Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

126results about How to "Reduce production processing time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for making stewed duck with bean sauce

InactiveCN101715974ASolve processabilitySolve for uniformityFood preparationBiotechnologyAdditive ingredient

The invention relates to the field of food processing and discloses a method for making a stewed duck with bean sauce. In the invention, injection seasoning technology, vacuum massaging technology and compression marinating technology are integrated into a novel processing technique. The stewed duck with bean sauce made by the invention has the advantages of rich sauce fragrance, tender meat quality, proper elasticity and unique taste. The method overcomes the defects that the traditional stewed ducks with bean sauce cannot be pickled uniformly and the making period is too long, can effectively keep nutrient components in the duck, and can prolong the shelf life of the finished product. The raw materials and making parameters of the method are quantified, so the method can ensure the stable quality of products, facilitates the quality control, and has a prospect for large-scale industrialized production.

Owner:夏威夷

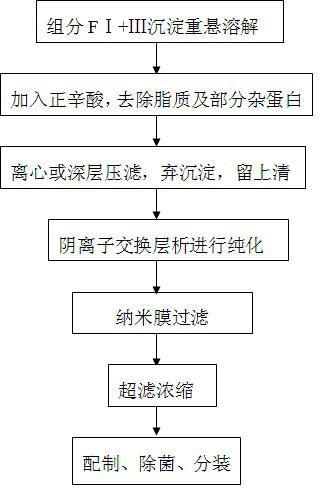

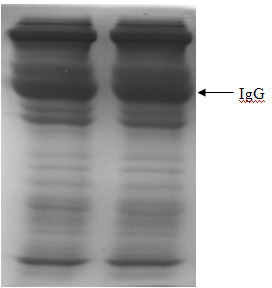

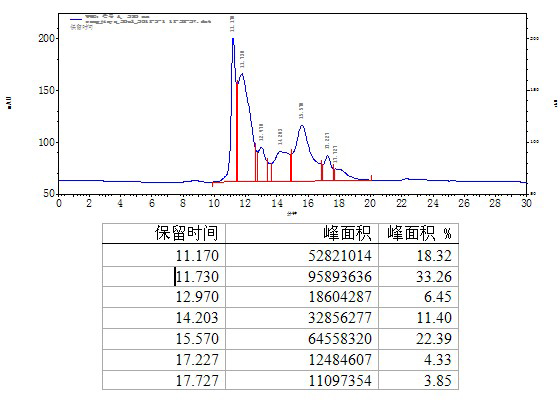

Method for purifying human immunoglobulin from separated component I+III of blood plasma

ActiveCN102250240ARealize comprehensive utilizationAvoid pollutionPeptide preparation methodsImmunoglobulinsBiotechnologyUltrafiltration

The invention relates to a method for separating and purifying human immunoglobulin from a component I+III of blood plasma, and aims to provide a high-efficiency method for recovering high-purity human immunoglobulin. According to the technical scheme provided by the invention, the method comprises the following steps of: a, fully dissolving component I+III precipitate; b, precipitating with octylic acid and removing lipid and a part of impurity protein to prepare IgG (Immunoglobulin G); c, purifying through anion exchange column chromatography; and d, collecting flow-through liquid, performing membrane nanofiltration, ultrafiltration and concentration, preparing the human immunoglobulin, sterilizing and packaging. The method has the beneficial effects of capability of being operated at the room temperature, simple and short steps, high yield, low energy consumption and high output and is suitable for mass production; comprehensive utilization of the blood plasma is fully realized; the time of the entire production process is shortened; the cost is reduced; extremely considerable economic benefit can be produced; the safety of a product is guaranteed by using two virus inactivation / elimination methods of different mechanisms; the environmental pollution is avoided; and the method has high economic and social values.

Owner:SHANDONG TAIBANG BIOLOGICAL PROD CO LTD

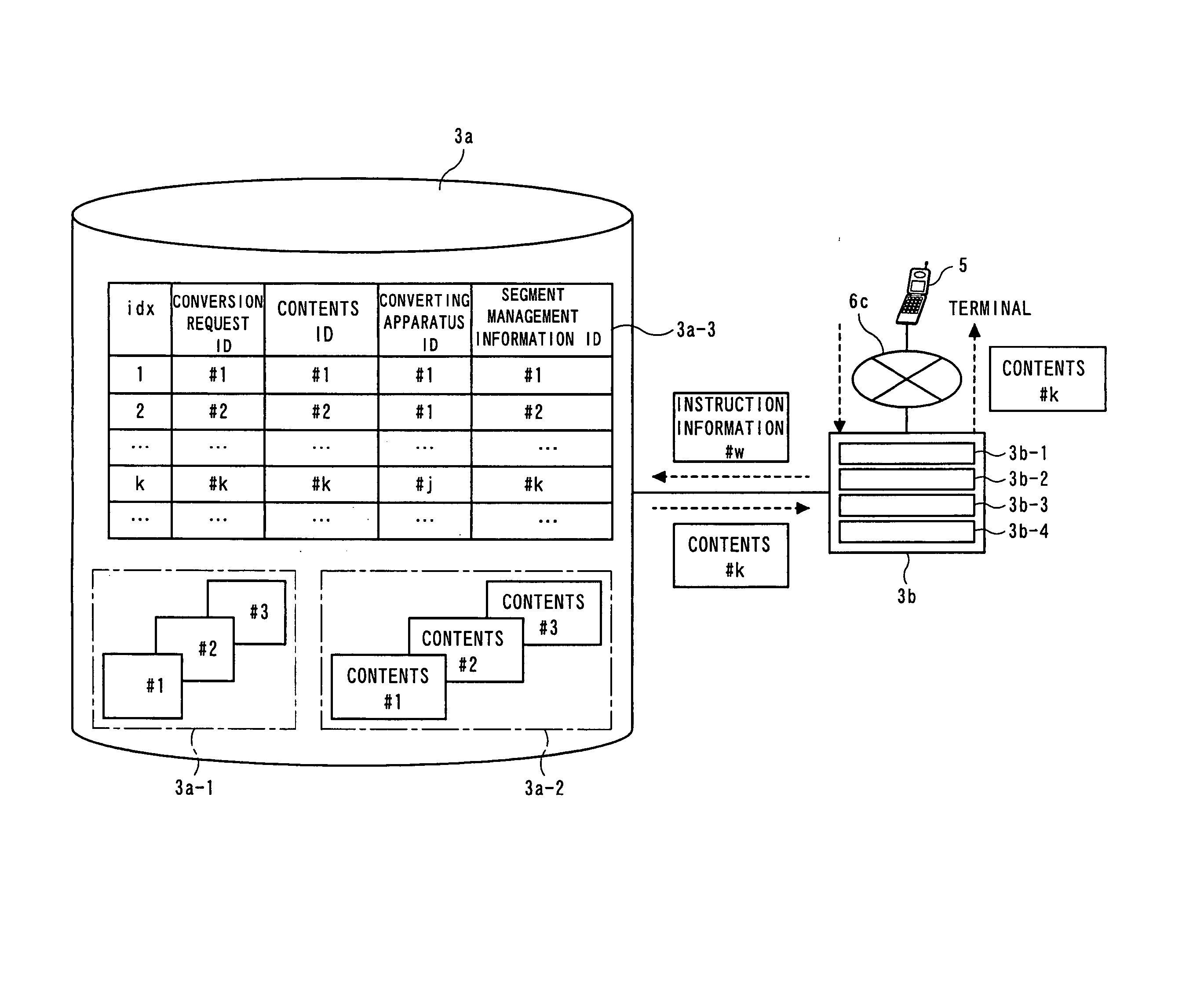

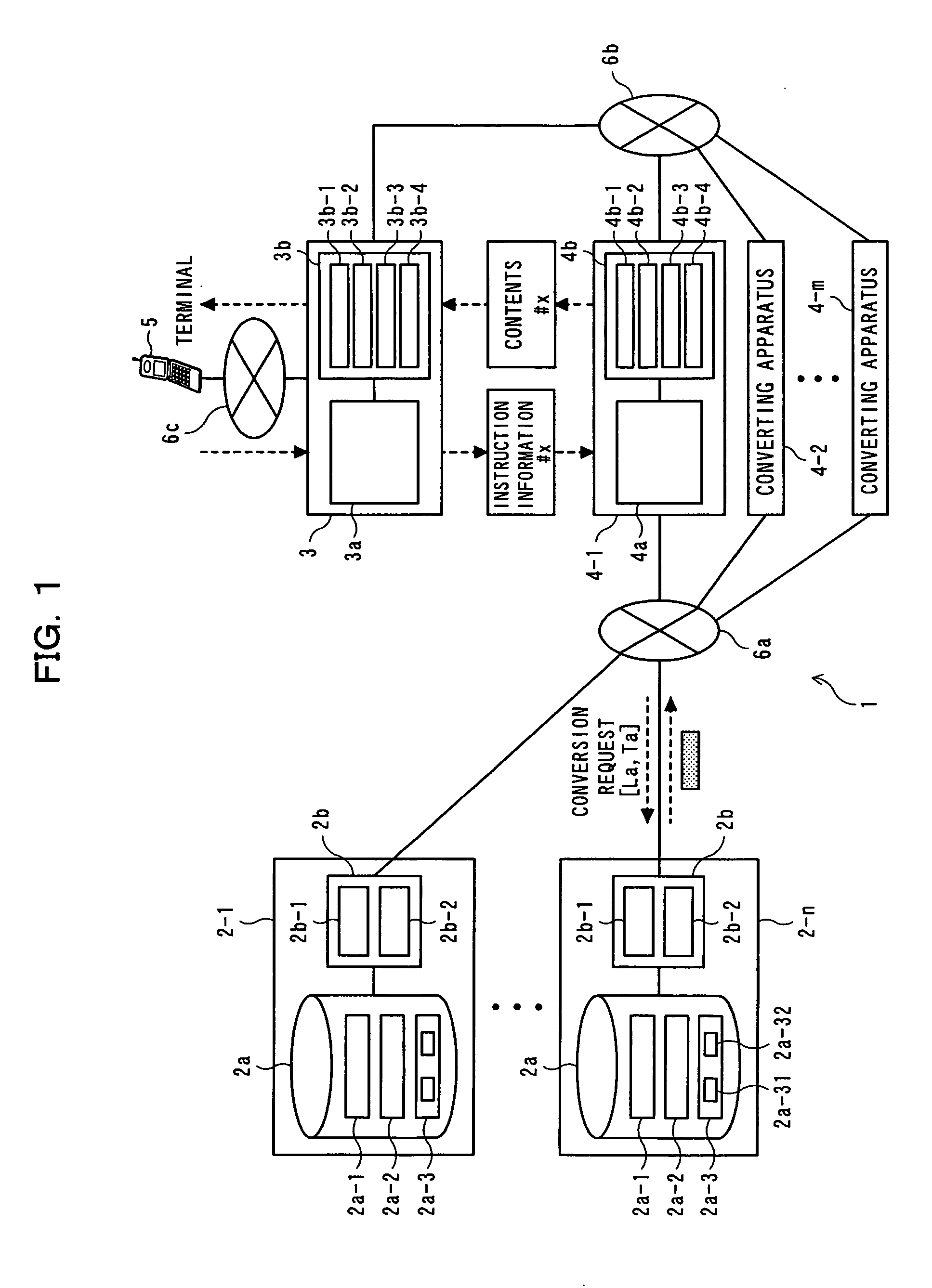

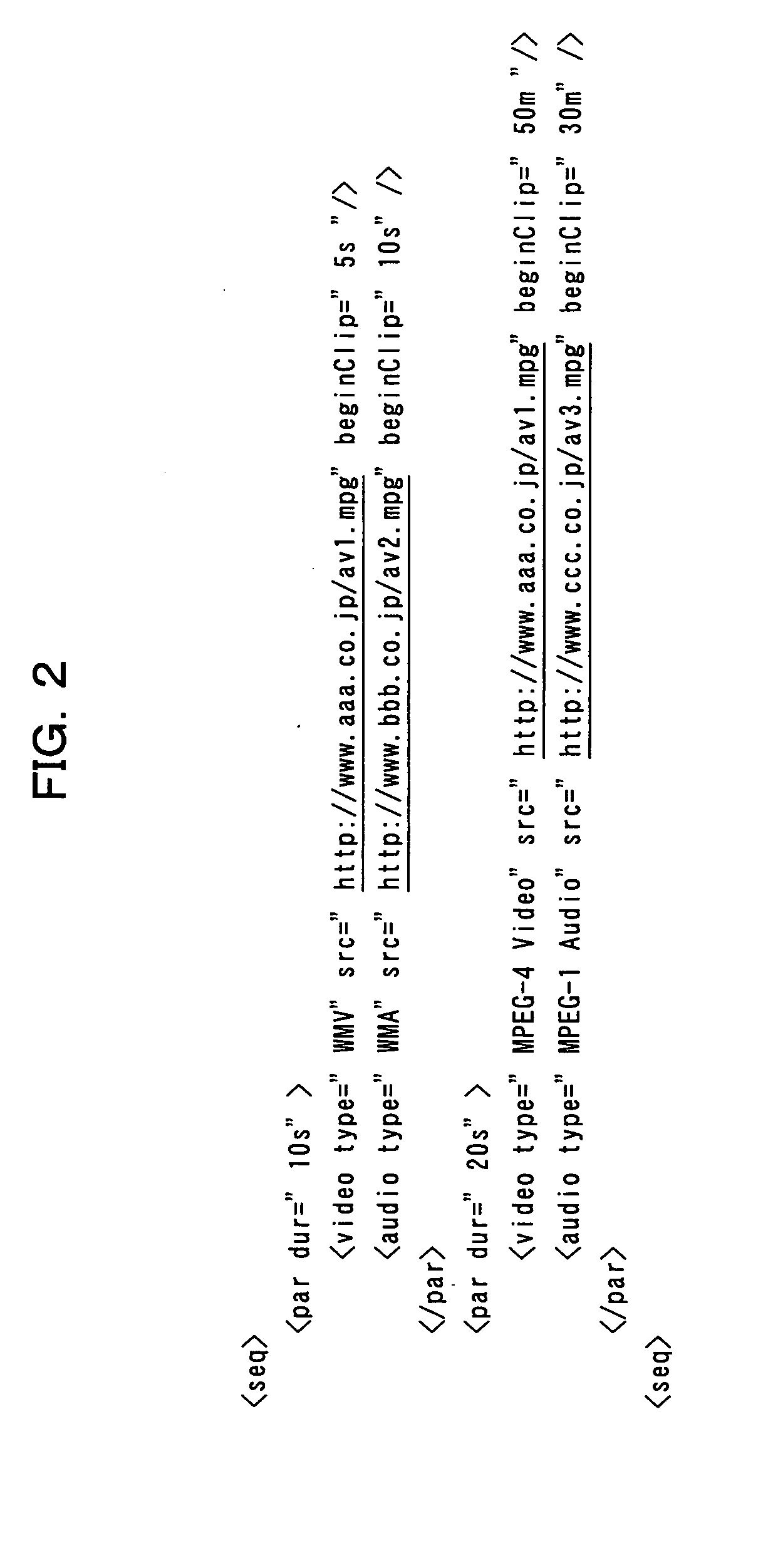

Compound contents delivery method and delivery system

ActiveUS20040267908A1Reduce production processing timeMultiple digital computer combinationsTwo-way working systemsComputer terminalInstruction step

The present invention relates to a compound contents delivery method capable of reducing the network transmission quantity and of distributing the system processing load. The method according to the present invention comprises a compound contents element acquisition step of, in each of contents servers, acquiring a compound contents element undergoing a conversion into an encoding format for a portable terminal in corresponding relation to a contents portion which is an object of a fetching instruction in a contents portion fetching instruction step to return it to an intermediate apparatus and a production step of, in the intermediate apparatus, combining the compound contents elements returned from the contents servers according to time series on the basis of instruction information from a management server to produce compound contents oriented to the portable terminal.

Owner:FUJITSU LTD

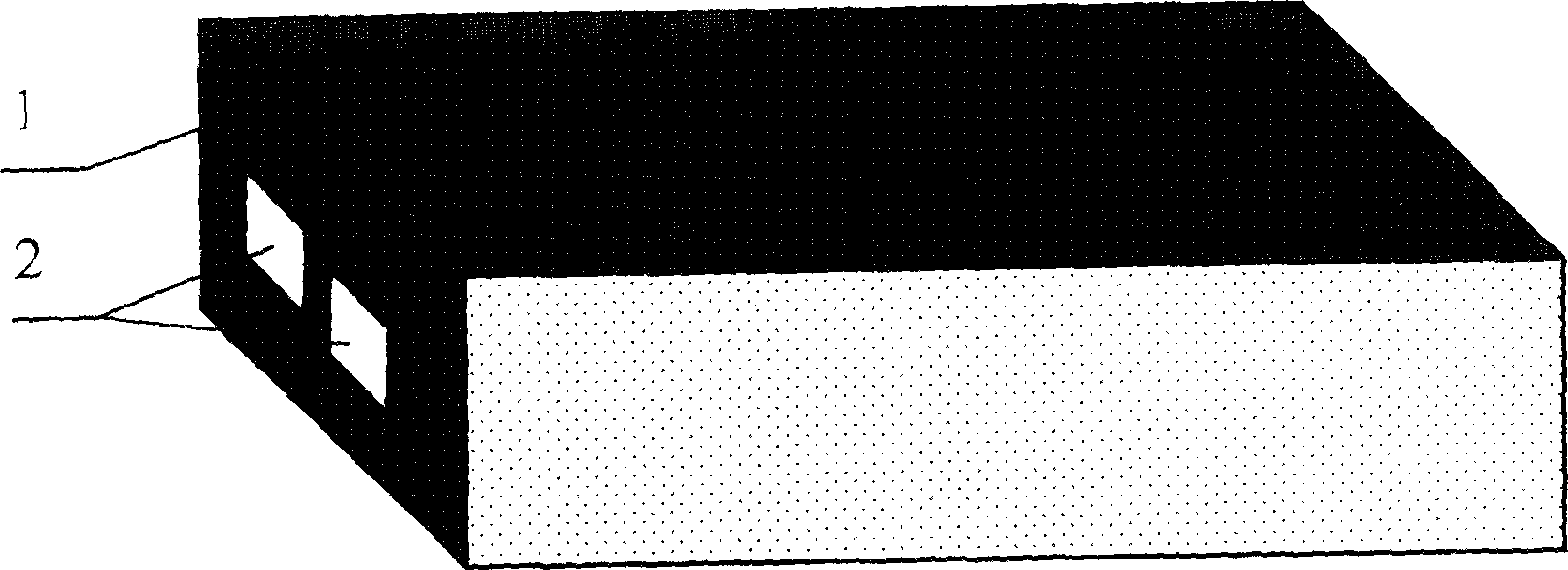

Preparation process for autoclaved curing aerated brick

ActiveCN102875183AReduce production processing timeAvoid crackingSolid waste managementCeramicwareBrickSlag

The invention discloses a preparation process for an autoclaved curing aerated brick. The process comprises the following steps of: weighing fluorite slag powder and gypsum in a weight ratio; adding an appropriate amount of water, stirring and mixing at the speed of 700 to 1,000rpm for 2 to 3 minutes, and grinding to obtain fluorite slag powder and gypsum mixed slurry; adding the residual raw materials which are required by preparing the aerated brick in a weight ratio, stirring and mixing at the speed of 2,000 to 2,800rpm for 3 to 5 minutes; pouring the obtained mixed slurry into a mould and forming; precuring at the temperature of between 40 and 50 DEG C for 1 to 3 hours; demoulding; lifting to a cutting part and cutting to obtain a brick blank; and putting the brick blank in a reaction kettle, performing autoclaved curing and putting in storage. The raw materials are mixed according to an optimized formula; and the intensity and the freezing resistance of the brick are improved obviously.

