Coating and repairing methods of medium-low temperature multi-frequency-band compatible coat of engine jet nozzle part

A tail nozzle and engine technology, applied in coatings, devices for applying liquid to surfaces, pre-treatment surfaces, etc., can solve problems such as scratches, scratches, bubbling of coatings, and complex parts structure, and improve service life. and reliability, saving rework costs, and the effect of quick rework

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

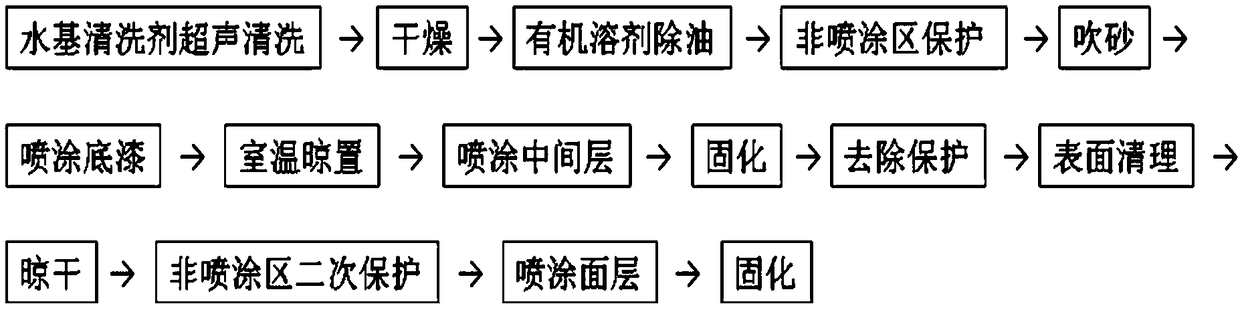

[0046] A medium-low temperature multi-band compatible coating method for engine tail nozzle parts, the schematic diagram of which is shown in figure 1 , including the following steps:

[0047] Step 1: Pre-processing

[0048] The elastic element of the engine tail nozzle is ultrasonically cleaned with 781 water-based cleaning agent → dried at 80°C → wiped with absolute ethanol → non-sprayed area protection → sand blowing to obtain the pretreated elastic element of the engine tail nozzle; among them, 250 mesh is used for sand blowing Corundum sand, wind pressure is 0.1MPa;

[0049] After observing the initial state of the elastic element of the engine tail nozzle and the surface state after pretreatment, it can be seen that the carbon deposit and oxidation color of the elastic element of the engine tail nozzle have been cleaned after ultrasonic cleaning and sand blowing.

[0050] Step 2: Spraying

[0051] Spray the primer on the elastic element of the engine tail nozzle after...

