Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

61results about How to "Fully adhered" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

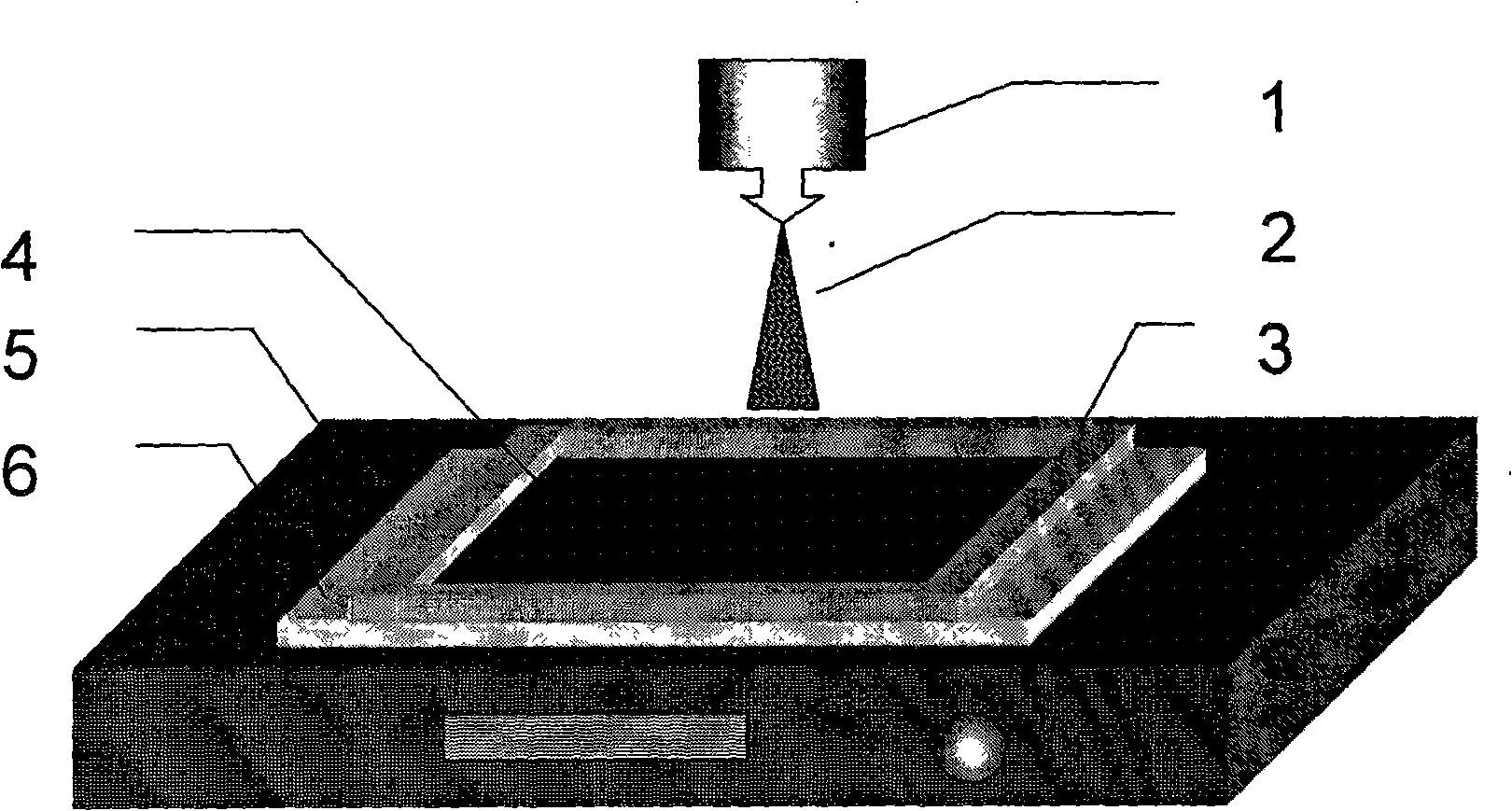

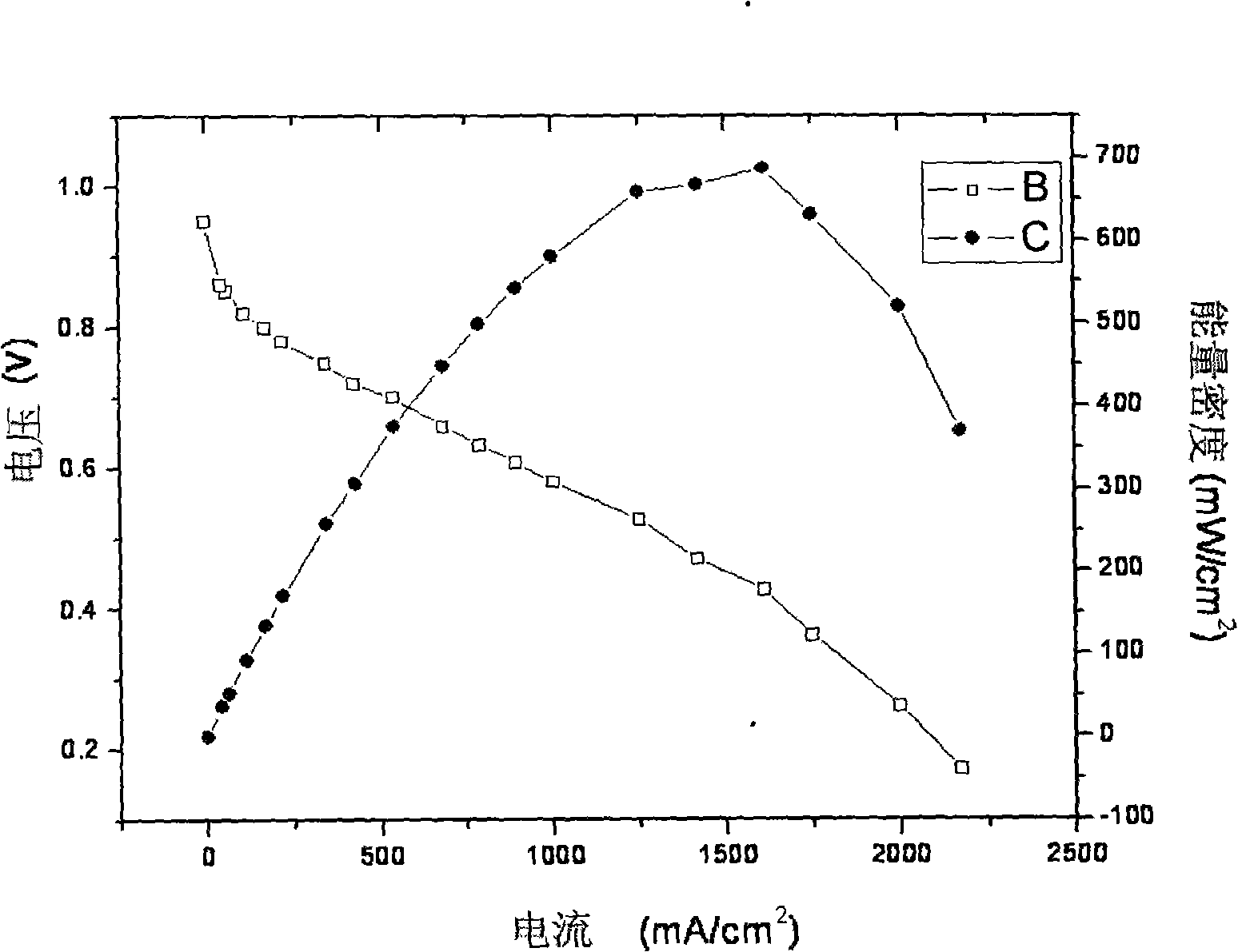

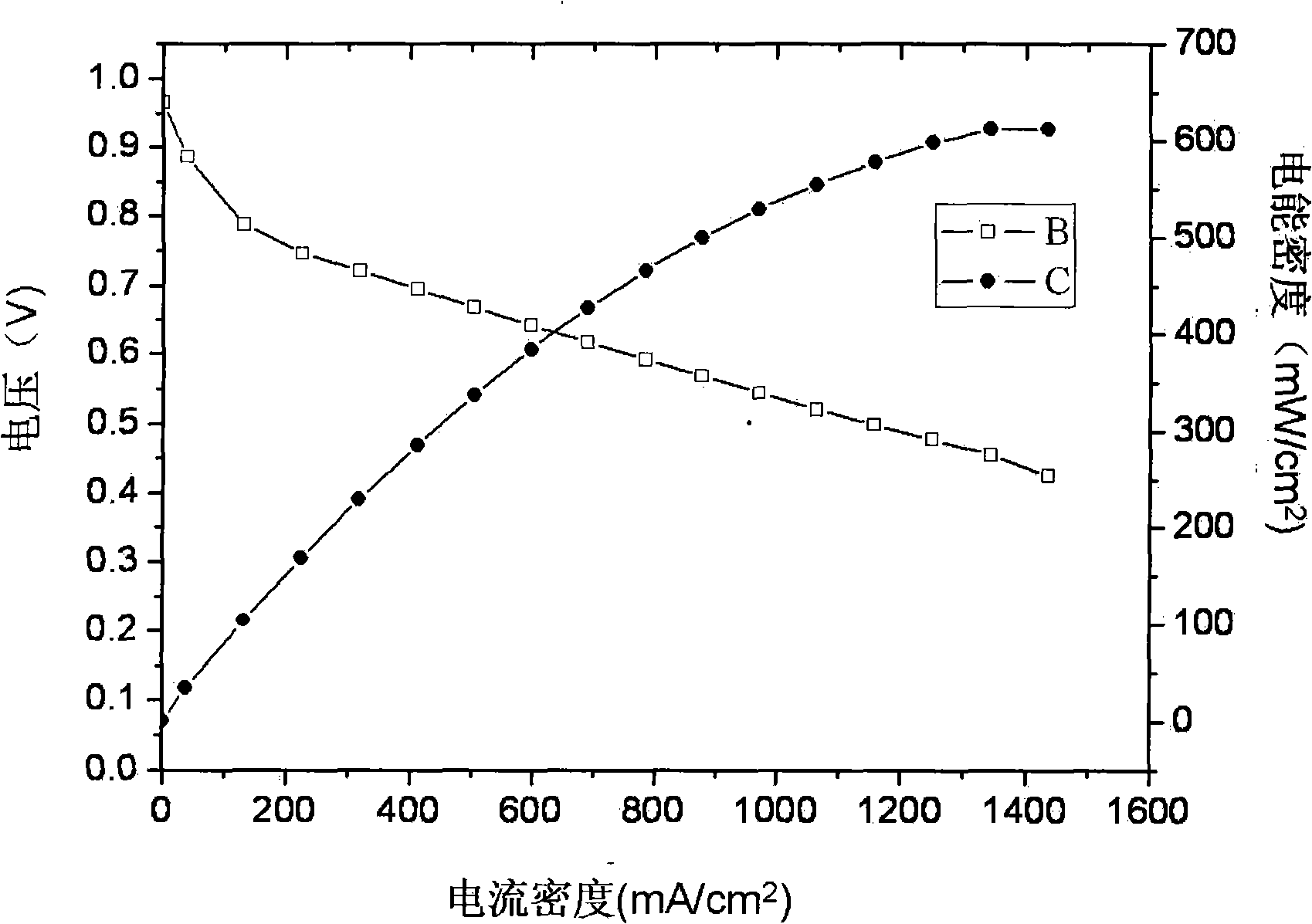

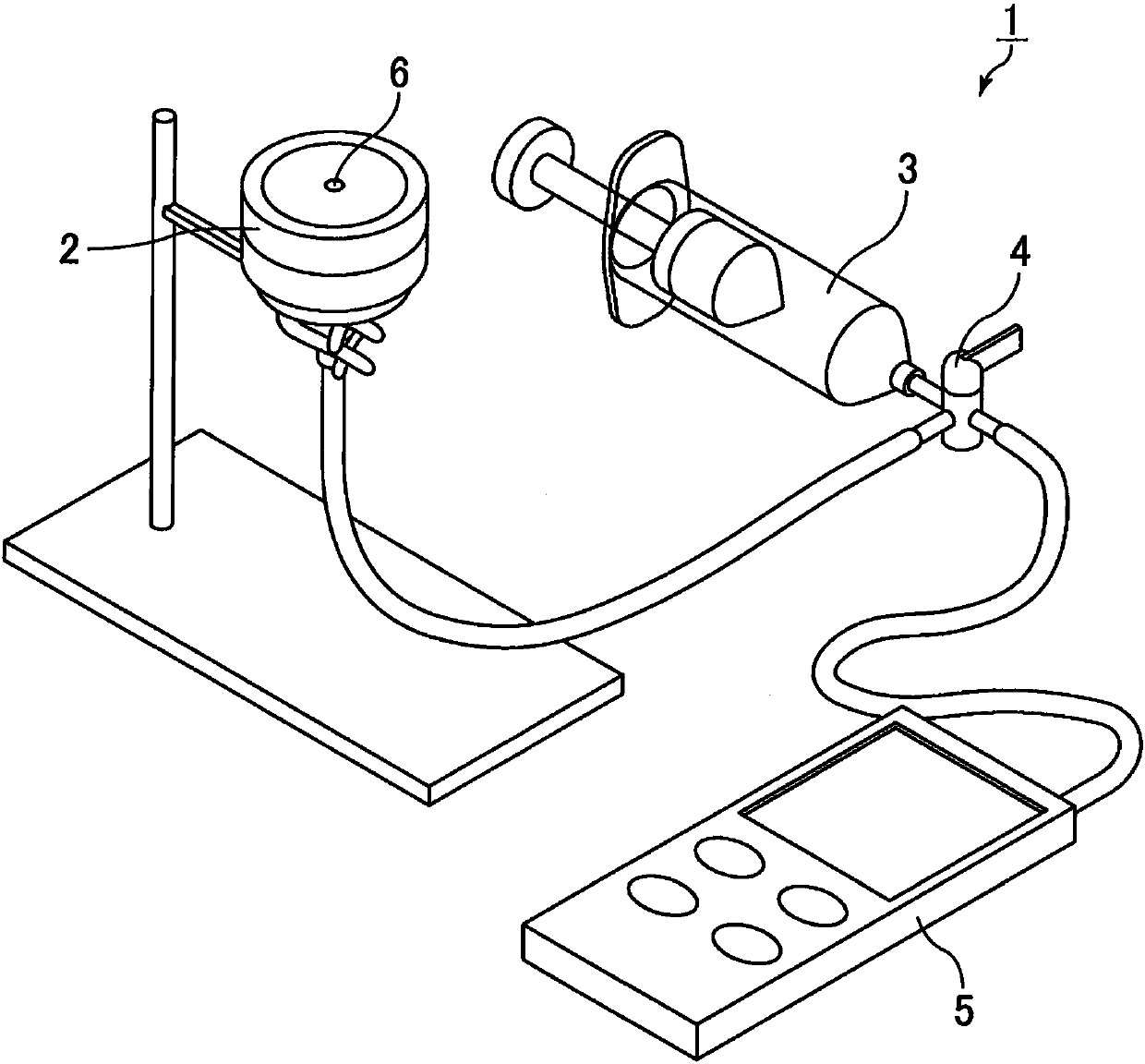

Preparation technique for membrane electrode of proton exchange film fuel cell

ActiveCN101276919AImprove solubilityNo pollution in the processFinal product manufactureCell electrodesState of artSpray coating

The invention relates to a technology that prepares a proton exchange membrane fuel cell electrode, comprising three parts of a pre-process of the proton exchange membrane, a preparation of a catalyst slurry and spray coating of a membrane electrode. The technology provided by the invention solves the problems that in prior art preparation process, the proton exchange membrane swells and rucks and the dosage of the catalyst is high and the preparation process is complicated. The prepared proton exchange resin has great elasticity and adhesive property, which is beneficial for improving adhesion of the catalyst layer and the proton exchange membrane and improves utilization ratio of the catalyst.

Owner:辽宁沐与康中氢燃料电池有限公司

Preparation method of compound refractory kiln furniture

The invention discloses a preparation method of compound refractory kiln furniture. In the preparation method, firstly, a kiln furniture main body is selected; surface pretreatment is carried out on the surface of the kiln furniture main body to cause the surface to have certain adsorption activity; a negative-pressure dipping method is adopted to evenly adsorb stable zirconia slurry prepared in advance to the surface of the kiln furniture main body and fill into the air holes or microcracks of the kiln furniture main body; and the obtained product is dried and sintered at high temperature to obtain the compound refractory kiln furniture of the invention. The compound kiln produced by the invention has the advantages of low cost, even coating, good integrity, small possibility of deforming, low volatility and the like. The manufacturing method is also scientific and reasonable, is easy to popularize and apply, etc.

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

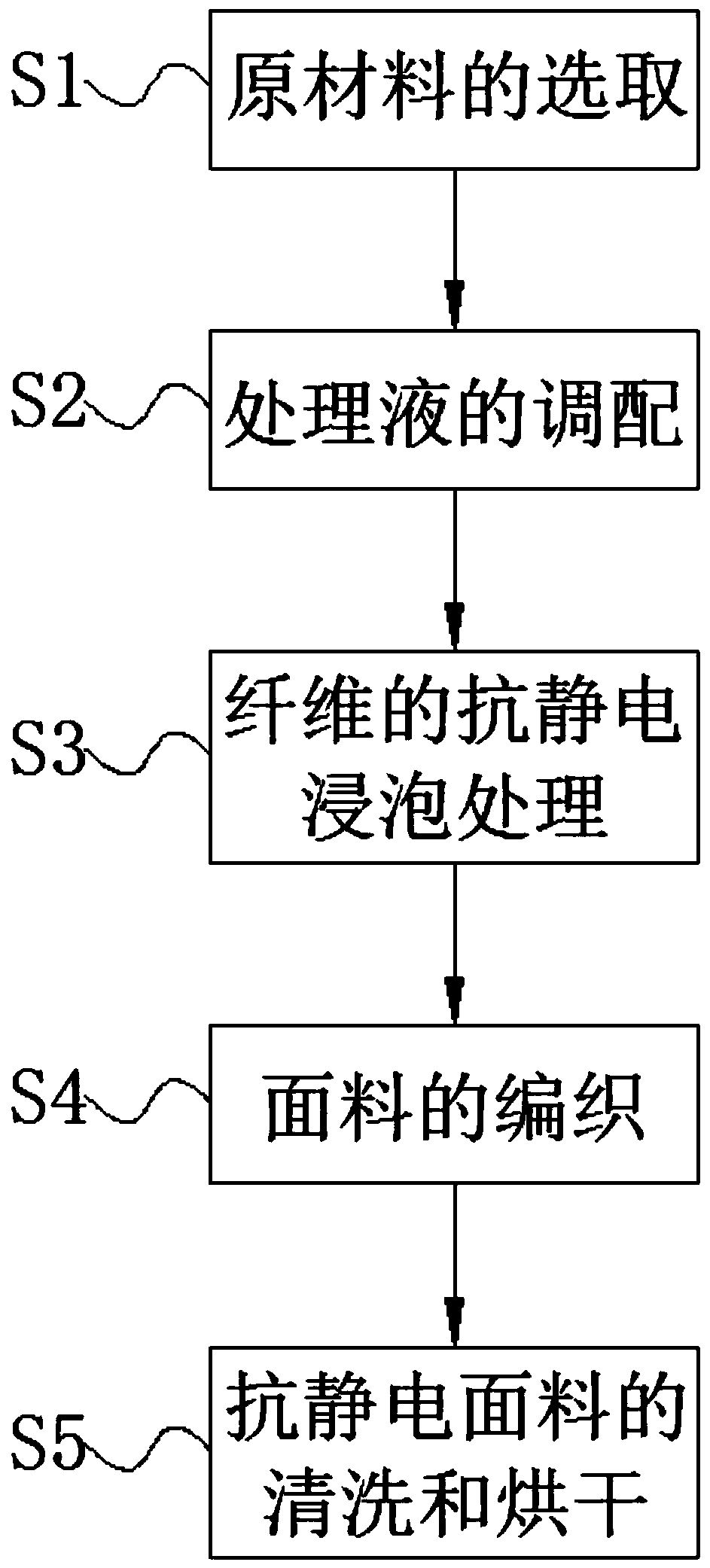

Antistatic fabric preparation method

InactiveCN111455522AImprove antistatic performanceImprove adhesionFibre typesWoven fabricsFiberPolymer science

The invention discloses an antistatic fabric preparation method, and relates to the technical field of textile material processing. The antistatic fabric preparation method specifically comprises thefollowing steps that S1, raw materials are selected; S2, a treatment fluid is blended; S3, antistatic soaking treatment is carried out on fibers; S4, a fabric is woven; and S5, the antistatic fabric is washed and dried. According to the antistatic fabric preparation method, the antistatic effect of the fabric can be enhanced in the aspect of materials by blending and weaving various antistatic conductive fibers, and the purpose that the antistatic treatment fluid can be fully adhered to the surface of each fiber is achieved by firstly performing antistatic soaking treatment on the non-conductive base fibers and then performing blending and weaving, the adhesive force of the treatment fluid is greatly enhanced by adding a thickening agent into the antistatic treatment fluid, the antistaticeffect of the antistatic fabric is greatly enhanced, and therefore large benefits to use of the antistatic fabric are achieved.