Owner:日照百固特新型建材有限公司

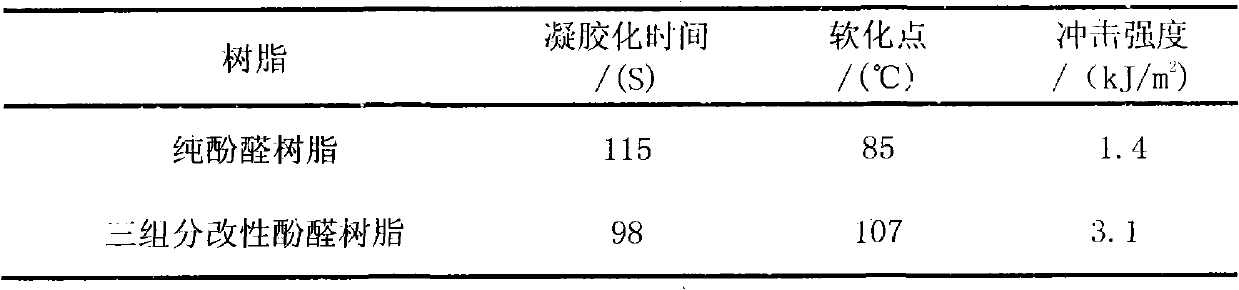

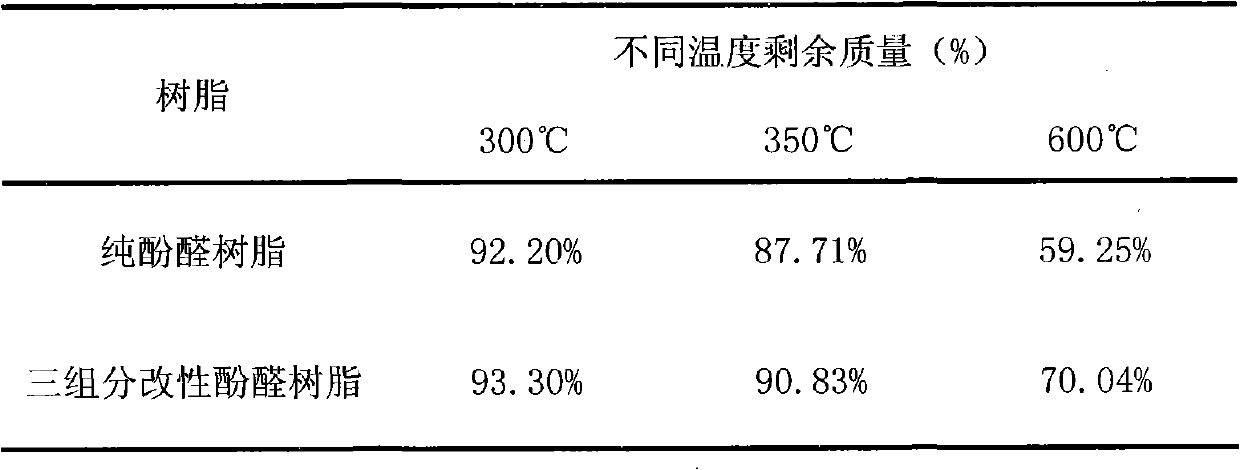

Boron, nano-montmorillonite and nitrile-butadiene rubber modified phenolic resin and preparation method thereof

The invention relates to a boron, nano-montmorillonite and nitrile-butadiene rubber modified phenolic resin and a preparation method thereof, and the boron, nano-montmorillonite and nitrile-butadiene rubber modified phenolic resin comprises the following raw materials in parts by weight: 100 parts of phenol, 60-80 parts of aldehyde, 0.5-10 parts of catalyst, 0.5-20 parts of boron-containing substance, 0.5-20 parts of nano-montmorillonite and 0.5-10 parts of nitrile-butadiene rubber. The phenolic resin is modified for three times, thereby improving the heat resistance, the toughness and the abrasive resistance of the phenolic resin and completely being capable of serving as an adhesive for friction materials.

Owner:BEIJING UNIV OF CHEM TECH

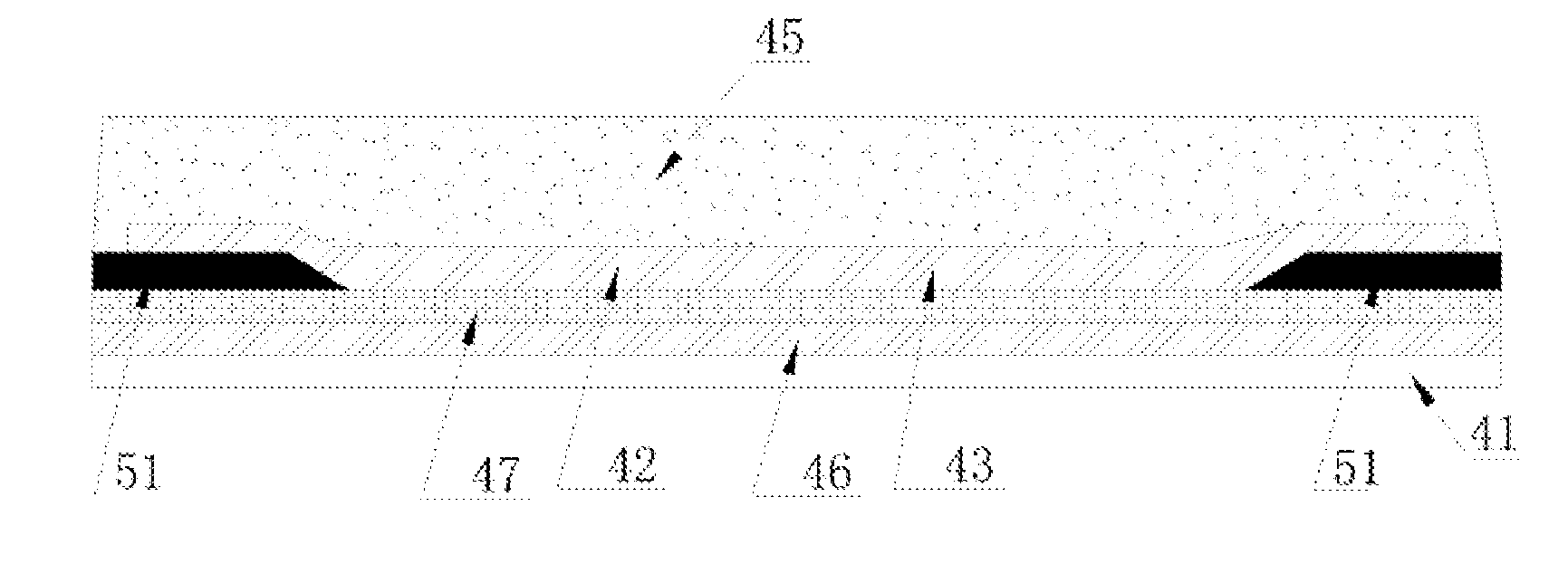

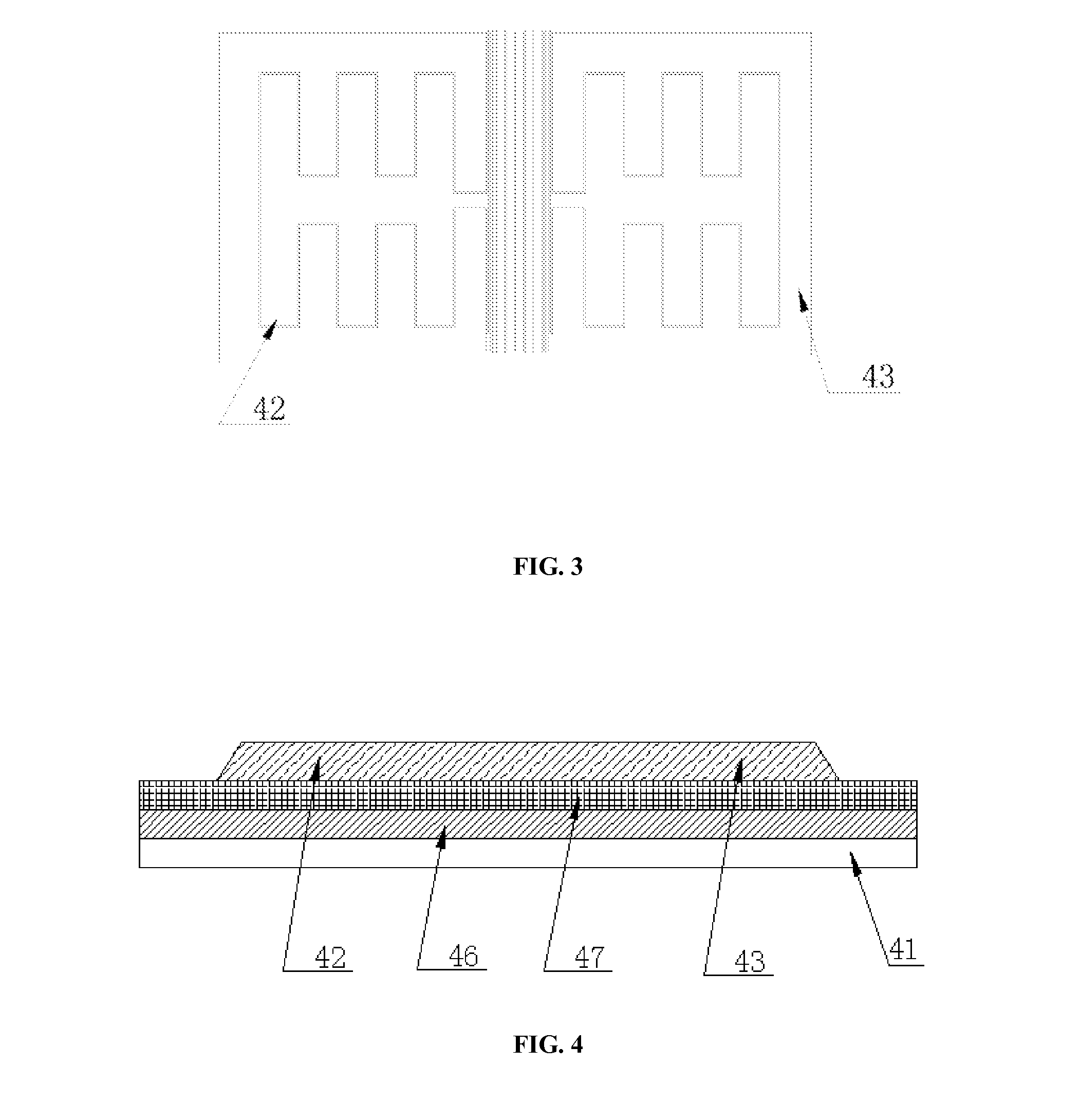

Non-overlapped integral capacitive touch screen with ITO (indium tin oxide) layer and manufacturing method thereof

InactiveUS20150234494A1Improve transmittanceEnhance reliabilityLayered product treatmentDigital data processing detailsTransmittanceVisibility

Disclosed are a non-overlapped integral capacitive touch screen with an ITO (indium tin oxide) layer and the manufacturing method thereof. The non-overlapped integral capacitive touch screen with the ITO layer comprises a transparent substrate, and a silicon dioxide layer, a niobium pentoxide layer, a black resin layer, ITO electrodes and an insulating layer sequentially laminated on the transparent substrate. The silicon dioxide layer convers the transparent substrate completely, and the niobium pentoxide layer covers the silicon dioxide layer completely. The ITO electrodes are horizontally or vertically conductive electrodes having regular graphic structures. The ITO electrodes include the first ITO conductive electrode and the second ITO conductive electrode, and the first ITO conductive electrode and the second ITO conductive electrode are positioned on the same plane, independent and insulated mutually and are staggered. The transparent substrate comprises a windowing region and a non-windowing region, and the black resin layer covers the non-windowing region of a display screen. Since the laminated structure of the capacitive touch screen is designed reasonably, transmittance of the capacitive touch screen is improved effectively, visibility of ITO graphics is lowered, and reliability of the touch screen is improved further.

Owner:SHENZHEN BAOMING TECH

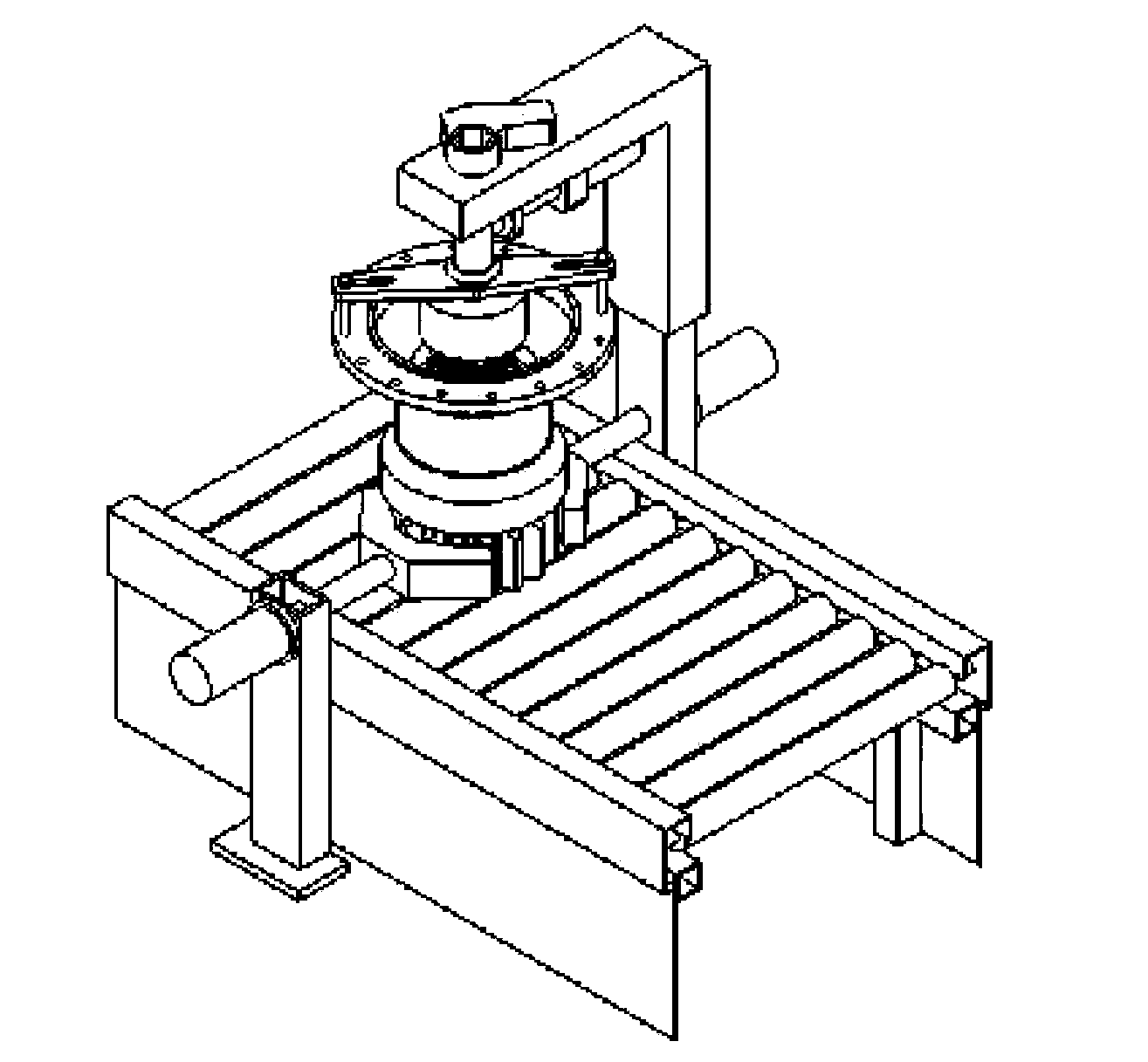

Device for tightening and assembling circular nut on output shaft of planetary gearbox and testing torque

ActiveCN103846669AReduce production processing timeWork measurementTorque measurementReduction driveTransducer

A device for mounting and fastening a circular nut on an output shaft of a planetary gear reducer and measuring the moment of resistance of the output shaft mainly comprises a wrench frame column, a wrench holder, a circular nut torque wrench, a hydraulic wrench, a turnover device cylinder body, a turnover device fixture, a reducer torque transducer, a bevel gear, a pull rod fixing frame, a pull rod and the like. Through the adoption of the device, the circular nut can be mounted on the output shaft of the planetary gear reducer without manual striking any longer, the mounting process is enabled to be simpler and faster, and the damage to the nut during striking is reduced, so that the production process is improved. The device also has the advantages of high reliability, convenience in use and improvement of production efficiency.

