Preparation technique for membrane electrode of proton exchange film fuel cell

A proton exchange membrane and fuel cell membrane technology, which is applied to fuel cell parts, fuel cells, battery electrodes, etc., can solve the problems of proton exchange membrane swelling, complex preparation process, and high catalyst dosage, and achieves improved effective contact and simplified Preparation process, the effect of simplifying the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Hydrophobic treatment of carbon paper / carbon cloth: firstly, carbon paper (as the current collecting layer) is dipped in 35% PTFE emulsion to obtain hydrophobic carbon paper / carbon cloth.

[0041] Leveling treatment of carbon paper: Grind Vulcan-72 carbon powder in 20% PTFE emulsion high-energy ball to emulsified carbon paste, and use screen printing to evenly coat and water-repellent the surface of carbon paper. A carbon paper with a microdiffusion layer is formed. The loading amount of carbon powder in the micro-diffusion layer is 3mg / cm 2 . The carbon paper has the function of managing the gas distribution of the fuel cell and at the same time collecting the current.

[0042] Proton exchange membrane treatment: first with 3% H 2 o 2 Hydrogen peroxide to 5*5cm 2 The nafion212 proton exchange membrane was treated for 1 hour to remove surface pollutants, and the proton exchange membrane was boiled with double distilled water and washed twice. After washing, store ...

Embodiment 2

[0048] Adopt treated charcoal cloth, micro-diffusion layer is treated with example 1.

[0049] The processing of proton exchange membrane is the same as example 1

[0050] Preparation of catalyst slurry: 1) Get 5ml of perfluorosulfonic acid solution solution (Nafion520, 5wt%, DuPont company, U.S.) and pour it into a small beaker 2) Weigh the Pt / C catalyst according to the ratio of catalyst to Nafion mass 2:1 (Shanghai Panye), adding 40ml of ethanol without adding pore-forming agent, and performing high-energy ball milling for 1 hour to fully disperse the catalyst and fully mix it with Nafion to prevent the slurry from agglomerating during the spraying process.

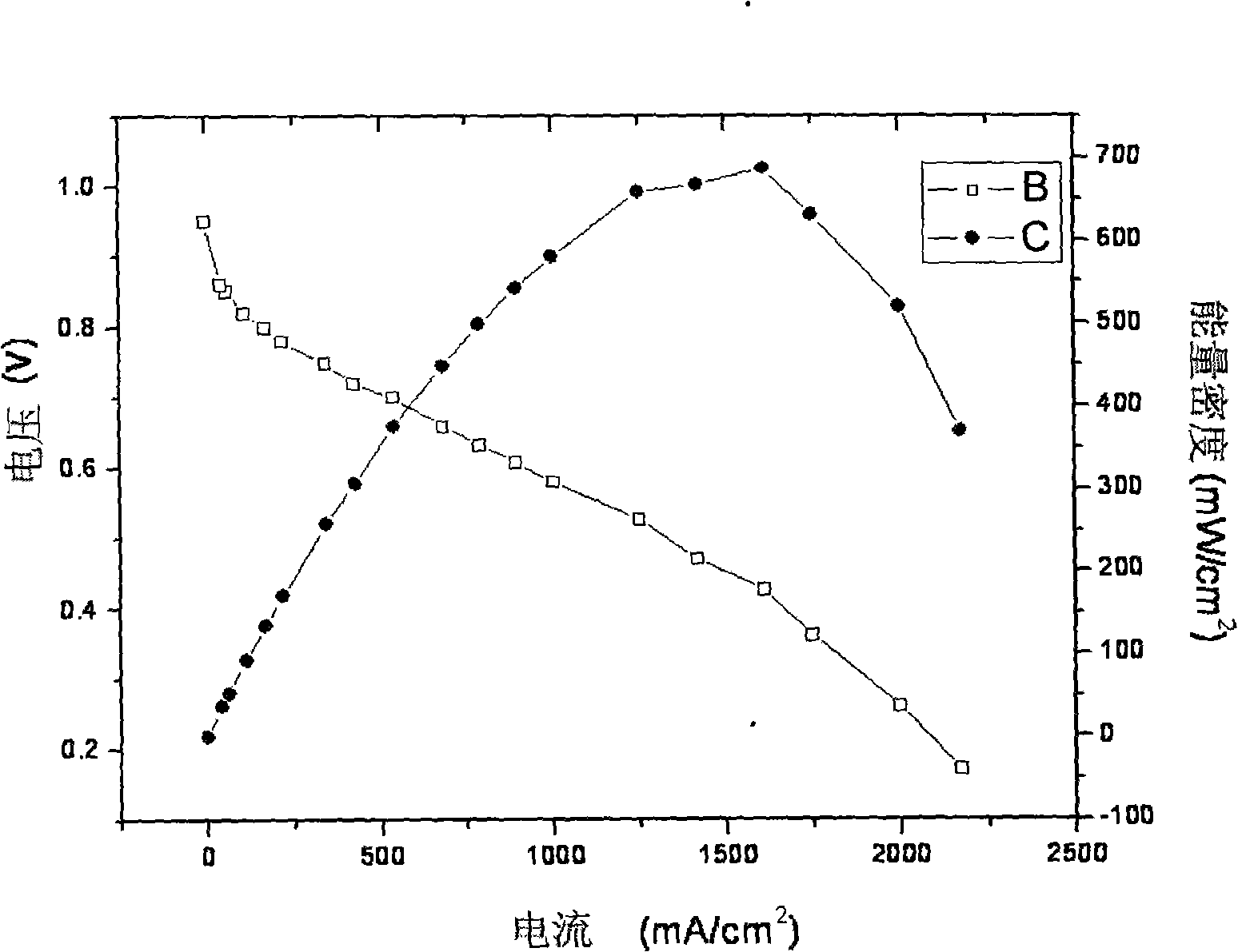

[0051] Preparation of Membrane Electrode: 1) Put the fully treated Nafion212 membrane on a glass plate, fix it with adhesive tape around it, and wipe off the water on the surface of the membrane with a glass rod. Place the glass plate on a heating platform and heat at 150°C to volatilize the moisture on the surface of...