Owner:广东蓝墨科技有限公司

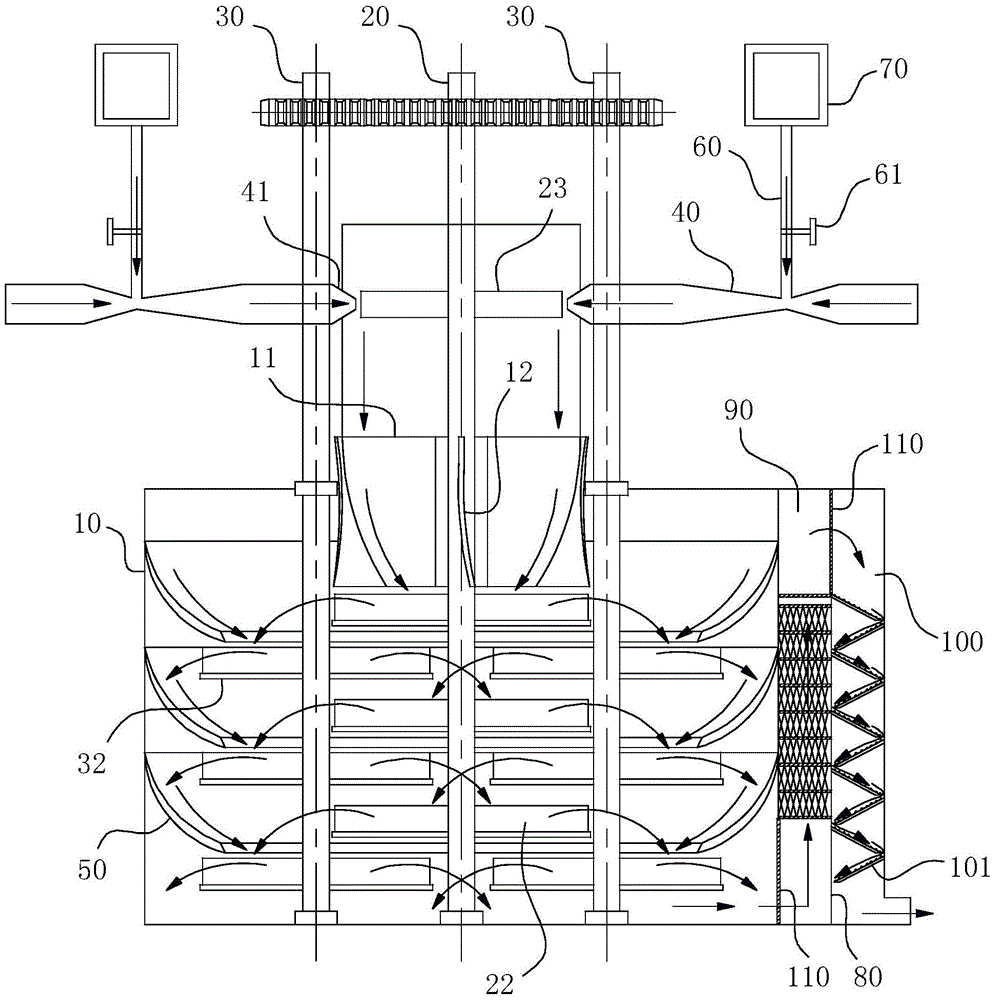

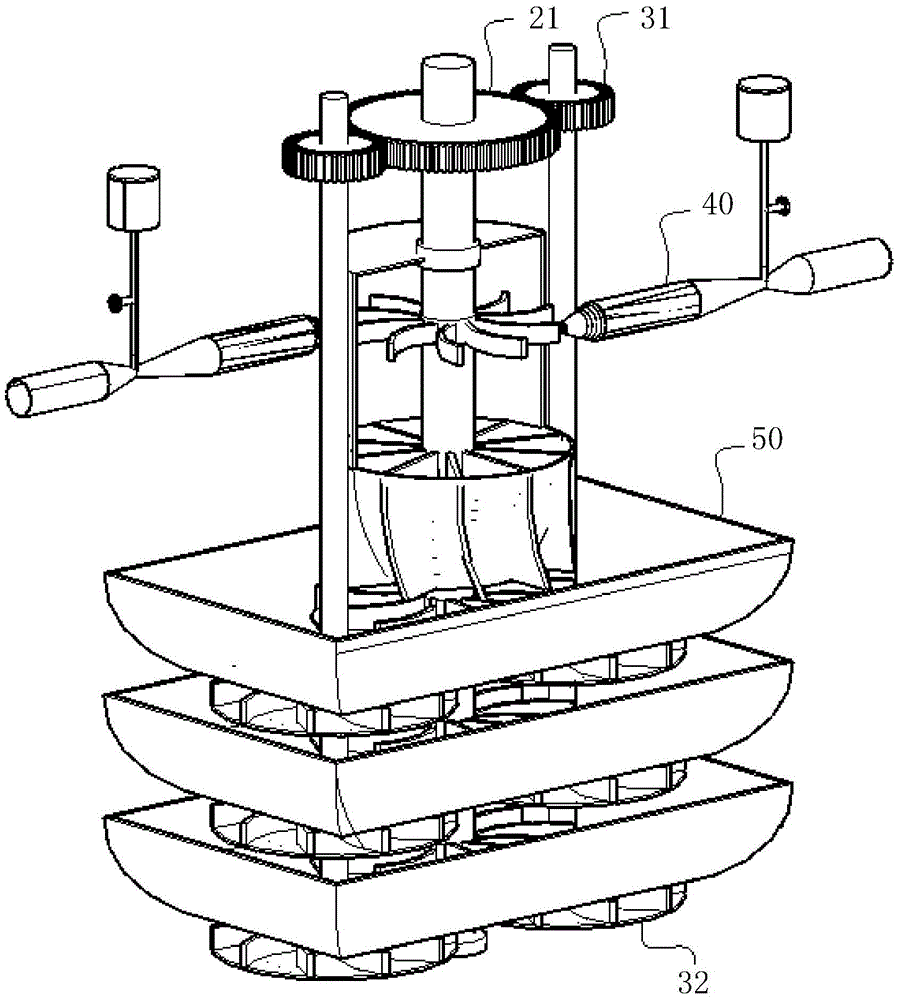

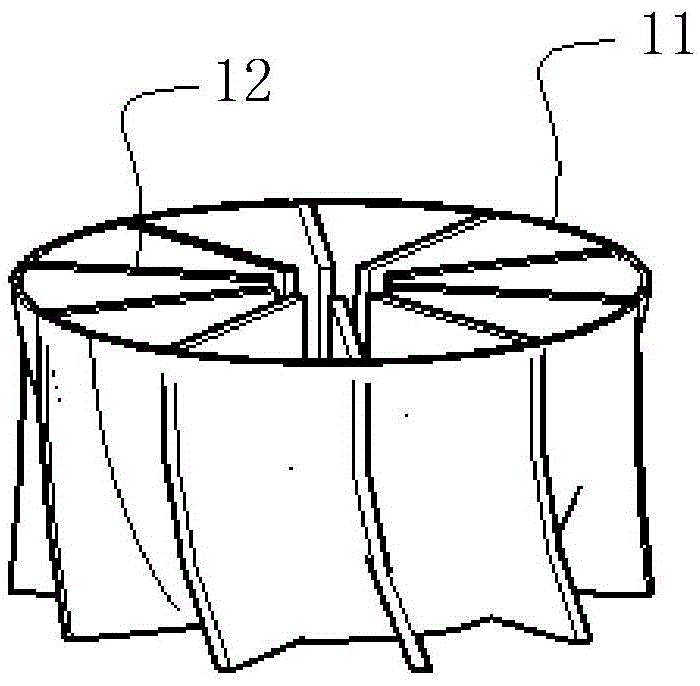

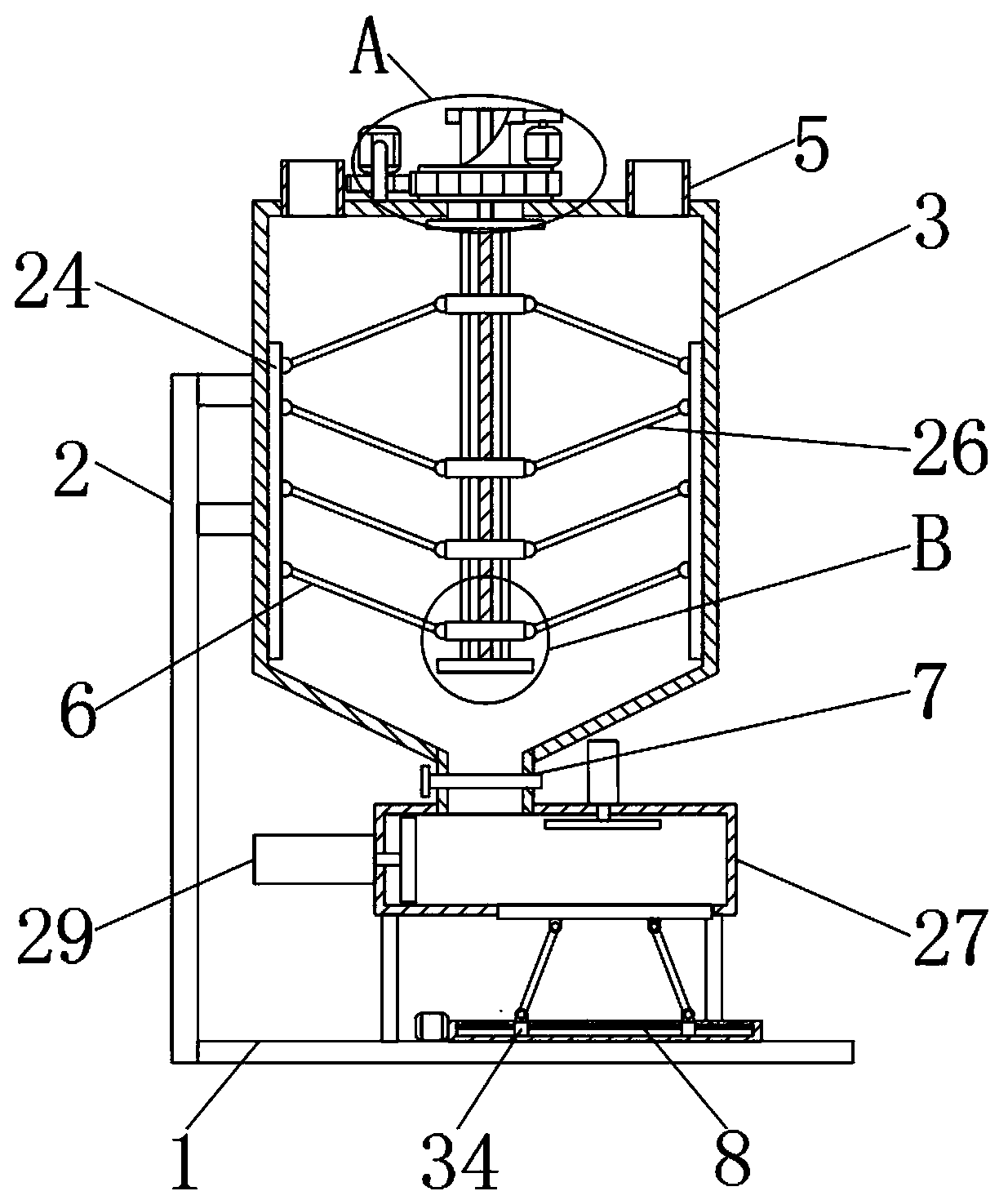

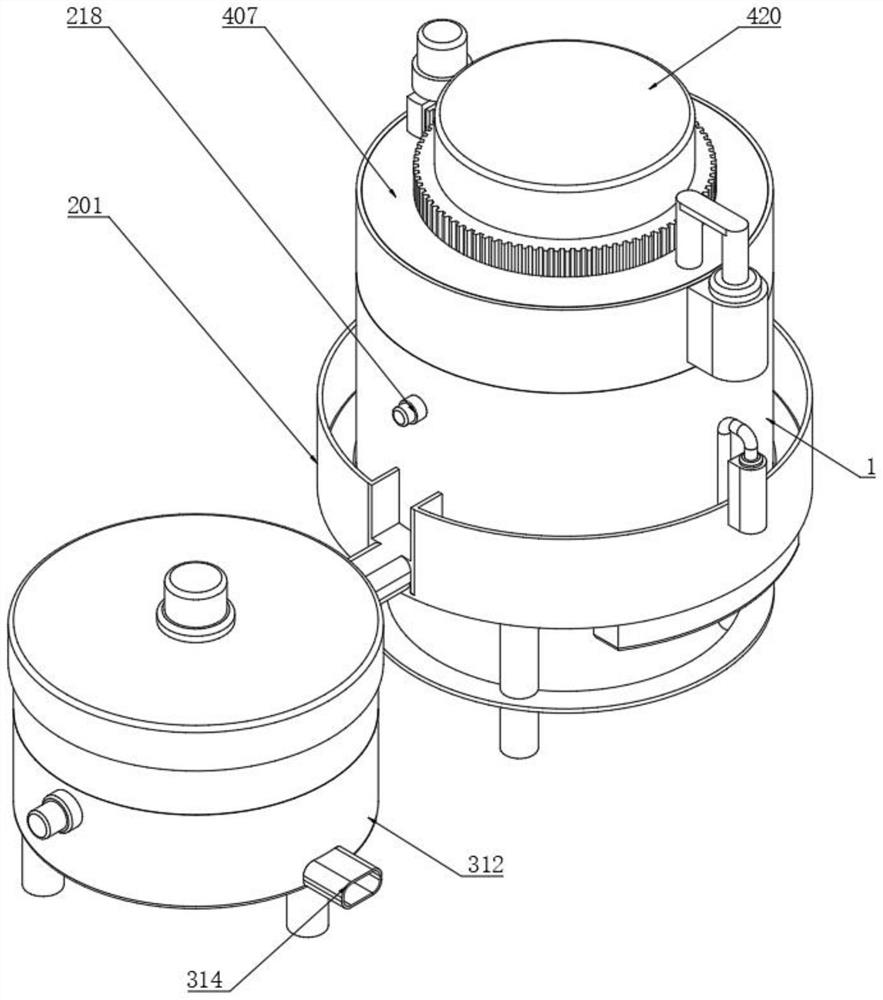

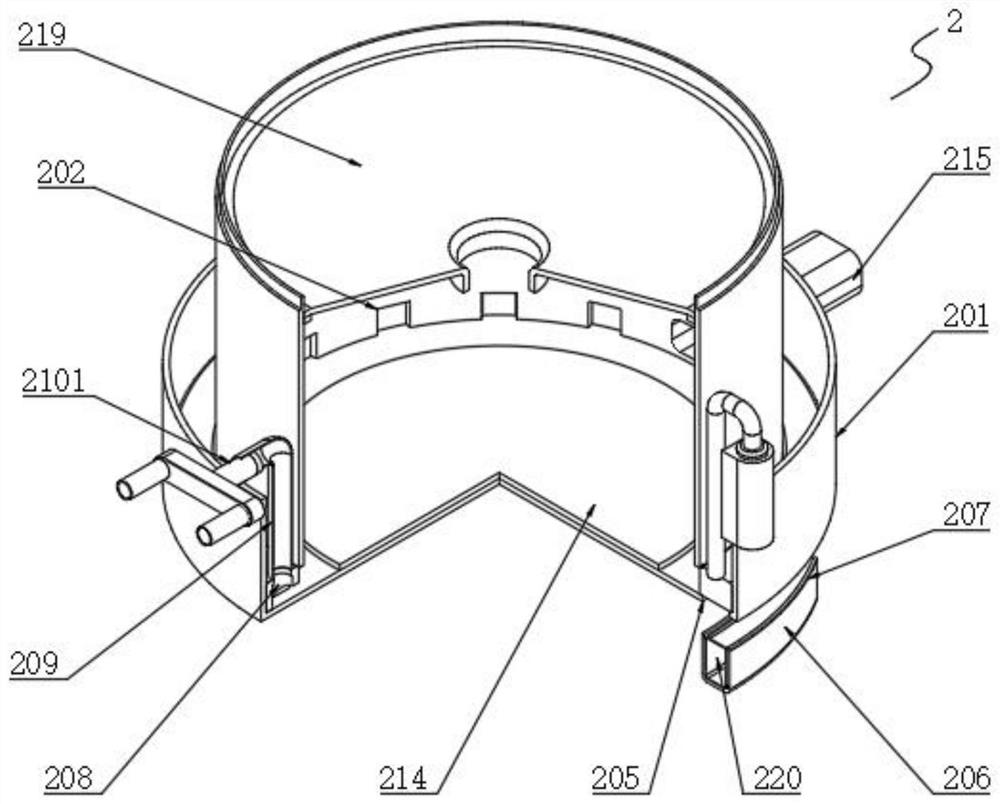

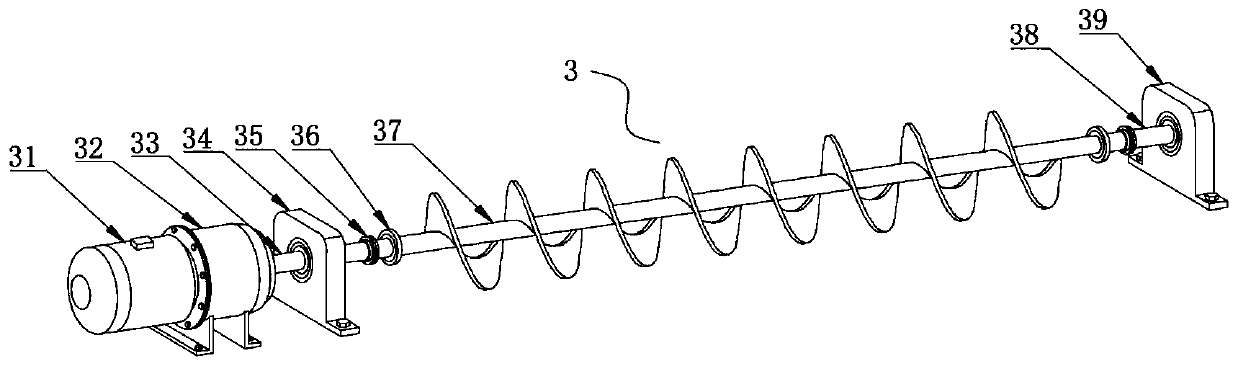

Multi-impeller mixed flow field ore pulp preprocessor based on ore pulp pipeline pressure drive

ActiveCN105536610AReduce consumption costImprove the mixing effectRotary stirring mixersTransportation and packagingImpellerMixed flow

The invention relates to the field of coal slurry pretreatment, in particular to a multi-impeller mixed flow field ore pulp preprocessor based on ore pulp pipeline pressure drive. The multi-impeller mixed flow field ore pulp preprocessor comprises a mixing box, a driving rotary shaft and a driven rotary shaft. A driving gear is coaxially arranged on the driving rotary shaft, and a driven gear is arranged on the driven rotary shaft to form the meshing relation. A driving turbine is further coaxially arranged on the driving rotary shaft. A group of stirring impellers is fixed to the driving rotary shaft, and a group of stirring wheels is fixed to the driven rotary shaft respectively in a coaxial and mutual equal-height mode. In the vertical direction, the stirring impellers and projections of the stirring impellers produce intersections. A guide sleeve is arranged under the driving turbine. Guide blades are arranged inside the guide sleeve in a circinate mode, and the rotating direction of the mixed liquid guided by the guide blades is mutually identical to the rotating direction of the stirring impellers under the guide blades. The multi-impeller mixed flow field ore pulp preprocessor can play a very good hardening and tempering effect on floated coal slime, is especially suitable for slurry-mixing and quality-improving demands of fine coal difficult to float and is high in working efficiency, and the preprocessing process is quick and convenient.

Owner:ANHUI UNIV OF SCI & TECH

Rendering test paper for quick detection of cyanides and preparation and detection methods thereof

ActiveCN108535243AImprove detection efficiencyShort reaction timeMaterial analysis by observing effect on chemical indicatorBarbituric acidTriton X-100

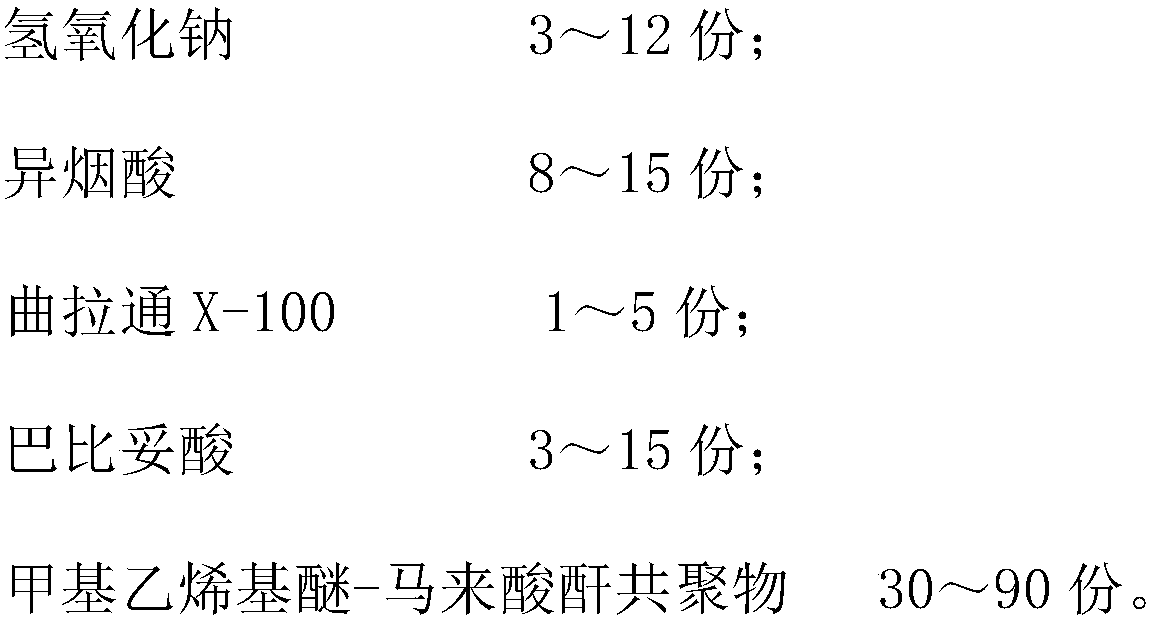

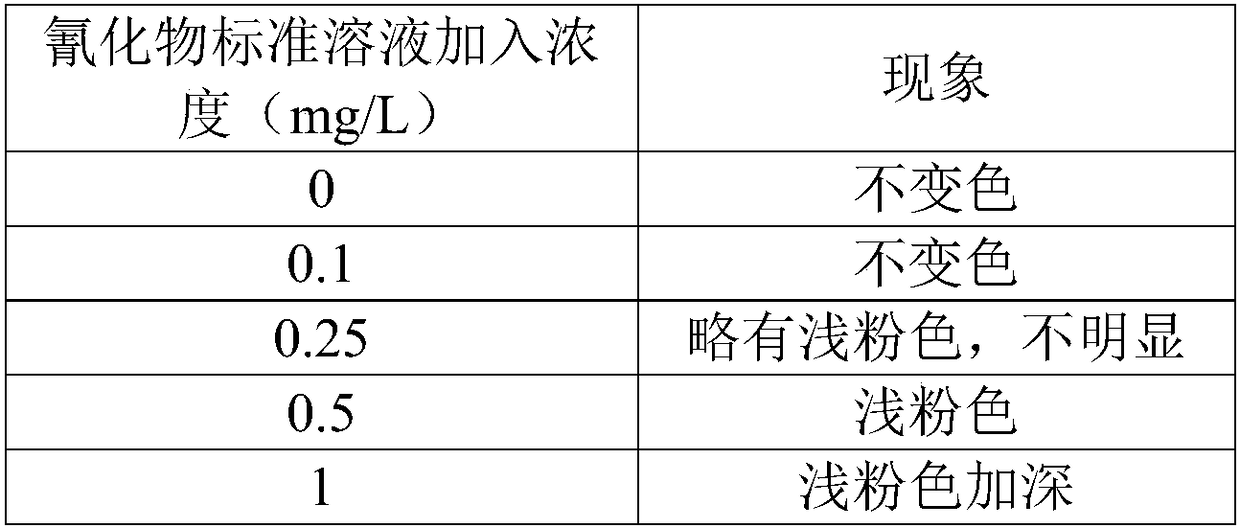

The invention provides rendering test paper for quick detection of cyanides, comprising a cyanide detection layer. The cyanide detection layer is composed of, by weight, 3-12 parts of sodium hydroxide, 8-15 parts of isonicotinic acid, 1-5 parts of triton X-100, 3-15 parts of barbituric acid, and 30-90 parts of methyl vinyl ether-maleic anhydride copolymer. The rendering test paper herein uses no bitter acids and other flammable explosive dangerous reagents during the detection process, the reaction time is short, the operating process is simple and fast, the detection cost is low, the detection cost for single sample detection is about 0.1 Yuan, the detection sensitivity and accuracy are high, rendered color uniformity is good, and the shelf life is long.

