Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

78results about How to "Reduce rework time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

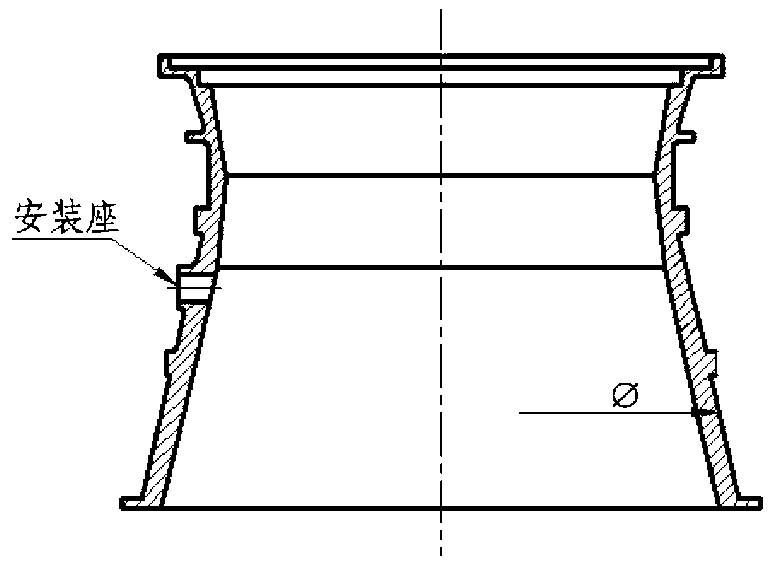

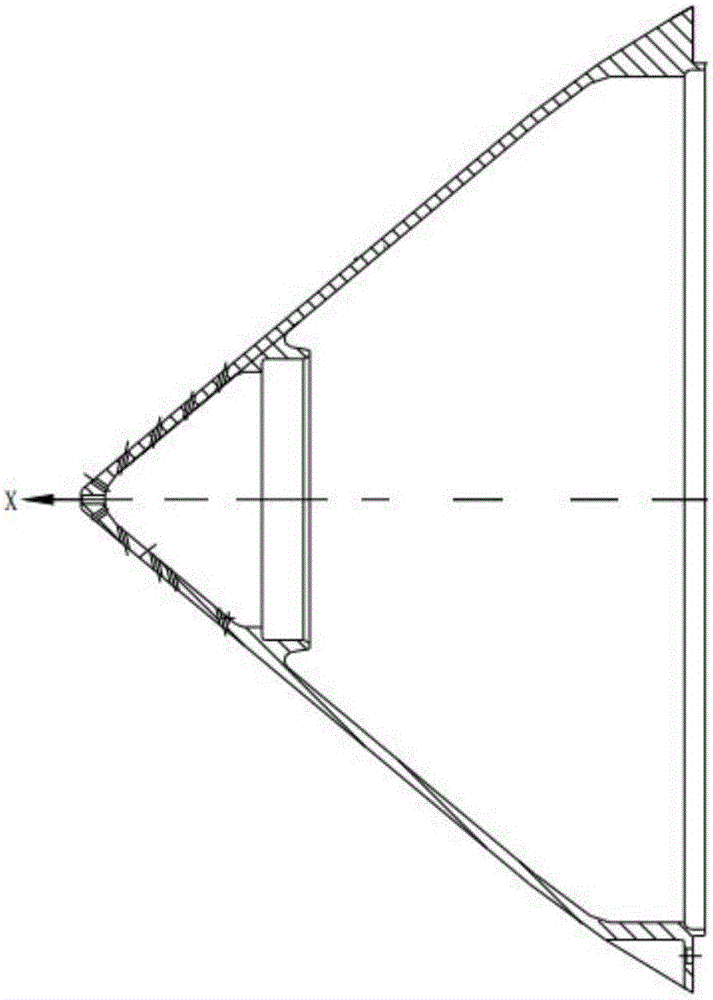

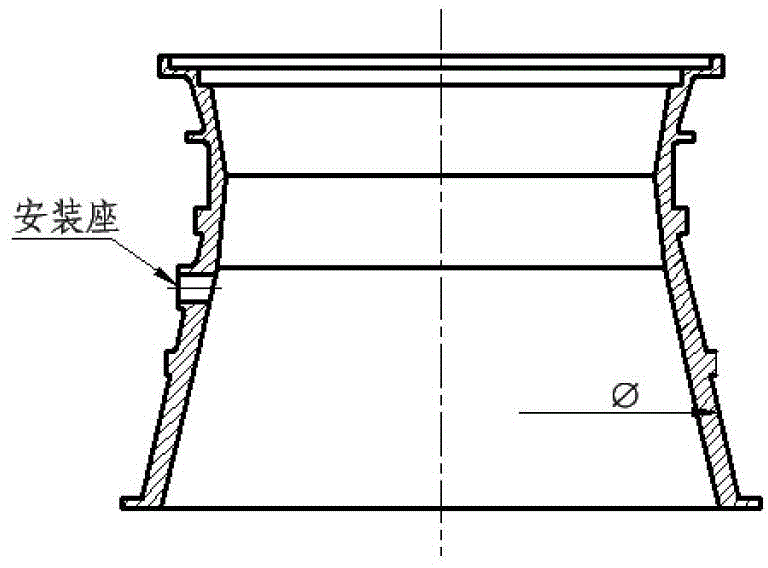

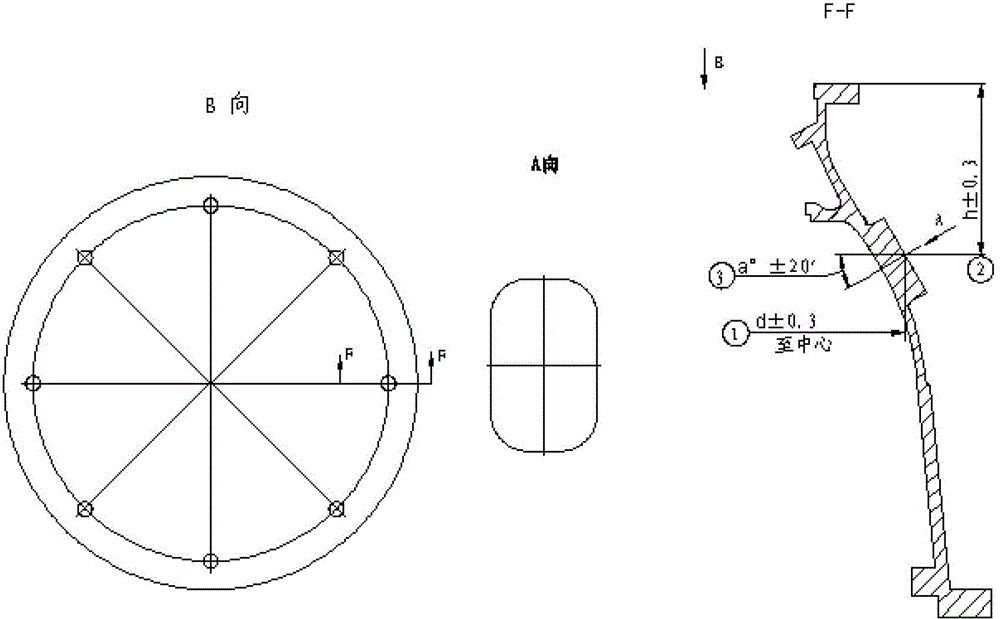

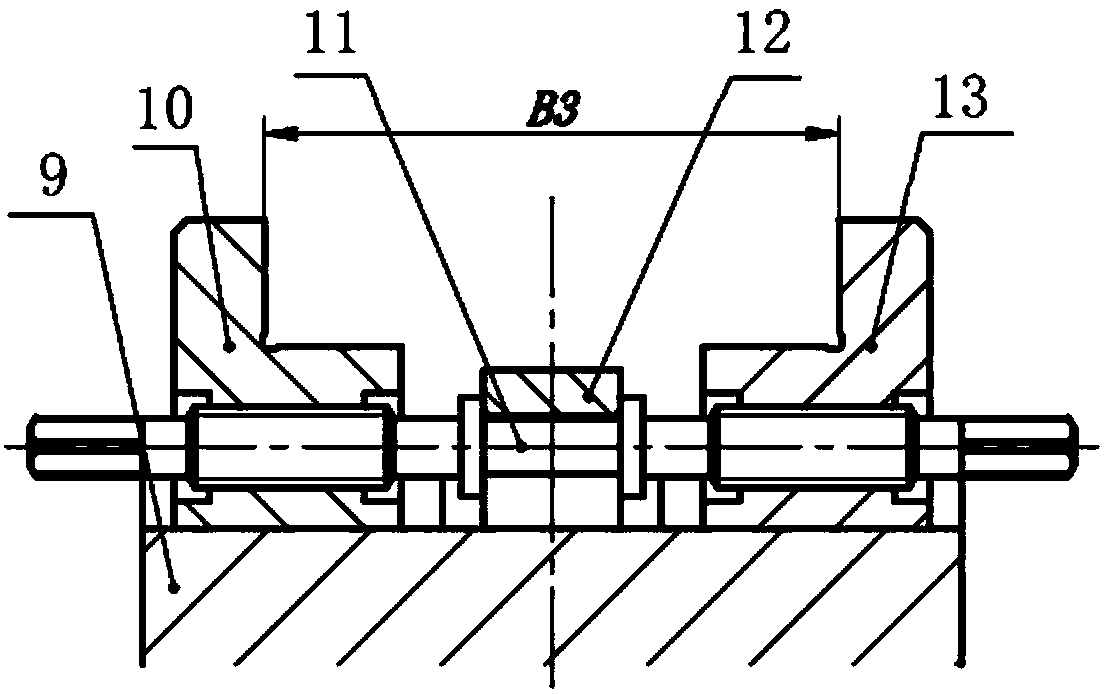

Method for detecting diameter of outer wall of tapered case of aviation engine on line

InactiveCN102927952AGuaranteed accuracyReduce manufacturing costMeasurement devicesNumerical controlAviation

The invention discloses a method for detecting the diameter of an outer wall of a tapered case of an aviation engine on line. According to the method, a five-coordinate numerical control milling center with a Renishaw MP10 trigger-type measuring head is equipped, tapered case parts and a mounting seat on the surface of a tapered case are equipped; a fine adjustment ring gauge of the used measuring head is measured on line; a point contact-type measurement mode is adopted; a machine tool siemens control system Sinumeric 840 D on-line measurement technology is adopted; and an on-line measurement quick tool path amendment and error compensation generation technology is adopted. The method has a broad application prospect; and by the on-line measurement technology, a numerically-controlled machine tool is impelled to form a machining and detecting integrated numerical control machining unit. By the method, the traditional manufacturing mode that a design characteristic is equipped with a set of measurement tool in the current industry is changed, the manufacturing cost of the tool is saved, repair labor-hour is saved, and first-pass yield of product processing is improved, so that the development period and the production cost of new products are reduced.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

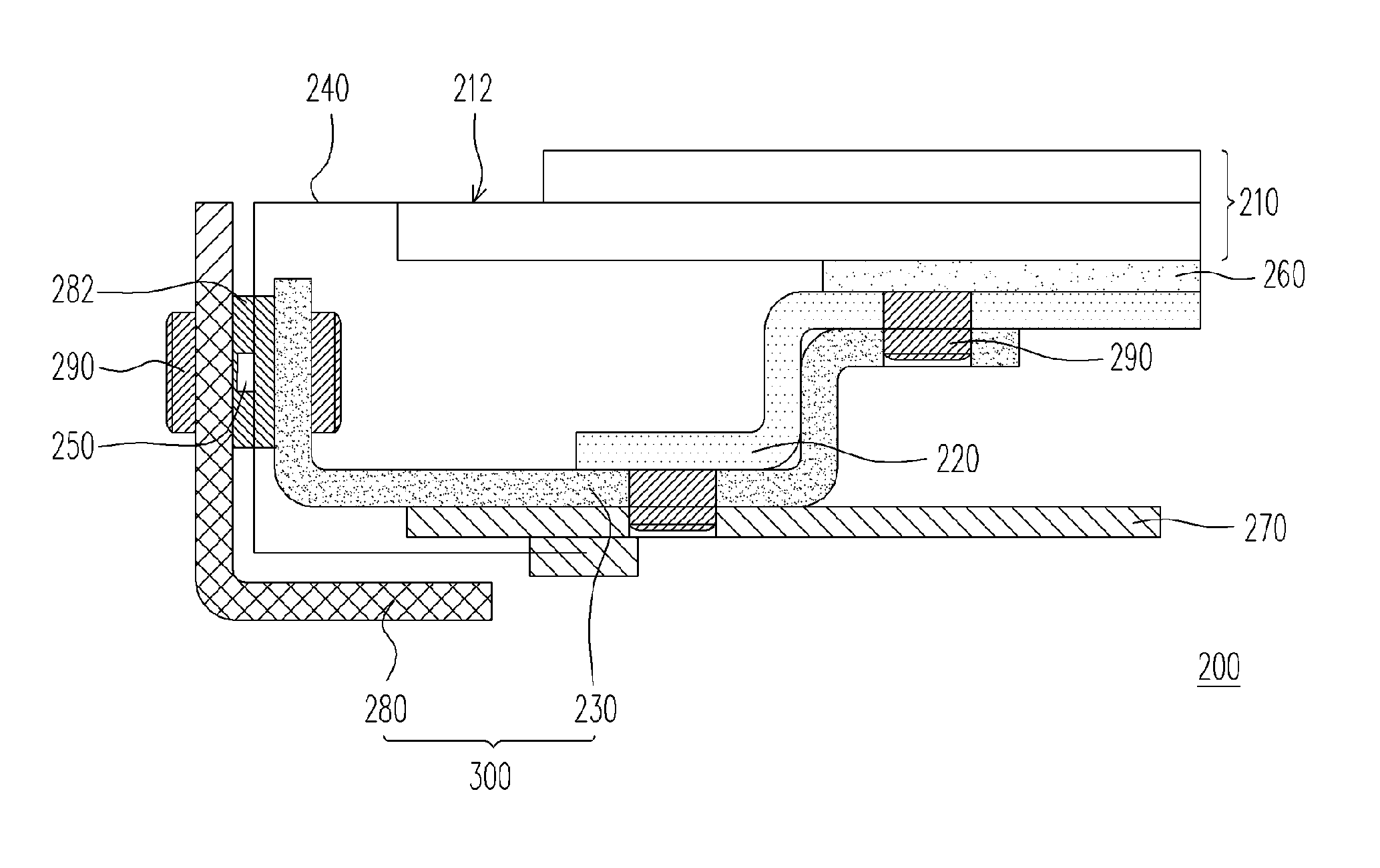

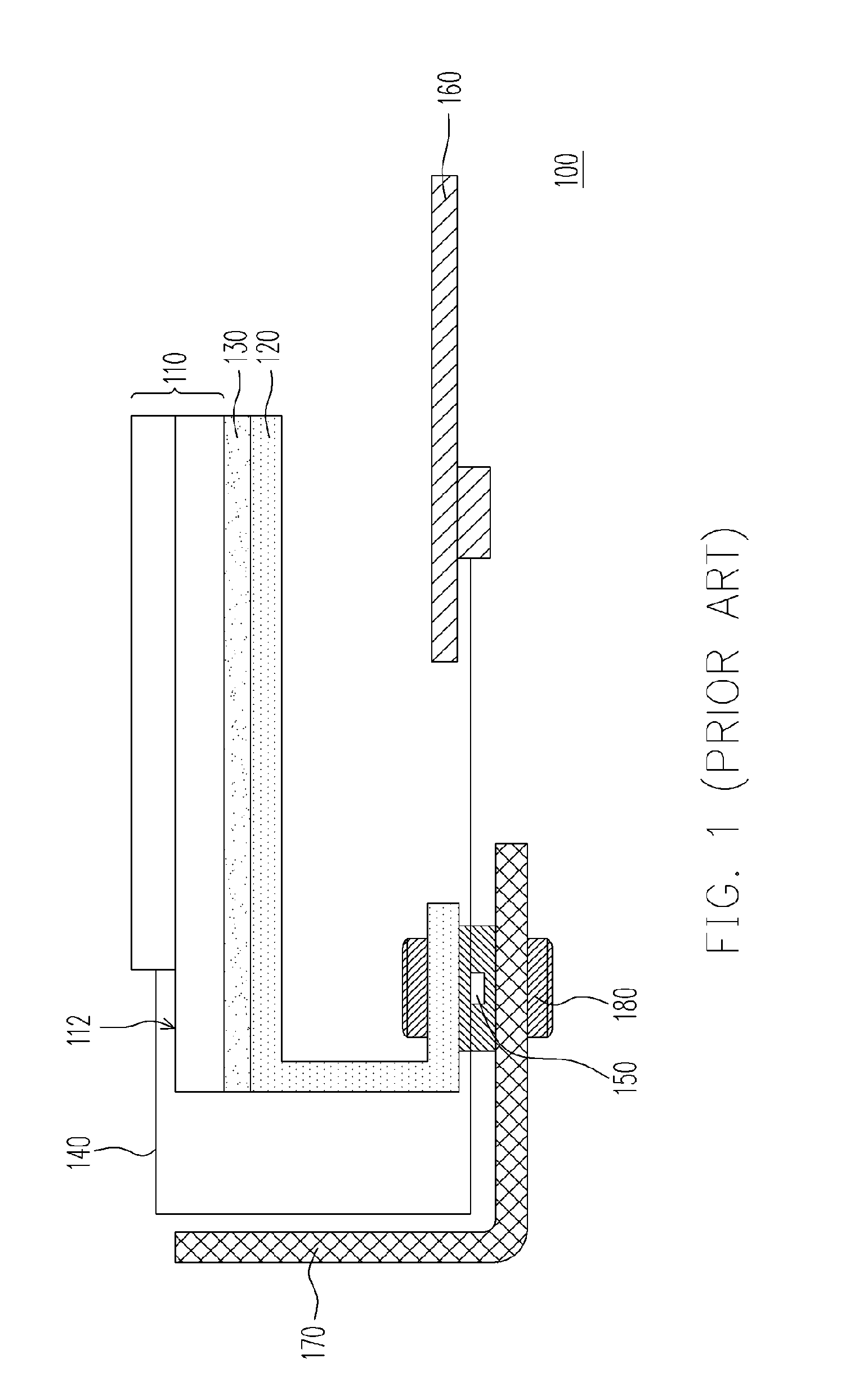

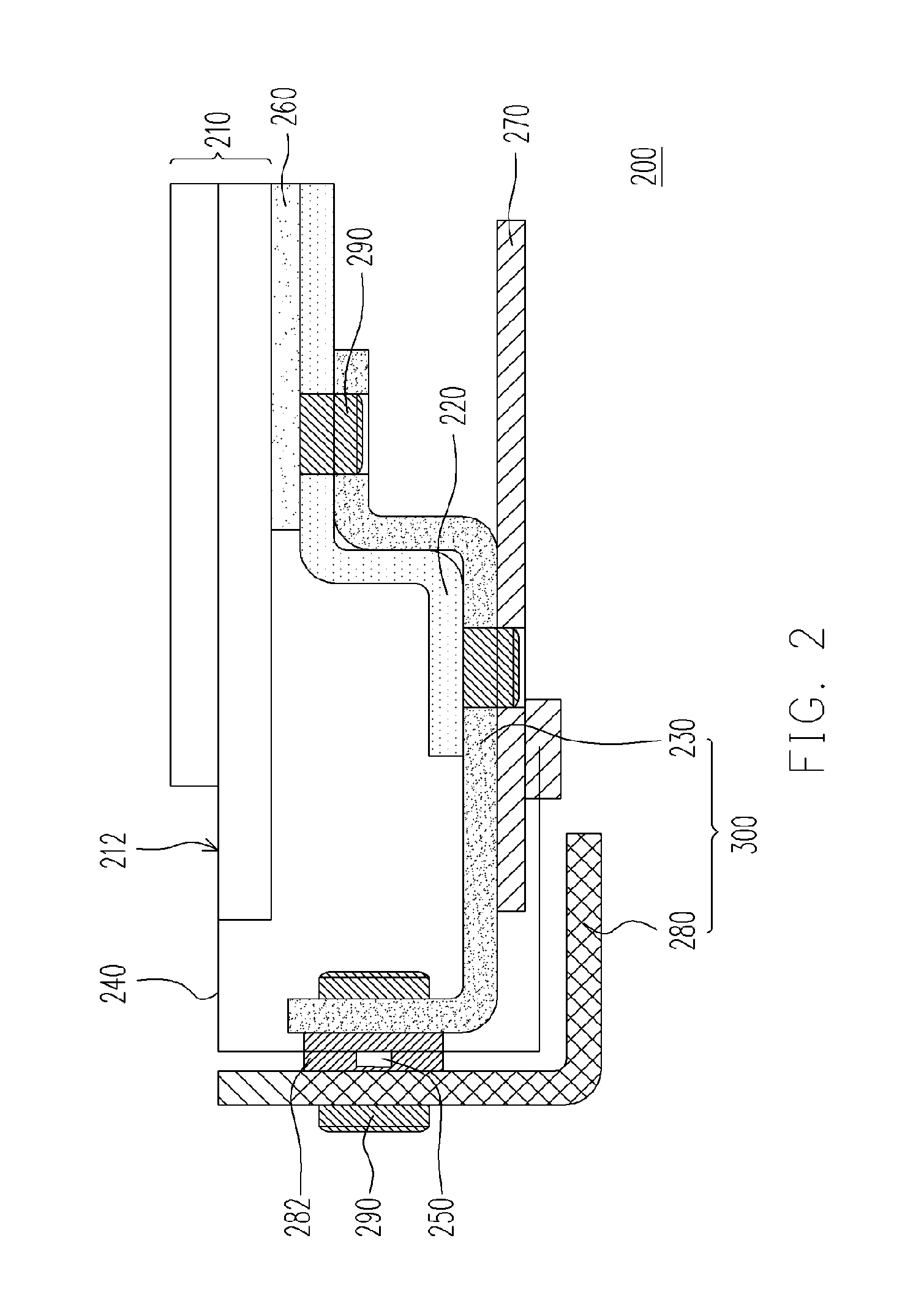

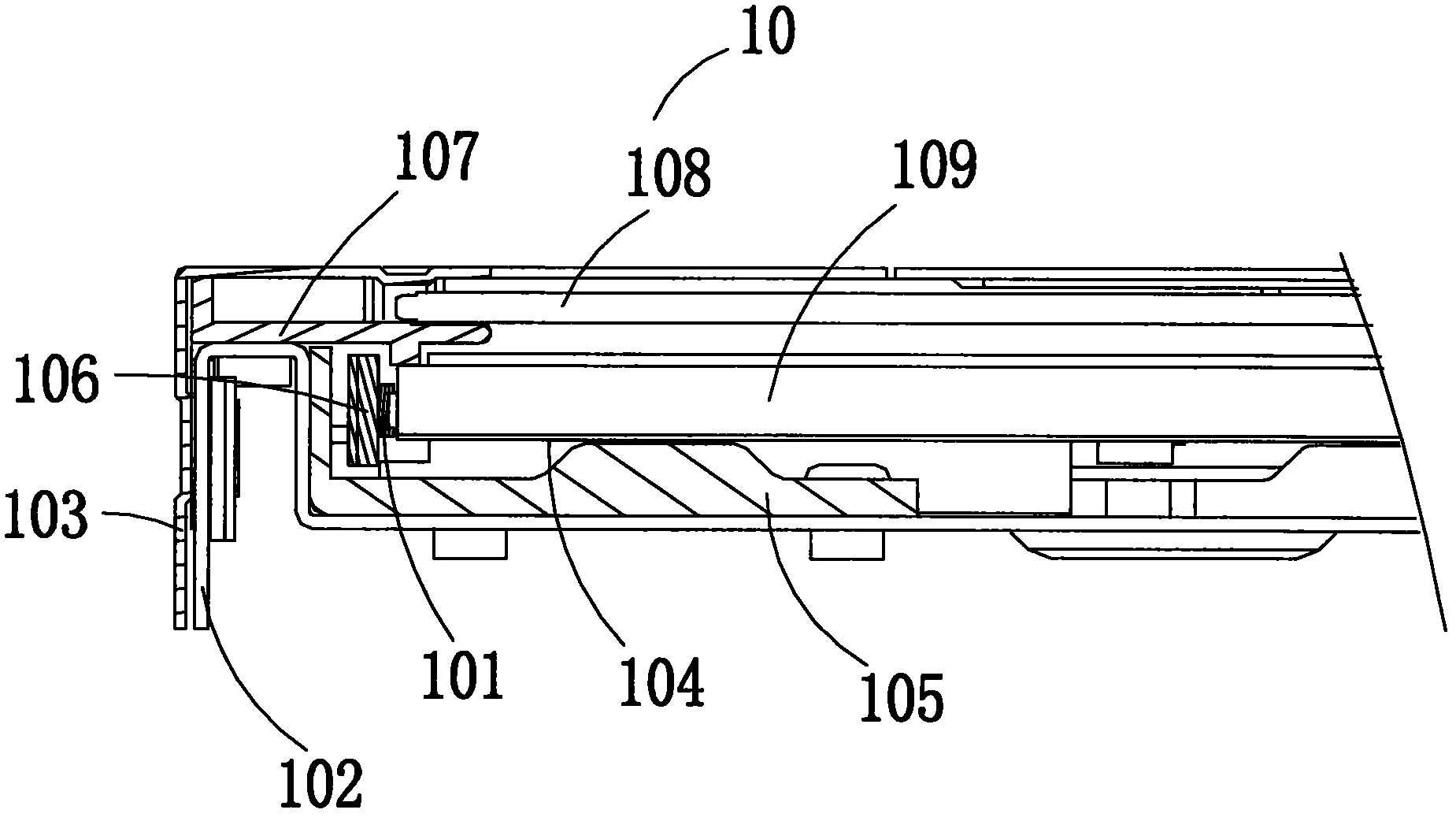

Display device with detachable heat-sink structure thereof

ActiveUS7064952B1Reduce rework timeShorten the lengthCasings/cabinets/drawers detailsNon-linear opticsElectricityDisplay device

A display device comprises a display panel, a back plate, a fixing plate, a flexible printed circuit board and a driving chip. The display panel has a peripheral circuit area. The back plate is fixed on the display panel such that the peripheral circuit area remains exposed. The fixing plate is detachably installed on the back plate, and the flexible printed circuit board is disposed on the fixing plate, wherein the flexible printed circuit board is electrically connected with the peripheral circuit area. The driving chip is electrically connected with the flexible printed circuit board. Compared with the back plate, the driving chip is disposed adjacent to the peripheral circuit area. Because the peripheral circuit area of the display panel is exposed, the flexible printed circuit board can be directly reworked to shorten its rework time on the premise of no separation between the display panel and the back plate.

