Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

378results about How to "Reduce total time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Image processing method and system, and image processing model training method and system

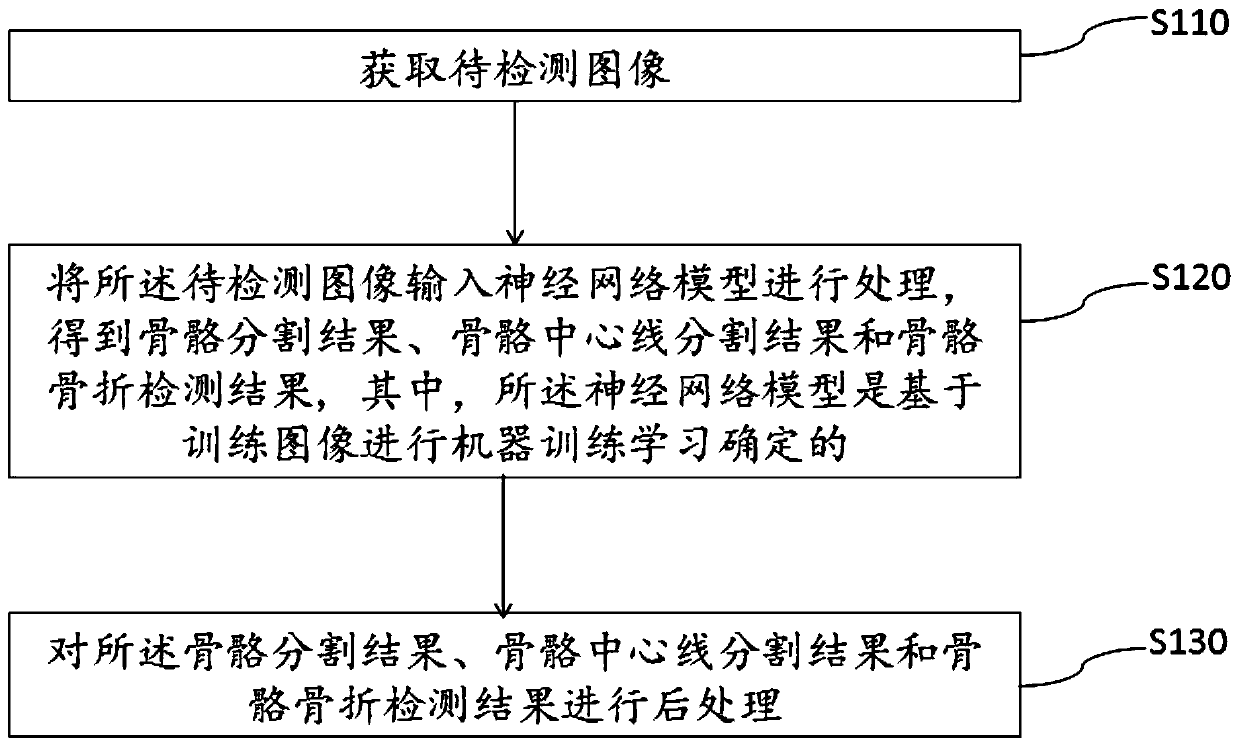

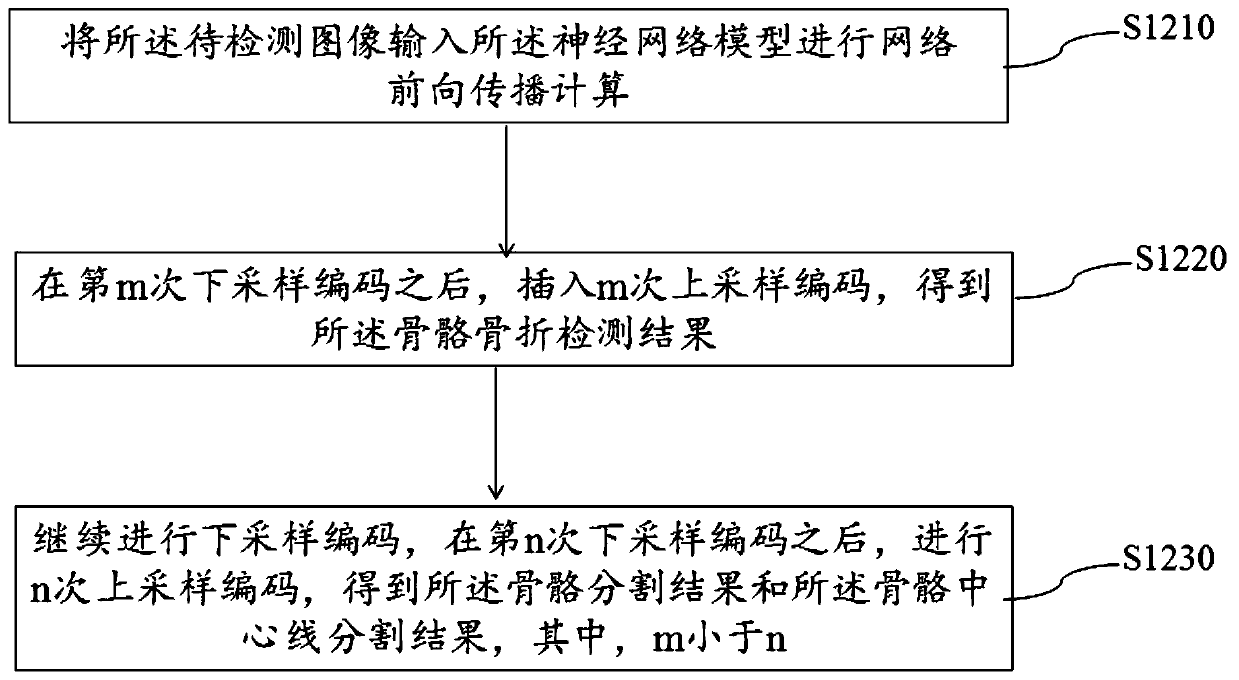

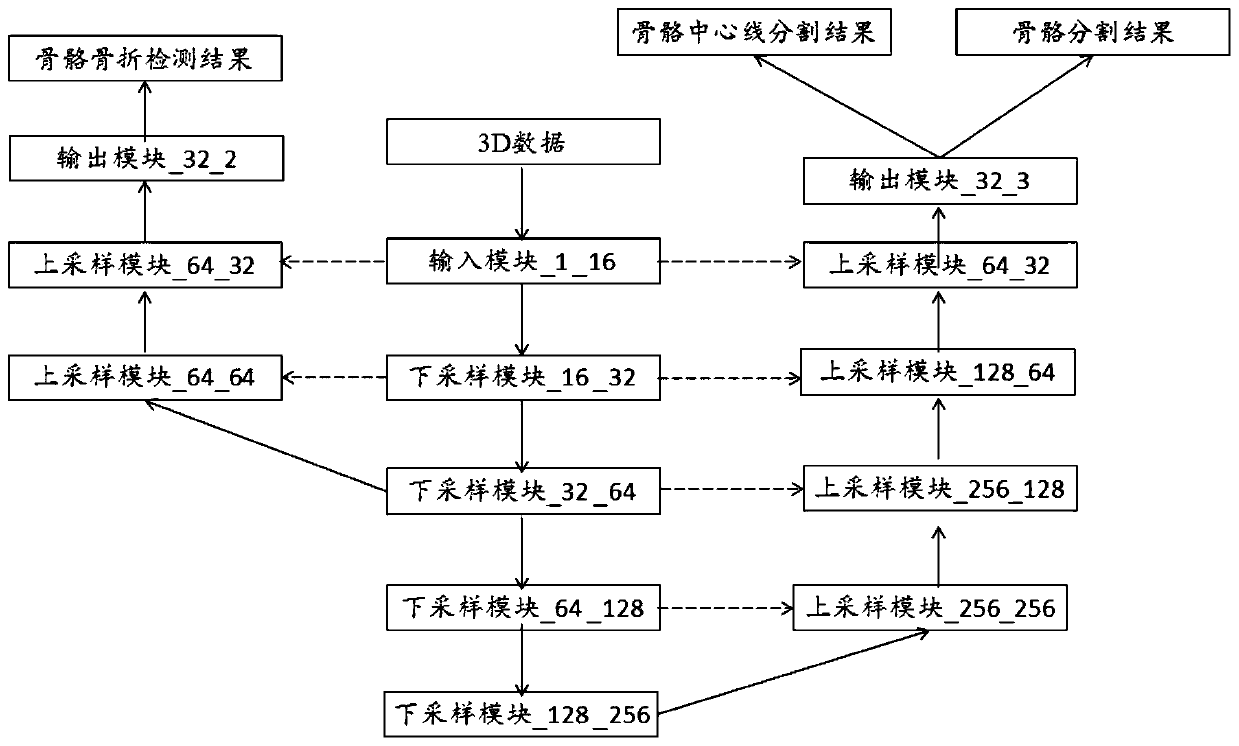

The invention discloses an image processing method and system, and image processing model training method and system. The image processing method comprises: obtaining a to-be-detected image; inputtingthe to-be-detected image into a neural network model for processing to obtain a bone segmentation result, a bone center line segmentation result and a bone fracture detection result; wherein the neural network model is determined by machine training learning based on a training image. The bone segmentation, bone center line segmentation and bone fracture detection functions are achieved at the same time through the trained deep learning network, the total consumed time can be shortened by 50%, the memory space of the model can be saved by 40%, and meanwhile a doctor can be helped to reduce the film reading burden, accelerate the film reading time, reduce the missed diagnosis probability and reduce the contradiction between the doctor and the patient.