Owner:BEIJING PRIMEBIOTEK COMPANY

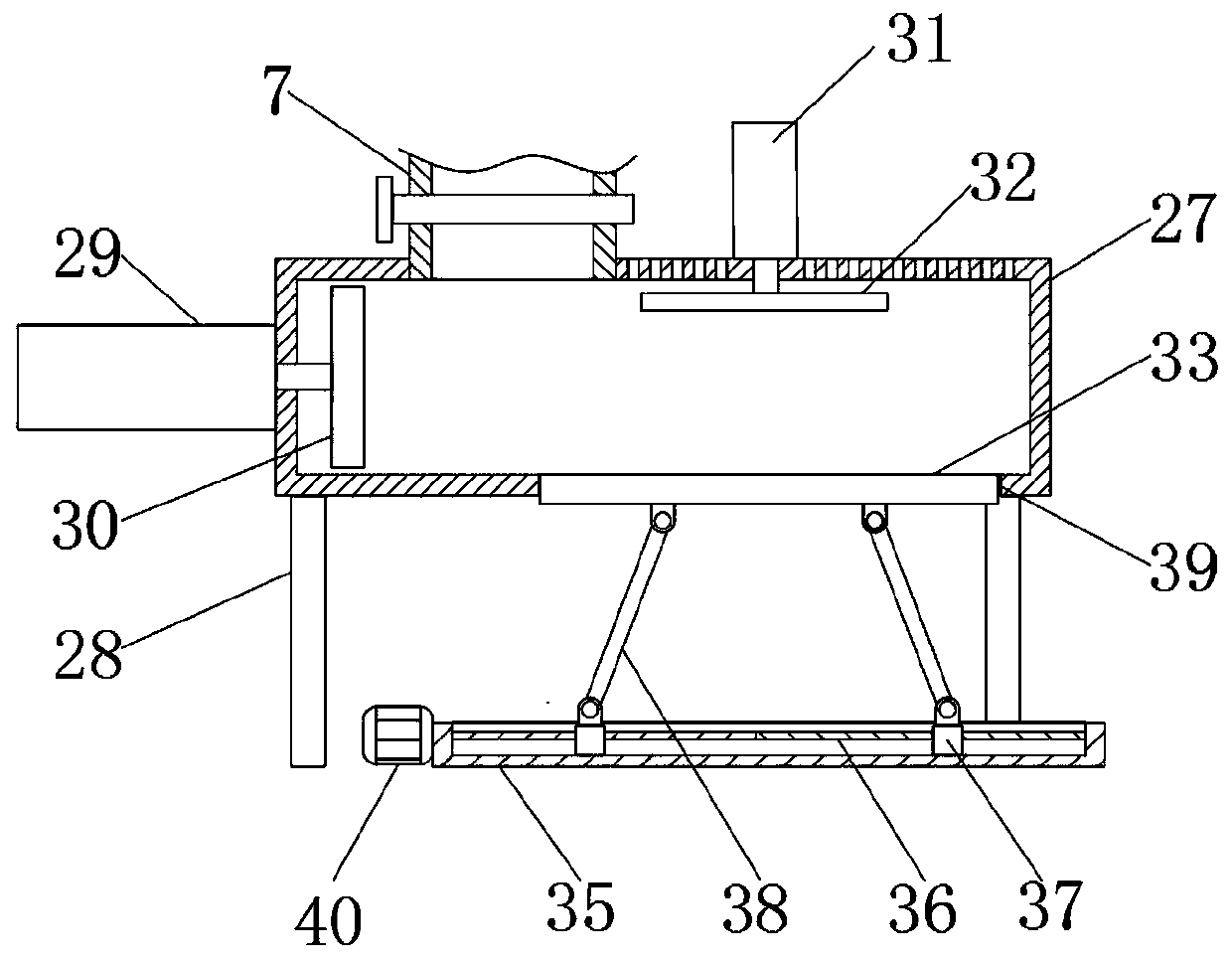

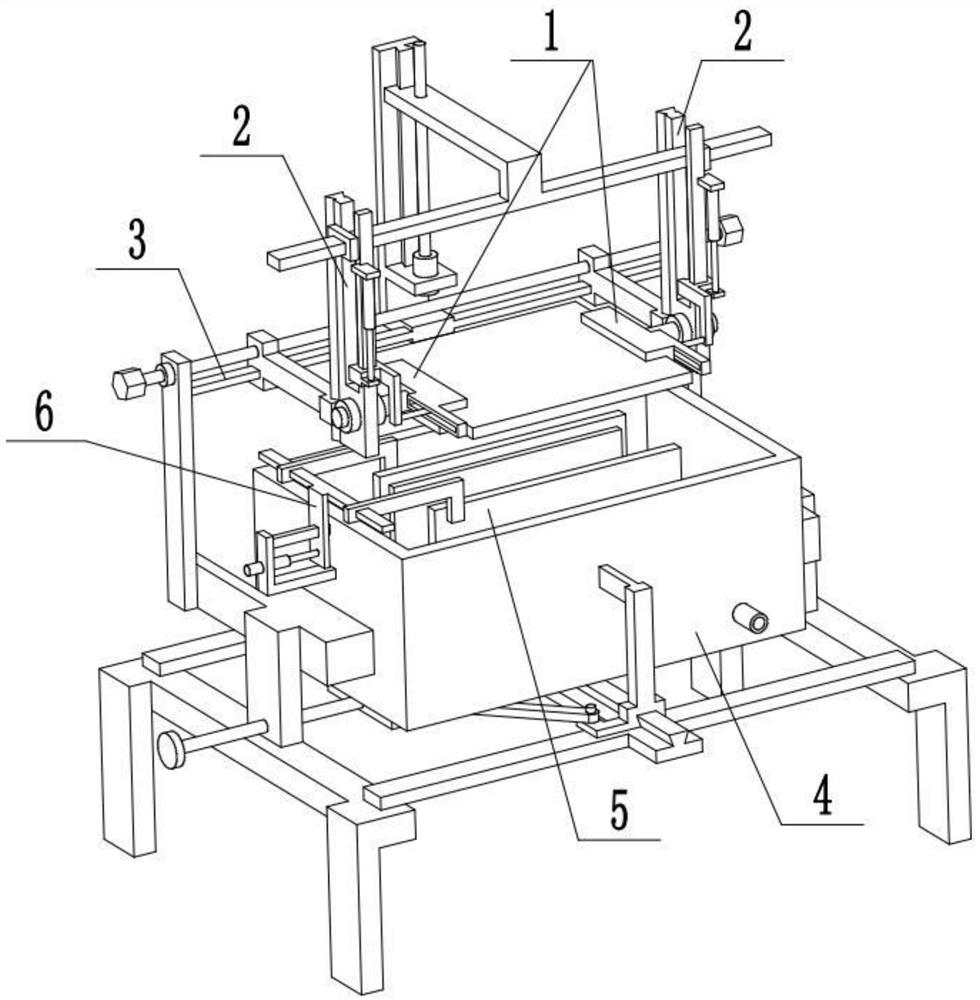

Preparation device and method of ginseng oyster okra tabletting candies

PendingCN110313535ARealize the effect of mixing and stirringFully scrapedConfectionerySweetmeatsOysterBiochemical engineering

The invention discloses a preparation device and method of ginseng oyster okra tabletting candies. The device includes a support plate, a support frame and a stirring box, the stirring box is fixedlyconnected onto the support plate through the support frame, and two feeding ports are symmetrically formed in the top of the stirring box. According to the preparation device and method of the ginsengoyster okra tabletting candies, by firstly adding a raw material mixture into the stirring box through the feeding ports, under common driving of a driving device and a stirring stripping device, theeffect of mixing and stirring raw materials inside the stirring box is achieved, in the process, subsidiary materials are added in sequence through the feeding ports again, at the moment, the raw materials and the subsidiary materials can be simultaneously stirred and mixed through the stirring stripping device, meanwhile, the stirring stripping device can fully strip the subsidiary materials which adhere to the inner wall of the stirring box so as to prevent the subsidiary materials from adhering to the inner wall of the stirring box, and the effect of simultaneously uniformly mixing the rawmaterials and the subsidiary materials is achieved.

Owner:深圳市润芝堂生物工程有限公司

Ethylene-vinyl acetate copolymer waxes

InactiveCN1488151ASave human effortLow costPlastic/resin/waxes insulatorsThin material handlingWaxVinyl acetate

Disclosed are ethylene-vinyl acetate ('EVA') copolymer waxes comprising at least about 10 % by weight, of moieties derived from vinyl acetate, the copolymer having a polydispersity ('Mw / Mn') of at least about 6 and a molecular weight ('Mw') of from about 15,000 to about 40,000. Also disclosed are coatings and films comprising the present EVA waxes that exhibit sufficient adherence to and removability from a wide range of substrates.

Owner:HONEYWELL INT INC

Preparation technique for membrane electrode of proton exchange film fuel cell

ActiveCN100530797CImprove solubilityNo pollution in the processFinal product manufactureCell electrodesState of artSpray coating

The invention relates to a technology that prepares a proton exchange membrane fuel cell electrode, comprising three parts of a pre-process of the proton exchange membrane, a preparation of a catalyst slurry and spray coating of a membrane electrode. The technology provided by the invention solves the problems that in prior art preparation process, the proton exchange membrane swells and rucks and the dosage of the catalyst is high and the preparation process is complicated. The prepared proton exchange resin has great elasticity and adhesive property, which is beneficial for improving adhesion of the catalyst layer and the proton exchange membrane and improves utilization ratio of the catalyst.

Owner:辽宁沐与康中氢燃料电池有限公司

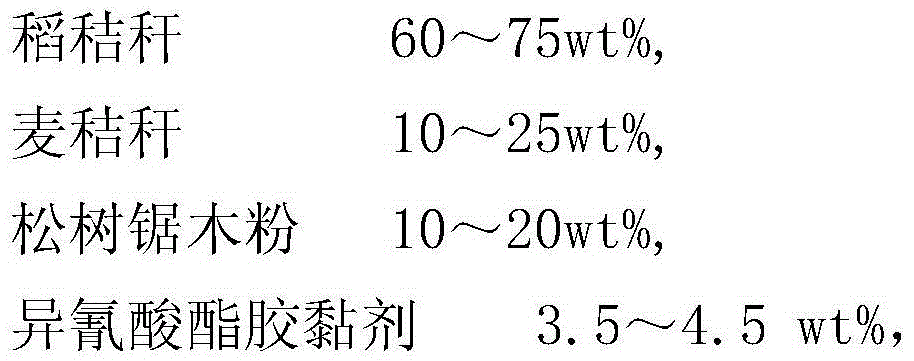

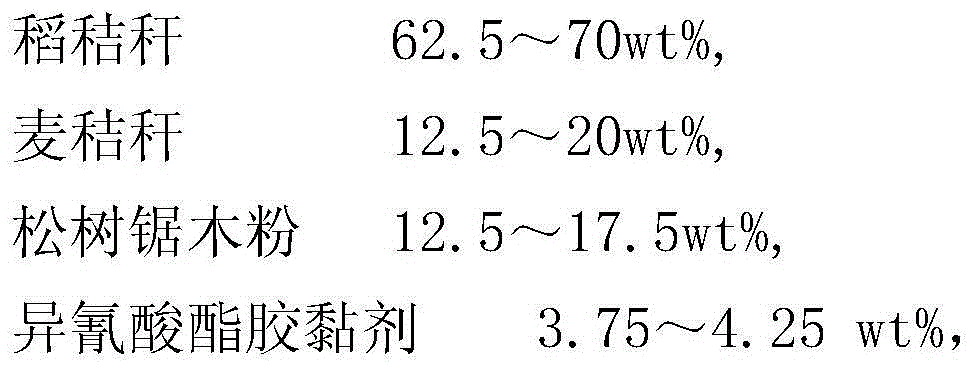

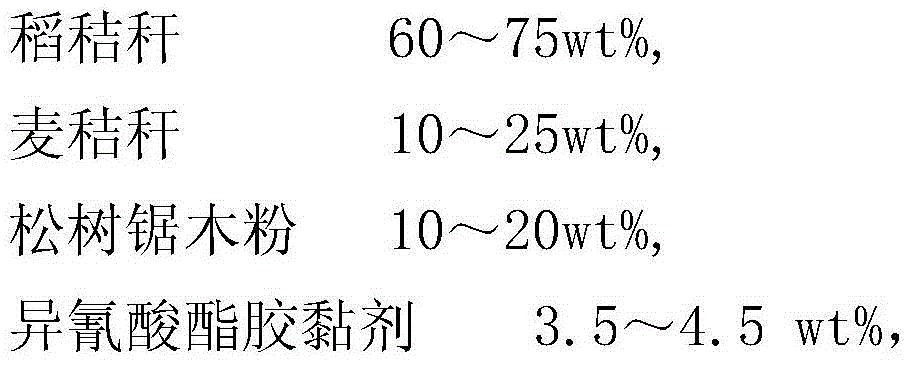

Straw mixture artificial board and processing method

ActiveCN104097246AReduce corruptionDegree of reductionDomestic articlesFlat articlesBiotechnologyOryza

The invention belongs to the technical field of artificial boards, and discloses a straw mixture artificial board and a processing method. The mixture artificial board is made of raw materials of the following components: 65-75 wt% of rice straw, 15-25 wt% of wheat straw and 10-20 wt% of pine saw wood powder, and the weight percentages of the components are calculated under the condition of the same water content. The pine saw wood powder is added to the rice straw and the wheat straw to produce the artificial board, thus the mechanical strength of the artificial board is higher than the rice straw and wheat straw artificial board by 30%-40%, and the nail holding force of the mixture artificial board is larger than that of the straw artificial board.

Owner:CHANGSHA CHUANGYUAN ENVIRONMENTAL PROTECTION TECH

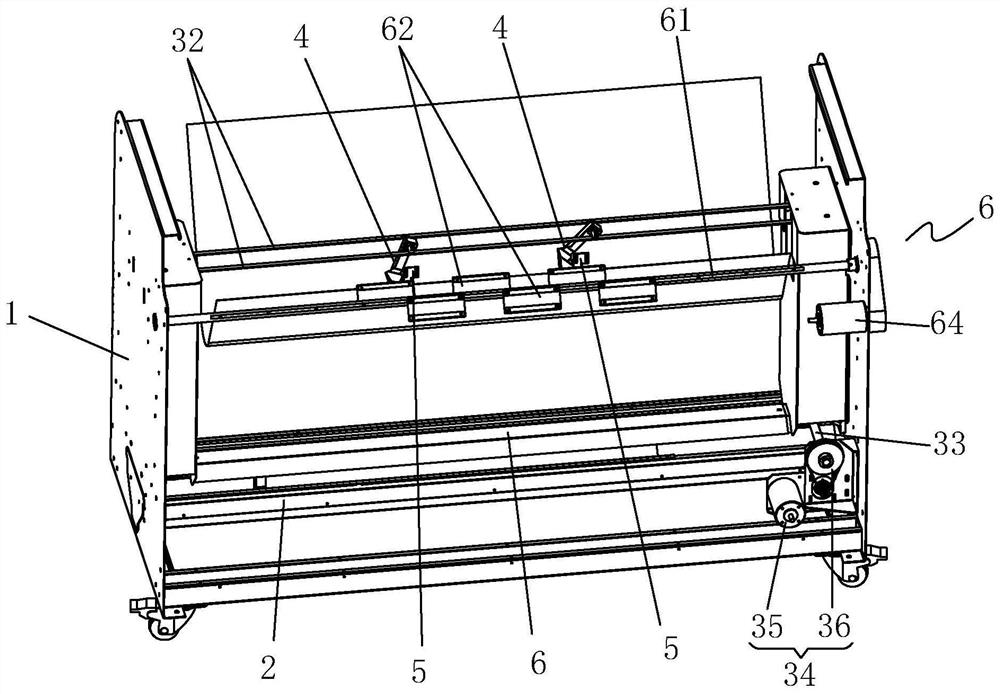

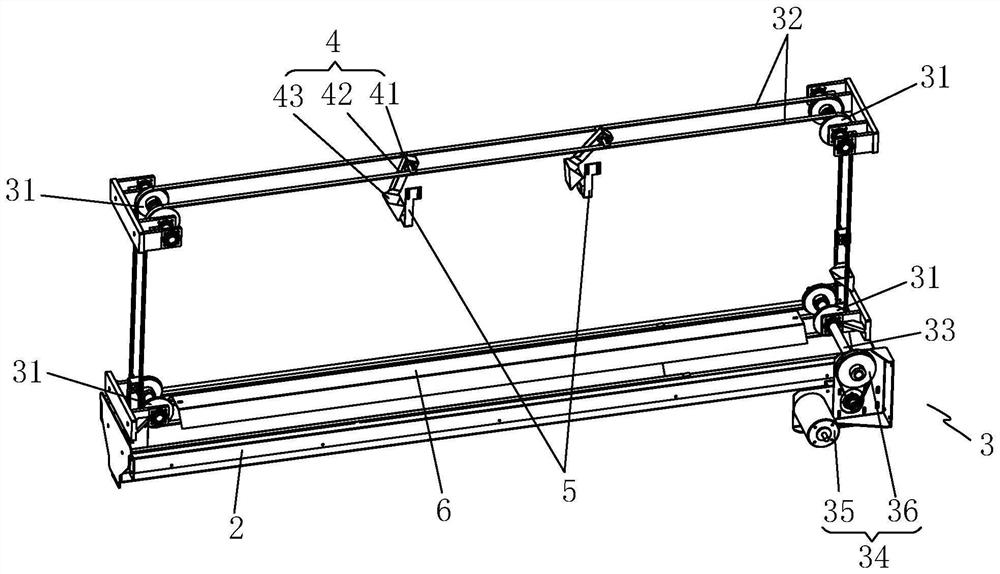

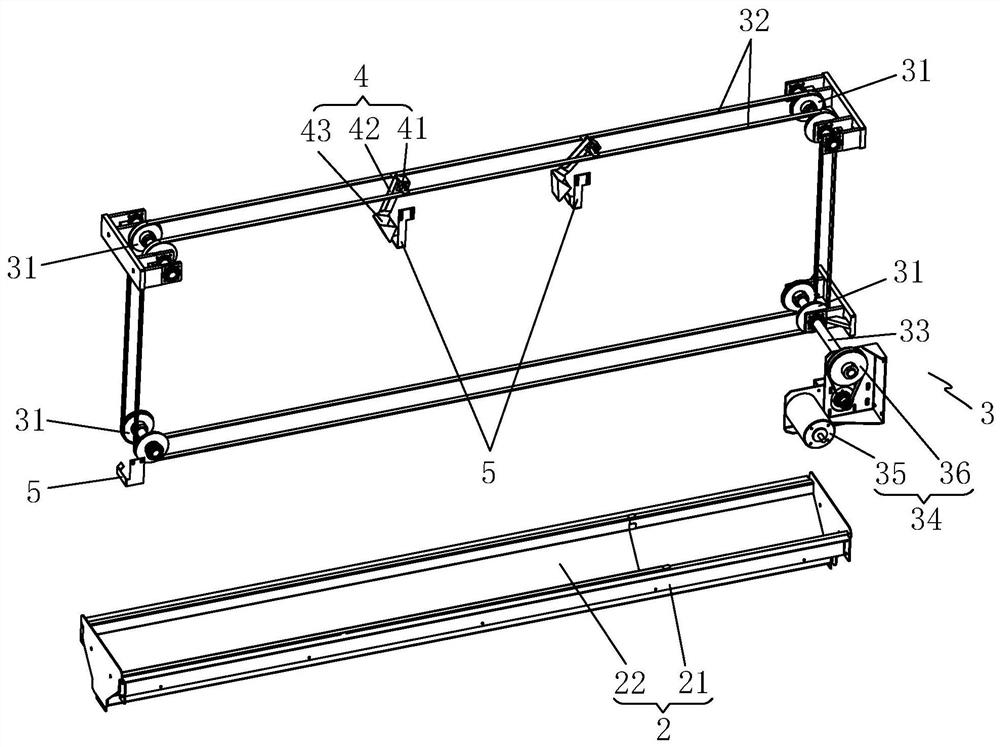

Full-automatic plane labeling machine

ActiveCN113479437AGuaranteed smoothAvoid wrinklesLabelling flat rigid surfacesLabelling machinesEngineeringComputer science

The invention discloses a full-automatic plane labeling machine in the technical field of plane labeling machines. The full-automatic plane labeling machine comprises a fixed support, the interior of the fixed support is in transmission connection with a conveying belt, the top of the conveying belt is connected with a plurality of groups of positioning mechanisms arrayed along the edge of the conveying belt, and the positioning mechanisms are used for positioning a labeling part. According to the full-automatic plane labeling machine, when labeling is carried out on a large labeling part every time, the front end and the rear end of a label are adhered and tensioned through a label pulling mechanism, the head of the label is prevented from wrinkling, the label is smoothly attached to the top of the labeling part advantageously, when the labeling part moves to a labeling position, the label pulling mechanism is slowly made to roll to be separated from the label, In cooperation with a limiting mechanism and a rotating mechanism, a leveling mechanism enables the label to be flatly attached to the top of the labeling part in the rightward conveying process of the label, and therefore it is guaranteed that the large label is flat in labeling process, and the phenomena of wrinkles and bubbles during labeling of the large label is avoided.

