Multi-impeller mixed flow field ore pulp preprocessor based on ore pulp pipeline pressure drive

A technology of pipeline pressure and preconditioning, which is applied to mixers with rotating stirring devices, mixers, chemical instruments and methods, etc., which can solve the problems of on-site operation and maintenance work, excessively high speed requirements of drive motors, fogging discs, etc. Poor working environment and other problems, to achieve the effect of fast and convenient pretreatment process, convenient mixing uniformity, stirring effect and efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

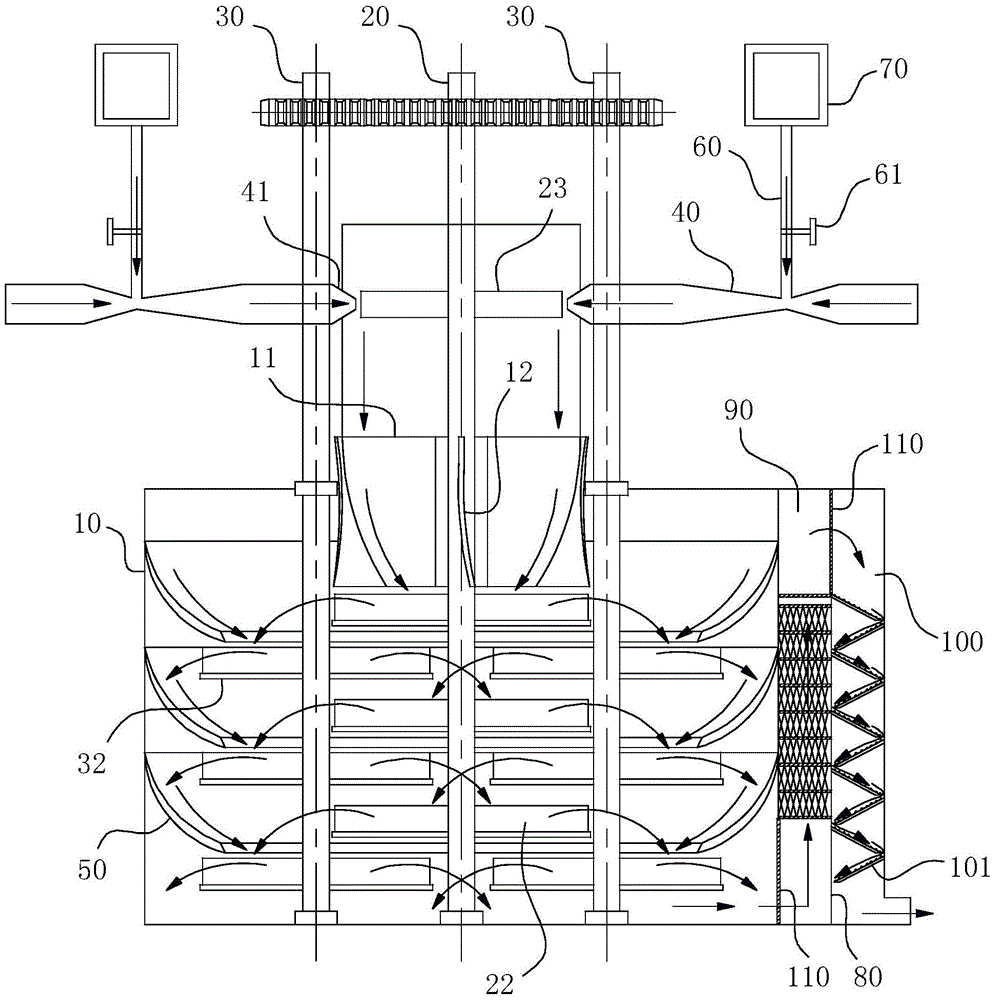

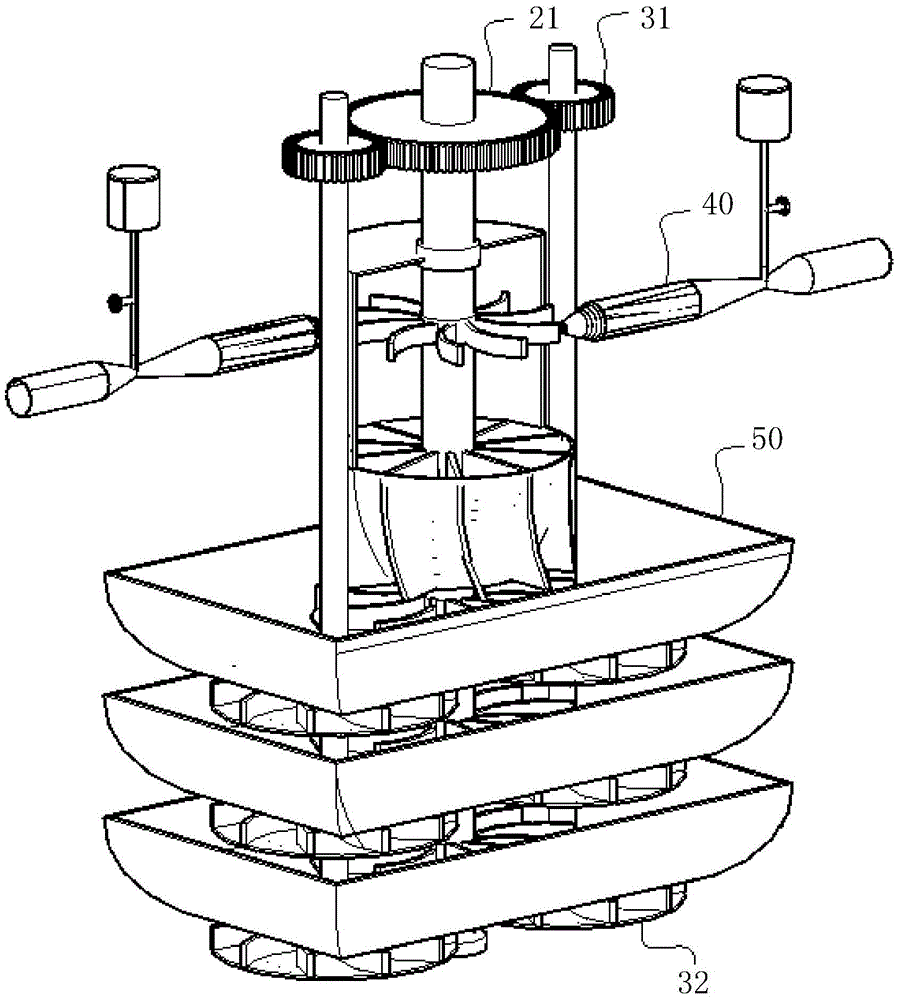

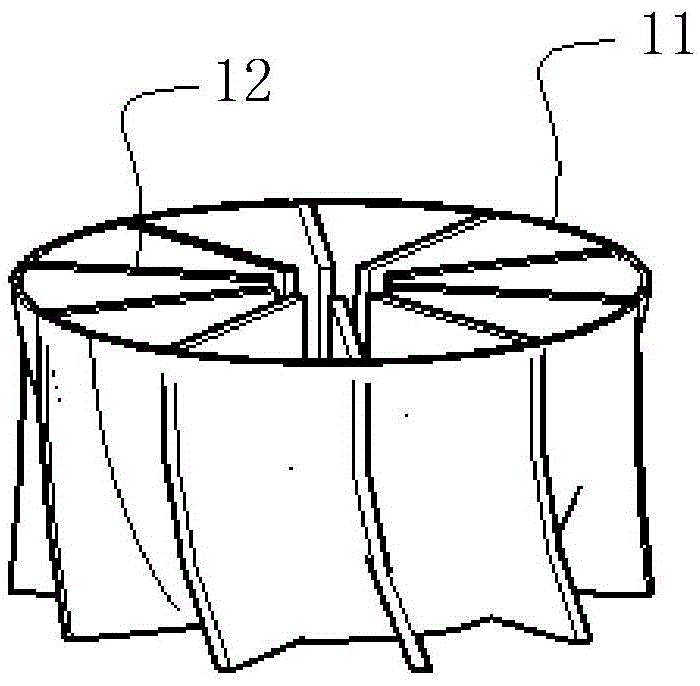

[0053] For ease of understanding, combined here Figure 1-12 , the specific embodiments of the present invention are further described as follows:

[0054] 1.1 Introduction of main components

[0055] (1) Mixing box

[0056] The mixing box 10 is designed to provide a platform for the pulp and chemicals to react with each other, so that each part of the pulp and chemicals can be contacted and mixed efficiently, thereby finally forming a mixed solution with high uniformity. Mixing box 10 can be cylindrical or hexahedron etc., certainly also can be other shapes, as figure 1 Shown is exactly square cylindrical mixing box 10.

[0057] (2) Medicine feeding system

[0058] The drug feeding system includes a variable-section feeding pipe 40 similar to a Venturi tube. The other end of the feeding pipe 40 opposite to the nozzle 41 is connected to the external slurry equipment, and its throat pipeline is connected to the chemical tank 70 by the chemical pipe 60 . A control valve 61...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com