Damage repair process and device for carbon-fiber-enhanced thermoplastic super-hybrid composite laminates

A technology for enhancing thermoplastic and damage repair, applied in the field of damage repair technology and its devices, can solve the problems of electrochemical corrosion and stress corrosion damage at bolted joints, demanding complex process conditions, and damage to the interlayer performance of composite laminates, etc. The effect of restoring basic mechanical properties, broad prospects for promotion, and reducing repair costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

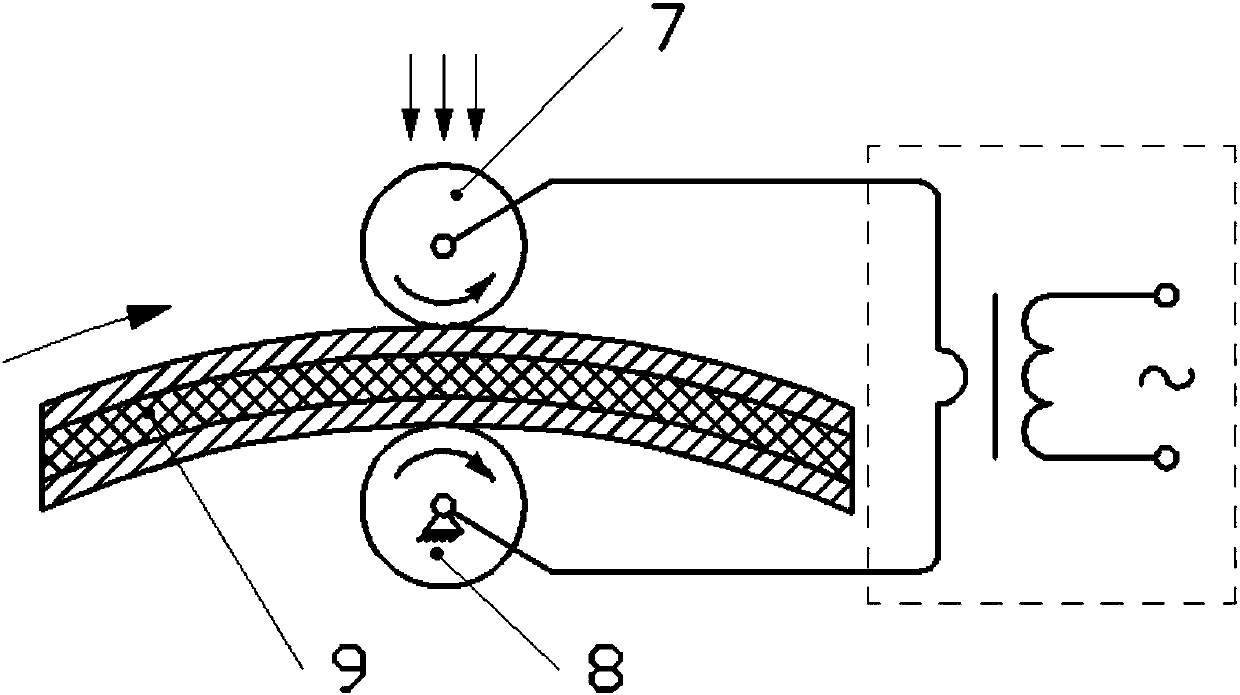

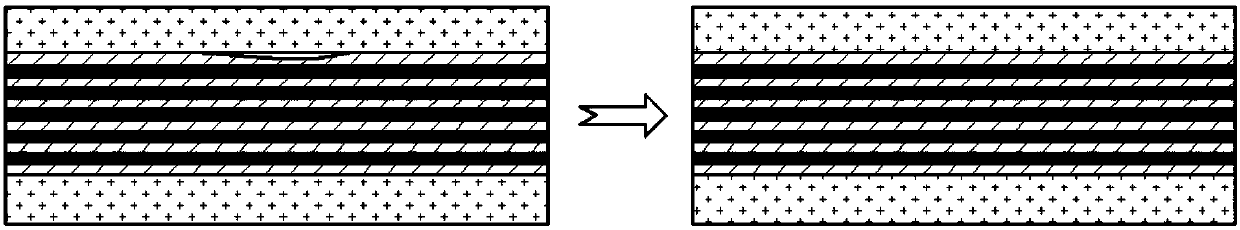

[0038] A damage repair device for a carbon fiber reinforced thermoplastic super-hybrid composite laminate, comprising electrodes, a pressure supply component, and a power supply component; the electrodes include vertical point pressing upper and lower electrodes and horizontal rolling upper and lower electrodes; the vertical The contact part between the upper and lower electrodes and the component is sleeved with a ceramic pressure ring; the lower electrode is fixed, and the pressure feeding component drives the upper electrode to move downward and gives constant pressure to the component; the horizontal rolling upper and lower electrodes maintain the angular velocity In the same direction and opposite rotation movement, when the component rolls along the upper and lower surfaces of the component in the horizontal rolling upper and lower electrodes, rolling friction occurs with the component, and relative movement occurs with the component; the power supply assembly is under the...

Embodiment 2

[0047] The damage repair device of the carbon fiber reinforced thermoplastic super-hybrid composite laminate is the same as that of the first embodiment.

[0048] A damage repair process for a titanium alloy / carbon fiber reinforced polyether ether copper matrix composite material laminate to make a vehicle chassis cover, comprising the following method steps:

[0049] The first step is to determine the damage location and scope of the super-hybrid composite laminate chassis cover through ultrasonic testing, and make corresponding marks for repair;

[0050] In the second step, in view of the fact that the vehicle chassis cover is a flat plate member and the damage area is small, vertical point pressure repair electrodes are used for repair, and the upper and lower electrodes are installed on one side edge of the damaged part of the component marked in step 1 place;

[0051] The third step is to work the pressure supply assembly, the lower point pressure electrode is kept fixed...

Embodiment 3

[0056] The damage repair device of the carbon fiber reinforced thermoplastic super-hybrid composite laminate is the same as that of the first embodiment.

[0057] A damage repair process for the leading edge of a wing made of an aluminum alloy / carbon fiber reinforced polypropylene-based composite material laminate, comprising the following method steps:

[0058] The first step is to determine the damage location and extent of the leading edge of the super-hybrid composite laminate wing through ultrasonic testing, and make corresponding marks for repair;

[0059] In the second step, since the leading edge of the wing is a single-curvature bending member and the damage area is large, a horizontal rolling repair electrode is used for repair, and the upper and lower rolling electrodes are installed to the damage of the component marked in step one. one side edge of the part;

[0060] In the third step, the pressure-feeding component works, the lower point pressure electrode is ke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com