Integrated equipment used for installation and detection of screws

A screw and equipment technology, which is applied in the field of integrated equipment for screw installation and testing, can solve the problems of laborious inspection and installation for workers, and achieve the effect of simple operation and saving repair time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

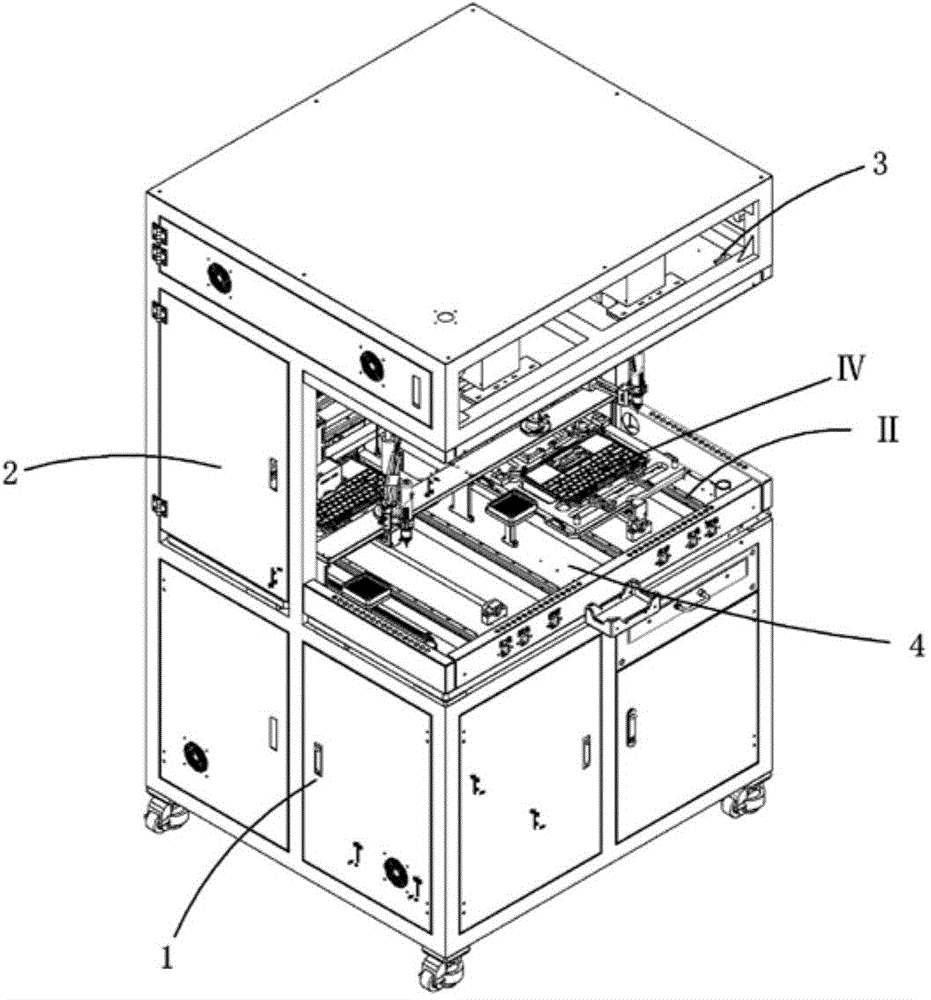

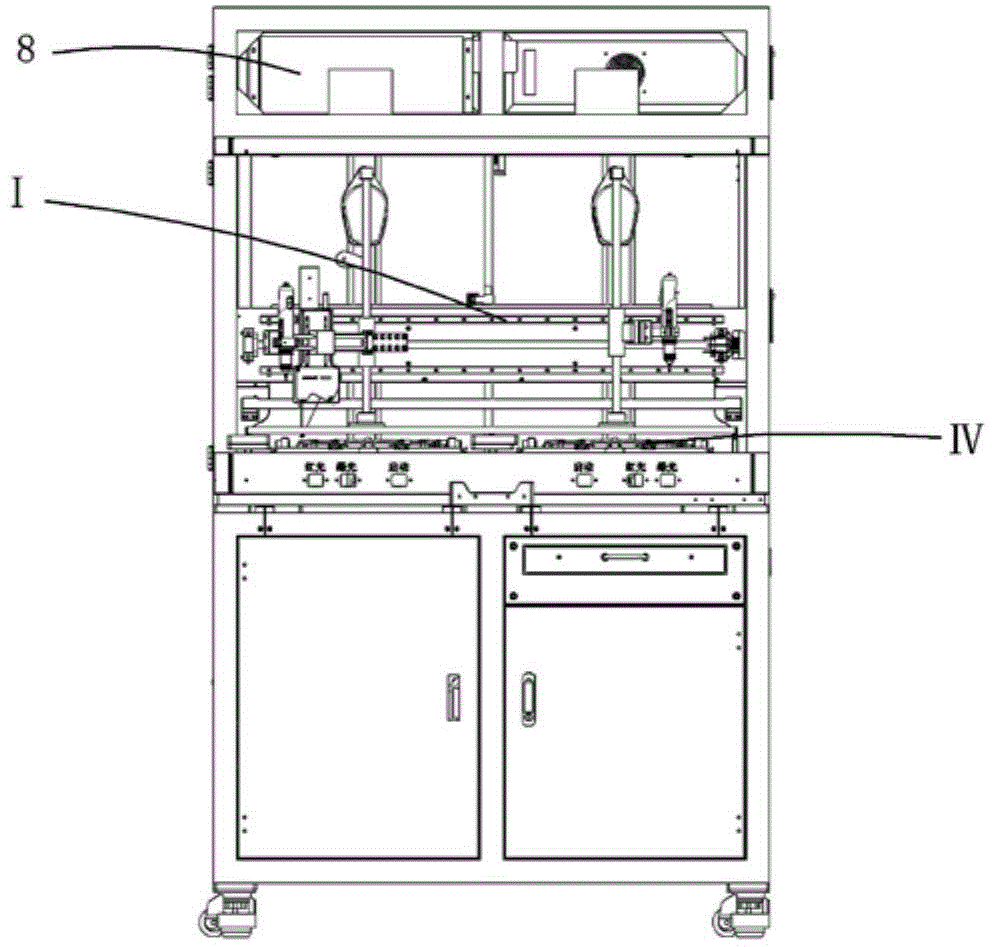

[0033] Examples, see attached Figure 1-12, an integrated device for screw installation and detection, which includes a lower machine base 1, a supporting side plate 2 is respectively installed on the left and right sides of the upper rear end of the lower machine base, and an upper machine is installed on the two supporting side plates. Frame 3, base plate 4 is installed on the upper part of the lower machine base, bases 5 are respectively installed on the left and right sides of the rear part of the base plate, a fixed plate 6 is installed on each base, and the front parts of the two fixed plates are vertically fixed with The fixed vertical plate 7 is reinforced and fixed between the fixed plate and the fixed vertical plate by reinforcing ribs, and the X-axis mechanism I is installed on the fixed vertical plate. Two sets of Y-axis mechanism II are installed on the front part of the base plate; X-axis connecting block and X-axis slider are installed on the X-axis screw connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com