Owner:南京恒誉名翔科技有限公司

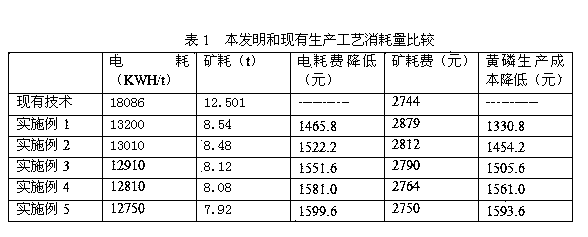

Energy-saving method for preparing yellow phosphorus from low-quality phosphate ore

InactiveCN103466573AShorten drying timeReduce production processing timePhosphorus compoundsPhosphoriteProcess engineering

The invention discloses an energy-saving method for preparing yellow phosphorus from low-quality phosphate ore. According to the method, phosphate ore with P2O5 content of less than 25% is taken as raw material, the drying process is carried out before the balling process in the production process, and the yellow phosphorus reduction production can be carried out after the balling process. The method overcomes the defects in the prior art, complies with the sustainable development policy of China, and comprises the steps of firstly, before baling, carrying out flash drying on wet concentrate after washing, carrying out dynamic calcination, namely, thoroughly burning the phosphate ore, then balling and carrying out reduction treatment to obtain the yellow phosphorus. The method is in accordance with the policies of energy conservation and emission reduction in China, is minimum in energy consumption and lowest in cost on the existing basis, utilizes the phosphate ore to the utmost extent, and solves the problems that the prior art is more in energy consumption and high in production cost, and is not in accordance with the policies of energy conservation and emission reduction in China.

Owner:罗宗恬

Method for extracting vanadium from vanadium-containing ferrophosphor

The invention discloses a method for extracting vanadium from vanadium-containing ferrophosphor. In the method, vanadium-containing ferrophosphor is used as a raw material, and mixed with Na2CO3 and CaX (such as CaO) to be roasted at one time, the roasted product is leached in water, the leaching solution contains vanadium, a vanadium-containing fine solution is obtained after removing phosphor from the leaching solution with a phosphor-removing agent, and the fine solution is used to extract vanadium to obtain high-purity vanadium pentoxide. The method has the advantages that: the productionprocess is simple and free from coating; a lower ratio of phosphor to vanadium is achieved to reduce the loss of vanadium in the phosphor removal process; the production cost is low, and the investment is small; the method is suitable to extract vanadium from vanadium-containing ferrophosphor with different ingredients; and the leaching rate of the vanadium can reach 80 to 85 percent.

Owner:HONG JING ENVIRONMENT

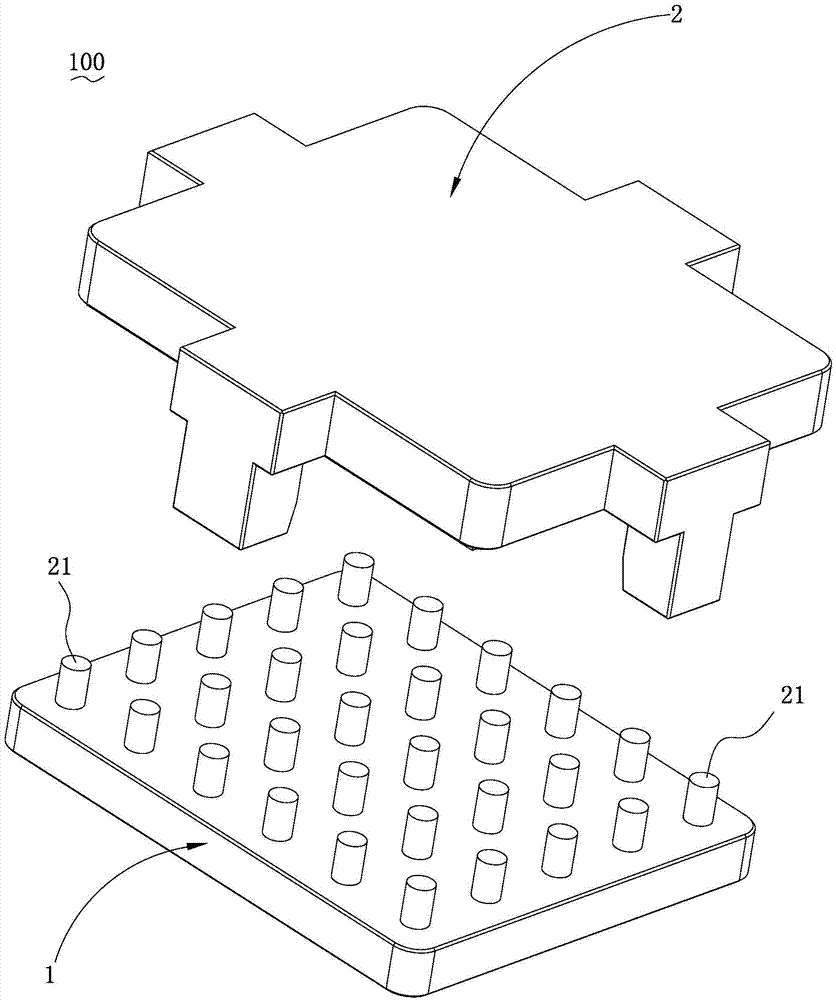

Jig and method of using jig for machining camera lenses

InactiveCN104493711AReduce manual interventionGuaranteed DimensionsEdge grinding machinesGlass severing apparatusNumerical controlEngineering

The invention is applicable to the technical field of lens machining and provides a jig and a method of using the jig for machining camera lenses. The jig comprises a first jig and a second jig, the first jig is provided with grooves used for placement of to-be-machined lens materials, and ejector pins vertically extend at positions, corresponding to the grooves, of the second jig and can be embedded in the corresponding grooves. The to-be-machined lens materials are placed on the jig, the jig can be fixed by a CNC (computer numerical control) machine tool by means of vacuum suction due to the fact that the size of the jig is larger than that of the lens materials, and accordingly CNC machining can be carried out. By means of the CNC machining process, adoption of a profiling machine for profiling and a beveling machine for beveling in the traditional process is replaced, and manual intervention is reduced; in addition, owing to precision of CNC equipment, profiling and beveling procedures can be completed on the lens materials for one time by the aid of a CNC tool, and product production time is shortened while production efficiency and product yield are increased on the premise that external dimensions of products are guaranteed.

Owner:深圳市尊宝精密光学有限公司

Lean making method for Goodyear seam shoes

The invention discloses a lean making method for Goodyear seam shoes. The method comprises the steps that all components of a shoe body are divided into standard components, namely a vamp, a welt, an insole, a packing layer and an outsole; the vamp, the welt and the insole are sewn into a whole; the packing layer and the outsole are mounted, and then a Goodyear seam shoe is made through a heat setting process and a cold setting process. According to the lean making method, five processes including upper clamping, nail pulling, upper foot cutting, grinding and upper bottom bonding in the traditional art are omitted, production cost is lowered, investment of personnel is reduced, the making process is simplified, and more consumers can put on the novel Goodyear seam shoes which are firm and durable; besides, a whole plastic piece is used as the packing layer of the insole, and the insole is more comfortable than a traditional insole filled with cork; moreover, bonding through mucilage glue is not needed, so that time and labor are saved, and environmental friendliness is achieved.

Owner:KANGNAI GROUP

Method for preparing wood plastic composite material sections with embossing

The invention discloses a method for preparing wood plastic composite material sections with embossing, which has the advantages that: an embossing processing procedure is increased between shaping processing and cooling processing; the sections subjected to shaping processing are still in a softened and molten state, an embossing die arranged between a shaping die and a cooling water tank is used for performing embossing processing on the sections subjected to shaping processing, and the embossed sections are subjected to subsequent cooling, so crusts formed in the process of cooling the wood plastic composite material sections cannot be damaged; therefore, the excellent mechanical properties of the wood plastic composite material sections can be kept. Because the embossing die arranged between the shaping die and the cooling water tank is used for embossing processing, the sections are not needed to be conveyed by manpower in the embossing process, and are conveyed through mechanical transmission so as to greatly save manpower; and the product extruding and embossing are synchronously carried out, so the production and processing time is greatly saved, and the production cost iseffectively saved.