Owner:NYTELL SOFTWARE LLC

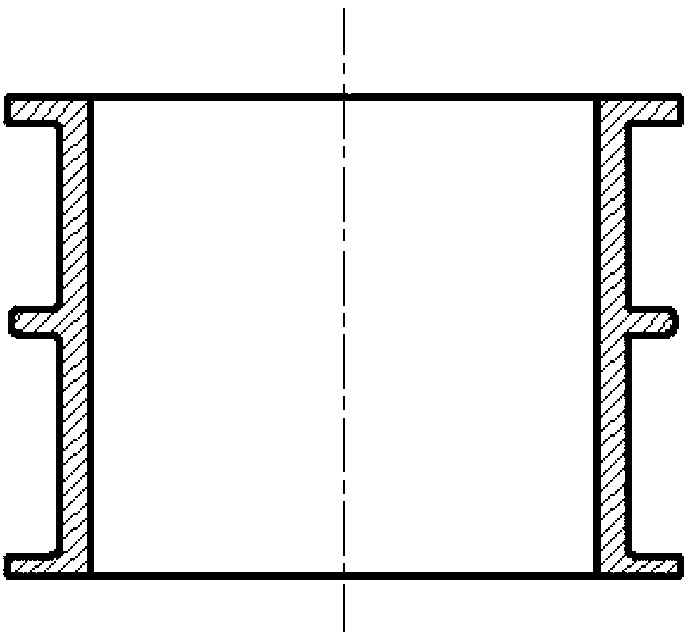

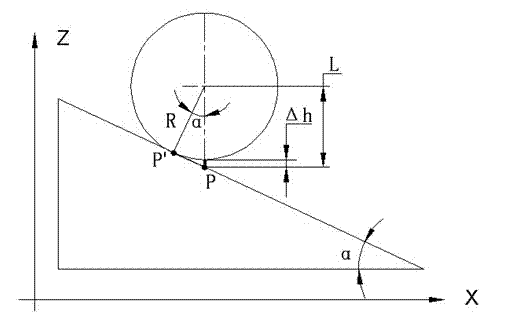

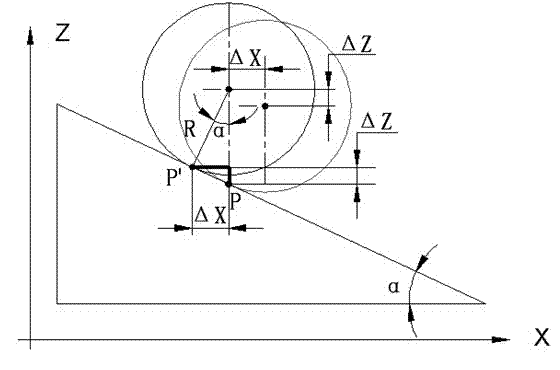

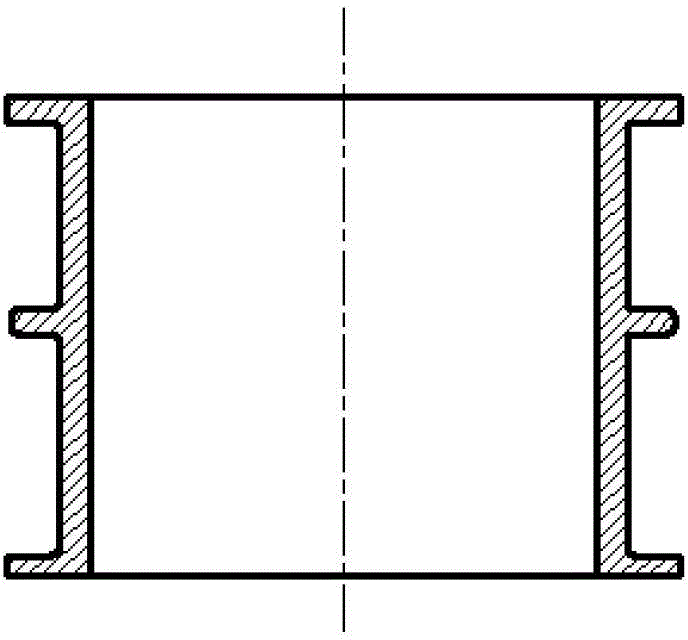

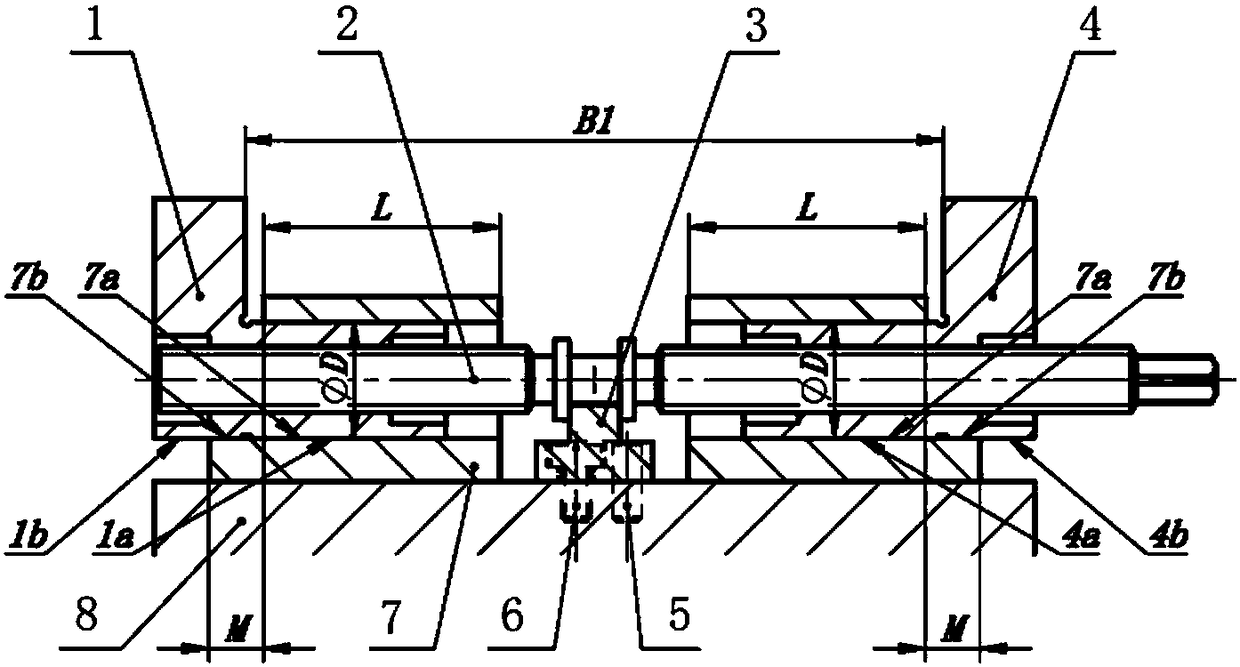

On-line measuring method for radials profile of compressor disc-like part of engine

InactiveCN102814512AAvoid errorsHas measurement limitationsAuxillary equipmentMeasurement/indication equipmentsReworkProcessing

The invention belongs to the field of automatic detection, particularly relates to an on-line measuring method for the radials profile of a compressor disc-like part of an engine. The method comprises the following steps that the measuring path of a measuring head is planned; the radius of sphere of the measuring head is corrected; characteristic points on the profile of a compressor disc are selected as measuring points; the motion program of the measuring head is edited; the motion track of the measuring head is optimized in virtual simulation software; the motion program of the measuring head is run; the measuring head traverses all the measuring points; the mean value of the measured values of the measuring points after errors are compensated is compared with the design theoretical value of the compressor disc part; when the measured values are within the design tolerance zone scope of the part, the processing size of the measured compressor disc part is considered to be qualified; otherwise, the processing and measurement are carried out again, until the size of the part is qualified. According to the method, a traditional manufacturing mode in the current industry that a design characteristic is matched with a set of measuring tooling is changed, so that the tooling manufacturing cost and the rework hours are saved, the one-time qualified rate of product processing is improved, the new product development cycle is shortened and the production cost is reduced.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

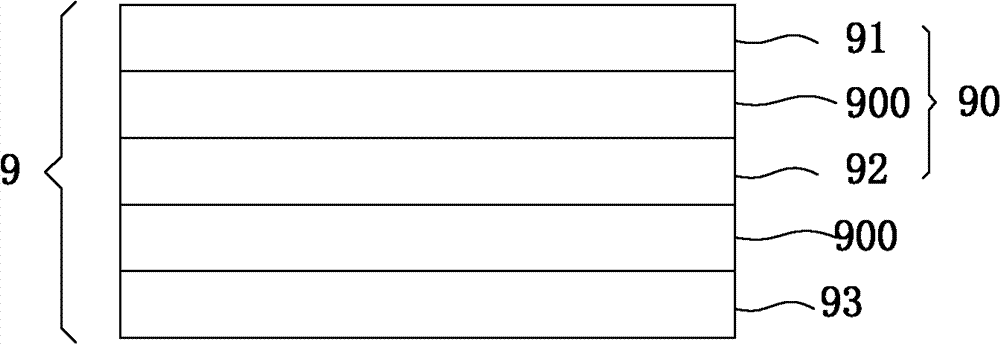

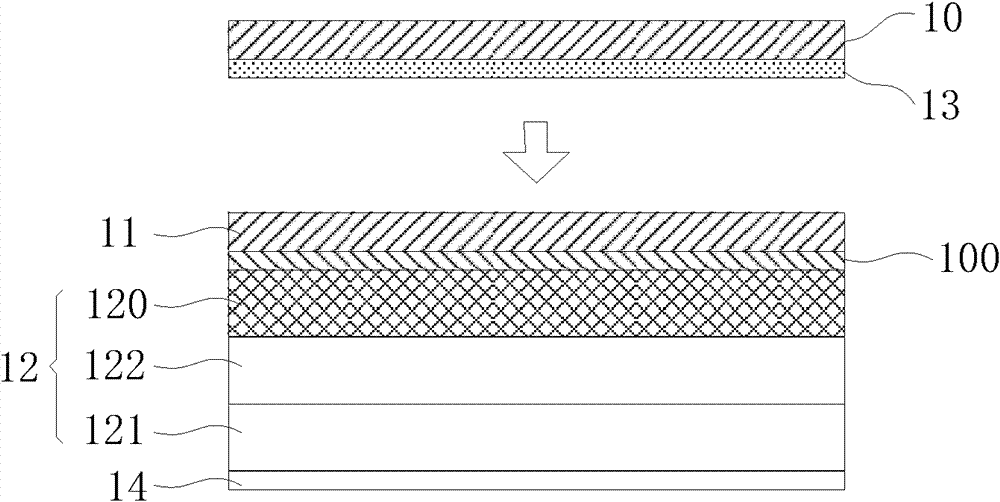

Lateral light-entering type LED liquid crystal backlight module

InactiveCN102588848AQuick dismantlingReduce the chance of badPoint-like light sourceLight fasteningsLight guideEngineering

The invention discloses a lateral light-entering type LED liquid crystal backlight module, which comprises an outer frame, a middle frame, liquid crystal glass, a back plate, a reflective sheet, a light guide plate, an optical diaphragm, a radiating plate and an LED light bar. The back plate comprises a bearing surface and a radiating surface, the reflective sheet, the light guide plate and the optical diaphragm are sequentially stacked on the bearing surface of the back plate from bottom to top, the radiating plate is fixed to the radiating surface of the back plate, the radiating plate is close to the edge of the light entering side of the light guide plate, a light bar fixing portion is arranged on the light guide plate in a projecting manner, and the LED light bar is fixed to the light bar fixing portion. The radiating plate can be rapidly detached from the back plate, the LED light bar is replaced by a non-defective light bar, rework process is greatly simplified, rework time is shortened, the probability of leading other materials to be defective during rework can be greatly reduced, and radiating effects are greatly improved owing to the designed structure.

Owner:SKYWORTH LCD SHENZHEN CO LTD

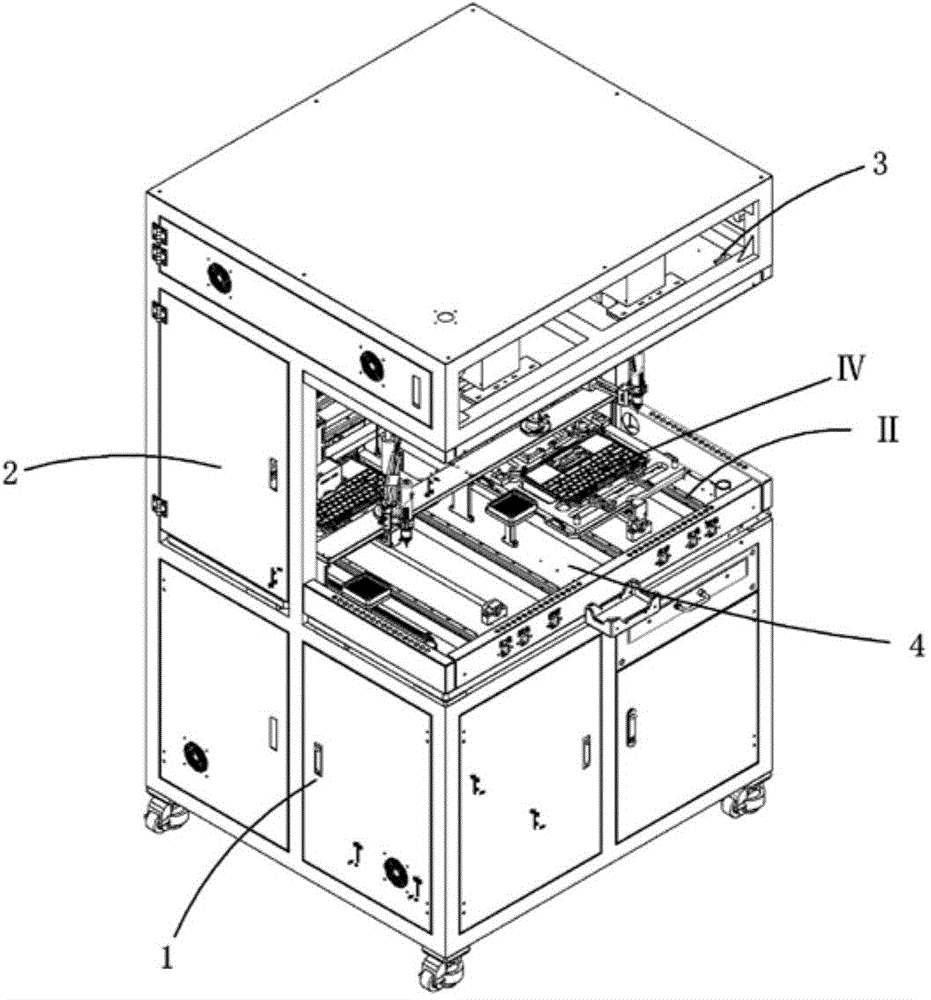

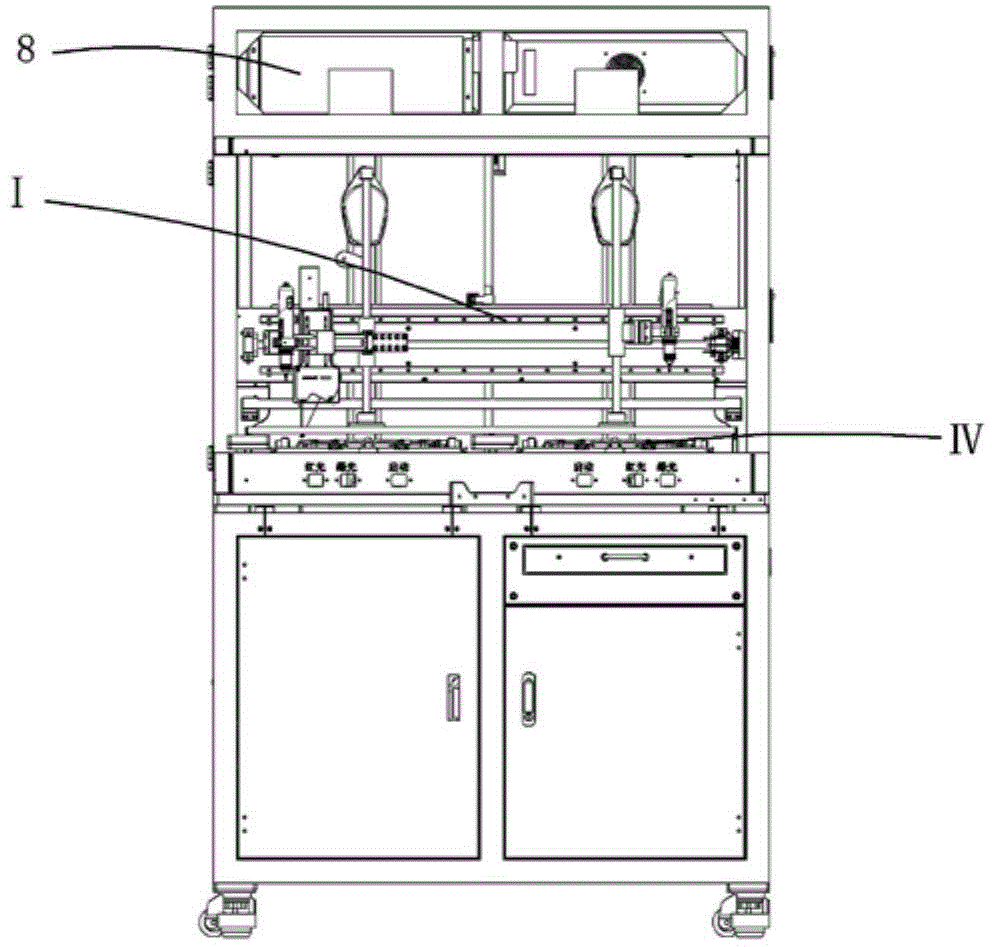

Integrated equipment used for installation and detection of screws

InactiveCN104440069AEasy to detectEasy to take outUsing optical meansMetal working apparatusElectricityRepair time

The invention relates to integrated equipment used for installation and detection of screws. According to the integrated equipment used for installation and detection of the screws, an upper machine frame is installed on a lower machine base through supporting side plates, a base plate is installed on the lower machine base, an X-axis mechanism is installed at the rear of the upper portion of the base plate, and two Y-axis mechanisms are installed at the front of the upper portion of the base plate; a laser detection mechanism is installed on the X-axis mechanism, a carrier mechanism is installed on each Y-axis mechanism, two RG lasers are installed inside the upper machine frame, and two screw boxes are installed on the base plate; the left side and the right side of the middle of the base plate are each provided with an electric screw driver support, an electric screw driver fixing plate is installed on the two electric screw driver supports, two electric screw driver force arms are installed on the electric screw driver fixing plate, the upper end of each electric screw driver force arm is installed at the bottom of the upper machine frame, an electric screw driver clamping block is installed on each electric screw driver force arm, and an electric screw driver is installed on each electric screw driver clamping block. The integrated equipment used for installation and detection of the screws is easy to operate, can rapidly and accurately detect whether installation of the screws is qualified or neglected installation occurs, guides an operator to carry out repairing and installation, adopts a double-station alternative operation mode, and saves back repair time.

Owner:BOZHON PRECISION IND TECH CO LTD

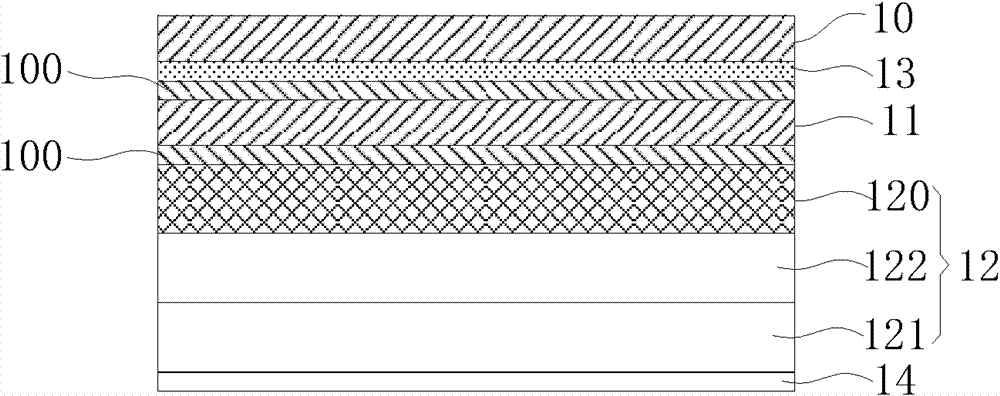

Touch panel module

InactiveCN102736762AAvoid damageReduce cost lossStatic indicating devicesNon-linear opticsTouch SensesTouch panel

The invention discloses a touch panel module including a touch sensing structure, a protection piece, an upper polaroid and a liquid crystal box, wherein the protection piece is arranged at the top of the touch sensing structure through optical cement; the upper polaroid is arranged between the touch sensing structure and the protection piece; and the liquid crystal box is arranged at the bottom of the touch sensing structure. The touch panel module can prevent the upper polaroid from being damaged when the touch sensing structure and the liquid crystal box are attached and reworked, thus reducing material cost loss caused by attaching and reworking of the optical cement.