Owner:SHANGHAI UNITED IMAGING INTELLIGENT MEDICAL TECH CO LTD

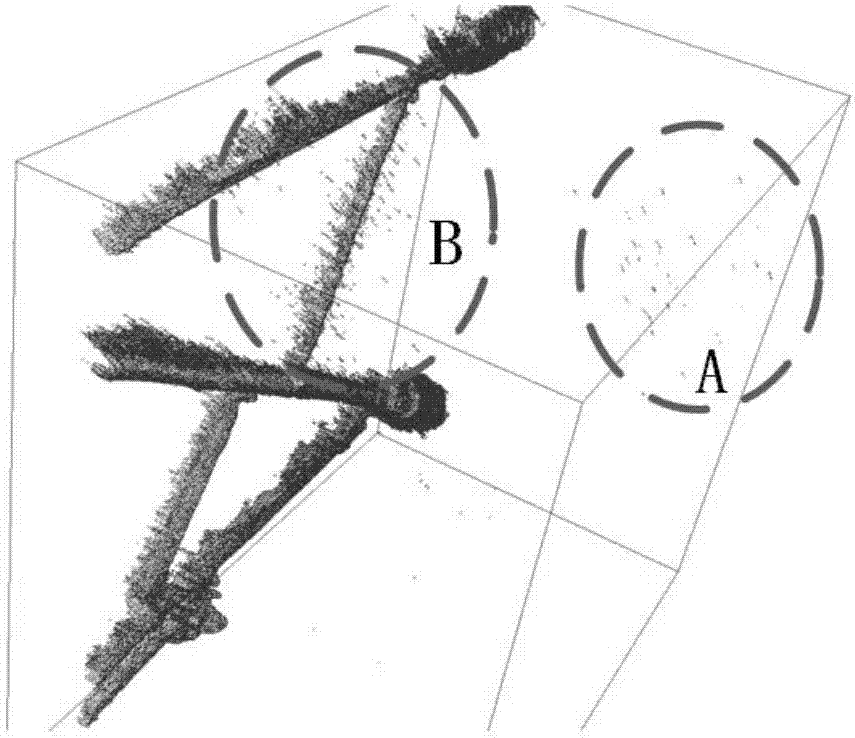

Overhead line device parameter detection method based on BIM and three-dimensional point cloud fusion

InactiveCN107578400AHigh precisionReduce total timeImage enhancementImage analysisReal time acquisitionDevice parameters

The present invention discloses an overhead line device parameter detection method based on BIM and three-dimensional point cloud fusion. The method includes acquiring the three-dimensional point cloud image of an overhead line support device in real time; preprocessing the point cloud data of overhead line support device to realize point cloud data de-noising and structure plane detection and correction; establishing an overhead line BIM model and performing the point cloud processing to generate the standard overhead line support device point cloud data; registering the preprocessed overheadline support device point cloud data and the standard overhead line support device point cloud data to realize the registration segmentation of the overhead line support device point cloud data; andperforming the column structural component extraction on the local areas after the overhead line support device point cloud data segmentation to calculate the geometric structur parameters of the overhead line support device. According to the method, the processing time of the system is effectively shortened, and the accuracy and the real-timeness of system detection are improved, and the requirements of online detection on the geometric structure parameters of the high-speed railway overhead line support device on real-timeness and precision are met.

Owner:SOUTHWEST JIAOTONG UNIV

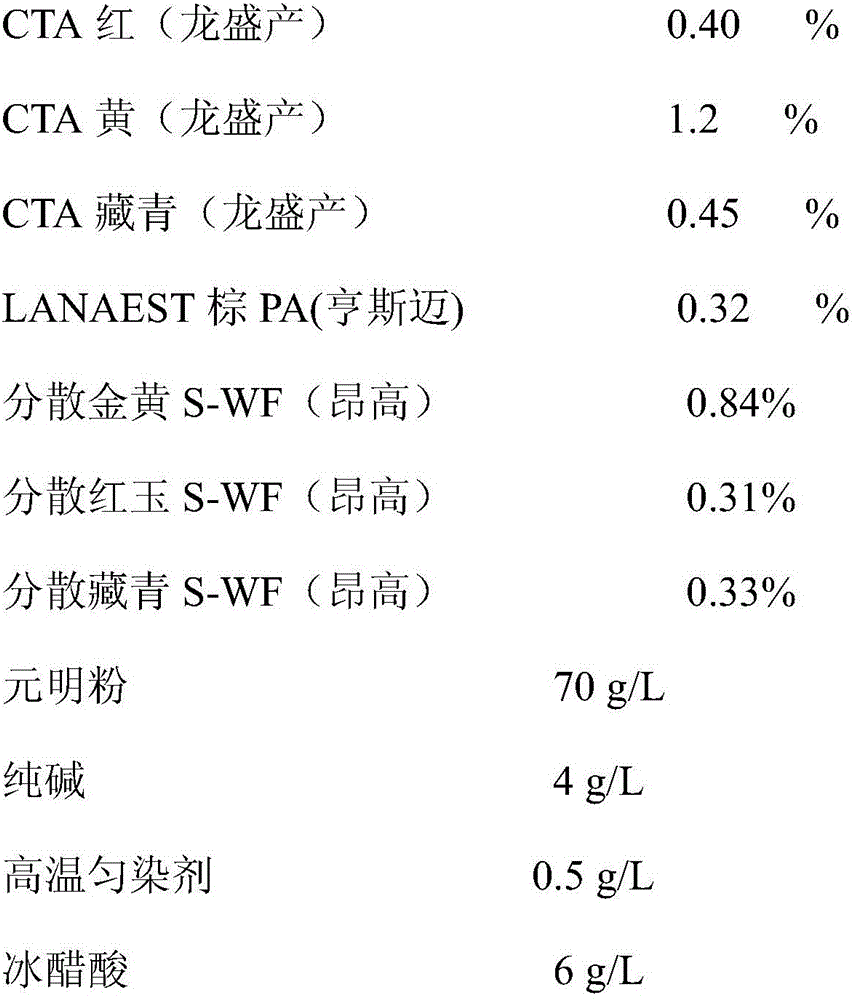

Modified terylene/chinlon/spandex multi-component seamless underwear one-bath-process dyeing technology

ActiveCN102660878AShort processShorten dyeing timeDry-cleaning apparatus for textilesDyeing processWater rinsingDyeing

The invention relates to a modified terylene / chinlon / spandex multi-component seamless underwear one-bath-process dyeing technology, and belongs to the technical field of knitting product dyeing process. The technology comprises the following steps of: putting a modified terylene / chinlon / spandex multi-component seamless underwear into a dyeing cylinder; feeding water and adding an additive and dye, and carrying out one-bath, refining and deoiling, and dyeing the modified terylene / chinlon / spandex; and then carrying out hot water rinsing, soaping and water rinsing, wherein the modified terylene / chinlon / spandex is soft. According to the invention, the dyeing process is shortened effectively, the dyeing time is shortened, the production efficiency is improved, and pollution discharge is reduced.

Owner:ZHEJIANG QIAOERTINGTING FASHION

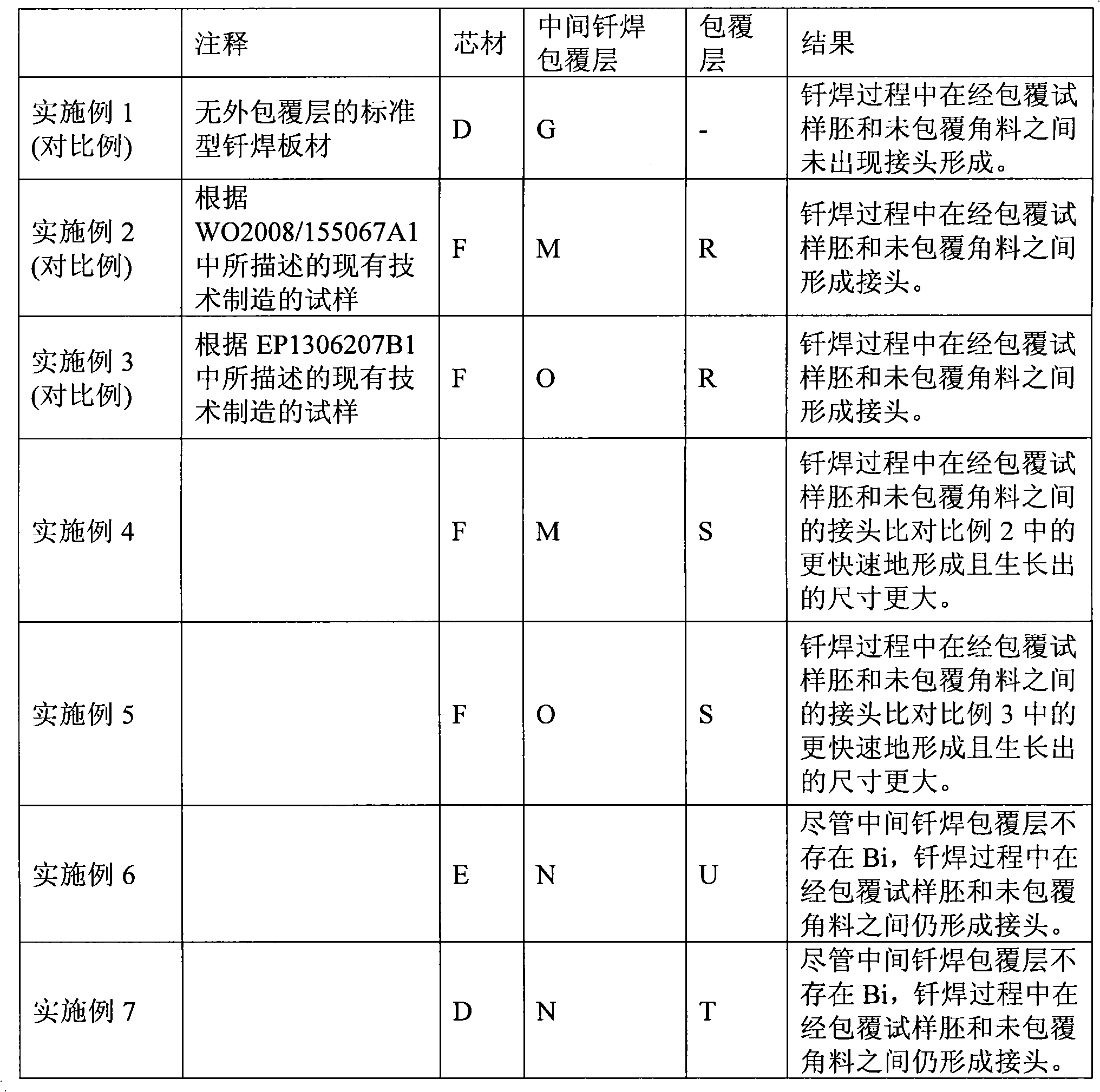

Aluminium brazing sheet

ActiveCN102574248APrevent disengagementLow costWelding/cutting media/materialsHeat exchange apparatusBraze alloyMelting temperature

A multi layered aluminium alloy brazing sheet consisting of: a core material that on either one or both sides has an intermediate layer consisting of an Al-Si braze alloy interposed between the core and a thin covering layer on top of the intermediate layer, where the said core material and the covering layer has a higher melting temperature than the Al-Si, braze alloy, the covering layer containing Bi 0.01 to 1.0 wt%, Mg <= 0.01 wt%, Mn <= 1.0 wt%, Cu = 1.2 wt%,Fe <= 1.0 wt%, Si <= 4.0 wt%,Ti <= 0.1 wt%, Zr, Cr, V and / or Sc in total <= 0.2%, and unavoidable impurities each in amounts less than 0.05 wt%, and a total impurity content of less than 0.2 wt%, the balance consisting of aluminium; and a heat exchanger comprising the alloy brazing sheet.