Embodiment 3

[0053] The micro-diffusion layer of carbon paper is treated with example 1.

[0054] The processing of proton exchange membrane is the same as example 1

[0055] The preparation of catalyst slurry: 1) get 1.2g 5% Nafion solution (DuPont company, the U.S.) and pour in the small beaker 2) weigh PtRu / C catalyst (Shanghai Panye) according to the ratio of catalyst and Nafion mass 5:1 , add 6ml of deionized water, add 2.4g of ammonium sulfate as a pore-forming agent and carry out high-energy ball milling for 1 hour to fully disperse the catalyst and mix it with Nafion to prevent the slurry from agglomerating during the spraying process.

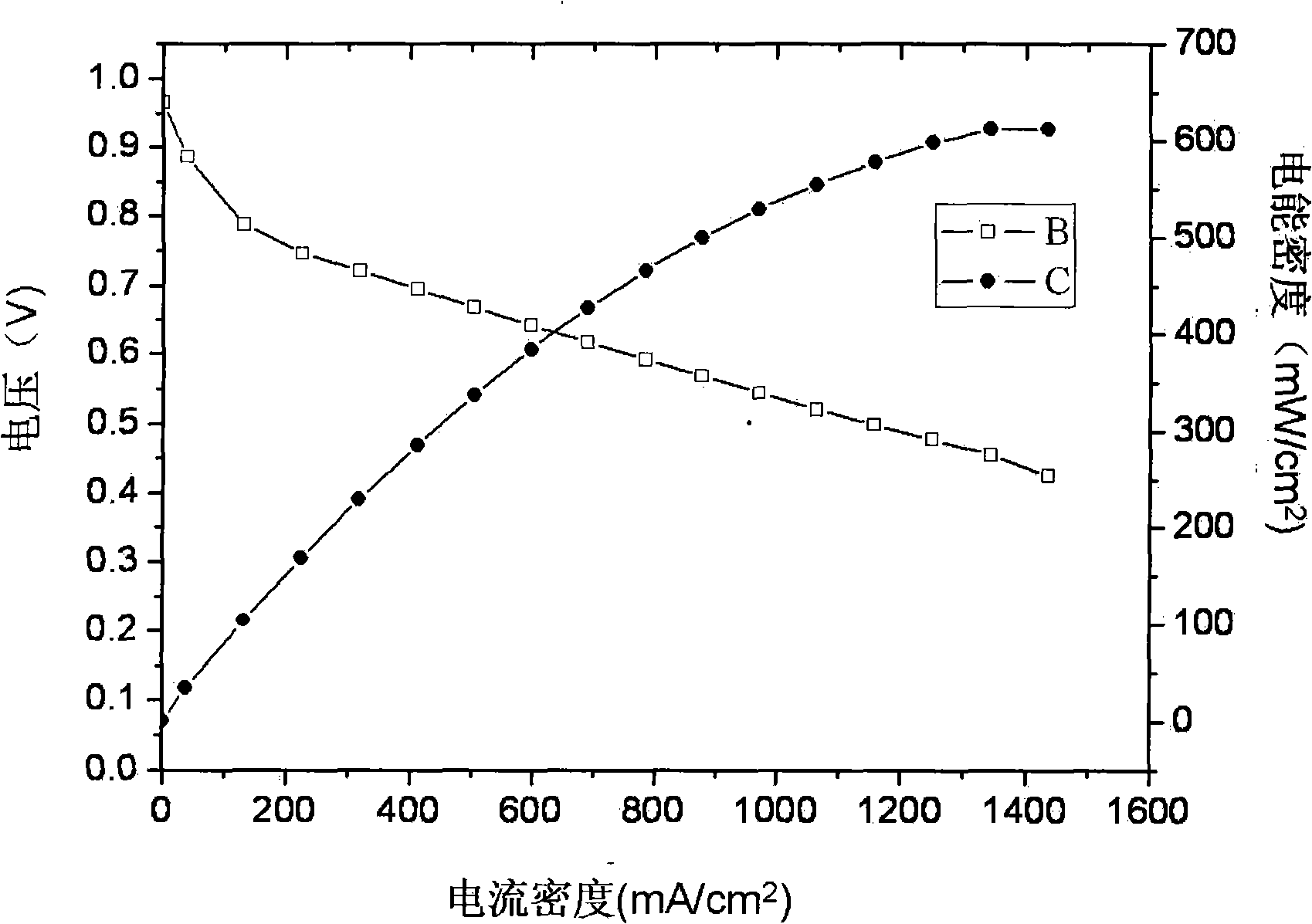

[0056] Membrane electrode preparation: 1) Place the fully treated Nafion112 membrane on a smooth quartz plate, fix it with a strip-shaped fixing plate around it, and wipe off the moisture on the membrane surface with absorbent cotton. Place the graphite plate on a heating platform and heat it at 180°C to volatilize the moisture on the surface of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com