Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

176results about How to "Guaranteed Dimensions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Production process method of pipe whip restraint steel structure of main power house of nuclear power station conventional island

ActiveCN101862942AImprove perforation rateReduce distortionArc welding apparatusBoring/drilling machinesNumerical controlGusset plate

The invention belongs to the technical field of pipe whip restraint steel structures of main power houses of nuclear power station conventional islands, in particular to a production process method of the pipe whip restraint steel structure of the main power house of the nuclear power station conventional island, which comprises the lofting process, the marking-off and scribing process, the cutting processing process, the bevel processing process, the hole-making process, the correction process, the polishing surface, the material splicing process, the pre-splicing process of a steel member, the assembly process, the processing process of a friction surface, the welding process of the steel structure and the anti-slip test of the friction surface of the steel member before leaving a factory, sandblasting, derusting and coating of a base coat are carried out in the factory, and the production of the steel structure is divided into the production processing of a welded H-shaped steel column, the production of a steel beam, the assembly and the welding of a support part, the production of a combined steel beam, the assembly and the welding of a girder box body and an inclined support below the girder box body, and the assembly and the welding of a pipe whip restraint key. The production process method can improve the drilling precision, utilize a numerical control planar drilling machine to complete the drilling on a gusset plate, determine a variety of processing processes and welding process parameters, and ensure the dimension of the member after the assembly and the smooth proceeding of field installation.

Owner:EAST STEEL STRUCTURE BRIDGE

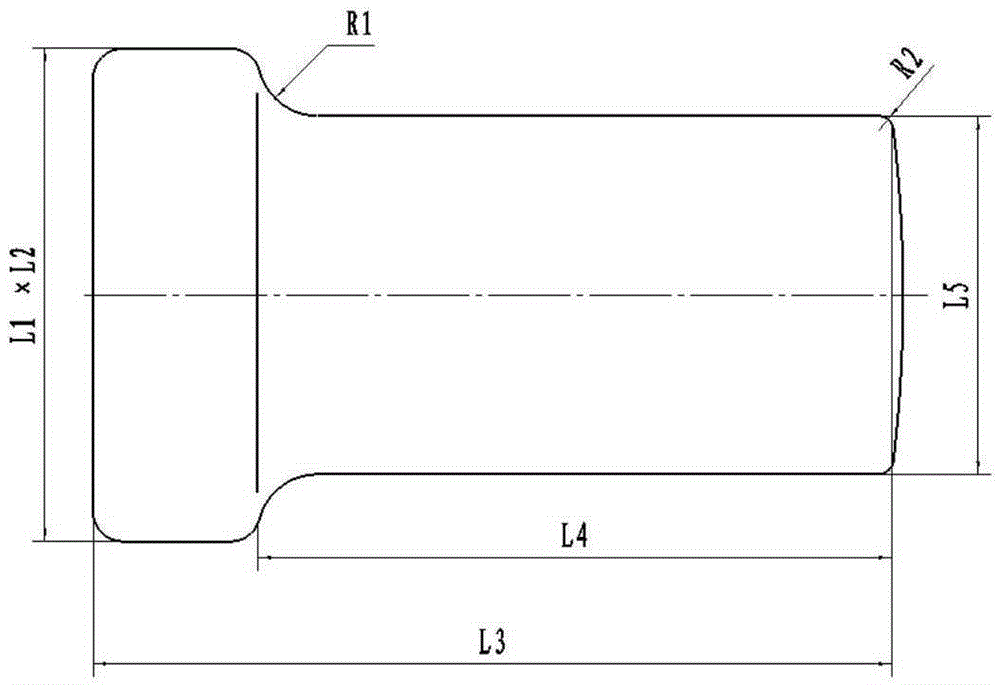

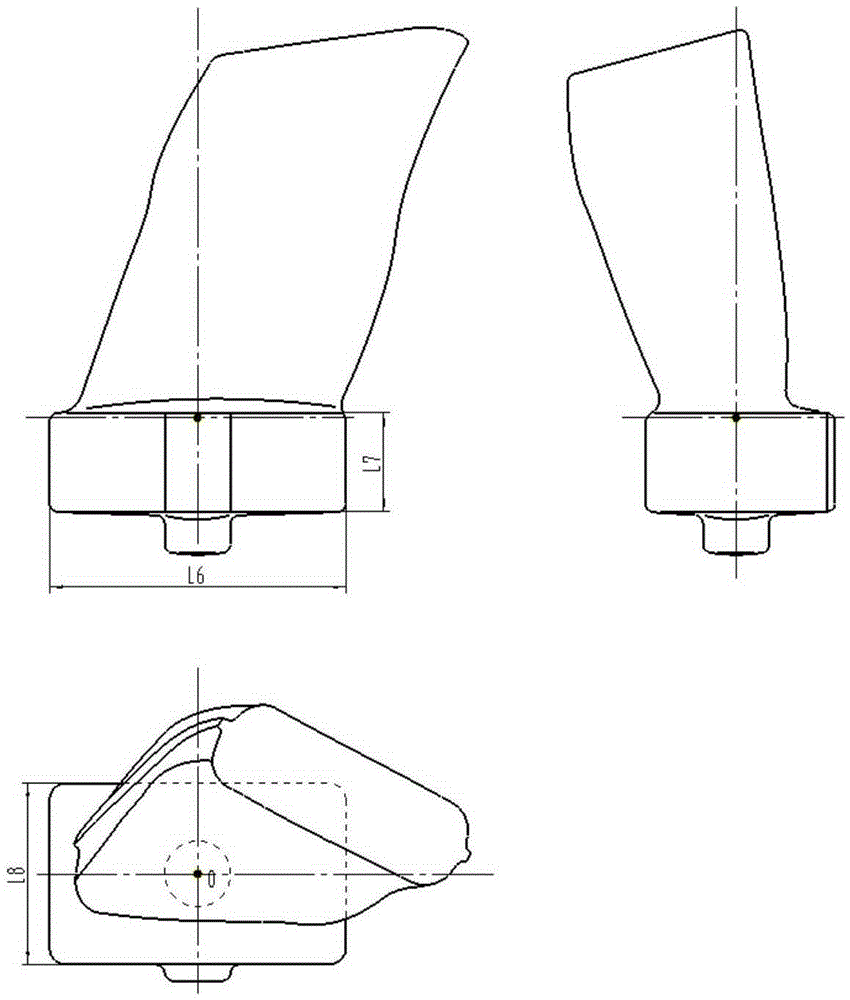

Isothermal beta forging method for TC17 titanium alloy blade

ActiveCN106607540AGuaranteed DimensionsReplaceableEngine componentsHeating/cooling devicesTitanium alloyMachining

The invention discloses an isothermal beta forging method for a TC17 titanium alloy blade, and the problem that the process requirement of existing TC17 blisk forging is high can be solved to a certain extent. The process requirement of TC17 blisk forging is high, and the machining requirement of forge pieces in the machining link is quite high. Machining errors in machining of the blade can cause scrapping of a whole blisk forge piece, time and labor are saved, and the economic cost is high. A wheel disc and the blade are forged separately, the identical isothermal beta forging method is adopted for the blade and a compressor blisk, and thus the forging forming difficulty is low, and subsequent machining is greatly facilitated.

Owner:SHAANXI HONGYUAN AVIATION FORGING

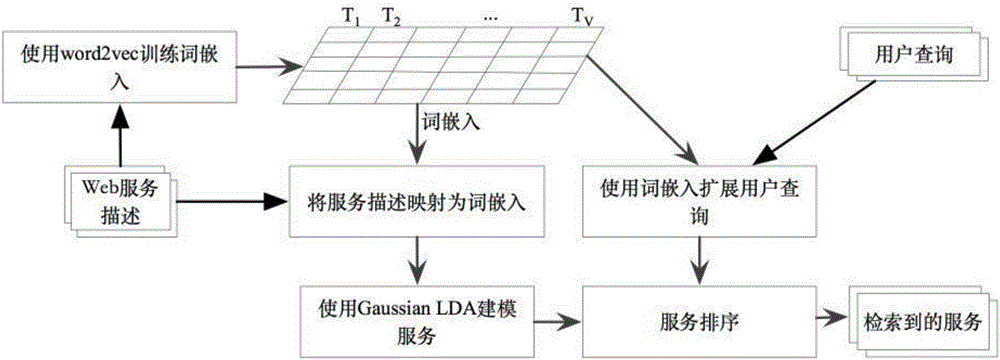

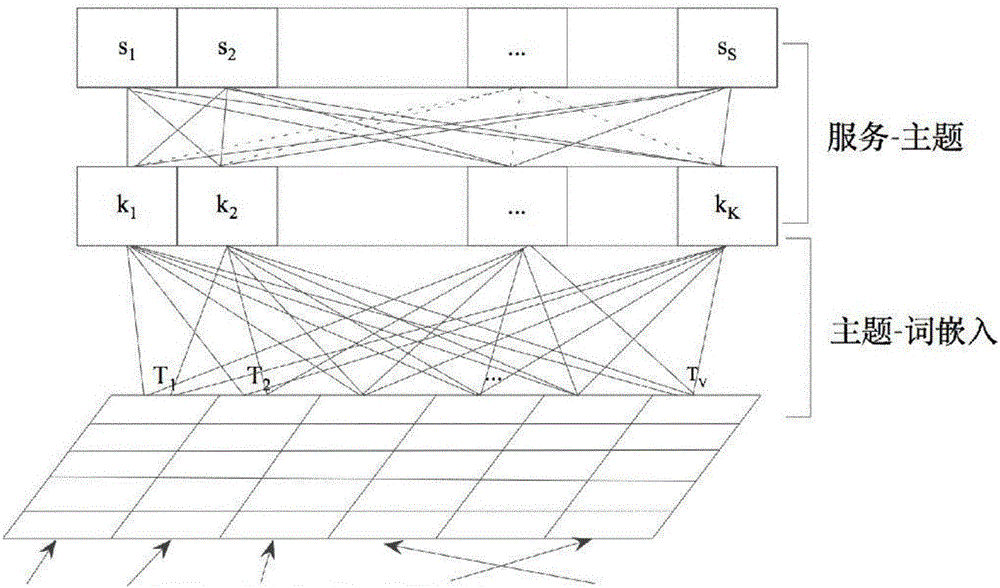

Semantic sparse Web service discovery method based on Gaussian LDA and word embedding

InactiveCN106599086ARealize the organizationAchieve retrievalWeb data indexingSpecial data processing applicationsServices computingEuclidean vector

The invention discloses a semantic sparse Web service discovery method based on Gaussian LDA and word embedding, and specifically relates to the technical field of service computing. The method specifically comprises the following steps in order: collecting a Web service description document, preprocessing the collected Web service description document, obtaining characteristic vocabularies in the Web service description document, preprocessing the vocabularies in the Web service description document, and obtaining a set of a group of prototype words; using a word embedded training model Word2Vec to train the set of the prototype words obtained in step 1, and obtaining a continuous vector representation of each word in the set of the prototype words; using a Gaussian LDA model to train the set of the prototype words obtained in step 1, and acquiring each Web service hierarchical structure; enriching user query by using a set of continuous vectors obtained in step 2 by training, and obtaining extended user query; and using the service hierarchical structure obtained in step 2 and using a probability ranking method to obtain query output corresponding to the extended user query.

