Nano fiber and textile electrode integrated wearable sensing member

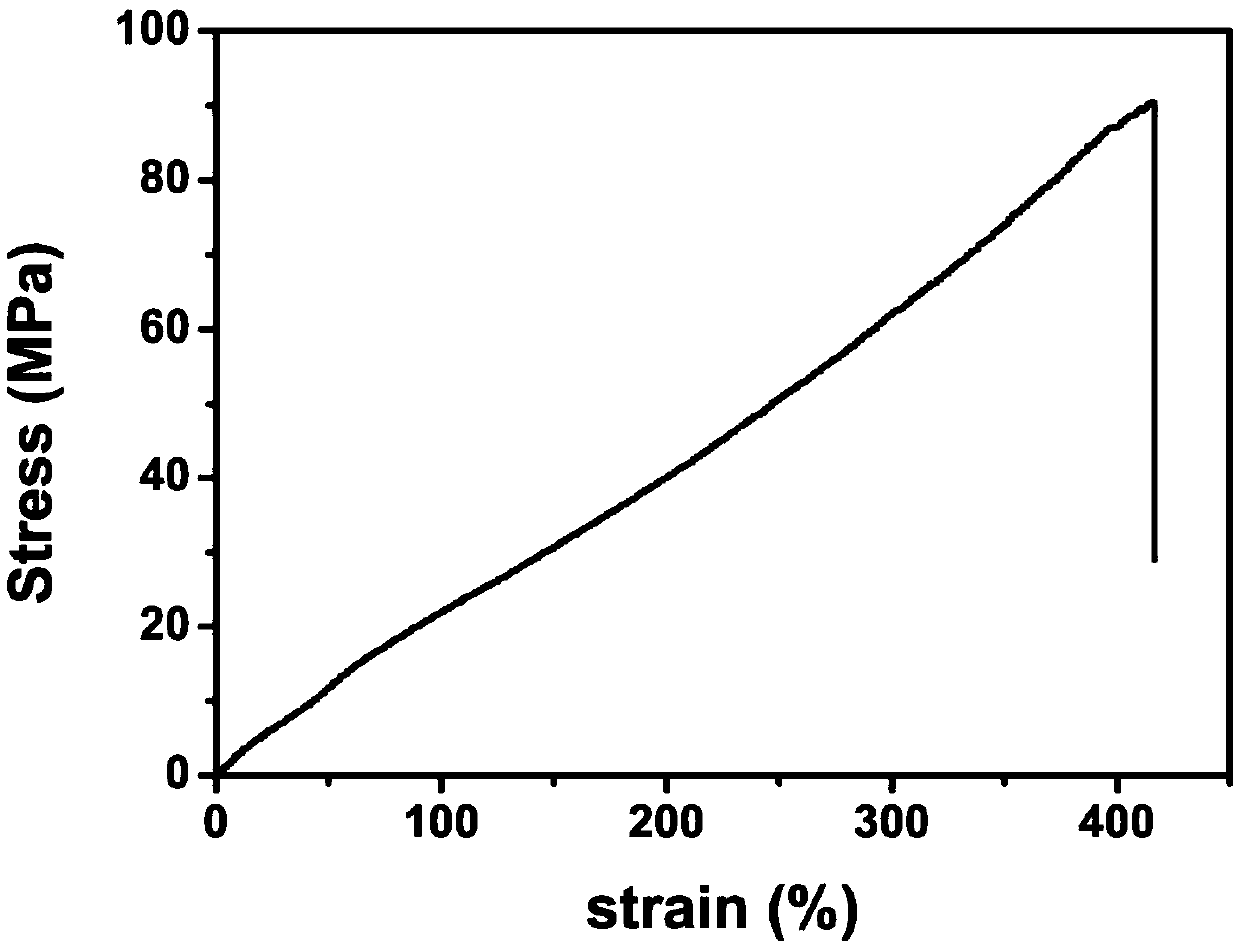

A technology for fabric electrodes and sensing devices, applied in the direction of sensors, non-woven fabrics, textiles and papermaking, can solve problems such as reducing comfort, affecting electrical conductivity, affecting air permeability, etc., achieving good tensile properties, mature preparation technology, Practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

