High-efficient sticking and purifying method and apparatus for papermaking white water microstickies

A paper-making white water and sticky technology, which is applied in papermaking, paper machine, textile and paper making, etc., can solve the problem of large accumulation of stickies, and achieve the effect of mitigating harm and negative impact, smooth flow, and promoting contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

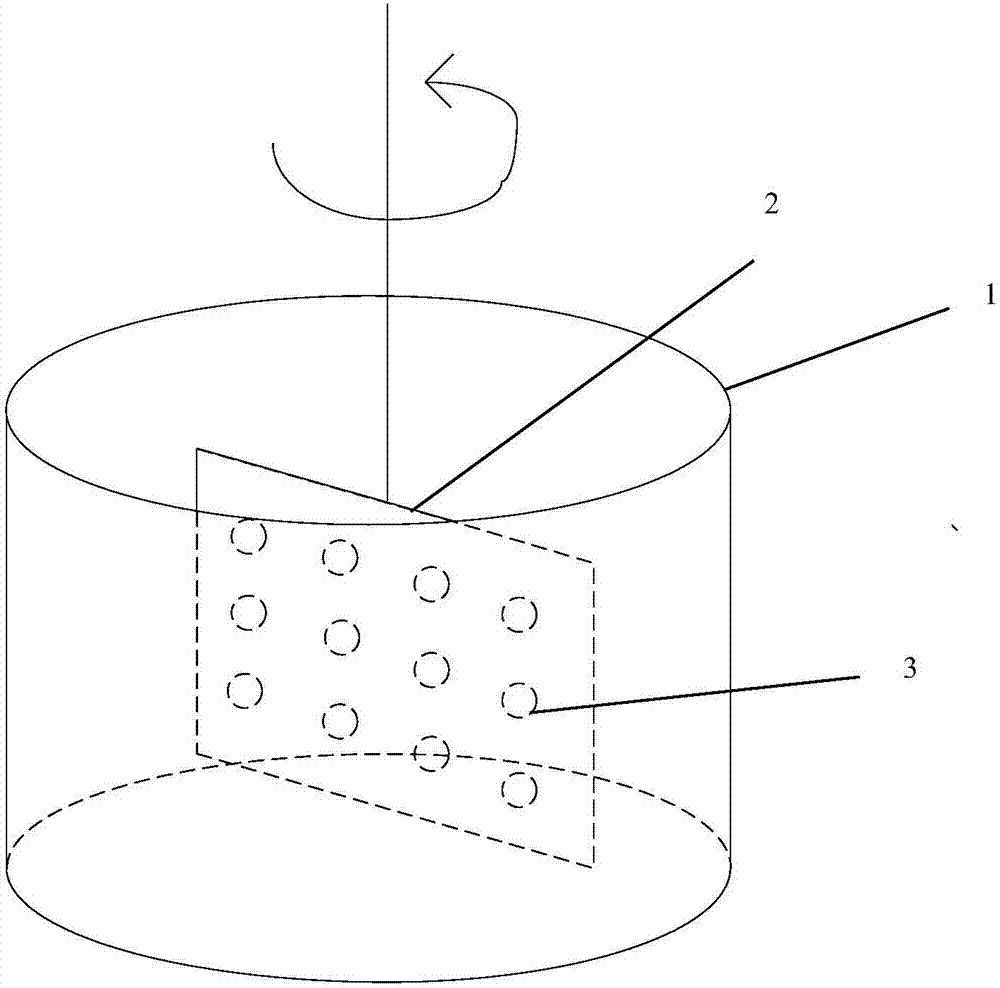

Embodiment 1

[0035] Prepare the slurry with label paper and copy paper with pressure-sensitive adhesive, then sieve, and filter and recover the fibers, fillers and other components contained in it with a dynamic water filter with a mesh number of 200 mesh, and obtain the fine The papermaking white water (white water of office waste paper mixed with pressure-sensitive adhesive) with a solid content of 0.1% of the fiber, fine sticky matter, filler and other components is taken. Part of the white water is selected from a laser particle size analyzer. Detected at room temperature, and compared with the standard curve established by standard particles, the content of fine stickies was 2.66×10 -3 mm 3 / mL, its surface energy is 46.3mJ / m 2 , and then use a rotor covered with a hydrophobic polyethylene film, with an opening ratio of 50% and a hole diameter of 15mm. Stir in the container at room temperature and 800rpm at a constant speed for 60min to adhere to the fine stickies. The surface energy...

Embodiment 2

[0039] With the same slurry in Example 1, the fiber and part of the filler in the recycled slurry are reused with the dynamic water filter of the same 200 mesh filter screen to obtain the papermaking white water (mixed with pressure-sensitive The white water of the office waste paper of glue) filter and recover the components such as fibers and some fillers contained therein, take part of the treated white water, and use the same fine sticky matter measuring instrument and method in Example 1 to measure the content of fine sticky matter therein is 3.28×10 -3 mm 3 / mL, its surface energy is 46.3mJ / m 2 , and then a rotor of the same size, but with a surface porosity of 30%, a pore diameter of φ10mm, and a rotor covered with a hydrophobic polytetrafluoroethylene film, stirred at a constant speed of 800 rpm in the container for 80 minutes at room temperature to adhere to the fine stickies, The surface energy of the film is 48.2mJ / m 2 , and then take the same method to detect th...

Embodiment 3

[0043] Retrieve the white water from the old newsprint machine from the newsprint factory, and use the same 200-mesh filter to reuse the fibers and some fillers in the slurry to obtain papermaking white water with a solids concentration of 0.1%. , take part of the white water, and use the same micro-sticky analysis instrument and method in Example 1 to measure the micro-sticky content in it to be 12.26×10 - 3 mm 3 / mL, its surface energy is 50.7mJ / m 2 , and then use the rotor covered with film on the surface to stir the fine stickies in the container at room temperature and 900rpm at a constant speed for 90min. The surface energy of the film is 68.7mJ / m 2 , and then adopt the same method to check that the content of fine stickies in white water after adhesion is 11.45×10 -3 mm 3 / mL, the calculated adhesion removal efficiency of fine stickies was 6.61%.

[0044] In addition, take the same recycled white water, put it in the same container, and replace the surface of the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com