Owner:HANNSTAR DISPLAY CORPORATION

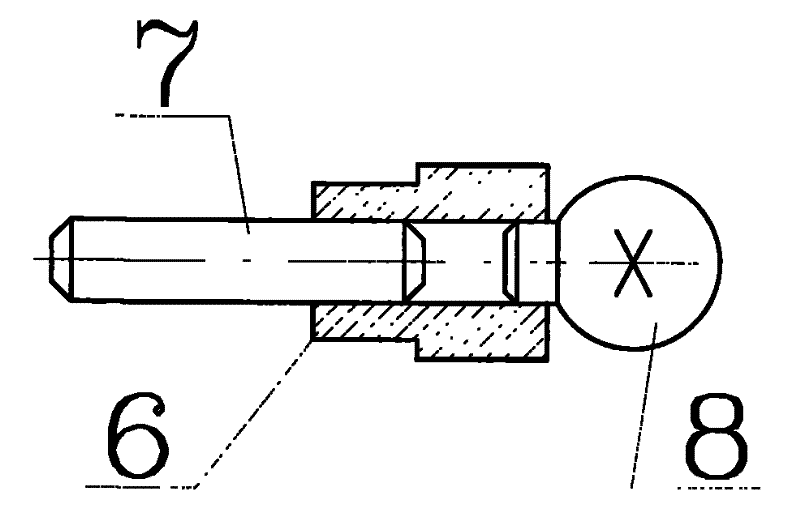

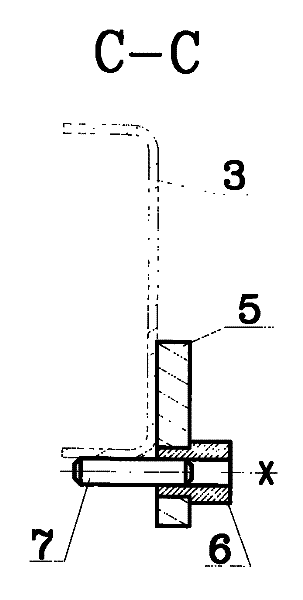

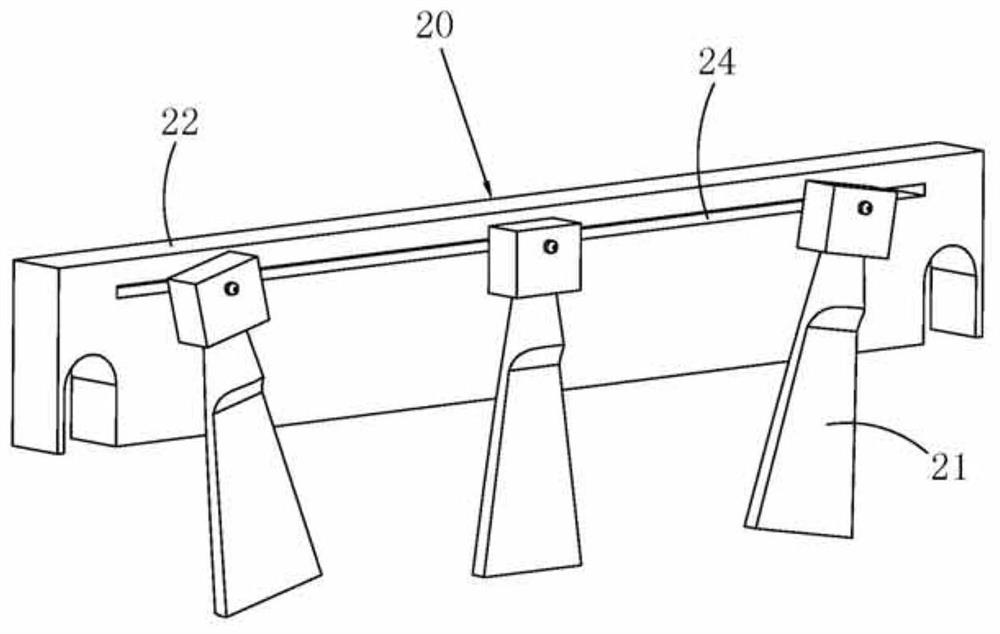

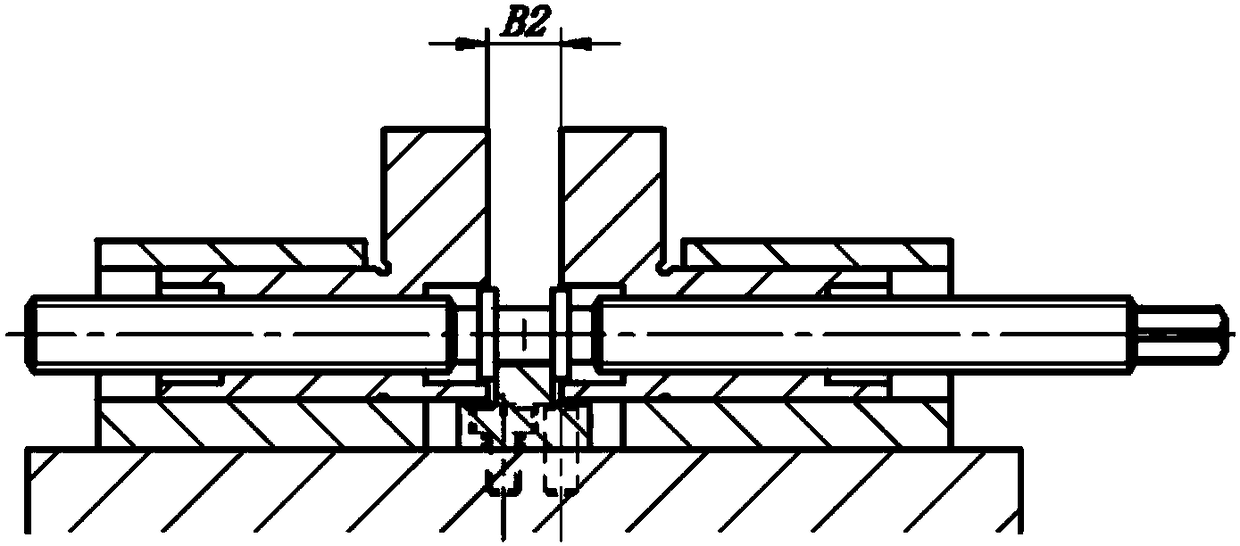

Simple flexible positioning method for continuous external surface of workpiece

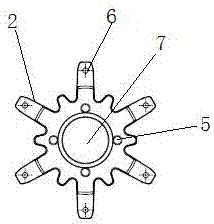

ActiveCN101745824AReduce consumption costReduce usagePositioning apparatusMetal-working holdersMultiple pointLaser beams

The invention provides a simple flexible positioning method for a continuous external surface of a workpiece, which comprises the following steps: external surface elements-positioning points or lines are selected on the continuous positioning external surface of the workpiece, and the shape of the workpiece is determined and positioned discontinuously by the multiple points or multiple lines; positioning pins which are in point contact or line contact with the external surface of the workpiece are installed on the selected positioning points or lines, and shape positioning pins (7) are distributed along the shape of the workpiece; the positioning pins are positioned by tangent points or tangent lines which are in contact with the shape of the workpiece; the shape positioning pins (7) areinstalled in a step bushing (6); the shape positioning pins (7) are assembled at one end of the step bushing (6), and a target ball (8) of a laser tracking instrument is arranged at the other end of the step bushing (6); laser beams are received by the target ball (8); and the laser tracking instrument emits and receives the laser beams fedback by the target ball (8) and judges the space positionof the positioning points by a computer. The method for flexibly positioning the shape of the workpiece provided by the invention has high manufacturing accuracy, small technology difficulty, high work efficiency and short manufacturing cycle.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

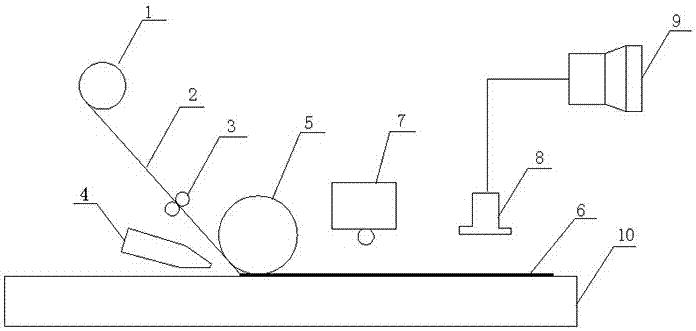

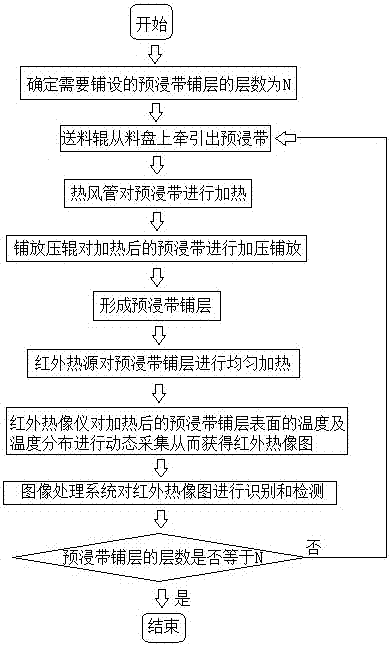

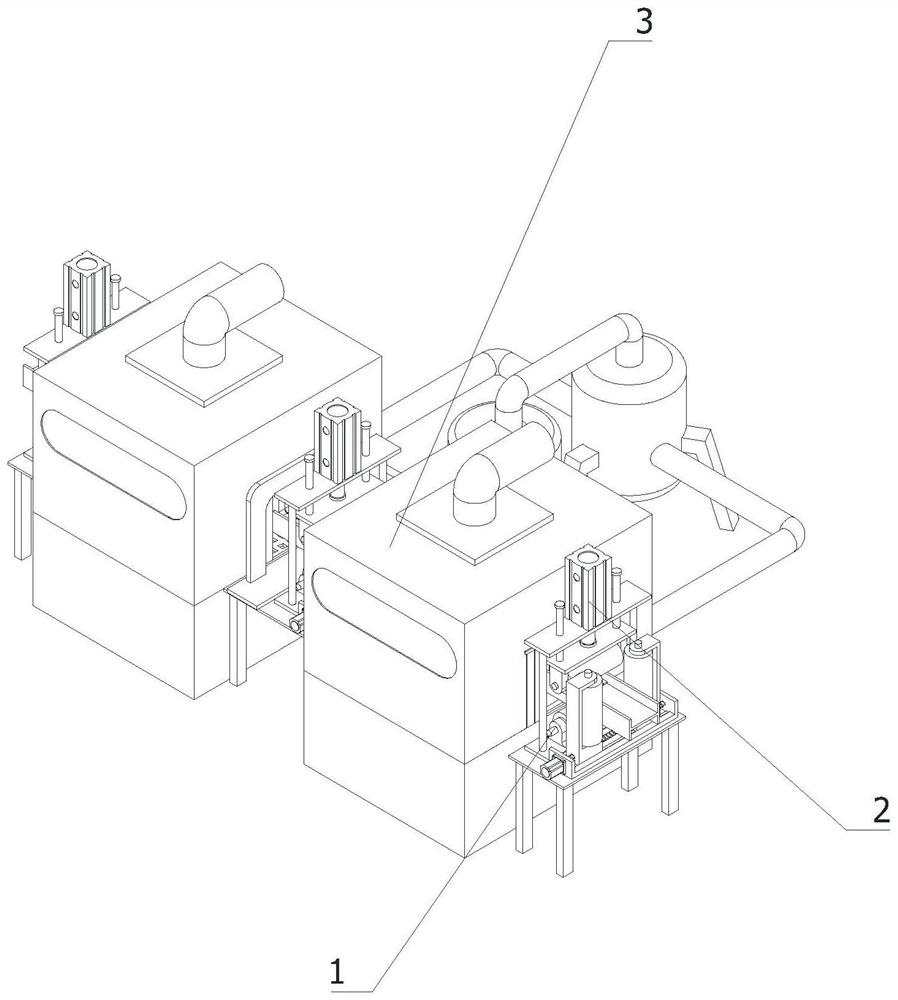

Infrared imaging-based on-line dynamic automatic laying defect detection apparatus and infrared imaging-based on-line dynamic automatic laying defect detection method

InactiveCN106872521AHeating evenlyImprove lay-up molding qualityMaterial flaws investigationImaging processingEngineering

The invention discloses an infrared imaging-based on-line dynamic automatic laying defect detection apparatus and an infrared imaging-based on-line dynamic automatic laying defect detection method. The infrared imaging-based on-line dynamic automatic laying defect detection apparatus comprises a laying unit and a defect detection unit, the laying unit comprises a spool, feed rollers, a laying press roller, a hot blast tube, and a laying die, the defect detection unit comprises an infrared heat source, an infrared thermal imager, and an image processing system, a prepreg tape is arranged on the spool, the prepreg tape is sequentially transmissively connected to the feed rollers, the laying press roller and the laying die, the infrared heat source is arranged over the laying die, the infrared thermal imager is arranged over the laying die, and the infrared thermal imager is connected to the image processing system. The invention can implement the rapid and accurate detection of laying defects, has high capability in identifying typical laying defects, and can implement the quantitative analysis of defect dimensions.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