Owner:SAPA HEAT TRANSFER AB

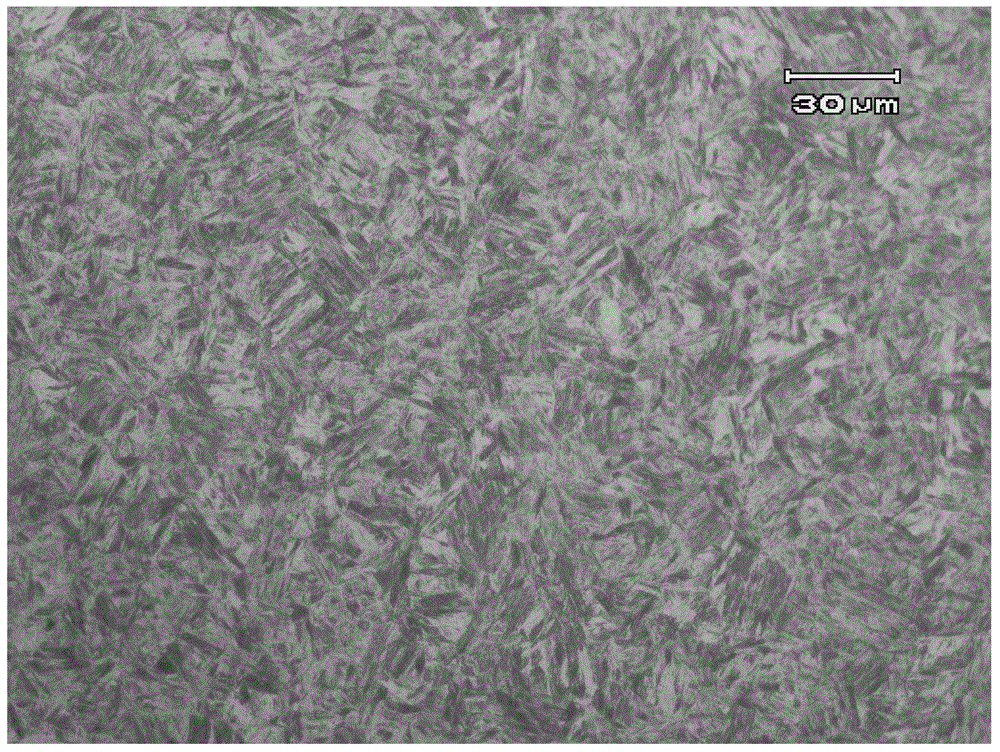

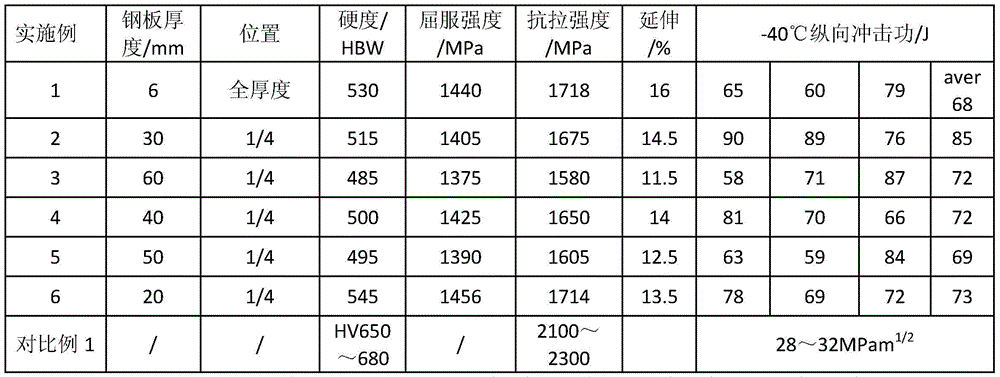

Armor steel plate with high anti-bullet property and manufacturing method of armor steel plate

The invention relates to an armor steel plate with a high anti-bullet property and a manufacturing method of the armor steel plate. The armor steel plate comprises chemical components in percentage by weight as follows: 0.20%-0.28% of carbon, smaller than or equal to 0.10% of silicon, 0.20%-0.50% of manganese, smaller than or equal to 0.012% of phosphorus, smaller than or equal to 0.003% of sulfur, 0.90%-1.30% of chromium, 0.20%-0.40% of molybdenum, 0.015%-0.035% of titanium, 0.020%-0.050% of aluminum, smaller than or equal to 0.00020% of hydrogen, smaller than or equal to 0.0040% of nitrogen, smaller than or equal to 0.65% of carbon equivalent and the balance of iron and inevitable impurities. The hardness of armor steel with the high anti-bullet property reaches 480-550 HBW, the shock absorption energy at the temperature of subzero 40 DEG C is larger than or equal to 20 J, and the armor steel plate has penetration resistance, can prevent armor steel from cracking, breaking or stripping and has the characteristics of low cost, stable quality, simplified process and easiness in large-scale industrial production.

Owner:SHANDONG IRON & STEEL CO LTD

UV printing and coating process for metal lettering cover

ActiveCN102390192AImprove efficiencyReduce energy consumption and waste emissionsOther printing apparatusWaxPrinting ink

The invention relates to a UV printing and coating process for a metal lettering cover, comprising the following steps: (1) plate making; (2), surface treatment for a base material; (3) UV printing; (4) continuous curing of a UV light cluster; (5) coating on a printed pattern to protect the printed pattern; (6) inside coating, wherein epoxy-phenolic coating is adopted for coating; (7) spraying wax, wherein wax is sprayed on the front face and back face of the printed and coated base material. In the UV printing and coating process, pretreatment is carried out on the surface of the base material through a flame treatment machine so that quality defects caused by abrasion of the surface of the material are avoided, and better adhesive force between UV printing ink and the surface of the base material is ensured. In addition, the flame treatment machine and a material transporting part of a UV metal printing machine are integrated so as to form a processing pattern of on-line continuous base material surface treatment and printing production and avoid treatment of the surface of the base material by a drying house. Therefore, the production processes are reduced, the production efficiency is improved, consumption of natural gas energy and discharge of waste gas are greatly reduced, and the purposes of energy saving and environment protection are achieved.

Owner:SHANGHAI BAOYIN METAL DECORATION

Large-sized multi-nozzle pipe hot extrusion forming process formulation and mold design method

InactiveCN103537509AIncrease productivityShorten the manufacturing cycleExtrusion diesExtrusion containersStructure propertyEngineering

The invention discloses a large-sized multi-nozzle pipe hot extrusion forming process formulation and mold design method. Taking a double-nozzle pipe for example, the method comprises the following steps: determining the size of each part of an unmachined double-nozzle pipe after hot extrusion forming; determining the size of an initial pipe blank; determining the position of the center of a prefabricated hole and the size of the aperture; determining amount of compression in the axial direction of the pipe blank with the prefabricated hole, of which oxide skin is removed, required for finishing hot extrusion forming of a second nozzle; determining amount of compression in the axial direction of the pipe blank required for continuing to finish hot extrusion forming of a first nozzle; determining the dimensional parameter of a key part of the hot extrusion mold; selecting the structural form of the hot extrusion mold; determining the extrusion capacity parameter and selecting forming equipment; determining a technological flow of the double-nozzle pipe hot extrusion forming process. According to the method, a pipe inner hole and a nozzle inner hole can be directly formed, the structural strength at the nozzle is improved, the metal mechanic property and the structure property are improved, the manufacturing period is shortened, and the material utilization rate is improved.