Owner:SHANDONG UNIV OF SCI & TECH

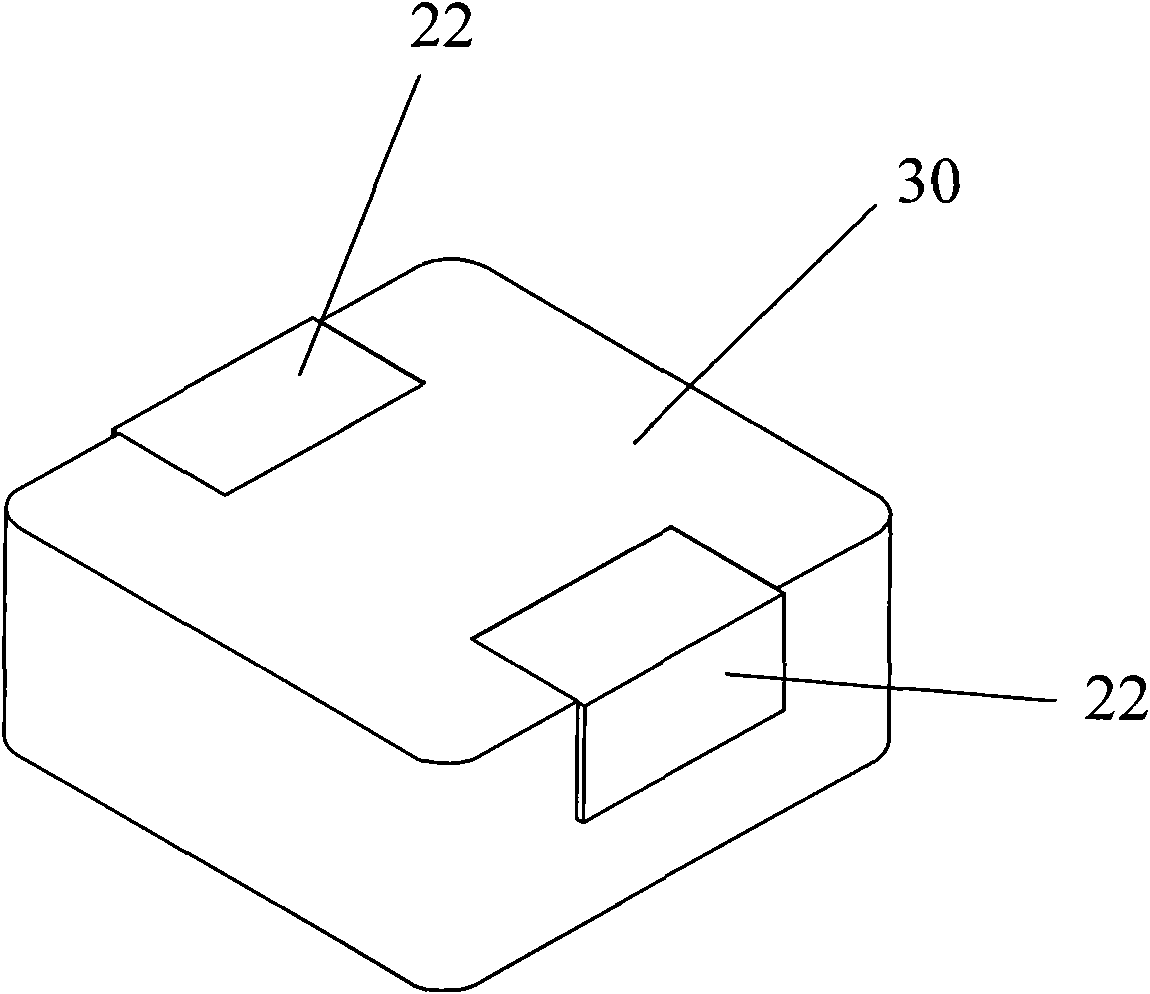

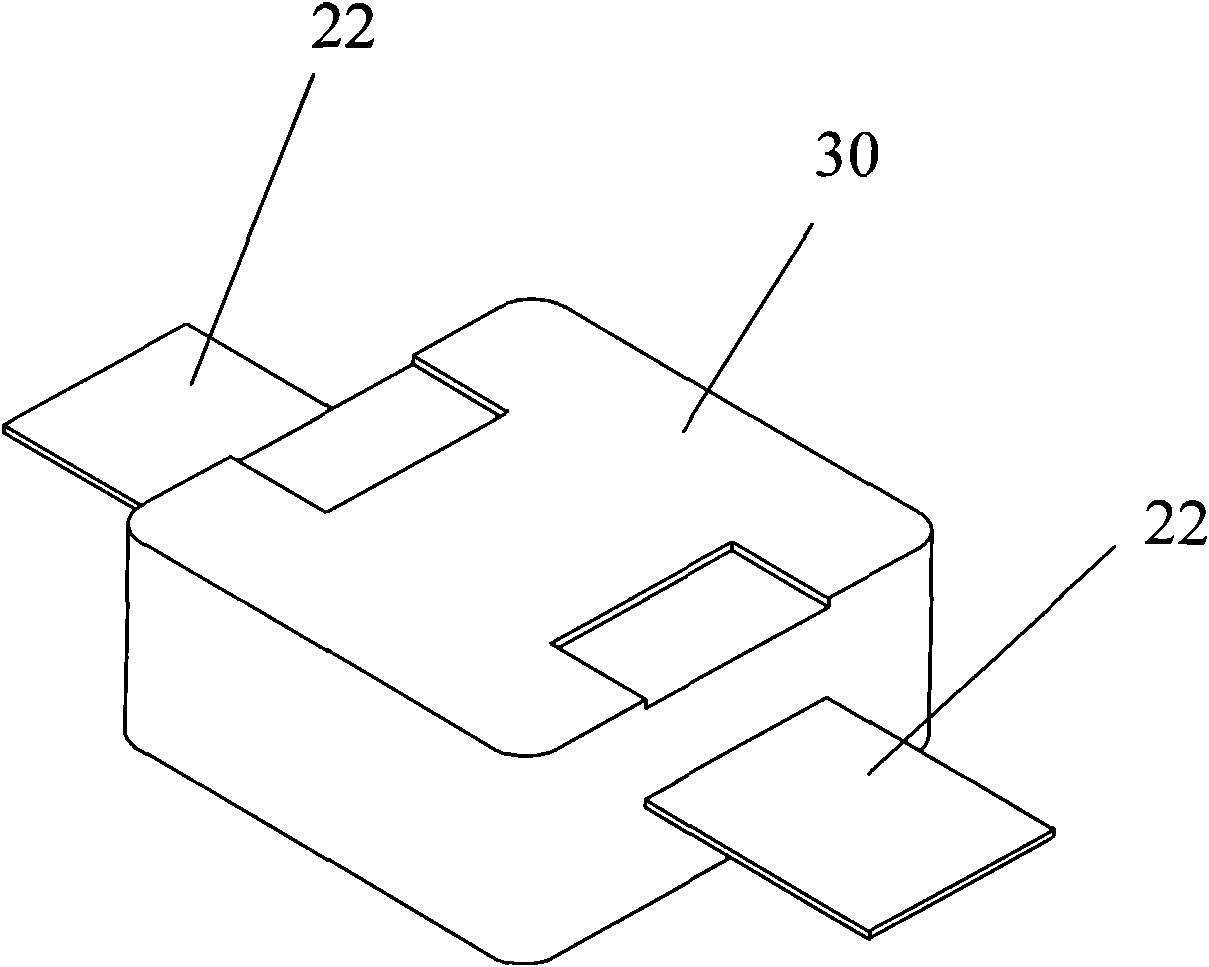

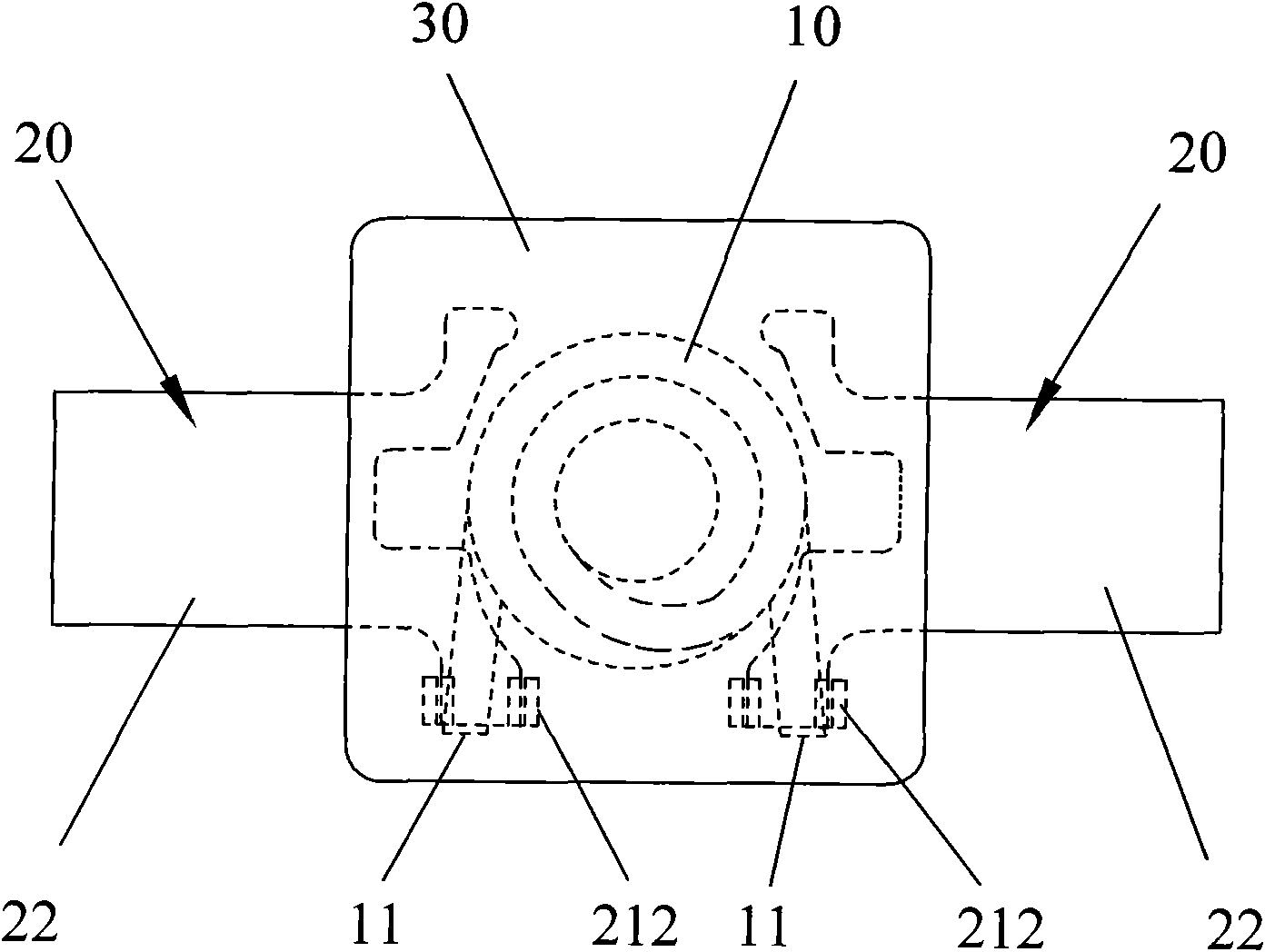

Integrally formed inductor and manufacture process thereof

InactiveCN101615480ABetter connection qualityImprove connection strengthTransformers/inductances coils/windings/connectionsTransformers/inductances magnetic coresL&D processInductor

The invention discloses an integrally formed inductor and a manufacture process thereof, comprising a coil, two electrode pins and a magnetic solid body formed by press powder. The coil is embedded in the magnetic solid body; first end parts of the two electrode pins are embedded in the magnetic solid body with electric clearances and are electrically connected with two pins of the coil; second end parts of the two electrode pins are bent and tightly attached to the surface of the magnetic solid body; the first end part of each electrode pin is provided with two vertical clamping pieces which are integrally bent and formed; and the pins of the coil are clamped in the two vertical clamping pieces and are welded and electrically connected. By adopting the structure, the connection strength between the coil and the electrode pins is enhanced, the connection reliability between the coil and the electrode pins is ensured, thereby avoiding the quality hidden trouble and finally greatly improving the quality of products. In addition, through reasonably arranging the manufacture process of the inductor and simplifying the manufacture flow, the invention ensures that the manufacture of the inductor can be finished automatically, simply and fast, and has the remarkable characteristics of high efficiency and high quality.

Owner:奋发电子(东莞)有限公司

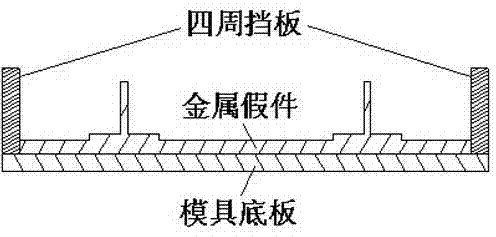

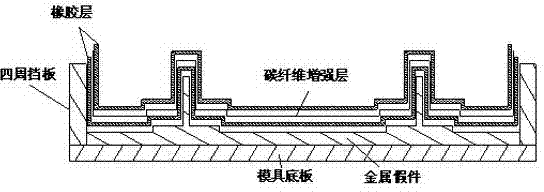

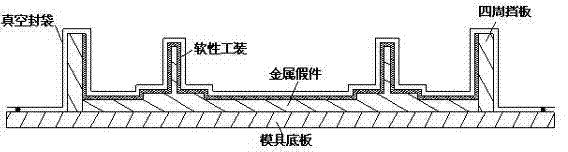

Method for realization of co-curing of reinforcing rib web composite produced part by high strength soft tooling

The invention discloses a method for realization of co-curing of a reinforcing rib web composite produced part by high strength soft tooling, rubber produced soft tooling is formed by use of a metal false piece, and the composite produced part is formed by use of the soft tooling. The soft tooling self is provided with a carbon fiber reinforced layer, the size of the product formed by use of the soft tooling can be guaranteed, outside pressure and temperature can be better transferred to the composite produced part, uneven partial pressure, heating rate hysteresis and other phenomena of the produced part can be avoided, the soft tooling is provided with a support structure, paving and preloading and other operation of the produced part can be completed on the soft tooling, the relative position precision and shape size of each part of the formed produced part can be ensured, the soft tooling can be used repeatedly, the reproduction is also more convenient, and the production cost and the manufacturing cycle are effectively reduced.

Owner:航天海鹰(镇江)特种材料有限公司

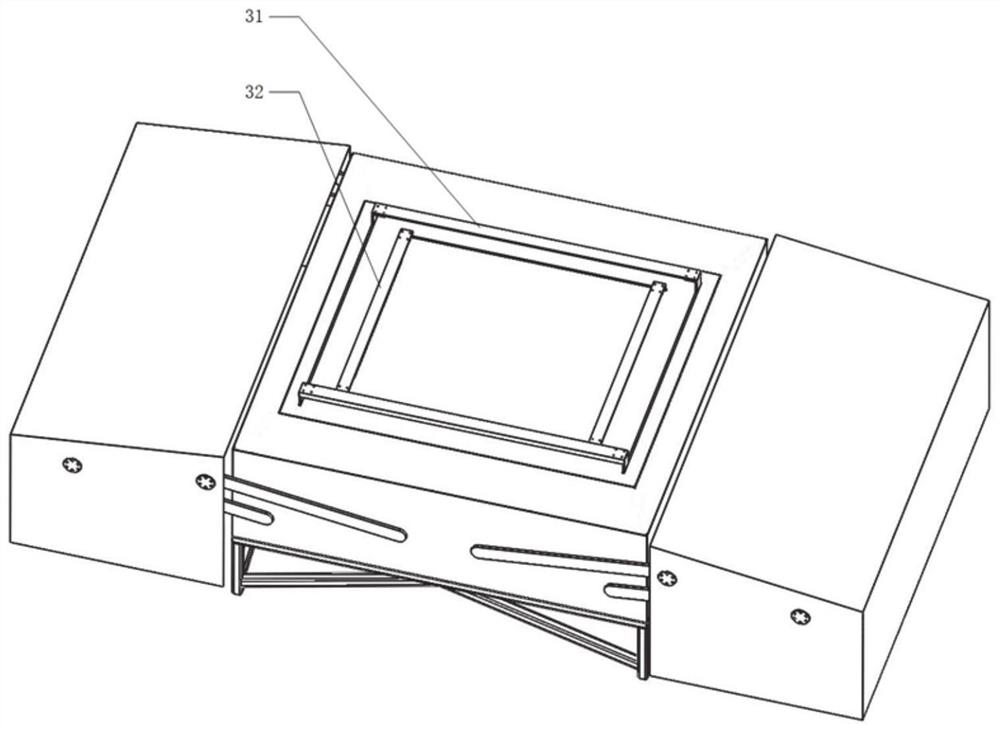

Compact overturning type double-unmanned-aerial-vehicle nest and control method

ActiveCN112482855AImplement storageThe order of use does not affect each otherLanding aidsRemote controlled aircraftRotational axisMarine engineering

The invention provides a compact overturning type double-unmanned-aerial-vehicle nest and a control method. The double-unmanned-aerial-vehicle nest comprises a box body, a cabin door and a overturningplatform. The overturning platform is arranged at an opening position of the box body through a rotating shaft; the cabin door is movably connected with the box body; the distance between the top ofthe cabin door and the surface where the opening of the box body is located is larger than or equal to the height of an unmanned aerial vehicle when the cabin door is closed; and unmanned aerial vehicle fixing mechanisms are arranged on two opposite side faces of the overturning platform. According to the compact overturning type double-unmanned-aerial-vehicle nest and the control method, the storage of the two unmanned aerial vehicles is realized with a small nest size; through a control program, the two unmanned aerial vehicles can automatically execute a written inspection task, and the usesequences of the two unmanned aerial vehicles do not influence each other; and the internal space of the nest can be utilized to the maximum extent, the parking requirements of two unmanned aerial vehicles are met, the inspection efficiency of the unmanned aerial vehicles can be effectively improved, and the equipment cost is saved.

