On-line measuring method for radials profile of compressor disc-like part of engine

A technology of a compressor disc and a measuring method, which is applied to metal processing mechanical parts, measuring/indicating equipment, accessories of tool holders, etc., can solve the problems of high cost, restricting the development cycle of new products, and taking a long time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

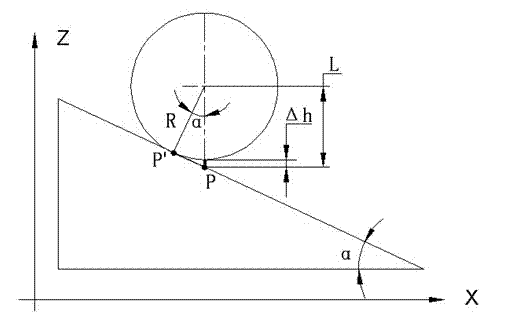

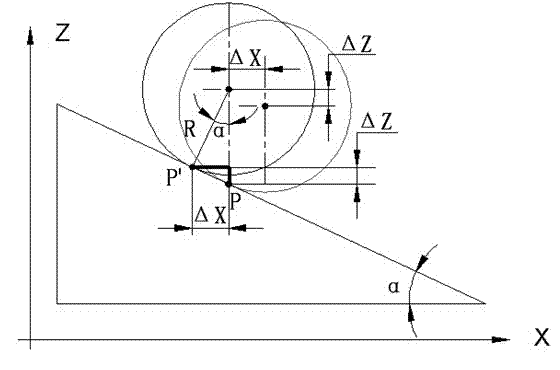

[0037] right image 3 The online measurement procedure for the compressor disc part shown in is:

[0038] (1) Planning the measurement path of the probe: the measurement system is located on the vertical CNC turning machining center, where the signal receiver of the measurement system is connected to the controller of the CNC machining center, and the probe is installed in the tool magazine of the machining center for waiting The horizontal plane where the front and rear end faces of the air compressor disk parts are installed or the front and rear edge end faces is the measurement reference plane, the X origin of the coordinate system is on the central axis of the center hole of the part, the direction of the horizontal guide rail of the machine tool is the X axis, and the machine tool spindle is Z axis, establish a measurement coordinate system;

[0039] (2) Calibrate the radius of the probe ball: Calibrate the radius of the probe ball: Call out the probe from the tool libr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com