Owner:UNIV OF SCI & TECH BEIJING

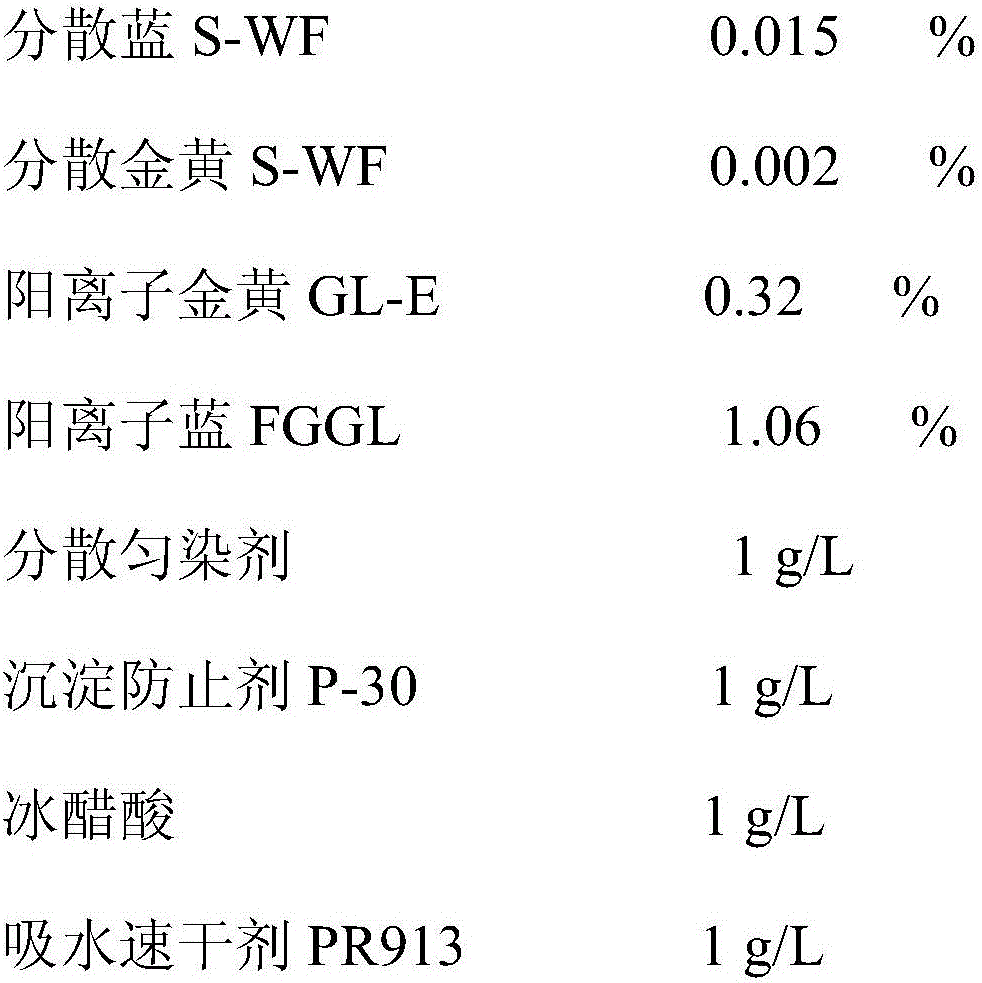

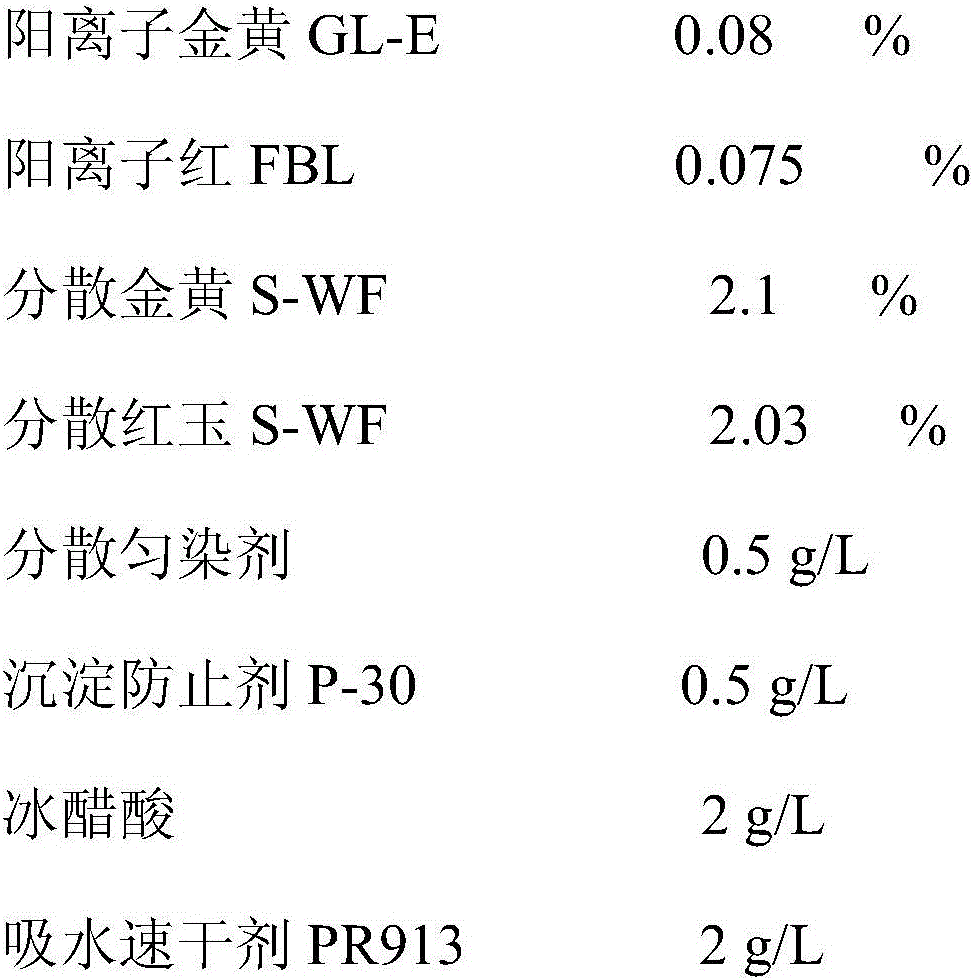

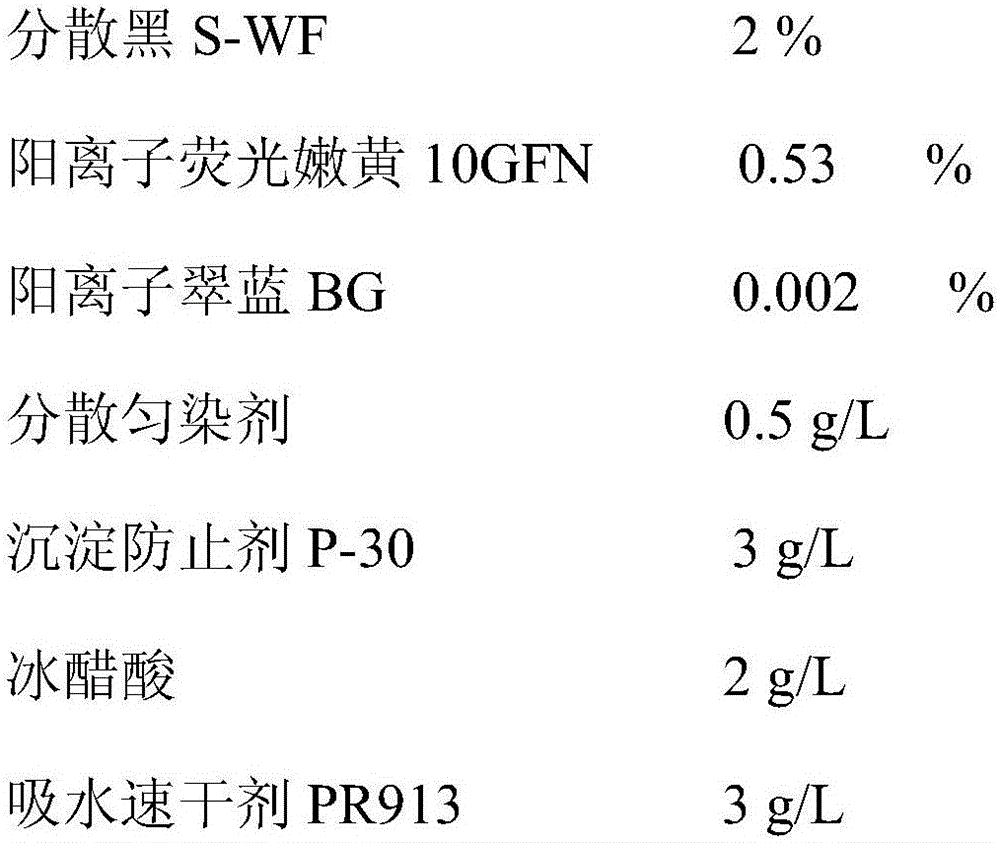

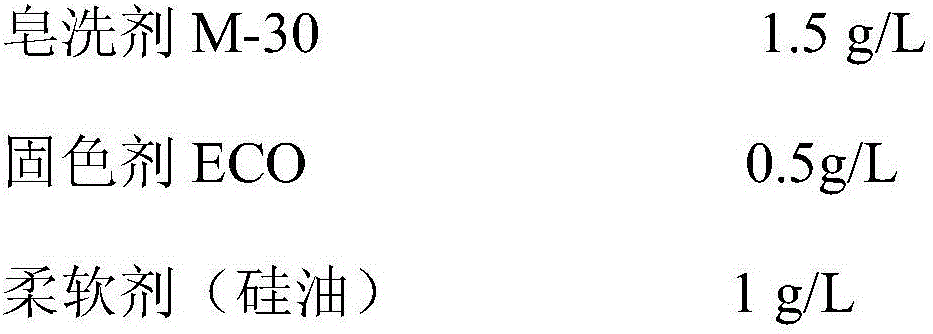

Cationic modified polyester/polyester one-bath process dyeing technology

The invention relates to a one-bath dyeing process for yarns and fabrics prepared by blending, doubling and interweaving cationic modified polyester and polyester, and belongs to the technical field of yarn and fabric dyeing processes. The process comprises the following steps: putting yarns or fabrics containing cationic modified polyester or polyester into a dye vat, heating in water, adding a water-absorbing quick-dry agent, a dispersing and leveling agent and glacial acetic acid for uniformly rotating; adding disperse dyes for uniformly rotating, adding an anti-settling agent for uniformly rotating, adding cationic dyes, heating to the temperature of 80+ / -2 DEG C at a speed of 1-1.5 DEG C per minute after uniform rotating, maintaining the temperature for 8-12 minutes, heating to the temperature of 100+ / -2 DEG C at a speed of 0.5-1 DEG C per minute, heating to the temperature of 130+ / -2 DEG C at a speed of 1.5-2 DEG C per minute, maintaining the temperature for 55+ / -5 minutes, cooling to 80 DEG C or below and draining, performing hot washing, soaping, washing and softening. According to the invention, the dyeing time can be reduced, the production efficiency is improved, pollution discharge is reduced, and the dyeing cost is reduced.

Owner:ZHEJIANG QIAOERTINGTING FASHION

Middle-thickness board-shape control method

ActiveCN101069896ASave resourcesReduce weightProfile control deviceEngineeringMechanical engineering

The present invention relates to a heavy and medium plate shape control method. Said method is characterized by including the following steps: setting roll gap opening of end pass and making it be finished product thickness + 1mm - 2mm and adopting rolling procedure of even-numbered pass plus planishing pass to implement said rolling process.

Owner:ANGANG STEEL CO LTD

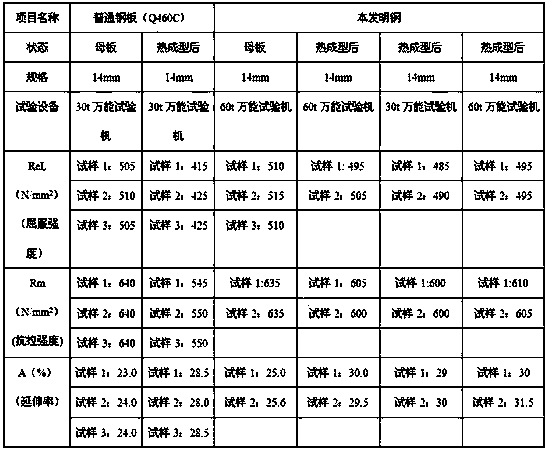

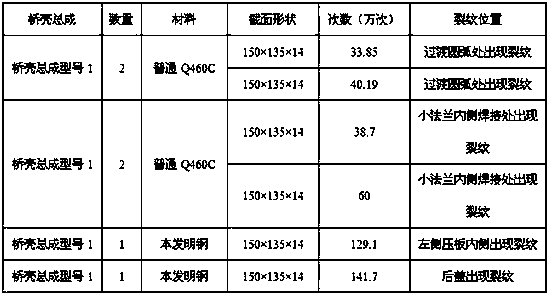

Steel plate for punching-welding axle housing and manufacturing method thereof

The invention relates to a 600MPa steel plate which is used for punching and welding an axle housing after being heated and is good in hot punching formability and a manufacturing method of the steel plate. Nb, V and other elements which guarantee the high temperature performance of steel are added, the content of C, Si and other elements which influence punching performance is lowered, Ti, Al and other nitrogen fixation elements are in cooperation, the steel plate is fundamentally guaranteed to have the good formability, meanwhile, high-temperature strength is improved, low-temperature toughness is excellent, welding performance is improved, fatigue strength is obviously improved, and the fatigue life of the component is prolonged by more than 50%. The steel plate can be widely applied to the production of medium plate rolling pieces in large structures of hot forming, a large air blower, a vibrating screen and the like under a high temperature condition, and the steel for the medium plate rolling pieces requires for high-temperature strength.