Owner:东莞市欧尚自动化设备科技有限公司

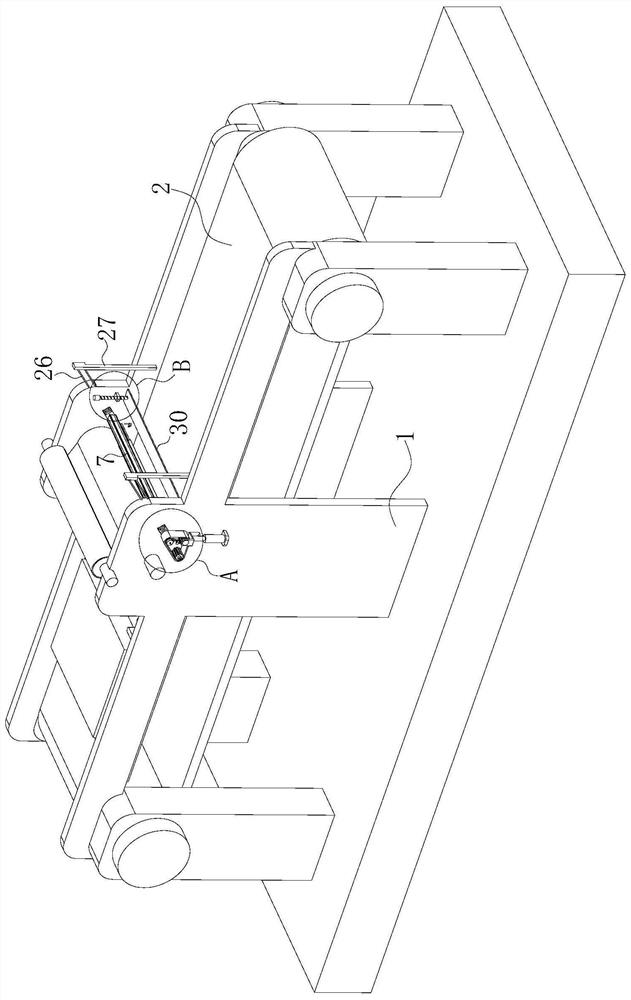

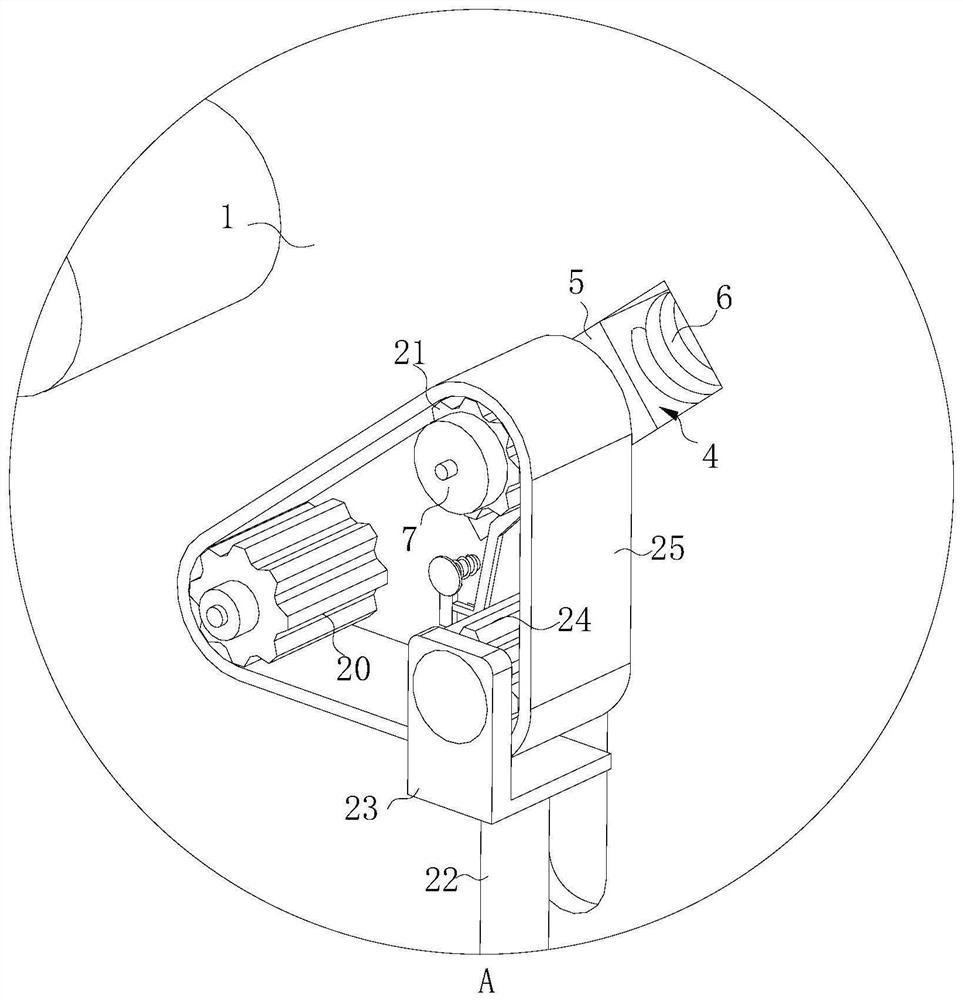

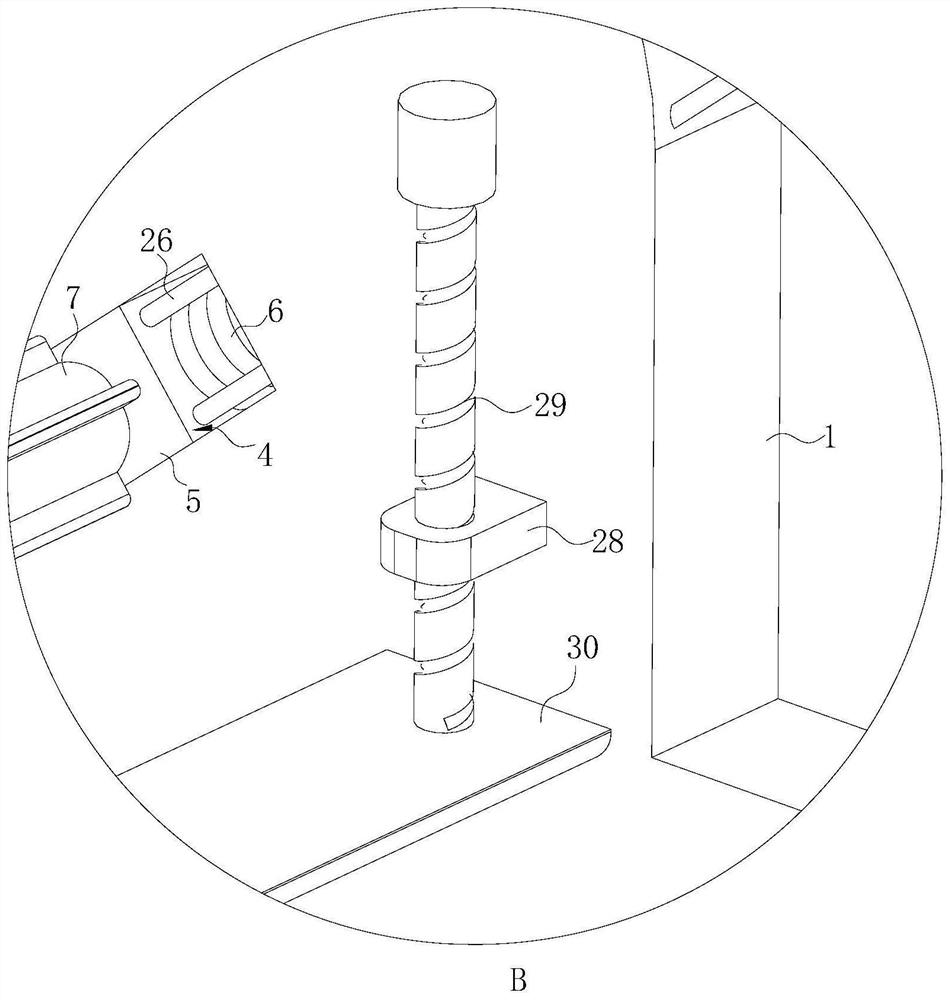

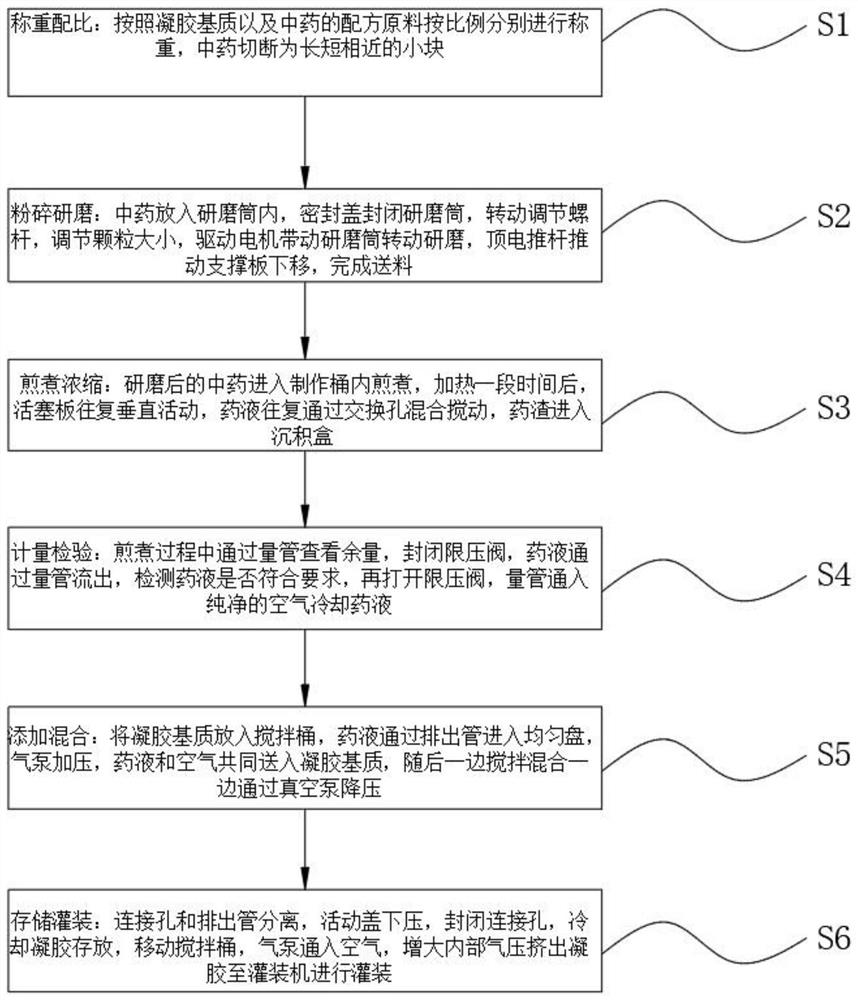

Preparation method of gynecological gel capable of balancing PH

PendingCN114533558AScientific and reasonable structureEasy to useAntibacterial agentsAntimycoticsLactic acid bacteriumSophorae Radix

The invention discloses a preparation method of gynecological gel capable of balancing PH. The gynecological gel is prepared from, by weight, 25%-40% of water, 1%-5% of lactic acid bacteria fermentation products, 3.5%-10% of propylene glycol, 0.5%-3.0% of carbomer, 2%-7.5% of glycerin, 3%-8.5% of surfactants, 5.5%-8.5% of radix sophorae flavescentis, 5.5%-8.5% of radix stemonae, 5.5%-8.5% of fructus cnidii, 1.5%-6.5% of licorice roots and 5.5%-15% of herba houttuyniae. According to the present invention, with the radix sophorae flavescentis, the radix stemonae, the fructus cnidii and the herba houttuyniae in the formula, the stable treatment and sterilization effects are improved, the effects are limited during the mixing at the low temperature, the protection of the lactic acid bacteria fermentation product and the surfactant mixing, and the sterilization effect is good; after entering the human body, the gel becomes soft, and the surfactant plays a better role, so that the gel, the lactic acid bacteria fermentation product and the medicine are fully adhered to the inner wall of the vagina, and a better treatment effect of balancing the PH in the vagina is played.

Owner:李崴

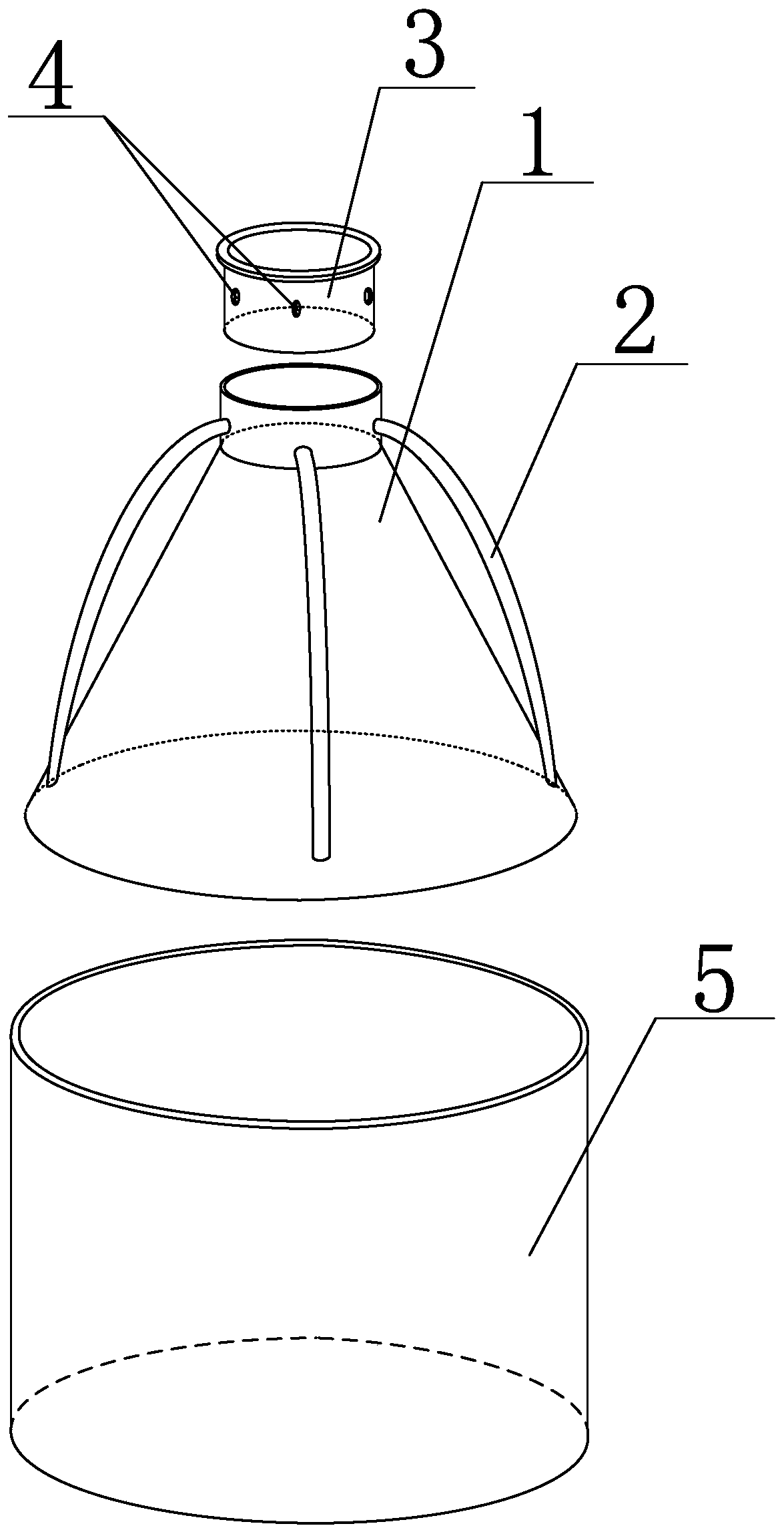

Floating island for mariculture

InactiveCN111567455AAvoid fatal situationsReduce damageFishing netsSeawater treatmentMaricultureEnvironmental engineering

The invention relates to a floating island for mariculture. The floating island comprises a floating island culture comprehensive device and a seawater comprehensive treatment device. The full processof seedling culture and fish culture on seawater is realized by large-scale seawater floating culture. The device can resist the negative effects caused by daily waves, and can also utilize the waveenergy to be used by a power generation worker floating island; and meanwhile, by arranging the specific seawater comprehensive treatment device, workers working on the floating island can also carryout daily work and life on the floating island for a long time.