Owner:宁波维卡绿建科技有限公司

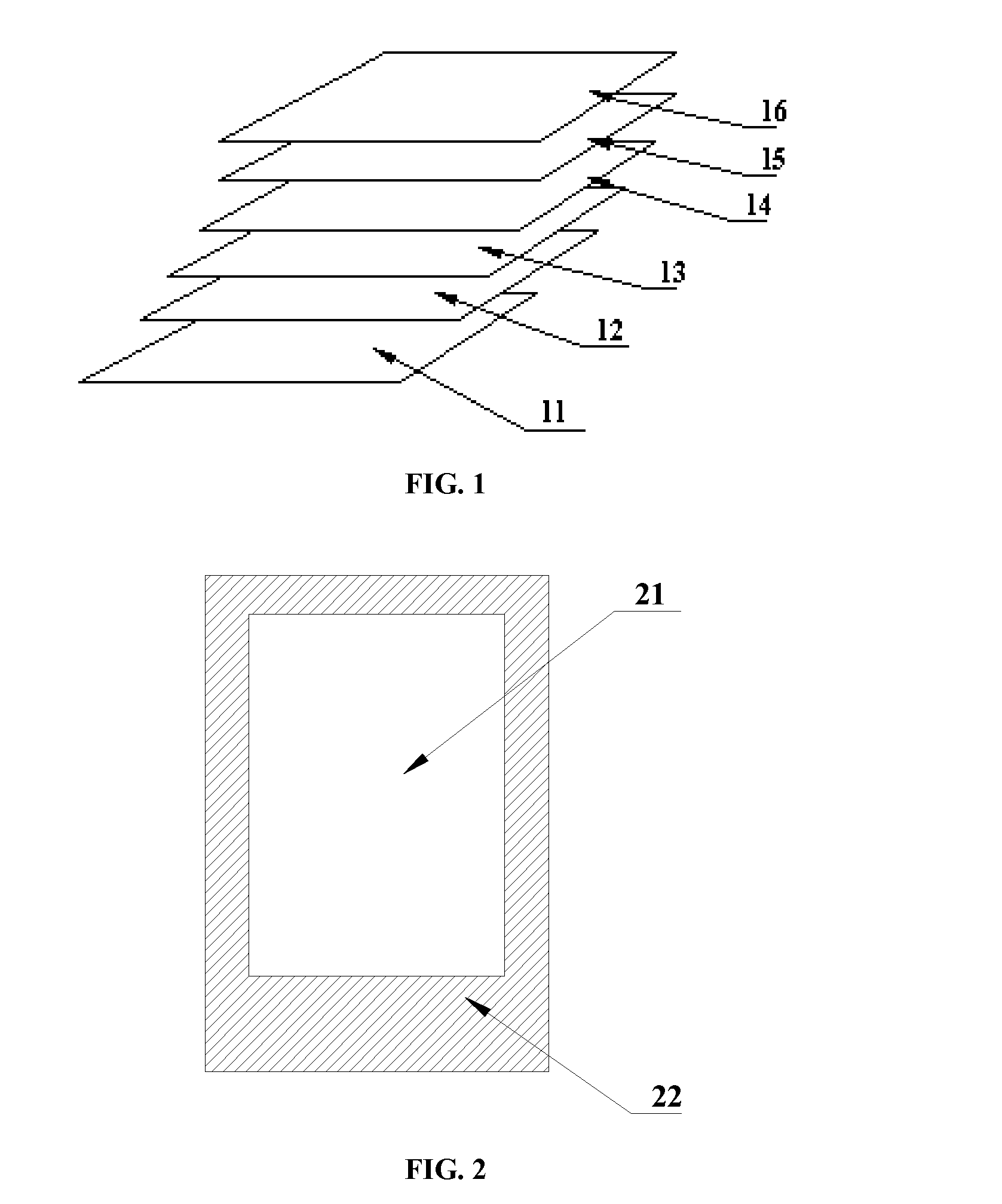

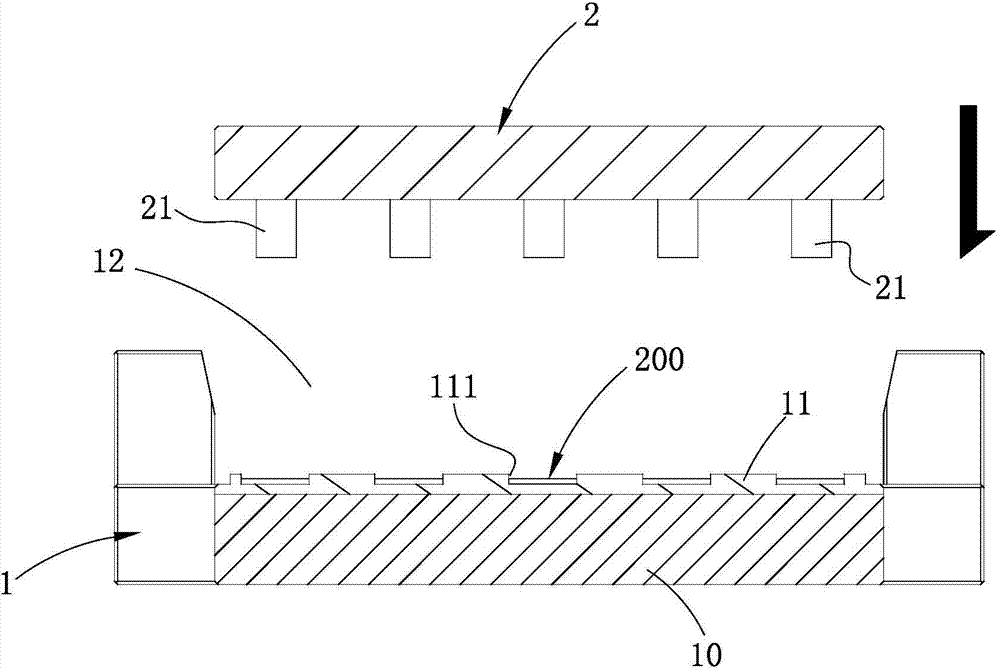

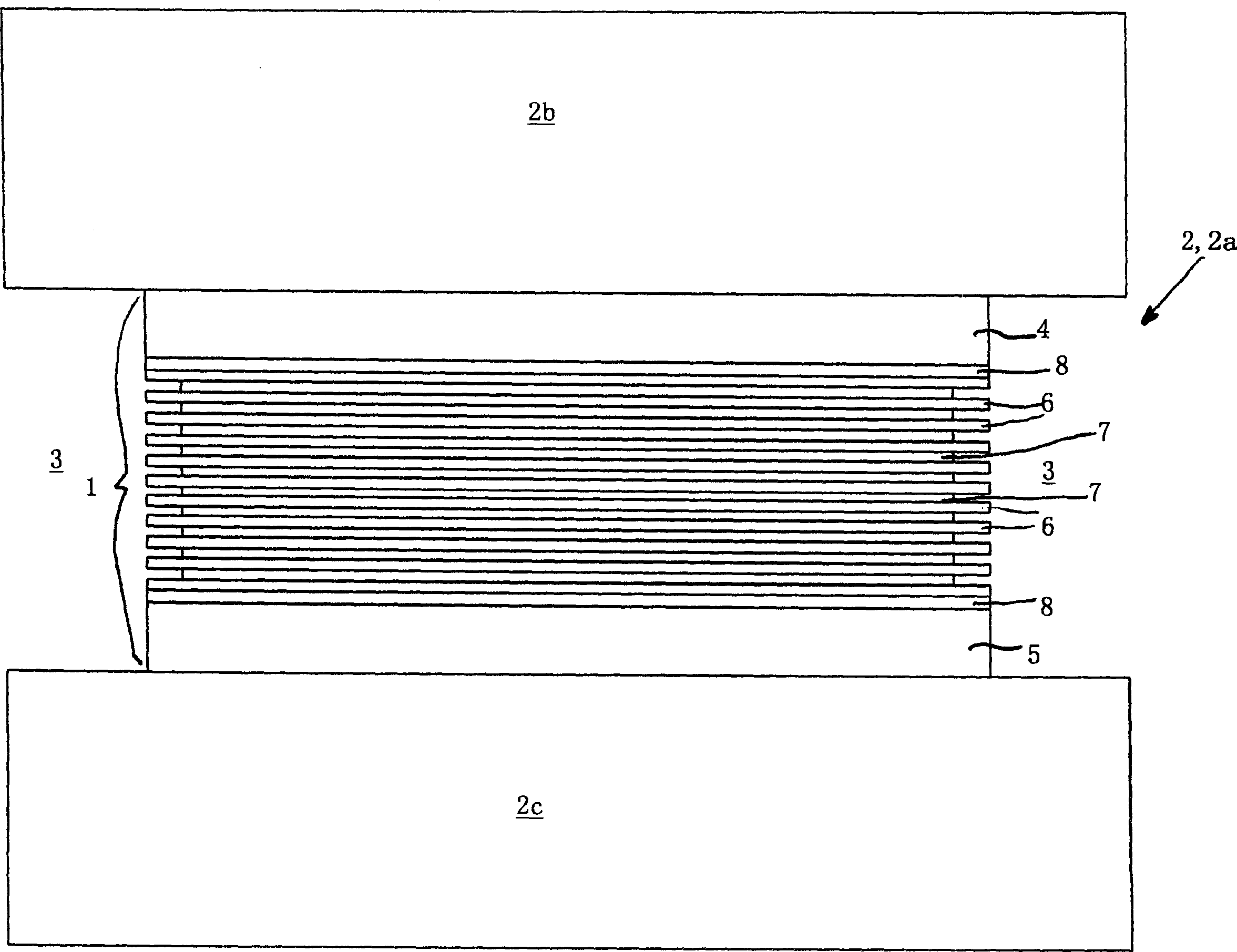

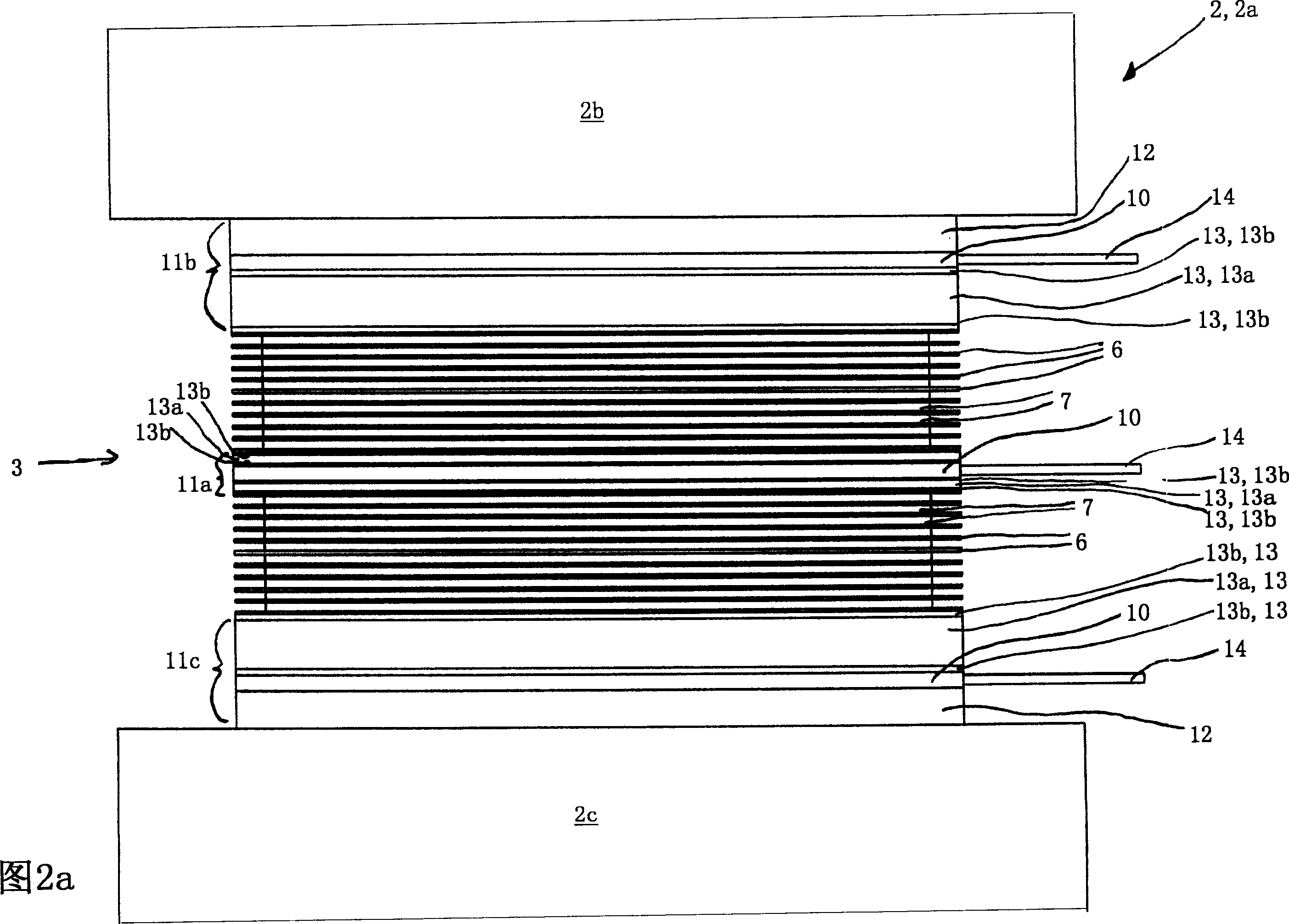

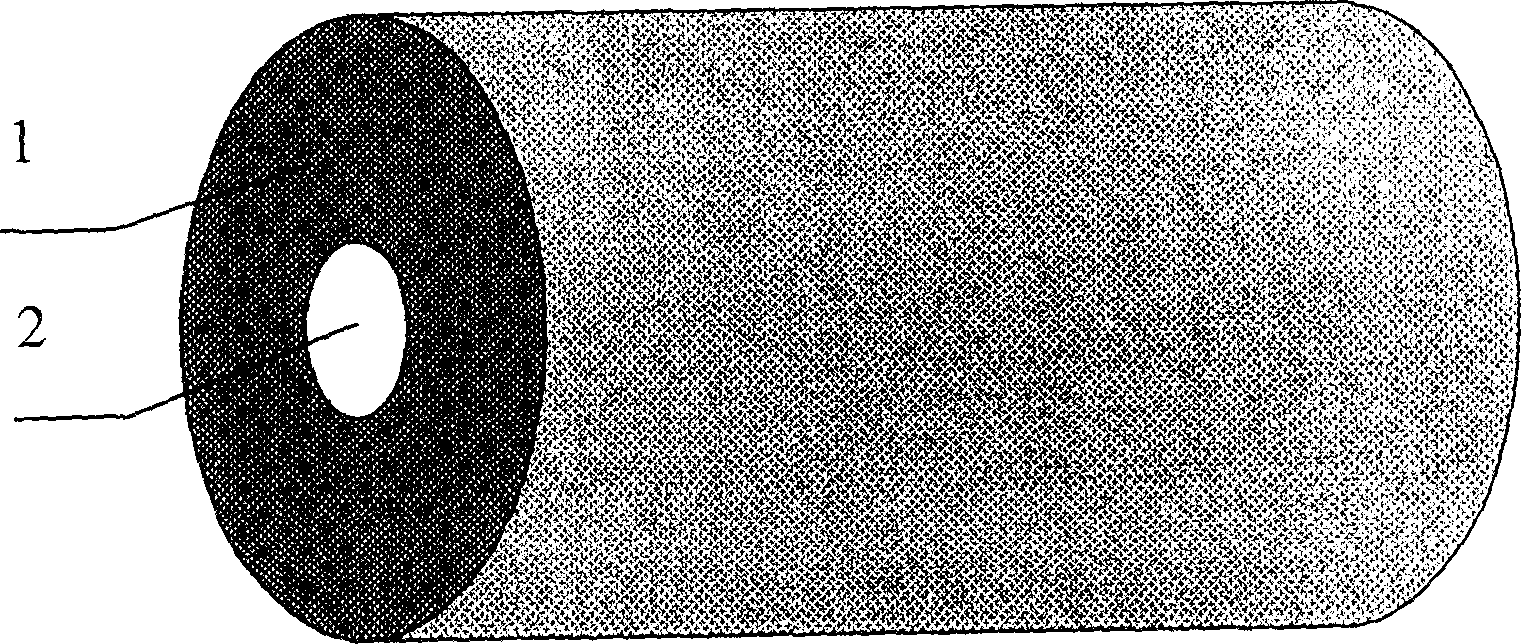

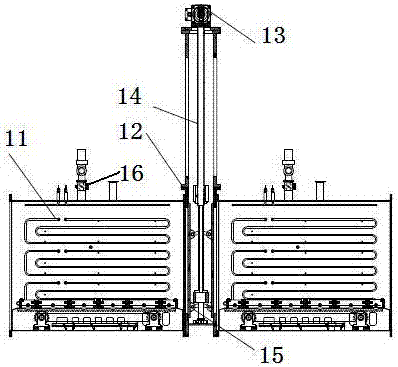

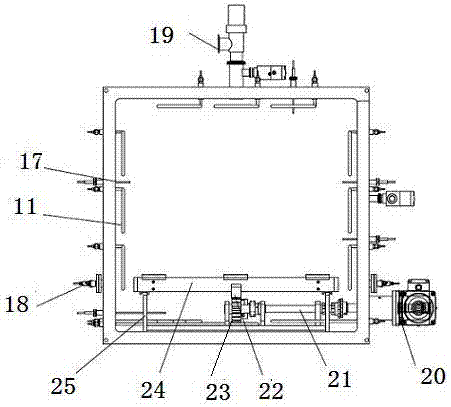

Multilayer press packet, packet structure and multilayer, tool and press for pressing multilayer

InactiveCN1899809AEven heat distributionFast and even heatingLaminationLamination apparatusEngineeringMachine press

The invention relates to a tool (11a, 11b, 11c) for pressing a multilayer press packet (1b), particularly for placing inside a press (2), preferably for inserting into the insertion opening (3) of a multiplaten press (2a). The multilayer press packet (1b), in particular, has a number of multilayers (7) that are separated from one another by at least one separating plate (6). Advantages are achieved by virtue of the fact that the tool (11, 11b, 11c) can be electrically heated. To this end, at least one electrically operable heating element (10) is provided.

Owner:M·巴克豪斯

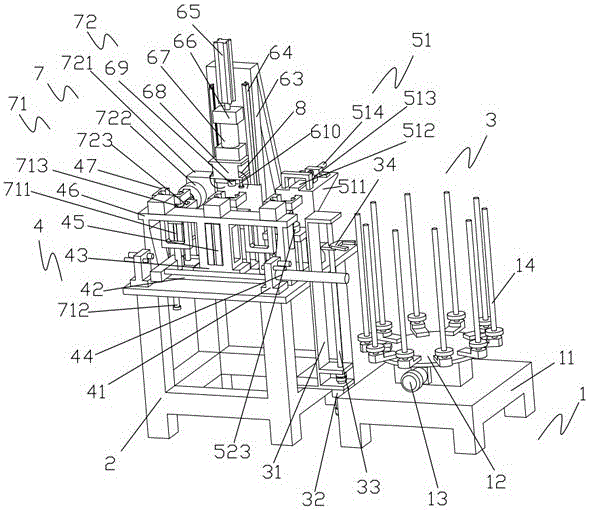

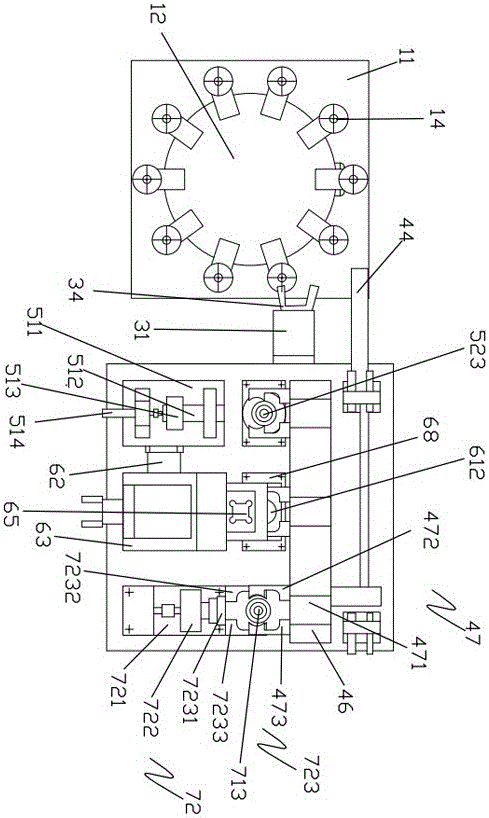

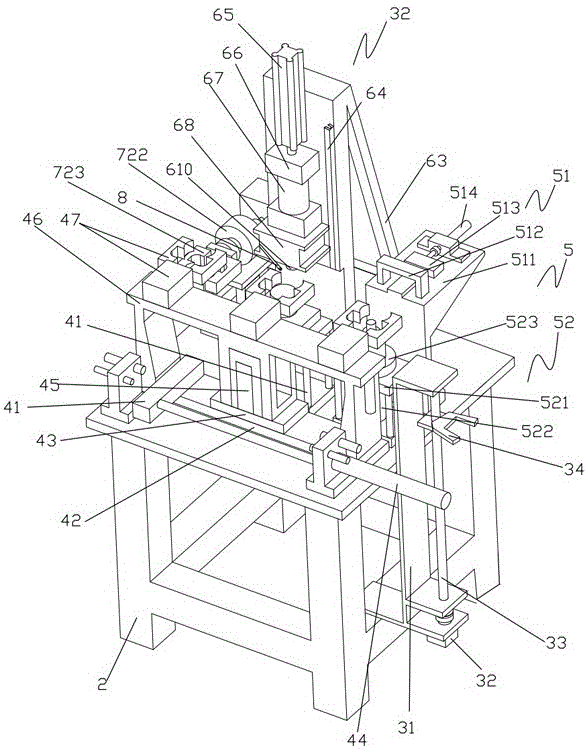

Scarf rope twisting and knot tying machine and rope twisting and knot tying method

The invention relates to a scarf rope twisting and knot tying machine and a rope twisting and knot tying method, wherein the scarf rope twisting and knot tying machine can automatically twist weft yarns reserved in a scarf into even and unified rope-shaped tassels in a strand-split mode, cut off the yarns and tie off. The scarf rope twisting and knot tying machine comprises a machine frame, a positioning device, a rope twisting device and a knot tying machine. The machine frame comprises a bottom beam and a middle beam, a bush-hook groove vertically penetrates through the middle of the bottom beam, lifting arrangement type bush-hooks are arranged in the bush-hook groove in the middle of the bottom beam, a lower twisting plate is arranged on the bottom beam of the machine frame, slide ways are arranged on the left side and the right side of the bottom beam, and the knot tying machine is installed in a middle cross beam of the machine frame. The scarf rope twisting and knot tying machine and the rope twisting and knot tying method have the advantages of 1 being capable of automatically fishing work that the weft yarns reserved in the scarf are twisted into ropes and tied off, greatly saving producing and processing time and simultaneously reducing work amount of workers, and 2 very uniformly performing rope twisting and knot tying work and enabling produced tassels to be even in thickness, delicate in appearance and perfect and ideal in effect.