Owner:JIGANG GRP

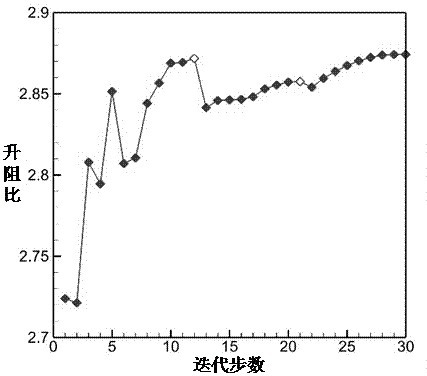

Gingival deformation simulation method based on mass-spring model of long axis of tooth

ActiveCN106504329ATo achieve the simulation effectDeformation effect is fullMedical simulationSpecial data processing applicationsDeformation effectLong axis

The invention discloses a gingival deformation simulation method based on a mass-spring model of the long axis of a tooth. The method comprises steps of: determining a gingival model; calculating the position of the long axis of the tooth; storing the initial position, the adjacent point, and the mapping point, corresponding to the long axis of the tooth, of a mass point; determining the position, the speed, and the borne force of the mass point in each time step, namely each iteration; calculating the new position of the long axis of the tooth according to a moving matrix when a dental crown is dragged; and determining a stop condition and outputting a simulation result. The gingival deformation simulation method achieves a good simulation effect because an improved mass-spring model is better than a simplified mass-spring model in the deformation effect and is greatly reduced in time consumption.

Owner:秦皇岛知聚科技有限公司

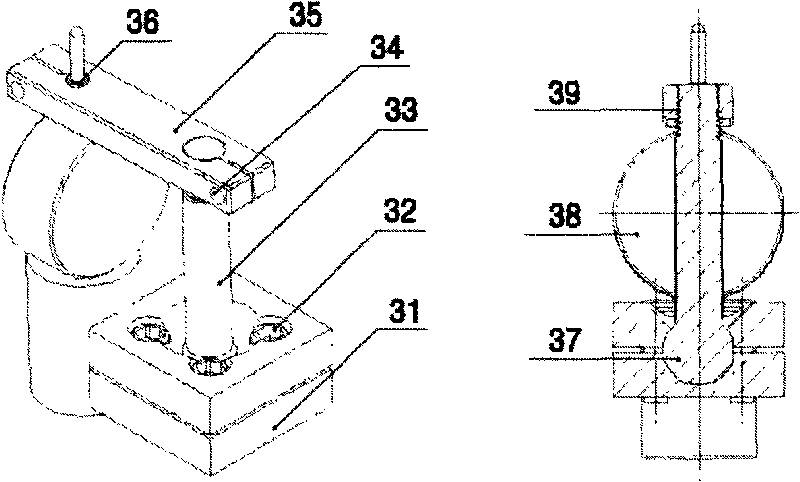

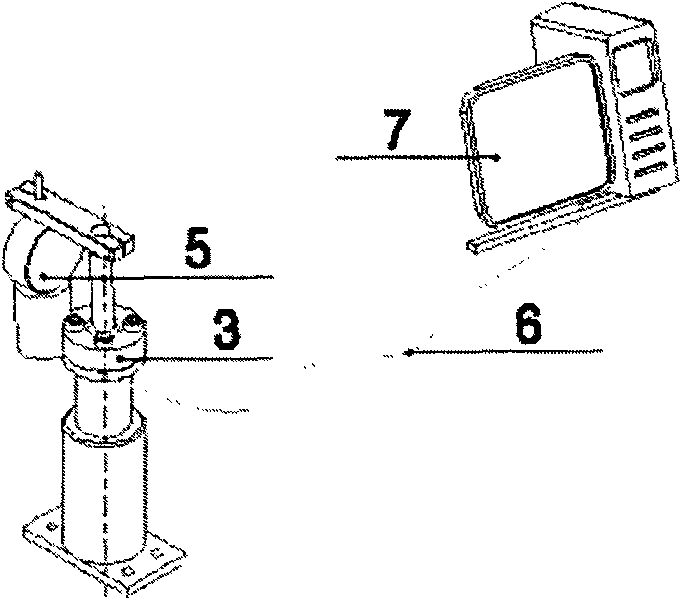

Detection system of automatic flexible checking tool based on contact measuring head

InactiveCN101750005AMature technologyEasy to installUsing electrical meansCommunication interfaceMechanical products

The invention discloses a detection system of an automatic flexible checking tool based on a contact measuring head, which comprises an adjustable tool, a measuring head seat, the contact measuring head, a controller, software and a main control computer, wherein the system uses the adjustable flexible tool to fix a workpiece and uses a contact measuring head with a communication interface to measure a relative dimension error. The measuring head is mounted on the measuring head seat capable of freely adjusting the gesture of the measuring head. Through the controller, one or more measuring heads are connected with the main control computer which controls the collection and treatment of measured data and realizes the automatic detection of the workpiece error. The system software makes statistic of the measured data, provides the information needed for controlling a statistic process and realizes the self-adapting calibration of the system. The invention has the advantages of good adjustability, low cost, high precision, fast speed, full automation, measures of quantization and the like, is an effective alternative scheme of current manual visual mechanical checking tool, and is also an excellent on-line detection scheme for dimension error of mechanical products.

Owner:涂成生

Cotton or viscose/chinlon/spandex seamless underwear one-bath-process dyeing technology

The invention relates to a cotton or viscose / chinlon / spandex seamless underwear one-bath-process dyeing technology, and belongs to the technical field of a knitwear dyeing technology. The technology comprises the following steps: keeping to-be-dyed cotton or viscose / chinlon / spandex seamless underwear in a dyeing jar, adding water to a specified water amount, heating up to 25-35 DEG C, sequentially adding salt or anhydrous sodium sulfate and a leveling agent, and keeping operating for 5-10min; then adding a reactive dye, a weak acid dye or a neutral dye and operating for 5-10min; heating up to 58-62 DEG C at 0.5-1 DEG C / min, then adding sodium carbonate and preserving heat for 30-50min; neutralizing sodium carbonate with dyeing acid, slowly regulating pH value to 6-7, heating up to 93-97 DEG C at 1-1.5 DEG C / min after rotating evenly and preserving heat for 40-60min; and cooling, draining, and finally carrying out post-treatment. The technology disclosed by the invention can effectively shorten dyeing process, shorten dyeing time, improve production efficiency, reduce discharged pollution and lower dyeing cost.

