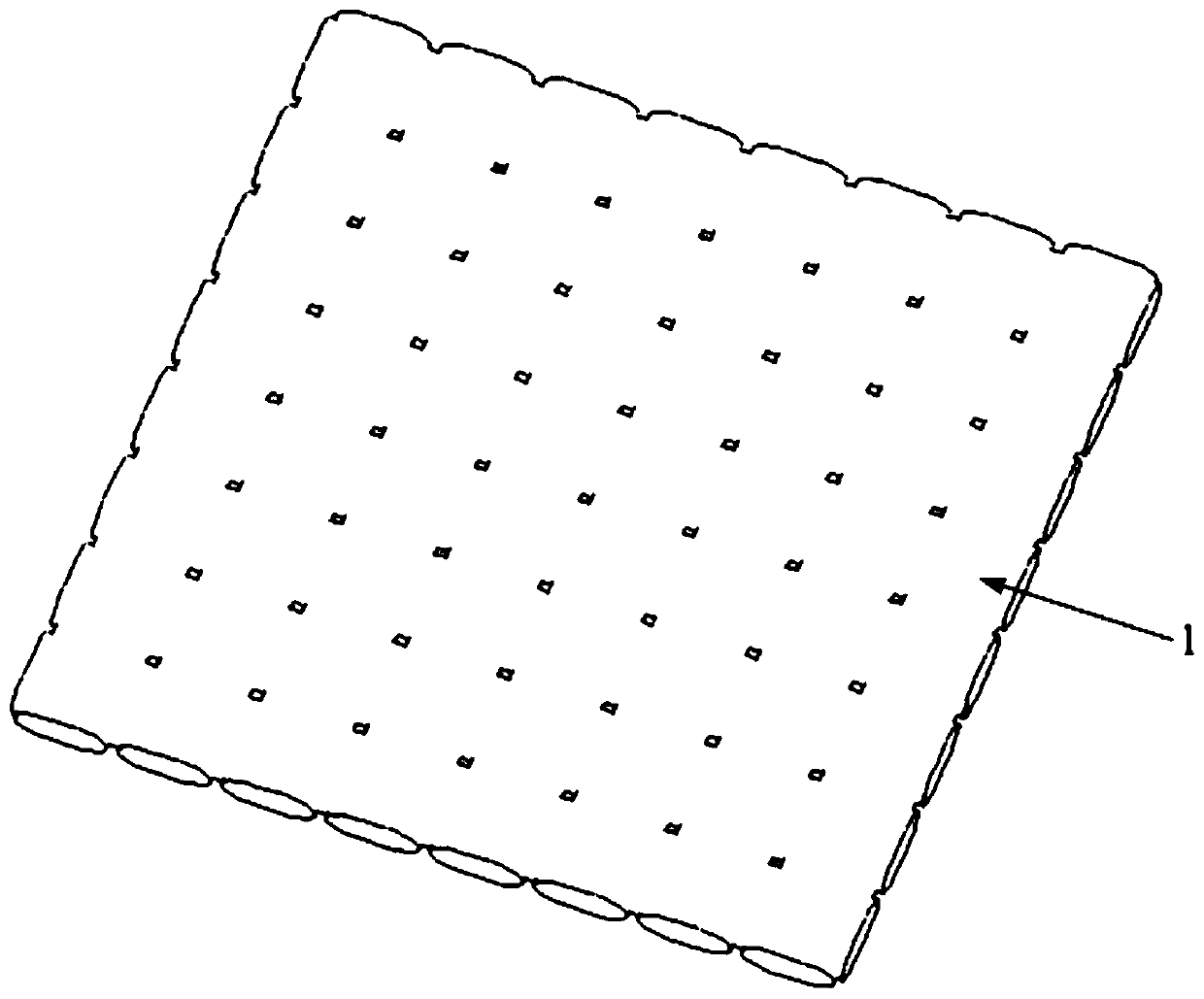

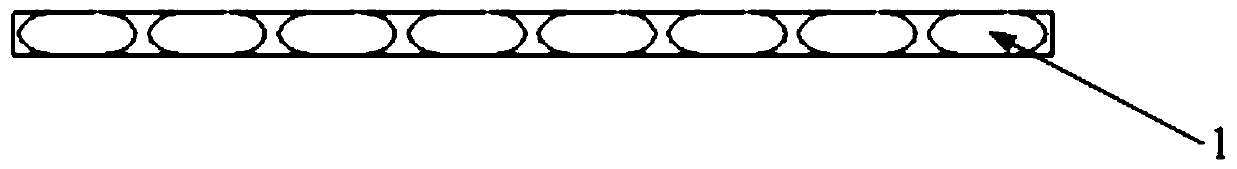

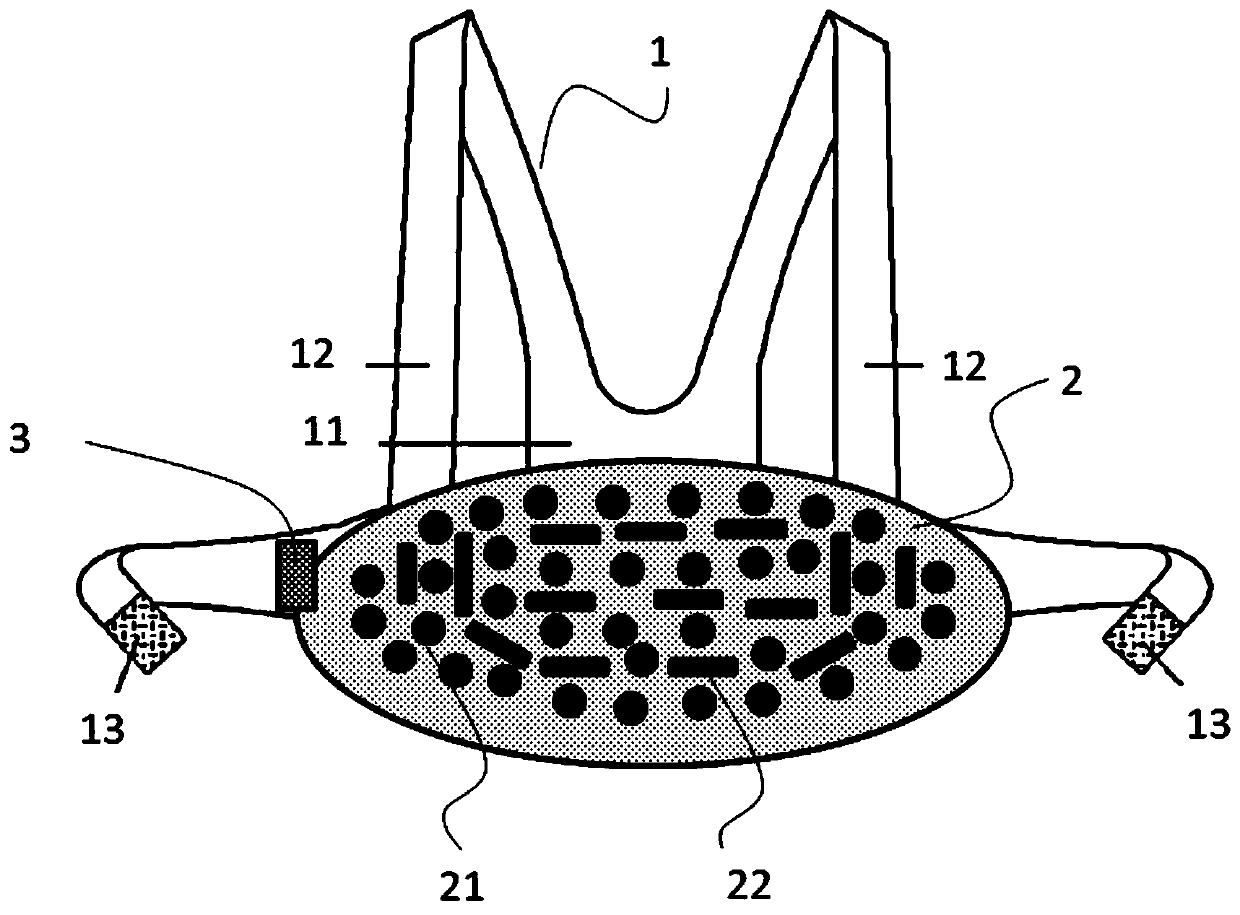

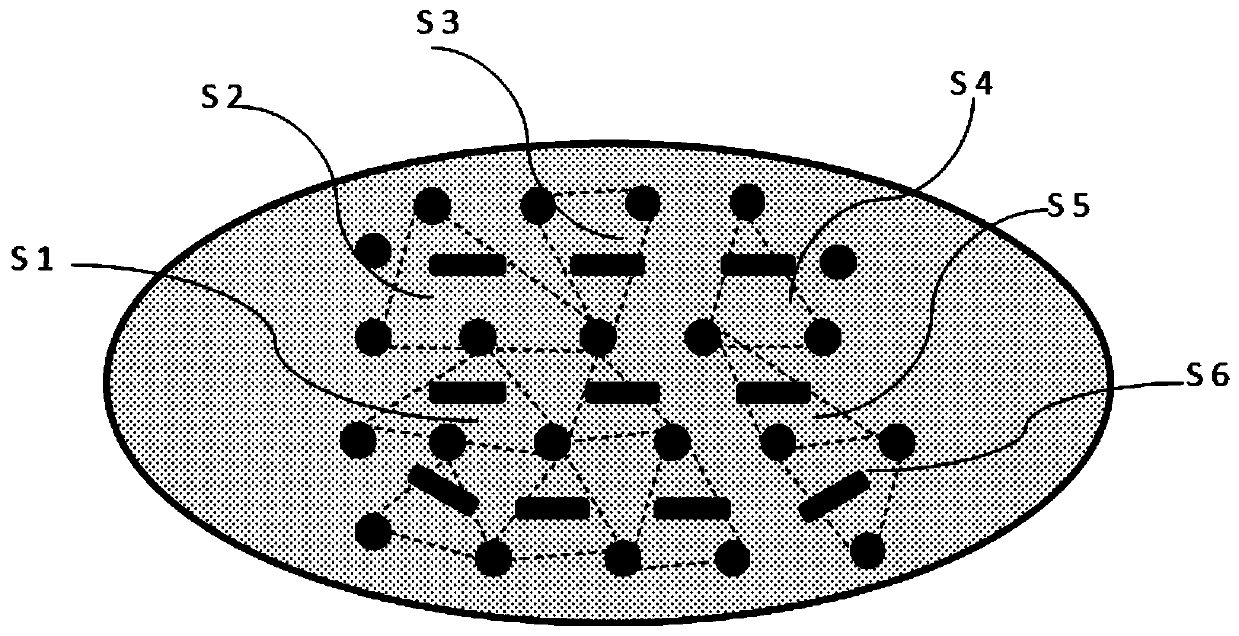

a belly belt

ActiveCN111467107BAcquisition stableSolve the technical problem of unstable signalDiagnostic recording/measuringSensorsData connectionEngineering

The invention relates to an abdominal support belt, comprising a wearable abdominal support belt body, a textile monitoring layer detachably arranged in the physiological monitoring area of the abdominal support belt body, and a data processing module connected to the data of the textile monitoring layer, the textile monitoring layer There are several flexible pressure sensors and several textile electrodes that transmit monitoring information to the data processing module, and the data processing module is composed of any three flexible pressure sensors that are located around the strip-shaped textile electrodes and not on the same side of the strip-shaped textile electrodes. The triangular plane and its epitaxial surface are used as the monitoring plane where the strip-shaped textile electrodes are located, and the average pressure values of the three flexible pressure sensors forming the triangle are counted, and the marked average pressure value is the electrode pressure value of the monitoring plane where the strip-shaped textile electrodes are located. When the electrode pressure value reaches the preset pressure range, the data processing module performs statistics and analysis on the monitoring information collected by the strip-shaped textile electrode. The textile electrode of the invention can collect signals stably.