Owner:申雪丽

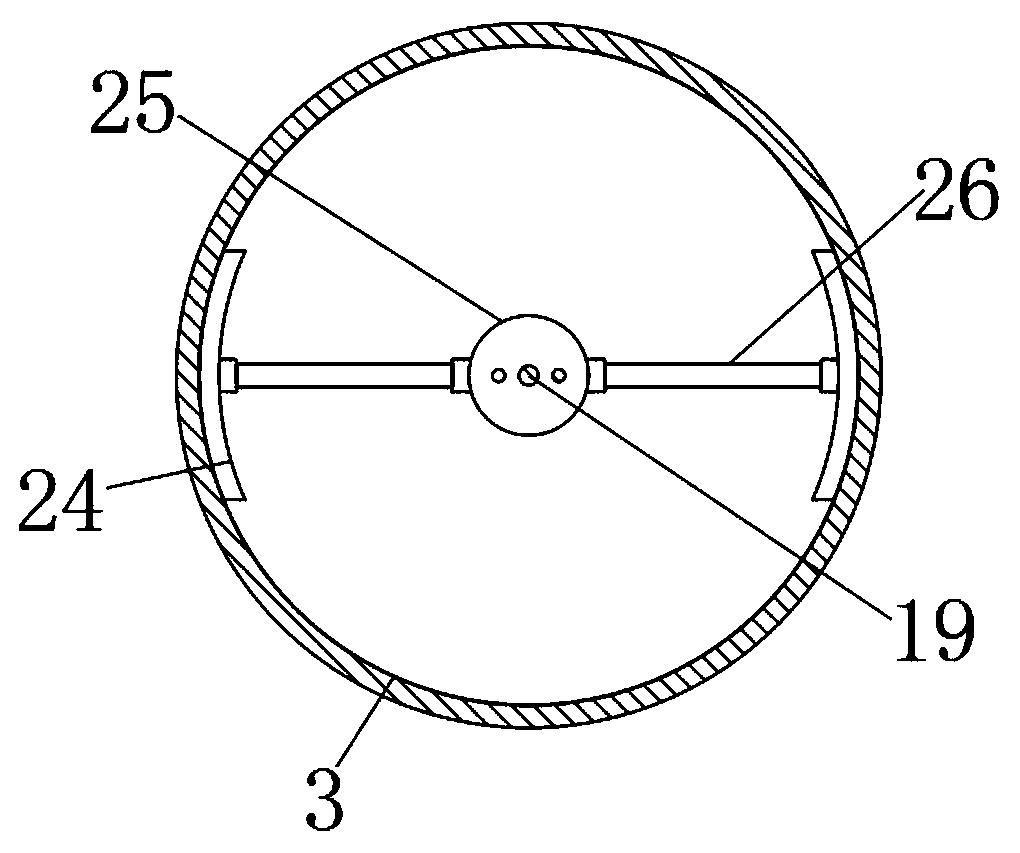

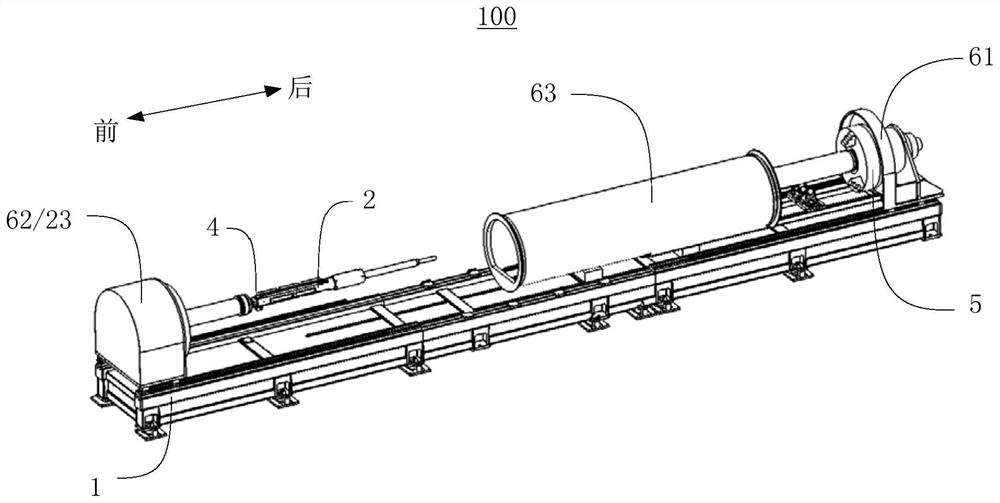

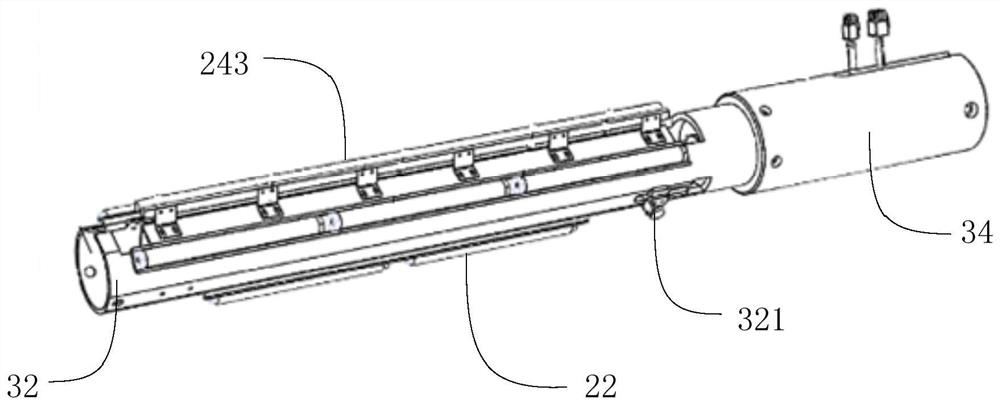

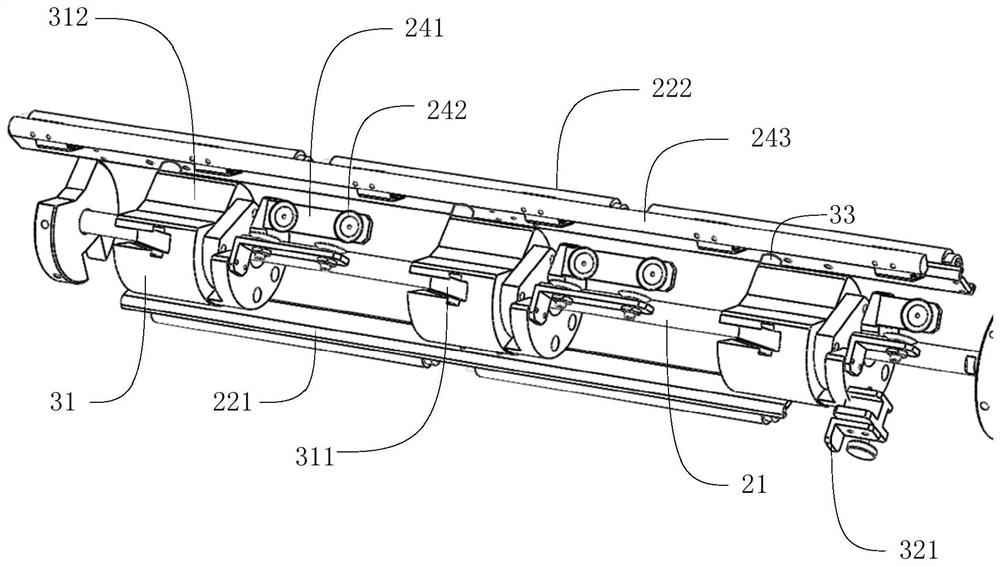

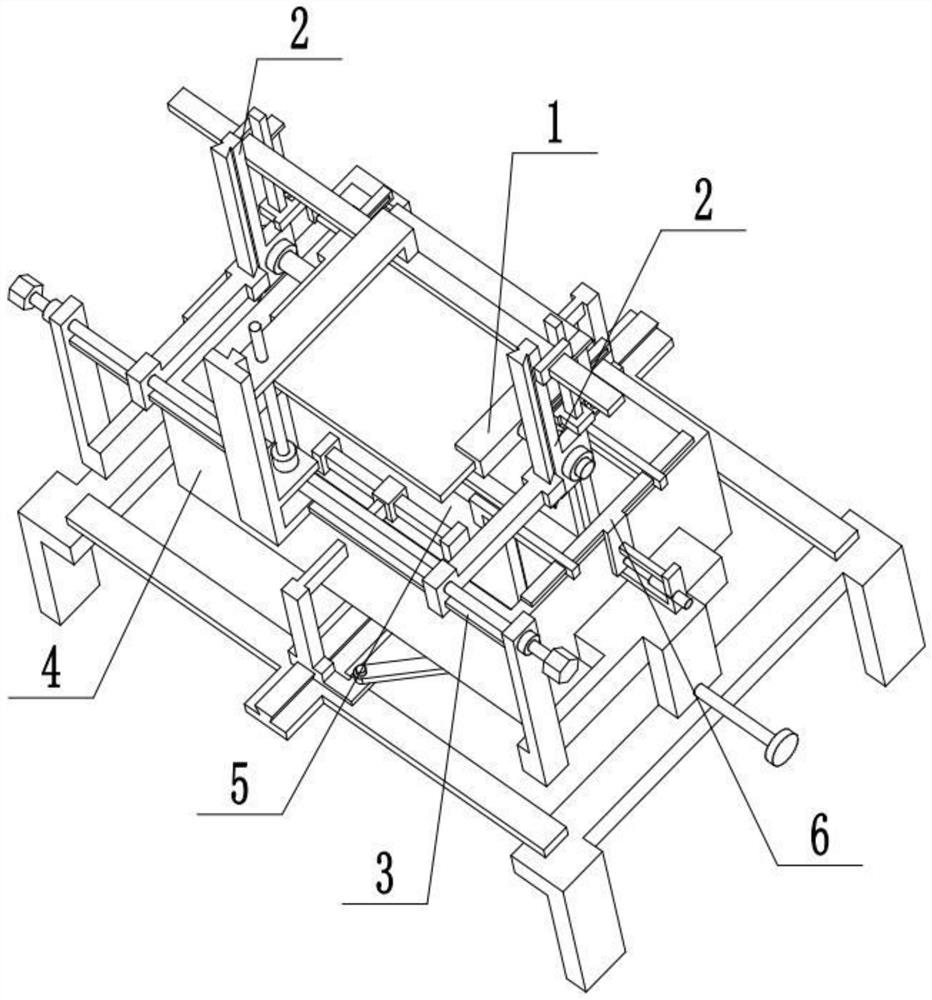

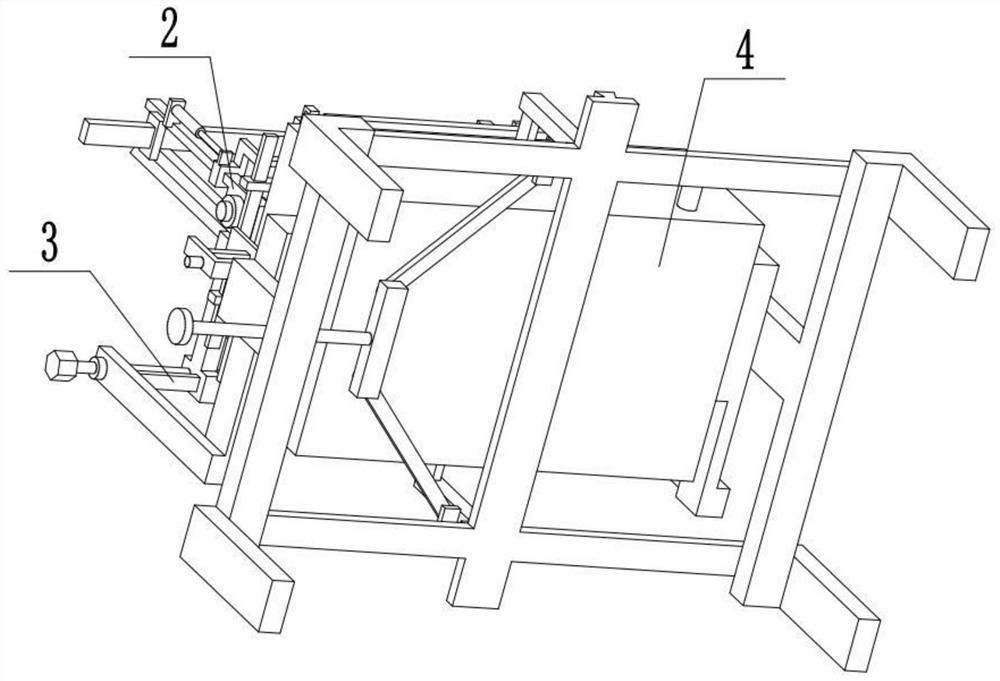

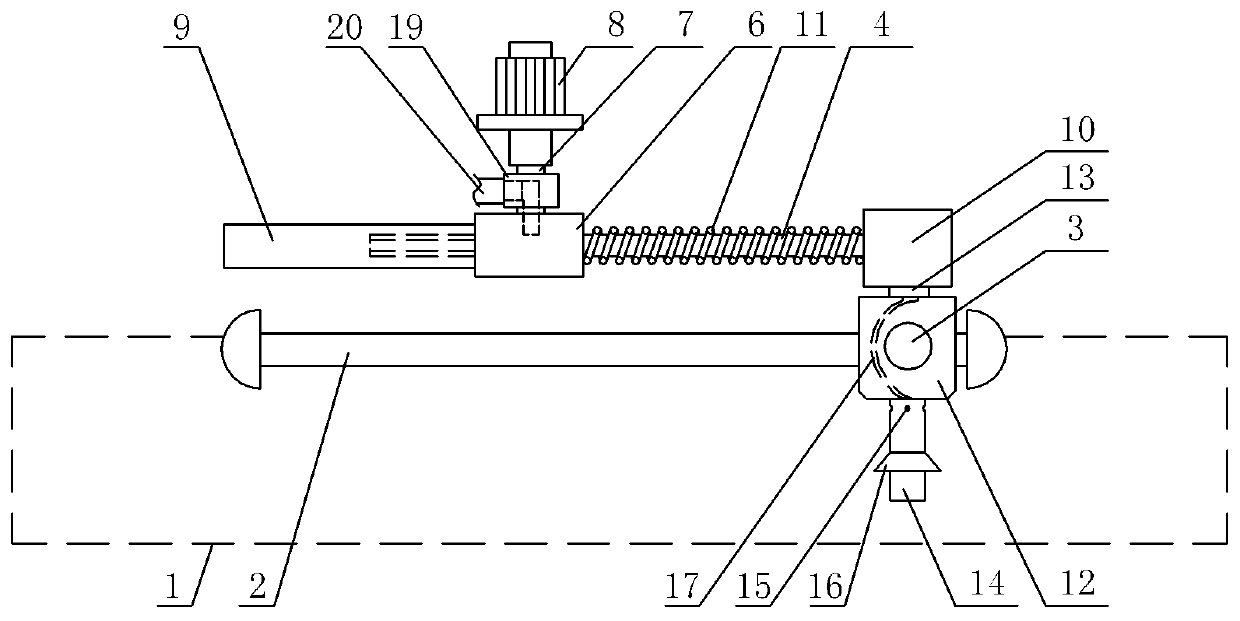

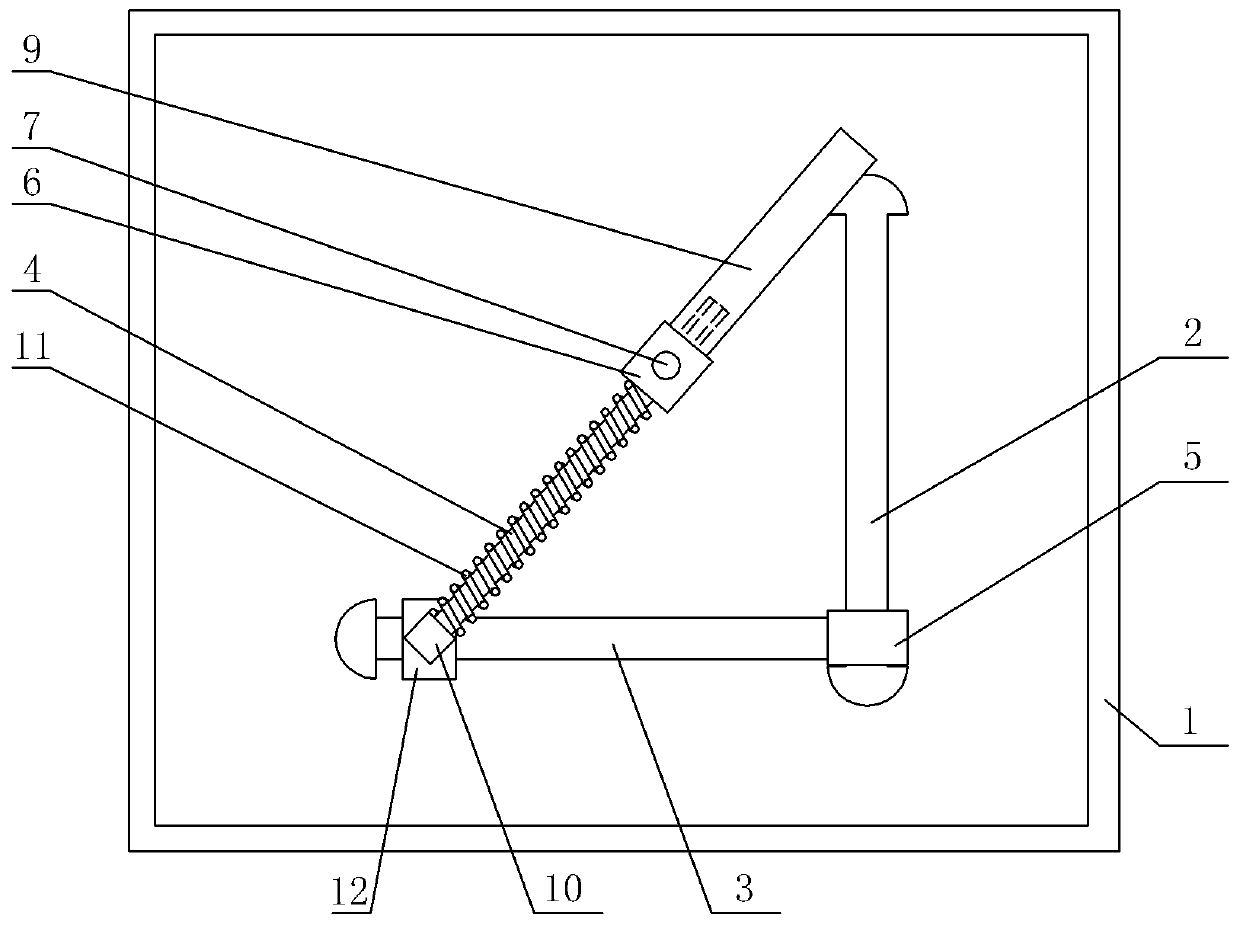

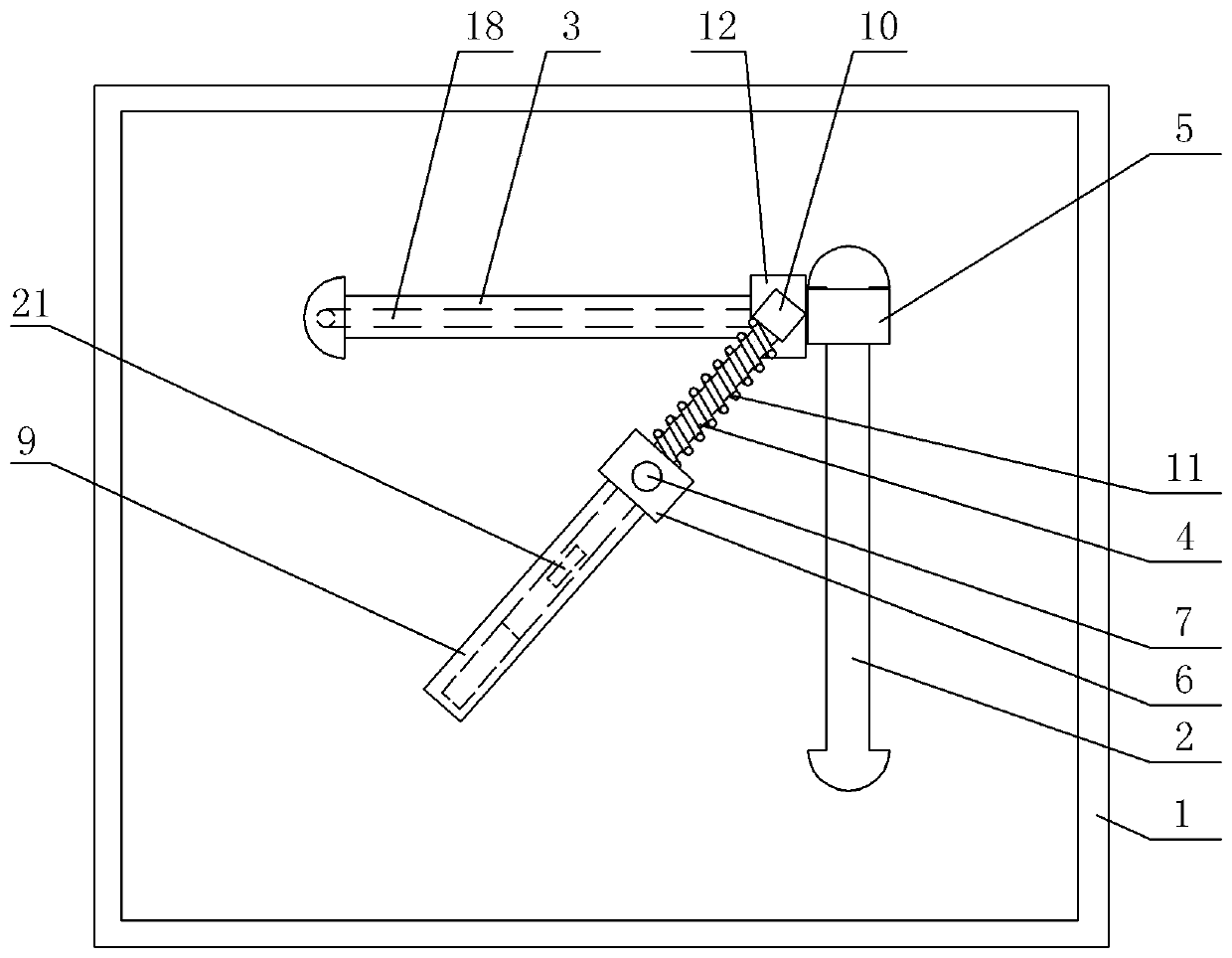

Cylinder inner wall sheet pasting mechanism

The invention discloses a cylinder inner wall sheet pasting mechanism. The cylinder inner wall sheet pasting mechanism comprises a machine base, a straight section sheet pasting device and a synchronous driving device, and the end, in the front-back direction, of the machine base is used for mounting a cylinder workpiece. The straight section sheet pasting device comprises a mounting rod and multiple supporting structures arranged on the peripheral side of the mounting rod, the multiple supporting structures are used for jointly mounting cylindrical soft sheets / films with the outer walls coated with glue in a sleeving manner, the multiple supporting structures can be movably mounted in the radial direction of the mounting rod, and the mounting rod is movably mounted to the machine base in the front-back direction so as to drive the multiple supporting structures to extend into the cylindrical workpiece. The synchronous driving device is mounted on the mounting rod, and the synchronous driving device is in driving connection with the multiple supporting structures. The mounting rod drives the cylindrical soft sheets / films with the outer walls coated with the glue to move backwards to extend into the cylindrical workpiece, the synchronous driving device drives the multiple supporting structures to synchronously move to make contact with the straight section of the inner wall of the cylindrical workpiece, and therefore the cylindrical soft sheets / films with the outer walls coated with the glue are pasted to the straight section of the inner wall of the cylindrical workpiece.