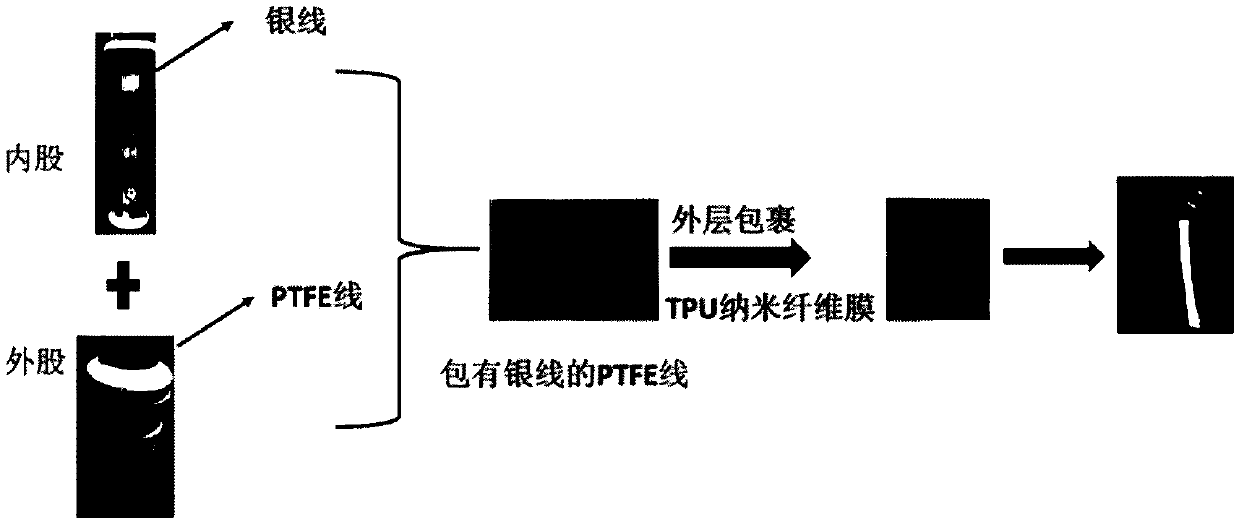

[0025] A method for preparing a wearable sensor device integrated with nanofibers and fabric electrodes, comprising the steps of:

[0026] 1). Coaxial fabric electrode weaving: take the conductive silver wire as the axis, and use weaving technology to wind multiple yarns with strong electronegativity outside it. The number of yarns wrapped outside the conductive silver wire is 12. ~24 wires, do not expose the silver wire to the outside to make it a coaxial fabric electrode; the conductive silver wire in the axis is the electrode material of the sensor, and the yarn wound on the outer layer is used as the friction negative electrode material, and the outermost layer Electrospun nanofibrous membranes as tribocathode materials.