Owner:蒋富烈 +2

Wireless type electrocardiogram monitoring device

InactiveCN108186007AEasy to monitor in real timeImprove comfortSensorsMeasuring/recording heart/pulse rateWireless transmissionEngineering

The invention discloses a wireless type electrocardiogram monitoring device. The device comprises a textile electrode, the textile electrode is connected with a first electrode buckle through a lead wire, the first electrode buckle is clamped with a second electrode buckle matching with the first electrode buckle, an electrocardiogram monitoring sticker is fixedly connected with the second electrode buckle, and the second electrode buckle is located on the surface of the electrocardiogram monitoring sticker. According to the device, the wireless type electrocardiogram monitoring device can beintegrated on clothes and has better comfort degree and insulation performance; not only can the heart rate be monitored, but also an electrocardiogram can be collected, and by analyzing the wave formand time order of the electrocardiogram, indicators for determining whether a heart is healthy or not are obtained; the electrocardiogram monitoring sticker can be connected with a mobile phone, a pad and the like through wireless transmission devices such as a Bluetooth and the like to perform heart rate monitoring to facilitate real-time monitoring of a user; the textile electrode and the electrocardiogram monitoring sticker can be removed, and the clothes after the textile electrode and the electrocardiogram monitoring sticker are removed can be directly washed by a washing machine or replaced to meet the demand of capable of washing by the washing machine while the cost is reduced.

Owner:XI'AN POLYTECHNIC UNIVERSITY

Abdomen supporting belt

ActiveCN111467107ASolve the technical problem of unstable signalEasy to monitorDiagnostic recording/measuringSensorsData connectionPhysiological monitoring

The present invention relates to an abdomen supporting belt. The abdomen supporting belt comprises a wearable abdomen supporting belt body, a textile monitoring layer detachably arranged in a physiological monitoring area of the abdomen supporting belt body and a data processing module connected with the textile monitoring layer, the textile monitoring layer is provided with a plurality of flexible pressure sensors and a plurality of textile electrodes which transmit monitoring information to the data processing module, the data processing module takes a triangular plane formed by any three flexible pressure sensors positioned at periphery of the strip-shaped textile electrode and not positioned at the same side of the strip-shaped textile electrode and an extension plane of the triangularplane as a monitoring plane where the strip-shaped textile electrode is positioned, calculates average pressure values of each three flexible pressure sensors forming a triangle and also marks the average pressure values as electrode pressure values of the monitoring planes where the strip-shaped textile electrodes are positioned, and under the condition that the electrode pressure values reach apreset pressure range, the data processing module carries out statistics and analysis on the monitoring information acquired by the strip-shaped textile electrodes. The textile electrodes can stablyacquire signals.

Owner:蒋富烈 +2

Textile electrode

ActiveUS9089273B2Reduce evaporationElectroencephalographyElectrocardiographyVapor barrierConductive textile

The present invention is related to a textile electrode (1) for measuring an electrical signal from a body part, said electrode comprising, successively from the side to be applied on the body part to the outside: a conductive textile contact (3) to be applied to said body part; a textile support (2) for supporting said textile contact (3); a vapor barrier sheet material (7) able to reduce, in use, evaporation of liquid from said textile electrode (1).

Owner:CECOTEPE ASBL

Fabric electrode and accumulator containing the electrode

InactiveCN101449409BMaterial nanotechnologyElectrode manufacturing processesMetal fiberNano structuring

The invention relates to an electrode comprising (a) an electron collector containing one or more transition metals from the groups 4 to 12 of the Periodic Classification of the Elements, and (b) a material that is electrochemically active, present on the surface of the electron collector in the form of a nano-structured conversion layer containing nano-particles or agglomerates of said nano-particles, wherein the nano-particles have a mean diameter of between 1 and 1000 nm, preferably between 10 and 300 nm, wherein said electrochemically active material contains at least one compound of the transition metal or transition metals present in the electron collector, characterized by the fact that the electrode is a textile formed by metallic wires or fibers. The invention also relates to a half-accumulator and an accumulator containing such a textile electrode.

Owner:ELECTRICITE DE FRANCE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com