Owner:沈文标

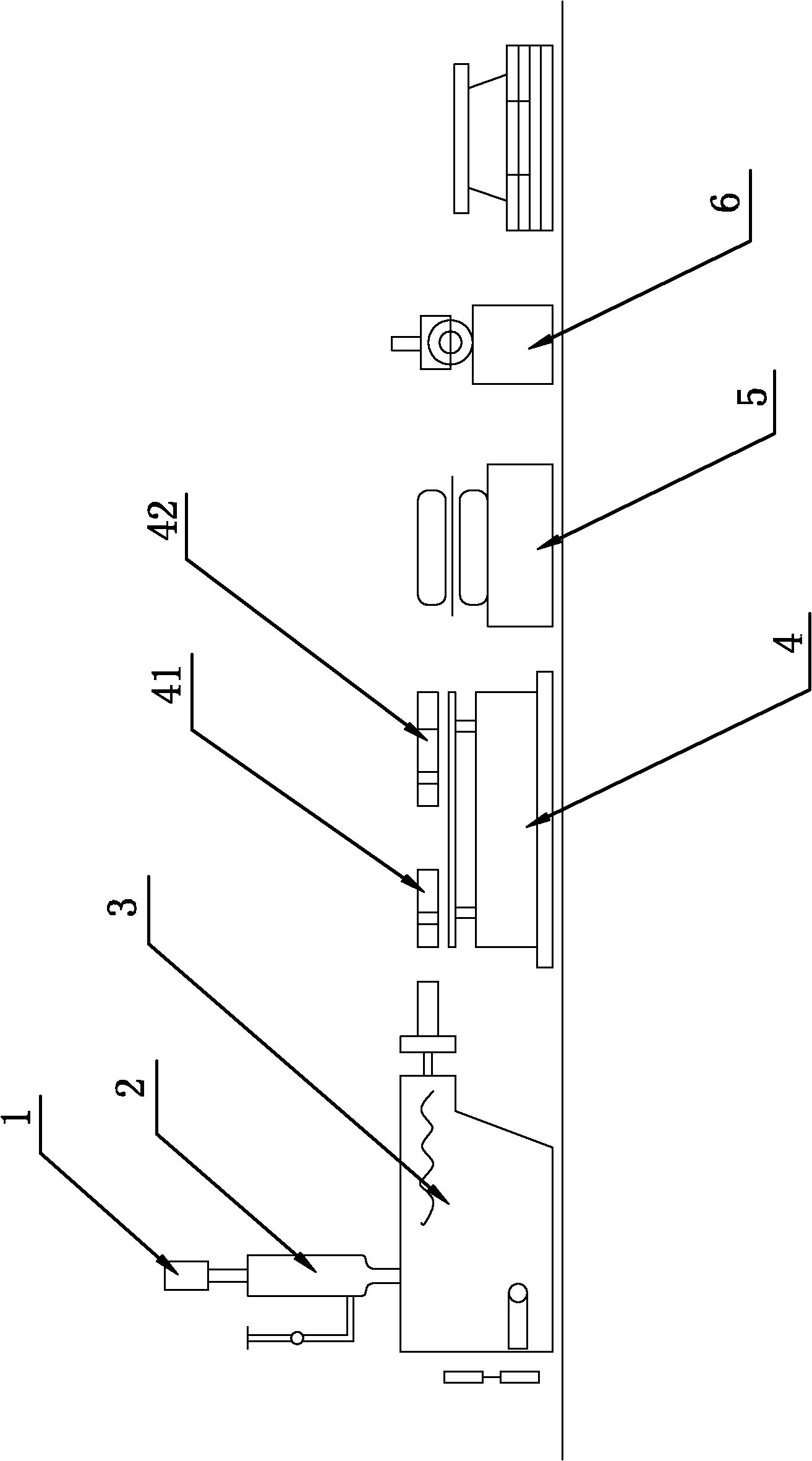

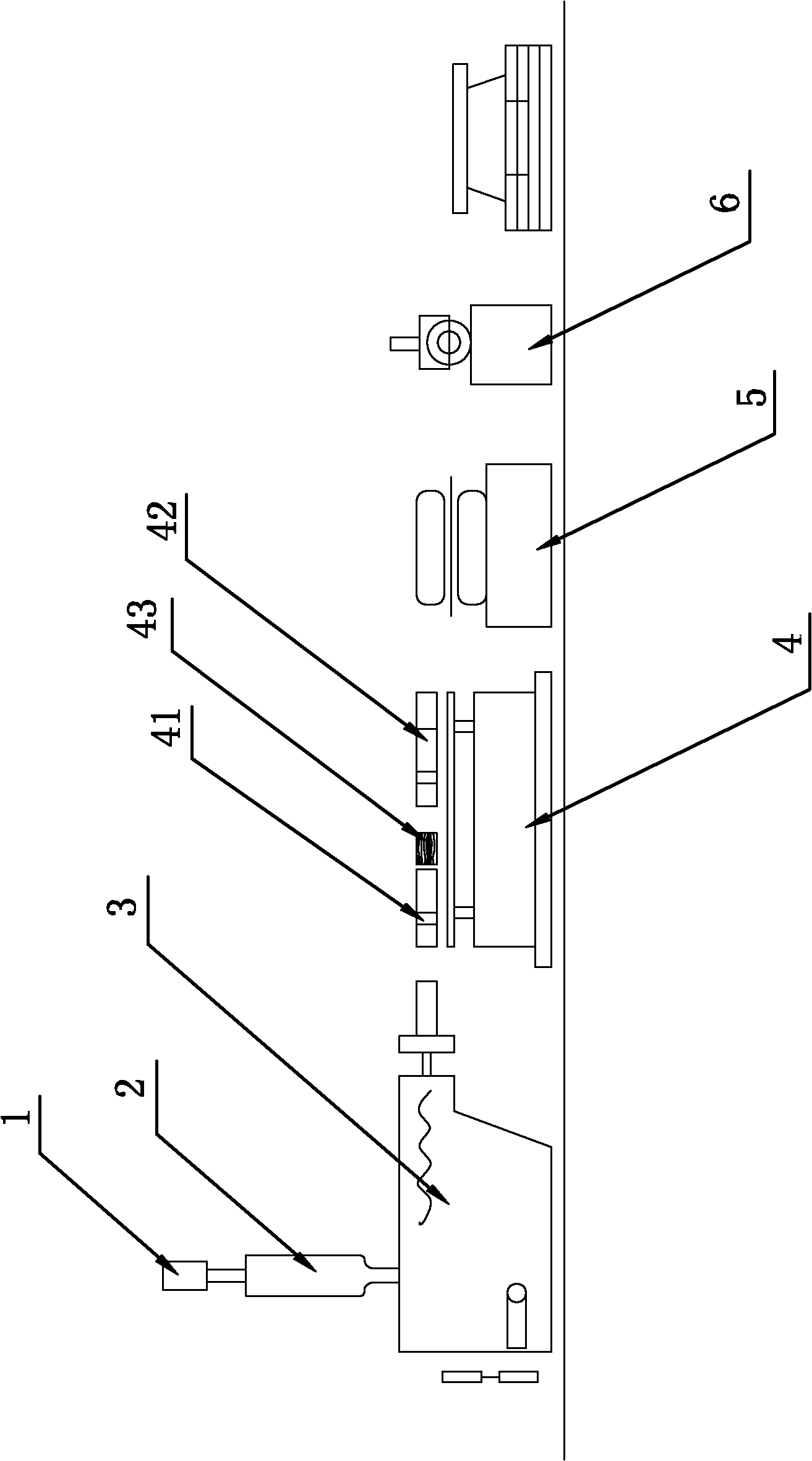

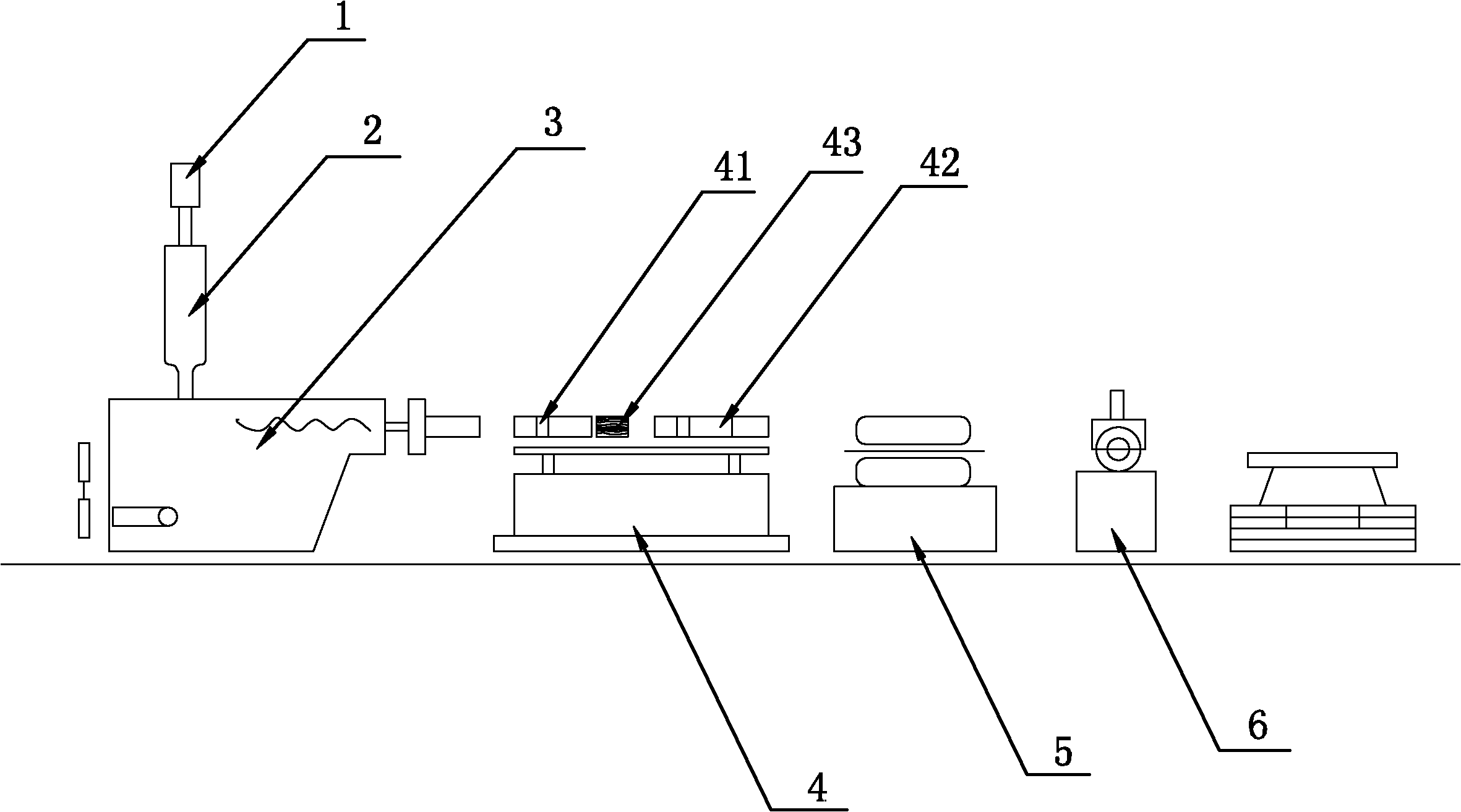

Welding chamfering machine for supporting seat of compressor

ActiveCN106392661AEasy to take outReduce production processing timeOther manufacturing equipments/toolsMetal working apparatusEconomic benefitsEngineering

The invention discloses a welding chamfering machine for a supporting seat of a compressor. The welding chamfering machine comprises a material storage assembly and a rack, wherein a loading mechanism, a moving mechanism, an aligning mechanism, a chamfering mechanism and a turnover mechanism are arranged on the rack; the material storage assembly is connected with the moving mechanism through the loading mechanism; the aligning mechanism, the chamfering mechanism and the turnover mechanism are sequentially arranged at one side of the moving mechanism; and the aligning mechanism is positioned at one side of the loading mechanism. The welding chamfering machine disclosed by the invention can automatically process the supporting seat, so that quantity and workload of operators are reduced, production efficiency is improved, producing processing cost is reduced, and economic benefits are improved; and moreover, moving efficiency of the supporting seat is improved, producing processing time for chamfering is shortened, welding chamfering quality of the supporting seat is improved, production efficiency is improved, scrap iron is prevented from scattering in a production workshop, workload after production of the operators is reduced, production environment is improved, processing efficiency is improved, processing chamfering precision is improved, and chamfering quality of the supporting seat is improved.

Owner:TCL RUIZHI (HUIZHOU) REFRIGERATION EQUIP CO LTD

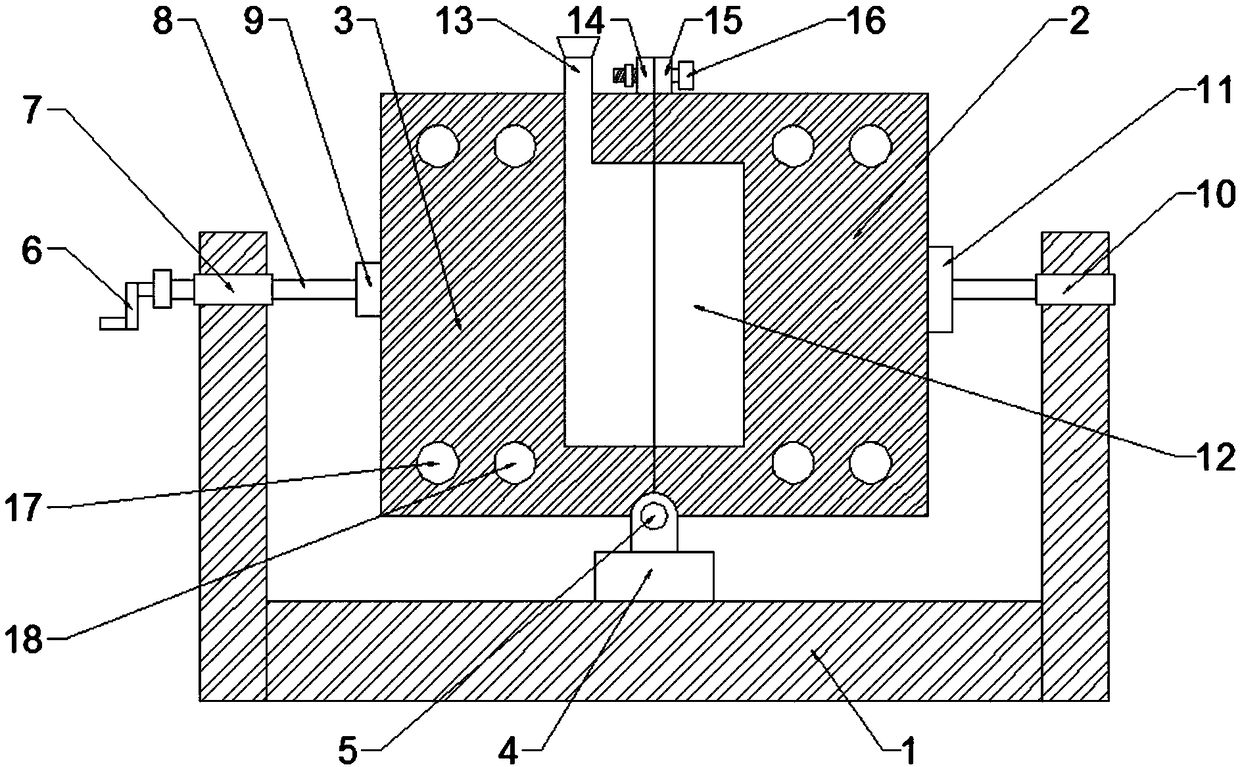

Vehicle brake disc casting die

The invention discloses a vehicle brake disc casting die which comprises a casting base, a first die holder and a second die holder. The first die holder and the second die holder are arranged above the casting base; a supporting table is arranged at the middle part of the casting base; a rotary table is arranged at the upper end of the supporting table; a thread bushing is arranged at the left side of the casting base; the inside of the thread bushing is meshed with a strut; a handle is arranged at the left side of the strut; a clamping plate is arranged at the right side of the strut; and the clamping plate is attached to the second die holder. In the using process, the casting die is simple in design structure, convenient to fix the die holders, labor-saving and high in efficiency; a hot-air blower is started up to inject hot air into a heating pipe to carry out preheating on the first die holder and the second die holder so as to reduce defects of forming difficulty, film adhesion,casting cracks and the like, thereby improving production quality; and a water pump is started up and cooling liquid takes the cyclic motion in a cooling pipe to carry out cooling on the die holders,so that cooling efficiency is improved and production machining time is saved, thereby saving cost.

Owner:广德亚太汽车智能制动系统有限公司

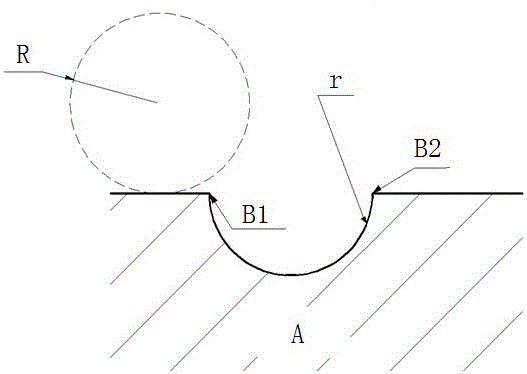

UG-based optimization method of planar-cavity small-curvature radius arc numerical control processing

InactiveCN106843143AReduce finishing timeReduce total timeNumerical controlMachining timeResidual volume

The invention discloses an optimization method for numerically controlled machining of arcs with small curvature radius based on UG plane cavity. The method includes: (1) Finding out the starting point and end point of the arc where r<R in the contour of the workpiece, where R is the radius of the tool , r is the radius of the machining contour; (2) Use the starting point and end point of the arc as the center respectively, and make an arc with R as the radius; (3) Use the radius R of the tool for displacement compensation for the remaining curves of the workpiece contour; (4 ) The curve obtained by intersecting the two arcs with the displacement compensation curve is the optimized tool center trajectory. The invention can leave a smaller residual amount for finishing, greatly reduce the finishing time, can shorten the product manufacturing processing time, thereby reducing the production cost.

Owner:MAOMING POLYTECHNIC

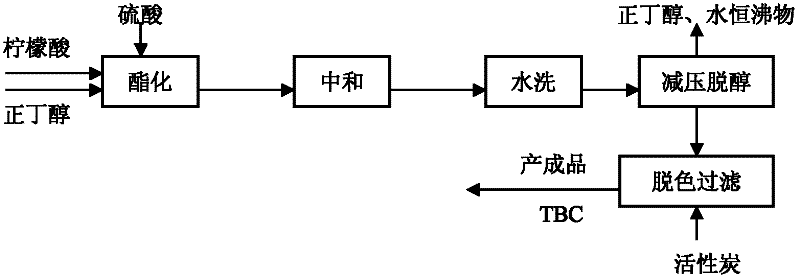

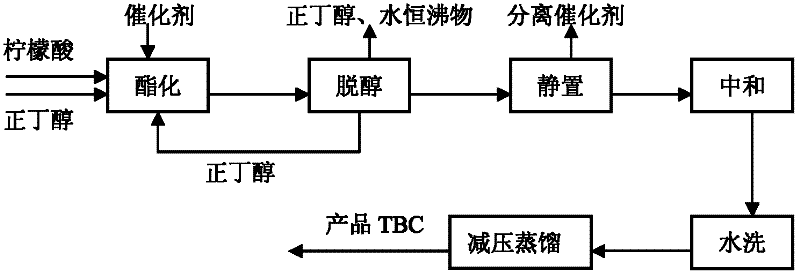

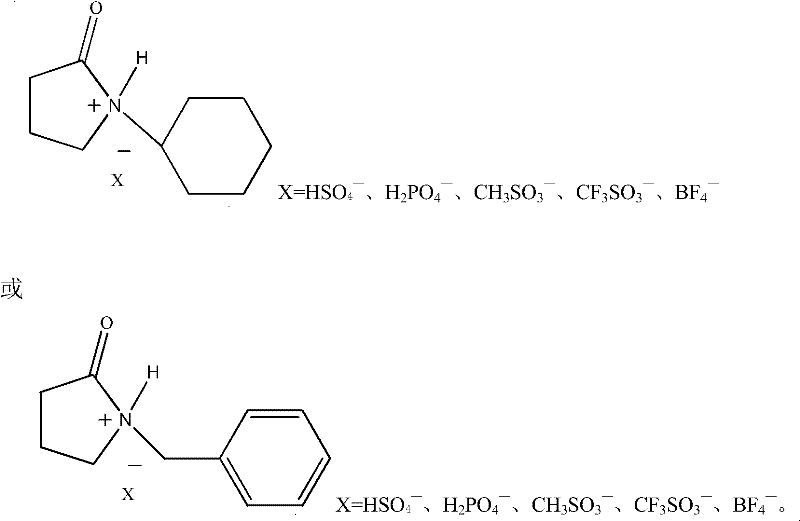

The method that adopts composite ionic liquid catalyst to synthesize tri-n-butyl citrate

ActiveCN102285883AEasy to separateThe synthesis process is simpleOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsDistillationFiltration

The invention provides a method for synthesizing tributyl citrate (TBC) by adopting a composite ionic liquid catalyst. The method is characterized by comprising the following steps: firstly carrying out esterification on taking citric acid and n-butyl alcohol which serve as raw materials in the presence of the catalyst, after esterification is qualified, directly utilizing the waste heat to reduce pressure and eliminate alcohol in a reaction kettle to obtain a crude product of tributyl citrate containing the catalyst, then carrying out acetylation and finally carrying out deacidification, standing, cooling, catalyst separation, neutralization, washing and reduced pressure distillation, thus obtaining the colorless transparent liquid TBC without decoloration and pressure filtration. The method has the following advantages: the same amount of the same catalyst is used in esterification and acetylation, thus realizing reuse of the catalyst; the conversion rate is high, the by-products are few and the yield is more than 98%; aftertreatment is simple and convenient, excessive alkaline water for neutralization and washing is not needed, the washing clear water can be reused and no pollutants are discharged; and the reaction temperature is low, the production period is short, the equipment investment is low, the energy consumption is low, and the cost is low.

Owner:YICHANG WUDI ELECTROMECHANICAL CO LTD

Waste rubber crawler belt material recycling production line

PendingCN110435048AImprove cutting recovery efficiencyNo displacementPlastic recyclingMetal working apparatusProduction lineSurface layer

The invention discloses a waste rubber crawler belt material recycling production line. The waste rubber crawler belt material recycling production line comprises a segmenting and cutting-off tool, asurface rough cutting tool, a surface treatment and separation device, a reclaimed material conveying structure and a vacuum recycling device; the segmenting and cutting-off tool is used for segmenting and cutting off a crawler belt; the surface rough cutting tool is used for carrying out rough cutting treatment on cut-off long-strip-shaped crawler belt surface rubber; the surface treatment and separation device is used for carrying out cutting treatment, embedded part separation, steel wire separation and steel wire shearing short and recycling on the roughly cut crawler belt remaining surface layer rubber; the reclaimed material conveying structure is used for conveying the cut surface rubber and an embedded part; and the vacuum recycling device is used for carrying out vacuum collectionand recycling on rubber particles left by the rough cutting treatment. According to the waste rubber crawler belt material recycling production line, residual rubber scraping, embedded part separation and steel wire shearing short and collection of the waste rubber crawler belt can be realized, the functions of the equipment are various, the classification and collection of all components in thewaste rubber crawler belt are effectively realized, the working synergy of all the mechanisms in the equipment is high, and the working efficiency is high.