Owner:湖北华源翔供应链管理有限公司

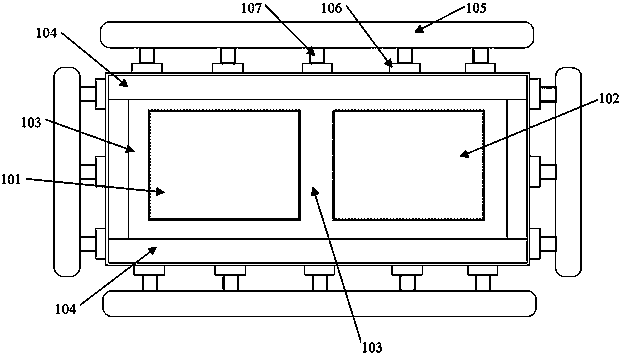

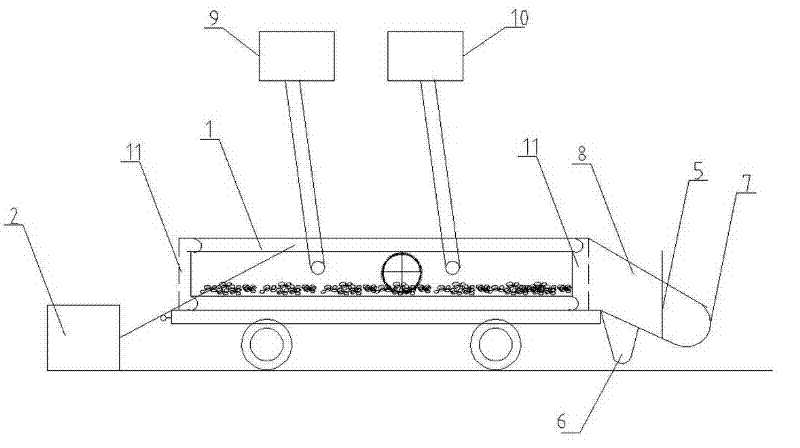

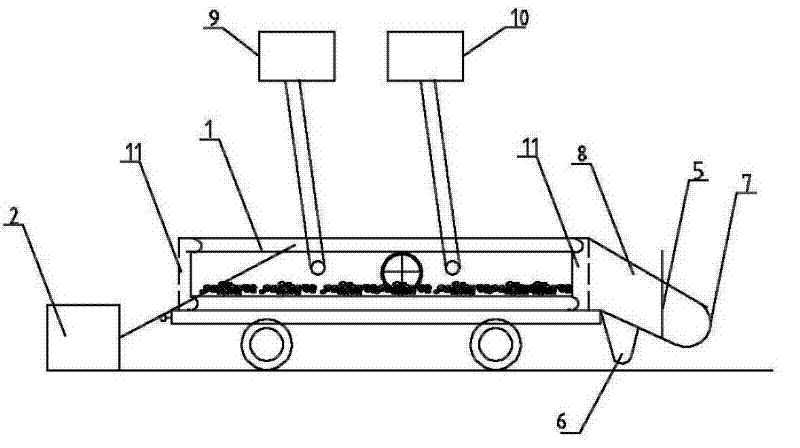

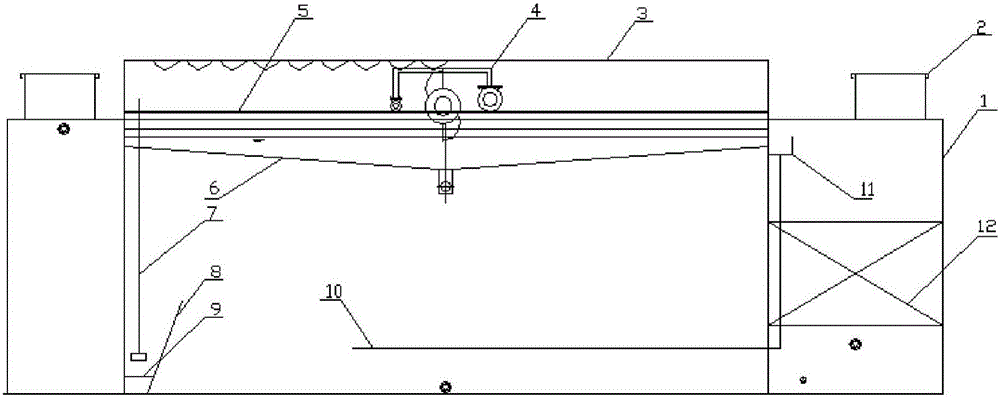

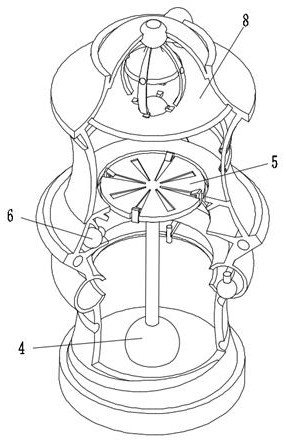

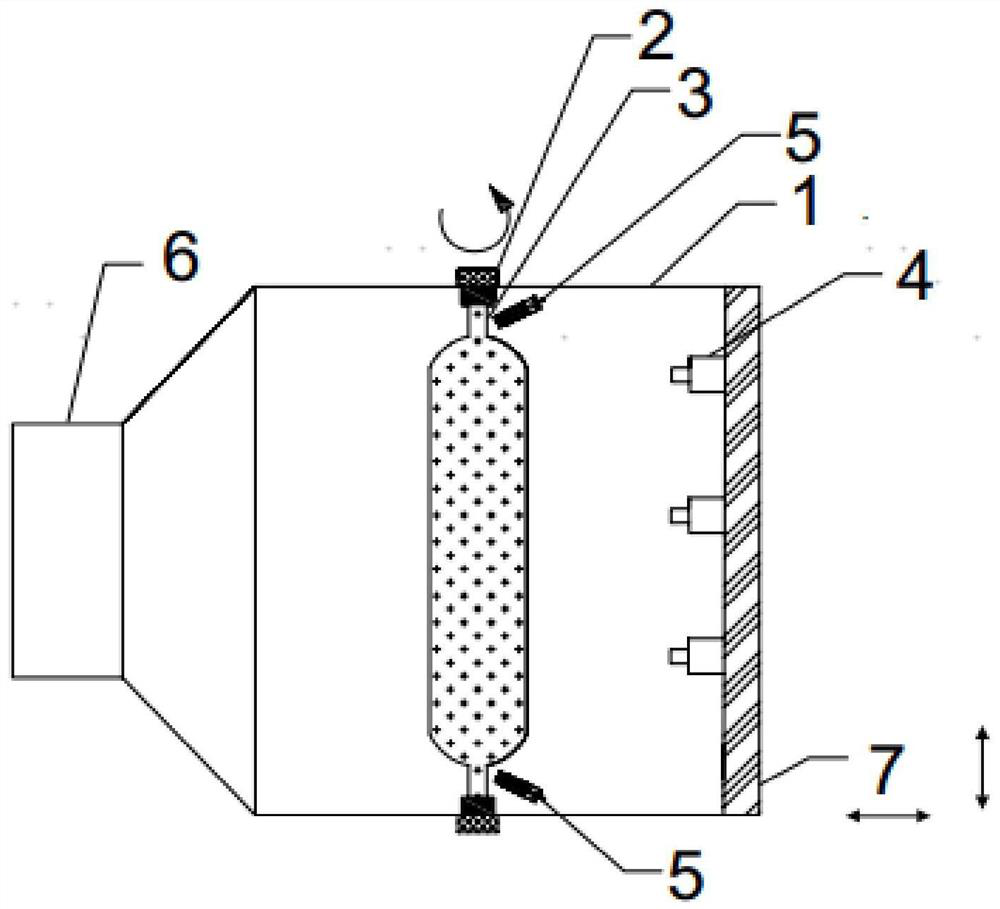

Asphalt recovery coating vibration reciprocating blender and asphalt coating process thereof

ActiveCN102493312ASolve the special heating modeFully adheredRoads maintainenceTemperature controlProcess engineering

The invention relates to an asphalt recovery coating vibration reciprocating blender and an asphalt coating process thereof. At present, the domestic and foreign asphalt mixing plants used in the rapid development of domestic highways all adopt direct heating which causes the defects of easiness in stone surface carbonization and poor coating. The asphalt recovery coating vibration reciprocating blender comprises a reaction kettle, a heat transfer oil filling station and a vibrator, wherein automatic heat-proof doors are arranged on two sides of the reaction kettle respectively; a discharging bin with a cold stirred material discharging port and a hot stirred material discharging port is arranged on one side of the reaction kettle; a cold stirred material-hot stirred material separating plate is arranged in the discharging bin; the heat transfer oil filling station is connected with a heat transfer oil pipe on an inner wall of the reaction kettle; the vibrator is arranged in the reaction kettle; and a shock-absorbing device is arranged at the bottom of the reaction kettle. The invention provides a special heating manner for milling and planing materials, in which the temperature is controlled within 190 DEG C, the mining and planing material as well as asphalt is heated, and the mining and planing material rolls over in a bin under the action of reciprocating vibration, so as to ensure sound adhesion and form a pre-coated recovery material.

Owner:西安砺研再生资源科技有限责任公司

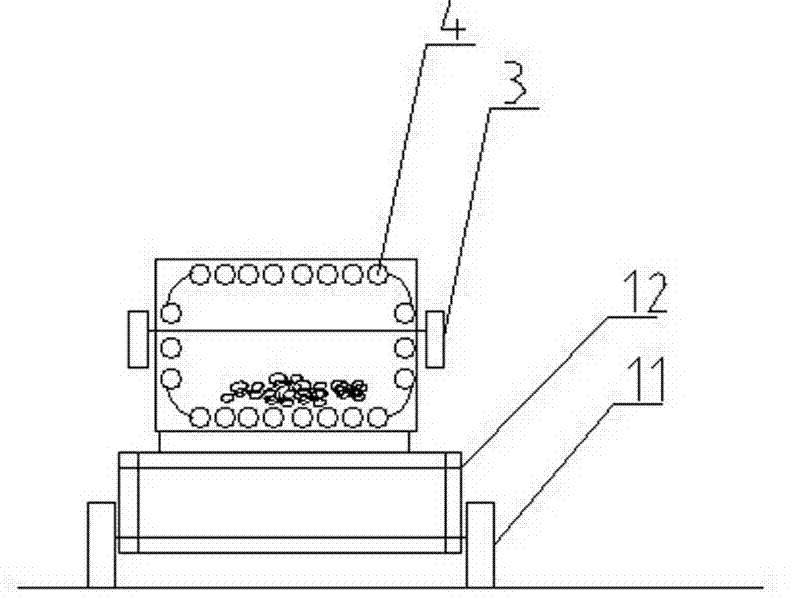

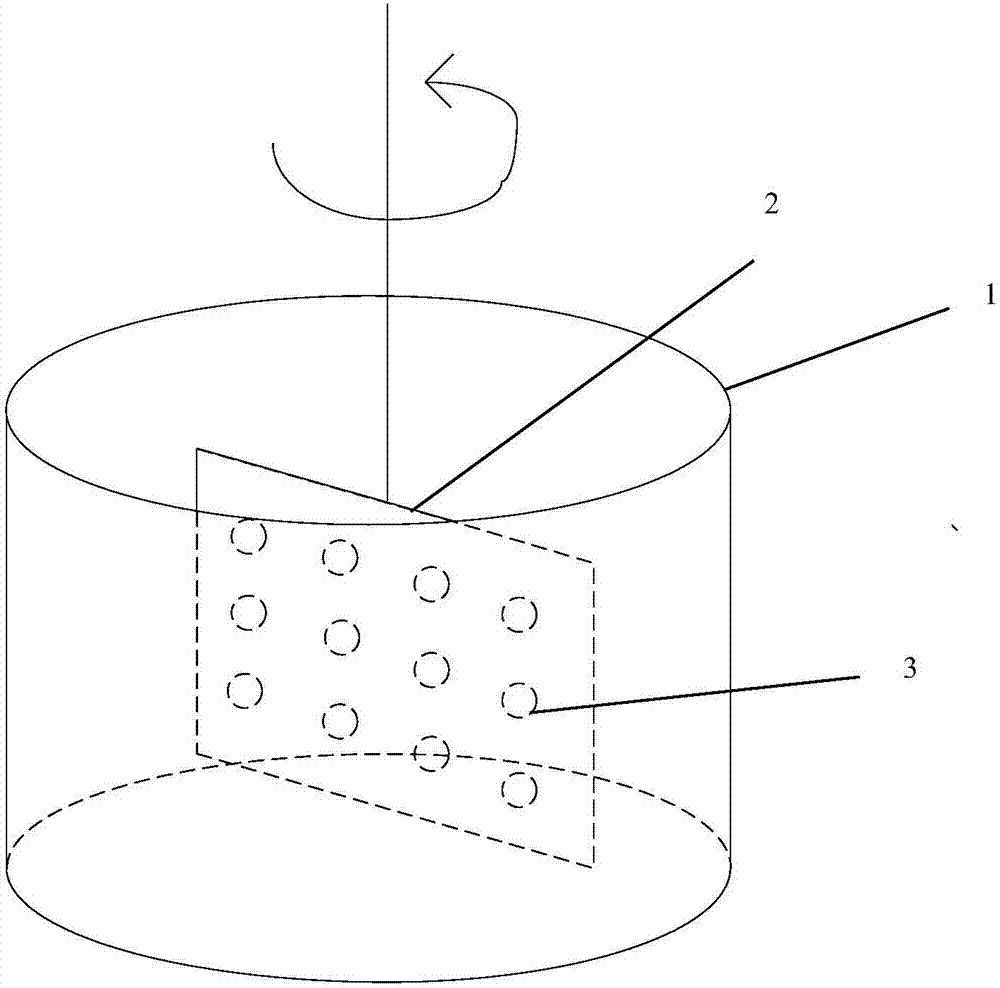

High-efficient sticking and purifying method and apparatus for papermaking white water microstickies

The invention discloses a high-efficient sticking and purifying method and apparatus for papermaking white water microstickies. The method comprises the following steps: recovering fibers and partial packing in papermaking white water by adopting a filtering or sieving way to obtain white water suspension; stirring the white water suspension at a constant speed under conditions that the temperature is 40 to 90 DEG C and the rotating speed is 200 to 1000 rpm, and enabling the microstickies in the white water suspension to be heated and be glutinous; and performing a white water microstickies sticking and purifying treatment process in a container with a rotor, and enabling the rotator to rotate at a constant speed, wherein the rotor is in a rectangular shape, a plurality of holes are uniformly formed in the surface of the rotor, an aperture ratio is 30 to 60 percent, a diameter of the small hole is phi 10 to 200 mm, and a macromolecular hydrophobic material or film with the surface higher than the microstickies covers the surface of the rotor. By adopting the method and the apparatus, microsticke particles in the white water can be effectively removed, the content of the microstickies can be significantly reduced, and no chemical reagent is introduced.

Owner:SOUTH CHINA UNIV OF TECH

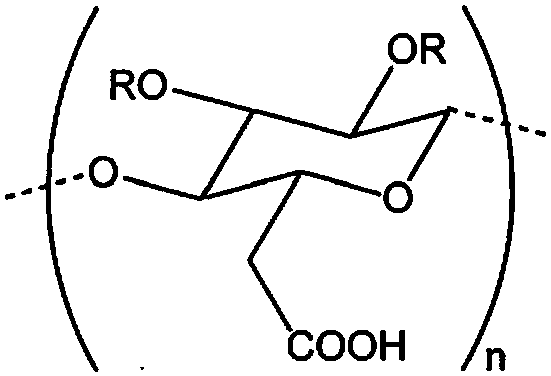

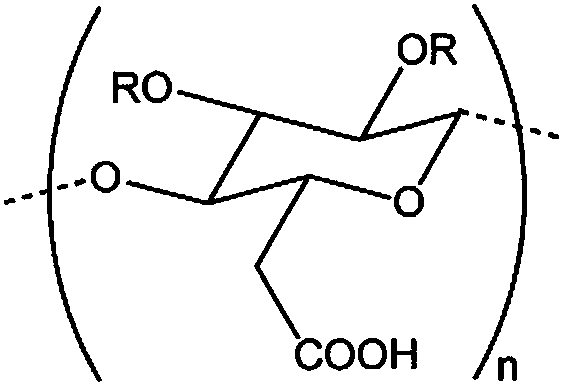

Medical fiber structure and medical laminate

InactiveCN107849154AStrengthen and weakenFully adheredAbsorbent padsNon-woven fabricsBiomedical engineeringFiber structure

A medical fiber structure and a medical laminate are provided and herein are capable of sufficiently adhering to damaged tissue to stop bleeding and more reliably reinforcing weakened tissue by preventing air leakage or fluid leakage. The invention relates to the medical fiber structure including a fiber structure made of cellulose which is produced through etherification and carboxylation of hydroxy groups of cellulose.

Owner:GUNZE LTD +1

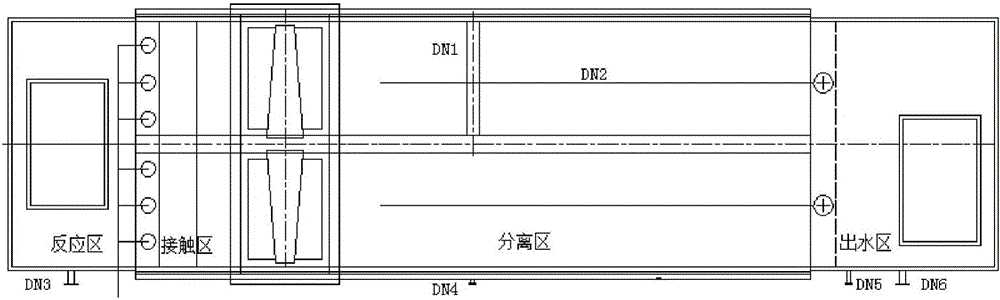

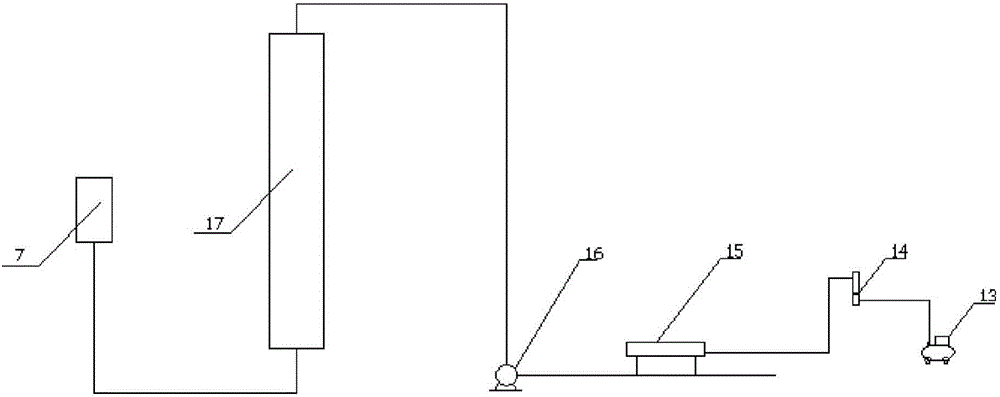

Molecular state gas floatation clarifier

ActiveCN105858774AGood dispersionHigh removal rateWater treatment parameter controlSpecific water treatment objectivesDispersitySlag

The invention relates to a molecular state gas floatation clarifier. A coagulant adding opening is formed in the upper end of a reaction region, and an air agitation pipe is arranged in the middle of the reaction region; a baffle is arranged at the bottom of a contact region, a water distribution pipe is arranged at the lower end of the baffle, a releaser is arranged at the upper end of the water distribution pipe, and the upper end of the releaser is communicated with a gas dissolving device; a slag remover track is arranged at the upper end of a gas flotation region, and is provided with a composite slag remover; a center slag collection pipe is arranged at the lower end of the slag remover track; a cable support is arranged at the top of the gas flotation region, and a water collection pipe communicated with a water outlet region is arranged at the bottom of the gas flotation region; and a water outlet weir plate is arranged at the tail end of the water collection pipe, and is arranged in the water outlet region. According to the molecular state gas flotation clarifier, air is dissolved in water in a molecular state, so that the dispersity of molecular-state micro-bubbles in water can be increased, the air can be adhered to alumen ustum particles more sufficiently, and the removal rate for colloids and other micro-suspended solids in wastewater can be improved.

Owner:HAINAN QINYUAN ENVIRONMENTAL ENG LTD

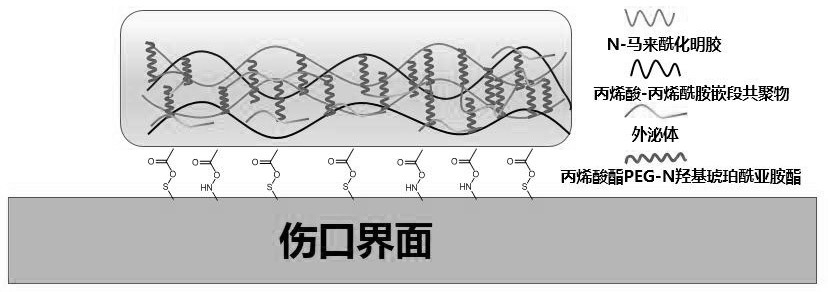

Adhesive repair-promoting hemostatic sponge and preparation method thereof

ActiveCN112007206AGuaranteed mechanical strengthGuaranteed swellingSurgical adhesivesPharmaceutical delivery mechanismMeth-Blood vessel

The invention discloses an adhesive repair-promoting hemostatic sponge and a preparation method thereof. The hemostatic sponge is prepared according to the following steps: subjecting N-maleinized gelatin, exosome, acrylate-PEG-N-hydroxysuccinimide ester, N,N'-methylenebisacrylamide to full reaction, adding maleic anhydride, acrylic acid and a first part of photoinitiator, performing neutralizingwith a neutralizer, carrying out prepolymerization, adding a mixed solution of acrylic acid N-hydroxysuccinimide ester and a second part of photoinitiator, fully performing polymerizing, and carryingout programmed freeze-drying. The hemostatic sponge prepared by the invention not only can quickly absorb blood or tissue fluid to form gel, form mechanical compression on damaged blood vessels on the surface of a cavity and promote hemostasis, but also can be adhered to the surface of the cavity, so that displacement is prevented while hemostasis is further promoted. The hemostatic sponge disclosed by the invention can slowly release gelatin and exosome, and has a long-acting repair promoting function. Therefore, the hemostatic sponge has the effects of quickly and efficiently stopping bleeding, achieving adhering and promoting repair.

Owner:SHANDONG BRANDEN MEDICAL DEVICE

Communication device insulation processing system

ActiveCN113000290AFully adheredFully contactedLiquid surface applicatorsCoatingsEngineeringStructural engineering

The invention discloses a communication device insulation processing system, and relates to the technical field of power electronic devices. The communication device insulation processing system comprises bottom frames, an oil tank, a brush plate, L-shaped rods, a third trapezoidal edge, an I-shaped frame, a hinge arm, a square plate and an external threaded rod. The communication device insulation processing system has the beneficial technical effect that electronic components can be fully adhered with insulation oil. The oil tank is fixedly connected between the two bottom frames, the two L-shaped rods are symmetrically connected to the front end and the rear end of the oil tank in a sliding mode, the inner ends of the two L-shaped rods are each provided with one brush plate, the outer ends of the two L-shaped rods are connected to the two ends of the third trapezoidal edge in a sliding mode, the third trapezoidal edge is fixedly connected to the middle of the I-shaped frame, and the I-shaped frame is fixedly connected to the two bottom frames. The external threaded rod is in threaded connection to the bottom frame at the left end, the right end of the external threaded rod is rotationally connected with a square plate, the square plate is rotationally connected with two hinge arms, and the two hinge arms are rotationally connected to the lower ends of the L-shaped rods respectively.

