Isothermal beta forging method for TC17 titanium alloy blade

A titanium alloy and isothermal forging technology, applied in the forging field of warm beta forging, can solve the problem of high process requirements, achieve the effect of good overall economy and ensure filling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] 1. Preliminary basic research

[0017] On the basis of computer simulation, the actual production test results of blanks with different geometric parameters and process parameters are studied respectively. Different geometric parameters and process parameters are: absolute deformation; relative deformation; holding time;

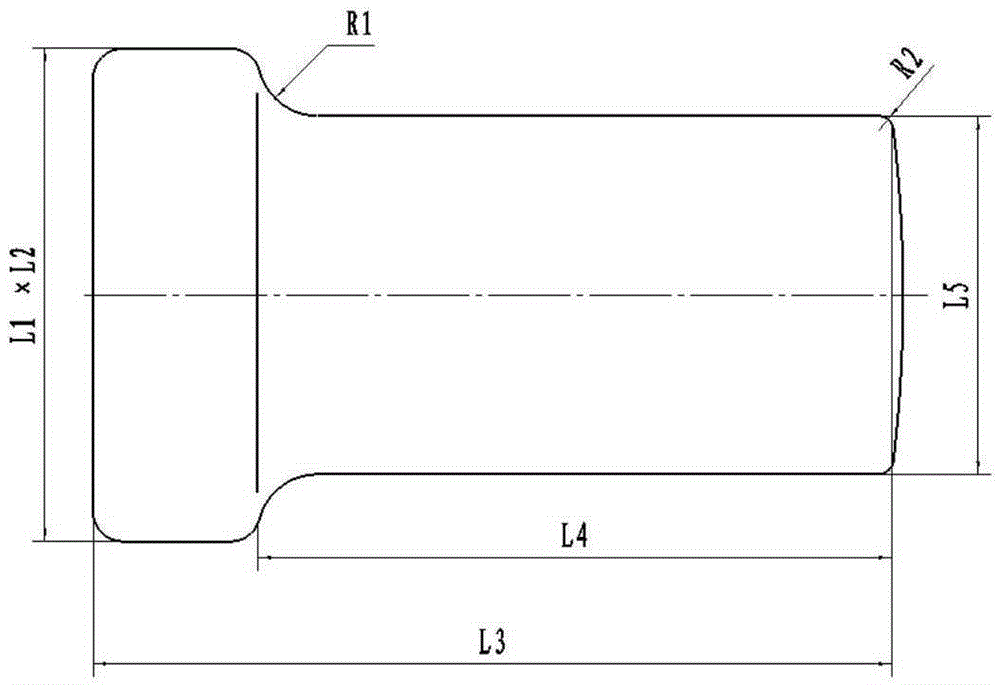

[0018] 2. Preform size and shape design

[0019] On the basis of determining the basic forging parameters, the size and shape of the preform can be designed and adjusted by computer simulation technology.

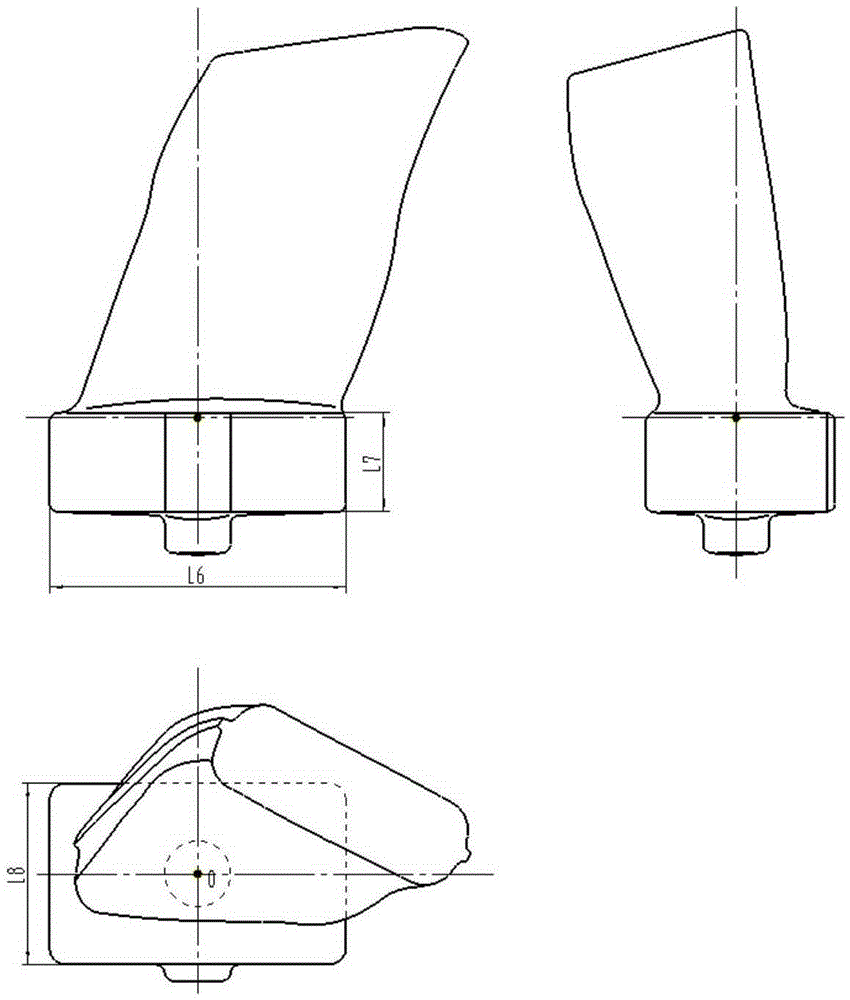

[0020] 3. Titanium alloy blade isothermal die forging

[0021] According to the factory's mold design manual for isothermal forging and the characteristics of blade forging, design the isothermal forging die reasonably.

[0022] 4. Formulation of heat treatment process for isothermal forgings of titanium alloy blades

[0023] For the heat treatment plan of the isothermal forging of the blade, in view of the comparison with the previous producti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com