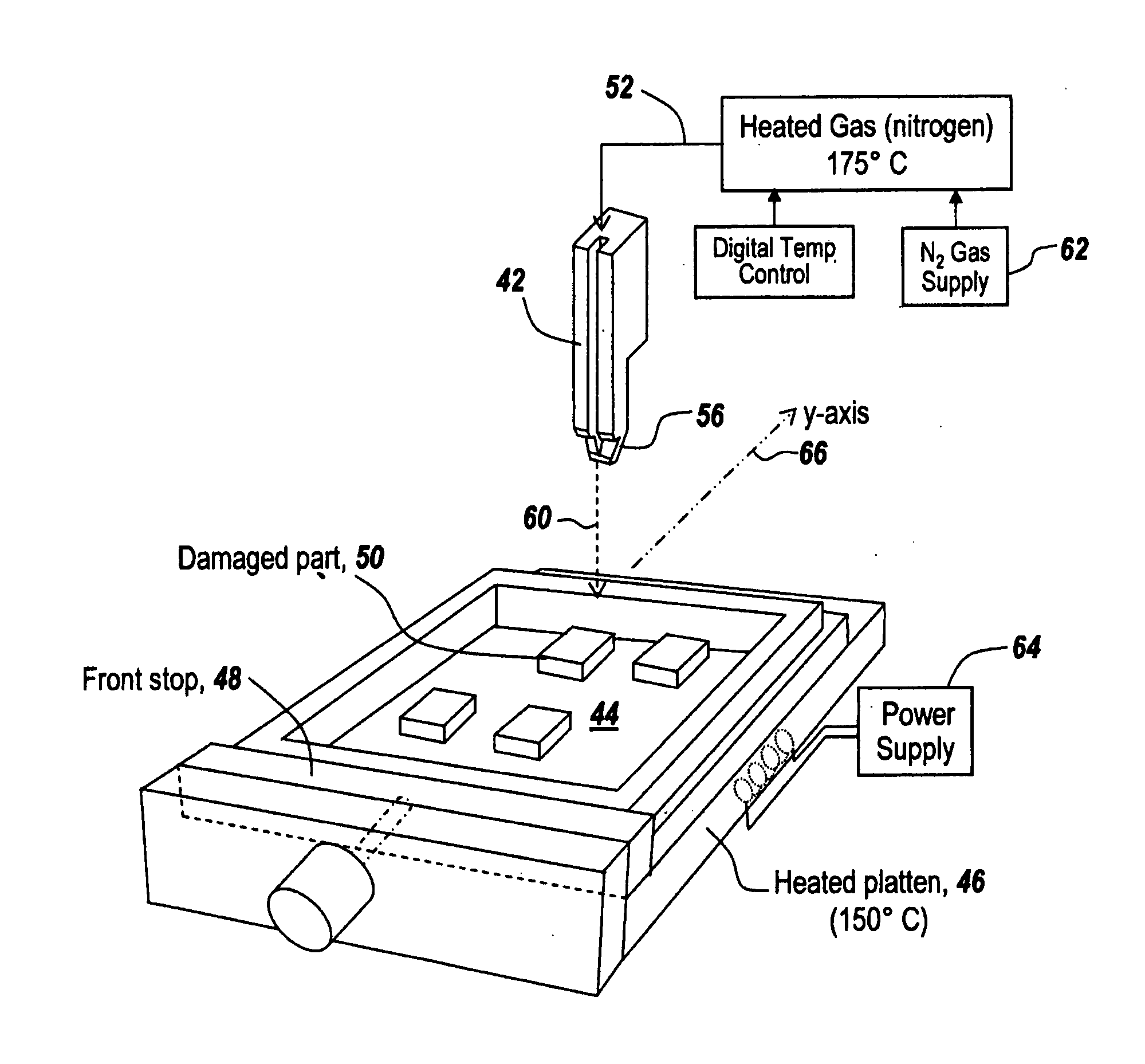

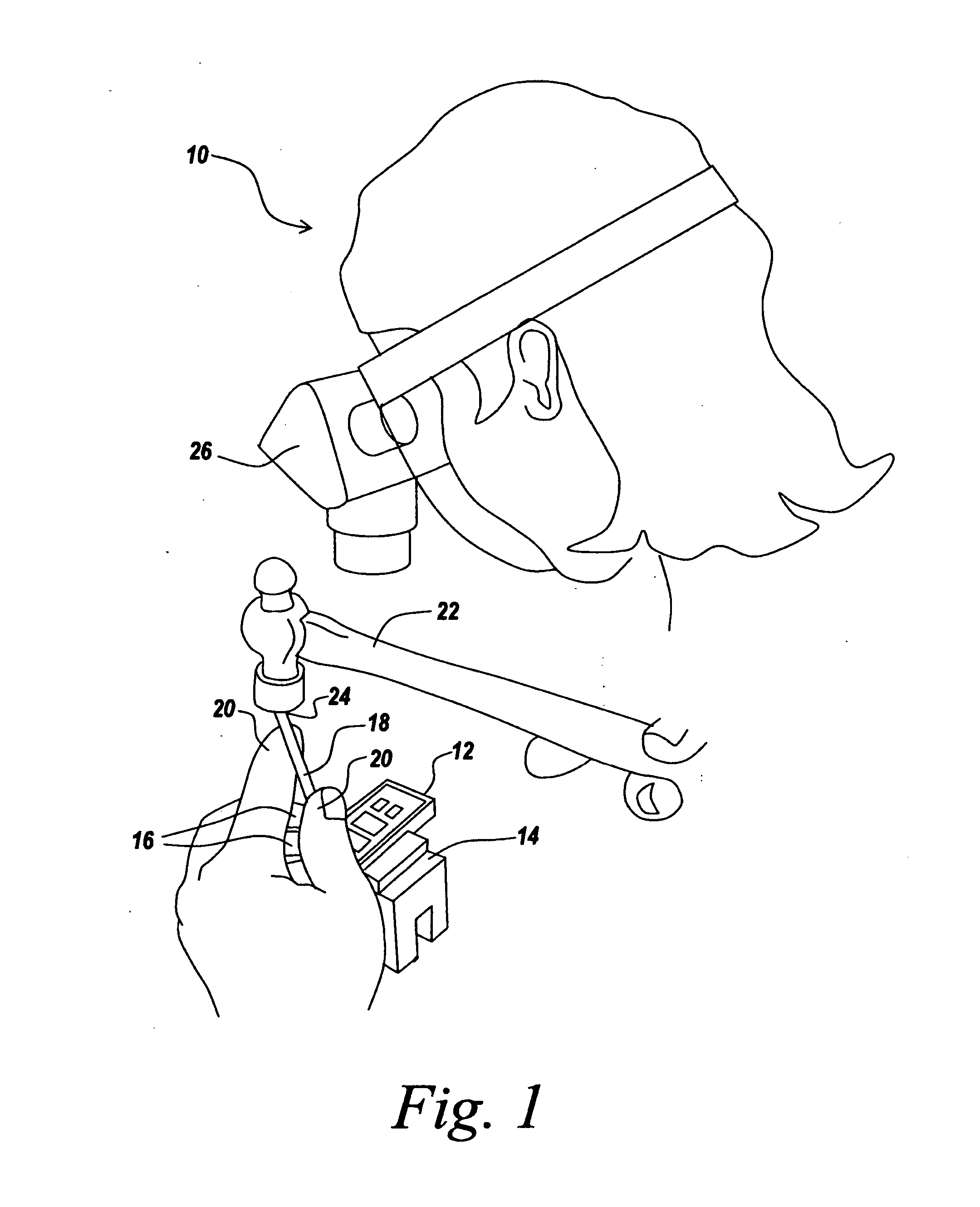

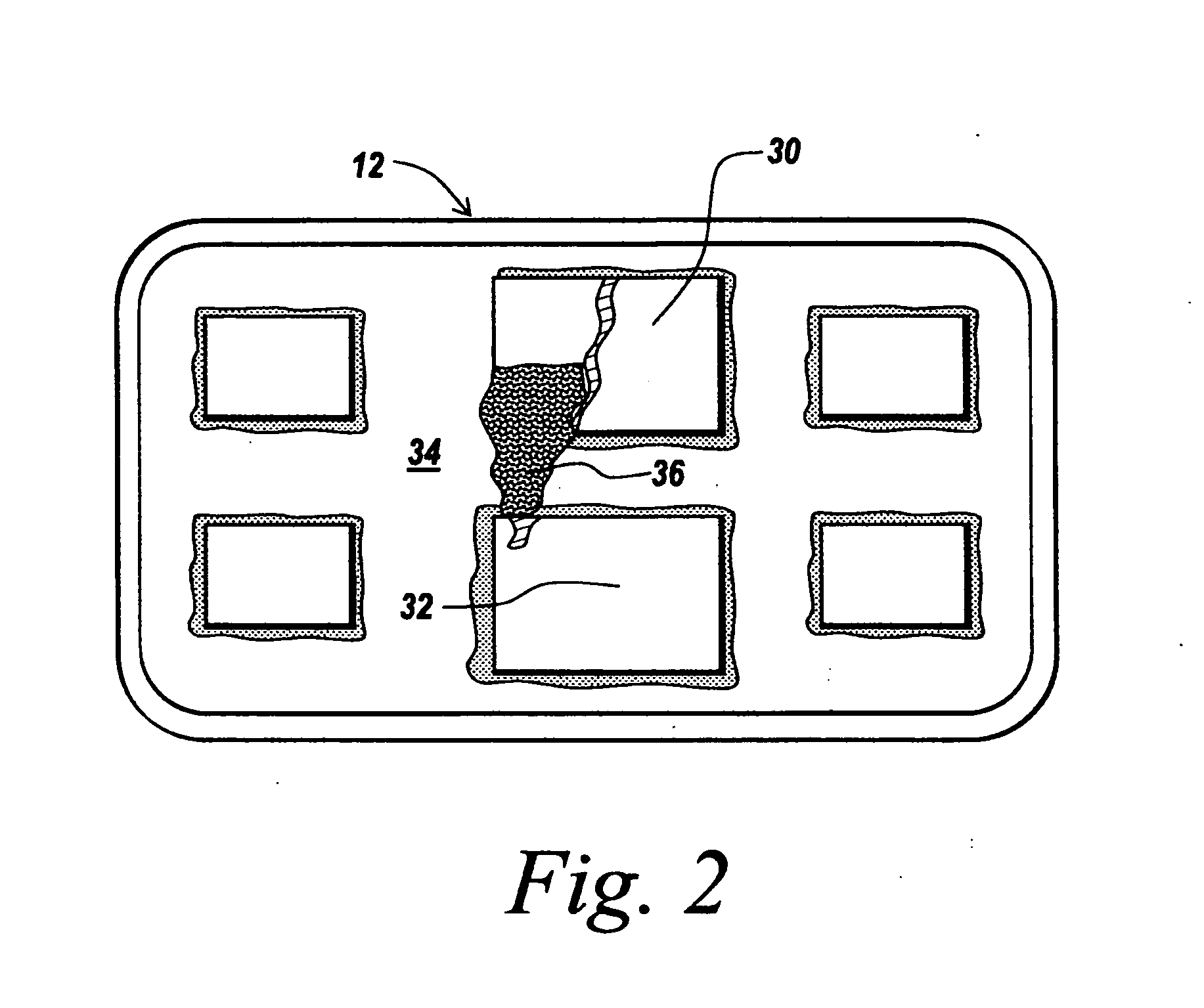

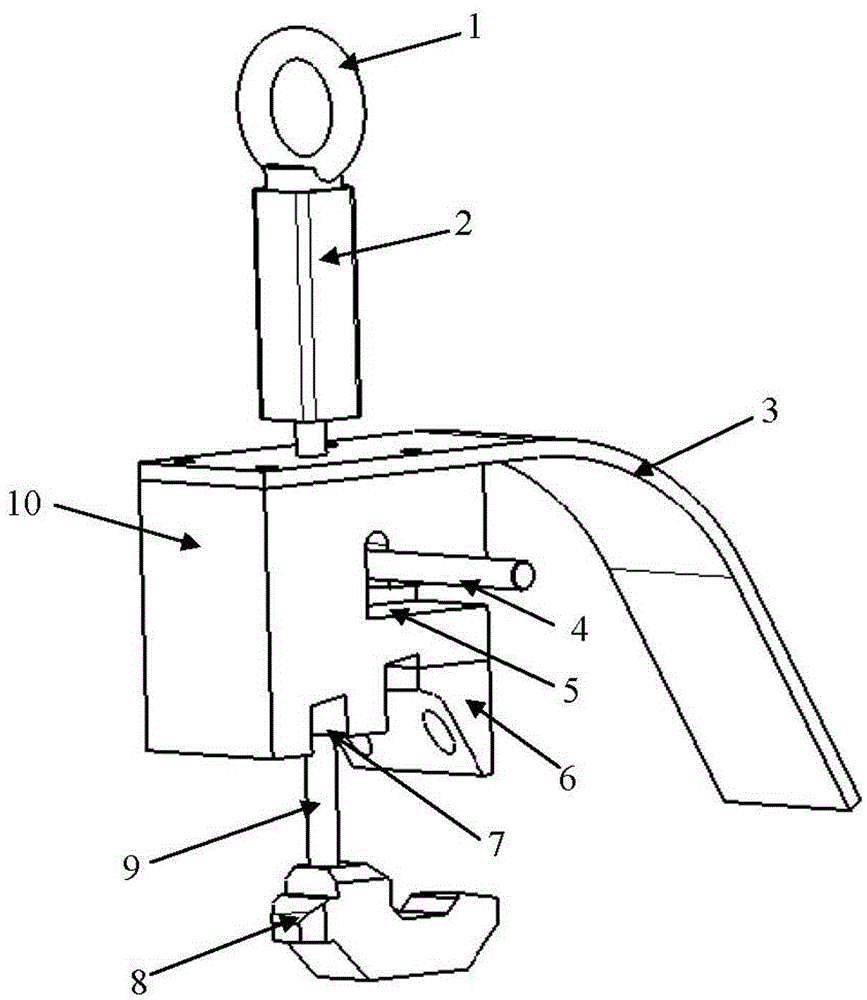

Method and apparatus for reworking a microwave module

InactiveUS20050171802A1Eliminates collateral damageReduce rework timeWelding/cutting auxillary devicesAuxillary welding devicesEpoxyMicrowave

A specialized tool is provided for the removal of components in a microwave module in which a fixed tool having a channeled tip is positioned adjacent the component to be removed. A hot stream of gas, in one embodiment nitrogen, is then forced through the channel onto the top surface of the component to be removed, with the microwave module lying on a heated platen, such that the local increase in temperature at the component to be removed is enough hotter than the ambient temperature of the module as determined by the heated platen to soften the silver epoxy used to mount the component to the module without damaging nearby components. With the fixed tool adjacent the component to be removed and with the component provided with targeted heating, the module is moved against the tool to cause a shear force that moves the component away from its original position, thus breaking the epoxy bond, after which the component is plucked from the module. The subject tool and technique eliminates collateral damage associated with the use of a ball peen hammer and chisel, and results in a tenfold decrease in rework time.

Owner:BAE SYST INFORMATION & ELECTRONICS SYST INTERGRATION INC

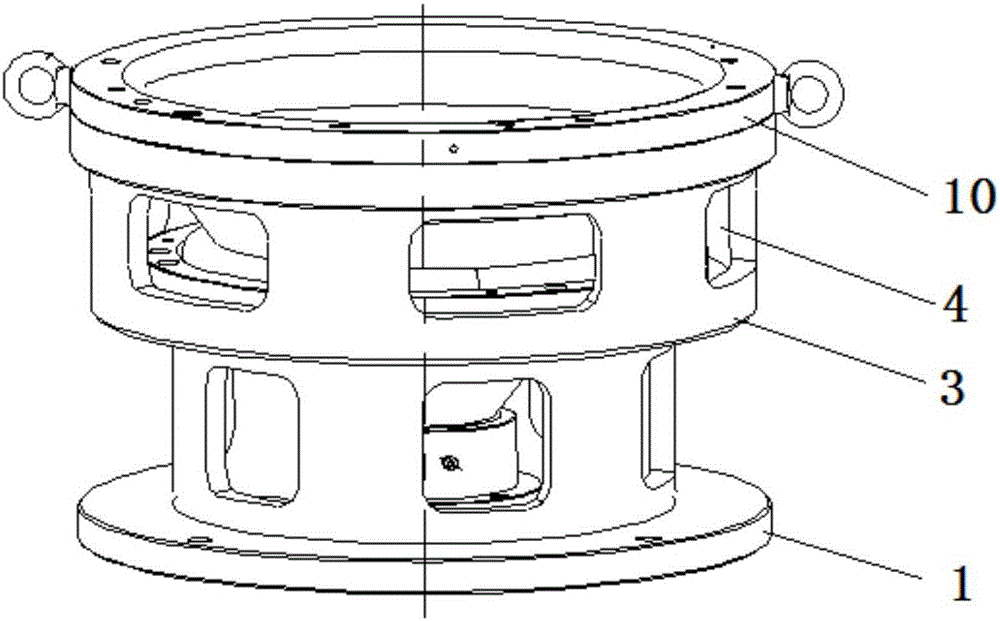

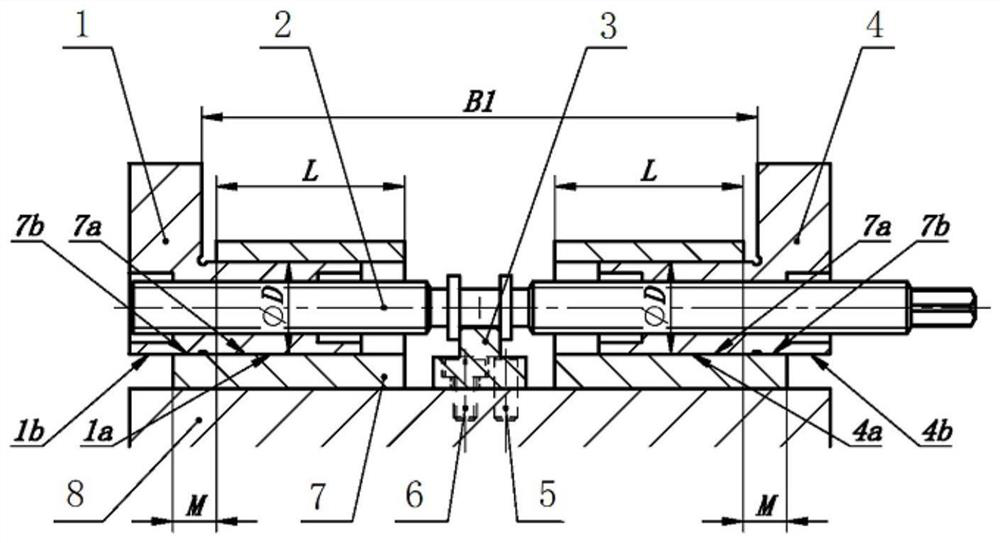

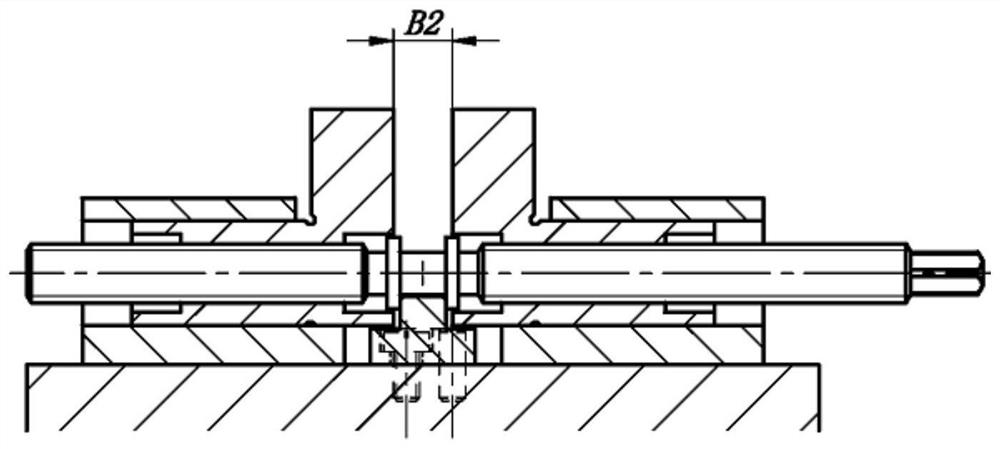

Process method of improving wall thickness uniformity of closed thin-walled rotary part

The invention discloses a process method of improving wall thickness uniformity of a closed thin-walled rotary part. The process method comprises the steps: (1) designing a finish turning clamp of a novel structure; (2) designing a following process route according to the finish turning clamp; and (3) adjusting the working allowance of a finish turning procedure. As the performance and reliability of a new generation engine are improved, a higher requirement is posed to the processing precision of a part; a designer requires the amount of unbalance of the rotary part more and more strictly. Therefore, reduction of the amount of unbalance of a cover hood part which is relatively great in processing difficulty will be widely applied by using the method. Meanwhile, the technology is suitable for both processing closed rotary parts which are different in structure and size and improving the processing precision of the part, and the process method has a wide application prospect.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

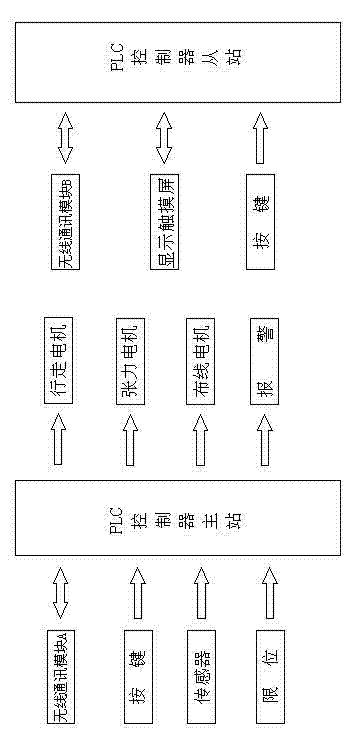

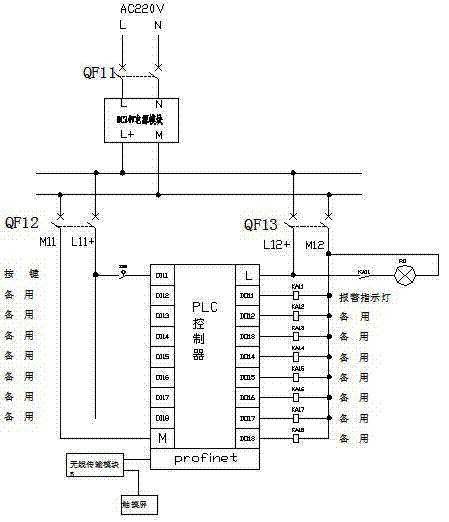

Wireless communication robot winding control system

InactiveCN102830653AAvoid attenuationAvoid volatilityProgramme control in sequence/logic controllersWireless transmissionProgrammable logic controller

The invention relates to a prestressed steel wire winding robot control system, in particular to a wireless communication robot winding control system. A programmable logic controller (PLC) master station serves as a core, finishes digital and analog quantity signal input / output, operation and control, and wirelessly communicates with a PLC slave station through a wireless communication module; and the slave station is auxiliary, finishes the parameter setting and records and transmits data in real time in the robot winding process. An input interface of the PLC master station comprises a sensor signal input interface which limits the wiring unit up and down, is arranged on a wound piece and detects the working condition of the robot; the output interface comprises a signal output interface for controlling a traveling motor, a signal output interface for controlling a wiring motor, and a signal output interface for controlling analog quantity of a tension motor. According to the system, the winding stability and high efficiency of the robot can be improved, and the system is powerful in function, flexible and convenient to control, stable in operation, easily communicates with the computer and realizes network monitoring.

Owner:CHINA 22MCC GROUP CORP

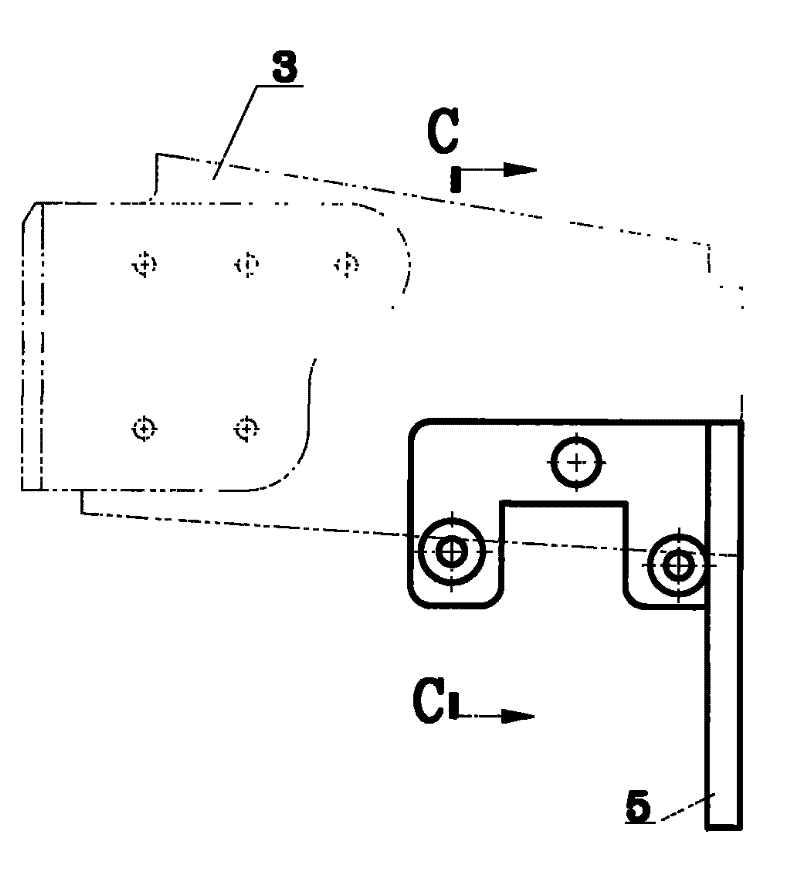

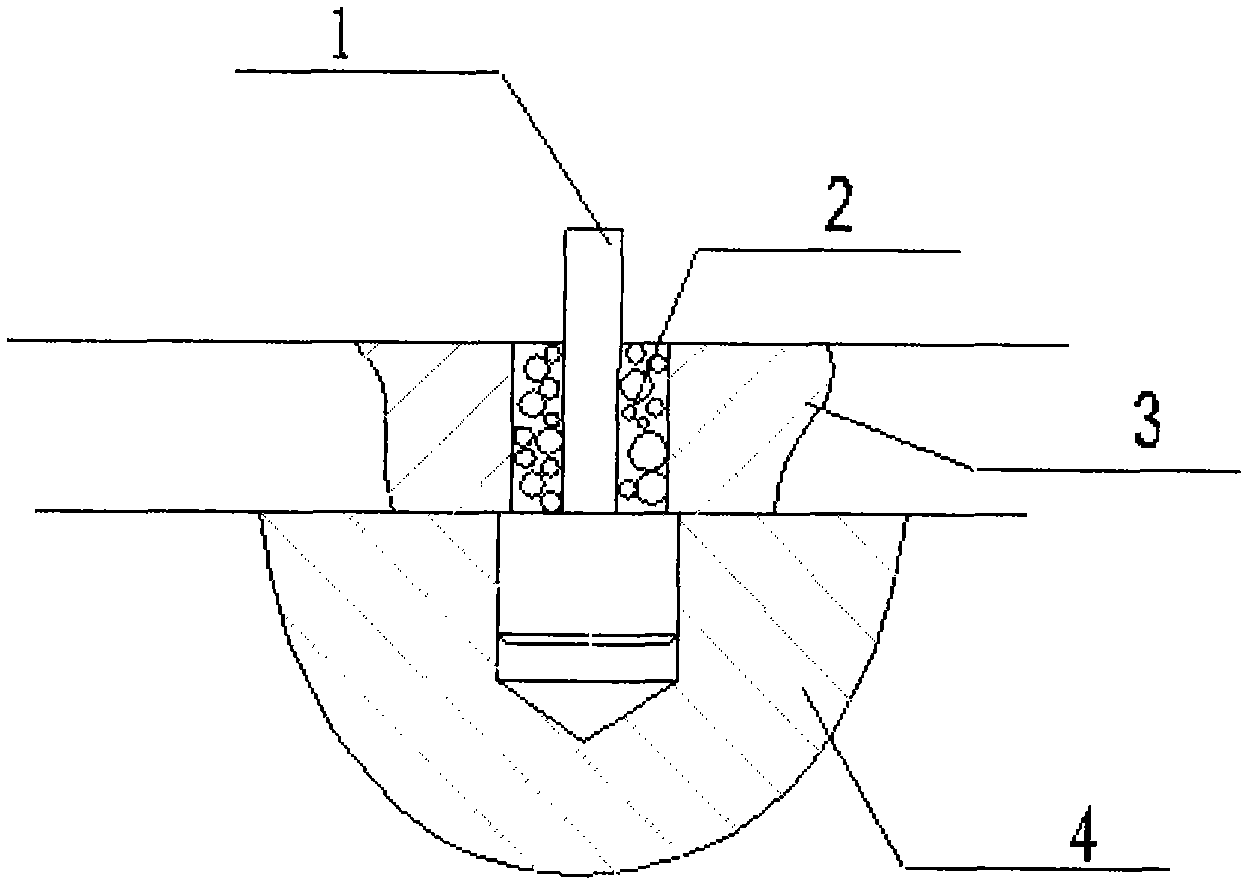

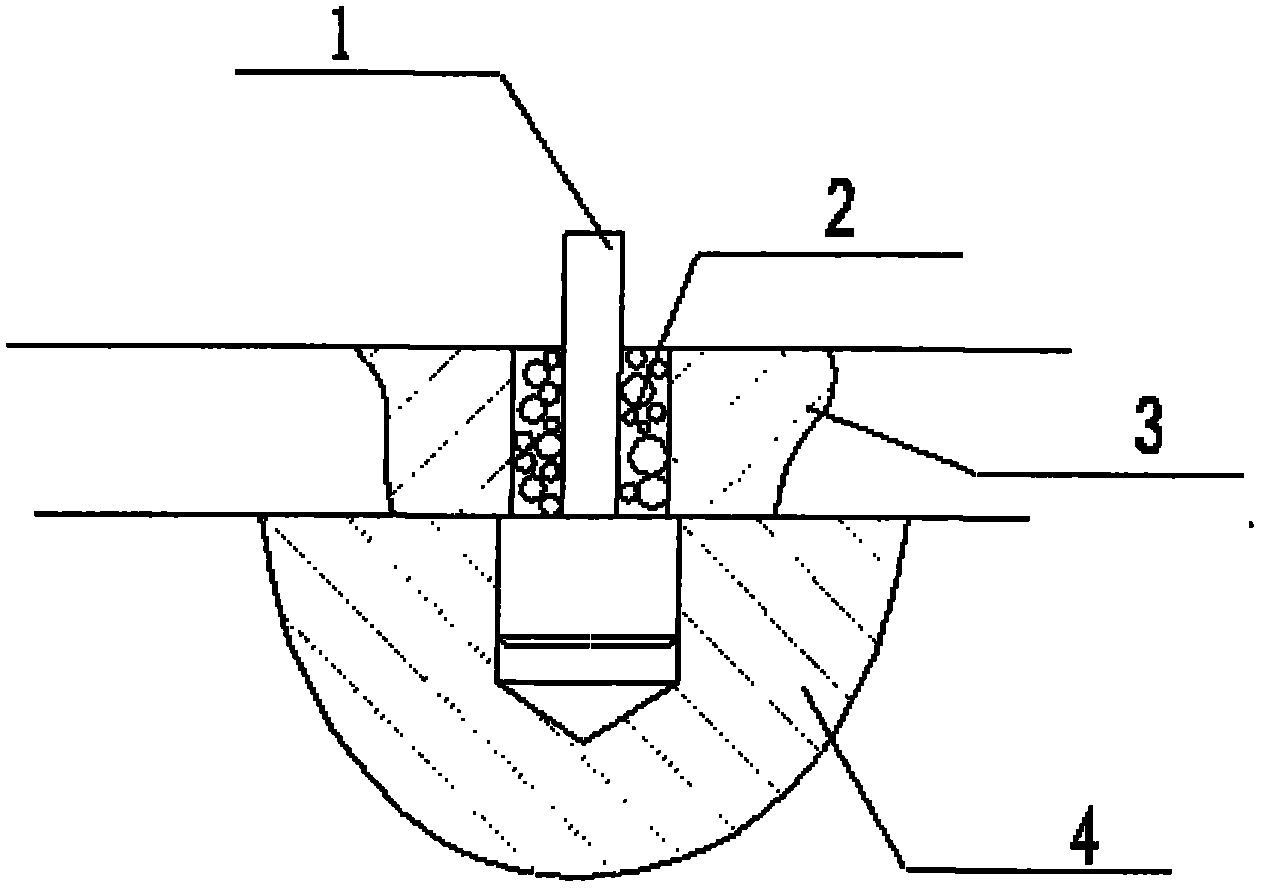

Method for processing locating hole of product locating piece in forming mould

The invention relates to a method for processing a locating hole of a product locating piece in a forming mould, relating to the technical field of processing of locating holes of product locating pieces in forming moulds. The method comprises the following steps of: manufacturing a small hole which is smaller than a final hole at the approximate position of the locating piece; manufacturing a step pin and pressing the step pin in the locating hole of a mould body; fixing the locating piece at the correct position by utilizing a connecting piece; filling epoxy resin mixed glue in the gap between the locating piece and the step pin; after a colloid is thoroughly dried, taking down the locating piece; centring the hole moulded by the mixed glue; and expanding the hole to form the required locating hole. According to the method for processing the locating hole of the product locating piece in the forming mould disclosed by the invention, the locating hole position of the locating piece to be repaired is taken out from the mould body; simultaneously, the bottom hole of the mould body cannot be damaged; the mould is prevented from being returned and processed again; the repairing time of the mould is shortened; and the labour production efficiency is increased.

