Korean standard SD400 ribbed threaded steel bar and production method thereof

A threaded steel bar and production method technology, applied in the field of metallurgy, can solve the problems that the shape of "bamboo ribs" is difficult to meet the standard requirements, the shape design of "bamboo ribs" is unreasonable, and the strengthening and utilization are not sufficient, so as to achieve good economic and social benefits. Benefits, reduced production costs, and excellent bending properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

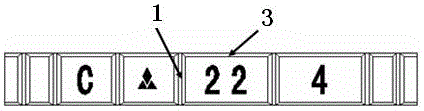

Image

Examples

Embodiment 1

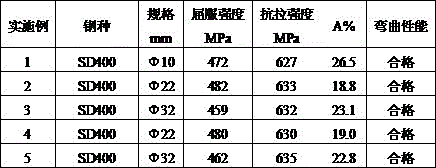

[0032] This Korean standard SD400 steel bar is prepared by the following specific process, and the rolling specification is Φ10mm.

[0033] Put the steel billet into a heating furnace with a temperature of 1105-1135° C. in the soaking section and heat it. The holding time in the soaking section is 32 minutes, so that the steel billet reaches 1066° C. before being released from the furnace. After the heated billet is descaled by high-pressure water, rough rolling, intermediate rolling and finishing rolling are carried out. The starting temperature of rough rolling is 1031°C; the final rolling temperature is 1062°C; The mechanical properties of the hot-rolled steel bar obtained in this embodiment are shown in Table 2.

Embodiment 2

[0035] This Korean standard SD400 steel bar is prepared by the following specific process, and the rolling specification is Φ22mm.

[0036] Put the billet into a heating furnace with a temperature of 1100-1130° C. in the soaking section and heat it. The holding time in the soaking section is 30 minutes, so that the billet reaches 1062° C. before being released from the furnace. After the heated billet is descaled by high-pressure water, rough rolling, intermediate rolling and finishing rolling are carried out. The starting temperature of rough rolling is 1030°C; the final rolling temperature is 1060°C; The mechanical properties of the hot-rolled steel bar obtained in this embodiment are shown in Table 2.

Embodiment 3

[0038] This Korean standard SD400 steel bar is prepared by the following specific process, and the rolling specification is Φ32mm.

[0039] Put the steel billet into a heating furnace with a temperature of 1095-1125° C. in the soaking section and heat it. The holding time in the soaking section is 28 minutes, so that the steel billet reaches 1055° C. before being released from the furnace. The heated slab is descaled by high-pressure water and then subjected to rough, medium and finish rolling. The starting temperature of rough rolling is 1028°C; the temperature of final rolling is 1058°C; The mechanical properties of the hot-rolled steel bar obtained in this embodiment are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com