Method for detecting diameter of outer wall of tapered case of aviation engine on line

A technology of aero-engine and detection method, applied in the direction of measuring devices, instruments, etc., can solve problems such as prolonging the processing cycle of products, and achieve the effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

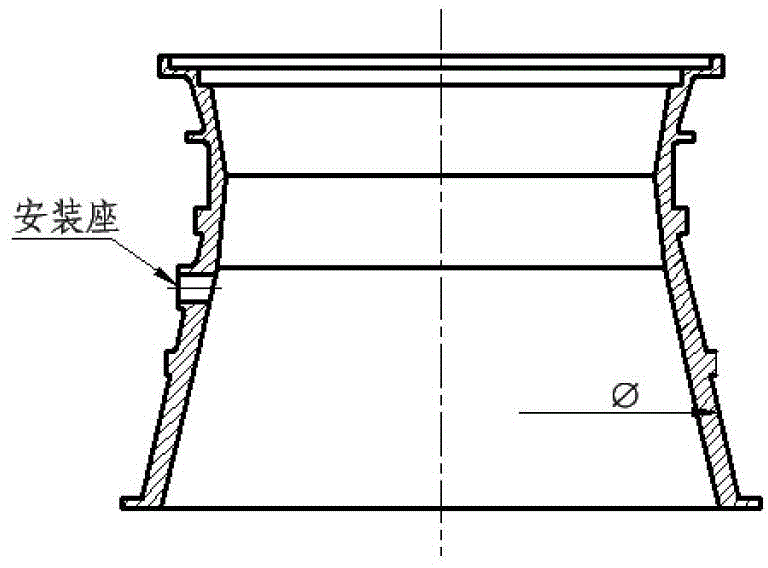

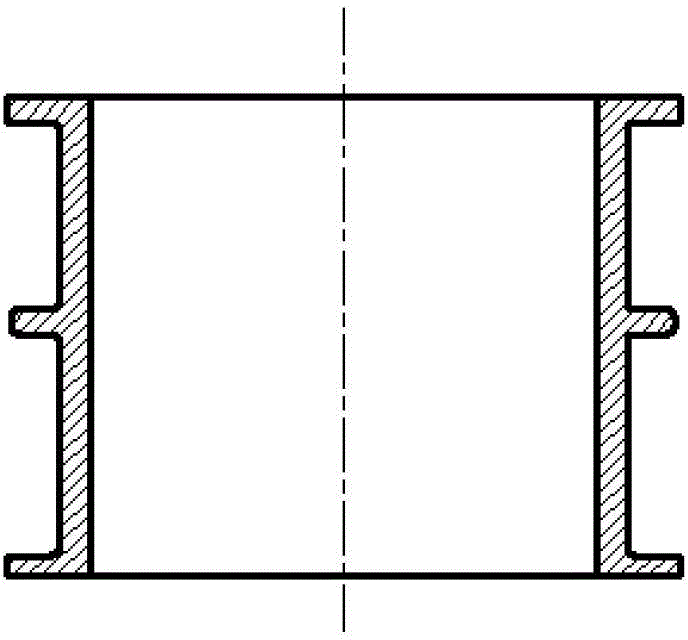

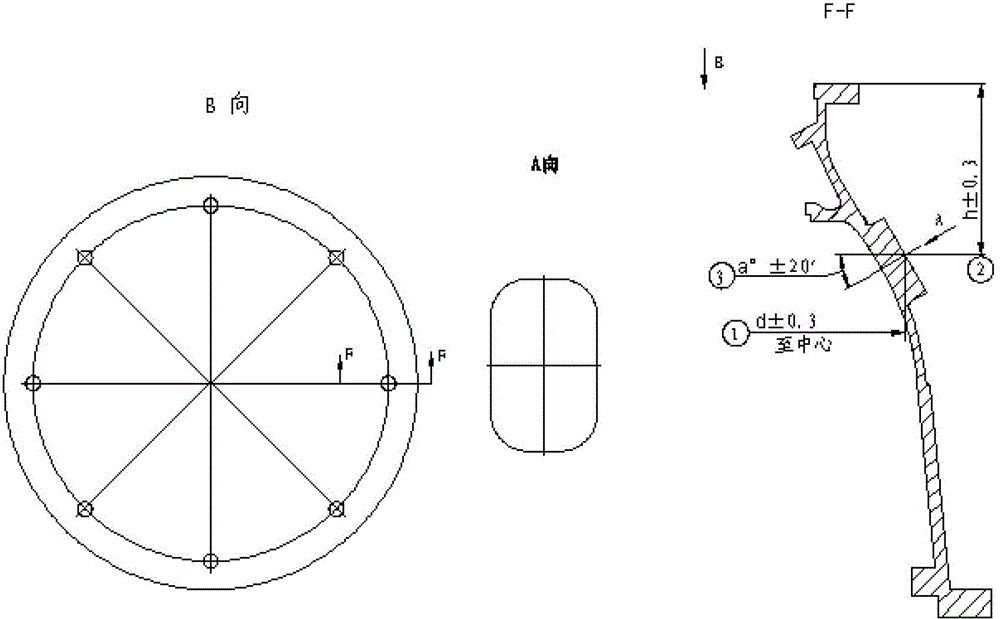

[0081] The invention provides an on-line detection method for the diameter of the tapered outer wall of an aero-engine casing, which is characterized in that: the online detection method for the diameter of the aero-engine casing's conical outer wall is as follows:

[0082] (1) Main components

[0083] (1) Five-coordinate CNC milling machining center equipped with Renishaw MP10 touch probe

[0084] (2) Cone casing parts and mounting seats on the surface of the cone casing

[0085] (3) Probe precision correction ring gauge for online measurement

[0086] (4), measurement method: point contact

[0087] (5) Sinumeric840D online measurement technology of Siemens control system for machine tools, including the following:

[0088] 1) Probe precision calibration technology

[0089] 2) Probe motion trajectory control program and measurement trajectory optimization strategy

[0090] 3) Selection of measurement locations, number of sampling points, and precision control strategies ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com