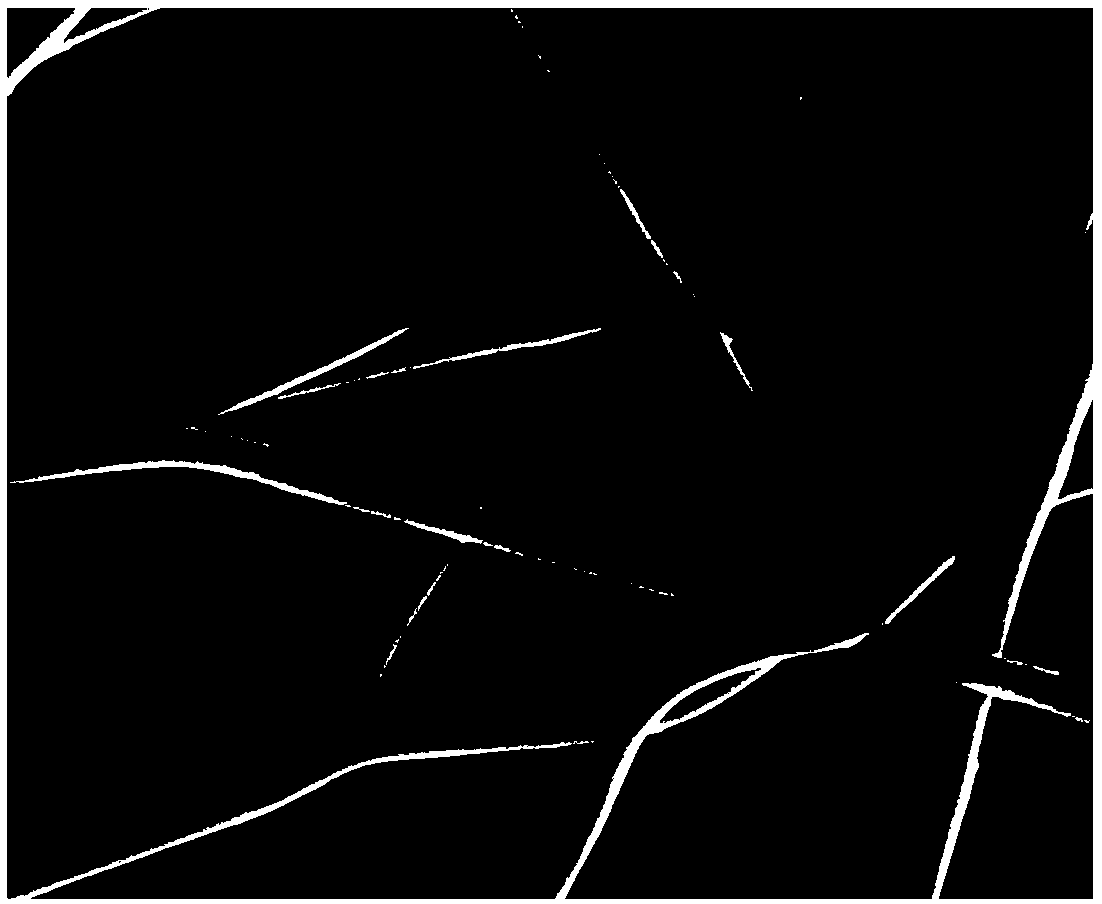

[0027] 2). Preparation of TPU electrostatic nanofiber membrane: Dissolve 1.0g of TPU in 10ml of mixed spinning solvent of dichloromethane and N,N-dimethylformamide, in which dichloromethane and N,N-di The volume ratio of methyl formamide is 1:5, and the...

Embodiment 2

[0032] A method for preparing a wearable sensor device integrated with nanofibers and fabric electrodes, comprising the steps of:

[0033] 1). Coaxial fabric electrode weaving: take conductive silver wire as the axis, and use weaving technology to wind multiple strands of yarn with strong electronegativity outside it. The yarn can be PVDF, PTFE, PTFE-HFP, FEP; Do not expose the silver wire to make it a coaxial fabric electrode;

[0034] 2). Preparation of FPU nanofiber membrane: Dissolve 3.0g of FPU in 15ml of a mixed spinning solvent of dichloromethane and N,N-dimethylformamide, wherein dichloromethane and N,N-dimethylformamide The volume ratio of methyl formamide is 1:1, and the FPU spinning solution is prepared for spinning; the electrospinning voltage is 18-25kV, the propulsion speed is 0.6-1mL / h, and the receiving distance is 15-20cm, and the FPU electrospinning solution is obtained. Nanofiber membrane, the thickness of the electrospun nanofiber membrane is 25-50 μm;

...

Embodiment 3

[0040] A method for preparing a wearable sensor device integrated with nanofibers and fabric electrodes, comprising the steps of:

[0041] 1). Conduct coaxial fabric electrode weaving: take conductive silver wire as the axis, and use weaving technology to wind multiple strands of yarn with strong electronegativity outside it. The yarn can be PVDF, PTFE, PTFE-HFP, FEP, Do not expose the silver wire to the outside to make it a coaxial fabric electrode, the conductive silver wire is the electrode material of this sensor, the outer wound yarn is used as the friction negative electrode material, and the outermost electrospun nanofiber membrane is used as the friction positive electrode Material, the number of strands of yarn wound on the outside of the conductive silver wire is 12 to 24;

[0042] 2). Preparation of PAN nanofiber membrane: Dissolve 1.0-3.0 g of PAN in 10-15 ml of a mixed spinning solvent of dichloromethane and N,N-dimethylformamide, wherein dichloromethane and N, T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com