Infrared imaging-based on-line dynamic automatic laying defect detection apparatus and infrared imaging-based on-line dynamic automatic laying defect detection method

An infrared imaging and dynamic detection technology, used in material defect testing and other directions, can solve the problems of polluted composite material layup, inability to identify and analyze, and insensitive to layered defects, so as to improve laying, improve quantitative analysis accuracy and save money. The effect of rework time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

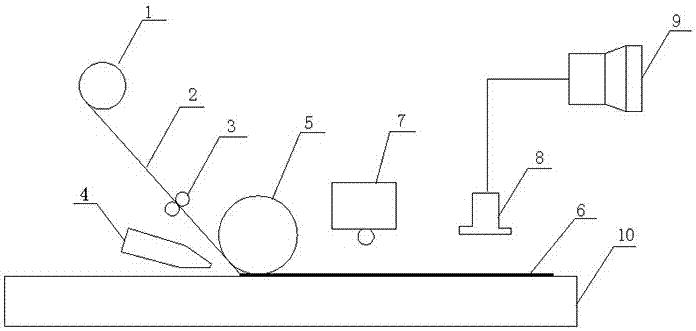

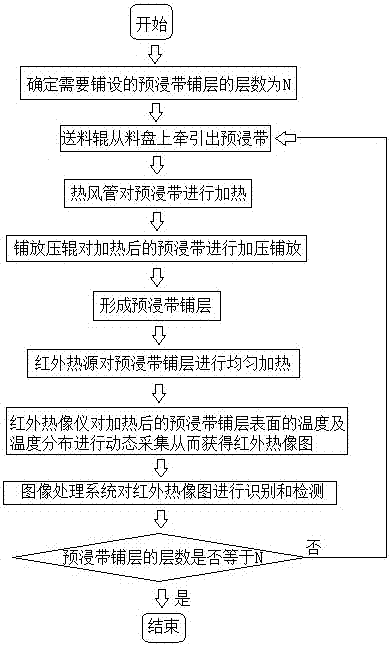

[0025] The following is based on figure 1 and figure 2 The specific embodiment of the present invention is further described:

[0026] see figure 1 , an automatic placement defect online dynamic detection device based on infrared imaging, including a placement device and a defect detection device, the placement device includes a material tray 1, a feeding roller 3, a placement pressure roller 5, a hot air pipe 4 and Lay the mold 10, the defect detection device includes an infrared heat source 7, an infrared thermal imager 8 and an image processing system 9, a prepreg tape 2 is arranged on the tray 1, and the prepreg tape 2 is sequentially connected with the feed roller 3 , the laying pressure roller 5 and the laying mold 10 are connected in transmission, the infrared heat source 7 is arranged above the laying mold 10, the infrared thermal imager 8 is arranged above the laying mold 10, and the The infrared camera 8 is connected with the image processing system 9 .

[0027]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com