Owner:STATE GRID INTELLIGENCE TECH CO LTD

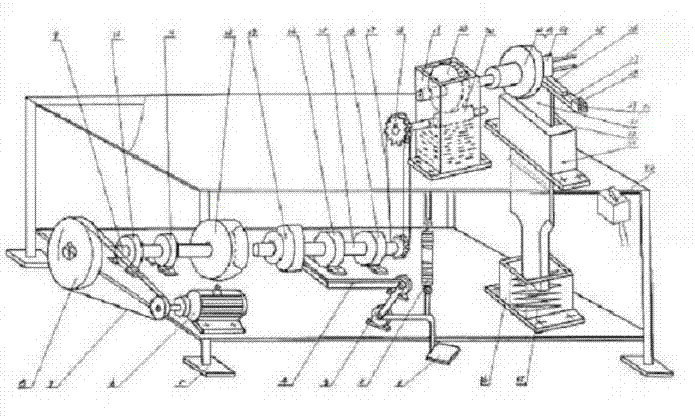

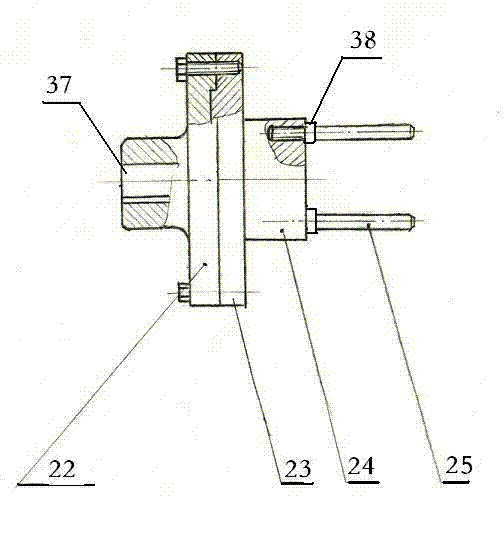

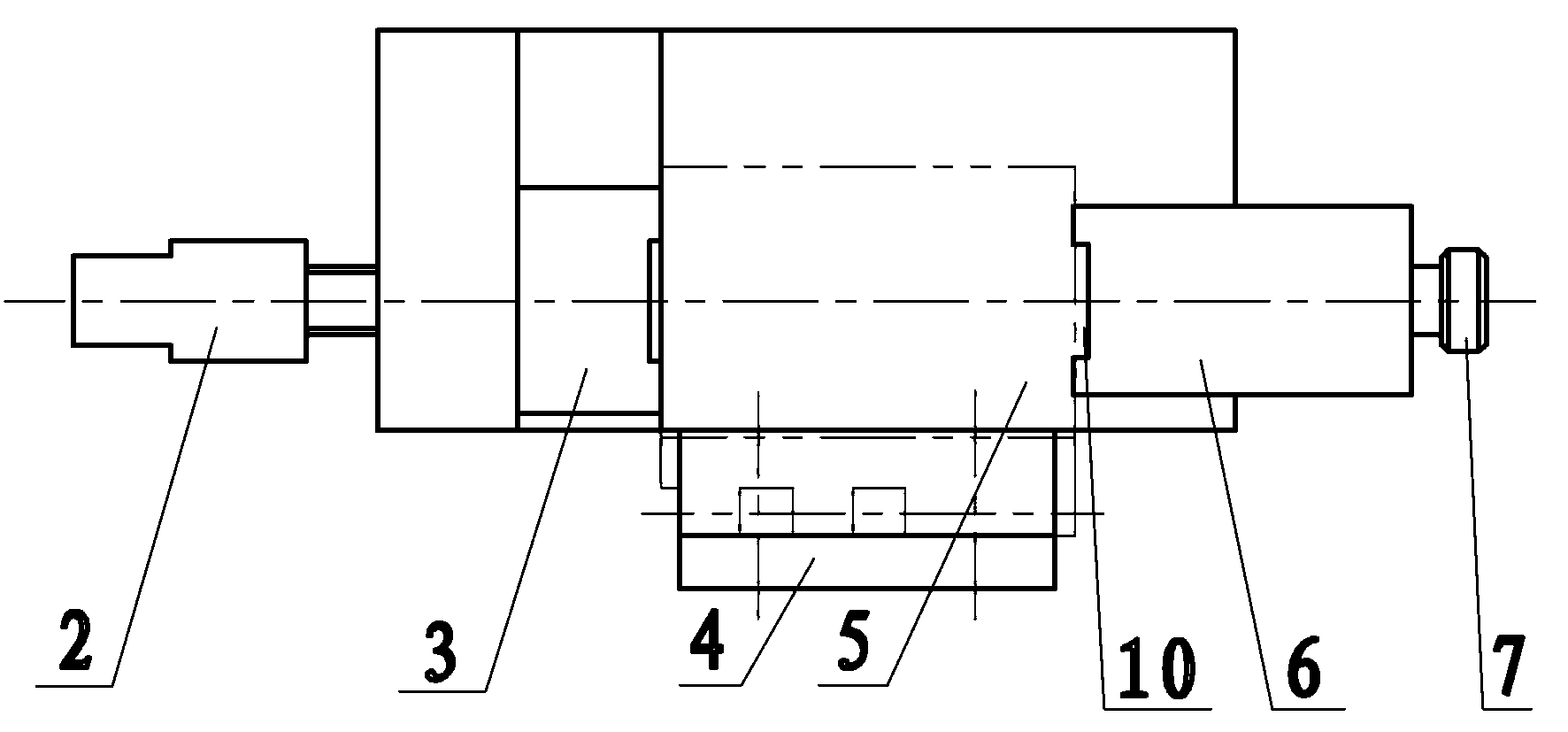

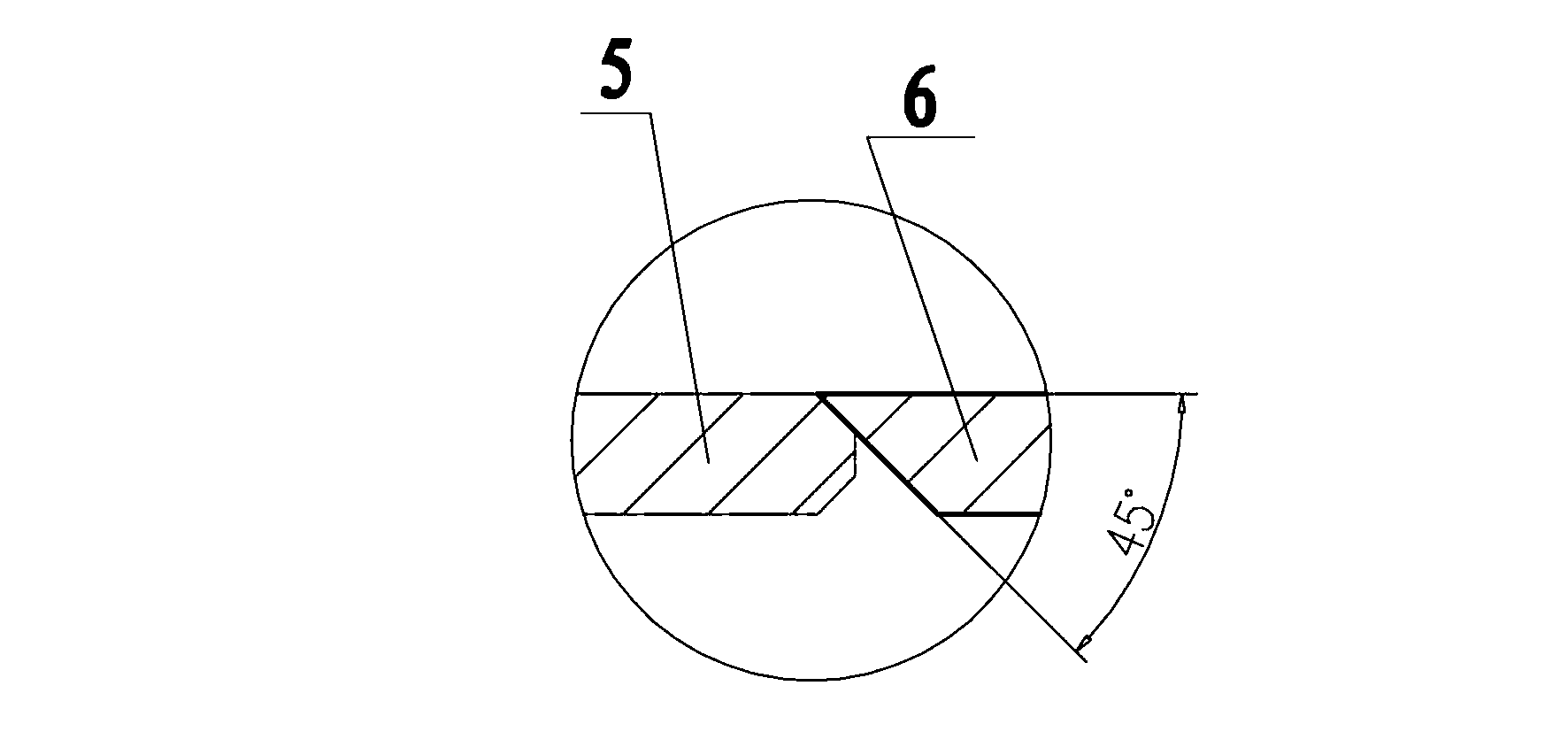

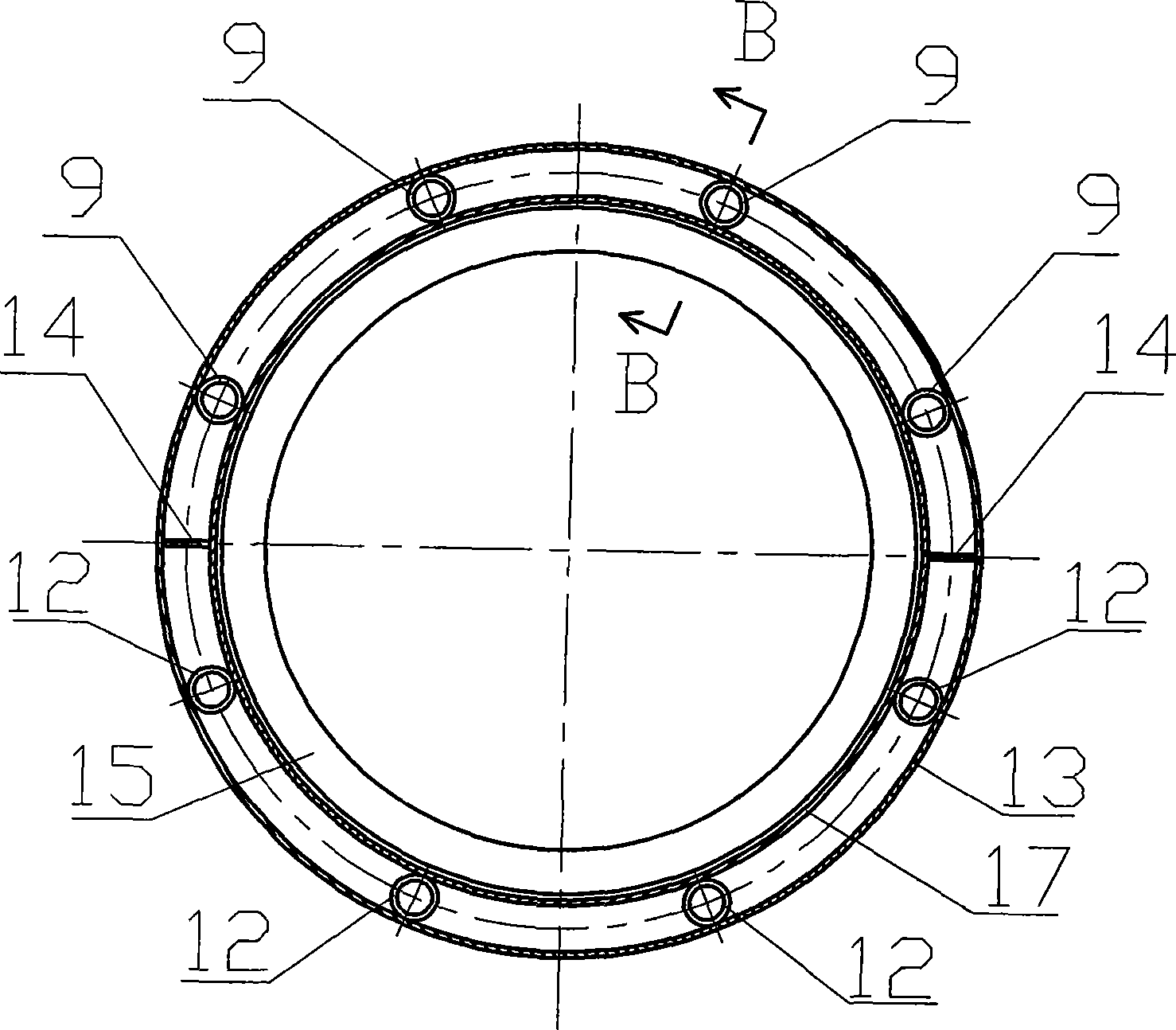

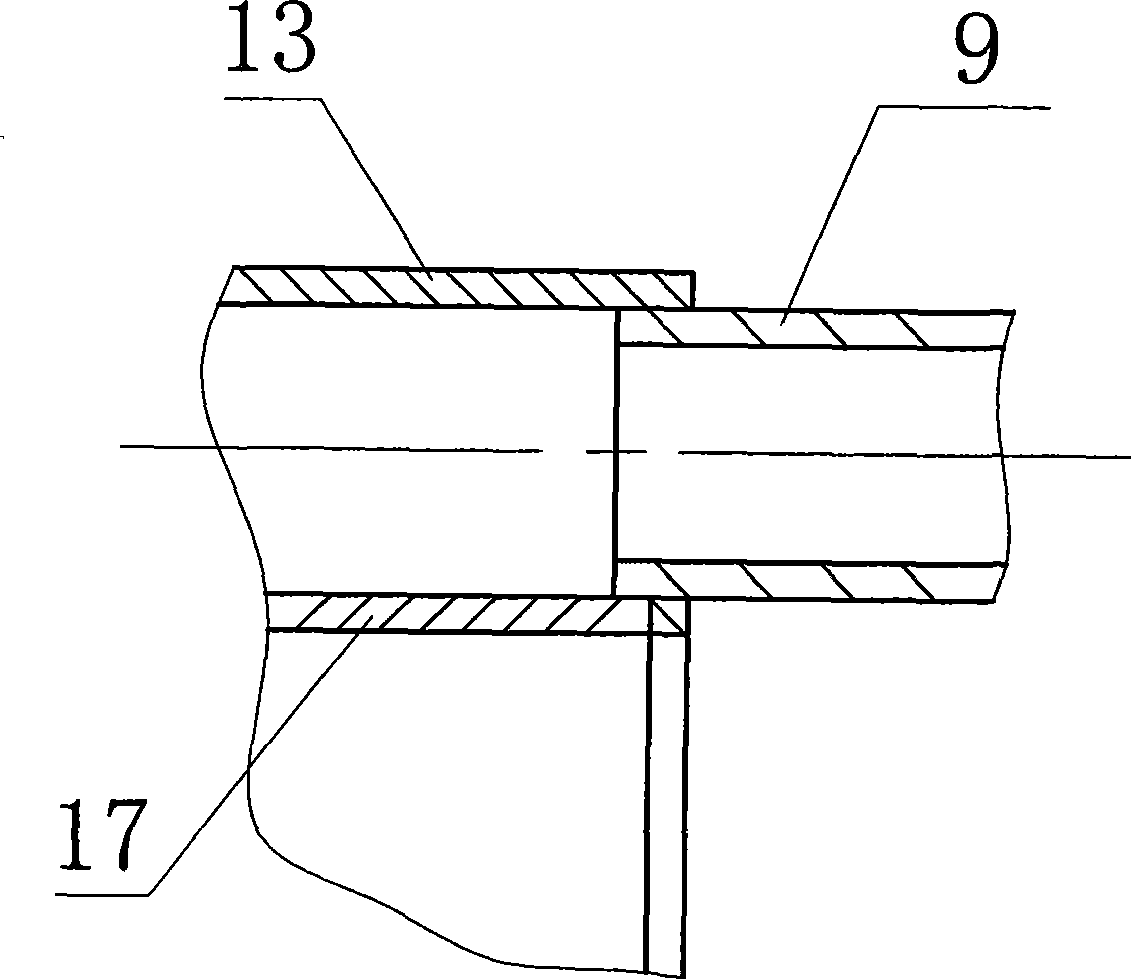

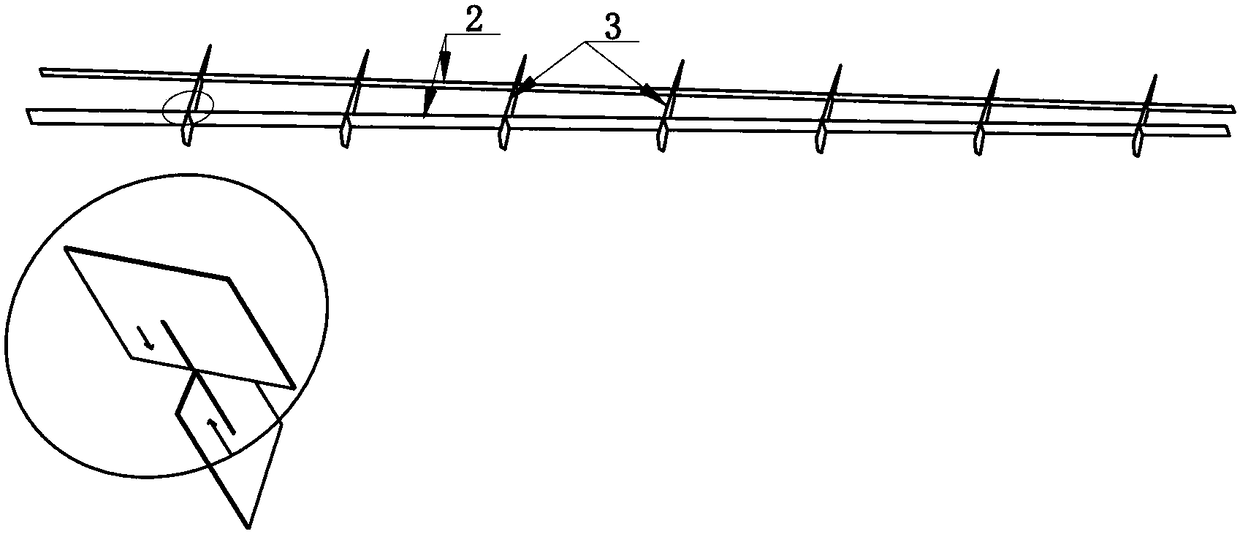

Flat wire vertical winding machine

ActiveCN102360934AGuaranteed DimensionsMore contact spaceCoils manufactureWinding machineBolt connection

The invention relates to a flat wire vertical winding machine which mainly comprises a vertical winding wire shift device, a vertical winding die head device, a vertical winding compression device, a power drive device and a control device, wherein a wire shift strengthening block in the vertical winding wire shift device is fixed onto a connecting platform at the rear end of a guide head by a screw; a wire shift device is fixed on the wire shift strengthening block by a screw, and one upper-strip-shaped side of the wire shift device is provided with a wire shift groove; the front end of the guide head is provided with parallel guide wheel grooves and a vertical guide wheel groove; and two parallel guide wheels and a vertical guide wheel are respectively installed in the parallel guide wheel grooves and the vertical guide wheel groove correspondingly and connected with compression device sliding blocks by bolts. The vertical winding compression device comprises a sliding block support seat, an embedded strip, the sliding blocks, a compression spring and a spring support seat; and the vertical winding die head device comprises a ring flange, a flange connecting block, a die head and a coil lifting rod. A flat wire of a secondary coil of a welding machine is vertically wound, a coil width surface has more contact space, and thereby the heat is easy to radiate during loading; and the flat wire vertical winding machine not only can be used to ensure the contour dimension and the width surface size of the coil but also has the advantages of saving materials and ensuring stable current output at the same time.

Owner:YUNNAN JUFENG ELECTRIC WELDING MACHINE

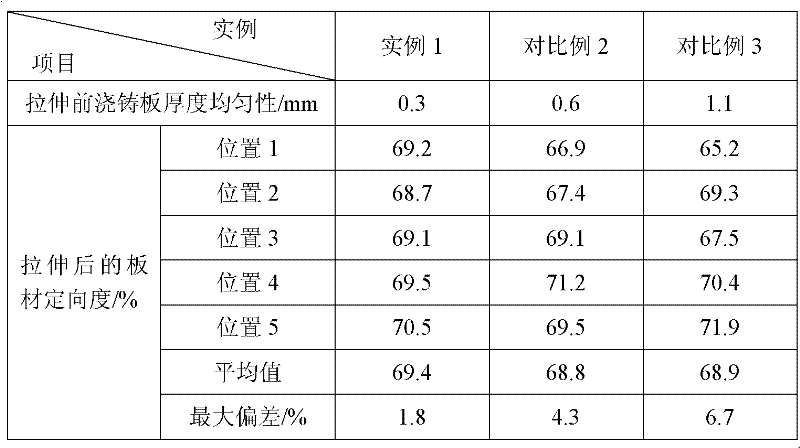

Preparation method for even-orientation-degree organic glass

Provided is a preparation method for even-orientation-degree organic glass. A grinded organic glass pouring plate is extended through an X-axis and a Y-axis in 125 DEG C to 160 DEG C. The organic glass pouring plate is methyl methacrylate homopolymerization or copolymerization plate prepared by a body pouring method and contains plasticizers, cross-linking agents or other performance addictives. The organic glass can be grinded flash through grinding equipment including grinders or lapping machines, and the height of grinded flash materials is smaller than 0.3mm. Stretching orientation can be performed through an X-Y double axis oriented stretching machine, and uniformity of the inner temperature of a thermal insulation cavity of the organic glass is smaller than 3 DEG C. The uniformity of orientation degree of prepared oriented stretched organic glass is no larger than 3%.