Owner:HUAIHUA JIANNAN ELECTRONICS TECH

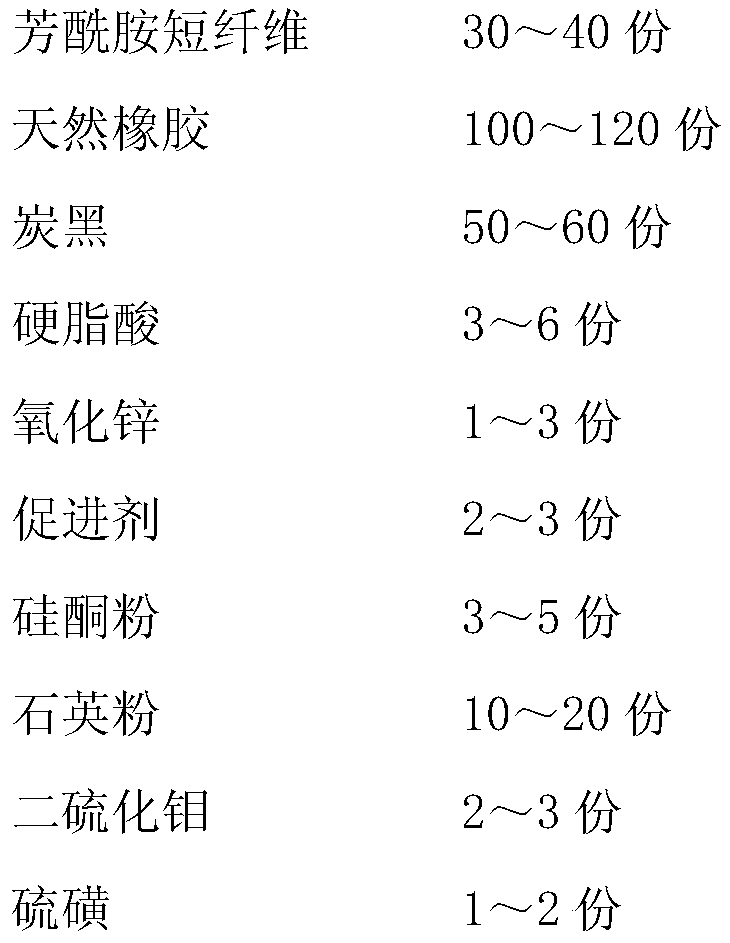

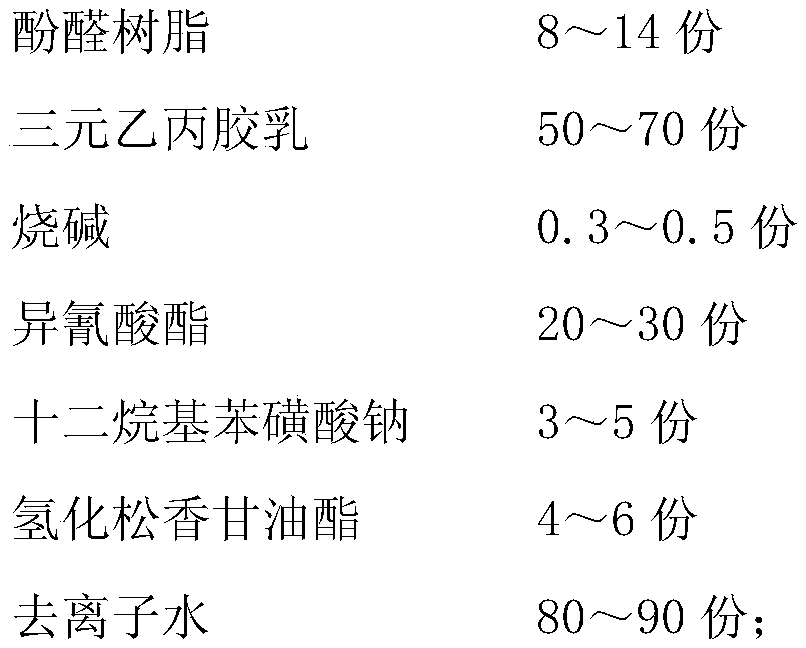

Impregnated aramid rubber-based special material and preparation method thereof

InactiveCN110776674AIncrease stickinessReduce coefficient of frictionFibre typesVulcanizationStearic acid

The invention discloses an impregnated aramid rubber-based special material. The material comprises the following raw materials: aramid short fiber, natural rubber, carbon black, stearic acid, zinc oxide, accelerator, silicone powder, quartz powder, molybdenum disulfide and sulfur. The invention also discloses a method for preparing the material. The method comprises the following preparation steps: Step 1: shearing; Step 2: pretreatment; Step 3: irradiation grafting; Step 4: dipping rubber; Step 5: preparing mixed rubber; Step 6: preparing a semi-finished product of the impregnated aramid rubber-based special material; and Step 7: vulcanization. The material aims at solving technical problems of poor wear resistance, low mechanical strength and the like of an aramid fiber and rubber composite material in the prior art, and has advantages of improving wear resistance and mechanical strength of a composite material of aramid fiber and rubber.

Owner:WUHU SHZ IND FABRIC

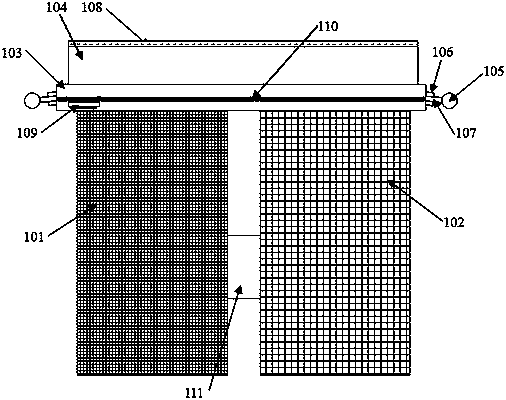

Defective fluff neatening device for textiles and neatening detection process thereof

InactiveCN114558760ATroubleshoot issues with automatic feedback adjustmentsFully adheredLiquid surface applicatorsTextile disintegration and recoveryTextile technologyStructural engineering

The invention discloses a defective fluff neatening device for textiles and a neatening detection process thereof, and relates to the technical field of textile, the defective fluff neatening device comprises a bottom wall, a shell is fixedly connected to the top of the bottom wall, a detection mechanism is fixedly connected to the upper position of the inner side face of the bottom wall, and a feedback mechanism is fixedly connected to the top of the shell. The detection mechanism comprises a scanner and a glue dripping assembly, the surface of the scanner is fixedly connected with the top of the inner side face of the bottom wall, an inner concave wall is fixedly connected to the middle of the inner side face of the bottom wall, the inner side face of the inner concave wall is fixedly connected with the bottom of the glue dripping assembly, and the feedback mechanism comprises an atomization nozzle and a mixing assembly. According to the defective fluff neatening device for the textiles and the neatening detection process of the defective fluff neatening device, through cooperative use of the detection mechanism, the glue dripping assembly, the feedback mechanism, the mixing assembly and other mechanisms, the problems of how to perform neatening detection on flocking fluff and how to realize automatic feedback adjustment on a detection result are solved.

Owner:南通益莱宏盛纺织有限公司

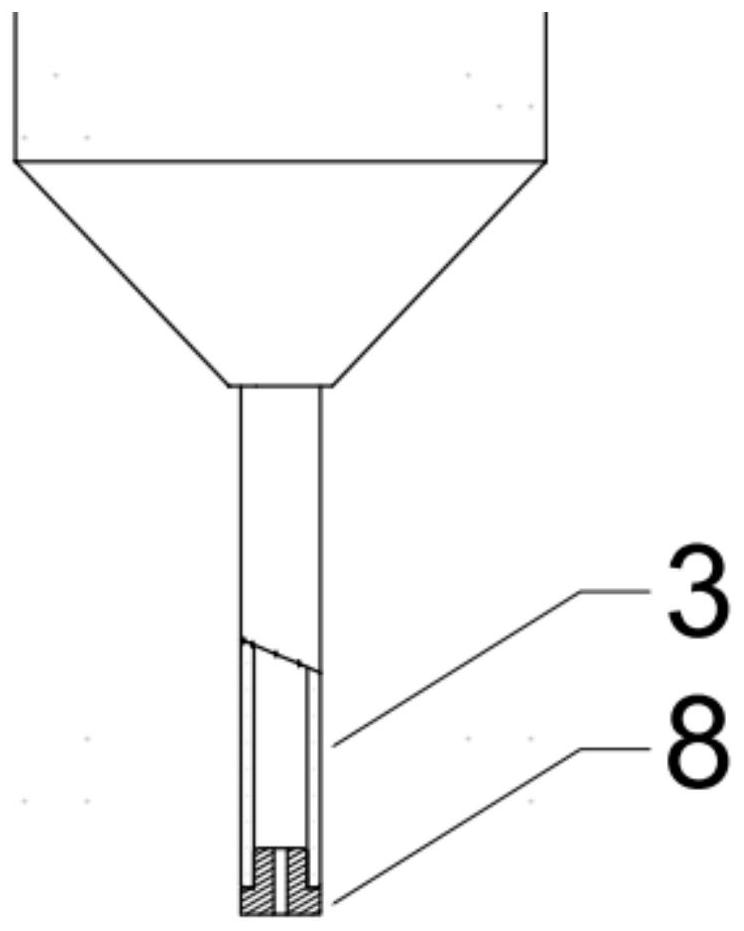

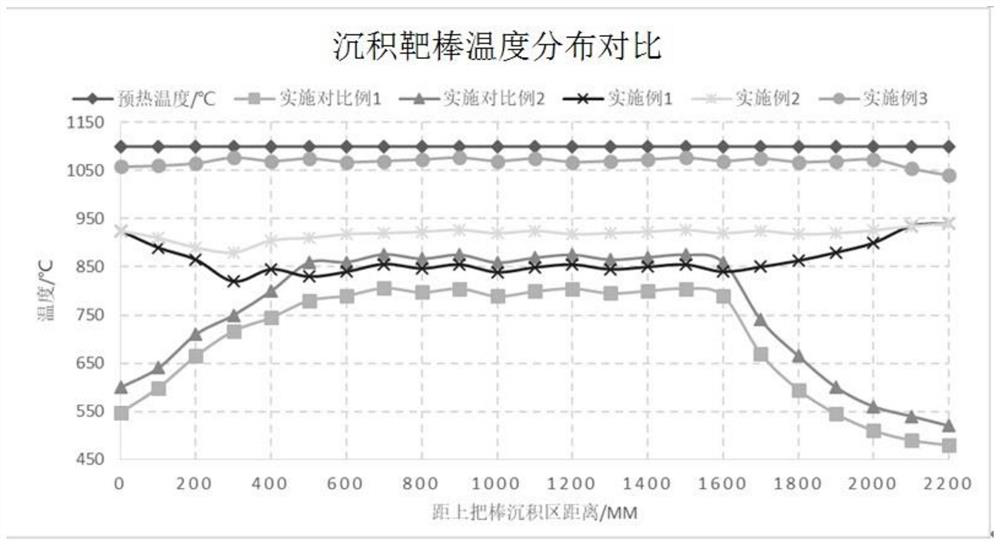

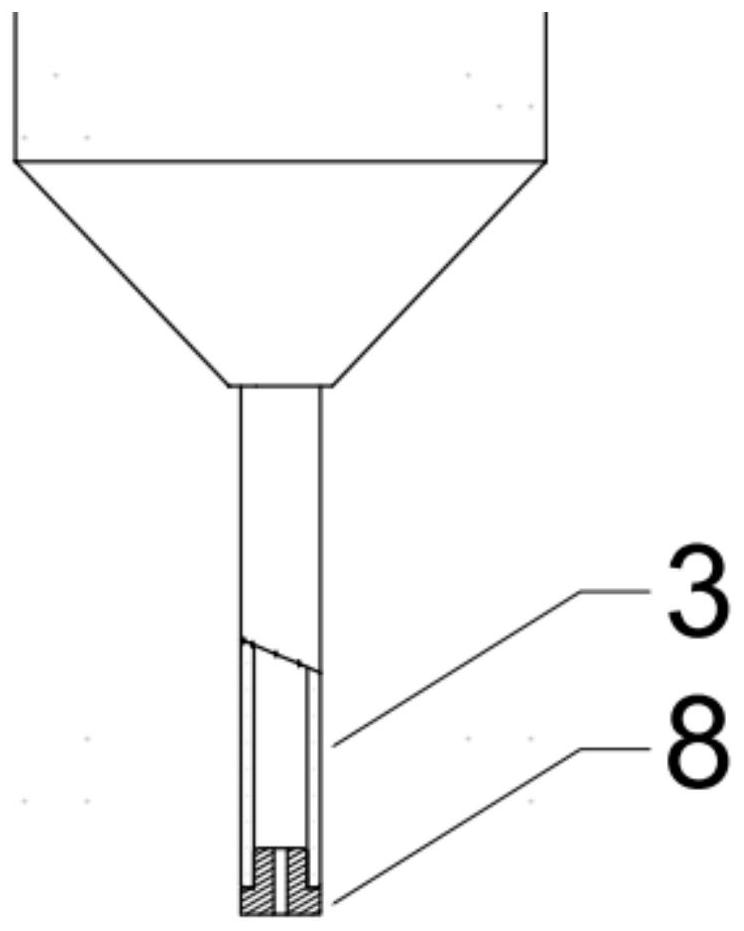

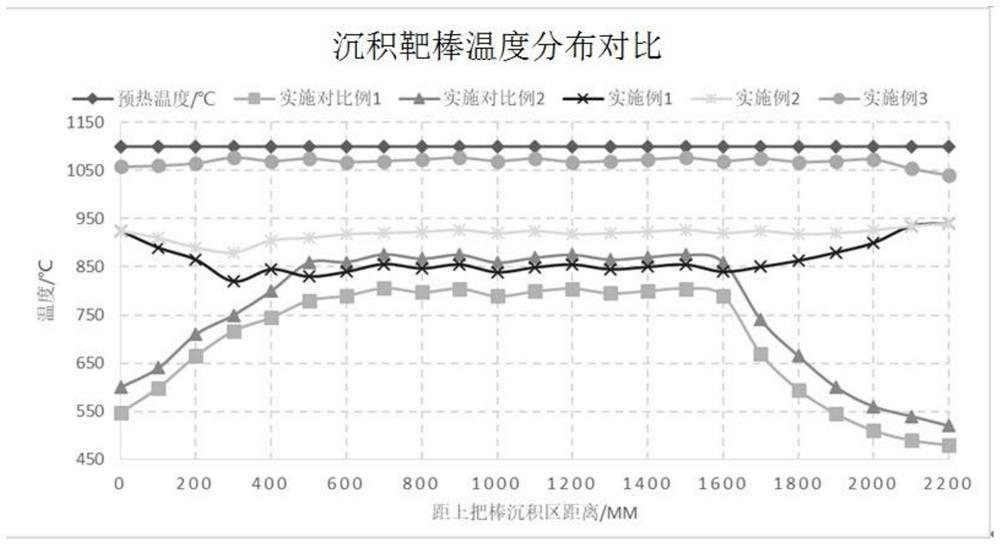

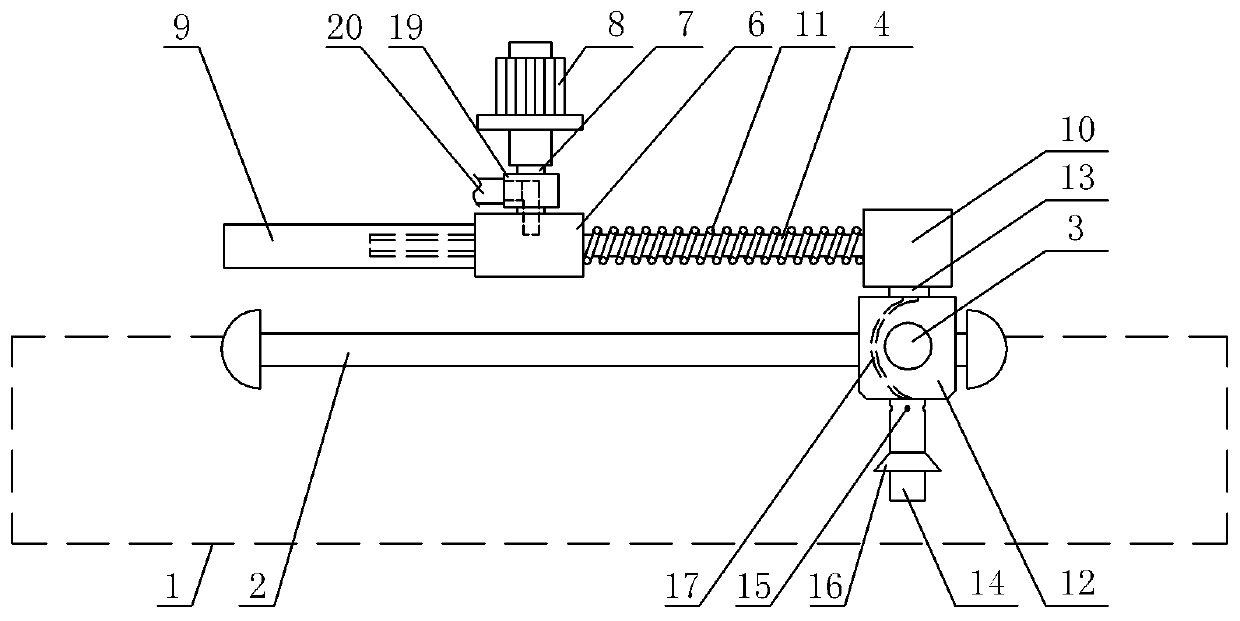

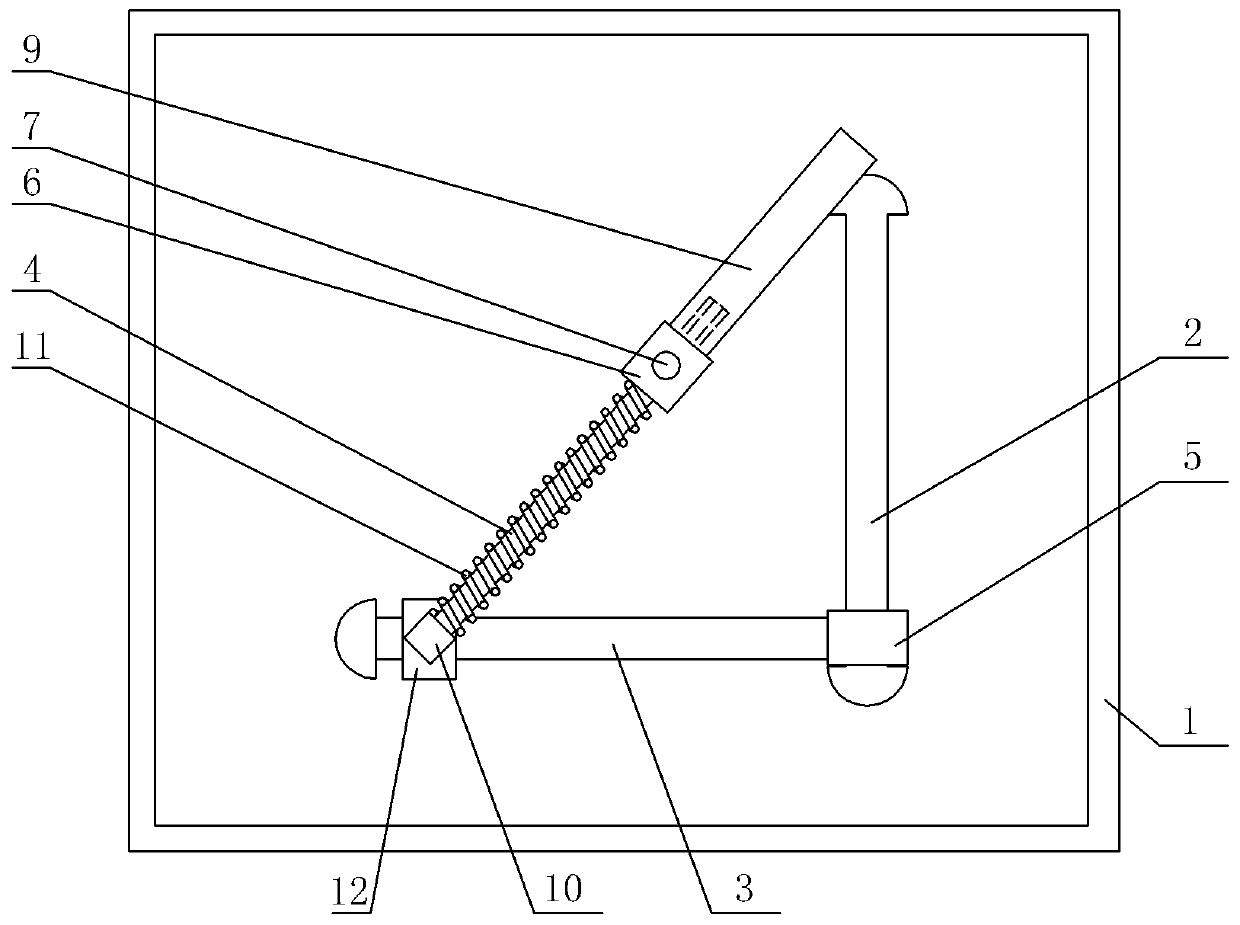

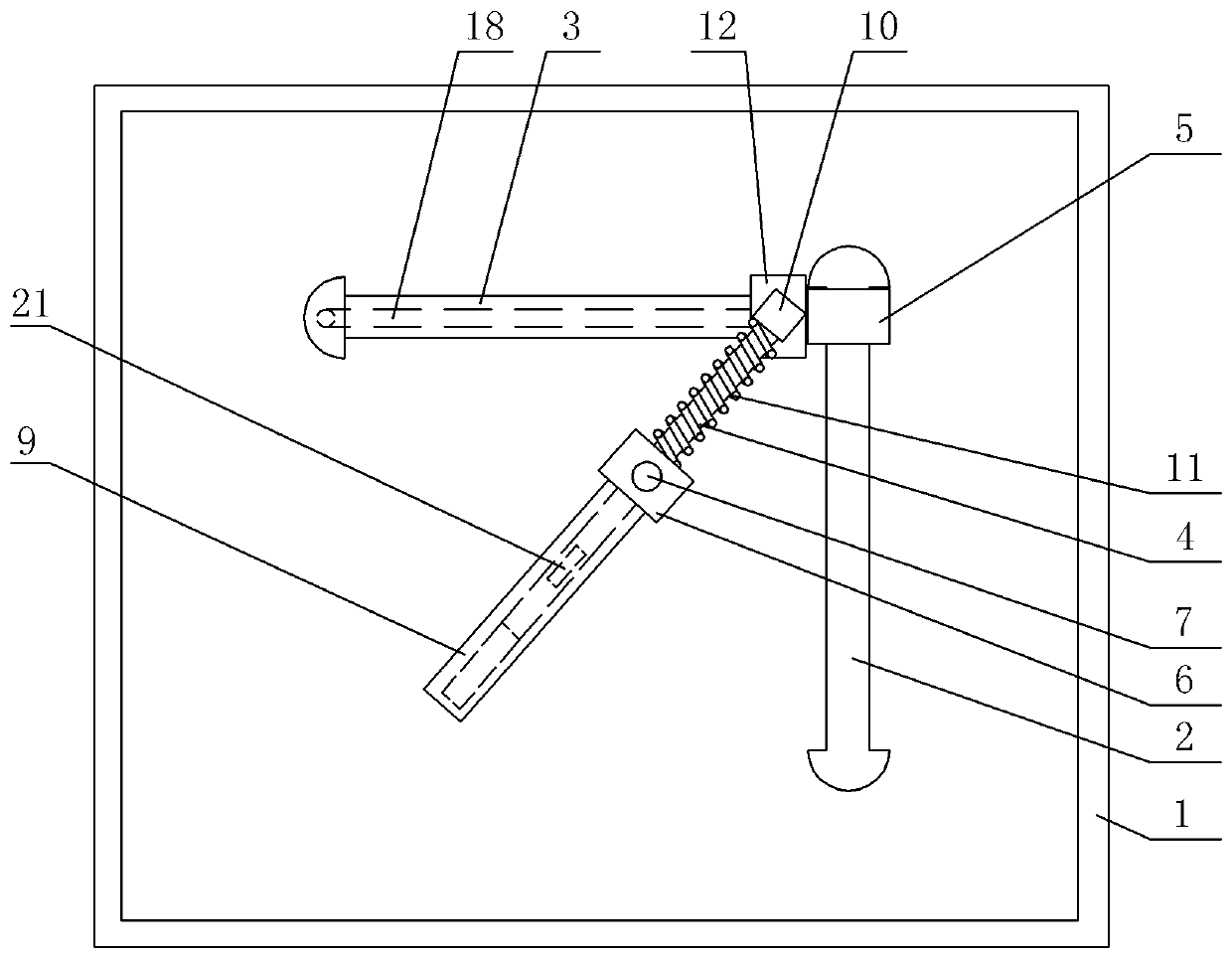

Manufacturing method of pure quartz glass hollow cylinder

The invention relates to a manufacturing method of a pure quartz glass hollow cylinder. The method adopts an external vapor deposition method to deposit a hollow glass cylindrical powder rod, a deposition cavity adopts a vertical target rod deposition mode, and the deposition target rod is a high-temperature-resistant and oxidation-resistant ceramic, alloy or a composite deposition target rod which takes alloy as a substrate and is coated with a ceramic layer. The surface of the deposition target rod keeps a certain roughness, and a blowtorch assembly is connected with a sliding seat capable of moving up and down and back and forth.During deposition, an upper rotating chuck and a lower rotating chuck drive the deposition target rod to rotate, the blowtorch assembly is started to spray deposition powder to the deposition target rod and move up and down in the direction parallel to the axis of the deposition target rod, a suction opening is opened, the temperature difference of the heated area of the whole deposition target rod is controlled within 350 DEG C, and after deposition is completed and cooling is conducted, the target rod is pulled out of the powder preform rod and sintered into the transparent pure silicon dioxide quartz glass hollow cylinder. The deposition forming quality of the powder rod is guaranteed, the processing stability is enhanced, the process is simplified, and the processing cost is reduced.