Owner:HARBIN

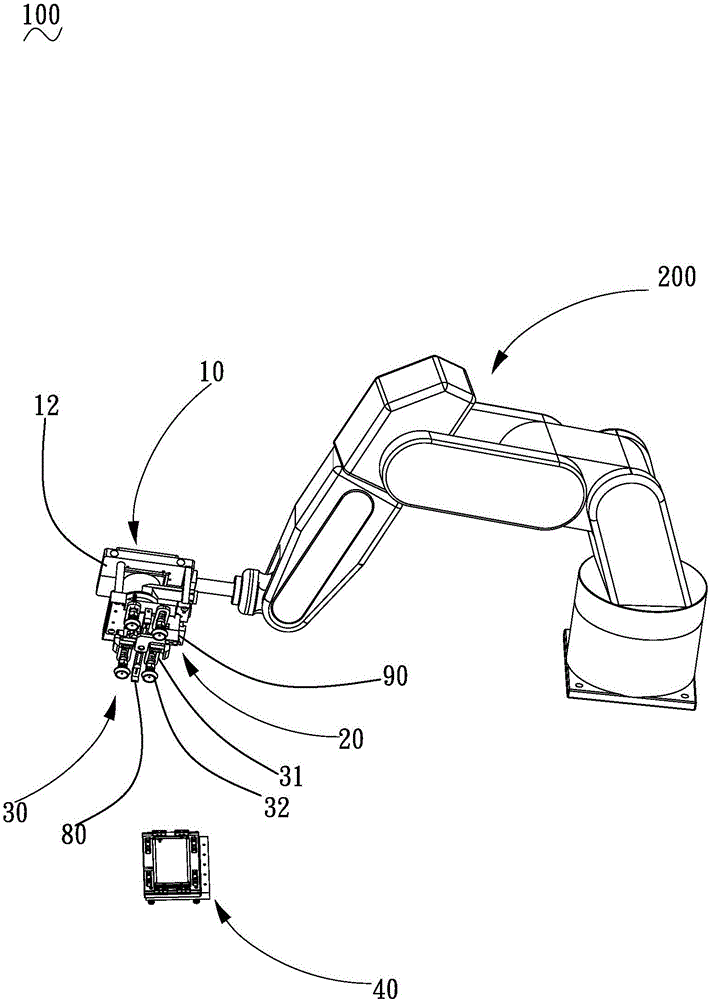

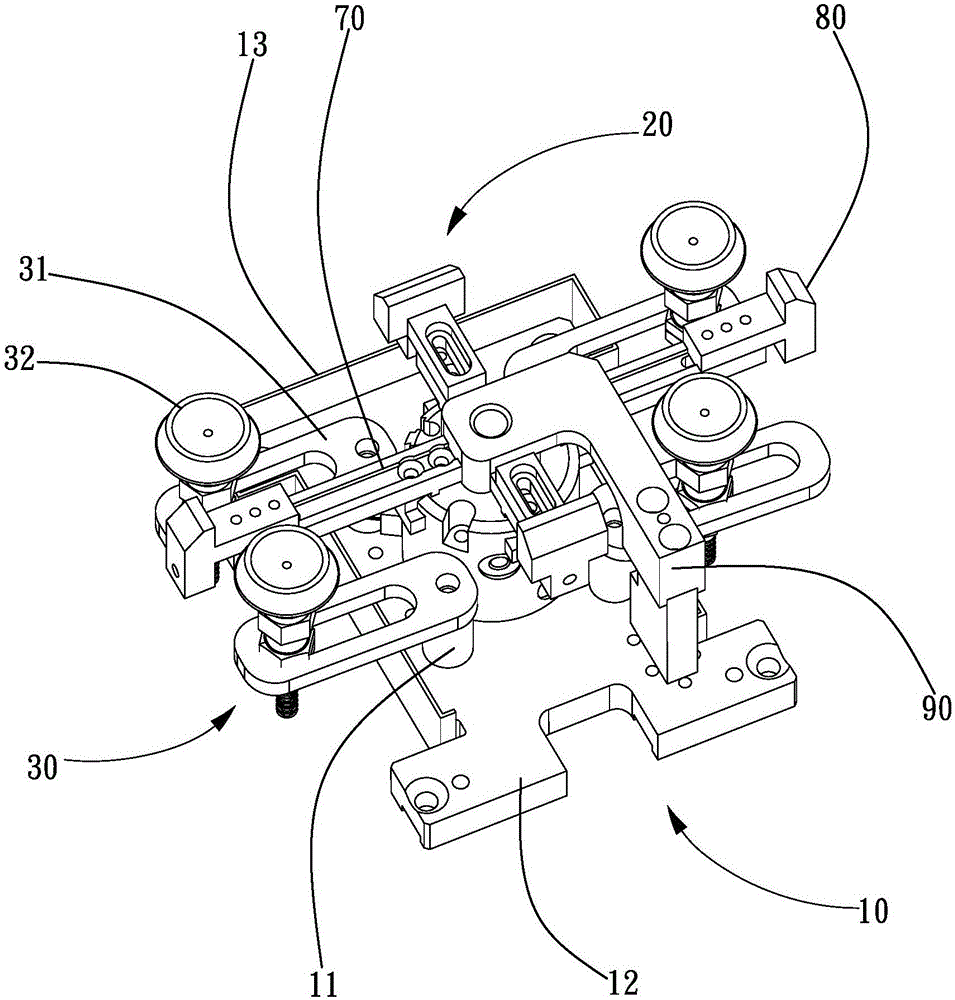

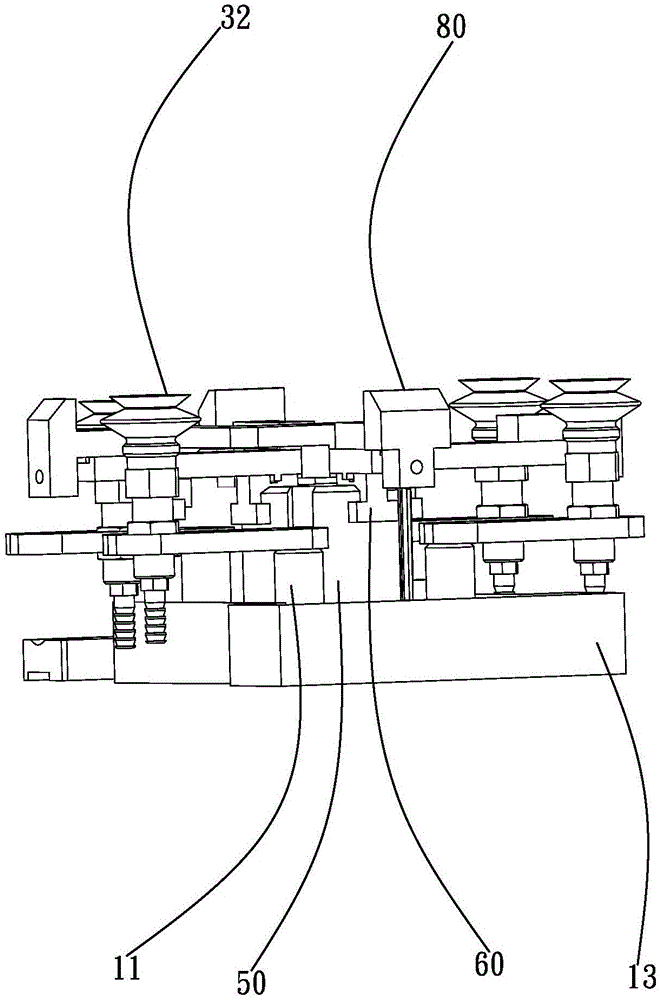

Grabbing jig

ActiveCN106695858APrevent scratchesReduce secondary positioning timeGripping headsArmsManipulatorEngineering

The invention relates to a grabbing jig which is used for operating a mobile phone shell. The grabbing jig comprises a robot and further comprises a base plate and a positioning mechanism, wherein the positioning mechanism comprises a mechanical hand grabbing base, a plurality of slide blocks, a plurality of slide rods and a positioning block; a drive mechanism and a plurality of mounting slots are arranged on the mechanical hand grabbing base; the drive mechanism is provided with a drive rod; the drive mechanism is connected with the slide blocks through the drive rod, so that each slide block is simultaneously controlled to slide in the mounting slots; and when the drive mechanism drives the slide blocks to slide outwards or inwards, the slide blocks drive the slide rods to drive the positioning block to move outwards or inwards. According to the grabbing jig, the mechanical hand grabbing base simultaneously controls the slide blocks to slide, and the slide blocks drive the positioning block to move, so that the mobile phone shell is positioned through the positioning block; and the mobile phone shell is sucked by a sucking disc, single surface of the mobile phone shell is prevented from being scratched by force, precise positioning of the mobile phone shell is realized, secondary positioning time of the mobile phone shell is reduced, product reworking time is reduced, and processing efficiency is improved.

Owner:GUANGDONG TIANJI IND INTELLIGENT SYST CO LTD

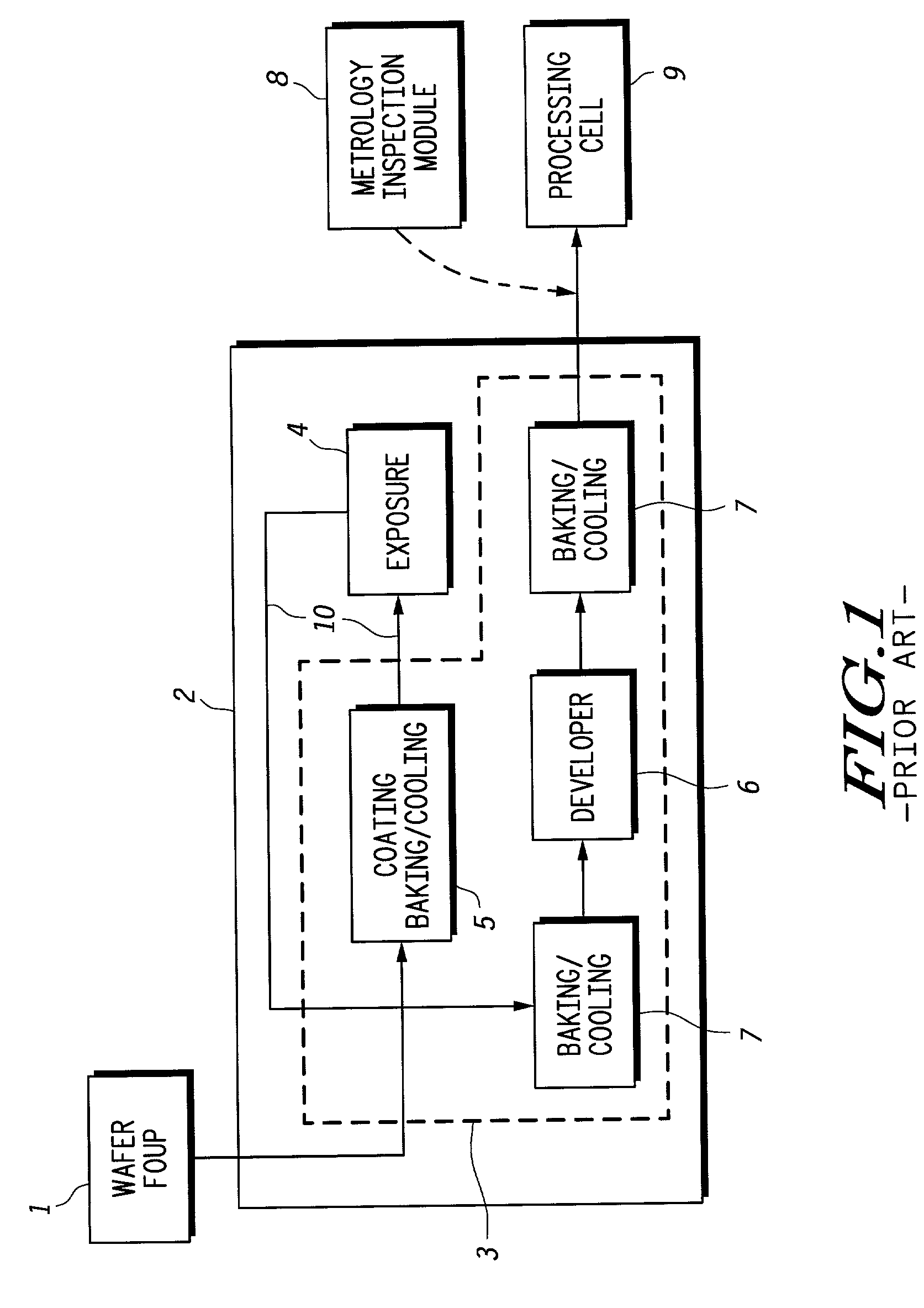

Lithography method for forming semiconductor devices on a wafer and apparatus

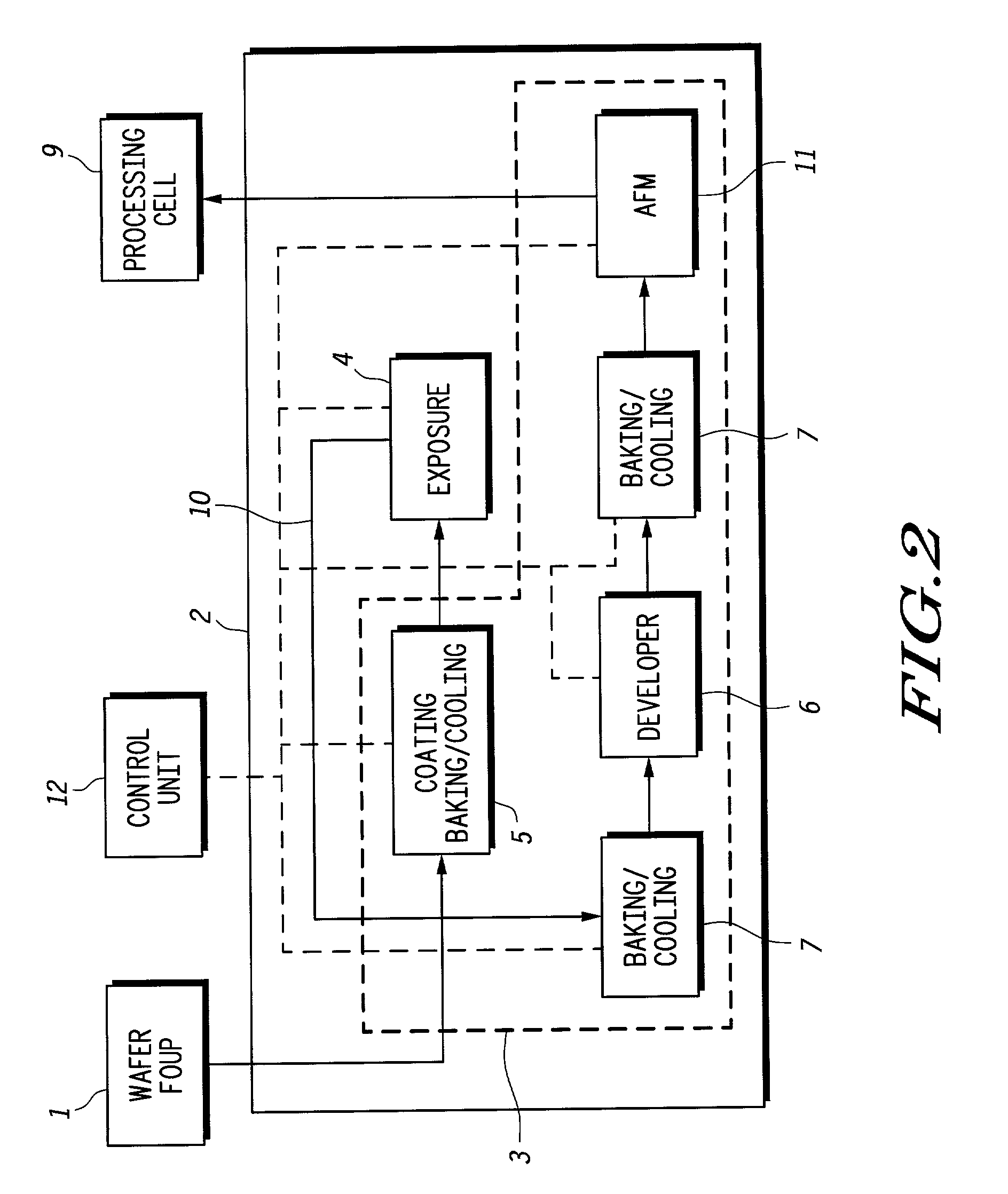

InactiveUS20020127482A1Shorten cycle timeEasy to monitorNanotechElectric discharge tubesResistAtomic force microscopy

A semiconductor device on a wafer is formed by lithography with the following steps of: coating (13) a lithography resist onto said wafer in a coating means (5), exposing (14) said wafer to an irradiation through a reticle in an exposure tool (4), stabilizing (15) said lithography resist for activating chemical reaction and developing said lithography resist in said predetermined areas in a developer means (6) so as to reveal a predetermined lithography resist pattern on the wafer surface, stabilizing (16) the lithography resist in a stabilization means (7) for strengthening said pattern on the wafer surface, performing (17) a metrology inspection of said lithography resist pattern on said wafer surface in a metrology tool (8), etching, wet processing or implanting ions (18) into said wafer in a processing cell (9), wherein said metrology inspection is performed by atomic force microscopy in a atomic force microscopy module (11) immediately after developing and baking said lithography resist adjacent to said stabilization means (7).

Owner:FREESCALE SEMICON INC

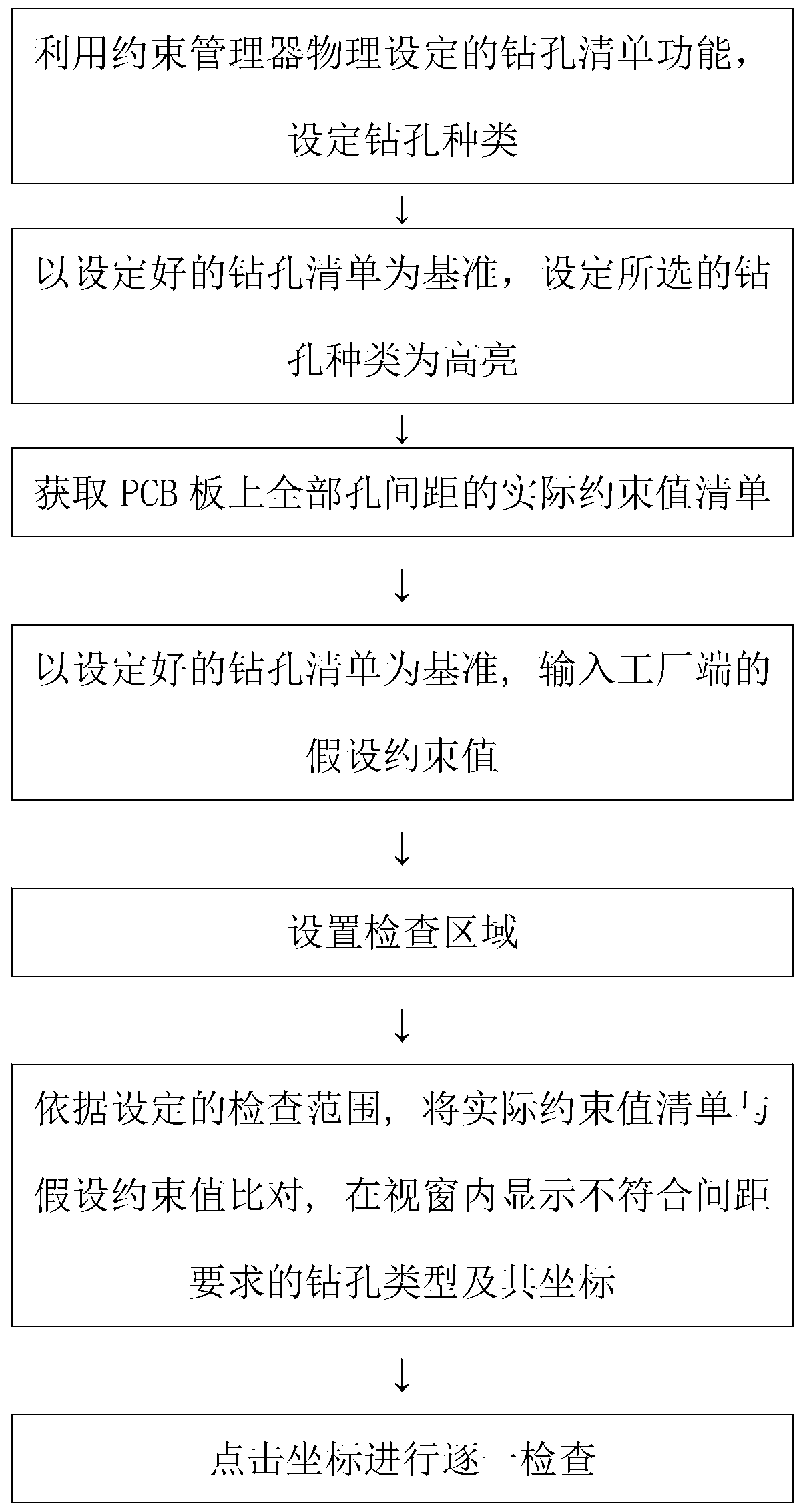

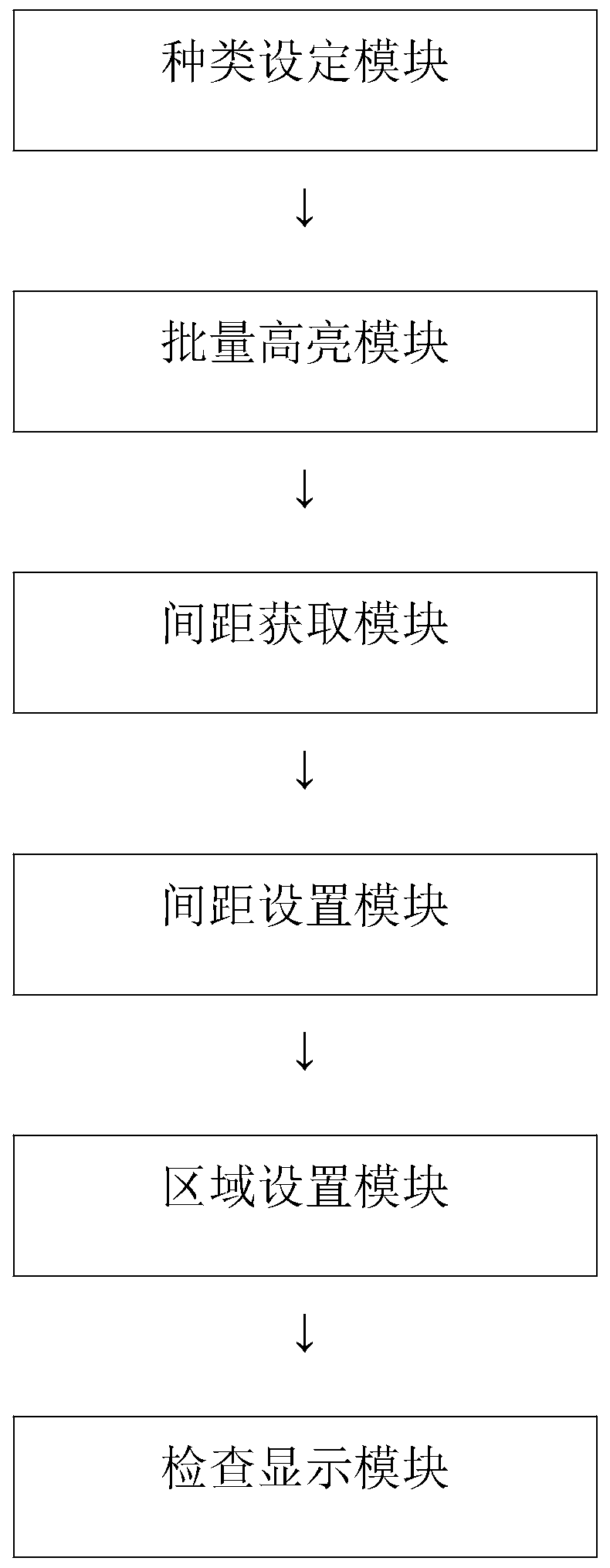

Method and device for checking hole spacing based on drilling classification

InactiveCN111274758AImprove work efficiencyImprove accuracyConstraint-based CADSpecial data processing applicationsAlgorithmMechanical engineering

The invention provides a method for checking hole spacing based on drilling classification, and the method comprises the steps: S1, setting a drilling type through employing a drilling list function physically set by a constraint manager; s2, taking the set drilling list as a benchmark, and setting the selected drilling type to be highlighted; s3, obtaining an actual constraint value list of all hole distances on the PCB; s4, taking the set drilling list as a reference, and inputting a hypothetical constraint value of the factory end; s5, setting an inspection area; s6, comparing the actual constraint value list with the assumed constraint value according to a set inspection range, and displaying the drilling types and the coordinates thereof which do not meet the spacing requirement in awindow; and S7, clicking the coordinates to check one by one. By means of the method, hole spacing checking operation of different types of drilled holes can be achieved in batches, the working efficiency and accuracy are greatly improved, and the design quality can be improved. Meanwhile, the invention also provides a device for realizing the method.