Embodiment 2

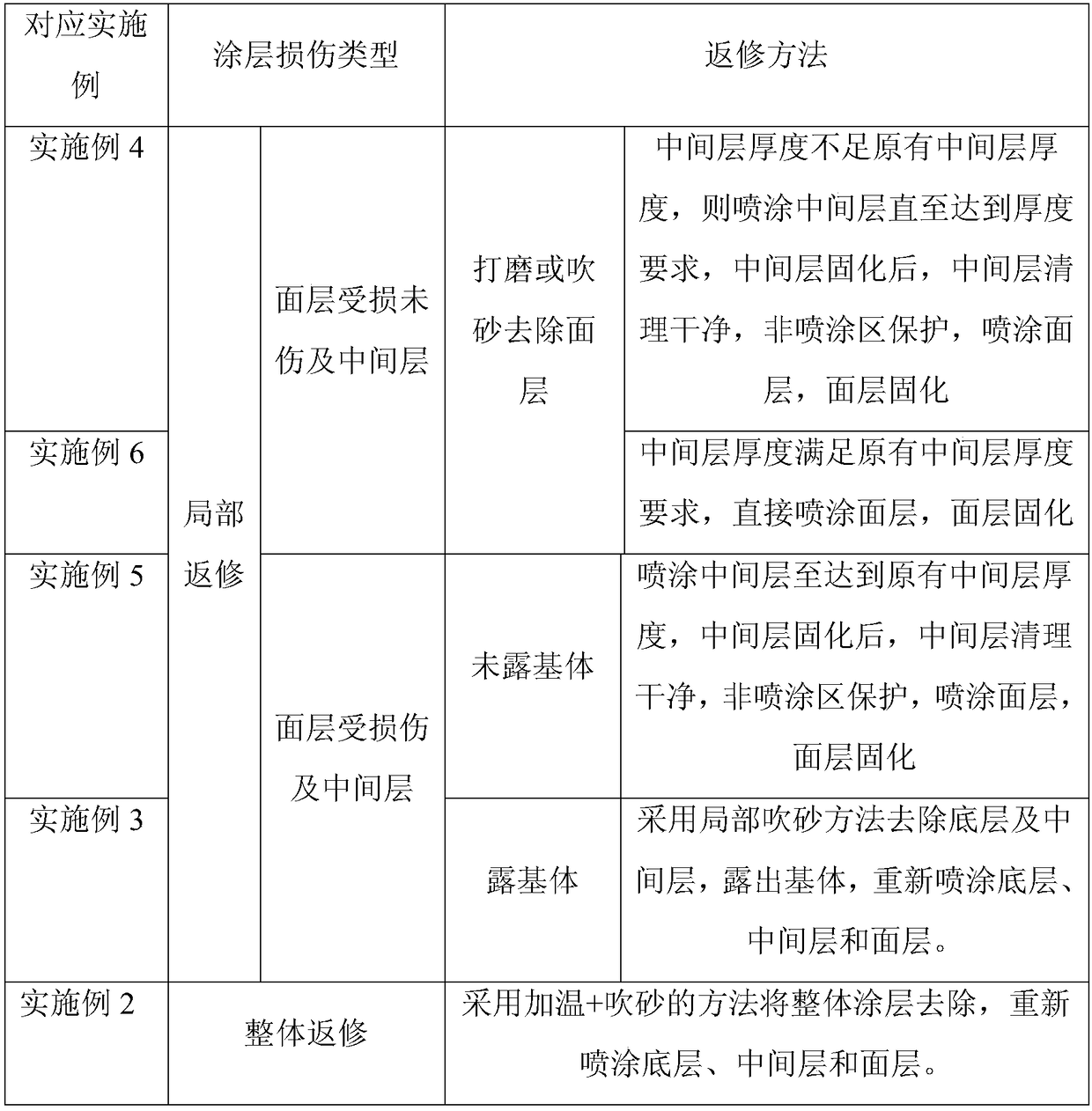

[0055] A method for reworking a low-temperature multi-band compatible coating for engine tail nozzle parts, comprising the following steps:

[0056] The outer regulating plate of the engine tail nozzle has a bulge in the low-temperature multi-frequency band compatible coating as a whole. The external regulating plate of the engine tail nozzle coated with the medium-low temperature multi-frequency band compatible coating is completely removed by heating + sand blowing. The sheet was heated to 350°C with the furnace, kept for 2 hours, then cooled to room temperature with the furnace and taken out, and the coating was removed by blowing sand with 200 mesh corundum sand and wind pressure 0.1MPa, and the entire coating was removed. After the parts were cleaned, the 1 Medium and low temperature multi-band compatible coating method for engine tail nozzle parts Re-spray the bottom layer, middle layer and surface layer.

[0057] In this example, the medium-low temperature multi-band co...

Embodiment 3

[0059] A method for reworking a low-temperature multi-band compatible coating for engine tail nozzle parts, comprising the following steps:

[0060] In this embodiment, the middle layer is partially damaged, and there is an obvious height difference between the locally damaged part of the middle layer and its surroundings, and the original coating needs to be removed to expose the substrate. In this embodiment, the surface layer is removed first, and the undamaged middle layer The layer is shielded and protected to expose the parts to be repaired. The bottom layer and the middle layer are removed by partial sand blasting. The coating method of Example 1 is used to re-spray the new bottom layer and middle layer, and then the surface layer is sprayed after curing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com