Owner:ZHENJIANG SHEN WARD MACHINERY CO LTD

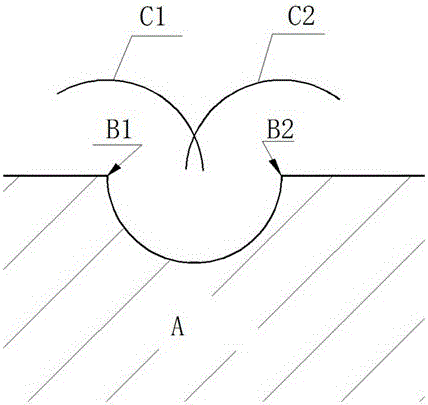

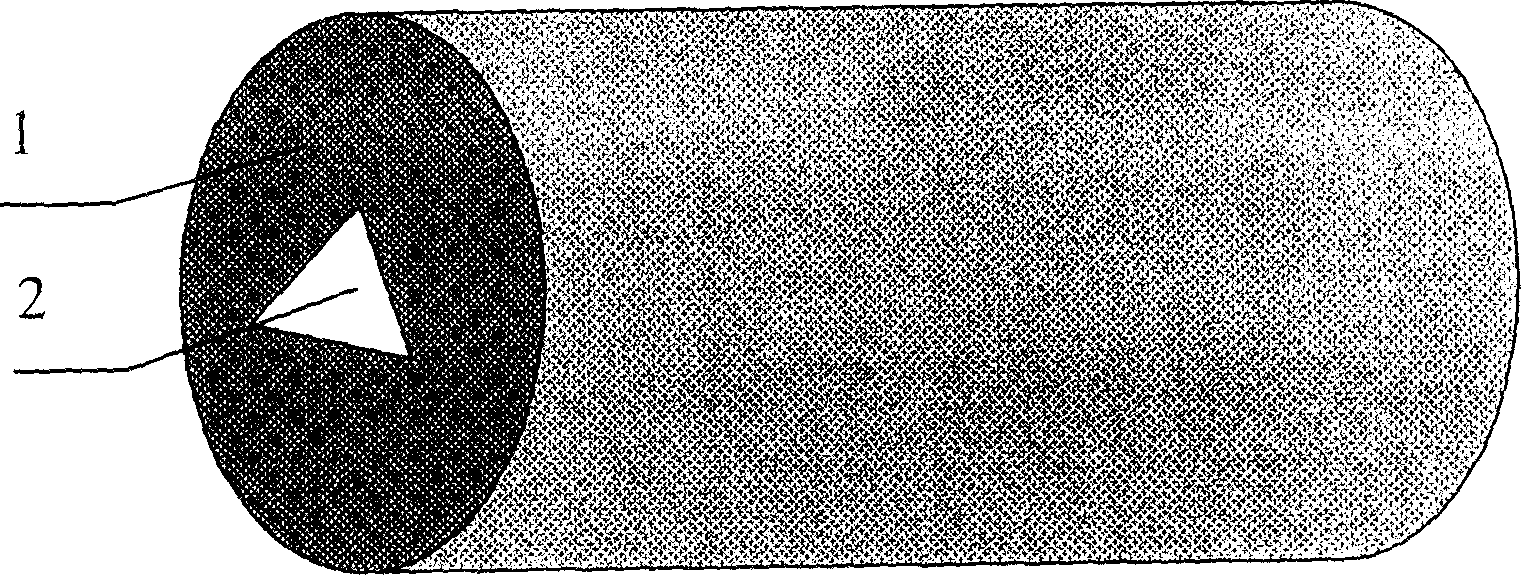

Method for synthesizing isotropic silicon nitride powder adopting hollow type annular material-distribution

InactiveCN1799994AUniform fine permeabilityImprove permeabilityNitrogen compoundsCombustionMetallic materials

The invention discloses a homogeneous silicon nitride powder synthetic method of hollow ring-shaped cloth combustion in the inorganic non-metal material domain, which is characterized by the following: grinding to mix the silicon powder and silicon nitride powder at different proportions; placing the material in the combustion synthetic reaction device with poromeric hollow pipe according to the hollow ring-shaped cloth method after drying; charging 1-20 Mpa nitrogen gas in the vacuum device; inducing the combustion synthetic reaction through igniting. The invention realizes the complete nitridation of whole reactant at isothermal pattern, which improves the uniformity of silicon nitride powder.

Owner:UNIV OF SCI & TECH BEIJING

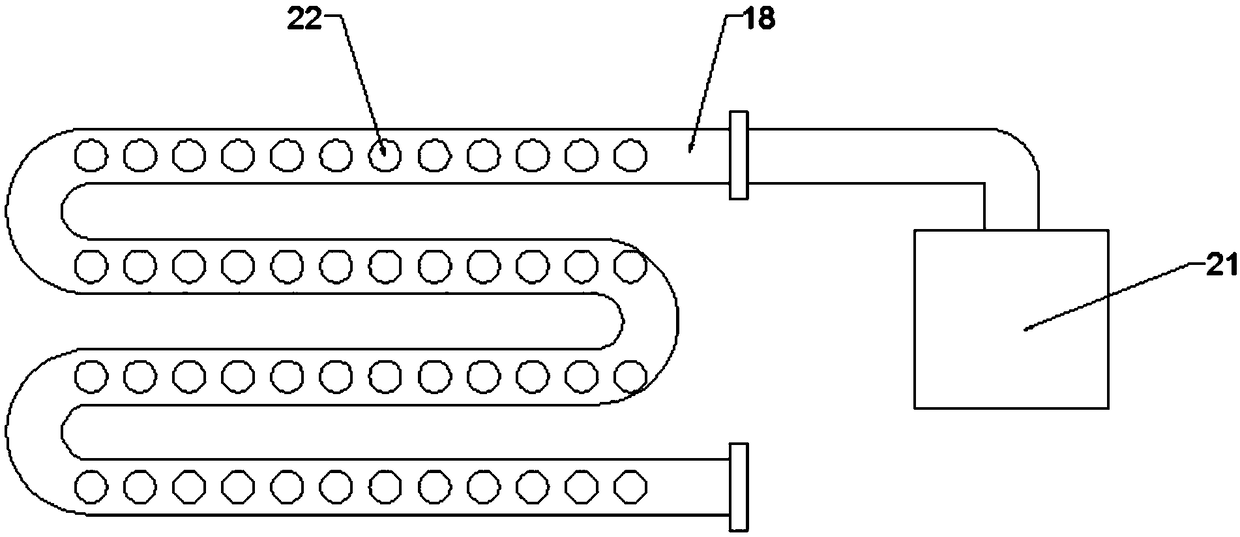

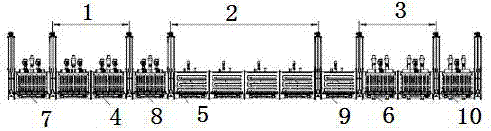

Efficient energy-saving internal heating vacuum baking intelligent system

PendingCN107270658AEvenly heatedHeating fastFinal product manufactureDrying solid materials without heatTemperature controlControl system

The invention discloses an efficient energy-saving internal heating vacuum baking intelligent system which comprises a preheating box group, a thermostat group, a cooling box group, a transitional box group, a plurality of brake valves, a transmission system and a control system, wherein the preheating box group comprises a plurality of preheating boxes sequentially connected in sequence; the thermostat group comprises a plurality of thermostats sequentially connected in sequence; the cooling box groups comprises a plurality of cooling boxes sequentially connected in sequence; the transitional box group comprises a first transitional box, a second transitional box, a third transitional box and a fourth transitional box; and the brake valves are arranged at two ends of the first transitional box, the second transitional box, the third transitional box and the fourth transitional box. Through the manner, the efficient energy-saving internal heating vacuum baking intelligent system adopts an internal heating system; independent intelligent temperature control is carried out on four internal surfaces; a lithium battery is uniformly heated to precisely control temperature so as to prevent the phenomena that a product is low in quality and is even scrapped due to the temperature problems including temperature overshoot and temperature instability; the entire baking system is full vacuum, less in heat consumption, high in heat efficiency and more efficient and energy-saving.

Owner:WUJIANG SONGLING ELECTRIC EQUIP

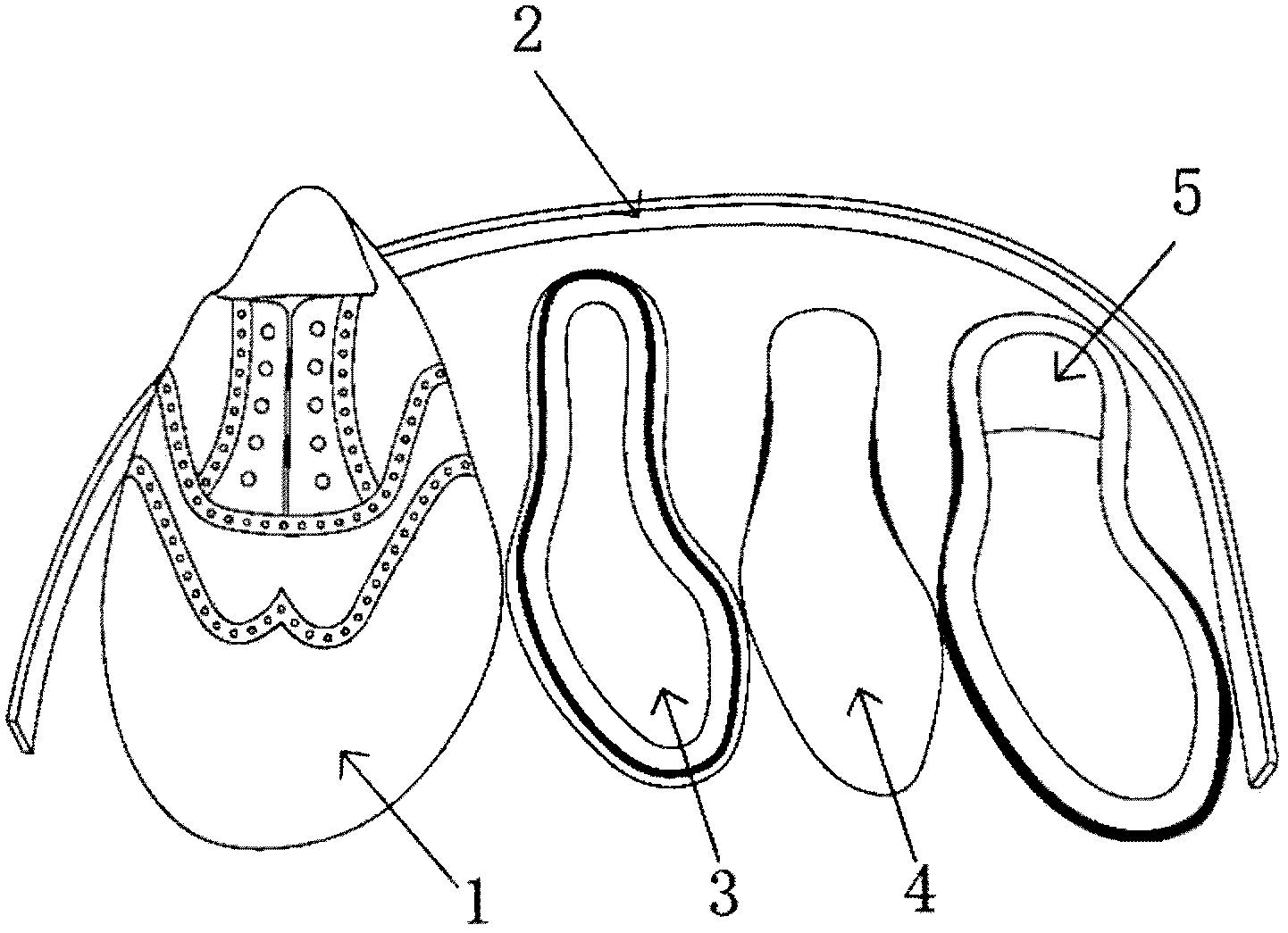

Enteric coated probiotics preparation

PendingCN107299071ASimple processEase of mass productionBacteriaMicroorganism based processesIntestinal structureMicrobiology

The invention provides an enteric coated probiotics preparation. The preparation is prepared by mixing and fermenting an aerobic bacterium and an anaerobic bacterium which are mutualistic. The aerobic bacterium is firstly inoculated in a fermentation vessel and is subjected to aerobic culture to the logarithmic phase, the oxygen is closed, the micro-aerobic fermentation continues, the anaerobic bacterium is inoculated in the process of the micro-aerobic fermentation, the aerobic bacterium and the anaerobic bacterium are in harmony and symbiosis, the culture continues under the anaerobic condition to the later period of logarithmic phase or the later period of the stable period of the anaerobic bacterium so as to obtain a fermentation product, and the fermentation product is centrifugally separated, spray-dried and coated with an enteric material to obtain the probiotics preparation. The preparation process is simple, the capacity utilization rate is high, the cost is low, the large-scale production is easy to realize; the aerobic bacterium and the anaerobic bacterium are in harmony and symbiosis in the early period in the mixing and fermenting processes, the compatibility is better; the surface of the probiotics preparation is coated with the enteric material, so that the preparation is insoluble under the environmental conditions of the gastric acid and bile, only starts to dissolve in the intestinal fluid environment, and plays a role in targeted regulation of the intestines.

Owner:KINRY BIOTECH JINAN CO LTD

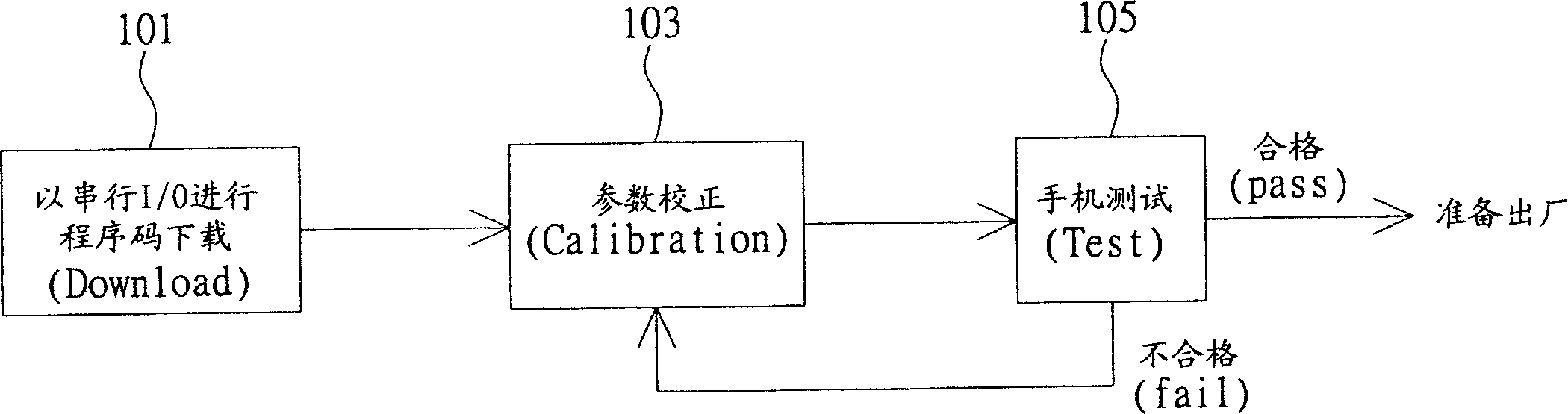

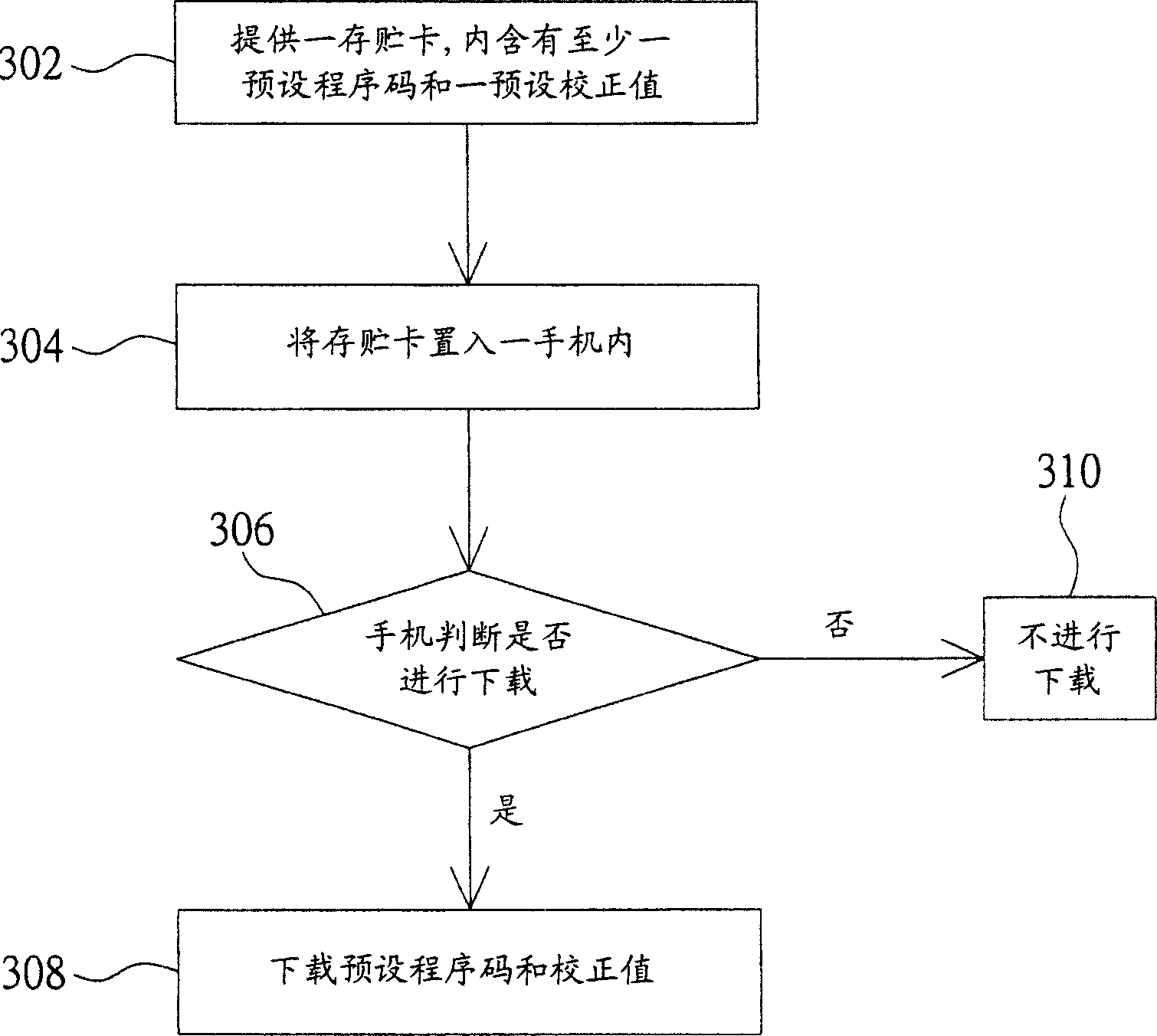

Method for improving mobile telephone production process

InactiveCN1708155AImprove download efficiencyReduce production processing timeRadio/inductive link selection arrangementsSubstation equipmentMobile phoneMemory cards

The program code downloading method is used in downloading at least one set of preset program codes to cellphone, and the cellphone has one memory card expanding slot and one stored initial code. The method includes the following steps: providing one memory card with stored preset program code set; setting the memory card inside the expanding slot; and judging whether the preset program code set in the memory card is the program codes to be downloaded, and if yes, downloading the program code set into inside the cellphone.

