Automatic centering and clamping device

A clamping device and automatic centering technology, applied in vices, manufacturing tools, etc., can solve the problems of cumbersome assembly and disassembly, difficult to control the mutual position and size, and influence on accuracy, so as to improve the efficiency of research and development, shorten tooling manufacturing, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

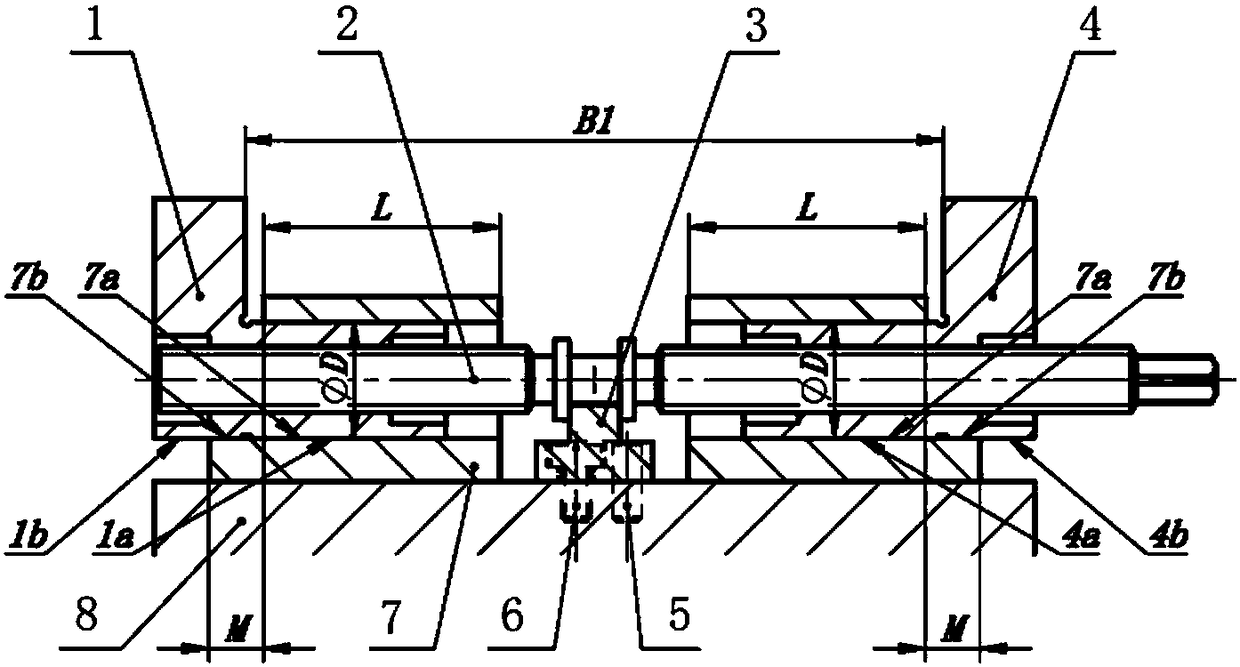

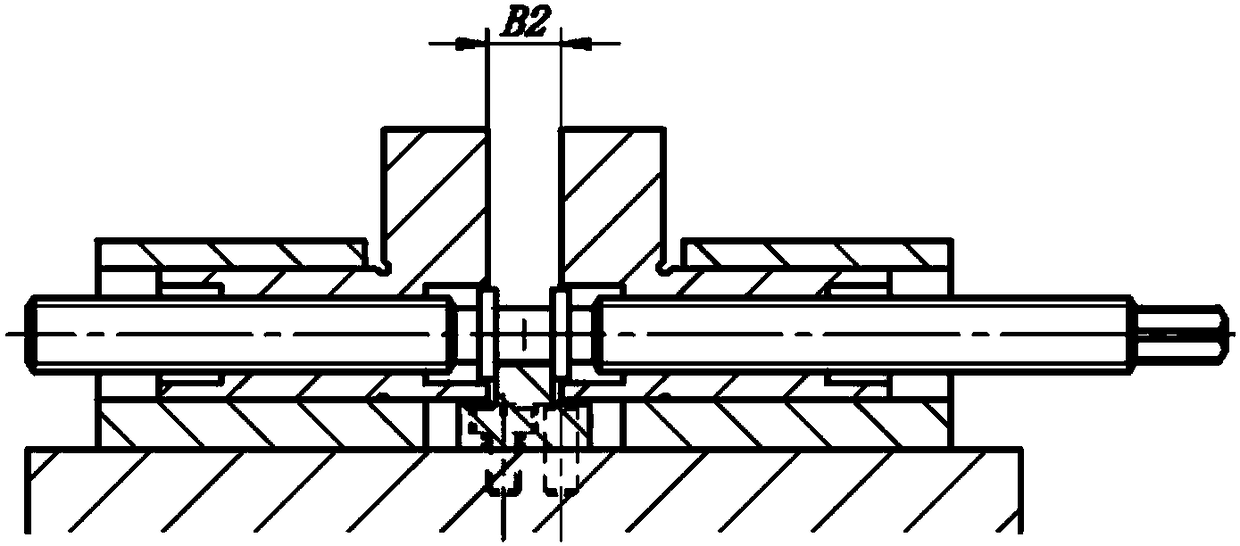

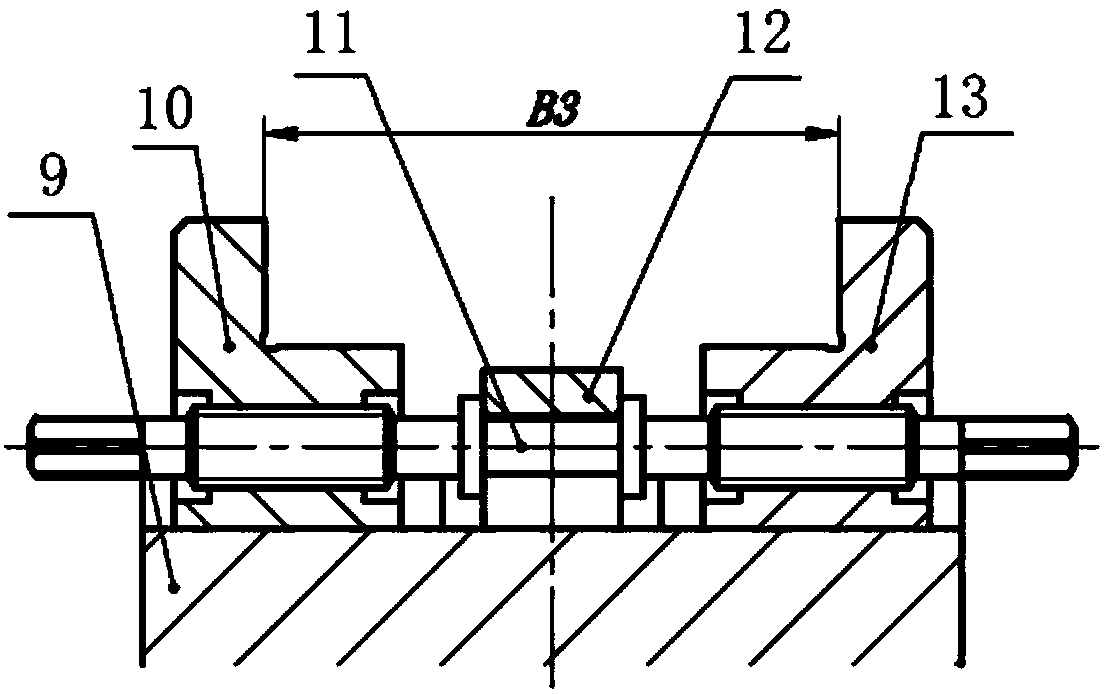

[0029] The technical solution of the present invention is further described below in conjunction with the accompanying drawings, but the scope of protection is not limited to the above.

[0030] Such as Figure 3 to Figure 9 As shown, an automatic centering clamping device according to the present invention includes a bottom plate A9, a left clamping block 10, a double-ended screw A11, a brake block A12, a right clamping block 13, a left guide plate 14 and a right guide plate 15. The left guide plate 14 and the right guide plate 15 are both installed on the bottom plate A by cylindrical pins A16 and screws B19, and the left guide plate 14 and the right guide plate 15 are installed on the bottom plate A9 to form a T-shaped guide groove. The two ends of the double-ended screw A11 are respectively Screw into the left clamping block 10 and the right clamping block 13 to form a component, which is installed in the T-shaped guide groove formed by the guide plate 14 and the right guide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com