Owner:锦西化工研究院有限公司

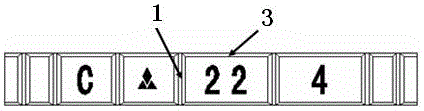

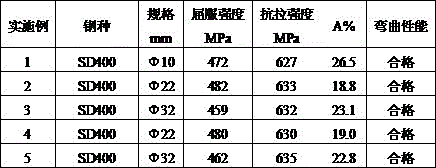

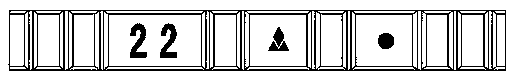

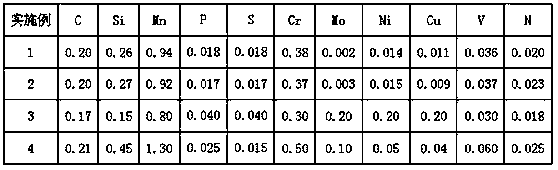

Korean standard SD400 ribbed threaded steel bar and production method thereof

InactiveCN106756556AReduce the temperatureHigh tensile strengthBuilding reinforcementsSocial benefitsChemical composition

The invention discloses a Korean standard SD400 ribbed threaded steel bar and a production method thereof. The steel bar comprises the chemical components of, by mass, 0.17-0.25% of C, 0.20-0.50% of Si, 0.80-1.30% of Mn, no larger than 0.045% of P, no larger than 0.045% of S, 0.030-0.060% of V, 0.30-0.50% of Cr, 0.018-0.025% of N, no larger than 0.20% of Mo, no larger than 0.20% of Ni, no larger than 0.20% of Cu, and the balance Fe and inevitable impurities. The production method comprises the procedures of heating, rough rolling, medium rolling, finish rolling and cooling. According to the production method, the Korean standard SD400 ribbed threaded steel bar which is produced at low cost and has qualified performance and excellent bending performance is achieved by adding vanadium into low carbon and low manganese for alloying in cooperation with the reasonably designed heating temperature and controlled rolling and controlled cooling process and has good economic and social benefits.

Owner:HEBEI IRON AND STEEL

Jig and method of using jig for machining camera lenses

InactiveCN104493711AReduce manual interventionGuaranteed DimensionsEdge grinding machinesGlass severing apparatusNumerical controlEngineering

The invention is applicable to the technical field of lens machining and provides a jig and a method of using the jig for machining camera lenses. The jig comprises a first jig and a second jig, the first jig is provided with grooves used for placement of to-be-machined lens materials, and ejector pins vertically extend at positions, corresponding to the grooves, of the second jig and can be embedded in the corresponding grooves. The to-be-machined lens materials are placed on the jig, the jig can be fixed by a CNC (computer numerical control) machine tool by means of vacuum suction due to the fact that the size of the jig is larger than that of the lens materials, and accordingly CNC machining can be carried out. By means of the CNC machining process, adoption of a profiling machine for profiling and a beveling machine for beveling in the traditional process is replaced, and manual intervention is reduced; in addition, owing to precision of CNC equipment, profiling and beveling procedures can be completed on the lens materials for one time by the aid of a CNC tool, and product production time is shortened while production efficiency and product yield are increased on the premise that external dimensions of products are guaranteed.

Owner:深圳市尊宝精密光学有限公司

Sheet metal bending technology

The invention discloses a sheet metal bending technology which comprises the following steps: 1, before a bending production process, preparing to calculate the unfold size and positions of all hole sites and notches of a component; according to the principle that the length of a bent neutral layer is not changed, calculating the unfold size of a component sheet matal; the unfold length of the part sheet matal is sum of length of a straight part and length of the neutral layer of a bent part; 2, according to the size and material thickness on a drawing, determining a cutter and a cutter groove during bending, wherein avoidance of deformation caused by collision between a product and the cutter is key to selection of an upper die, and selection of a lower die is determined according to the thickness of a sheet material; and 3, determining the bending sequence, wherein the bending rule is as follows: internal first and external second, small first and big second, and special first and common second; for a workpiece to be tightly pressed, firstly, the workpiece is bended by 30-40 degrees, and then the workpiece is tightly pressed by a leveling die. The sheet metal bending technology ensures that all machined hole sites, notches and the boundary dimension of the bended component meet the expected requirements.

Owner:昆山市力勋达精密机械有限公司

Forming tool for winglet of foam sandwich composite structure

The invention belongs to the technical field of composite aviation manufacturing and relates to a forming tool for a winglet of a foam sandwich composite structure. The forming tool is composed of an upper forming mold and a lower forming mold. The upper forming mold is a composite mold and is used for ensuring the outline dimension and the surface quality of the upper molded surface of the winglet in the winglet forming process. The lower forming mold is a composite frame mold and is used for supporting and fixing a whole part and ensuring the outline dimension and the surface quality of the lower molded surface of the winglet in the winglet forming process. The molded surface of the lower forming mold is a variable-thickness composite molded surface. The butt joint area of the front edge of the lower forming mold and the upper forming mold is provided with a thinning area to ensure the uniformity of a pressure field in the large-curvature area of the front edge of the winglet. The forming tool for the winglet of the foam sandwich composite structure is easy to operate, demolding is easy, the problem that large-curvature complex structure parts similar to the winglet are unevenly pressurized is solved, and the internal quality and the surface quality of the parts are well ensured.

Owner:AVIC COMPOSITES

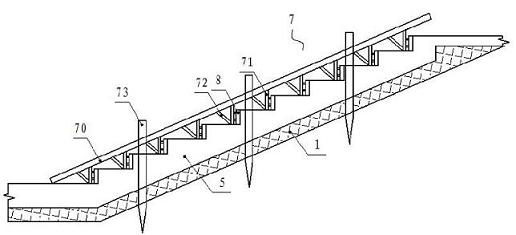

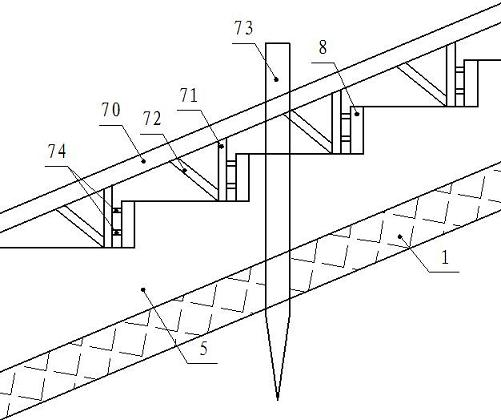

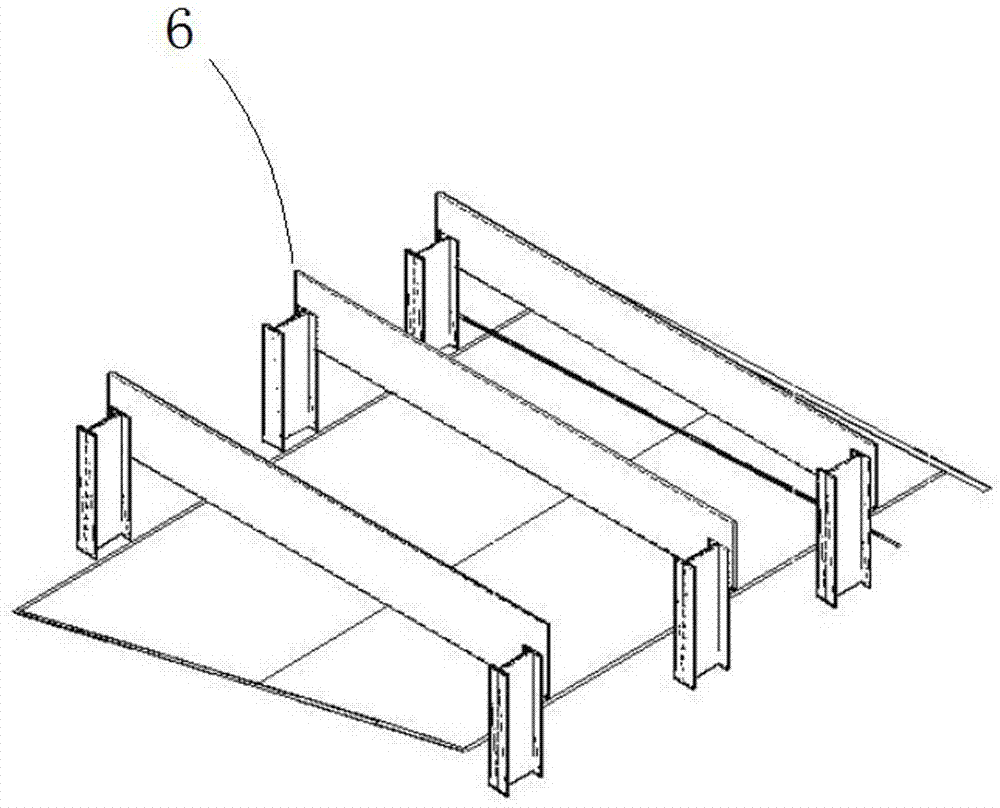

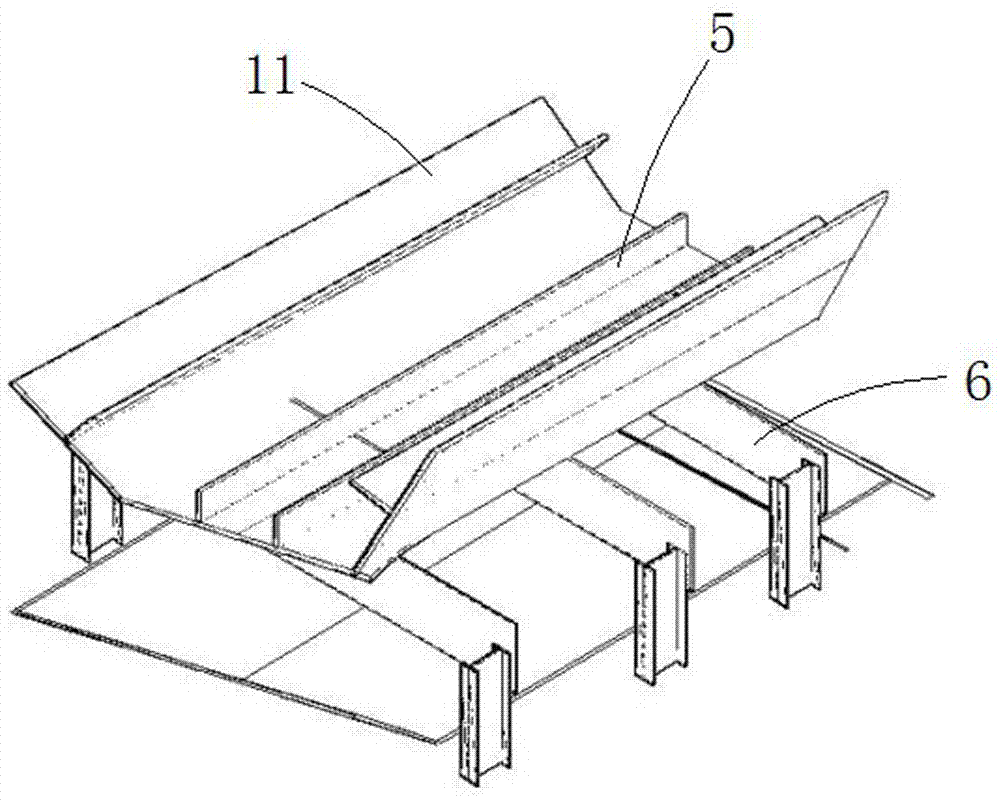

Suspended formwork pouring method for concrete foundation steps

ActiveCN102677895AEasy to assemblePrecise positioningForms/shuttering/falseworksBuilding material handlingStructural engineeringUltimate tensile strength

The invention relates to a suspended formwork for concrete foundation steps and a suspended formwork pouring method for pouring concrete foundation steps by using the suspended formwork. The suspended formwork comprises one or a plurality of formwork racks, each formwork rack comprises at least one longitudinal beam and a plurality of structural units distributed along the longitudinal beams in turn, each structural unit comprises a vertical formwork rack for mounting a vertical formwork and an inclined strengthening rib for fixing the vertical formwork rack, one end of the vertical formwork rack is fixedly connected with the longitudinal beam, and the two ends of the inclined strengthening rib are fixedly connected with the longitudinal beam and the vertical formwork rack respectively to form a steady triangular structure. The method comprises the following steps: (1) leveling up and tamping a foundation; (2) mounting a suspended formwork; and (3) pouring concrete foundation steps by use of the suspended formwork fabricated in step (2). The suspended formwork provided by the invention has the advantages of simple structure, accurate positioning and easiness in operation, and can be repeatedly used. The steps constructed using the method provided by the invention have the advantages of regular structure, esthetic appearance, high strength, and greatly improved quality.

Owner:北京正和恒基滨水生态环境治理股份有限公司

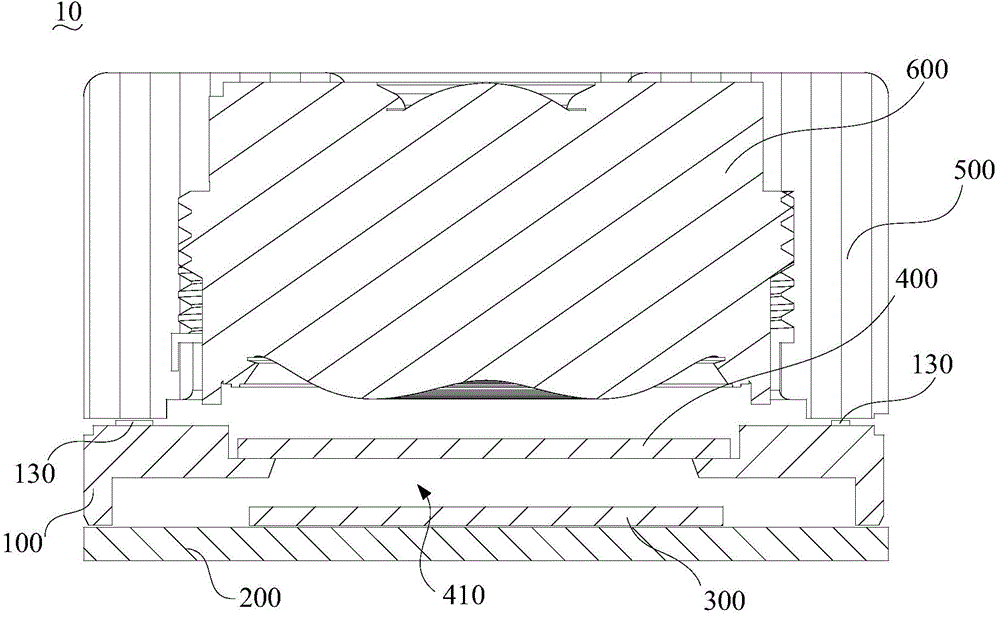

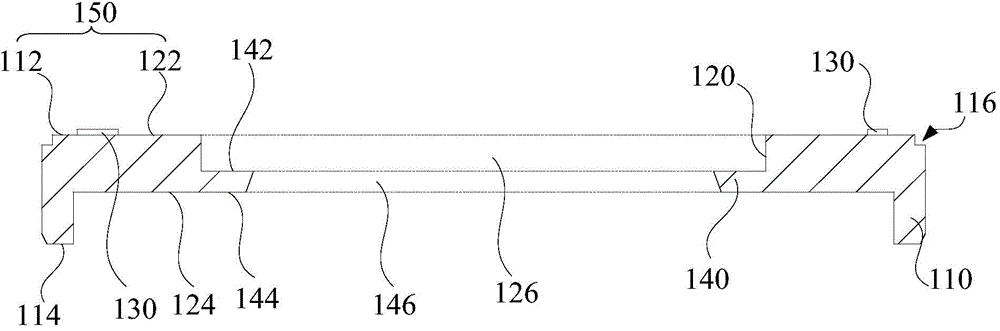

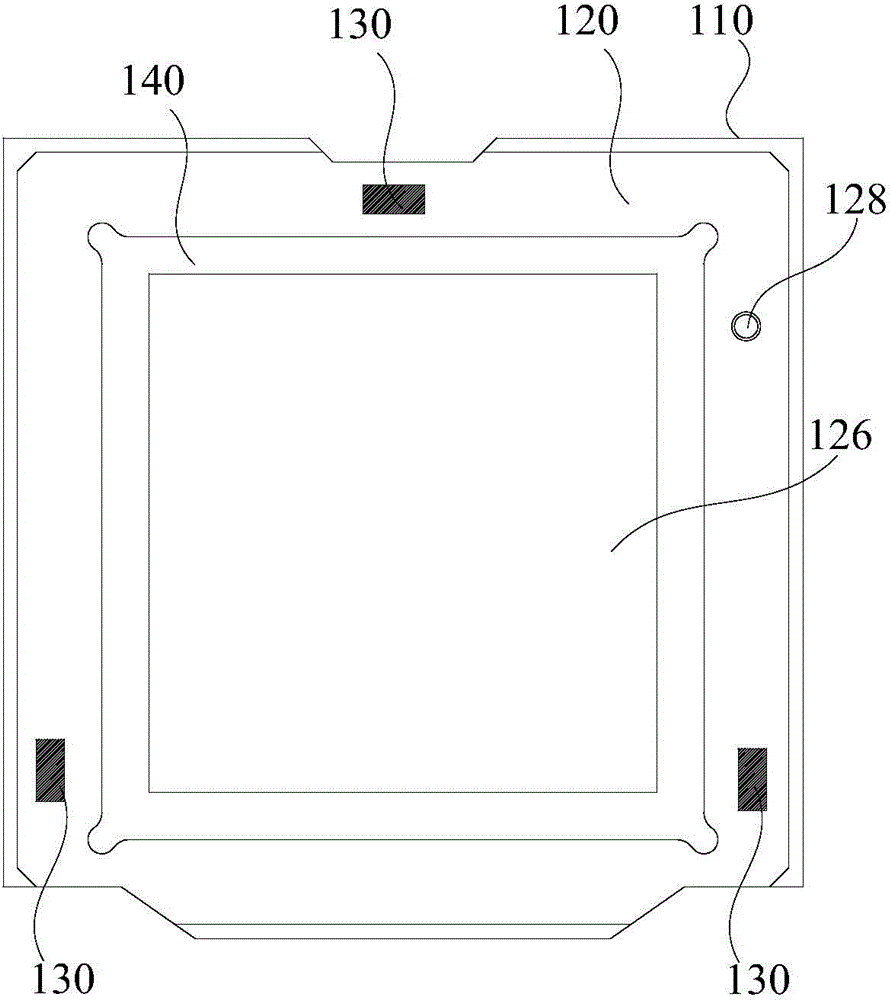

Camera module and bracket thereof

ActiveCN104902156AAvoid flowing toNot easy to separateTelevision system detailsColor television detailsEngineeringInfrared cut-off filter

The invention relates to a camera module and a bracket thereof. The bracket comprises a barrel, a mounting plate and lugs, wherein the barrel has a first end face and a second end face which are opposite to each other; the mounting plate has a first surface and a second surface which are opposite to each other; the mounting plate is arranged in the barrel; the first surface and the first end face are flush with each other and constructed a mounting surface; the mounting plate is provided with a light hole passing through the first surface and the second surface; the light hole is used for accommodating an infrared cut-off filter of the camera module; the lugs are arranged on the mounting plate; one side of each lug far away from the mounting plate is used for carrying a voice coil motor of the camera module; a plurality of lugs are distributed in such a way that the voice coil motor of the camera module can be erected on the lugs under the condition of no external force; a space between the mounting surface and the lugs far away from the mounting surface is taken as a glue accommodating area; and the second end face is used for connecting a circuit board of the camera module. During assembly of the bracket, the overall dimension of the camera module can be ensured, and the voice coil motor can be prevented from being separated from the bracket in the case of falling.