Owner:SUZHOU LANGCHAO INTELLIGENT TECH CO LTD

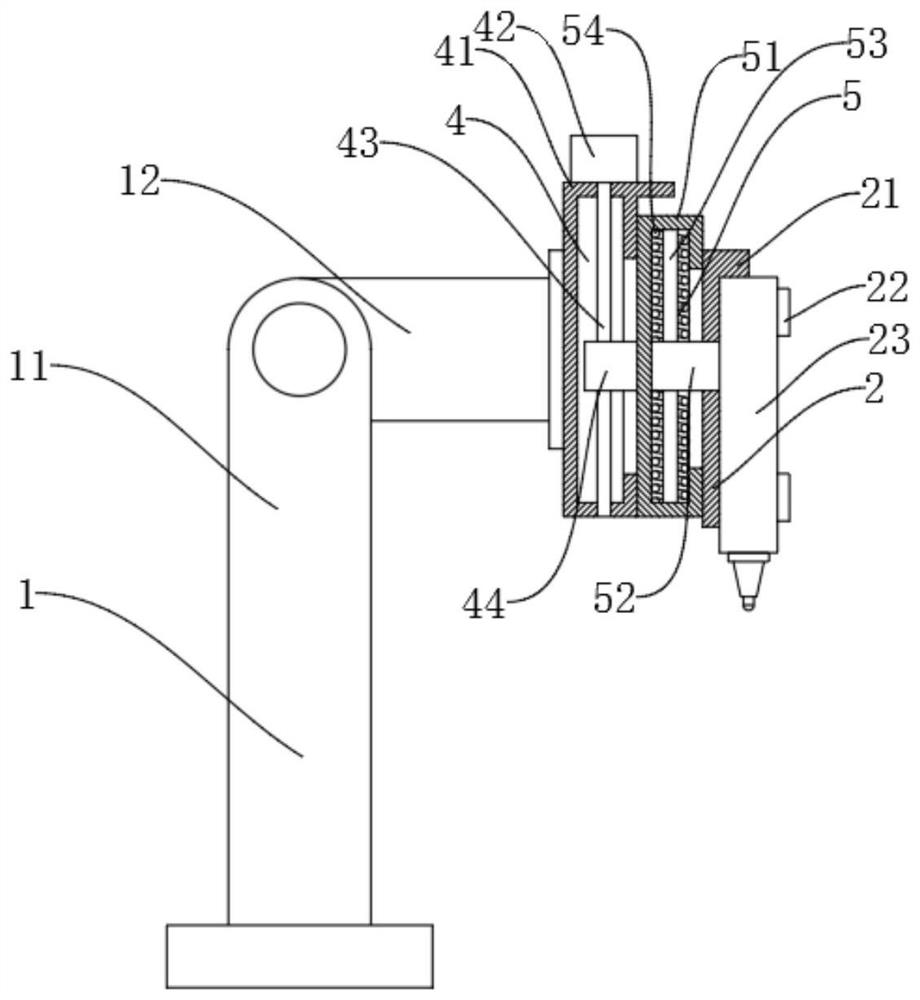

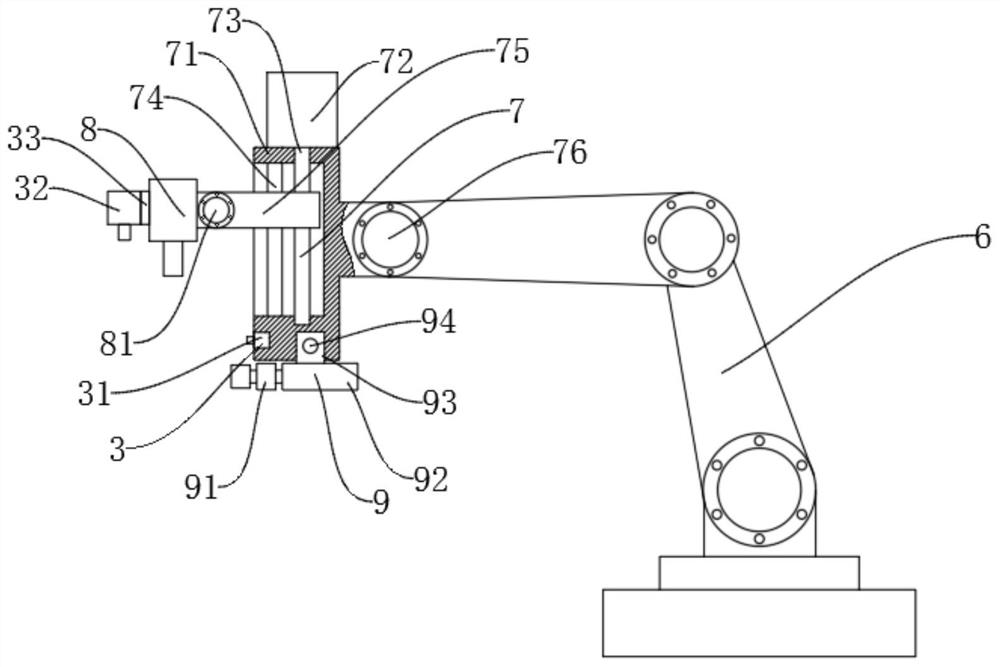

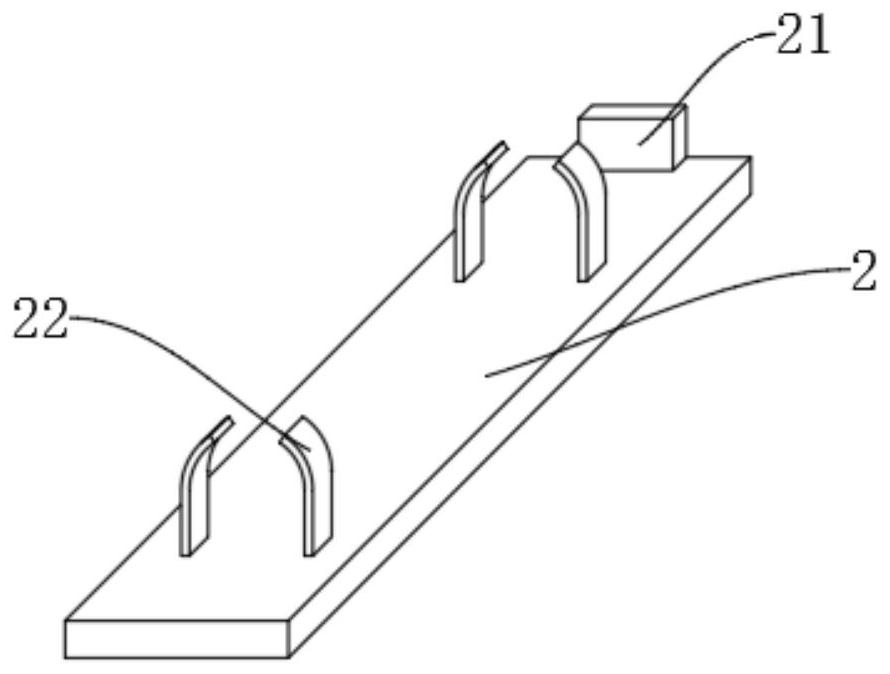

Intelligent factory automatic discharging robot based on 5G network

InactiveCN112692829AReduce rework timeImprove performanceProgramme-controlled manipulatorGripping headsControl engineeringMarking out

The invention discloses an intelligent factory automatic discharging robot based on a 5G network, and relates to the field of industrial robots. The problem that in the prior art, unqualified products cannot be placed in a classified mode in the discharging procedure is solved. The intelligent factory automatic discharging robot is characterized in that the intelligent factory automatic discharging robot is used for automatic discharging in a multi-stage detection assembly line and comprises a marking unit and a classified discharging unit, wherein the marking unit is used for marking the types of the unqualified products and connected with a detection procedure control module of the detection procedure where the marking unit is located, and the classified discharging unit discharges products on a production line and places the products on different station devices according to the types marked by the marking unit. According to the intelligent factory automatic discharging robot, the unqualified products are marked through the marking unit and placed in the classified mode through the discharging unit, thus, workers can save the repair time during repair, and meanwhile product performance analysis and productivity improvement are facilitated.

Owner:程小龙

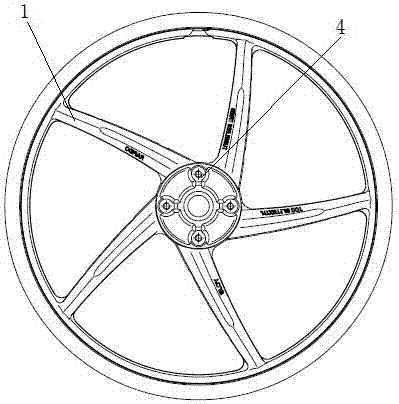

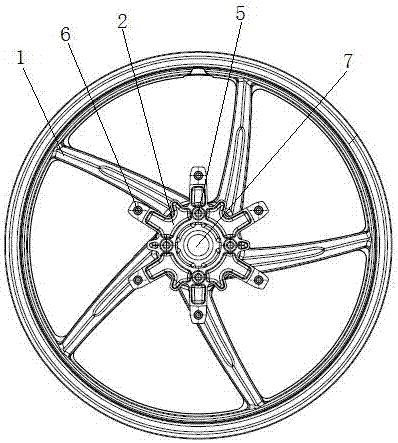

Production process for motorcycle wheel hub

InactiveCN107457531AMeet quality requirementsGood effectNon-metallic wheel bodyHardnessComposition analysis

The invention discloses a motorcycle hub production process, including 1) smelting and component analysis; 2) casting; 3) cutting and drilling; 4) deburring; 5) heat treatment; 6) calibration; 7) shot blasting; 8) valve drilling Hole; 9) Hardness test 10) Processing 11) Spline pulling 12) Impact test; 13) Air tightness test; 14) Cleaning, spraying; 15) Finish paint; 16) Pressing; 17) Assembly; 18) Packaging ; This processing technology improves and adjusts the processing steps. Through process improvement, the appearance quality of the product can be improved to meet higher customer quality requirements. It can improve the product's anti-injury ability, protect the product from oxidation, and reduce molds and save mold costs. , shorten production and processing time, and improve processing efficiency.

Owner:ANHUI YONGCHANG METAL PROD

Method for detecting diameter of outer wall of tapered case of aviation engine on line

InactiveCN102927952BReduce manufacturing costImprove automationMeasurement devicesNumerical controlAviation

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

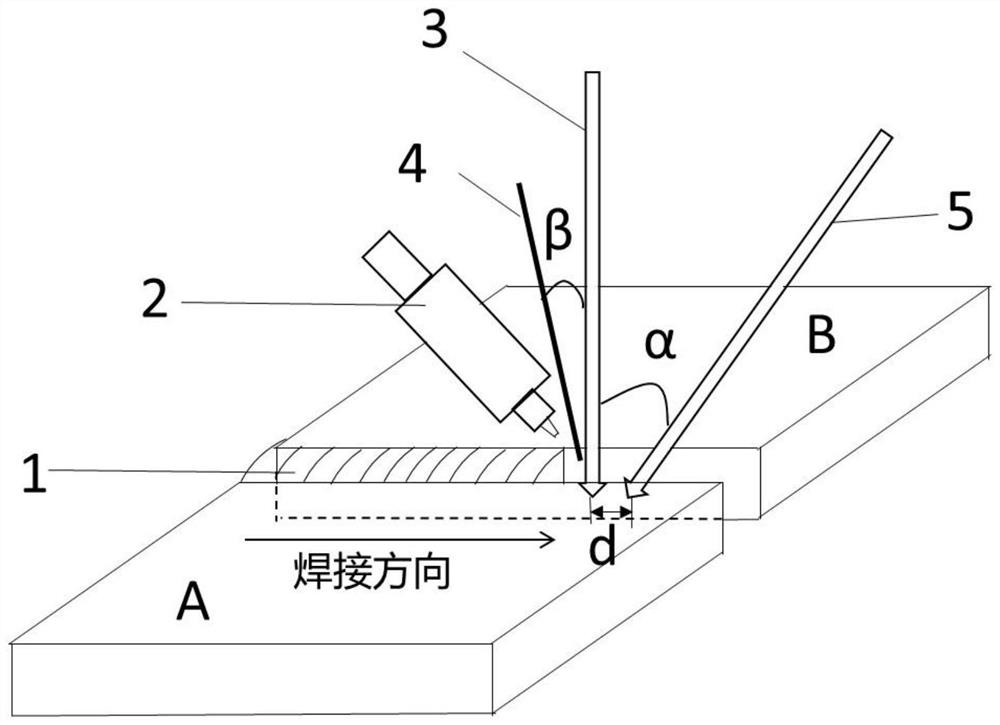

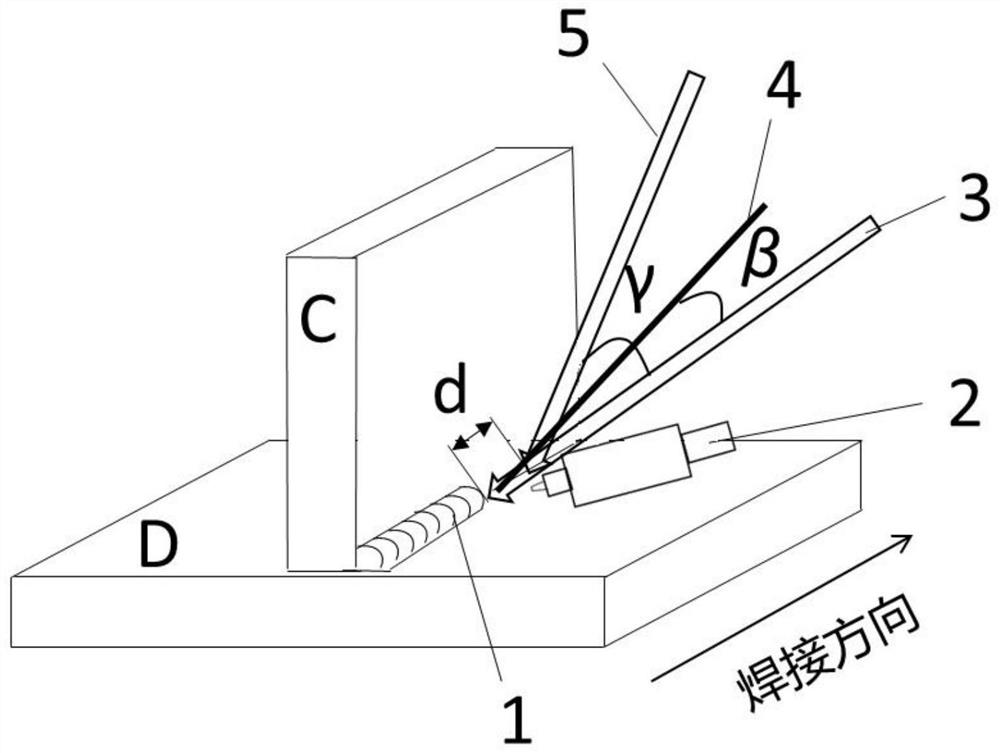

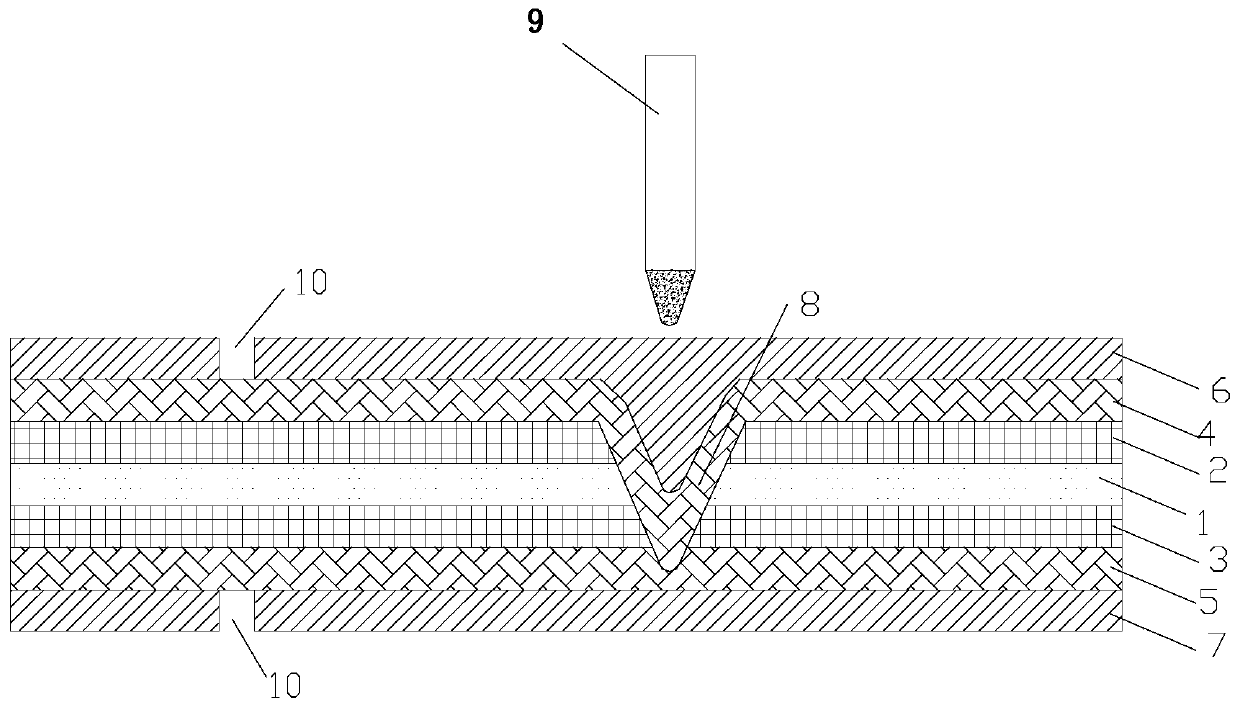

Double-beam laser welding method for medium plate

PendingCN113523615ALow difficulty requirement for dot gap controlLow control difficulty requirementLaser beam welding apparatusSlag (welding)Light spot

The invention discloses a double-beam laser welding method for a medium plate. The double-beam laser welding method comprises the steps that 1, a plate welding bead and the positions, within the range of 20 mm, of the two sides of a plate are polished for slag removal; 2, the plate subjected to polishing and slag removal is fixedly clamped on a welding platform; 3, laser welding process parameters of a main light beam and an auxiliary light beam are set, the laser power of the main light beam is larger than or equal to the laser power of the auxiliary light beam, the laser power of the main light beam is larger than or equal to 3 KW, the laser power of the auxiliary light beam is larger than or equal to 2 kW, the welding speed is 0.2-1 m / min, the wire feeding speed is 1-8 m / min, and the defocusing amount is 10-30 mm; 4, a light spot of the auxiliary light beam is focused at the root part of one side of a welding seam plate; 5, the light spot of the main light beam is focused at the center of a welding seam; and 6, the main light beam and the auxiliary light beam move in the same direction to achieve welding. The welding seam gap stability control difficulty can be effectively reduced; the universality is high, the welding seam form can be a butt joint form or a corner joint form, and the welding mode can be filler wire welding or filling-free welding; and the swinging direction of a laser beam is controllable and adjustable.

Owner:XCMG EXCAVATOR MACHINERY

Liner taking out method from blind hole

The invention discloses a method for taking a lining out of a blind hole, belongs to the mechanical assembly technology, and relates to a method for taking a lining out of a blind hole on a workpiece. The invention is characterized in that the method for taking the lining out of the blind hole comprises the following steps: firstly, grease in the liquid state, the semi-liquid state or the solid state is injected into the inner hole of the lining, and the injection amount is 30%-60% of the depth of the blind hole; then a straight pin shaft with the diameter being 0.02-0.03mm larger than the inside diameter is driven into the inner hole of the lining in a knocking manner until the lining is separated from the blind hole. The method can take the lining to be repaired out of the blind hole of the workpiece without breaking the lining underport on the workpiece, thereby avoiding re-machining the lining underport on the workpiece, shortening the repair time of the workpiece, and improving the labor productivity.

Owner:HARBIN

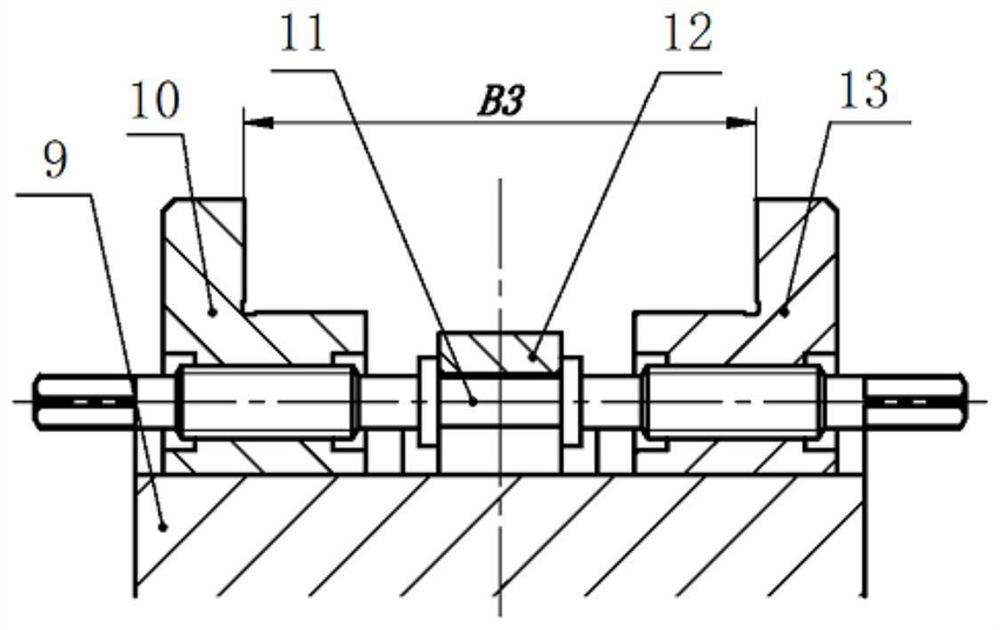

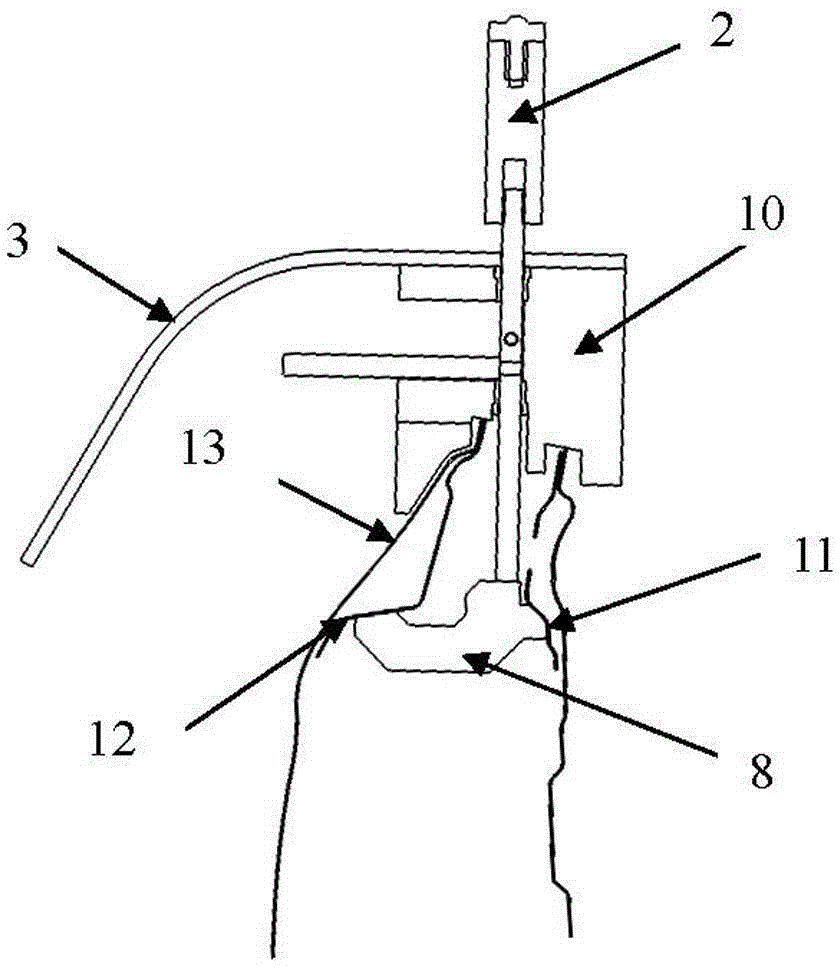

Adjustable rolling tool for automobile four-door sealing strip

PendingCN110217320AReduce work intensityImprove passabilityVehiclesEngineeringMechanical engineering

The invention provides an adjustable automobile four-door sealing strip rolling tool which comprises a transmission mechanism, a pressing mechanism, a shell, and an elastic adjusting device. The transmission mechanism comprises two rolling wheels, and when a sealing strip is installed, two rolling wheels act on two sides of the sealing strip correspondingly and provide guiding force for the sealing strip. The pressing mechanism is used for abutting against a sealing strip on the automobile door, so that the sealing strip is tightly attached to the automobile door; the shell is used for supporting the transmission mechanism and the pressing mechanism; and the elastic adjusting device is installed in the shell, and the elastic adjusting device is used for adjusting the distance between the upper portions of the two rolling wheels on the transmission mechanism and preventing the two rolling wheels from being stuck in the working process. The wheel base with the rolling wheels is providedwith the elastic adjusting device, so that the trafficability is good in the working process, and the jamming phenomenon is avoided in the working process.

