Flexible circuit board used for LED lamp band and manufacturing method thereof

A flexible circuit board and LED light strip technology, applied in printed circuit manufacturing, circuit substrate materials, printed circuits, etc., can solve the problems of inconsistent expansion and shrinkage ratio of circuit boards, affecting quality, scrapping circuit boards and electronic components, etc. The effect of reducing the production process, improving the patch yield and reducing the production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

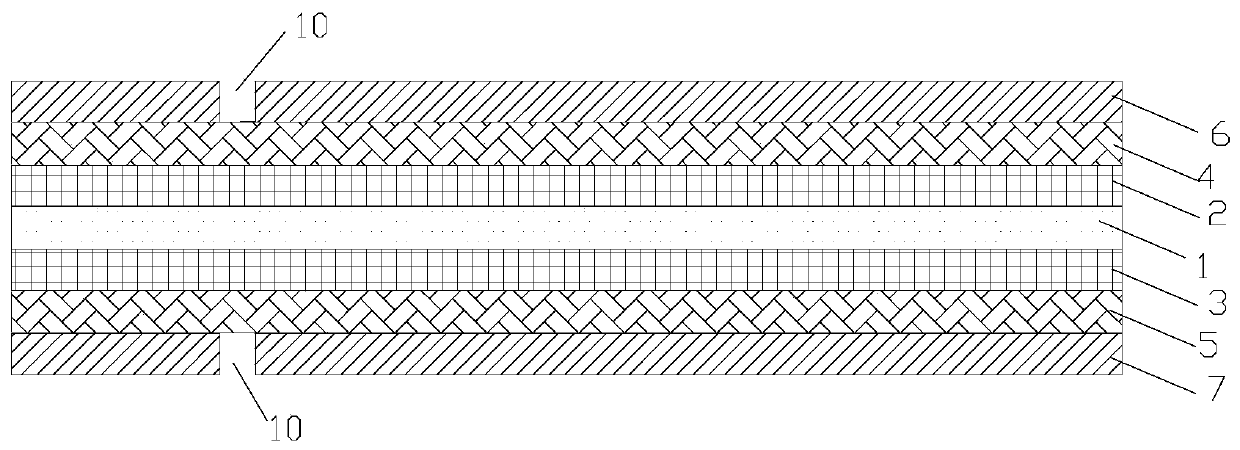

[0043] The above-mentioned preparation method of the flexible circuit board for the LED light strip comprises the following steps:

[0044] S1. Apply insulating glue to the front and back of the PET film layer 1 to form the front insulating adhesive layer 2 and the reverse insulating adhesive layer 3:

[0045] S2. Then paste the aluminum foil on the front and back of the insulating glue, and remove the unnecessary aluminum foil on the front and back through chemical etching or mold cutting or laser ablation according to the pre-designed circuit pattern to form the front circuit layer 4 and the reverse circuit. layer 5;

[0046] S3. Cover the surface of the front circuit layer 4 and the reverse circuit layer 5 with ink or film to form a front cover layer 6 and a reverse cover layer 7. The front cover layer 6 and the reverse cover layer 7 reserve areas for welding electronic components, and part of them is exposed. The front line layer or the back line layer is used as a pad fo...

Embodiment 2

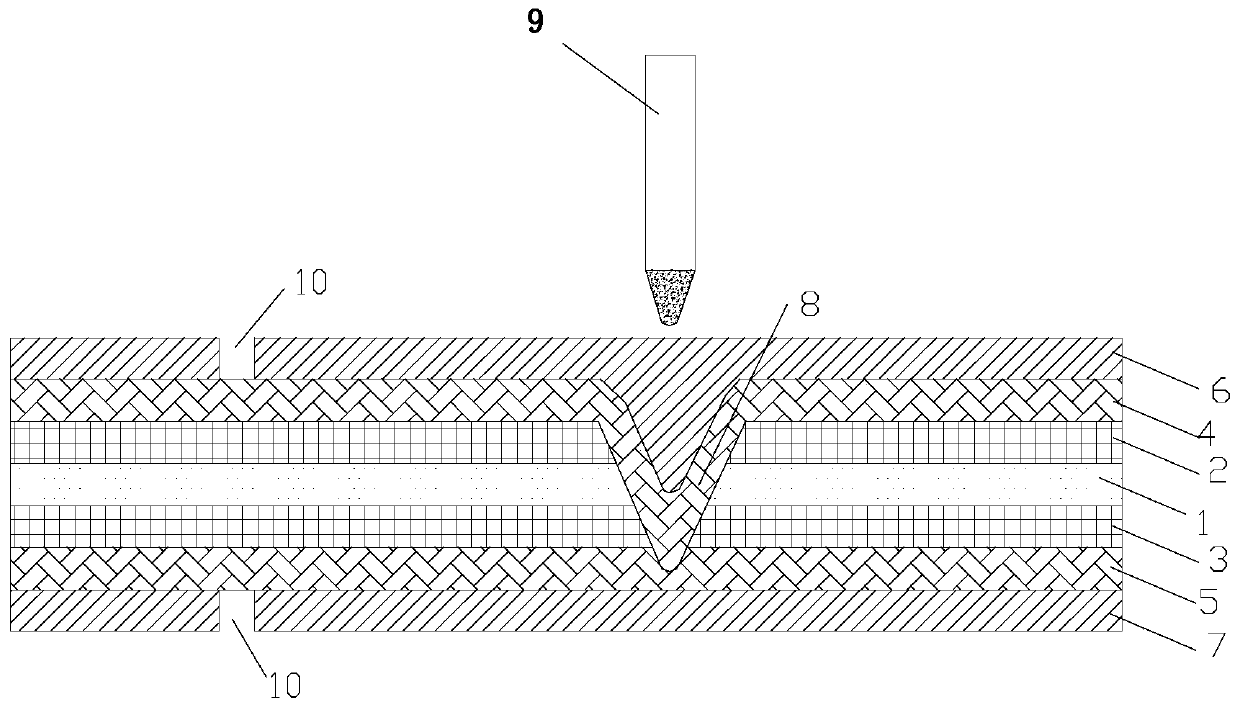

[0049] refer to Figure 2-4 , a flexible circuit board for LED light strips, including a PET film layer 1, the front and back of the PET film layer 1 are coated with a front insulating adhesive layer 2 and a reverse insulating adhesive layer 3, the The front insulating adhesive layer 2 is bonded with a front circuit layer 4, the reverse insulating adhesive layer 3 is bonded with a reverse circuit layer 5, the front circuit layer 4 is provided with a front cover layer 6, and the reverse circuit Layer 5 is provided with a reverse cover layer 7, the front circuit layer 4 and the reverse circuit layer 5 are both aluminum foils with certain ductility, and the front circuit layer 4 and the reverse circuit layer 5 are connected through The hole 8 conducts, and the conduction hole 8 realizes conduction by elongating the aluminum foil of the front circuit layer 4 or the reverse circuit layer 5 and closely contacting the aluminum foil of the reverse circuit layer 5 or the front circuit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com