Owner:QUISDA CORP

Method for extracting multiple pigments from cape jasmine fruits

The invention relates to a method for extracting multiple pigments from cape jasmine fruits, and belongs to the field of biological extraction. In the provided method, a homogenous extraction technology is adopted, a biological enzyme method is used to eliminate the impurities, and key technologies such as a column chromatography separation technology, an elution concentration control technology, and the like are used to extract multiple pigments from cape jasmine fruits. The impurities due to the long-time soaking in the conventional method will not be generated in the provided method, moreover, the production time is shortened, the cost is reduced, the labor and materials are saved, and the method is suitable for enterprises.

Owner:QINGDAO PENGYUAN KANGHUA NATURAL PROD

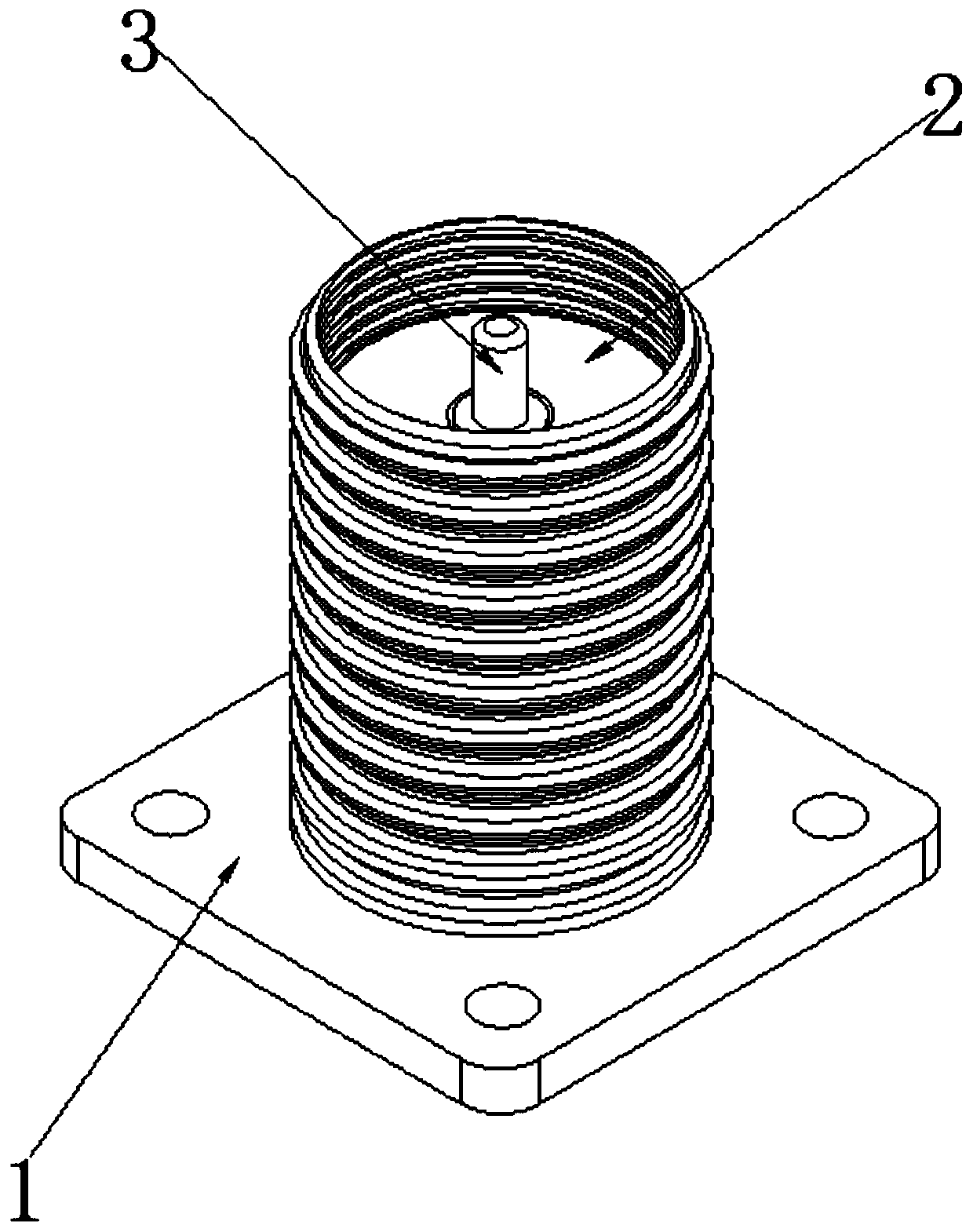

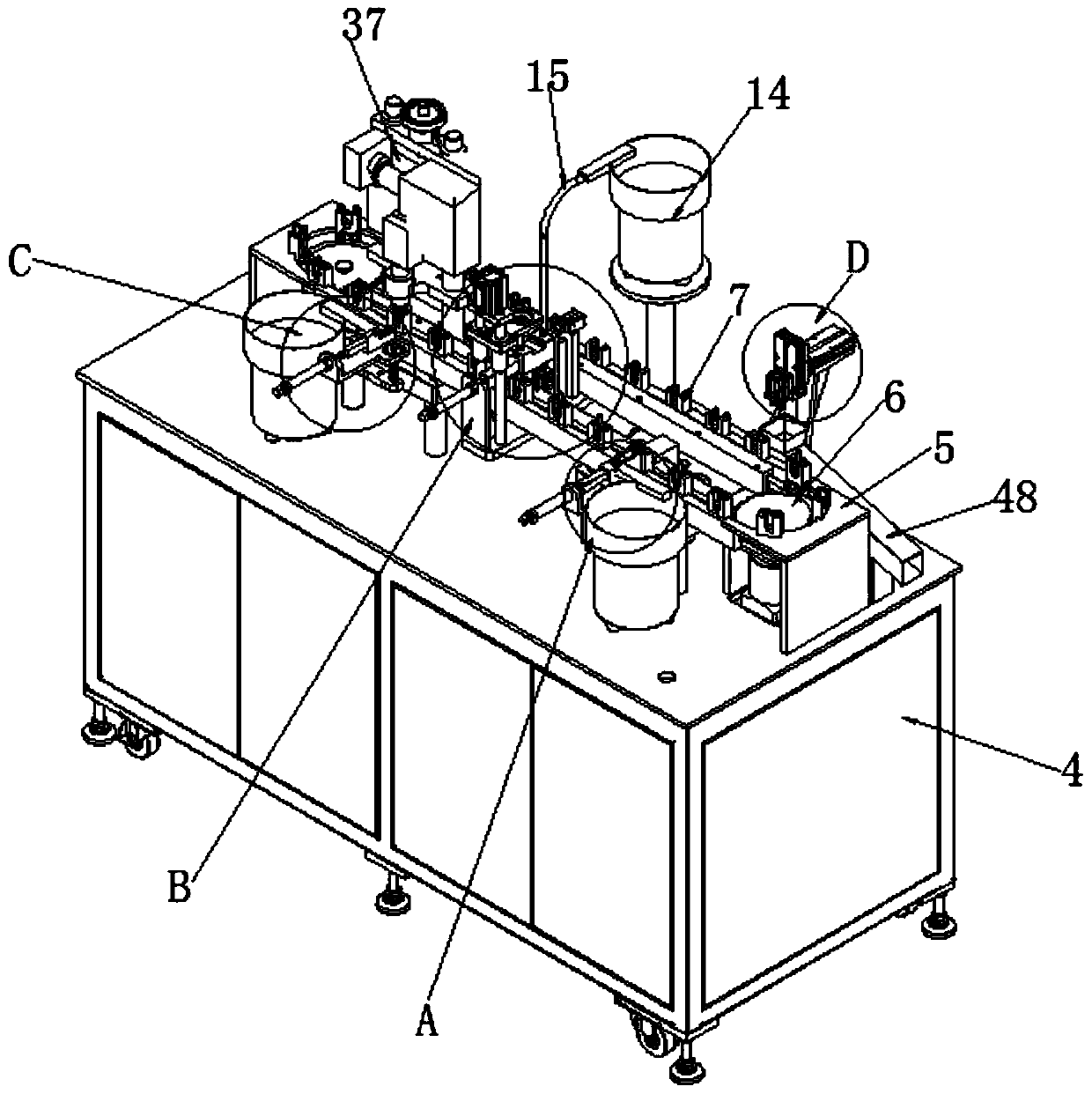

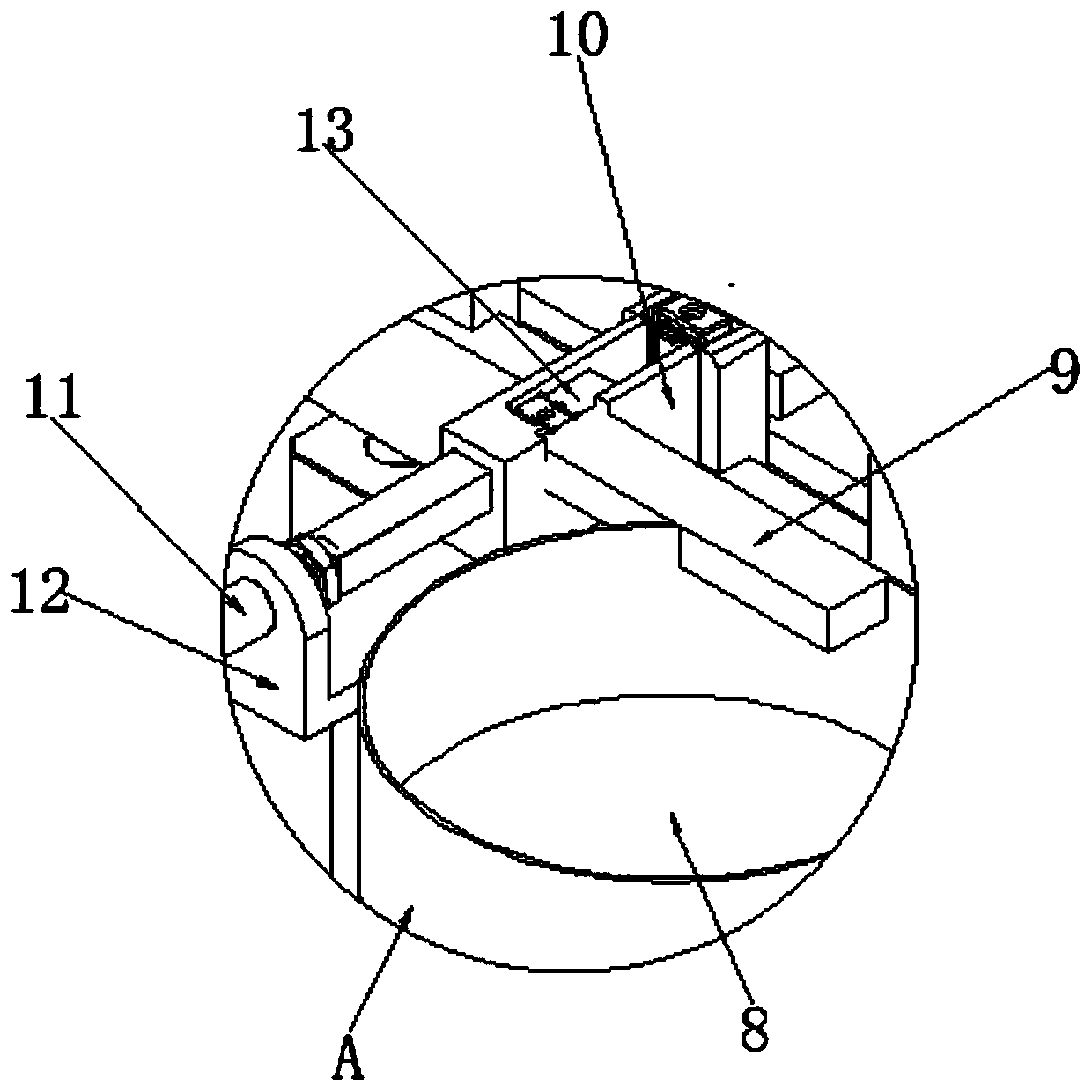

Production process of radio frequency coaxial connector for antenna connection

ActiveCN111029882AImprove the efficiency of the production processShorten production process timeContact member manufacturingContact member assembly/disassemblyRadio frequencyElectrical conductor

The invention discloses a production process of a radio frequency coaxial connector for antenna connection. The radio frequency coaxial connector comprises a shell, an inner insulator and an inner conductor, wherein the inner insulator is installed in the shell, and the inner conductor is installed in the inner insulator in a penetrating mode. The production process comprises the following specific operation steps of: sequentially producing the shell, the inner insulator and the inner conductor through a mold, and completing production on an assembling device for the shell, the inner insulatorand the inner conductor which are produced. Through work of the assembling device and a full-automatic operation mode, automatic feeding of the shell, the inner insulator and the inner conductor is completed, the shell, the inner insulator and the inner conductor are rapidly assembled on the device in sequence, the efficiency of the production process of a radio frequency coaxial connector is greatly improved, the time of the production process is shortened, and the percent of pass of radio frequency coaxial connector products is greatly improved.

Owner:扬州市精诚电子有限公司

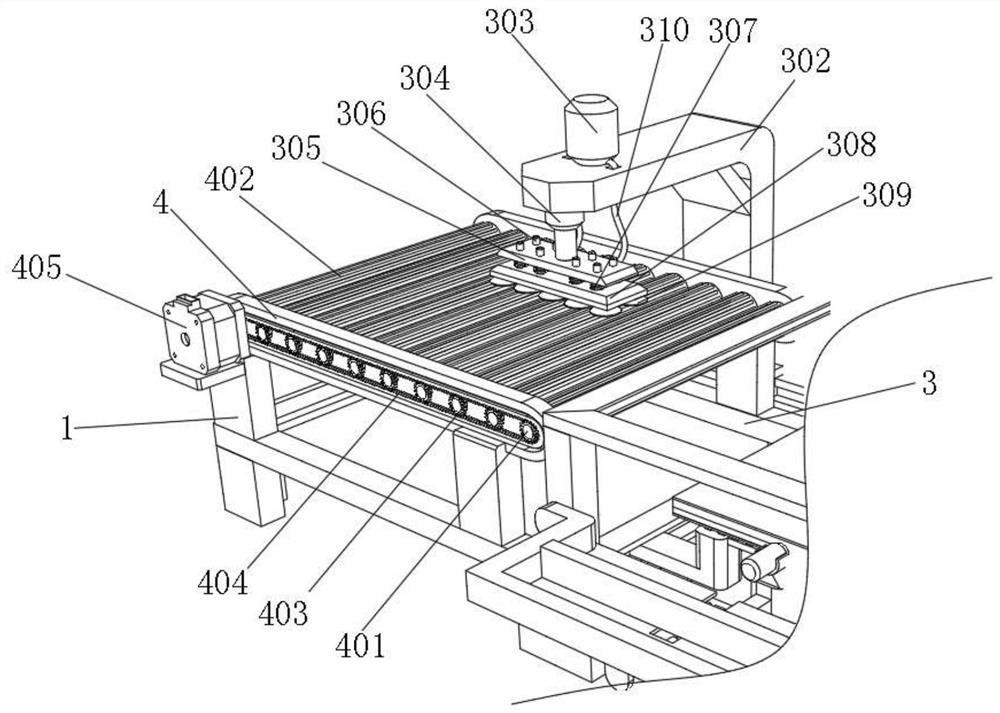

Solar photovoltaic cell production and processing equipment

ActiveCN113224203AImprove the installation effectPrecise alignmentFinal product manufactureSemiconductor devicesElectrical batteryEngineering

The invention relates to the technical field of photovoltaic cell production, and discloses solar photovoltaic cell production and processing equipment which comprises a supporting frame and a mounting frame, one side of the supporting frame is fixedly connected with one side of the mounting frame, a sliding way is fixedly connected to one side of the supporting frame and one side of the mounting frame, a transfer mechanism is slidably connected to one side of the sliding way, a conveying mechanism is fixedly connected to the upper surface of the supporting frame, a feeding groove is fixedly connected to one side of the mounting frame, a material guide plate is fixedly connected to one side of the feeding groove, a sliding hole is formed in the bottom of the material guide plate, a sliding block is slidably connected into the sliding hole, one end of the sliding block is fixedly connected with the bottom of the material guide plate, a pushing plate is fixedly connected to the top of the sliding block, and the bottom of the feeding groove is fixedly connected with a second electric push rod. According to the solar photovoltaic cell production and processing equipment of the invention, a frame can be aligned with a photovoltaic cell body more accurately, so that the purpose of tight fitting is achieved, a traditional manual frame mounting method is abandoned, the frame mounting efficiency can be improved, and the photovoltaic cell mounting effect can also be improved to a great extent.