Owner:ZHEJIANG QIAOERTINGTING FASHION +1

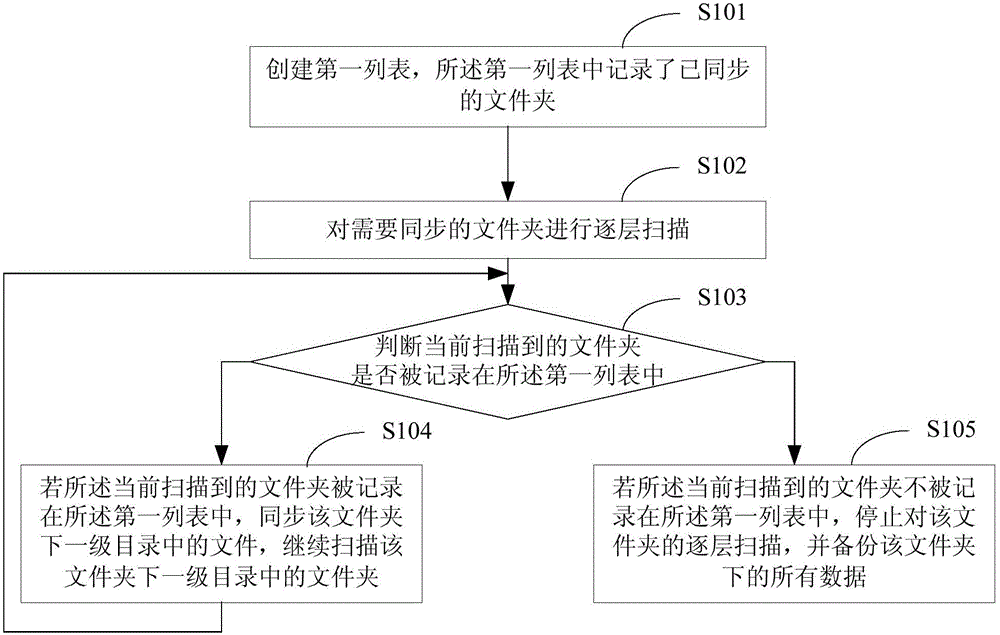

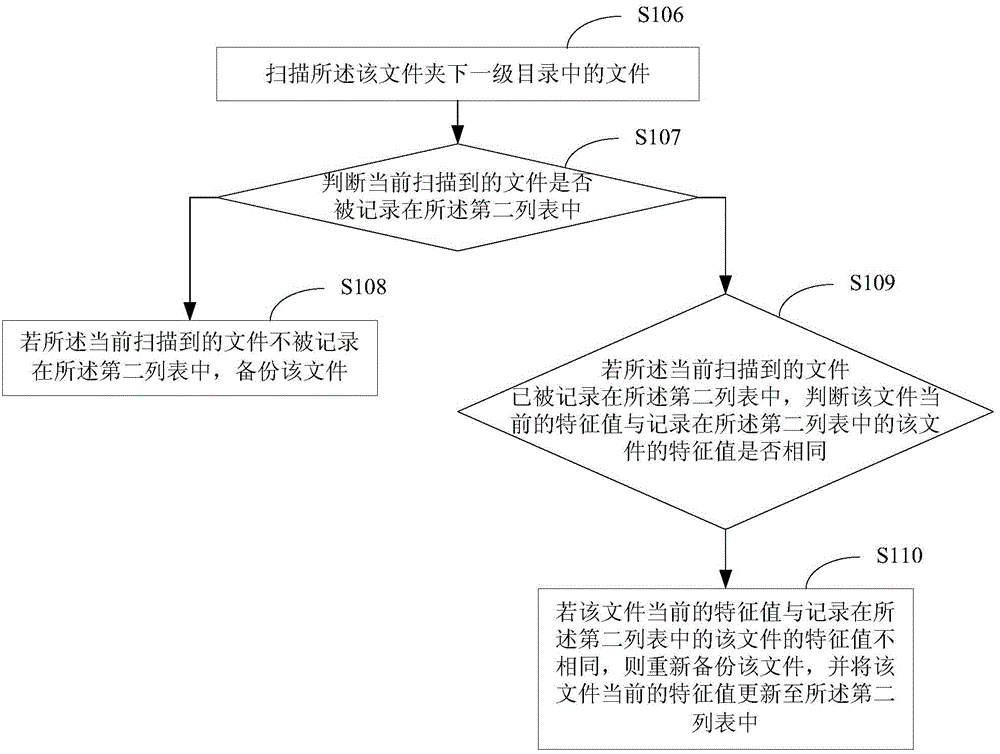

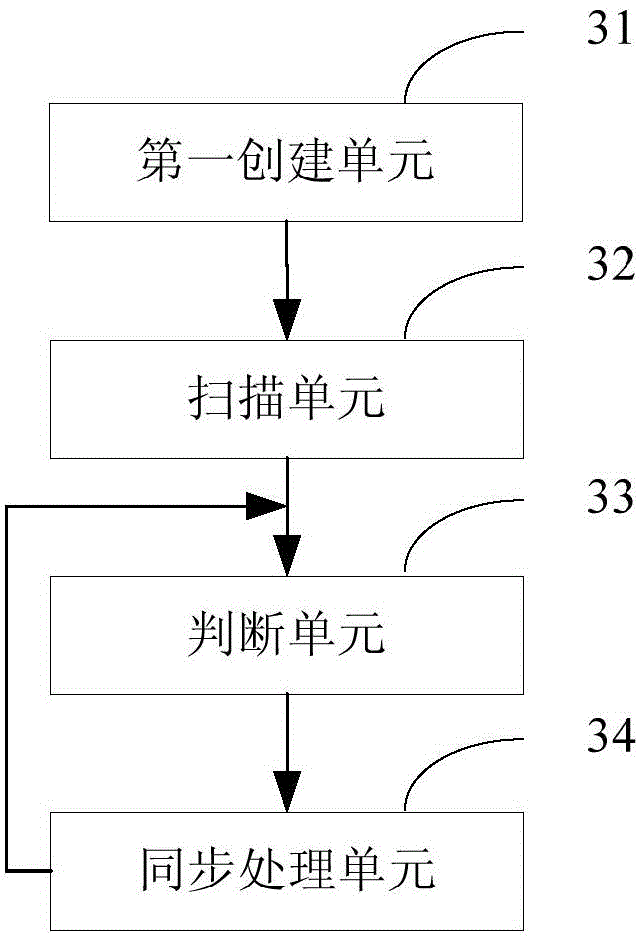

Data synchronization method and device

ActiveCN105376277AReduce total timeImprove backup efficiencyTransmissionSpecial data processing applicationsBackupData synchronization

The invention is applicable to the technical field of computers, and provides a data synchronization method and a device. The method comprises steps: a first list is built, wherein synchronized folders are recorded in the first list; layer-by-layer scanning is carried out on folders in need of synchronization; whether the currently-scanned folder is recorded in the first list is judged; if the currently-scanned folder is recorded in the first list, files in the next level directory of the folder are synchronized, and folders in the next level directory of the folder are scanned continuously; if the currently-scanned folder is not recorded in the first list, layer-by-layer scanning on the folder is stopped, and backup of all data in the folder is carried out. A magnetic disc scanning process in data synchronization is simplified, folders which are not synchronized yet are recognized quickly, total consumed time for data synchronization is reduced, and the data backup efficiency is improved.

Owner:TCL CORPORATION

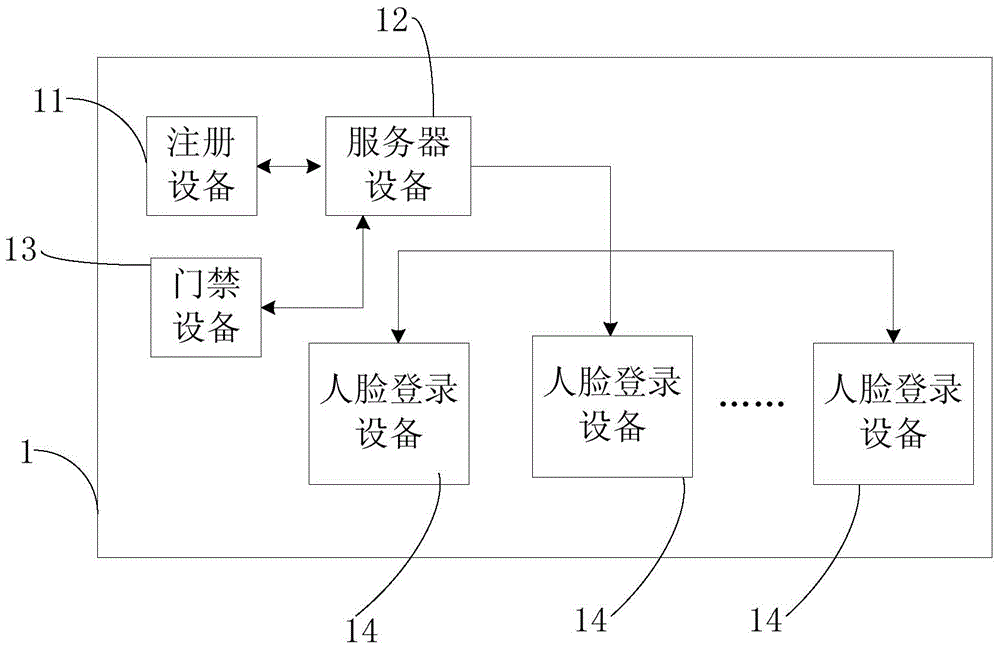

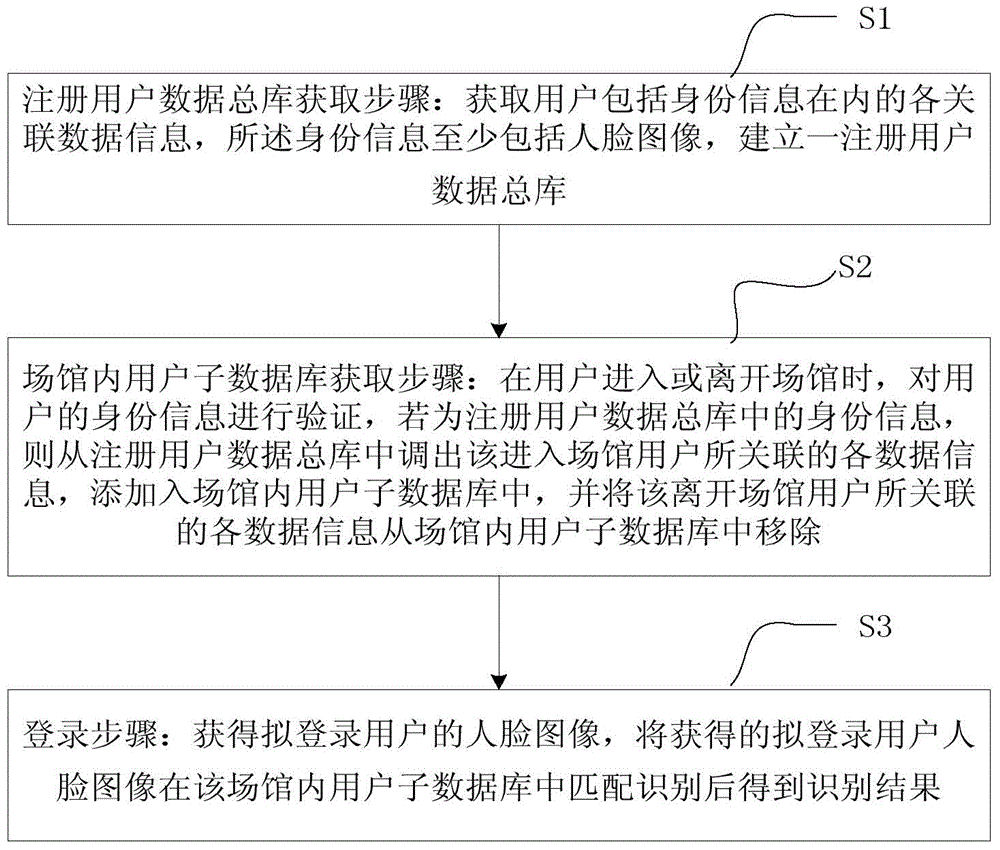

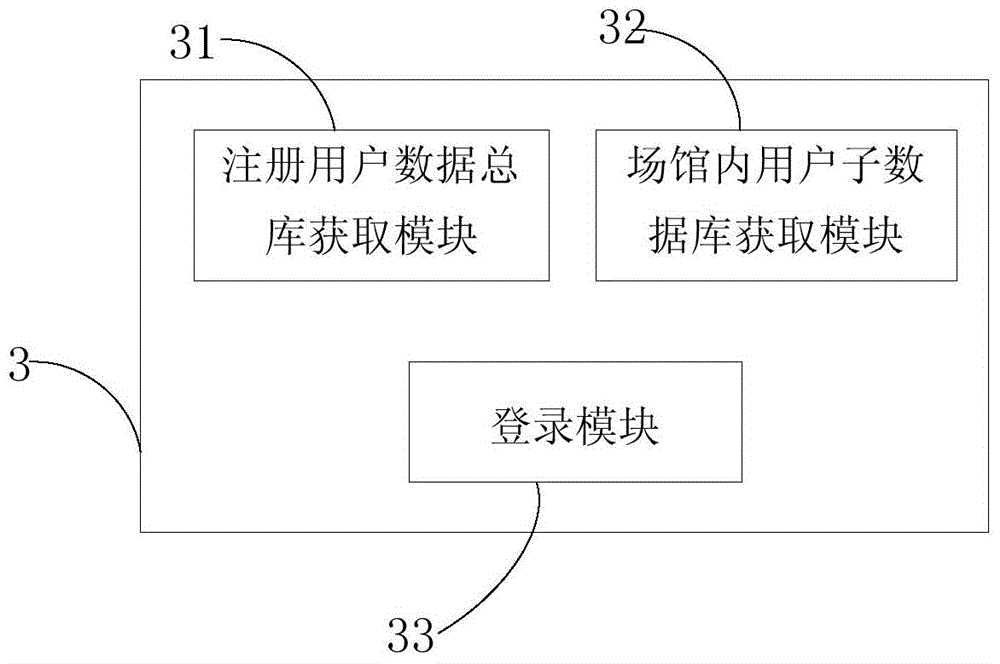

Quick large-number face recognition method and system

ActiveCN104537351AFast face recognition speedFast recognitionMatching and classificationSpecial data processing applicationsData informationData mining

The invention relates to a quick large-number face recognition method and system. The quick large-number face recognition method includes the step of acquiring a registered user general database, the step of acquiring an in-venue user sub-database, and the login step. In the step of acquiring the registered user general database, associated data information including identity information of users is acquired, and the registered user general database is established. In the step of acquiring the in-venue user sub-database, when the users enter or leave a venue, the identity information of the users is verified, and if the identity information is identity information in the registered user general database, associated data information of the users entering the venue is called from the registered user general database and added to the in-venue user sub-database. In the login step, face images of the users about to conduct login operation are acquired and matched and recognized in the in-venue user sub-database, and then the recognition result is acquired. The quick large-number face recognition system comprises a registered user general database acquisition module, an in-venue user sub-database acquisition module and a login module. By the adoption of the scheme, the face recognition speed is high, and reliability is high.

