Porous activated carbon fiber adsorbing material of sheath-core composite structure and preparation thereof

A technology of porous activated carbon and adsorption materials, which is applied in the direction of alkali metal compounds, other chemical processes, alkali metal oxides/hydroxides, etc., and can solve the problems affecting the range of use and service life of ACF, strength loss, etc., and achieve a favorable load The effect of biological cells, prolonging the service life, and easy preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Viscose-based carbon fibers with a strength of 0.7GPa were placed in 0.1M Na 3 PO 4 The solution was left to stand for 3 hours, and then put into the activation furnace, and water vapor and N 2 , the temperature was raised to 1000°C at a rate of 20°C / min, and water vapor was passed through for constant temperature activation for 0.5 hours. After cooling down to 200°C, the inert gas and water vapor were turned off to prepare a porous activated carbon fiber adsorption material.

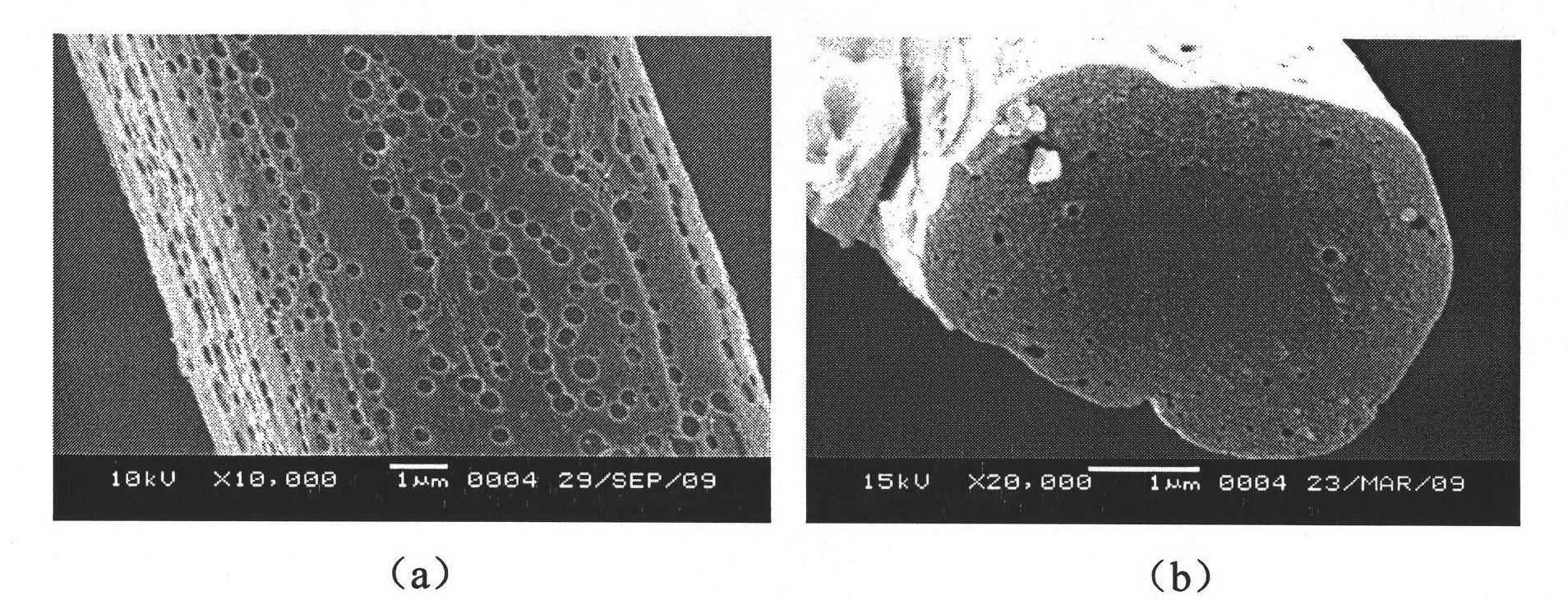

[0028] image 3 It is the electron microscope photo of the adsorption material of this embodiment, the pore size on the surface is 50nm2 / g.

Embodiment 2

[0030] Put viscose-based carbon fibers with a strength of 0.7GPa in 0.2M NaH 2 PO 4 Stand in the solution for 2 hours, then put it into the activation furnace, pass water vapor and N 2 , the temperature was raised to 1000°C at a rate of 10°C / min, and water vapor was passed through for constant temperature activation treatment for 1 hour. After cooling down to 200°C, the inert gas and water vapor were turned off to prepare a porous activated carbon fiber adsorption material.

[0031] Figure 4 It is the electron microscope photo of the adsorption material of this embodiment, the pore diameter on the surface is 100nm2 / g.

Embodiment 3

[0033] Viscose-based carbon fibers with a strength of 0.7GPa were placed in 0.1M Na 2 HPO 4 Stand in the solution for 4 hours, then put it into the activation furnace, pass water vapor and N 2 , the temperature was raised to 1000°C at a rate of 10°C / min, and water vapor was passed through for constant temperature activation for 0.5 hours. After cooling down to 200°C, the inert gas and water vapor were turned off to prepare a porous activated carbon fiber adsorption material.

[0034] Figure 5 It is the electron micrograph of the adsorption material of this embodiment, the pore diameter on the surface is 50nm2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com