Owner:O FILM IMAGE TECH (GUANGZHOU) CO LTD +4

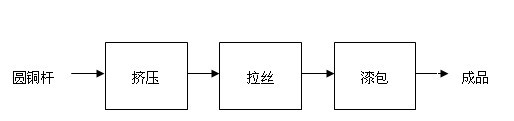

A kind of manufacturing process of enameled bare copper flat wire

InactiveCN102280220AOvercome inherent flawsGuaranteed DimensionsInsulating conductors/cablesElectrical performanceHardness

The invention discloses a process for manufacturing an enameled bare copper flat wire. The process comprises the following steps of: directly extruding a bare copper flat wire by using a round copper rod; drawing by one or two moulds to obtain the bare copper flat wire with satisfactory appearance, size, hardness and density performances; and finally, enameling the satisfactory bare copper flat wire to obtain the finished enameled bare copper flat wire. According to the invention, the inherent defect of the traditional drawing process is overcome effectively, the appearance and size can be guaranteed and the surface quality can be improved obviously; and the product has moderate hardness, excellent electrical performance and good quality.

Owner:JIANGSU JURONG UNITED COPPER MATERIAL

Japanese standard SD345 ribbed twisted steel bar and production method thereof

The invention discloses a Japanese standard SD345 ribbed twisted steel bar and a production method thereof. The Japanese standard SD345 ribbed twisted steel bar comprises chemical components, by masspercent: 0.17%-0.21% of C, 0.15%-0.45% of Si, 0.80%-1.30% of Mn, 0.040% or less of P, 0.040% or less of S, 0.030%-0.060% of V, 0.30%-0.50% of Cr, 0.018%-0.025% of N, 0.20% or less of Mo, 0.20% or lessof Ni, 0.20% or less of Cu, and the balance Fe and unavoidable impurities. The production method comprises the working procedures of billet heating, rolling and cooling. According to the production method, alloying is carried out through low carbon and low manganese by adding vanadium, by cooperating with the reasonably designed heating temperature and the rolling and cooling control process, thepurpose of producing the Japanese standard SD345 ribbed twisted steel bar with qualified performance and excellent bending performance with low cost is achieved, and good economic and social benefitsare achieved.

Owner:HEBEI IRON AND STEEL

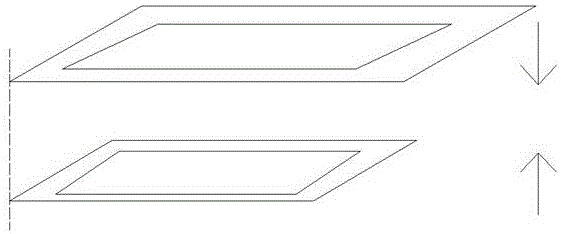

Forming method of wall-thickness-variable composite skirt

The invention discloses a molding method of a composite material skirt with variable wall thickness. The method comprises the following steps: attaching a component to be formed on the outer side of component one, and connecting component two end to end in a ring shape and attaching to the outer side of the component to be formed , set a vacuum bag on the outer side of the whole formed by the component to be formed and the second component and carry out vacuum treatment, put it into an autoclave for curing and molding, and after the forming of the component to be formed is completed, open the second component along the junction. , and then separate the component to be formed from the component 1 to complete the process of demolding, wherein the component 1 is an annular hard component, and the component 2 is a strip-shaped soft component. Compared with the prior art, the combination of the soft mold and the hard mold is beneficial to improve the quality of the surface forming. By disassembling the soft mold, rapid demoulding is realized without destroying the mold, and the mold can be reused, effectively saving the cost of the mold and reducing the manufacturing cost. .

Owner:成都联科航空技术有限公司

Touch screen and LCD (liquid crystal display) module attaching jig group and attaching method

InactiveCN105116575AEnsure consistencyGuaranteed DimensionsNon-linear opticsInput/output processes for data processingLiquid-crystal displayTouchscreen

The invention discloses a touch screen and LCD (liquid crystal display) module attaching jig group and an attaching method. The attaching jig group comprises a first jig used for attaching an LCD panel and a touch screen as well as a second jig used for attaching a backlight module and the whole after attachment of the LCD panel and the touch screen, wherein the first jig comprises a first bottom plate and four first positioning blocks connected with four corners of the first bottom plate respectively, and a first LCD panel positioning part and a touch screen positioning part are arranged in the position where each first positioning block and the first bottom plate are connected; the second jig comprises a second bottom plate and four second positioning blocks connected with four corners of the second bottom plate respectively, and a second LCD panel positioning part and a backlight module positioning part are arranged in the position where each second positioning block and the second bottom plate are connected. The LCD panel and the touch screen are attached together in a shape border aligning manner firstly, the consistency of peripheral borders of a product display area is guaranteed, then the whole and the backlight module are attached together in a shape border aligning manner, and the contour dimension of the backlight module is guaranteed very well.

Owner:深圳市联合盛电子有限公司

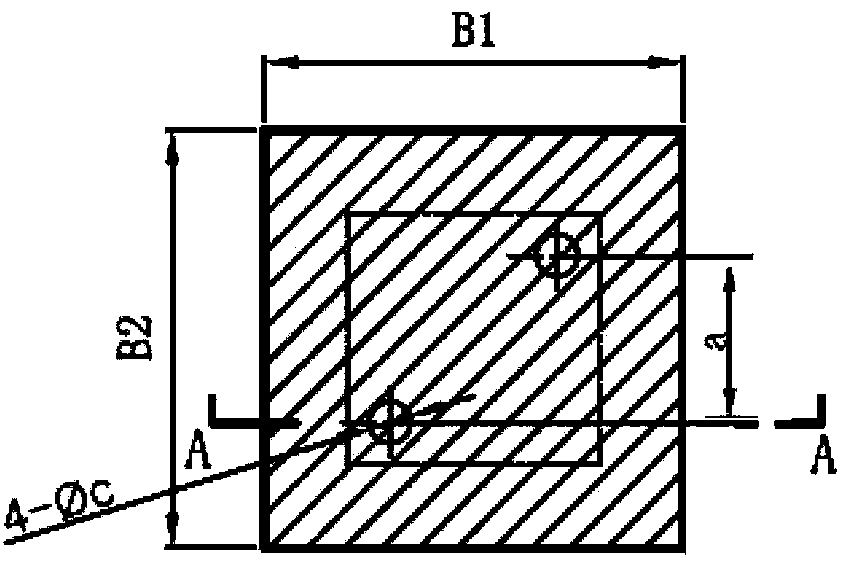

Chip capacitor provided with internal interconnection structure and manufacturing method thereof

InactiveCN103515093APole spacing is smallGuaranteed DimensionsFixed capacitor dielectricFixed capacitor terminalsCapacitanceEngineering

The invention discloses a chip capacitor provided with an internal interconnection structure and a manufacturing method of the chip capacitor. The chip capacitor provided with the internal interconnection structure comprises a multilayer chip capacitor body, inner electrodes and outer electrodes, wherein the multilayer chip capacitor body is integrally formed by sintering multiple dielectric medium layers; two oppositely arranged inner electrodes are arranged in the multilayer chip capacitor body; the outer electrodes are arranged on the upper surface and the lower surface of the multilayer chip capacitor body; the outer electrodes are electrically connected with the inner electrodes through interconnection holes in the multilayer chip capacitor body. A multiplayer ceramic manufacturing process is mainly adopted, tape-casting pieces are stacked and pre-pressed to manufacture the dielectric medium layers, the inner electrodes are manufactured by hole punching, hole filling and printing, the outer electrodes are sputtered and plated, and finally the capacitor is obtained. The chip capacitor is simple in process and easy to operate, and has higher capacitance compared with ordinary capacitors of the same appearance and size.

Owner:NO 55 INST CHINA ELECTRONIC SCI & TECHNOLOGYGROUP CO LTD

Core molding string casting and vertical casting method for small-size steel casting

InactiveCN103736927AHigh surface finishImprove the finishFoundry mouldsFoundry coresMolten steelSteel casting

The invention discloses a core molding string casting and vertical casting method for a small-size steel casting. The core molding string casting and vertical casting method comprises the following steps: (1) designing a casting form to be cast to be left and right parting and arranging in a left template and a right template, wherein each template is provided with a sand box; (2) covering the surface of the form with a layer of facing sands in a shaping process; (3) fully filling floor sand into the left sand box and the right sand box and compacting; (4) hardening foundry sands; (5) taking out a left sand mould and a right sand mould, and manufacturing inner cavity sand cores and a pouring cup; (6) respectively assembling the inner cavity sand cores with the left sand mould and the right sand mould together to form a casting mould, and carrying out convex-concave positioning on the left sand mould and the right sand mould; (7) putting the plurality of casting moulds into a special locking tool to form a string, locking, casting and mounting the pouring cup; and (8) pouring molten steel through the pouring cup, and taking the casting out after cooling and opening the box. Due to the adoption of the core molding string casting and vertical casting method disclosed by the invention, the production efficiency is improved, and the labor intensity and the production cost can be reduced.

Owner:柳州市江航工贸有限公司

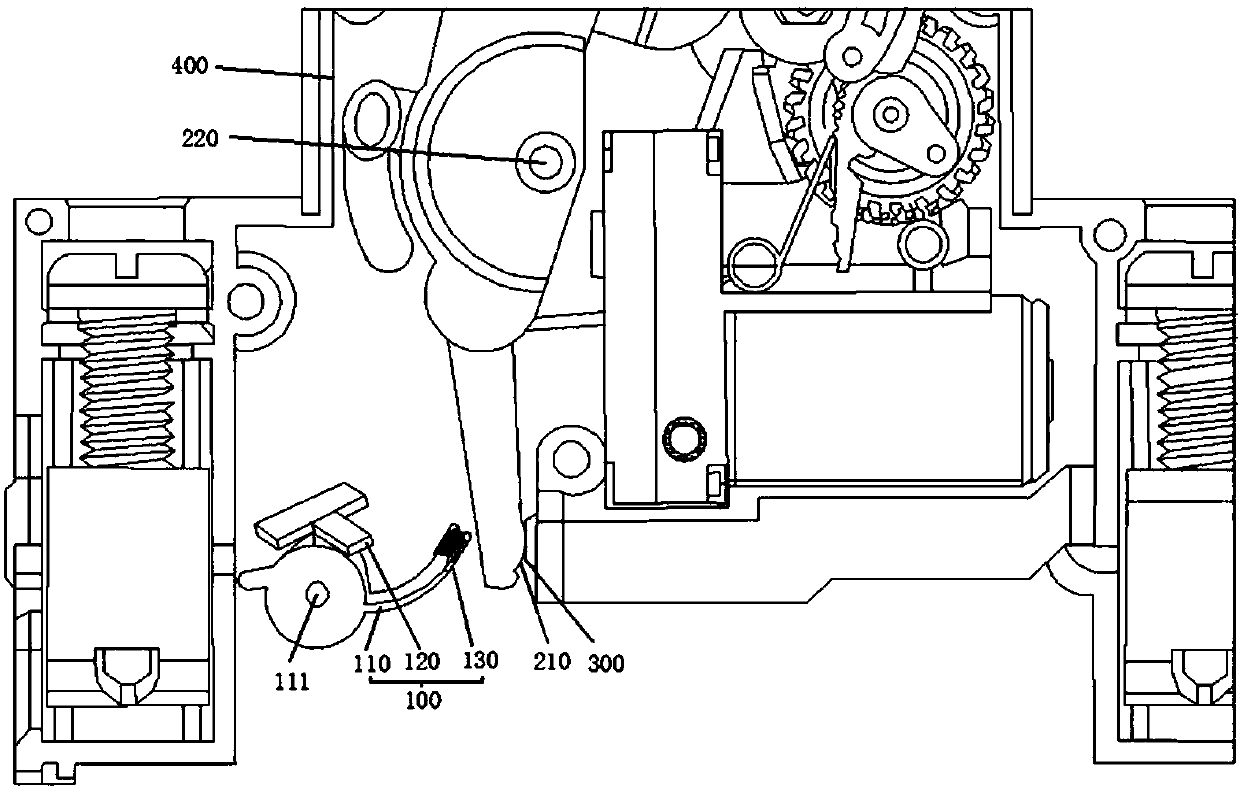

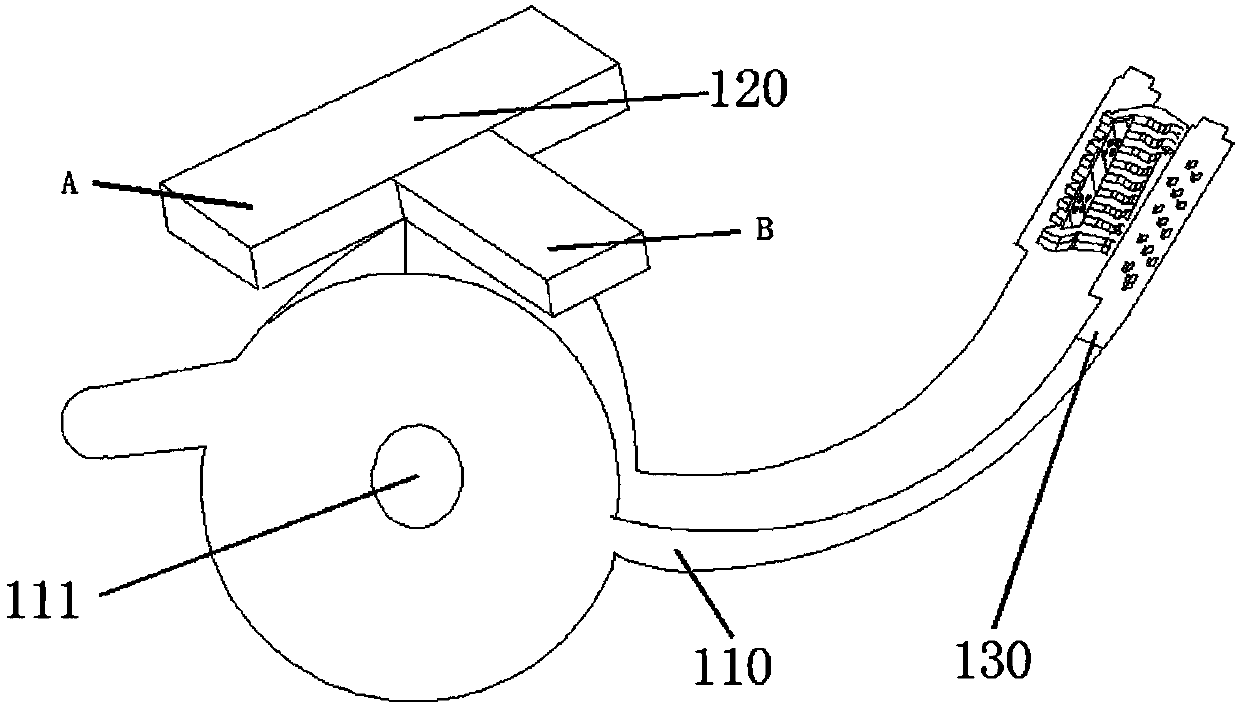

Arc extinguishing system of miniature circuit breaker

InactiveCN108022814AGuaranteed DimensionsImprove breaking capacityCircuit-breaking switch detailsEngineeringAtmospheric pressure

The invention relates to an arc extinguishing system of a miniature circuit breaker. The arc extinguishing system comprises a shell and an arc extinguishing piece, wherein the arc extinguishing piececomprises a connection part, a shift part and an arc extinguishing grid part, the connection part is rotatably connected with the shell and is provided with an initial position and an arc extinguishing position, the shift part is connected with the connection part, the arc extinguishing grid part is connected to the connection part, insulation material arc isolation plates are further arranged attwo side legs of an arc extinguishing grid and are provided with air holes, an arc isolation piece is formed by processing a high polymer insulation material capable of generating gas, the generated arc is isolated by an isolation plate, leg parts of the grid cannot be burnt, and the service lifetime of the arc extinguishing grid, a movable contact and a static contact is prolonged. On the other hand, the generated high-temperature gas can enter a gap between the legs of each grid through air outlet holes, air pressure of an arc extinguishing chamber is favorably reduced, metal vapor is enabled to be reduced, and the air pressure is also prevented from being excessively raised; and by a simple arc extinguishing structure, the breaking capability of the miniature circuit breaker is remarkably improved, and the service lifetime of the miniature circuit breaker is prolonged.