Owner:SHENZHEN TAISHAN SPORTS TECH CO LTD

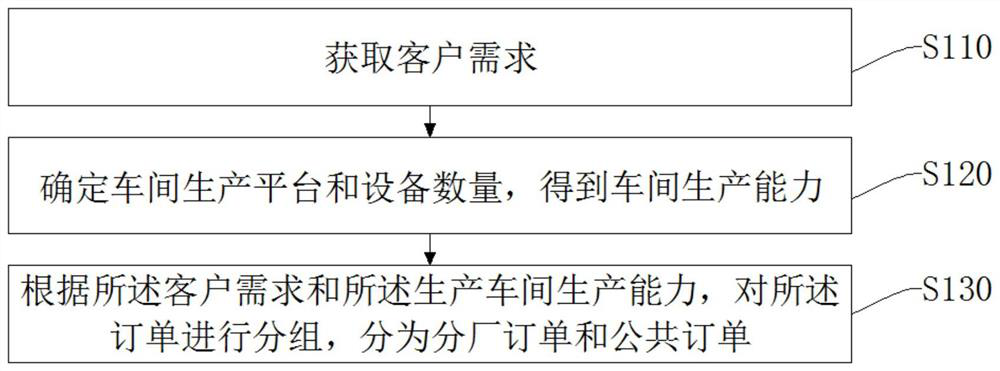

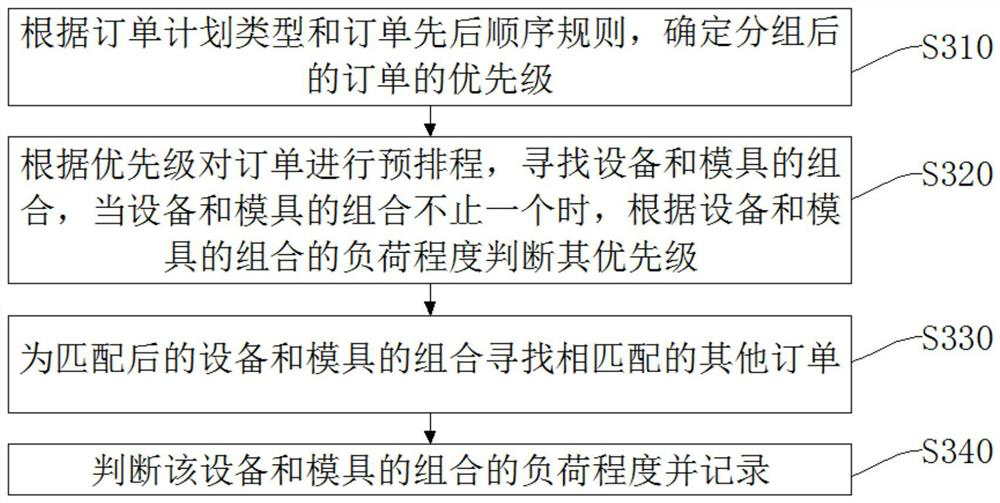

Profile extrusion production scheduling method, readable storage medium and device

PendingCN111882196AImprove production and operation efficiencyMeet production requirementsBuying/selling/leasing transactionsResourcesBusiness enterpriseProcess engineering

The invention discloses a profile extrusion production scheduling method, a readable storage medium and a device, and the method comprises the steps: S100) receiving a production scheduling request, carrying out the analysis of the production scheduling request, carrying out the grouping of orders, and obtaining a target production plan; S200) calling a target constraint mechanism corresponding tothe target production plan, wherein the target constraint mechanism comprises an order sequence rule and a resource load balancing principle; S300) performing pre-scheduling, determining an order priority and a production platform equipment priority, and matching production platform equipment for the order; S400) carrying out the production scheduling on production in a period of scheduling timeafter the current time, determining the order priority in the production scheduling, enabling the production scheduling to be matched with production platform equipment, and locking a scheduling result is locked. According to the method, the matching schedule meets the production requirements, the equipment utilization rate is obviously improved, the delivery time is shortened, and the enterpriseproduction and operation efficiency and the enterprise core competitiveness are improved.

Owner:安徽海螺信息技术工程有限责任公司

Manufacturing method of pure cotton color-mixed fancy fringe yarns

The invention discloses a manufacturing method of pure cotton color-mixed fancy fringe yarns. The manufacturing method comprises the following steps of: first, mixing a coloring cationic modified cotton fiber and a water repellency type cotton fiber in a proportion of 2-98%: 98-2%, spinning into fancy fringe yarns, weaving, baking at a high temperature, and then, carrying out dyeing process on a finished fabric. The pure cotton color-mixed fancy fringe yarns produced by using the method provided by the invention can be used for dyeing the effect of the color-mixed fancy fringe yarns of a needed tone once. In addition, the factory storage is reduced beneficially, and a product delivery period is shortened. Such novel pure cotton color-mixed fancy fringe yarns are top-grade raw materials for processing high-grade underwear, a T-shirt, sportswear and the like.

