Intelligent factory automatic discharging robot based on 5G network

An automatic cutting and robotic technology, applied in manipulators, manufacturing tools, program-controlled manipulators, etc., can solve the problem of inability to classify and place unqualified products, and achieve the effect of saving labor costs, improving cutting efficiency, and saving repair time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028]Next, the technical solutions in the embodiments of the present invention will be described in the following examples, and the described embodiments are merely, and embodiments are intended to be, in rather than all embodiments. Embodiments in the present invention, those of ordinary skill in the art will belong to the scope of the present invention in all other embodiments obtained without making creative labor.

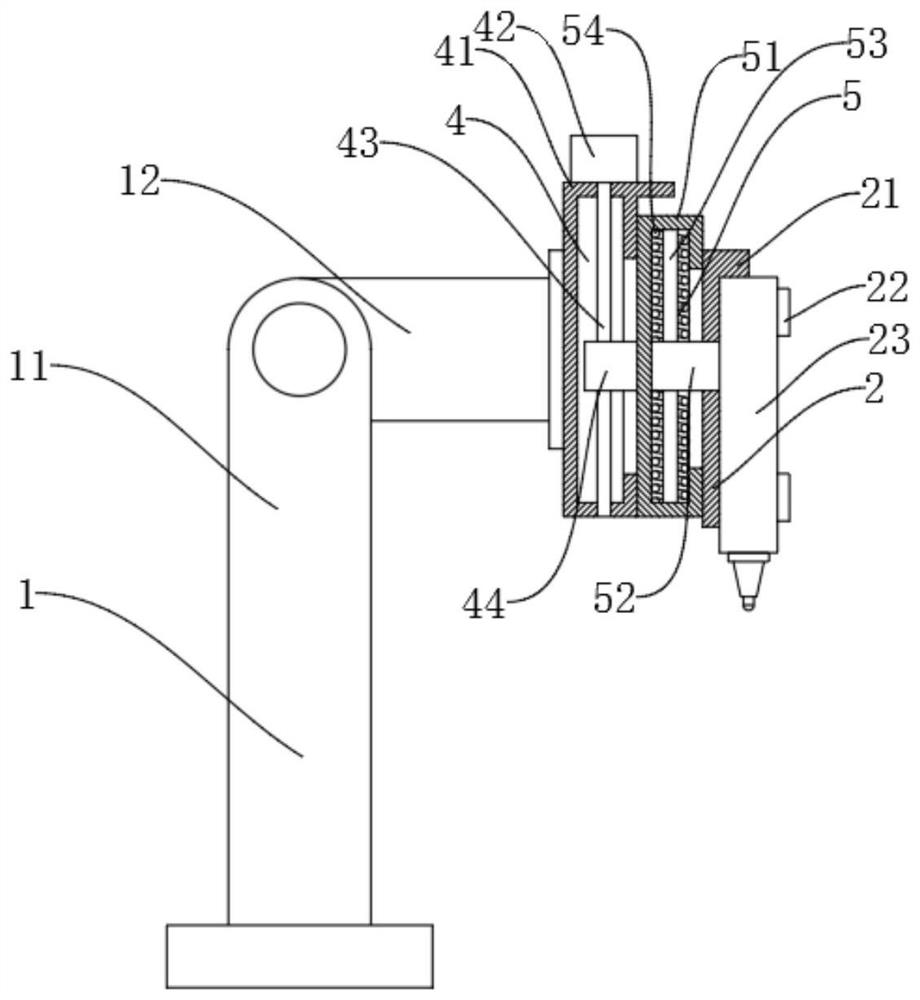

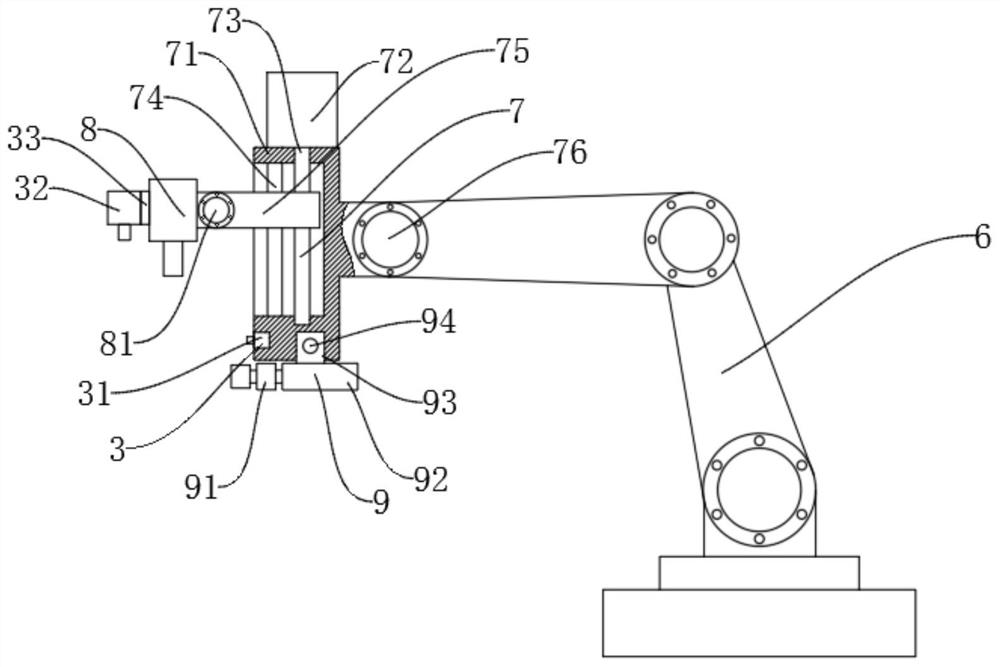

[0029]byFigure 1 ~ 2 As shown, a smart factory automatic filling robot based on a 5G network is used in multi-level detection assembly lines, including:

[0030]The marker unit is used to mark the type of unqualified product, the labeling unit to control the module connection with the detection process of the detection process;

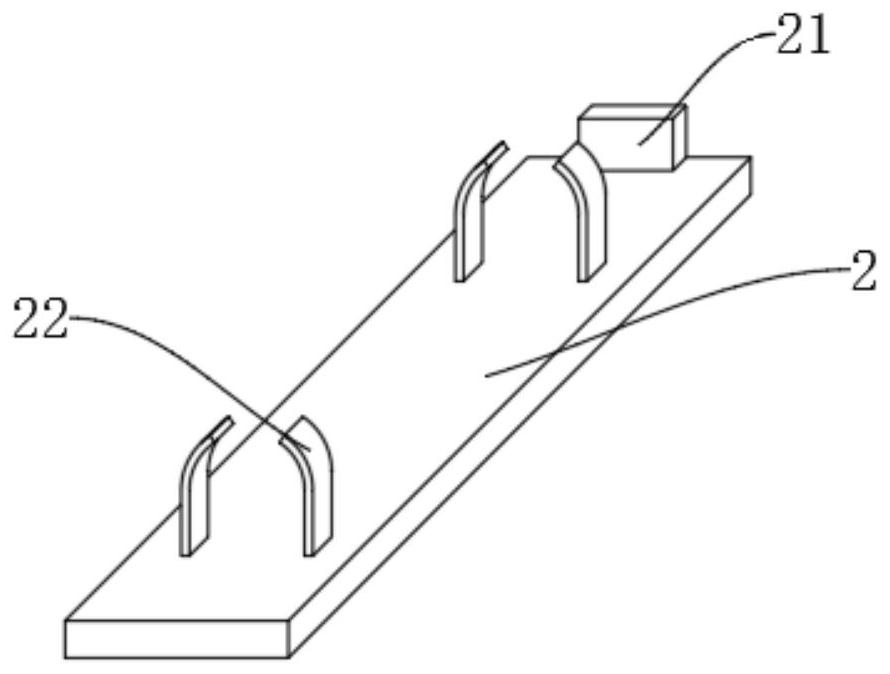

[0031]Classification of the following unit, the classified lowering unit places the product on the production line and places the product to different station appliances according to the species marked by the marker unit;

[0032]The labeling unit incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com