Owner:长飞石英技术(武汉)有限公司

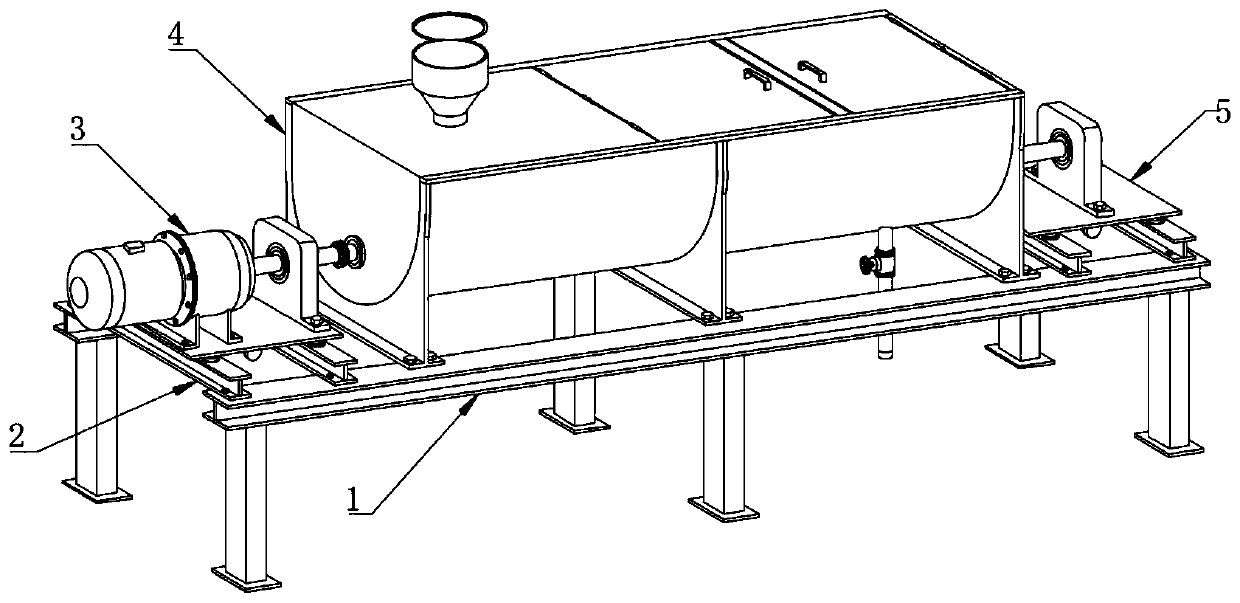

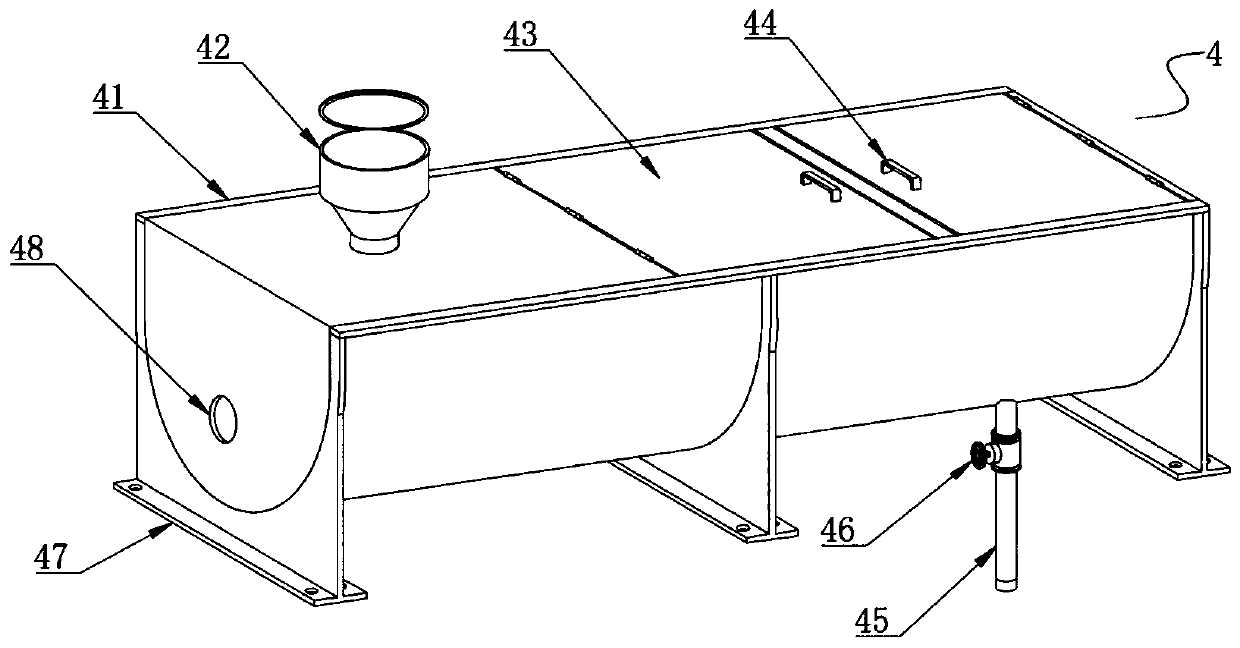

Vibration stirring device capable of improving distribution uniformity of cement particles

InactiveCN110978266ASmooth rotationSolve the phenomenon of fine aggregate "agglomeration"Cement mixing apparatusCouplingClassical mechanics

The invention discloses a vibration stirring device capable of improving the distribution uniformity of cement particles. The vibration stirring device capable of improving the distribution uniformityof the cement particles comprises a stock bin, a first vibration platform, a second vibration platform and a stirring mechanism, wherein a charge port is formed in the upper part of the stock bin, adischarge port with a valve is formed in the lower part of the stock bin, and shaft holes are formed in the two ends of the stock bin; the stirring mechanism comprises a stirring shaft, a stirring motor, a speed reducer, a first bearing seat and a second bearing seat; the two ends of the stirring shaft penetrate out of the corresponding shaft holes in a matching manner through elastic shaft seal,and are connected with one end of the first rotary shaft and one end of the second rotary shaft through a shaft coupling separately; the stirring motor, the speed reducer and the first bearing seat are arranged on a vibration surface of the first vibration platform; the stirring motor, the speed reducer and the other end of the first rotary shaft are sequentially connected; the first rotary shaftis supported on the first bearing seat in a matching manner; the second bearing seat is arranged on a vibration surface of the second vibration platform; and the other end of the second rotary shaft is supported on the second bearing seat in a matching manner. The device is capable of crushing cement balls and ash balls in a mixture through vibration, and uniformly distributing the cement balls and the ash balls into the mixture, and simple in structure.

Owner:CHINA FIRST METALLURGICAL GROUP

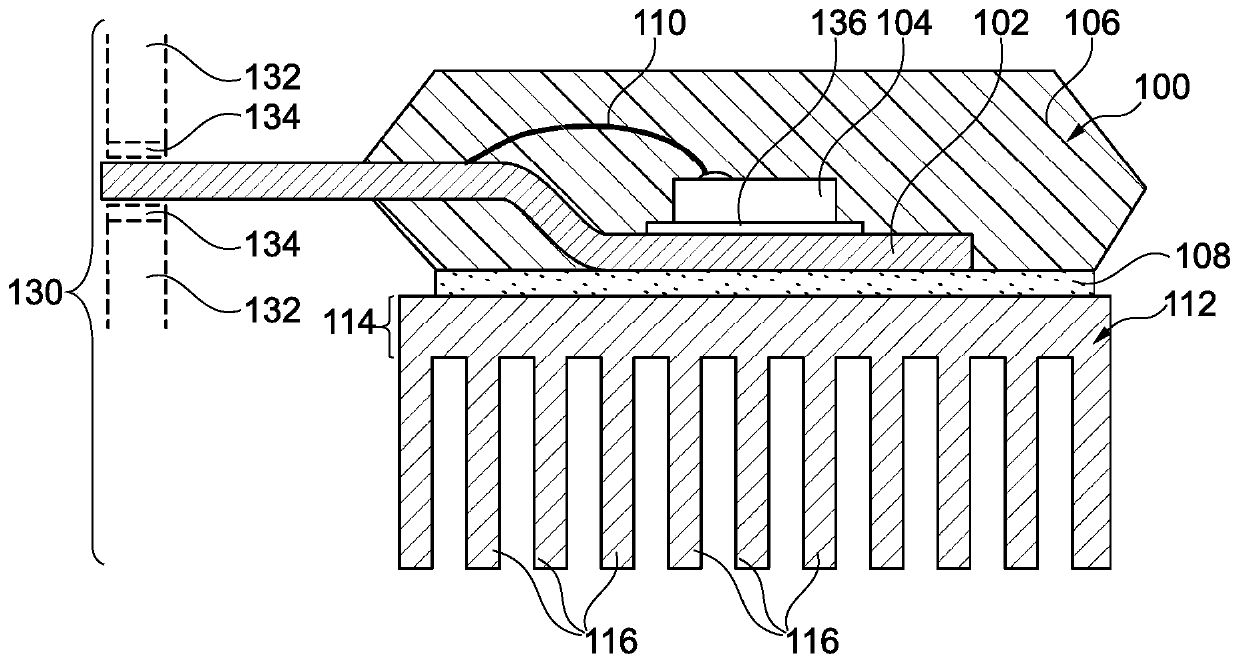

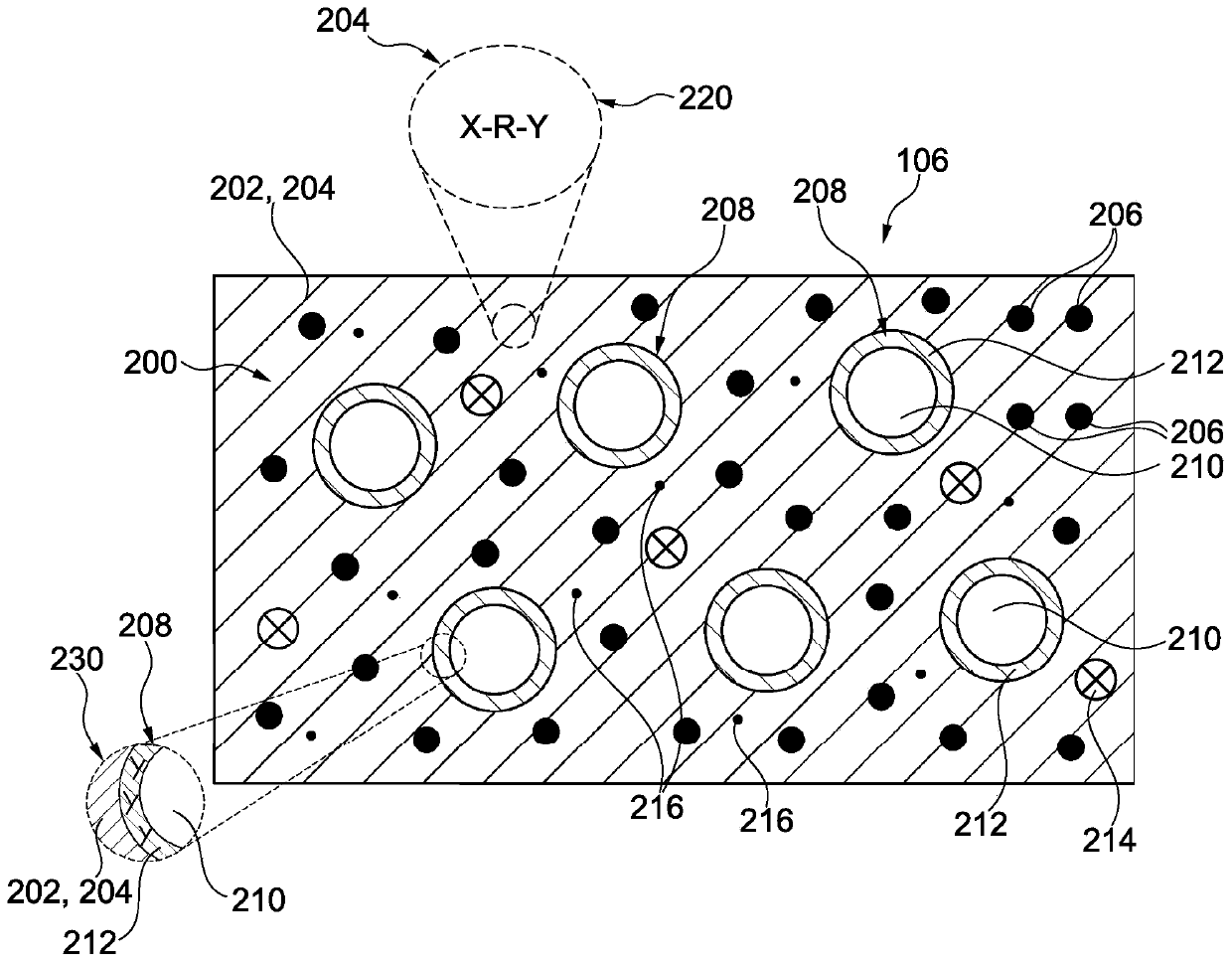

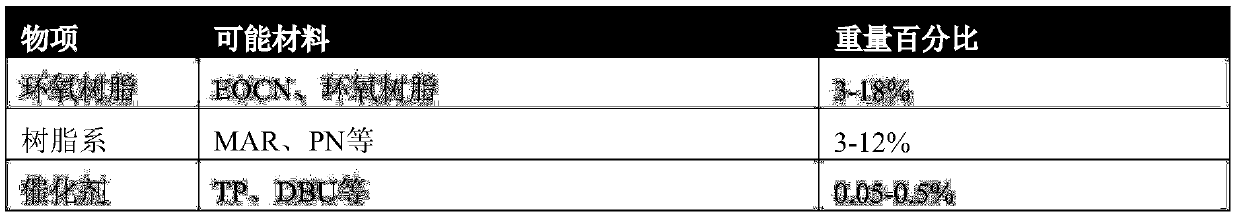

Corrosion protected mold compound

PendingCN111471271AAvoid corrosionImprove reliabilitySemiconductor/solid-state device detailsSolid-state devicesPolymer sciencePolymer resin

The invention discloses a mold compound (106). The invention relates to a mold compound (106) comprising the following components: a matrix (200) composed of a polymer resin (202), a free tackifier (204) for promoting adhesion of the mold compound (106), a curing agent (206) for curing the polymer resin (202), and a catalyst (214) for catalyzing the formation of the mold compound (106), the free tackifier (204) is less than 0.1 weight percent based on the total weight of the molding compound (106); and a filler (208).

Owner:INFINEON TECH AG

Preparation method of culture medium for organic fertilizer production

PendingCN111019846AMix well and evenlyFully adheredFungiShaking/oscillating/vibrating mixersPetri dishEngineering

The invention relates to the field of organic fertilizer production, in particular to a preparation method of a culture medium for organic fertilizer production. The preparation method comprises the following steps: step 1, preparing raw materials and preparation equipment; step 2, adding the raw materials and carrying out primary positioning on the adding amount of water; 3, mixing the raw materials, and allowing the raw materials to be attached onto eggs; 4, dispersing agglomerated raw materials; 5, positioning the adding amount of the water again; 6, putting oyster shells into a culture dish, and coating the oyster shells with the raw materials; and step 7, sterilizing the culture dish. When such a technical scheme is adopted, the culture speed of strains can be increased in the preparation process of the culture medium.

Owner:重庆酷熊科技有限公司

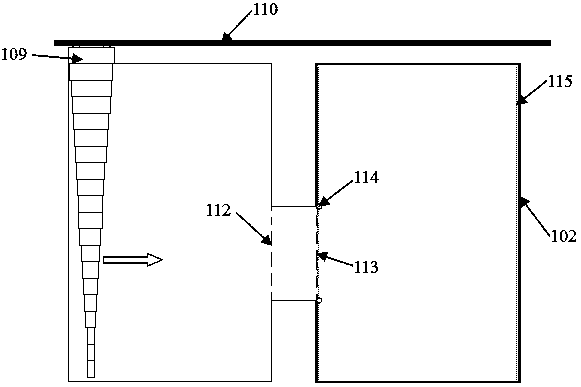

Circulating powder scattering device

PendingCN113400779AQuality improvementRealize the function of automatic cycle dustingTransfer printingEngineeringHot melt

The invention discloses a circulating powder scattering device. The circulating powder scattering device comprises a rack, wherein the rack is provided with a powder loading mechanism used for loading and collecting excessive hot melt powder, a circulating conveying mechanism where a heat transfer printing substrate penetrates, at least one powder conveying mechanism which moves along with the circulating conveying mechanism and conveys the hot melt powder in the powder loading mechanism to the position above the heat transfer printing substrate, and at least one blocking mechanism arranged above the heat transfer printing substrate and used for enabling the powder conveying mechanism to incline to scatter the hot melt powder on the heat transfer printing substrate. The hot melt powder is loaded and conveyed to the heat transfer printing substrate through a hanging basket in the powder conveying mechanism, so that the situation that the hot melt powder is changed into a block shape or a strip shape due to external force can be prevented, and the quality of a heat transfer image of a product is improved.

Owner:TAOTECH DIGITAL TECH

Veterinary enteric composition and preparation method thereof

ActiveCN108295038AProlong the action timeImprove stabilityPharmaceutical non-active ingredientsAntiparasitic agentsCoating drugsLesion

The invention provides a veterinary enteric composition, comprising a bioadhesive inner core and an enteric outer layer, wherein the bioadhesive inner core is prepared from toltrazuril, a framework material and an adhesive material; the enteric outer layer is prepared from an enteric coating material; the veterinary enteric composition is also prepared from pharmaceutically acceptable auxiliary materials. The invention also provides a preparation method of the composition; toltrazuril enteric bioadhesive sustained-release tablets are prepared by combining a bioadhesive technology with an enteric sustained-release technology. The veterinary enteric composition provided by the invention can directly reach the lesion, and can stay in poultry bodies for a longer time after being taken for once; the veterinary enteric composition has the dual functions of intestinal positioning and bioadhesion, can be released in a sustained way in the intestines, and is long in acting time and high in stability; therefore, the frequency of medication is reduced, and the medication is facilitated.

Owner:JIANGSU LINGYUN PHARMA

A kind of manufacturing method of pure quartz glass hollow cylinder

Owner:长飞石英技术(武汉)有限公司

Organic fertilizer convenient to ferment

PendingCN111056868AIncrease the cultivation areaIncrease the number of culturesBioreactor/fermenter combinationsBio-organic fraction processingAgricultural engineeringOyster shells

The invention relates to the field of organic fertilizer production, and in particular, relates to an organic fertilizer convenient to ferment. The organic fertilizer is composed of the following rawmaterials in parts by mass: 1500 to 2500 parts of leftovers, 20 to 40 parts of a beef extract, 10 to 20 parts of peptone, 40 to 60 parts of sodium chloride, 140 to 160 parts of agar, 160 to 240 partsof eggs, 150 to 450 parts of oyster shells and the balance being water. When the organic fertilizer is adopted, fertilizer fermentation can be accelerated.

Owner:重庆酷熊科技有限公司

Medium element water-soluble fertilizer production method

InactiveCN109721430AFull of nutritionNutritious and environmentally friendlyBio-organic fraction processingOrganic fertiliser preparationPeppermintsLicorice roots

The invention discloses a medium element water-soluble fertilizer production method, which comprises: 1) adding a water-soluble calcium fertilizer, a water-soluble magnesium fertilizer and a water-soluble boron fertilizer to water to obtain a medium element solution; 2) adding weathered coal powder to an ion exchange resin and hydrochloric acid to obtain a fulvic acid solution; 3) boiling fruit tree, and carrying out centrifugation to obtain a filtrate and waste residue; 4) decocting licorice root, honeysuckle and peppermint to obtain a medicine liquid and medicine residue; 5) uniformly mixingthe medium element solution obtained in the step 1), the fulvic acid solution obtained in the step 2), the filtrate obtained in the step 3), and the medicine liquid obtained in the step 4), and adding urea, diammonium phosphate and a fermentation bacterial liquid; and 6) adding straw and dry animal manure to plant ash, maize meal, the waste residue obtained in the step 3), and the medicine obtained in the step 4), mixing, adding the mixed liquid obtained in the step 5), fermenting, and carrying out solid-liquid separation to obtain the fertilizer. According to the present invention, with theproduction process, the nutrition of the fertilizer is substantially enriched; and by combining the mineral-derived fulvic acid and the biochemical fulvic acid, the obtained fulvic acid fertilizer canstably exist in the solid form, and can improve the antibacterial ability of the soil.

Owner:四川中农润泽生物科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com