Owner:吉林省祥和工业自动化有限公司

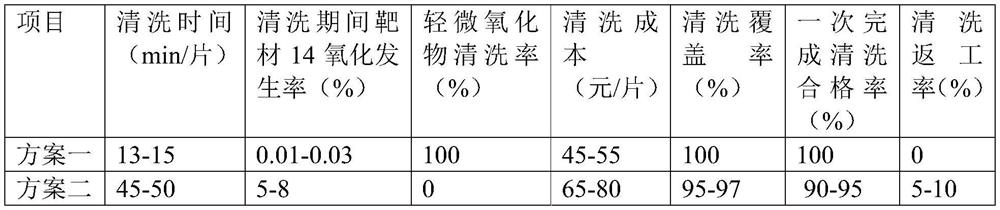

Target material cleaning method

InactiveCN112452946AReduce stepsReduce labor costsCleaning processes and apparatusDry iceEnvironmental engineering

The invention discloses a target material cleaning method. The cleaning method is characterized in that a dry ice spray gun group and a cleaning table move relatively, so that a dry ice spray gun completely covers a target material for cleaning. According to the target material cleaning method, dry ice is used for cleaning the target material through cleaning equipment, the target material is completely covered for cleaning, the cleaning time is shortened, and target material oxide is effectively removed.

Owner:东莞市欧莱溅射靶材有限公司 +1

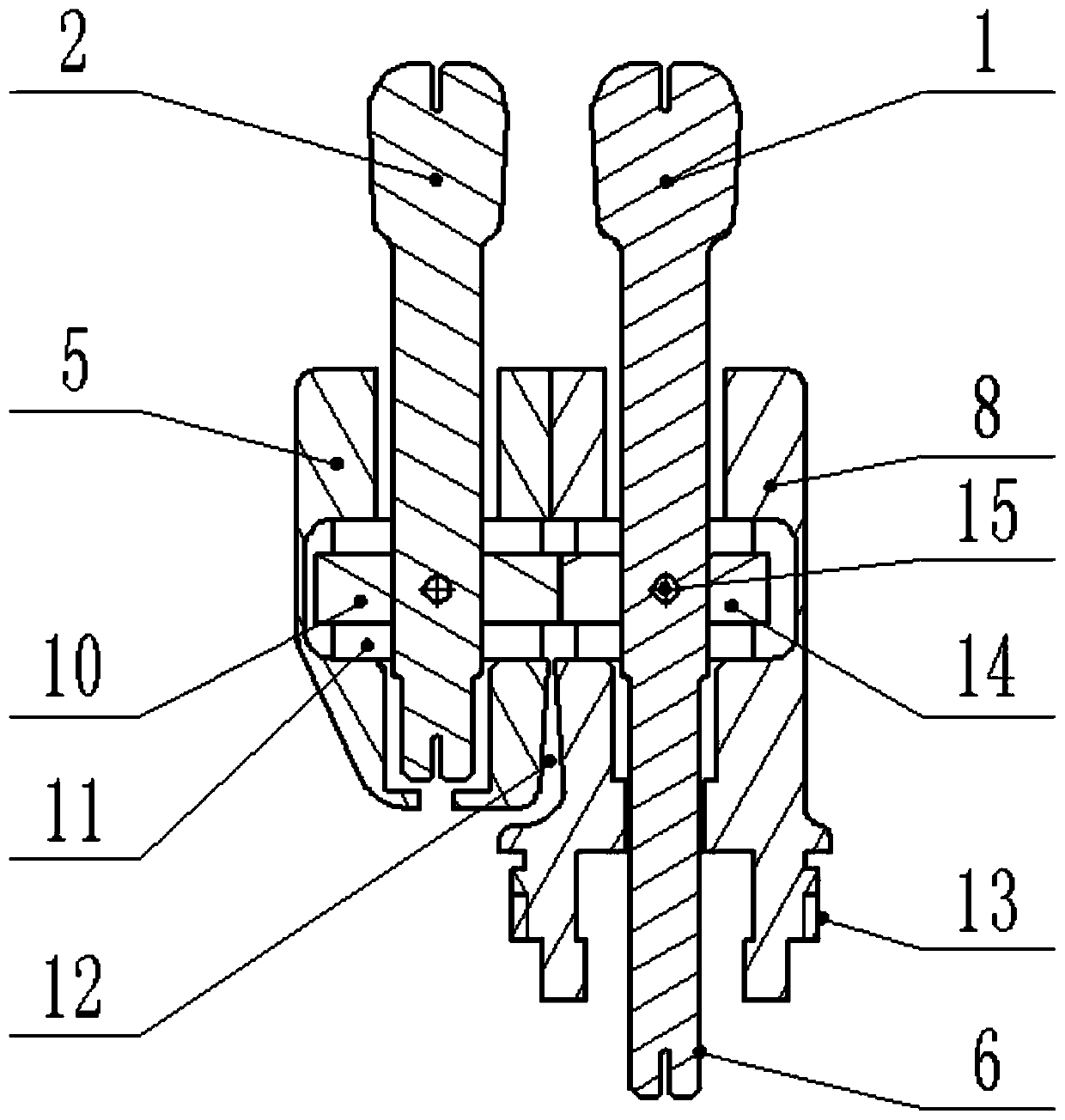

An automatic centering clamping device

Owner:CHINA HANGFA GUIZHOU LIYANG AVIATION POWER CO LTD

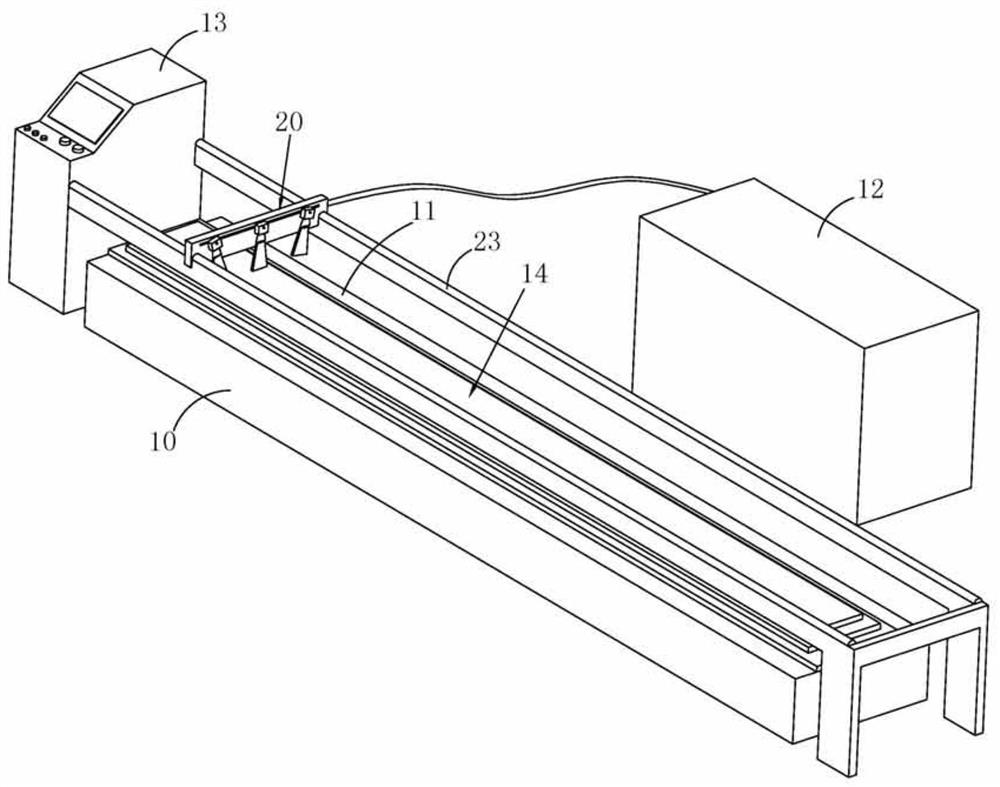

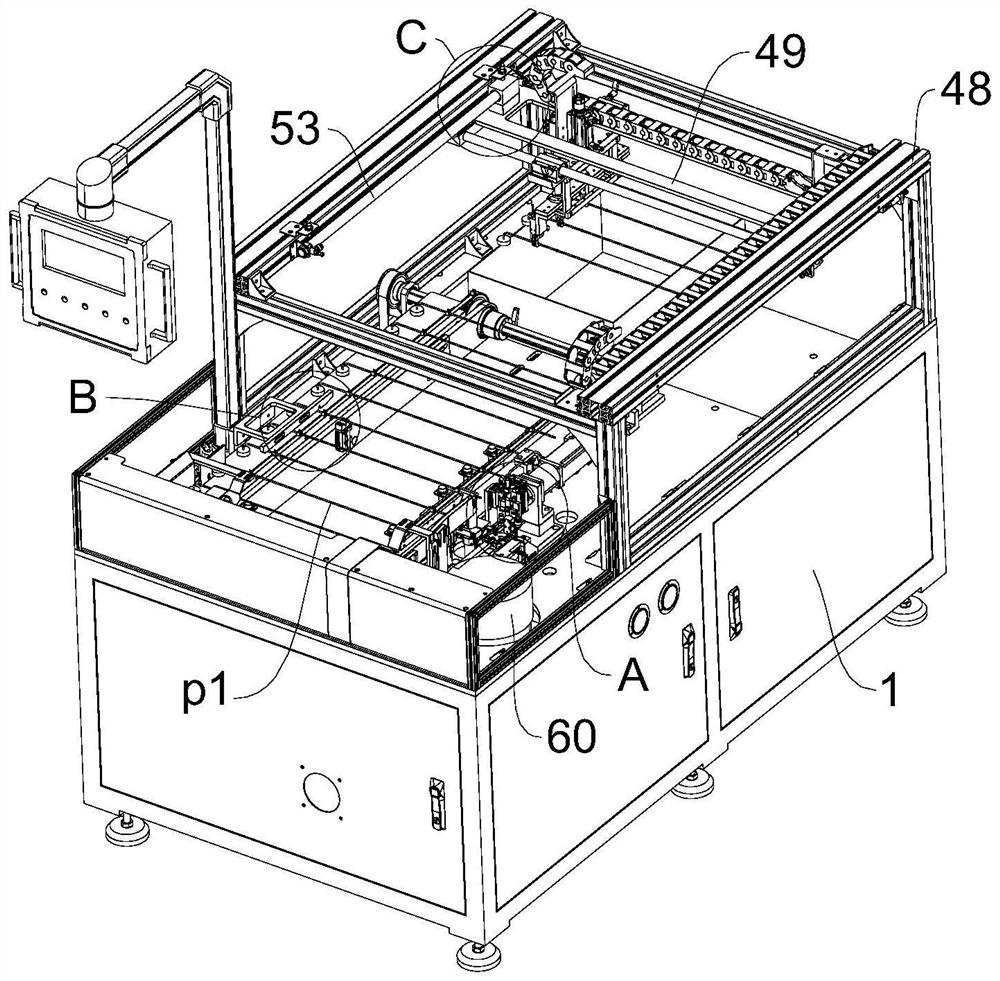

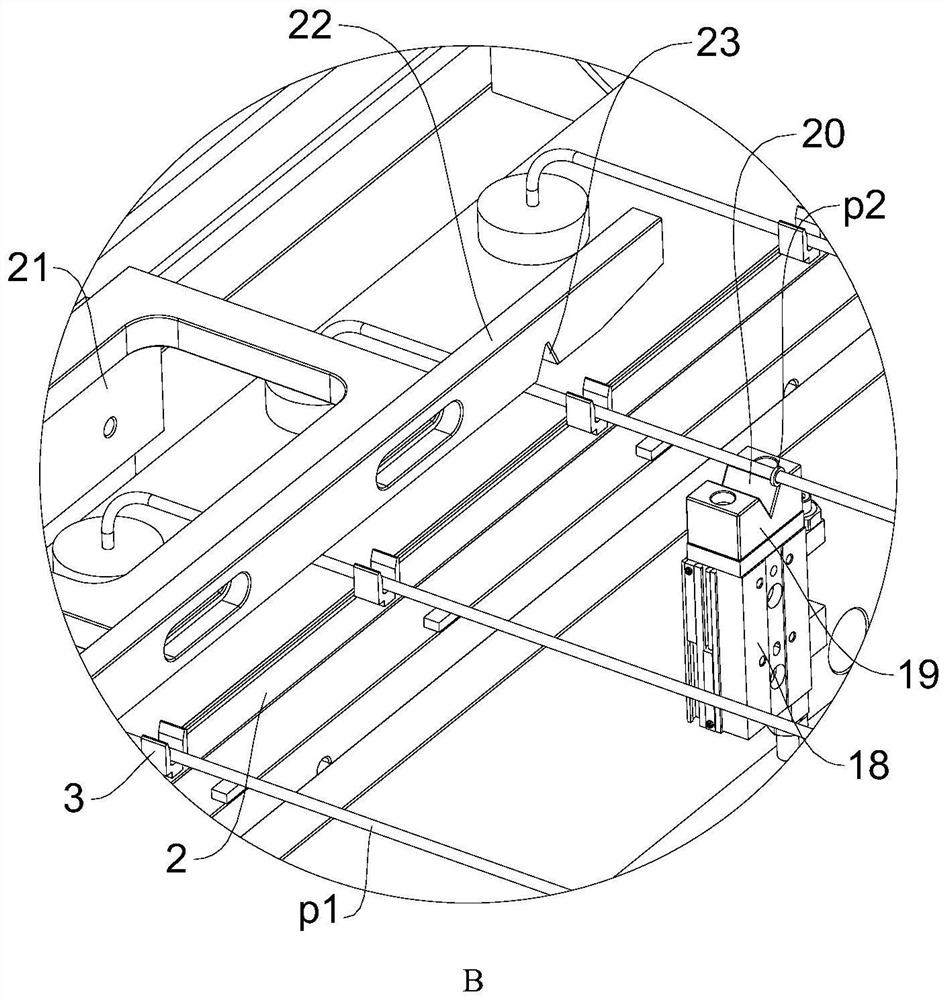

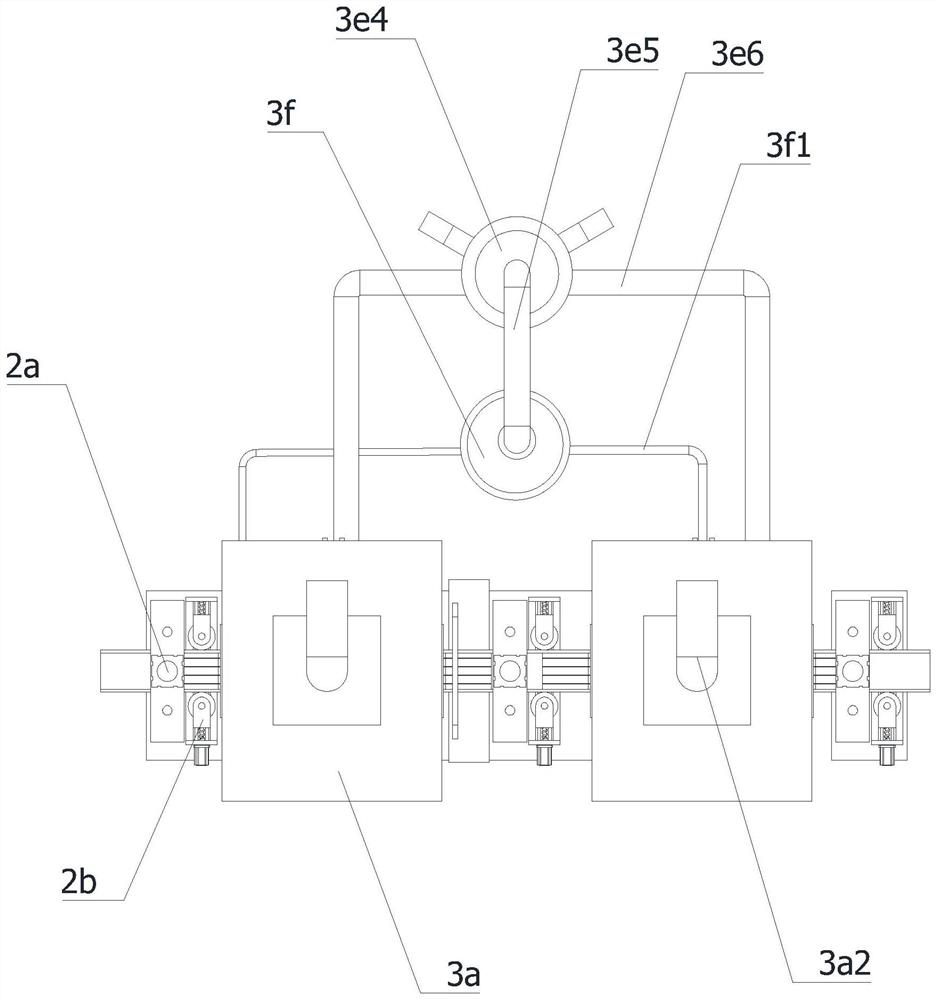

Machine for enabling brazing pipes to automatically penetrate through rings in automobile compressors

PendingCN113618378AImprove processing efficiencyReduce rework timeMetal working apparatusStructural engineeringManufacturing engineering

The invention relates to the technical field of compressors, and discloses a machine for enabling brazing pipes to automatically penetrate through rings in automobile compressors. The machine comprises a machine frame, at least two transmission belts arranged on the machine frame in parallel, a positioning structure and a ring feeding structure. Multiple transmission bodies with V-shaped openings are arranged on the outer side of each transmission belt, and the transmission bodies are used for supporting and conveying the brazing pipes. The positioning structure is used for fixing the positions of the brazing pipes. The ring feeding structure is used for enabling each welding ring to sleeve the end, located outside the transmission bodies, of the corresponding brazing pipe, and the positioning structure is located between the ring feeding structure and the transmission belts. According to the machine, the production efficiency can be improved.

Owner:湖北宇智自动化设备有限公司

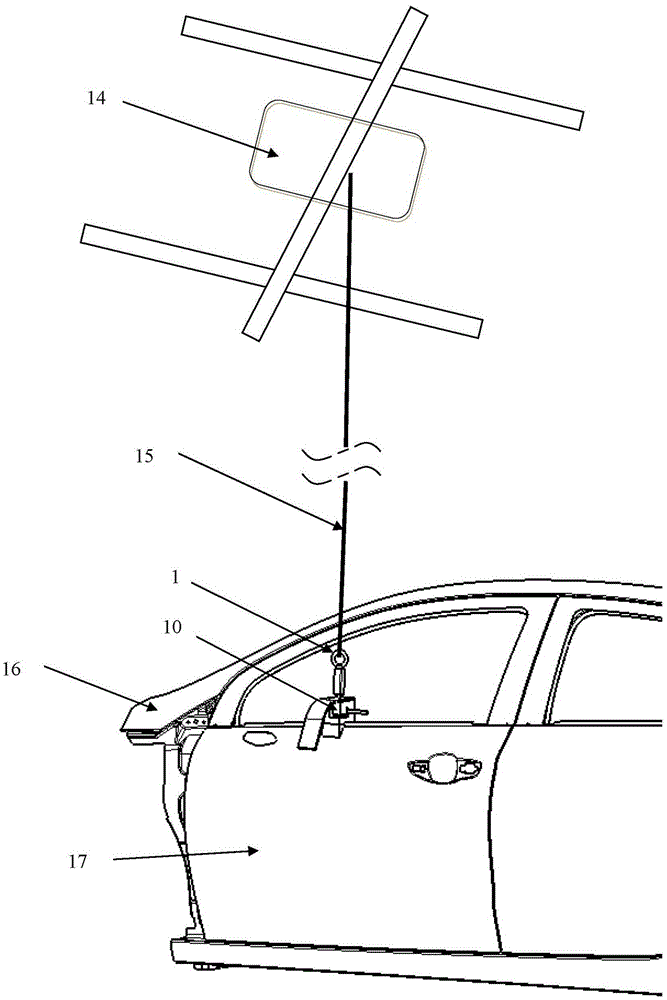

Motor vehicle door installation harness

InactiveCN105314004AMeet the needs of stable suspensionSimple structureVehiclesRotational axisControl theory

The invention provides a motor vehicle door installation harness. The motor vehicle door installation harness comprises a harness guide body. The motor vehicle door installation harness is characterized in that a rotating shaft is perpendicularly installed on the harness guide body and is in clearance fit with the harness guide body, a harness connecting ring is fixedly connected with the upper portion of the rotating shaft through a harness connecting rod, and a harness inner plate support block is fixedly arranged on the lower portion of the rotating shaft; a harness operation handle is transversely arranged on the harness guide body, and the other end of the harness operation handle is connected with the rotating shaft in a threaded mode; a soft profile limiting block is fixed to the lower portion of the harness guide block. The harness is positioned to an inner plate of a vehicle door through simple manual operation, and then the vehicle door is conveyed to a vehicle door installation position through a sliding system connected with the harness; installation of the vehicle door is achieved through a manual pneumatic tightening mode, time and labor are saved in the whole process, and the generalization performance is higher.

