Medical fiber structure and medical laminate

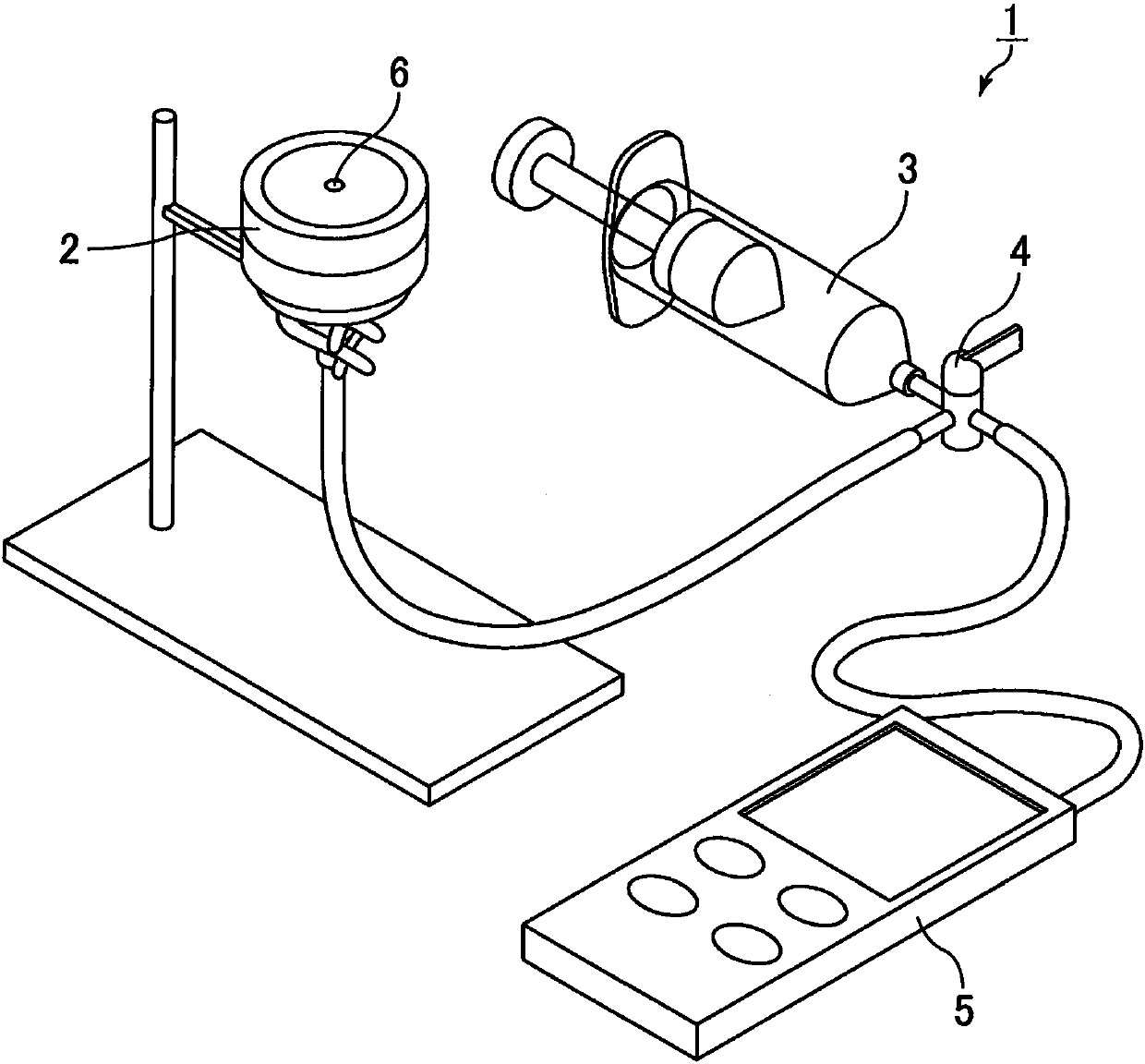

A fiber structure and laminate material technology, applied in fiber processing, plant fiber, medical science, etc., can solve the problems of gas leakage in the reinforcement area, insufficient hemostasis, and inhibition of wound healing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

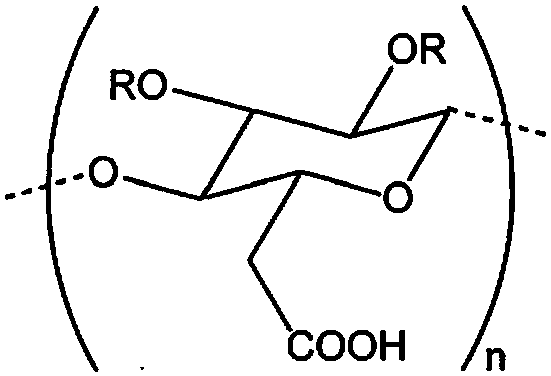

[0065] (1) Preparation of fiber structures made of hydroxyethylated and carboxylated cellulose

[0066] A 280 μm-thick single jersey fabric made of cellulose yarn with a yarn count of 80 was bleached by hydrogen peroxide bleaching as a raw material.

[0067] Soak the bleached knitted fabric in TEMPO oxidation solution (TEMPO concentration: 20% owf, 5% sodium hypochlorite concentration: 180% owf, NaBr: 17.5 owf, pH 10 aqueous solution) at 25 °C with a bath ratio of 1:30 10 minutes for oxidation. The oxidized knitted fabric was washed with water for 3 times, and then in sodium chlorite solution (25% sodium chlorite concentration: 20% owf, CG1000 concentration: 1.0 g / L, pH 3.8 aqueous solution) for 90 minutes to carry out carboxylation. The resulting knitted fabric was washed with hot water, then with water, at 70°C with a bath ratio of 1:20 in a hydrogen peroxide / sodium borohydride solution (30% hydrogen peroxide concentration: 1% owf, sodium borohydride concentration : 5% ow...

Embodiment 2

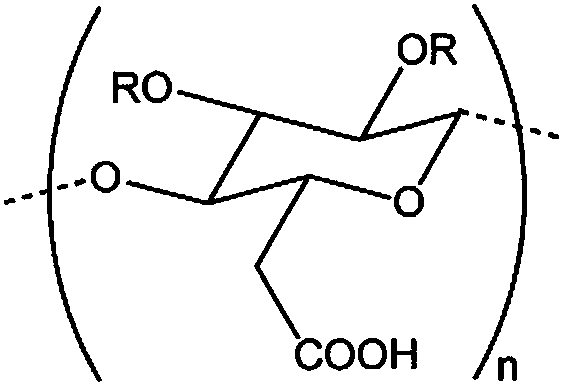

[0086] Fabrication of medical fiber structures and medical laminates, evaluation of adhesion to damaged tissue, and stress testing were performed in the same manner as in Example 1, except that the TEMPO oxidation solution used in the TEMPO oxidation step was TEMPO oxidation solution (TEMPO concentration: 20% owf, 5% sodium hypochlorite concentration: 350% owf, sodium bromide: 17.5% owf, pH 10 aqueous solution).

[0087] Tables 1 and 2 show the results.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com