Owner:苏州华瑞达科技有限公司

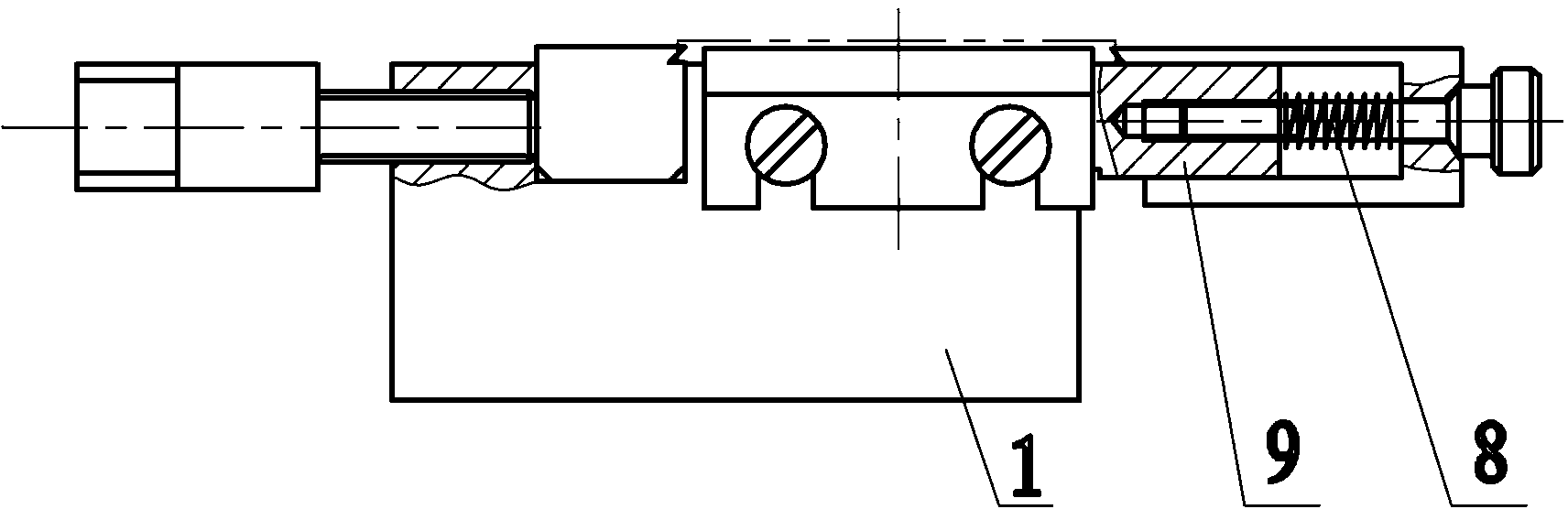

High-precision thin part processing method and auxiliary tool equipment thereof

ActiveCN102794611AGuaranteed DimensionsGuaranteed surface roughnessGrinding work supportsWire cuttingEngineering

The invention relates to a high-precision thin part processing method which comprises the following steps of: 1) carrying out ageing treatment on a thin part and removing inner stress of the part; 2) carrying out wire cutting on the appearance to achieve the size requirement; 3) milling the end face of a non-work area of the thin part into a chamfered angle and clamping the thin part in auxiliary tool equipment, wherein the clamping end of the auxiliary tool equipment is provided with a reverse chamfered angle which is matched with the chamfered angle on the thin part; and 4) grinding the surface of the thin part. The processing method is not only capable of solving the problems of bad part rigidity, clamping deformation in clamping and the like, but also simple in step and high in processing efficiency. At the same time, the auxiliary tool equipment is used for improving the clamping speed and preventing the problems of tilting in grinding and the like.

Owner:SHENYANG AEROSPACE XINLE

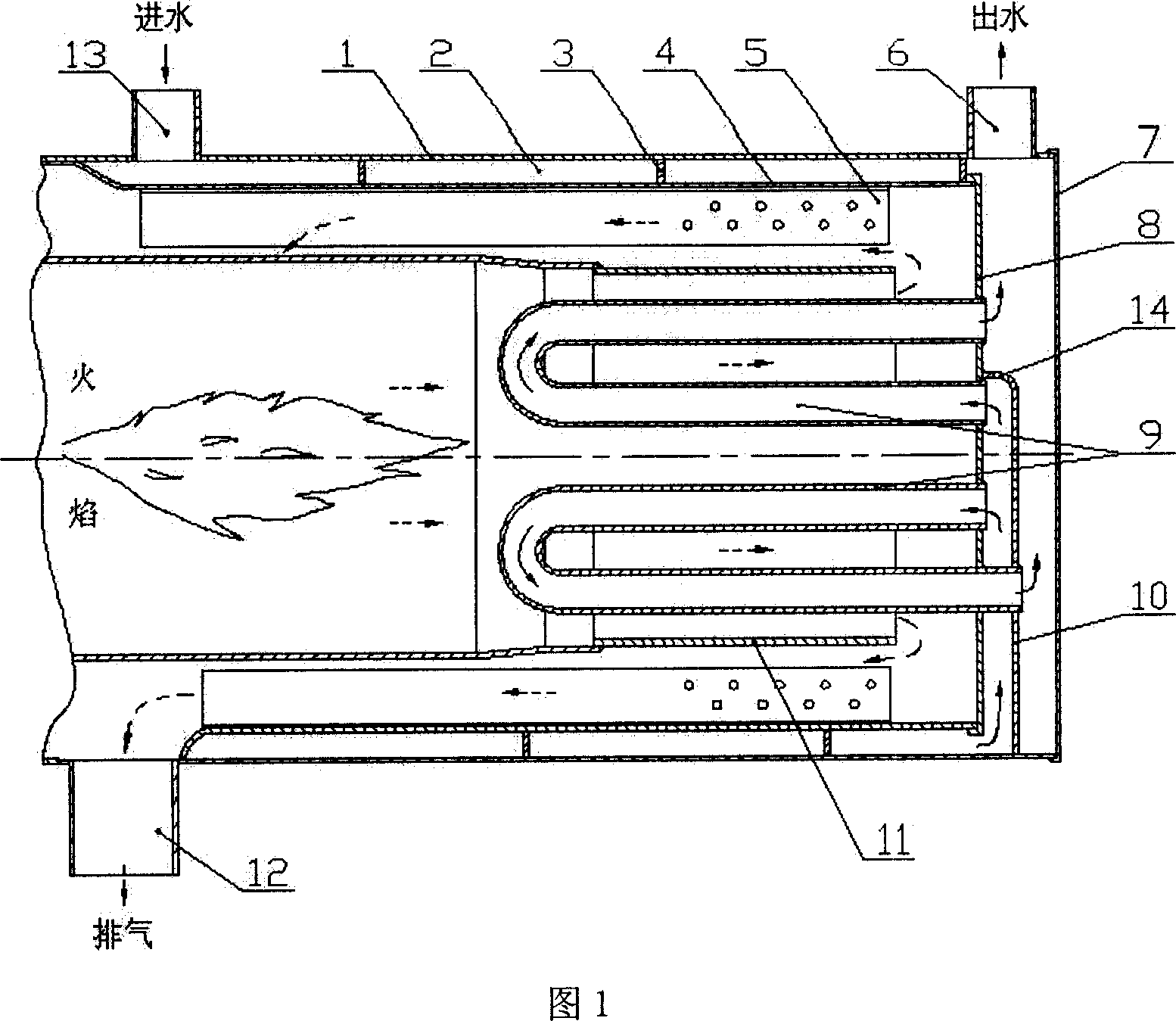

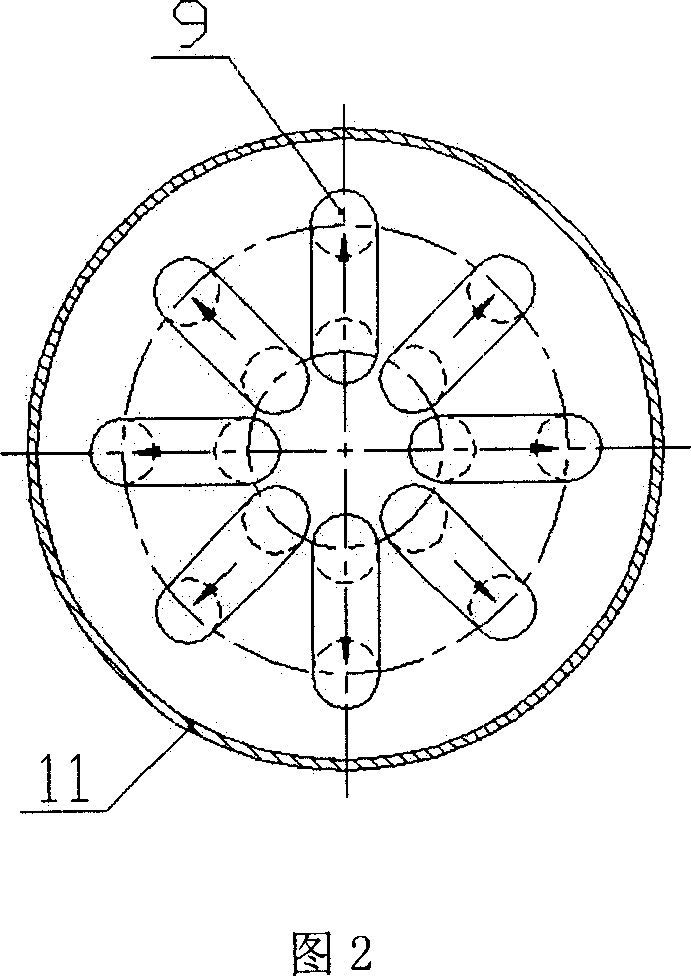

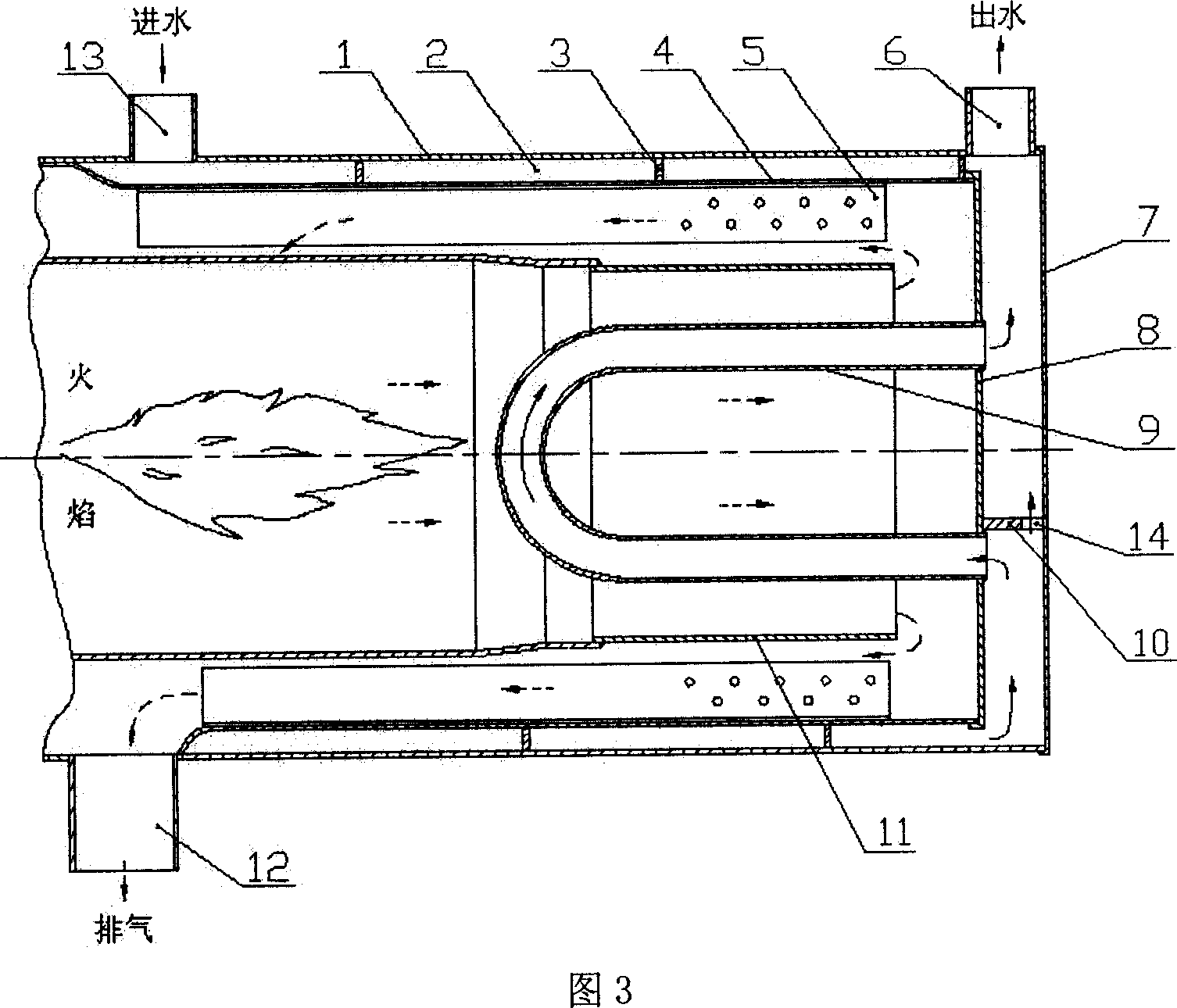

Heat exchanger for double water cavity fuel oil heater

InactiveCN101520232AIncrease the heat exchange areaHigh thermal efficiencyWater heatersPlate heat exchangerCombustion

The invention provides a heat exchanger for a double water cavity fuel oil heater. The heat exchanger for the double water cavity fuel oil heater comprises a outer water cavity and an inner water cavity, wherein the inner water cavity is arranged in the outer water cavity, the outer water cavity is connected in series with the inner water cavity by a water tube to form a steam loop; the outer water cavity consists of an outer sleeve of outer water cavity and an inner sleeve of the outer water cavity, an inner sleeve of the outer water cavity is sleeved in an outer sleeve of the outer water cavity, an outer sleeve of the outer water cavity is provided with a water inlet tube, a water outlet tube and a vent pipe, the tail part between the inner sleeve and the outer sleeve of the outer water cavity is provided with a water cavity caulking ring; the inner water cavity consists of an outer sleeve of the inner water cavity and an inner sleeve of the inner water cavity, the inner sleeve of the inner water cavity is sleeved in the outer sleeve of the inner water cavity, the inside of the inner sleeve of the inner water cavity is provided with a combustion taper cover, and the front end of the inner sleeve of the inner water cavity is provided with a positioning sleeve. The heat exchanger adopts double cavities which increase the heat exchange area of the heat exchanger and improve the thermal efficiency of a heater complete appliance; the inner water cavity is directly contacted with high-temperature combustion flame, so the phenomenon of bubbling fluidization ebullition in a water cavity generates, the heat exchange is strengthened, and the thermal efficiency of the fuel oil heater is improved by more than 10 percent.

