Fabric-like super capacitor based on graphene and polyaniline and preparation method thereof

A technology of supercapacitors and graphene, which is applied in the manufacture of hybrid/electric double layer capacitors and electrodes of hybrid capacitors, can solve the problems of high-cost materials, and achieve the effects of low cost, guaranteed dispersion, high practicability and feasibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

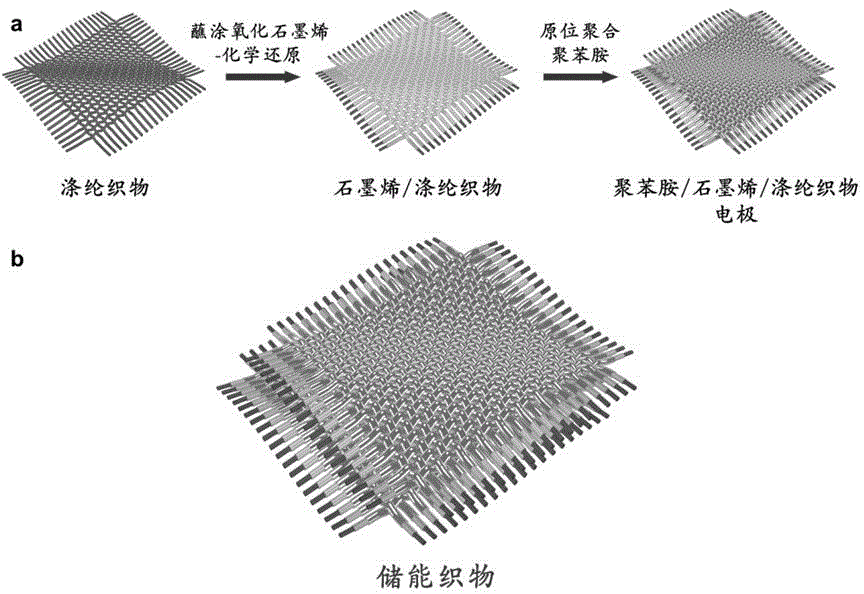

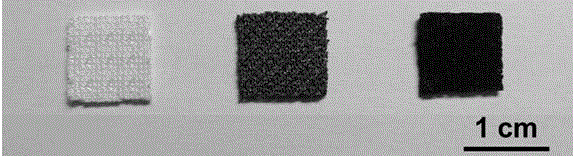

[0022] (1) Dipping-chemical reduction method to prepare graphene / polyester fabric electrode: use expanded graphite-redox method to prepare graphene oxide, dilute 20 cm 2 The polyester fabric was ultrasonicated in ethanol solution for 10 minutes, dried at 80°C, dipped in 2 mg / mL graphene oxide solution, dried at 80°C, and repeated dipping-drying process 6 times until the surface appeared A uniform golden brown. Under the condition of a water bath at 80°C, the graphene oxide was reduced in hydroiodic acid for 6 h and then taken out, and the fabric electrode was washed three times with ethanol and deionized water alternately to obtain a graphene / polyester fabric electrode;

[0023] (2) Preparation of polyaniline / graphene / polyester fabric electrode by in situ chemical polymerization method: the 20 cm 2 The graphene / polyester fabric electrode was immersed in 100 mL of hydrochloric acid solution (PH=0) with an aniline concentration of 0.5 M / L for 1 hour, and the same volume of ammo...

Embodiment 2

[0027] (1) Preparation of graphene / polyester fabric electrode by dipping-chemical reduction method: graphene oxide was prepared by expanded graphite-redox method, and 100 cm 2 The polyester fabric was sonicated in ethanol and isopropanol solutions for 10 minutes, dried at 80°C, dipped in a 3 mg / mL graphene oxide solution, dried at 80°C, and the dipping-drying process was repeated 8 Repeat until a uniform golden yellow color appears on the surface. Under the condition of a water bath at 80°C, the graphene oxide was reduced in hydroiodic acid for 8 h and then taken out, and the fabric electrode was washed three times with ethanol and deionized water alternately to obtain a graphene / polyester fabric electrode;

[0028] (2) Preparation of polyaniline / graphene / polyester fabric electrode by in situ chemical polymerization method: 100 cm prepared in (1) at room temperature 2The graphene / polyester fabric electrode was immersed in 250 mL of hydrochloric acid solution (PH=0) with an an...

Embodiment 3

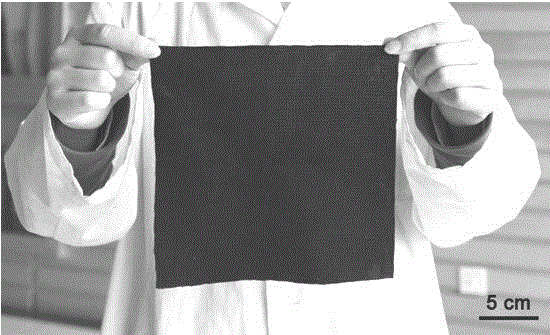

[0032] (1) Preparation of graphene / polyester fabric electrode by dipping-chemical reduction method: graphene oxide was prepared by expanded graphite-redox method, and 400 cm 2 The polyester fabric was ultrasonicated in ethanol and isopropanol solutions for 10 minutes, dried at 80 °C, dipped in a 4 mg / mL graphene oxide solution, dried at 80 °C, and the dipping-drying process was repeated for 10 Repeat until a uniform golden yellow color appears on the surface. Under the condition of a water bath at 80°C, the graphene oxide was reduced in hydroiodic acid for 10 h and then taken out, and the fabric electrode was washed three times with ethanol and deionized water alternately to obtain a graphene / polyester fabric electrode;

[0033] (2) Preparation of polyaniline / graphene / polyester fabric electrode by in situ chemical polymerization method: the 400 cm 2 The graphene / polyester fabric electrode was immersed in 500 mL of hydrochloric acid solution (PH=0) with an aniline concentratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com