Owner:苏州赛莱德自动化科技有限公司

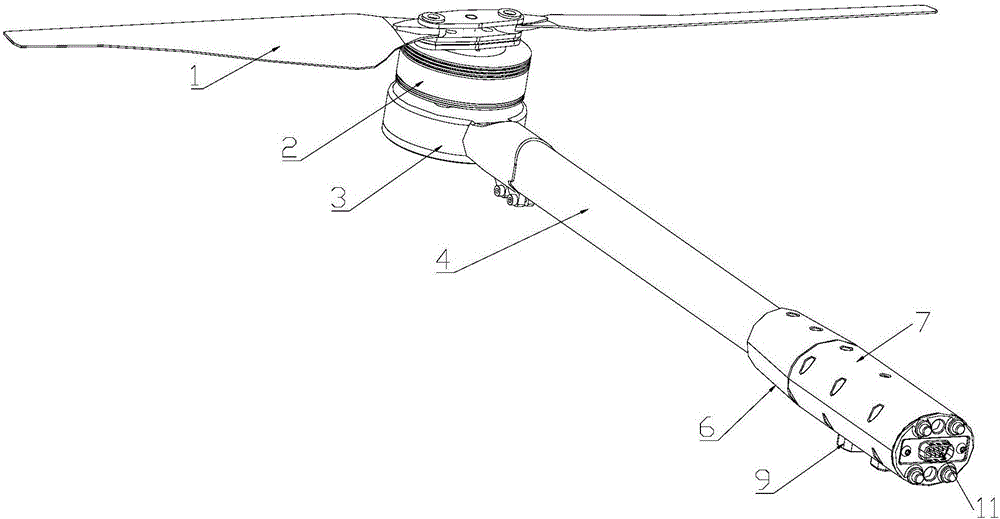

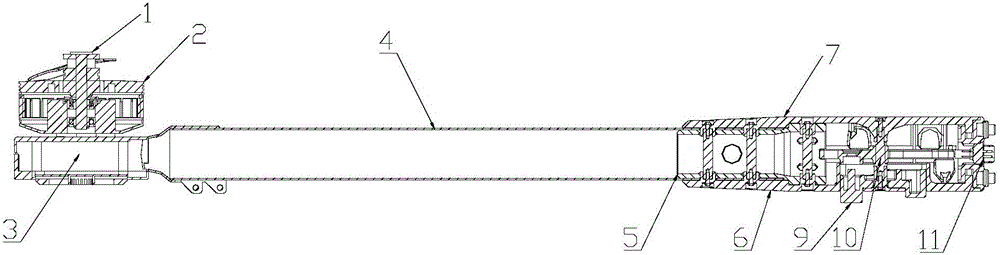

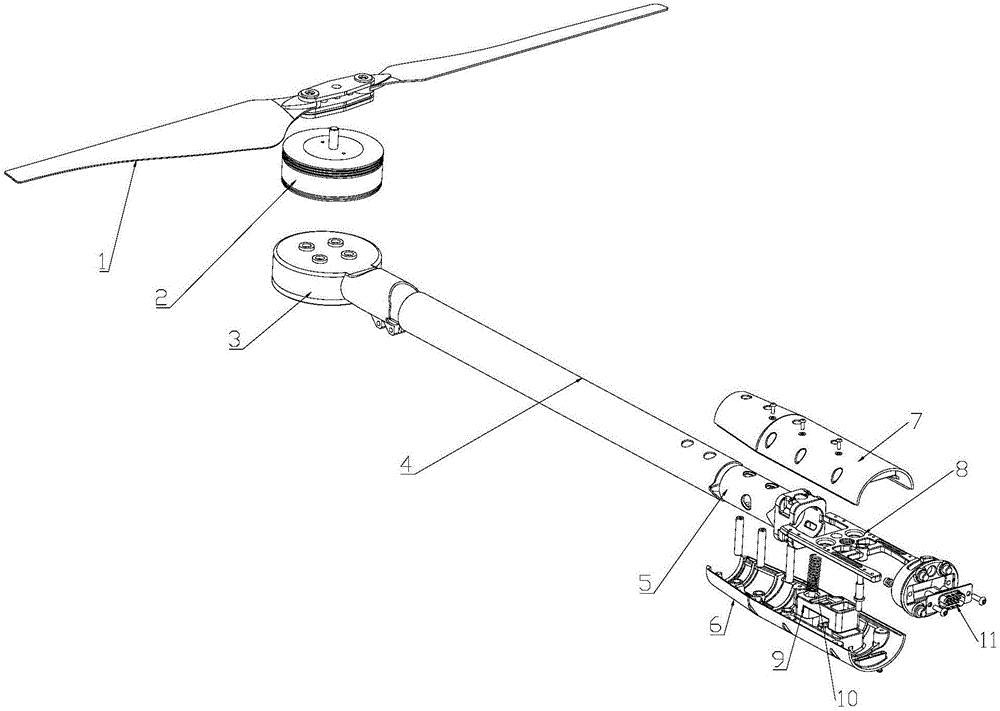

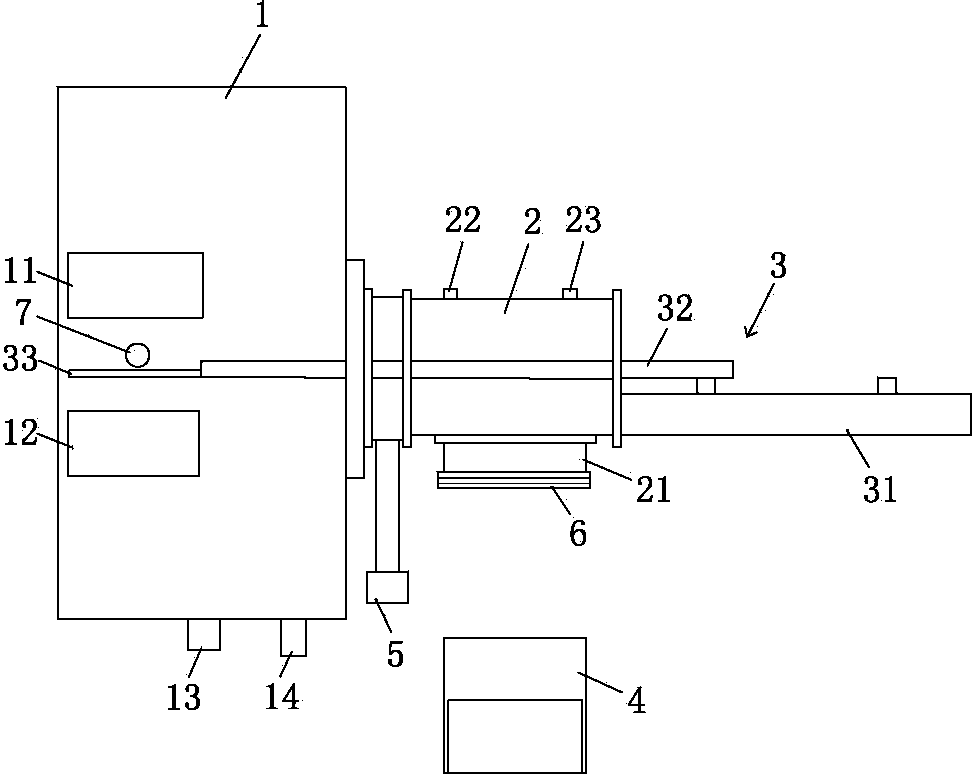

Six-rotor quick-release unmanned aerial vehicle arm

The invention provides a six-rotor quick-release unmanned aerial vehicle arm. The six-rotor quick-release unmanned aerial vehicle arm comprises a blade, a brushless motor, an electronic speed-regulating module, a blade arm carbon tube, a locking block, an arm fixing shell, an arm metal frame, a fixing buckle, a spring and a male head, wherein the electronic speed-regulating module is connected with the tail of the blade arm carbon tube; the brushless motor is located above the electronic speed-regulating module; the blade is fixed to the upper portion of the brushless motor; the locking block is inserted into the top of the blade arm carbon tube; the arm fixing shell is arranged outside the top of the blade arm carbon tube in a sleeving mode; and the fixing buckle is fixed to the inner side of the arm fixing shell. The six-rotor quick-release unmanned aerial vehicle arm has a high degree of integration and high utilization rate, all the parts can be replaced, disassembling and maintenance are convenient, cost is low, and the arm can be manufactured with high efficiency; and when the six-rotor quick-release unmanned aerial vehicle arm is in use, self-locking can be achieved, and disassembling is convenient.

Owner:TIANJIN ZHONGXIANGTENGHANG SCI & TECH CO LTD

Environmentally-friendly gold beneficiation agent and production method thereof

InactiveCN103060577AReduce production processing timeReduce manufacturing costSolid separationProcess efficiency improvementEnvironmentally friendlyBeneficiation

The invention relates to an environmentally-friendly gold beneficiation agent and a production method thereof. The production method comprises the following steps: 1) preparing a beneficiation agent; and 2) performing preparation before recovery. The environmentally-friendly gold beneficiation agent provided by the invention has the advantages of 1) environment friendliness; 2) harmlessness to a human body in use; 3) short leaching time; and 4) high gold extracting rate.

Owner:熊宝琳

Product taking-out device and method of vacuum die casting machine and vacuum die casting machine

The invention relates to the technical field of taking-out of amorphous alloy die castings, in particular to a product taking-out device and a product taking-out method of a vacuum die casting machine and the vacuum die casting machine. The product taking-out device of the vacuum die casting machine comprises a taking-out chamber, a taking-out part and a tank body, wherein the taking-out chamber is communicated with a die casting chamber; the taking-out part is connected with the taking-out chamber and can move back and forth between the die casting chamber and the taking-out chamber; the tank body filled with liquid is arranged below the taking-out chamber; a first automatic door is arranged between the die casting chamber and the taking-out chamber; a product outlet and a second automatic door are arranged at the bottom of the taking-out chamber; the second automatic door is used for closing and opening the product outlet. The product taking-out method comprises the step of taking out a die-cast product by using the product taking-out device of the vacuum die casting machine. The vacuum die casting machine comprises the die casting chamber and the product taking-out device of the vacuum die casting machine. According to the product taking-out device and the product taking-out method of the vacuum die casting machine, impact on the product can be reduced, and the product can be prevented from being oxidized. The vacuum die casting machine has the advantages of simple structure and small size.

Owner:WINTOP DONGGUAN INDAL TECH

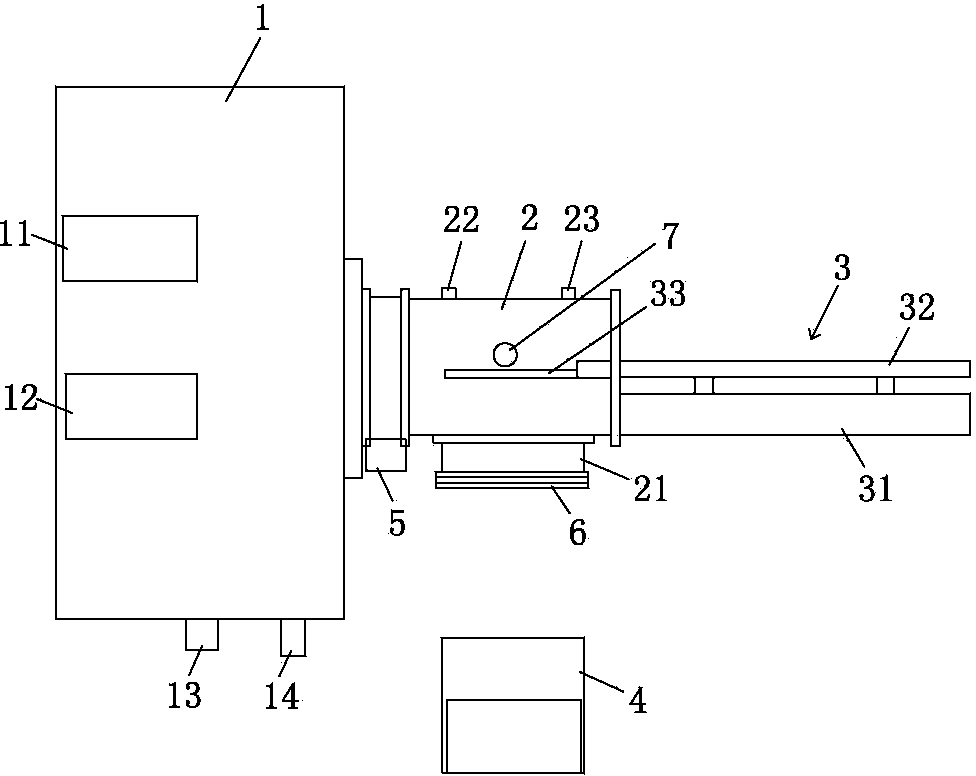

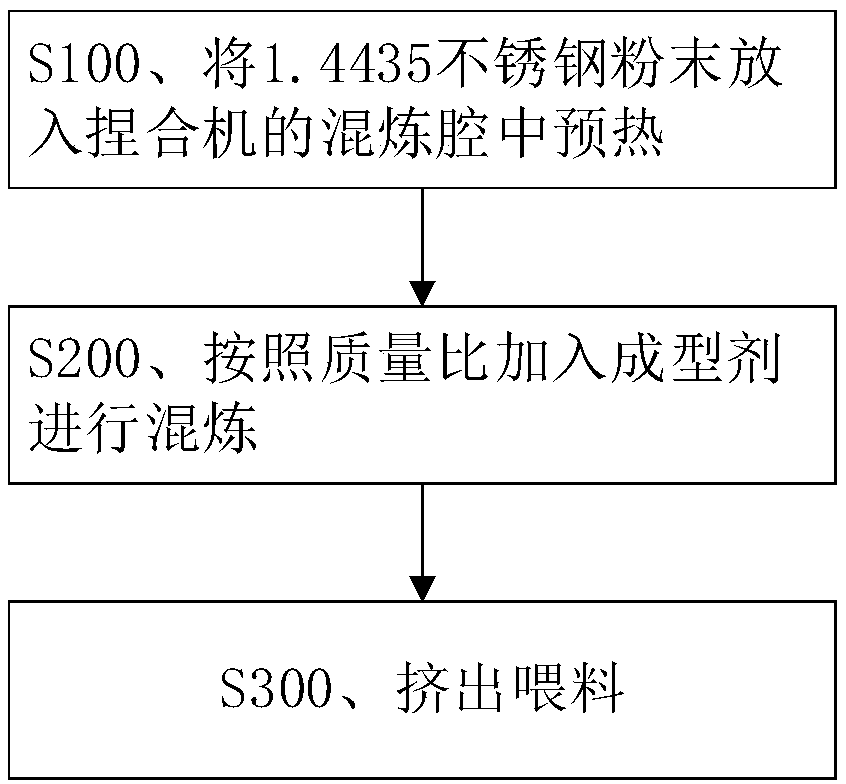

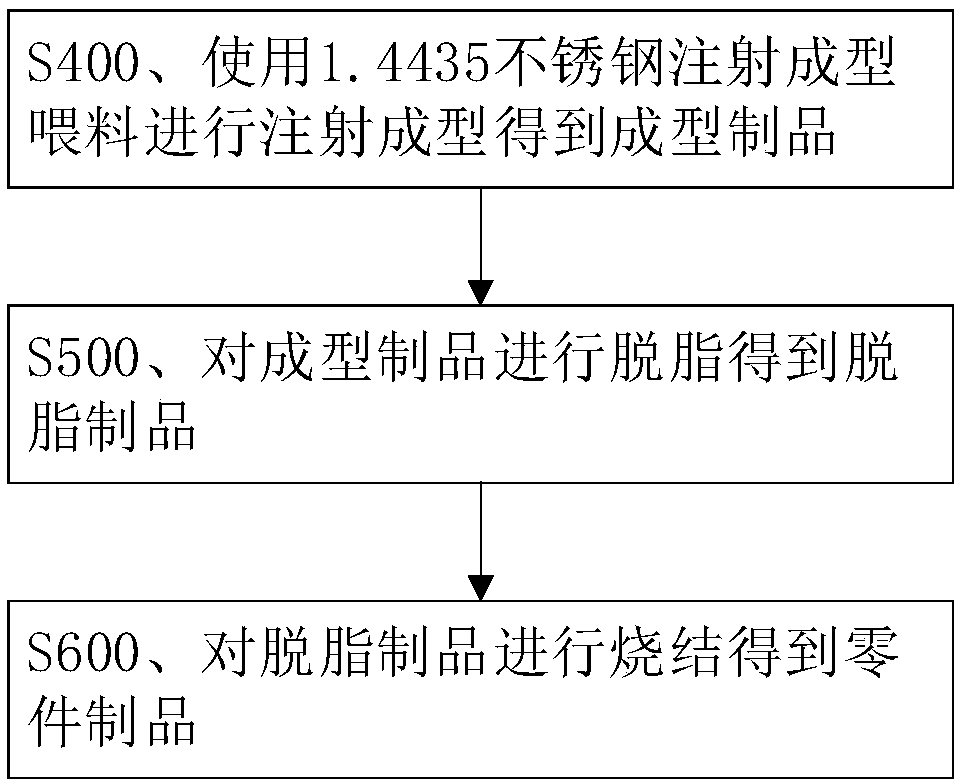

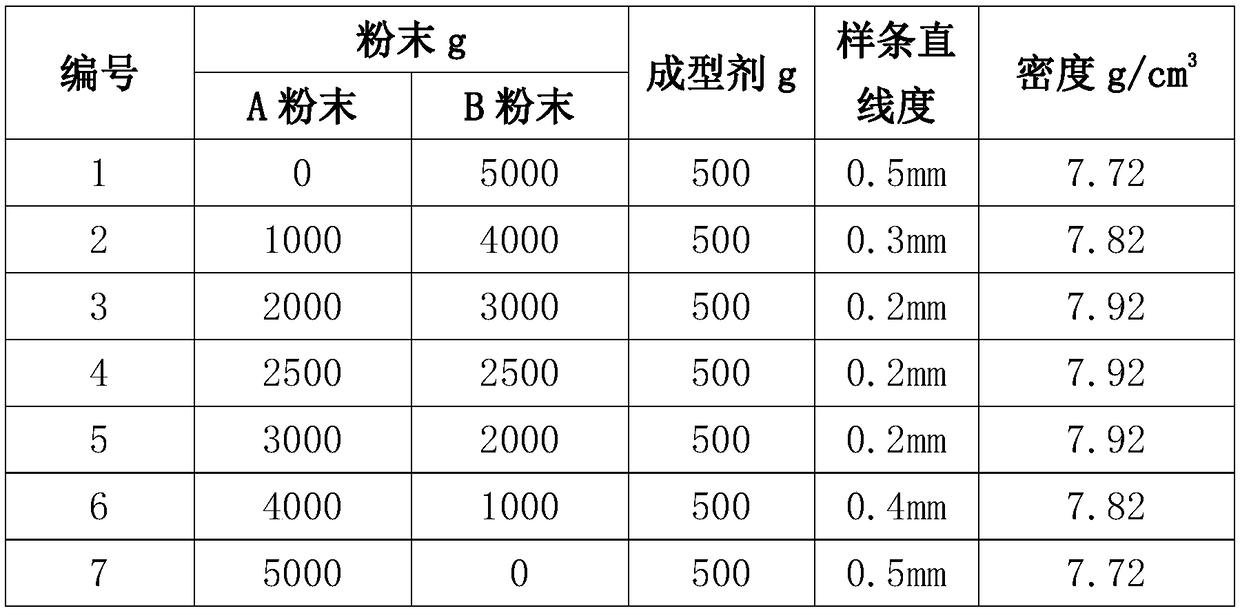

1.4435 stainless steel injection molded feedstock and preparation method thereof

ActiveCN108817401AImprove liquidityEnsure consistencyTransportation and packagingMetal-working apparatusWaxPolymer science

The invention provides a kind of 1.4435 stainless steel injection molded feedstock and a preparation method thereof. The feedstock comprises a forming agent and 1.4435 stainless steel powder. The massratio of the 1.4435 stainless steel powder to the forming agent is 92:8-90:10. The forming agent comprises, by mass, 7%-9% of high-polymer lubricant, 2%-4% of photo-thermal stabilizing agent, 5%-7% of high-density polyethylene with the molecular weight of 100000-500000, 3%-5% of injection-molding-stage polypropylene wax, 5%-7% of thin-film-grade ethylene-vinyl acetate copolymer and 72%-74% of copolyoxymethylene. The preparation method comprises the steps of feeding the 1.4435 stainless steel powder into a mixing cavity of kneading machine to be preheated; adding the forming agent at the massratio to conduct mixing; and extruding feed. Through the preparation method, the fluidity can be improved by 30% or more, the consistency of products can be ensured, and the production and processingtime can be saved.

Owner:DONGGUAN HUAJING POWDER METALLURGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com