A kind of antibacterial cotton fabric and preparation method thereof

A cotton fabric and antibacterial finishing agent technology, applied in the field of textile fabric processing, can solve the problems of no antibacterial effect, insufficient antibacterial effect of natural antibacterial agents, and non-washable organic antibacterial agents, so as to avoid adverse side effects and good killing effect , The effect of reducing the use of organic chemical reagents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

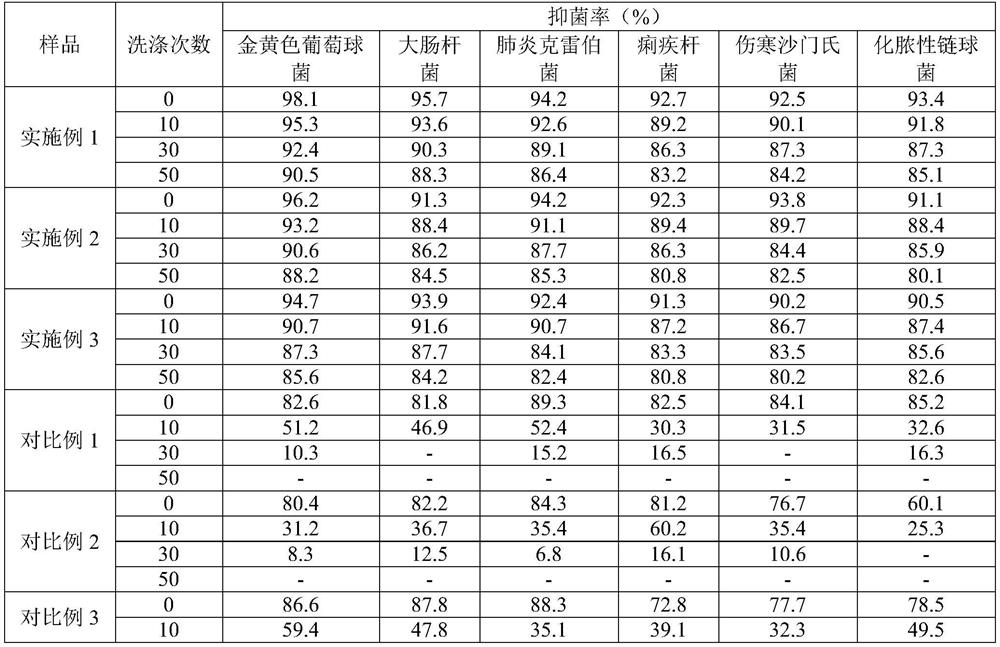

Embodiment 1

[0027] 1. The cotton fabric is subjected to plasma treatment. The conditions of plasma treatment are as follows: the gas uses oxygen, the treatment power is 200W, the pressure is 50Pa, and the treatment time is 25min;

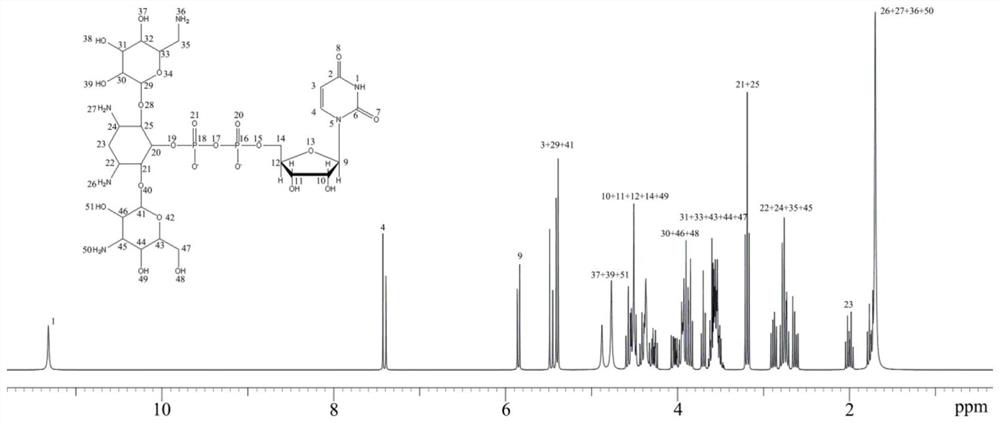

[0028] 2. Mix 4g of kanamycin, 5g of UMP, 12.5g of Saccharomyces cerevisiae extract, 15g of sugar, and 8g of potassium dihydrogen phosphate, add it to 100mL of water, react at 30°C for 10 hours, and then filter to obtain an antibacterial finishing agent;

[0029] 3. Crush 64g of apple seeds, put them into 100mL of PBS buffer solution, stir well, extract at 4°C for 24h, filter, and freeze-dry the filtrate at -22°C to obtain a glycosidase preparation;

[0030] 4. Immerse 1g of the cotton fabric treated in step 1 in 18mL of antibacterial finishing agent, and put in 0.6g of glucosidase preparation, fully impregnate at 30°C for 72h, then wash and air-dry to obtain antibacterial cotton fabric.

Embodiment 2

[0032] 1. The cotton fabric is subjected to plasma treatment. The plasma treatment conditions are as follows: the gas uses oxygen, the treatment power is 100W, the pressure is 40Pa, and the treatment time is 15min;

[0033] 2. Mix 3g of kanamycin, 4g of UMP, 10g of Saccharomyces cerevisiae extract, 10g of sugar, and 5g of potassium dihydrogen phosphate, add it to 100mL of water, react at 28°C for 8 hours, and then filter to obtain an antibacterial finishing agent;

[0034] 3. Crush 50 g of apple seeds, put them into 100 mL of PBS buffer solution, stir well, extract at 2°C for 12 hours, then filter, and freeze-dry the filtrate at -42°C to obtain a glycosidase preparation;

[0035] 4. Immerse 1g of the cotton fabric treated in step 1 in 15mL of antibacterial finishing agent, and put in 0.5g of glucosidase preparation, fully impregnate at 20°C for 48h, then wash and air-dry to obtain antibacterial cotton fabric.

Embodiment 3

[0037] 1. The cotton fabric is subjected to plasma treatment. The conditions of plasma treatment are as follows: the gas uses oxygen, the treatment power is 300W, the pressure is 60Pa, and the treatment time is 30min;

[0038] 2. Mix 5g of kanamycin, 6g of UMP, 15g of Saccharomyces cerevisiae extract, 20g of sugar, and 10g of potassium dihydrogen phosphate, add it to 100mL of water, react at 37°C for 12 hours, and then filter to obtain an antibacterial finishing agent;

[0039] 3. Crush 80g of apple seeds, put them into 100mL of PBS buffer solution, stir well, extract at 8°C for 48h, then filter, and freeze-dry the filtrate at -17°C to obtain a glycosidase preparation;

[0040] 4. Take 1g of the cotton fabric treated in step 1 and immerse it in 20mL of antibacterial finishing agent, add 0.8g of glycosidase preparation, fully impregnate, the impregnation temperature is 37°C, and the impregnation time is 100h, then wash and air-dry to obtain antibacterial cotton fabric.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com