Owner:BRILLIANCE AUTO

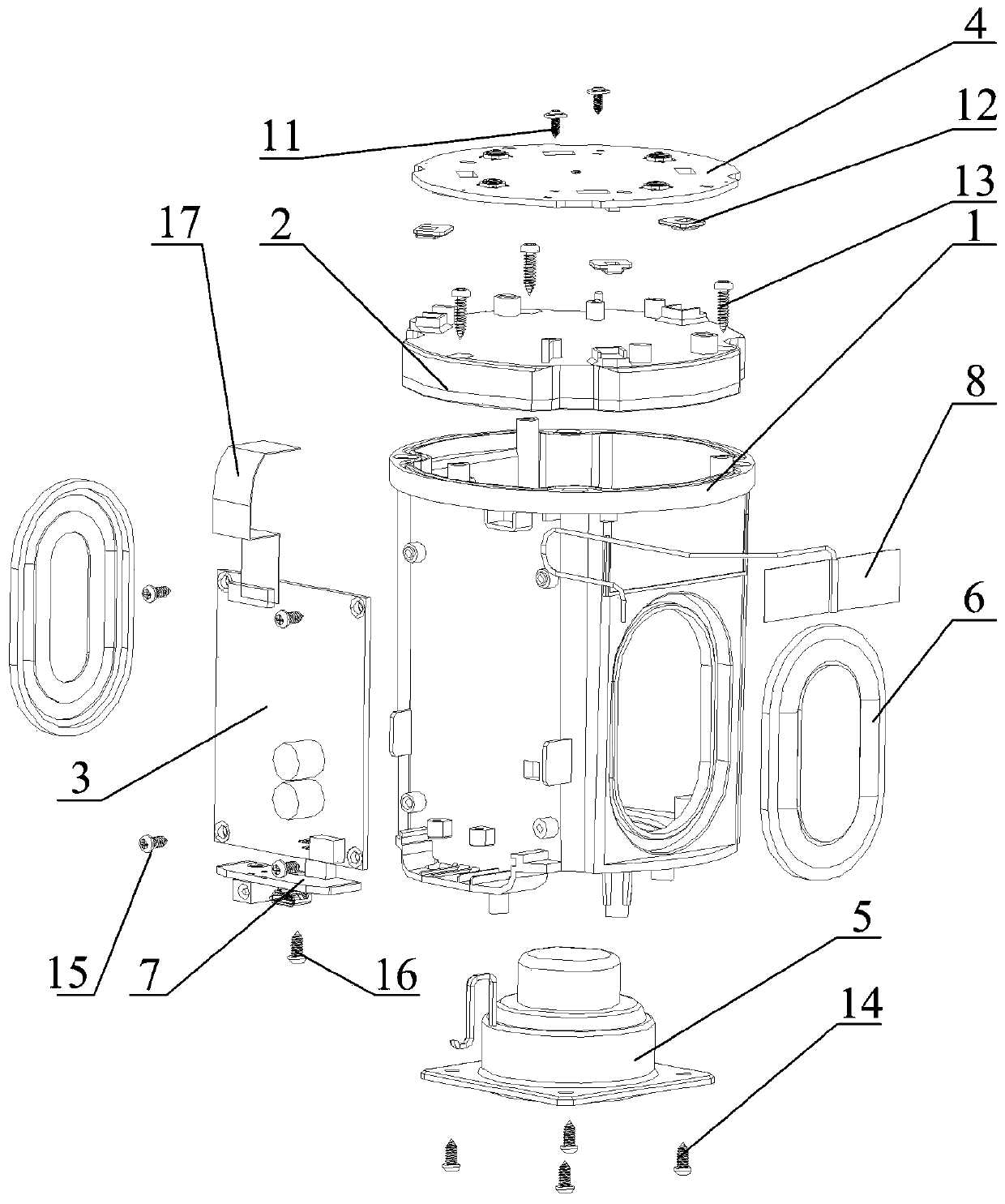

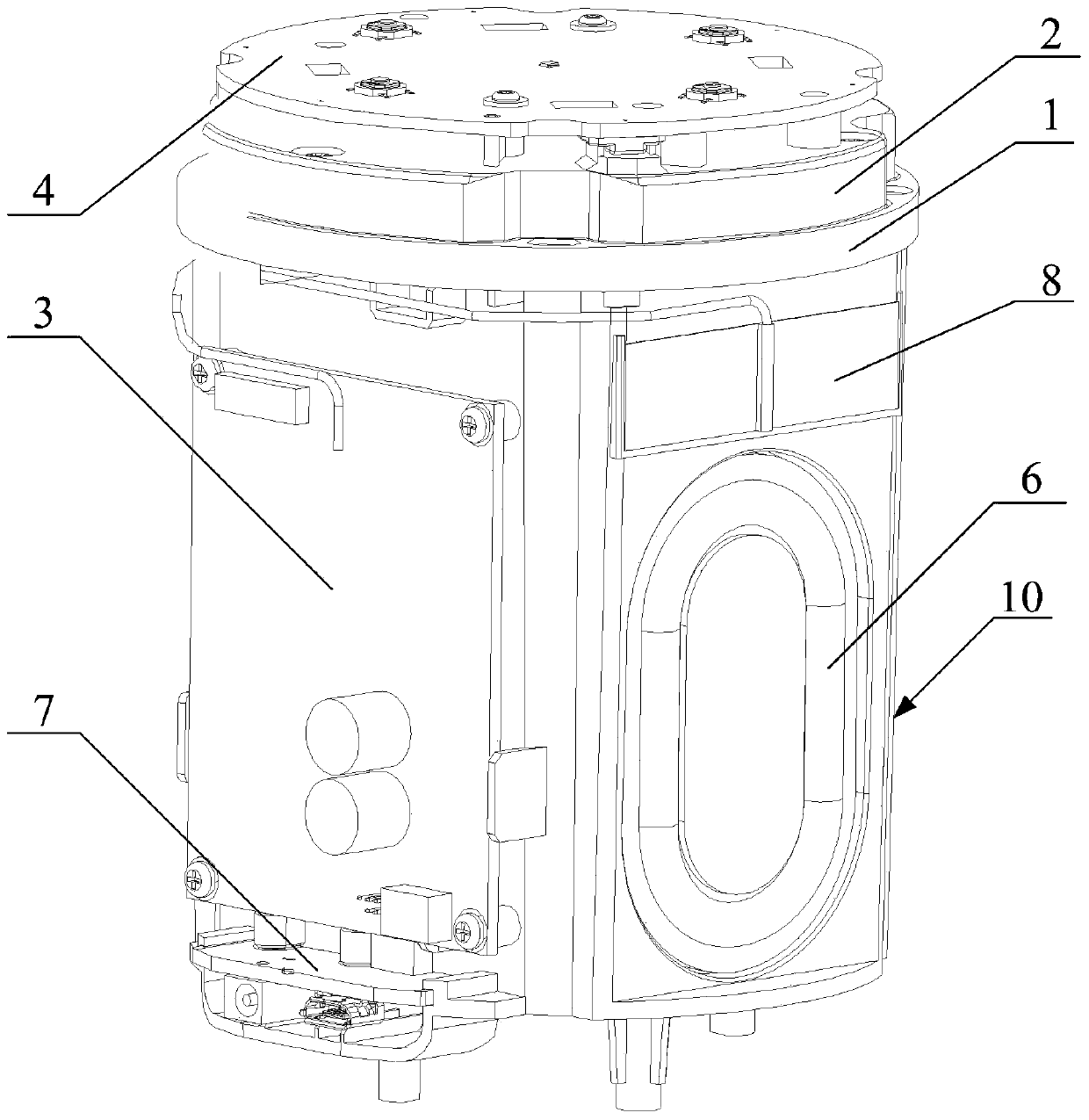

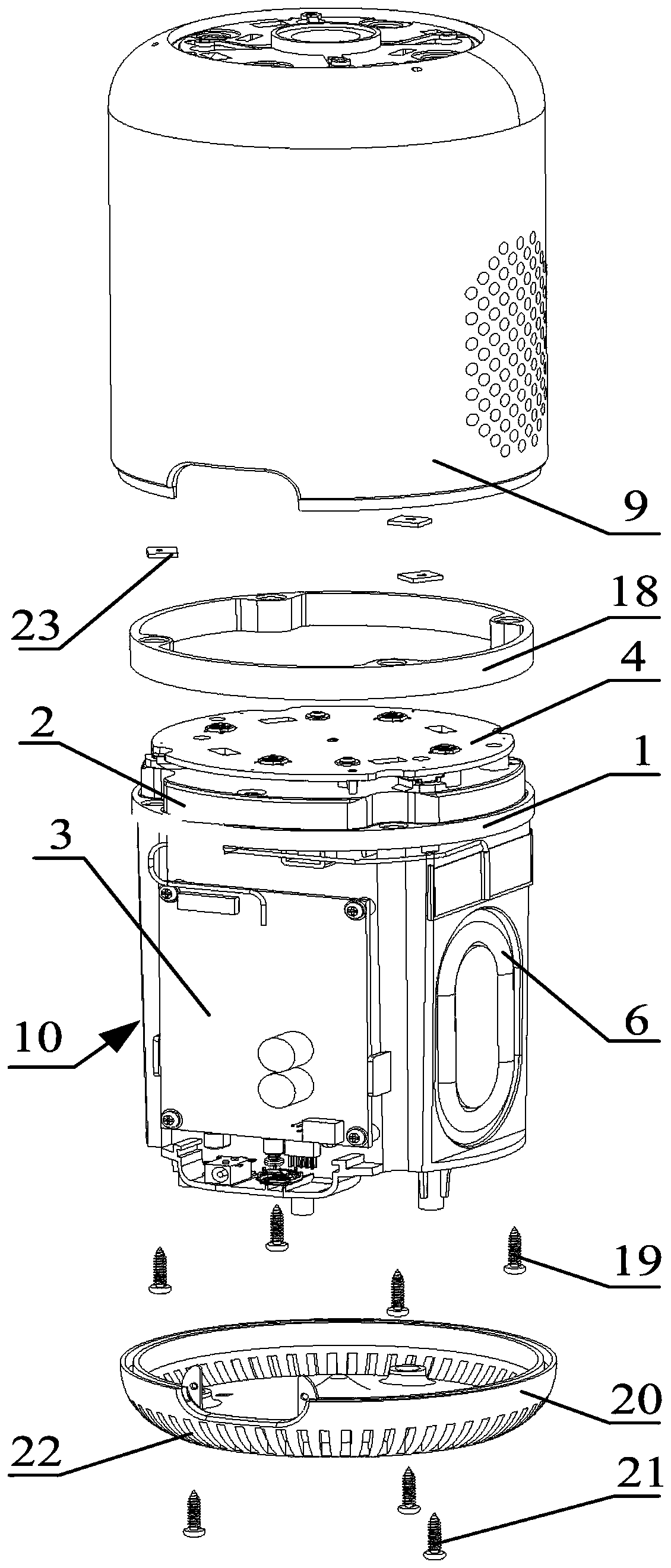

Intelligent sound box

ActiveCN109803205AReduce areaGuaranteed plugging reliabilityFrequency/directions obtaining arrangementsKey pressingCountermeasure

The invention discloses an intelligent sound box. A main circuit structure of the intelligent sound box is installed on a loudspeaker body and a semi-finished product, so that the whole machine can betested, the performance test of the whole machine is facilitated, and the repair time is saved; The keys are buffered by silica gel, and the key covers are mounted in the covering shell, so that theuniformity of gaps of the shell is ensured, the key covers are prevented from generating vibration sound, the use of key countermeasure auxiliary materials is optimized, and the cost is saved; The main board and the power board adopt a quick-plug 90-degree structure, so that the area of the main board is saved on the premise of ensuring the appearance, and the plugging stability of the external terminal is ensured; The sound separation plate and the lower cover are fused into a whole, so that the cost and the structural space are saved while the sound output effect is ensured; The overall cloth covering effect is used for appearance, appearance changes are diverse, the processing difficulty of the overall appearance mold closing line of the shell is reduced, and surface processing such asspraying of the shell is avoided.

Owner:SOUNDAI TECH CO LTD

Automatic centering and clamping device

The invention discloses an automatic centering and clamping device. The automatic centering and clamping device comprises a bottom plate A, a left clamping block, a dual-head screw A, a brake block A,a right clamping block, a left guide plate and a right guide plate; the left guide plate and the right guide plate are each mounted on the bottom plate A through a cylindrical pin A and a bolt B, theleft guide plate and the right guide plate are mounted on the bottom plate A to form a T-shaped guide groove, the two ends of the dual-head screw A are screwed into the left clamping block and the right clamping block to form an assembly, the assembly is arranged in the T-shaped guide groove formed by the left guide plate, the right guide plate and the bottom plate A, the brake block A is arranged in the middle of the dual-head screw A in a sleeved manner, and is arranged on the bottom plate A through a cylindrical pin B and a bolt A, the brake block A is located between the left clamping block and the right clamping block, and the brake block is of a covering type buckle saddle structure. An optimized manufacturing, assembling, detaching and adjusting scheme can be provided for the automatic centering and clamping device, the tool manufacturing and repair time can be shortened, cost is reduced, and the developing work efficiency is improved.

Owner:CHINA HANGFA GUIZHOU LIYANG AVIATION POWER CO LTD

Polishing and derusting equipment for intelligent manufacturing of steel structure

PendingCN114515998AReduce rust stainsReduce the burden onBlast gunsAbrasive machine appurtenancesSand blastingPolishing

The invention relates to the technical field of steel structure machining equipment, in particular to steel structure intelligent manufacturing polishing and derusting equipment which comprises a material moving mechanism, a positioning mechanism and a derusting device, and the derusting device comprises a first sand blasting assembly, a second sand blasting assembly, a raw material box, a detection mechanism, a recovery mechanism and two derusting boxes. Through the arrangement of the first sand blasting assembly and the second sand blasting assembly, rust stains, which cannot be removed by a grinding wheel, on the surface of a steel structure are reduced, the rust removal effect is improved, the reworking time is shortened, the automation degree of equipment is improved, and the burden of operators is reduced; through the arrangement of the recycling mechanism, waste materials and rust stains generated during rust removal work are recycled, the expenditure of raw material cost during rust removal work is reduced, meanwhile, through the arrangement of the two rust removal boxes, the waste materials, the rust stains and dust in the rust removal process are not prone to drifting away, the body health of workers is guaranteed, the workers are prevented from inhaling dust, and the working efficiency is improved. And the recycling mechanism can conveniently collect and recycle waste and rust stain dust.

Owner:柴会凯

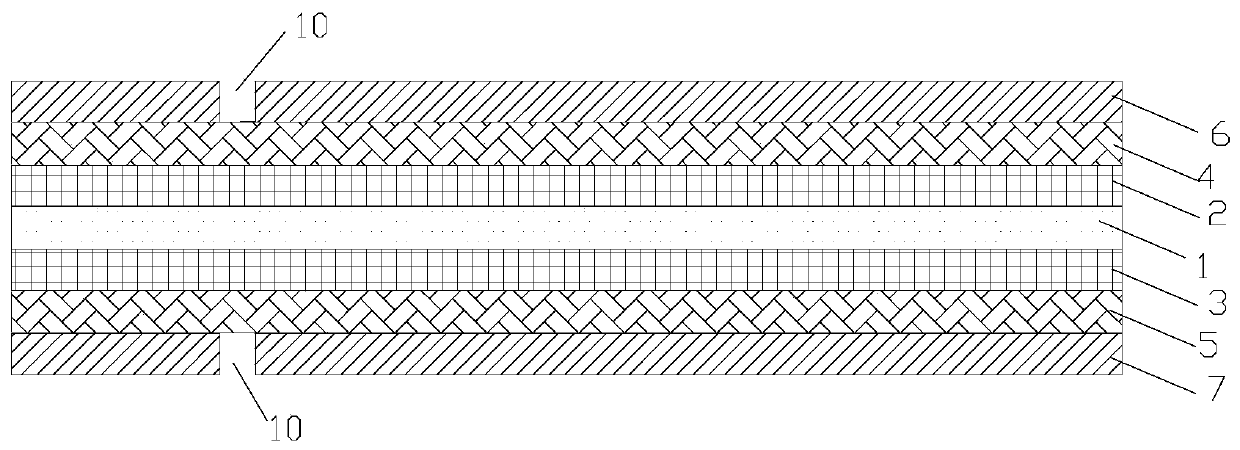

Flexible circuit board used for LED lamp band and manufacturing method thereof

PendingCN110475425AAdhesiveInsulationElectrical connection printed elementsCircuit susbtrate materialsFlexible circuitsEngineering

A flexible circuit board used for an LED lamp band comprises a PET thin film layer. Front and reverse surfaces of the PET thin film layer are coated with a front surface insulation bonding layer and areverse surface insulation bonding layer, the front surface insulation bonding layer is bonded with a front surface line layer, and the reverse surface insulation bonding layer is bonded with a reverse surface line layer. The front surface line layer is provided with a front cover layer, and the reverse surface line layer is provided with a reverse cover layer. The front surface line layer and the reverse surface line layer are aluminum foils having certain ductility. The front cover layer and / or the reverse cover layer are provided with bonding pad layers. One reverse surface line layer is arranged on a back surface of a circuit board, which is made of a metal aluminum foil material. Two sides of a PET thin film are supported by the metal aluminum foils. Under high temperature and welding conditions, the circuit board does not expand and contract that cause deformation and is very flat. After a lot of practice, bad phenomena such as tombstoning, insufficient soldering and false soldering and the like of a component can be eliminated. A yield rate of the flexible circuit board after reflow soldering can reach 99% or above, which has a significant economic value.

Owner:珠海市兴铝电子科技有限公司

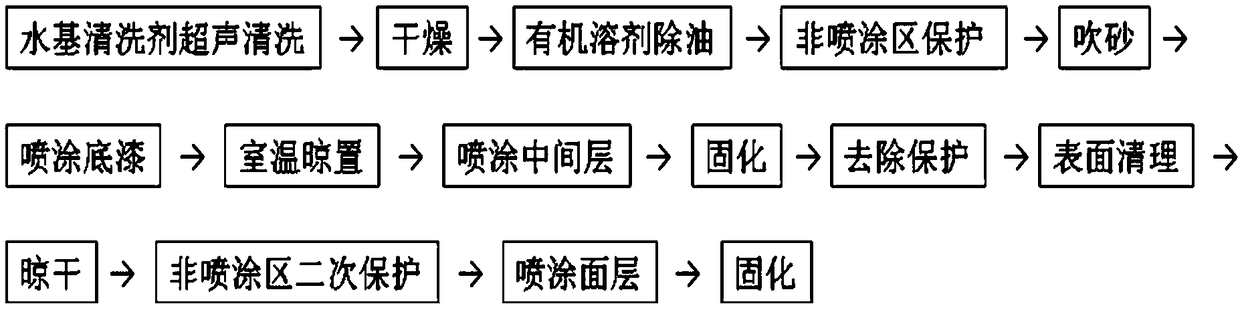

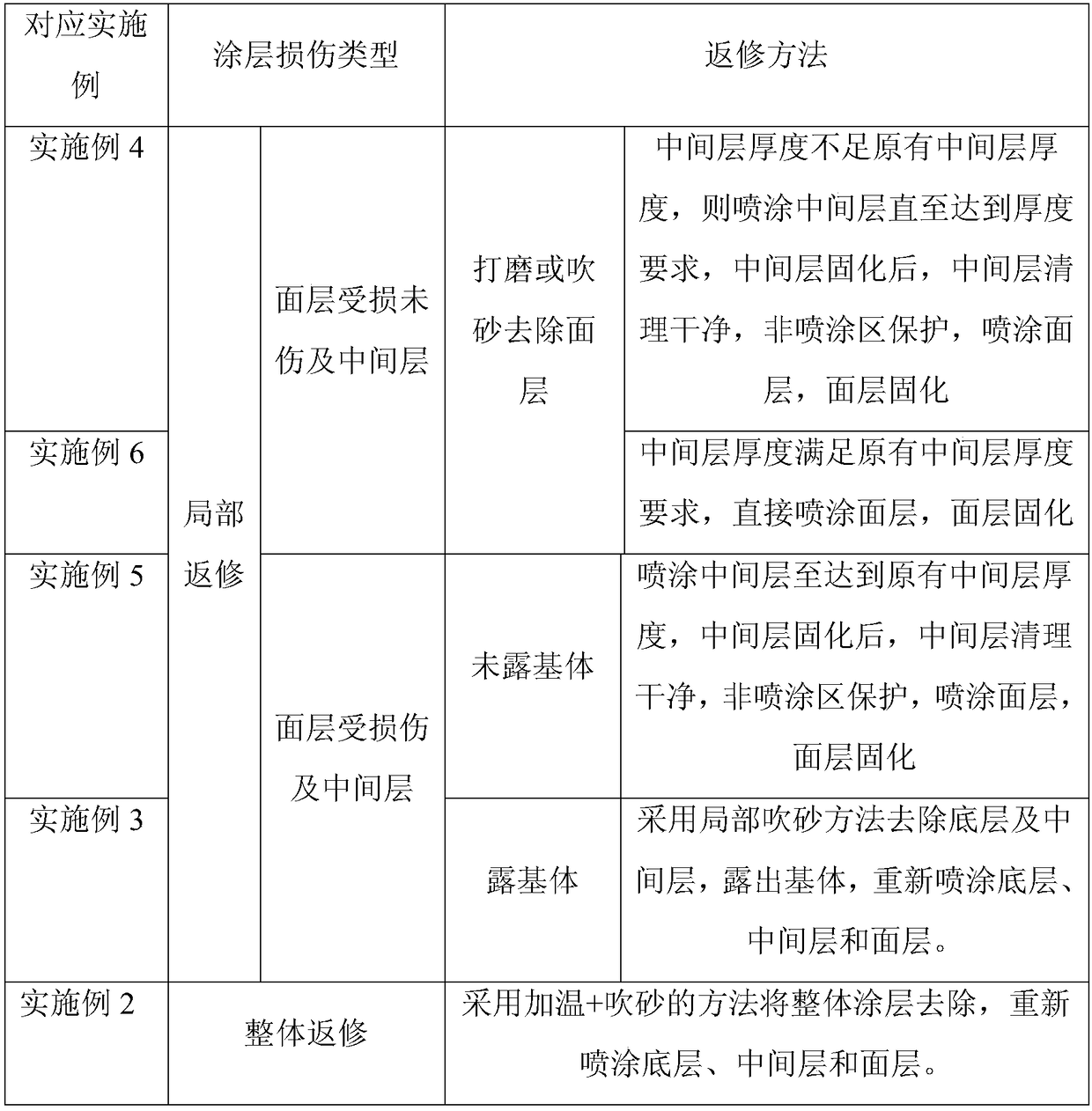

Coating and repairing methods of medium-low temperature multi-frequency-band compatible coat of engine jet nozzle part

InactiveCN109317377AImprove surface conditionImprove bindingPretreated surfacesSpecial surfacesJet aeroplanePretreatment method

The invention provides coating and repairing methods of a medium-low temperature multi-frequency-band compatible coat of an engine jet nozzle part and belongs to the field of coating of coats for aero-engines. The coating method comprises the steps that ultrasonic cleaning and drying are conducted on the to-be-treated engine jet nozzle part, organic solvent degreasing is conducted, protection of anon-coat area is conducted, and sand blasting is conducted; spray coating of a primer is conducted, indoor temperature cooling is conducted, spray coating of a middle layer is conducted, the middle layer is cured, protection of the non-coat area is removed, the surface of the middle layer is cleared, secondary protection of the non-coat area is conducted, spray coating of a finishing coat is conducted, the finishing coat is cured, and the product is obtained. The coating and repairing methods of the medium-low temperature multi-frequency-band compatible coat of the engine jet nozzle part meets the demand of an airplane for a medium-low temperature multi-frequency-band compatible coat; for the use and structure features of the engine jet nozzle part, the pretreatment method improves the surface quality of the engine jet nozzle part, and the binding force of the coat is improved beneficially; heating curing is applied to the coat, so that the production period is shortened; for variousdamaged states, probably appearing in the transportation process, the assembly process and the use process, of the coating, corresponding repairing methods are adopted, and therefore the coating and repairing methods have better pertinence.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com