Target material cleaning method

A technology of target material and cleaning table, applied in the direction of cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of low cleaning efficiency, high risk, human body hazards, etc., to reduce labor costs, reduce health hazards, and clean The effect of shortening time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following are only preferred embodiments of the present invention, and therefore do not limit the protection scope of the present invention.

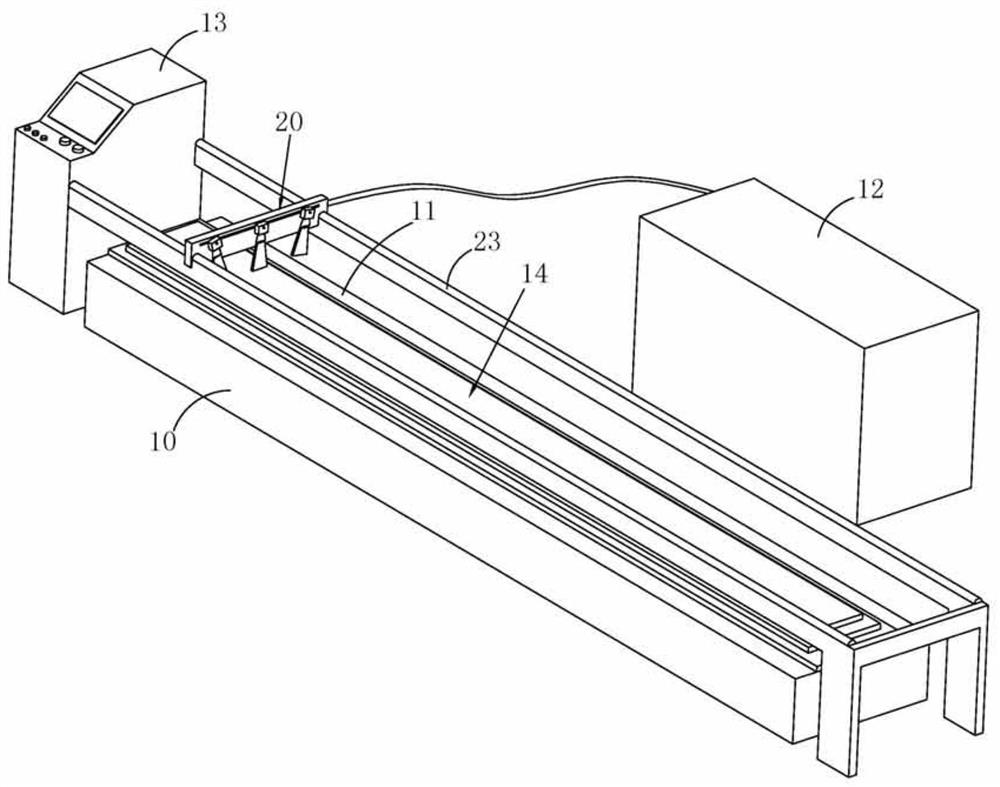

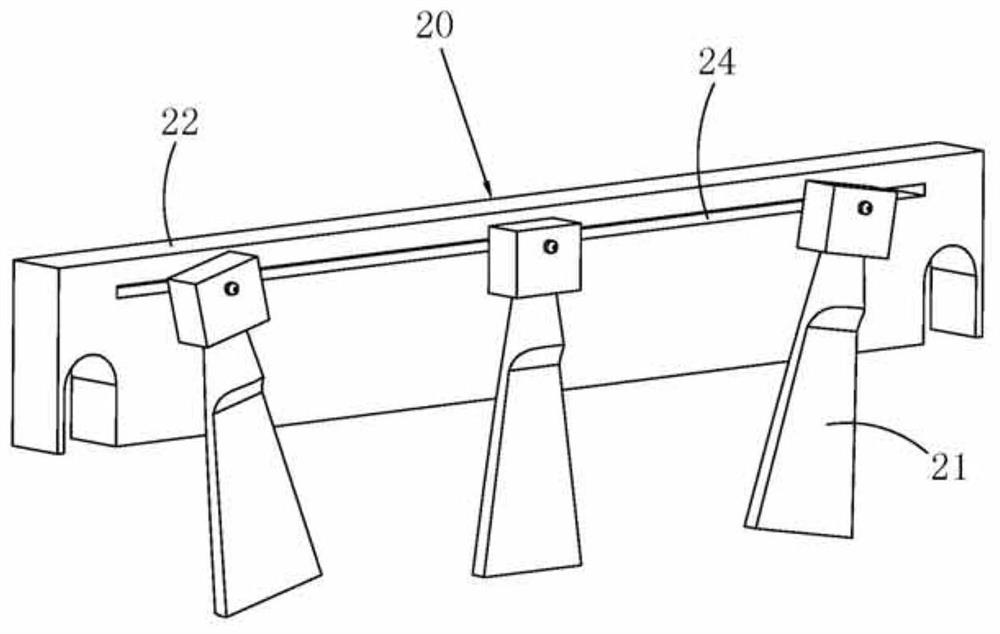

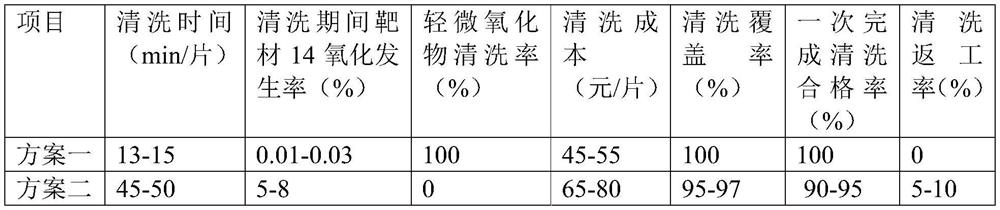

[0027] A method for cleaning a target, such as Figure 1 to Figure 2 As shown, the method for cleaning the target 14 of the present invention uses a target cleaning device to spray dry ice on the surface of the target 14 to be cleaned. The cleaning of the target 14 is characterized in that the material is easy to oxidize, the cleaning area is large, there are many surfaces to be cleaned, and there are various cleaning surfaces at different angles. Existing cleaning of the target 14 is done manually using chemicals such as alcohol or acetone. The target material 14 is cleaned manually with chemicals, which are harmful to the human body. Due to the large cleaning area of the target material 14 and the slow manual cleaning speed, it takes a long time to complete the cleaning of the entire target material 14, resulting in sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com