Owner:SHANDONG UNIV

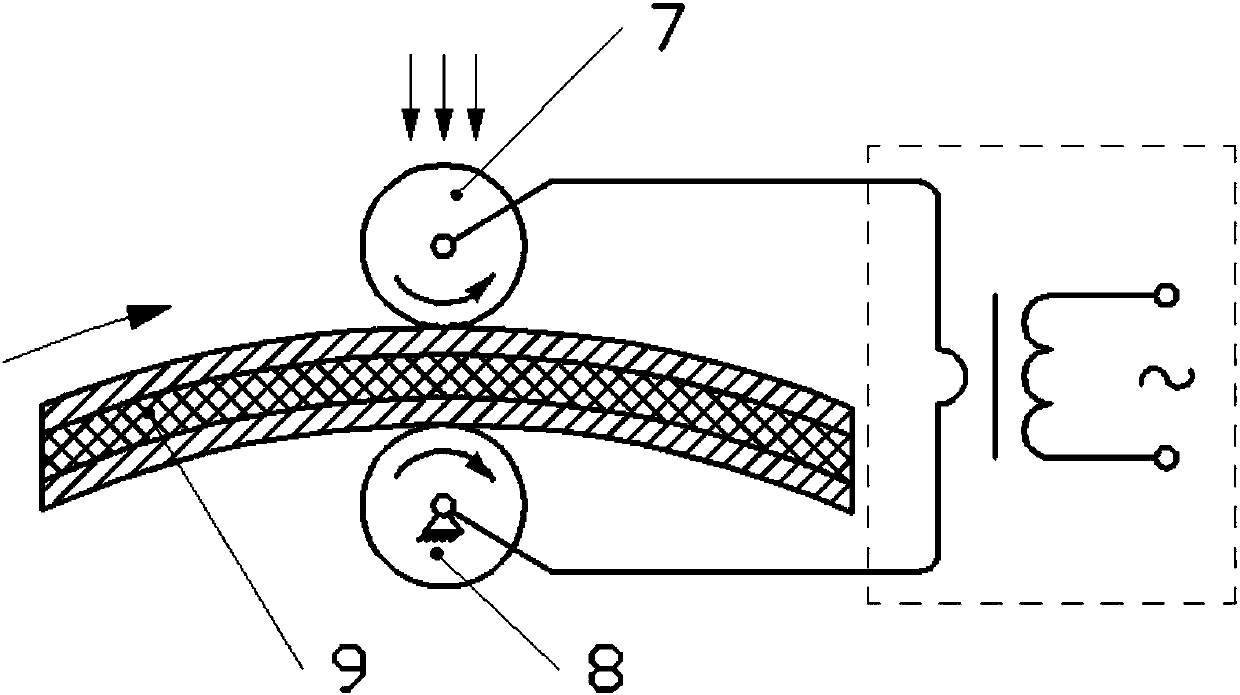

Damage repair process and device for carbon-fiber-enhanced thermoplastic super-hybrid composite laminates

The invention relates to a damage repair device for carbon-fiber-enhanced thermoplastic super-hybrid composite laminates. The damage repair device comprises an electrode, a pressure giving assembly and a power supply assembly. The electrode comprises a vertical type point pressure upper electrode body, a vertical type point pressure lower electrode body, a horizontal rolling pressure upper electrode body and a horizontal rolling pressure lower electrode body. The portions, in contact with a component, of the vertical type point pressure upper electrode body and the vertical type point pressurelower electrode body are sleeved with ceramic pressure rings. The lower electrode bodies are fixed, and the pressure giving assembly drives the upper electrode bodies to move downwardly to give the constant pressure to the component. The horizontal rolling pressure upper electrode body and the horizontal rolling pressure lower electrode body rotate at the same angular speed in opposite directions. Rolling friction with the component is generated when the horizontal rolling pressure upper electrode body rolls along the upper surface of the component and the horizontal rolling pressure lower electrode body rolls along the lower surface of the component. The power supply assembly can adjust the current under the synergistic effect of a built-in power source and a transformer, and the currentparameter changes according to the super-hybrid composite laminates with different sizes and made of different materials. The damage repair device and method have beneficial effects that the energy consumption is low, the method is simple and easy to implement, the repair cycle is short, and the repair cost of composites is reduced greatly.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Rudder surface manufacturing method with aspect ratio being more than 9 times

InactiveCN108146652AHigh rigidity requirementsGuaranteed DimensionsAircraft assemblyAviationGlass fiber

The invention belongs to the field of aviation, and particularly relates to a rudder surface manufacturing method with the aspect ratio being more than 9 times. According to the structural characteristics of the movable rudder surface of the large aspect ratio small fixed-wing aircraft and the manufacturing difficulties, from the aspect of improving the whole rigidity and intensity of outer ailerons, the whole foaming technology after a skeleton is embedded in a mold is skillfully adopted, a foaming internal lining piece is coated with a 0.2 mm glass fiber composite and mold forming is conducted to change local force bearing to whole force bearing of the ailerons, the rigidity and the intensity are greatly improved, mold outside skin molding is conducted, and the outline size of a rudder surface is well ensured. Through the technology, a process method for manufacturing the movable rudder surface of the small fixed-wing aircraft is found, and the aircraft movable rudder surface meetingthe large aspect ratio (the span direction to the chord direction being equal to 9:1) and high whole rigidity and intensity requirements can be manufactured through the method.

Owner:成都凯迪精工科技有限责任公司

Novel mold for automatically producing magnesite brick

ActiveCN105666661AIncrease productivityGuaranteed DimensionsMouldsMould fastening meansBrickEngineering

The invention discloses a novel mold for automatically producing a magnesite brick. The novel mold comprises a base and a plurality of parallel side molds, wherein the plurality of parallel side molds are arranged on the base; mold cavities are formed between adjacent side molds, bottom molds are arranged at the bottoms of the mold cavities, core rod assemblies are arranged in the mold cavities, end plates of the core rod assemblies are clamped in the end parts of the side molds, a rotatable upper cover is arranged on one side, which is close to the corresponding mold cavity, of the top of each side mold, and the upper cover is opened by virtue of an uncovering mechanism; limiting connecting plates which are fixedly connected with the side molds are arranged at the bottoms of the side molds, the bottom molds are in sliding connection with two adjacent limiting connecting plates, and the limiting connecting plates are used for limiting the relative moving distance of the adjacent side molds and the bottom molds; two outermost side molds are a fixed side mold and a first moving side mold, the first moving side mold is driven to move to the fixed side mold or to be far away from the fixed side mold by an external driving mechanism, and a positioning bolt is arranged on the first moving side mold. By using the mold, the magnesite brick can be automatically produced.

Owner:营口全顺佳明耐火材料有限公司

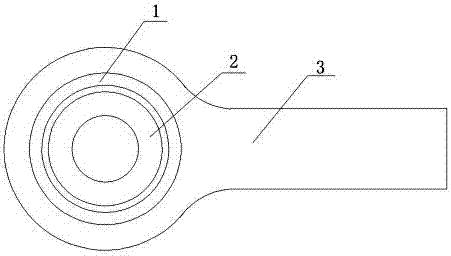

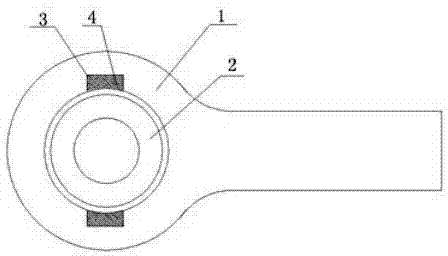

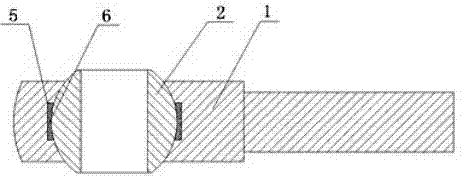

Knuckle bearing structure

InactiveCN104763741AGuaranteed wall thicknessAchieve separationBearing componentsSliding contact bearingsEngineeringKnuckle

The invention relates to a knuckle bearing structure. The knuckle bearing structure comprises an outer ring with a pulling rod, wherein the outer ring is internally provided with an inner ring. The knuckle bearing structure is characterized in that the inner sides of the two ends of the outer ring are respectively provided with a gap; the length of the gap corresponds to the outer diameter of the inner ring; the width of the gap corresponds to the thickness of the inner ring; the inner ring is placed in the outer ring by the gaps; and the outer ring and the inner ring form matched spherical-surface contact. The knuckle bearing structure has the advantages that the inner sides of the two ends of the outer ring are respectively provided with the gap, the length of the gap corresponds to the outer diameter of the inner ring, the width of the gap corresponds to the thickness of the inner ring, the inner ring is horizontally placed in the gaps and is placed into the outer ring by rotation, and the outer ring and the inner ring form matched spherical-surface contact, and since the inner ring is placed into the outer ring by rotation, the separation of the inner ring and the outer ring is conveniently realized, the convenient replacement of the inner ring or the outer ring is realized and the production cost is effectively reduced.

Owner:新昌县明瑞关节轴承有限公司

Heat exchanger for fuel oil heater with heat exchange pipe

InactiveCN1928454AIncrease the heat exchange areaHigh thermal efficiencyFluid heatersHeat conductingEngineering

The invention provides a heat exchanging equipment for fuel oil heater with heat exchanging pipe, comprising heat exchanging body, heat-conducting plate, shell, heat exchanging pipe, insulation board and helical guiding plate. Heat-conducting plate is distributed on the inside wall of heat exchanging body and helical guiding plate is set on the outside wall of heat exchanging body; the bottom of heat exchanging body is sealed by board and heat exchanging pipe is set on the board; shell is mounted on the heat exchanging body and helical guiding plate is set between them; the frontal end of shell is connected with heat exchanging body together and there is a plug at the back end; helical water cavity is formed by helical guiding plate between heat exchanging body and shell, heat exchanging pipe is connected to the end of helical water cavity in series; insulation board is set between plug and board; inlet and outlet pipes are set at two ends of shell respectively. The heat exchanging pipe can improve heat exchanging area and strengthen heat exchanging so that heat efficiency of heater is improved in the invention. Heat efficiency of fuel oil heater can improve more than 8% and bigger transporting declared power is gained in the invention.

Owner:SHANDONG UNIV

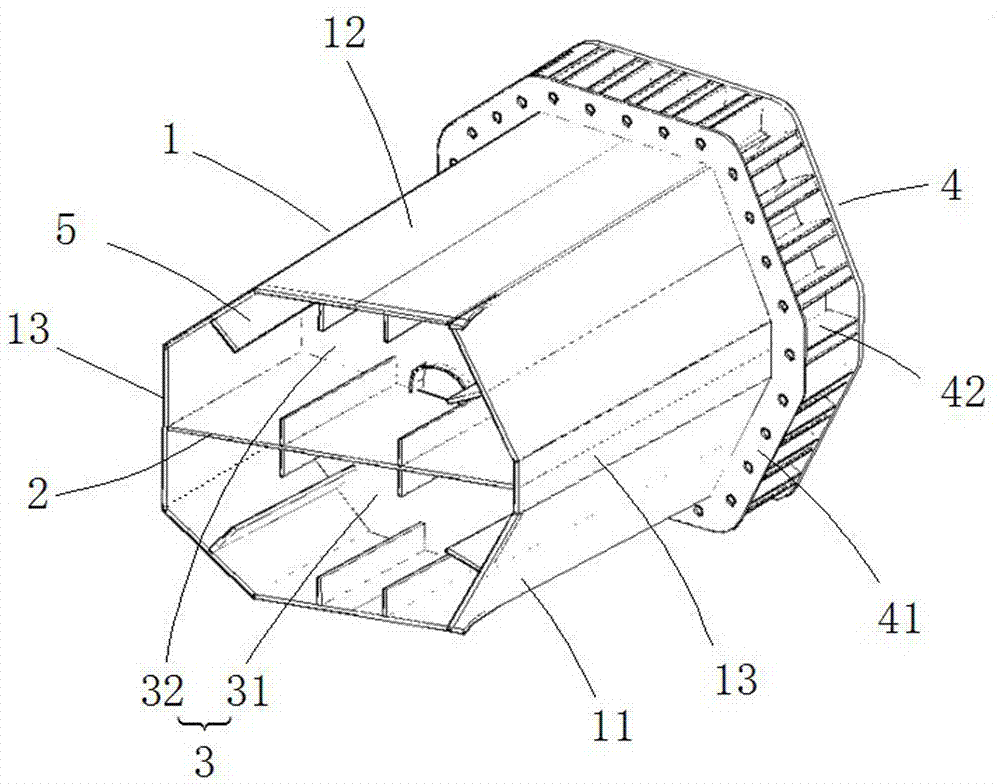

Octagonal-box-shaped pylon foot and manufacturing method thereof

InactiveCN107254938AIngenious structural designIncreased load-bearing capacityStrutsBridge structural detailsStress concentrationEngineering

The invention discloses an octagonal-box-shaped pylon foot which comprises a frame unit and a pylon bottom plate unit. The frame unit comprises a frame, a middle web and a transverse separating plate, wherein the frame is defined by a group of wallboards, the middle web is axially arranged in the frame, and the transverse separating plate is radially arranged in the frame. The pylon bottom plate unit is arranged at one end of the frame unit. The octagonal-box-shaped pylon foot is reasonable in design, firm in structure and good in bearing capacity, and guarantees the quality of a whole project. According to the method, the quality of each member and each unit is ensured, welding stress concentration is effectively controlled, accumulative errors generated by large members are prevented, and thus the machining quality of the whole pylon foot is guaranteed.

Owner:JIANGSU HUNING STEEL MECHANISM

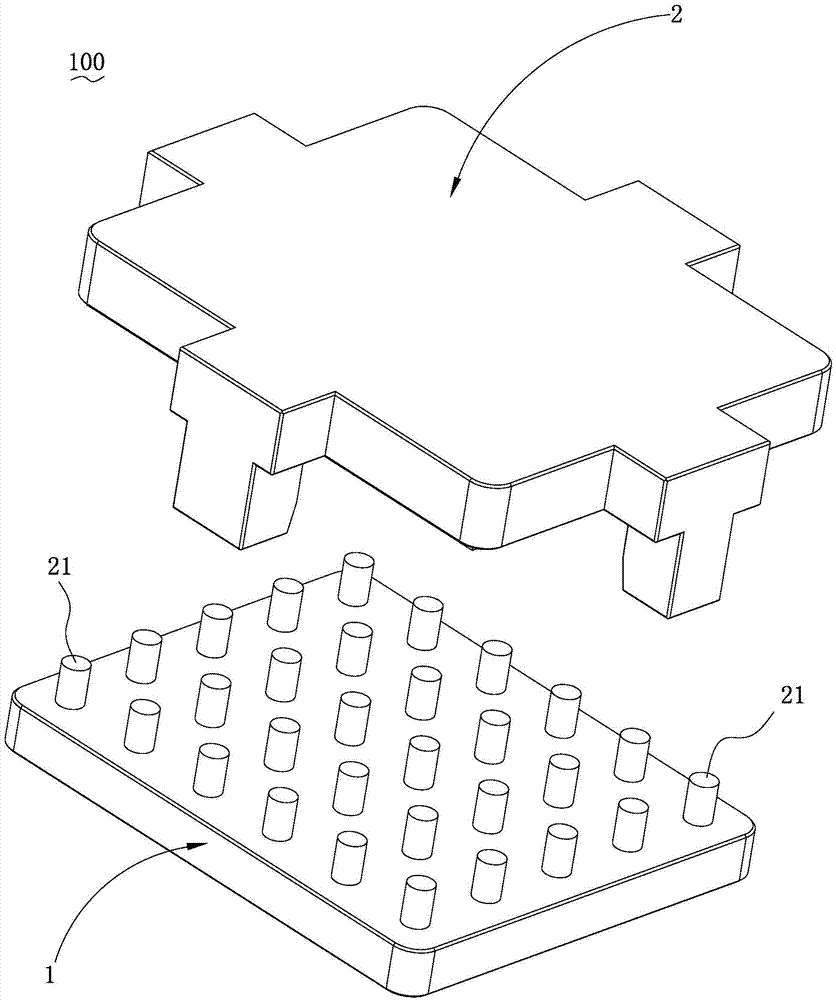

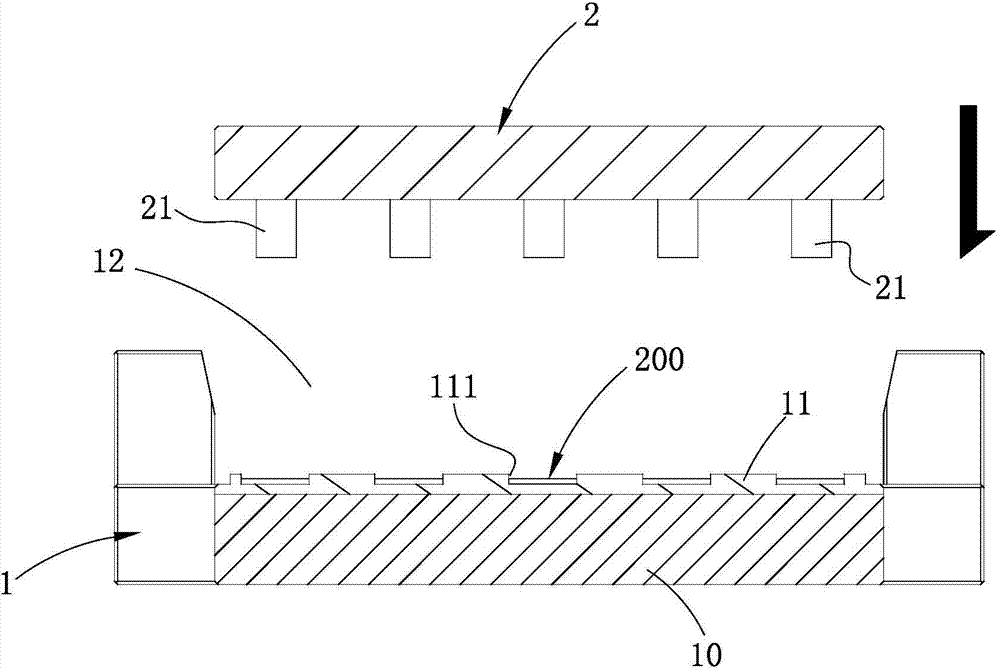

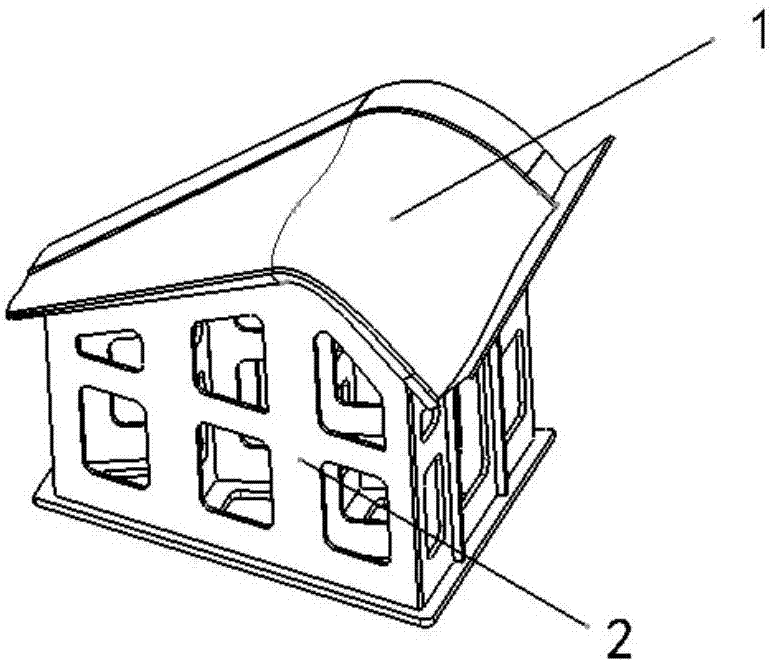

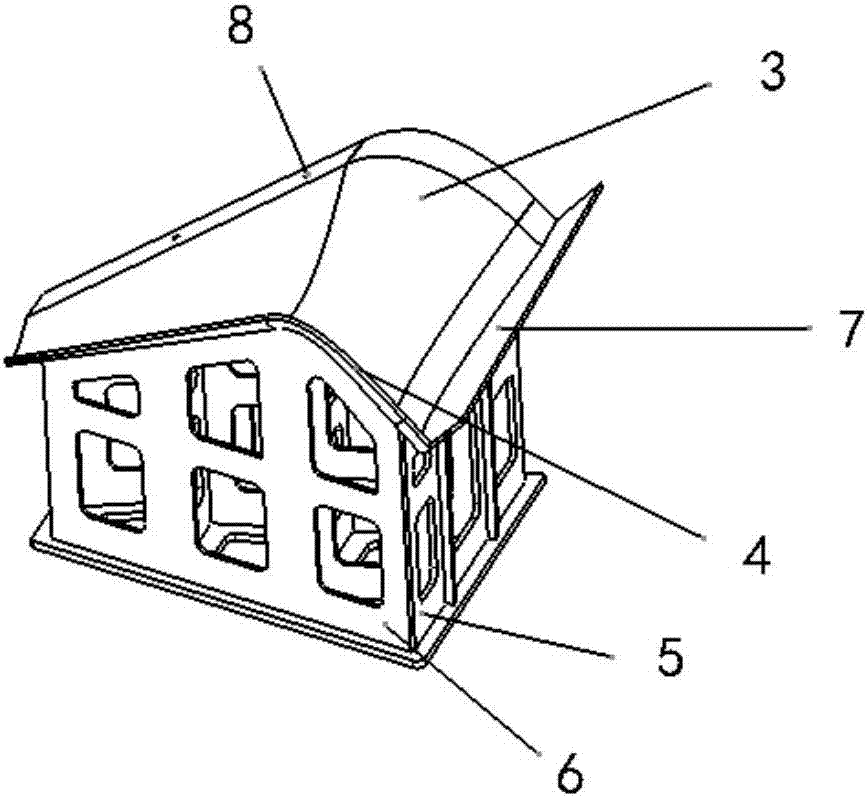

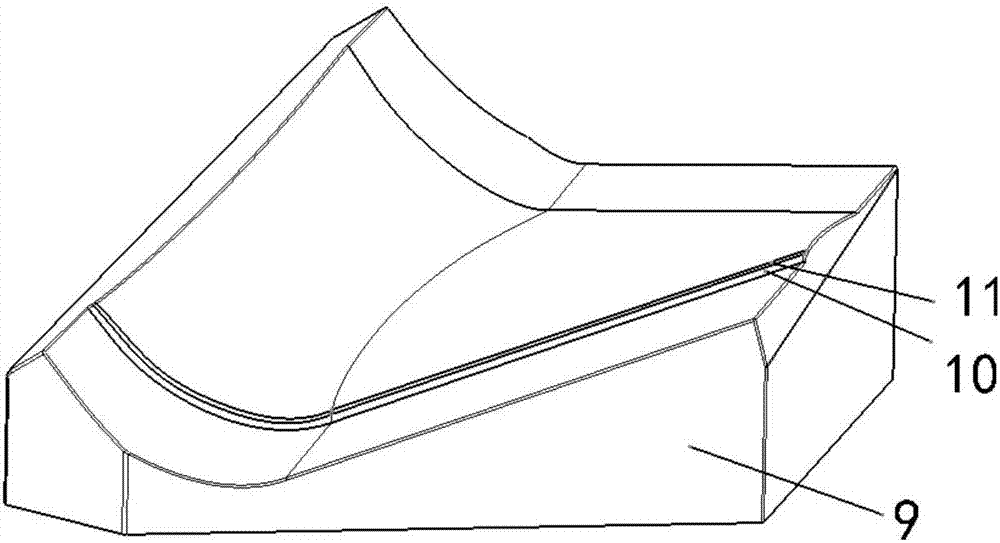

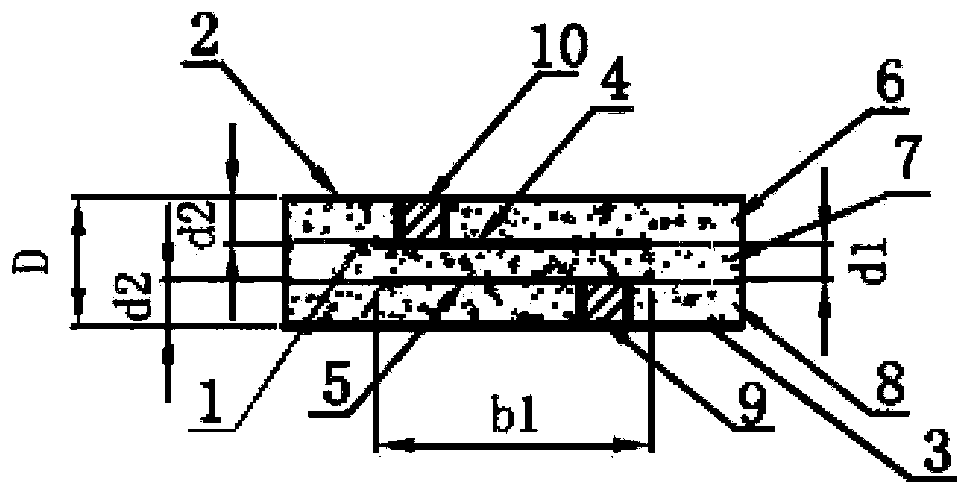

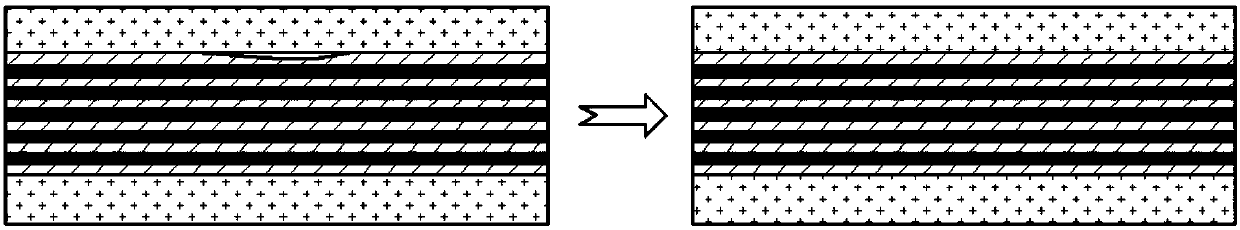

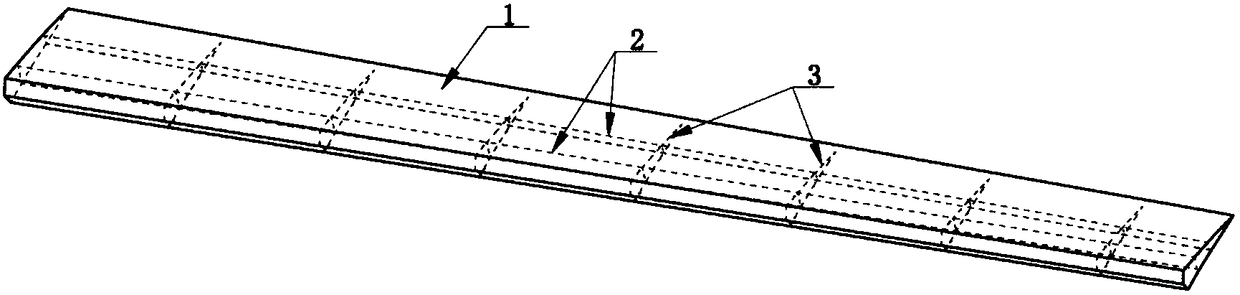

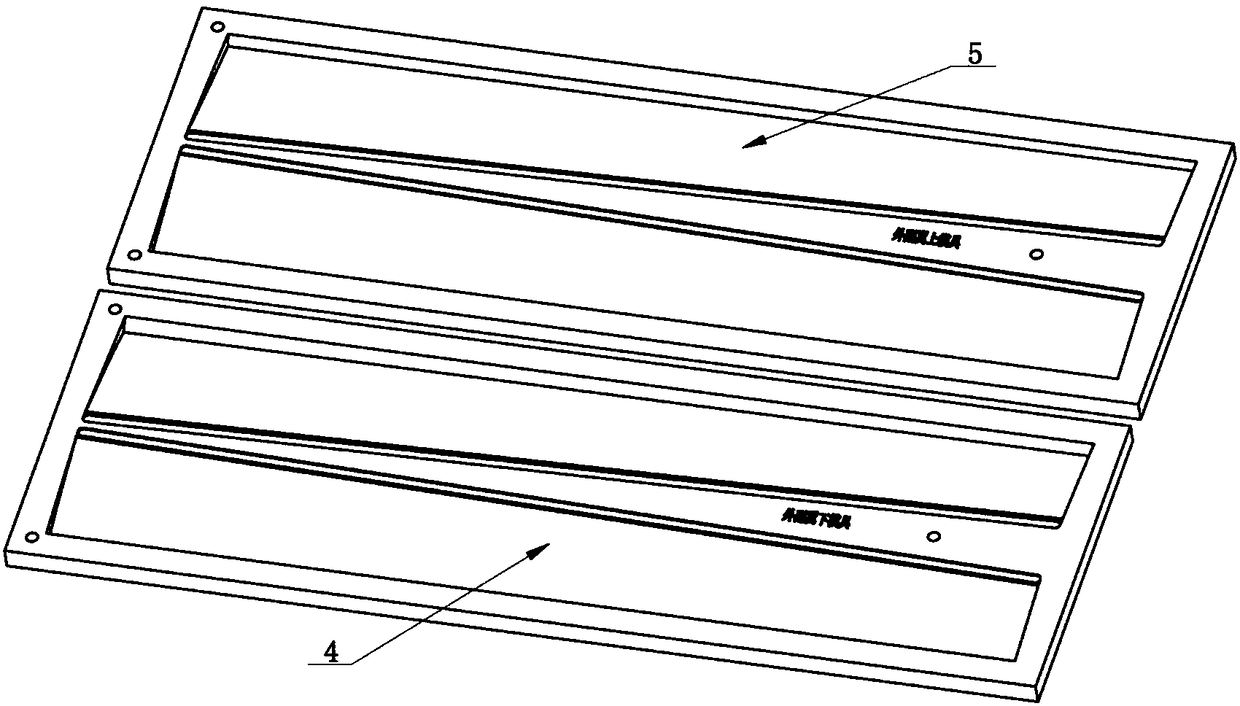

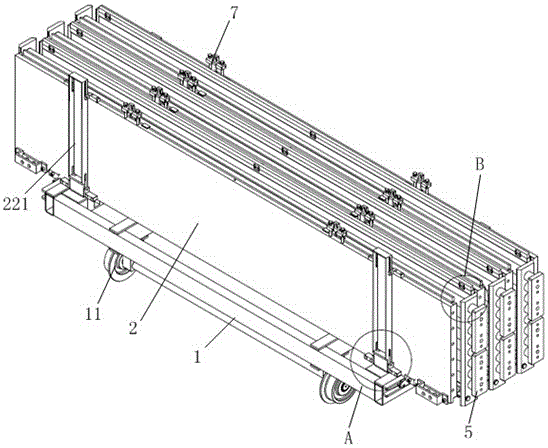

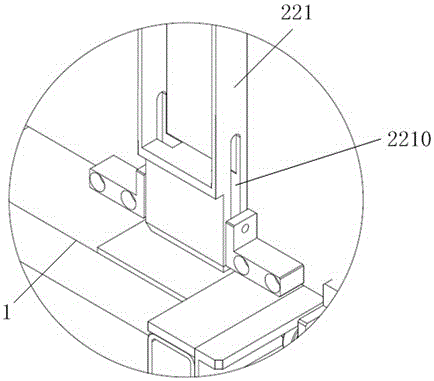

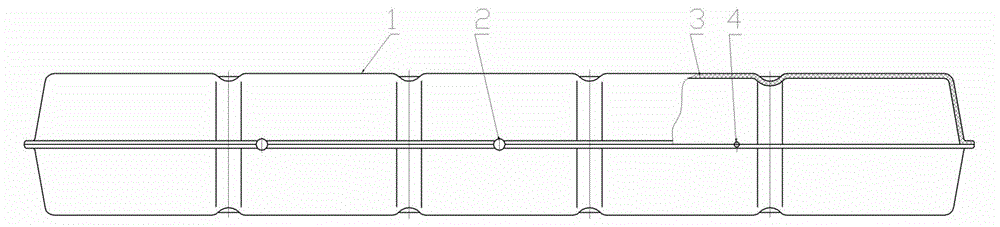

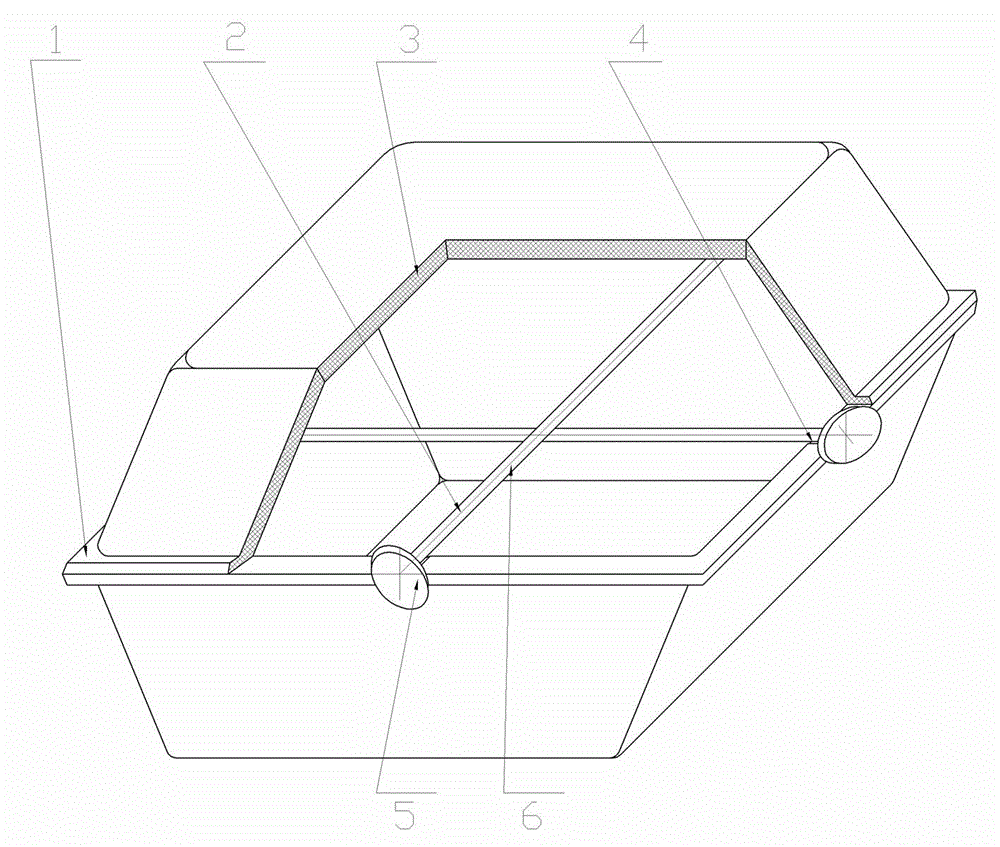

Combined core mold provided with compression-resisting tension bars and used for cast-in-place concrete

The invention provides a combined core mold provided with compression-resisting tension bars and used for cast-in-place concrete. The combined core mold provided with the compression-resisting tension bars and used for the cast-in-place concrete mainly solves the technical problems that an existing core mold is instable in size and can not resist pressure when being processed, assembled and used due to the fact that external force acts on mold shoes of the combined core. The combined core mold provided with the compression-resisting tension bars and used for the cast-in-place concrete is characterized in that the combined core mold (1) is formed by oppositely combining two mold shoes (3), the contact faces of the mold shoes (3) are each provided with one or more grooves (4), and the compression-resisting tension bars (2) are embedded in the grooves (4) and penetrate through the two edges of the core mold. The combined core mold provided with the compression-resisting tension bars and used for the cast-in-place concrete is mainly applied to long-space and large-bay civil and public buildings.

Owner:阳文皇

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com