Owner:BROS EASTERN

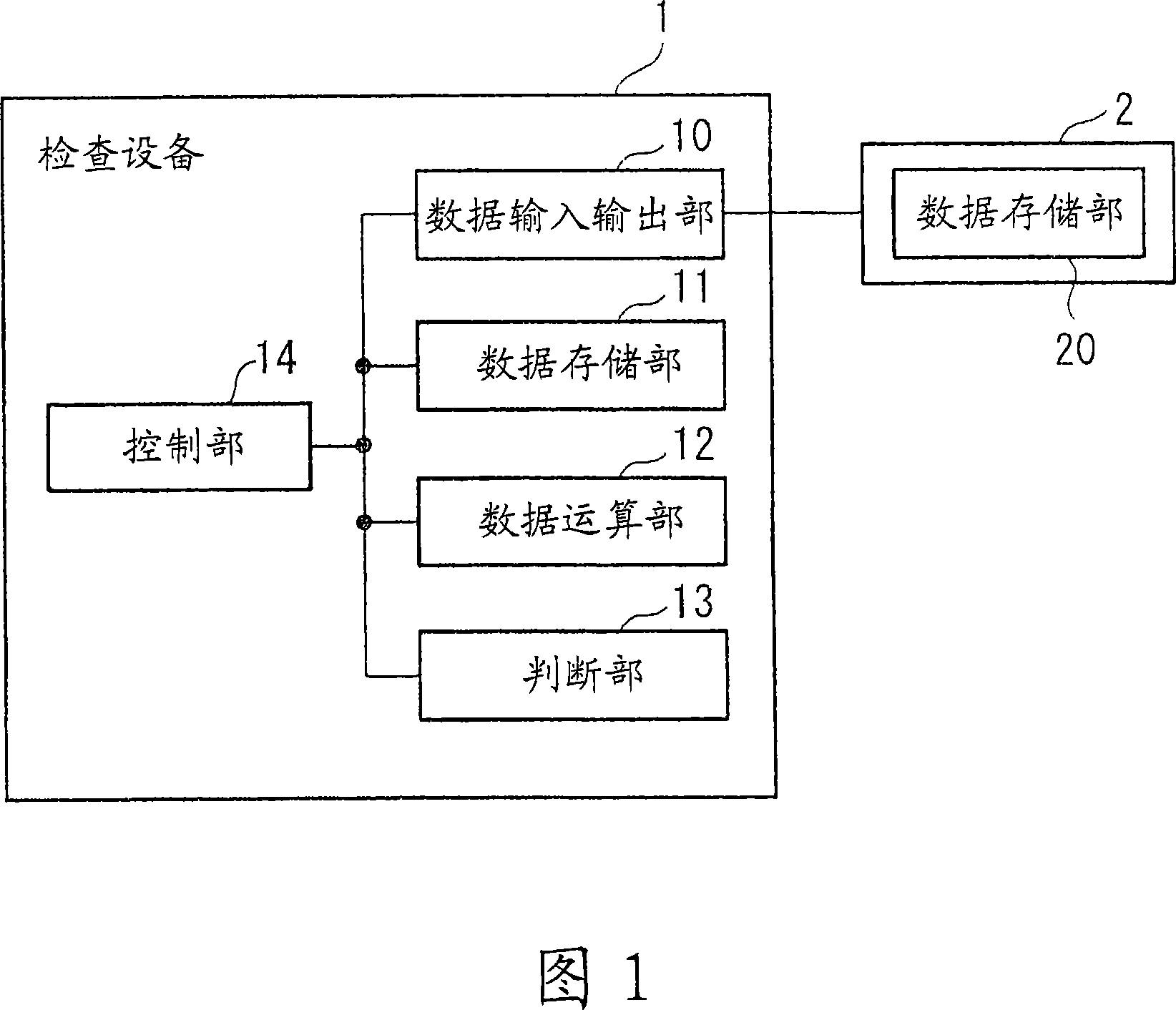

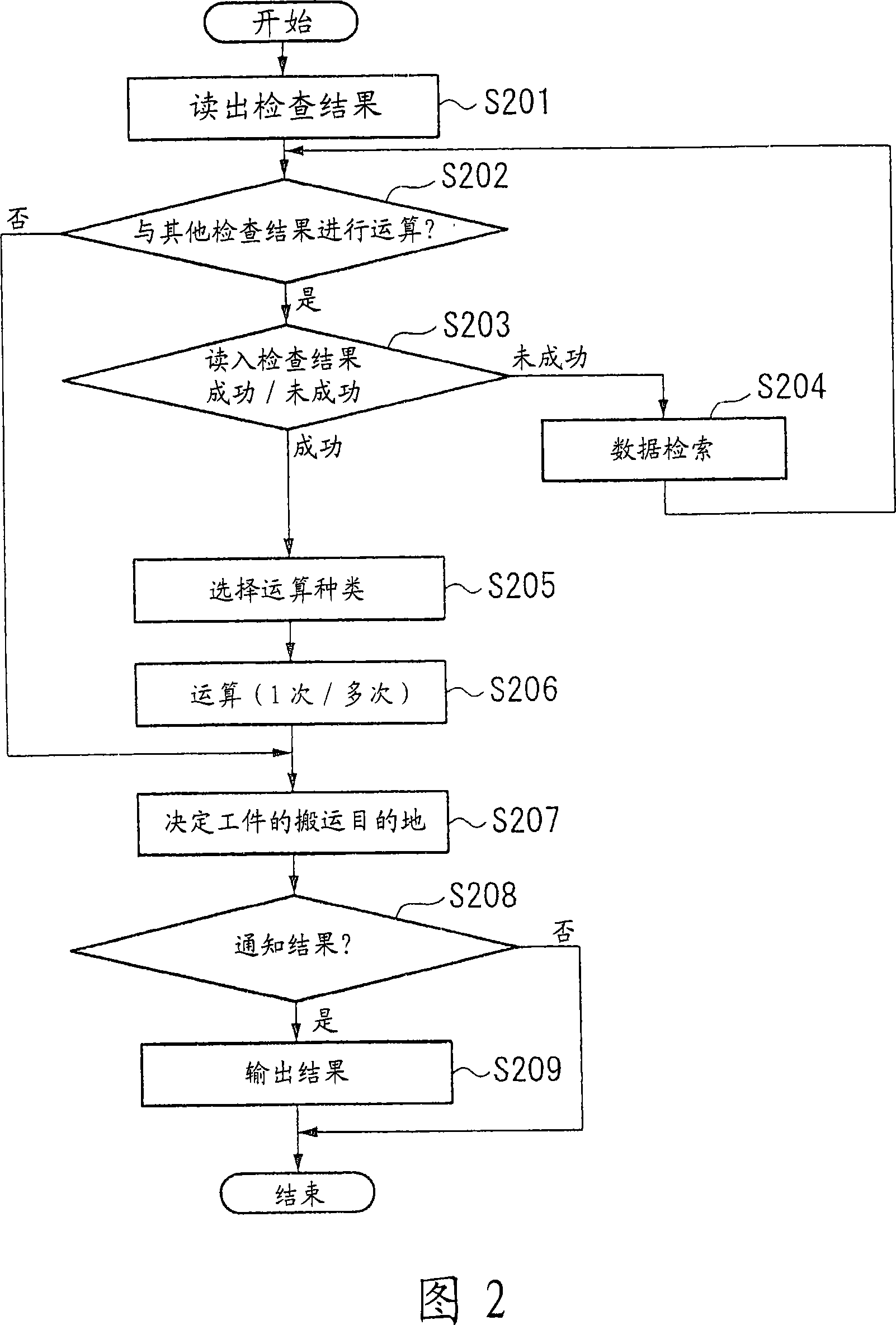

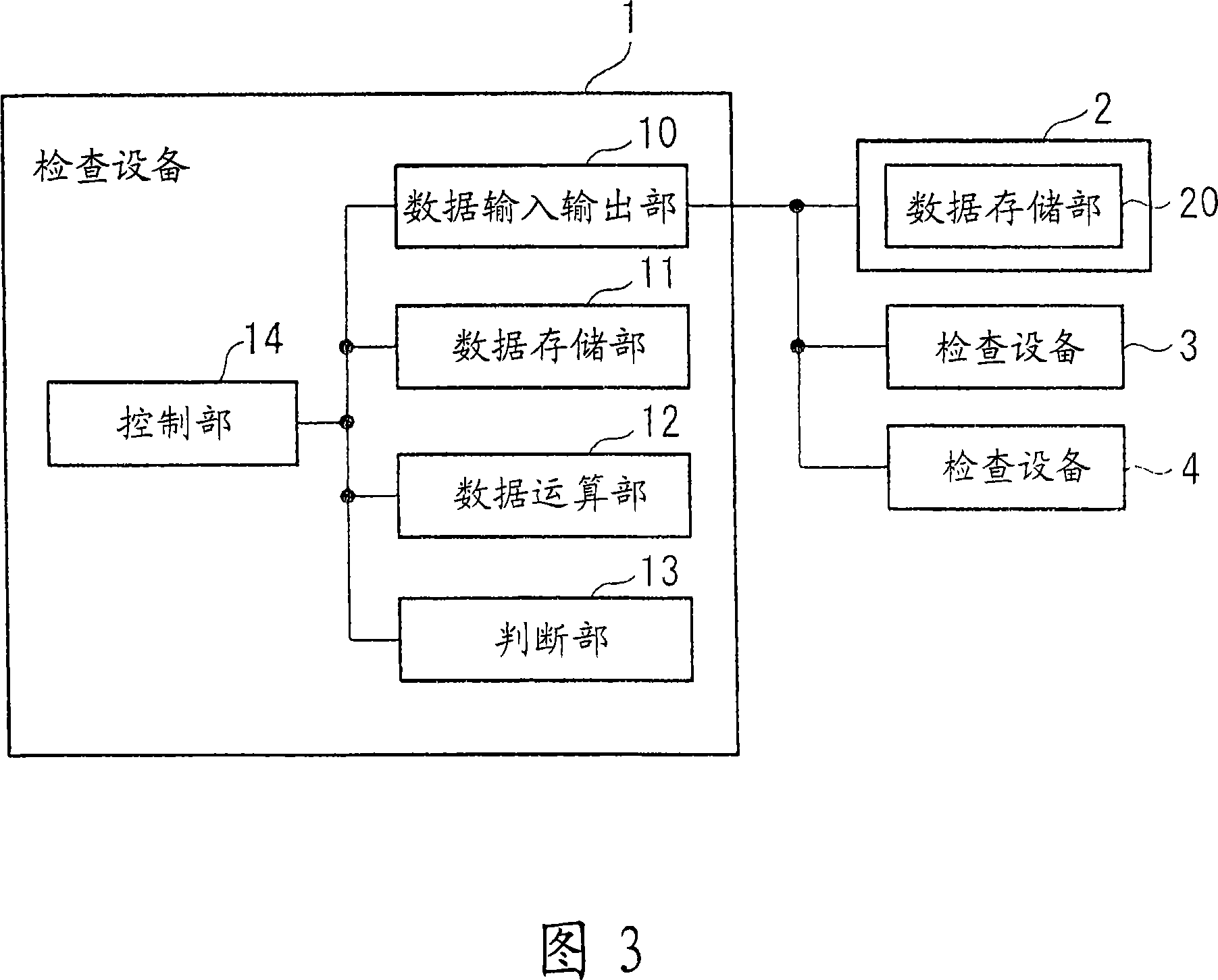

Defect detecting device and defect detecting method

InactiveCN101101266AReduce total timeMaterial analysis by optical meansNon-linear opticsData operationsSoftware engineering

The invention relates to a defect inspection device and defect inspection method, which can reduce the consignment stage of manufacturing process. A control devision (14) generates defect information of identifying the defect of substrate at the time of detecting substrate. After inspecting, the control devision (14) compares the defect information of said substrate generated at the time of inspecting with defect information generated at the time of an inspection of a lower layer of said substrate. The repeated defect repeated with the defect of the lower layer is removed to generate noted-flaws information which identifies a defect generated on said top layer layer. A decision means (13) which judges a taking-out place of said substrate based on said noted-flaws information of the top layer output from the data operation part, and informs control devision (14).

Owner:OLYMPUS CORP

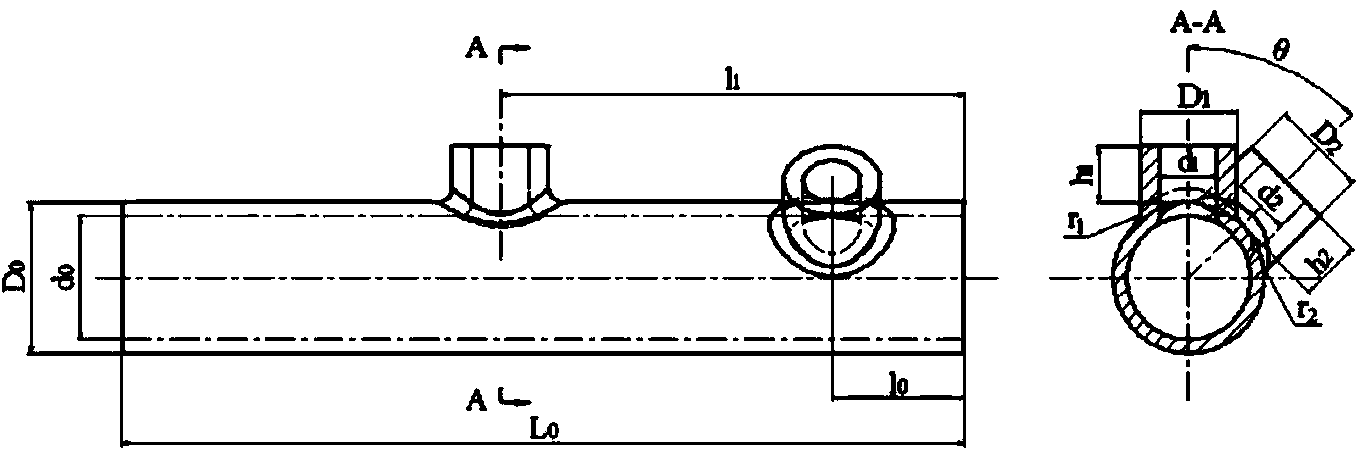

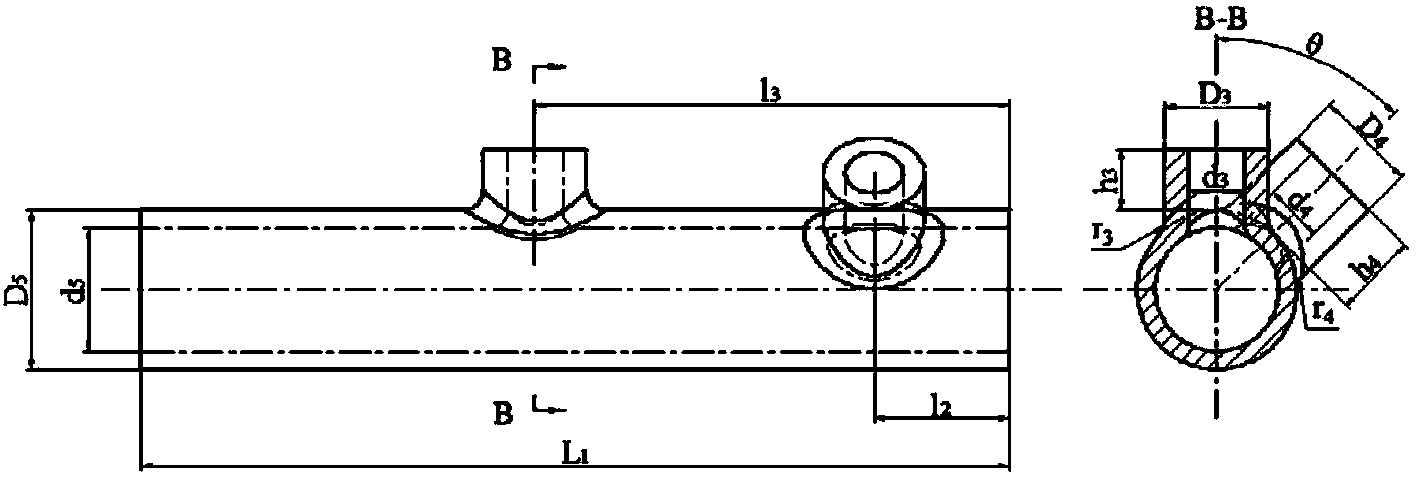

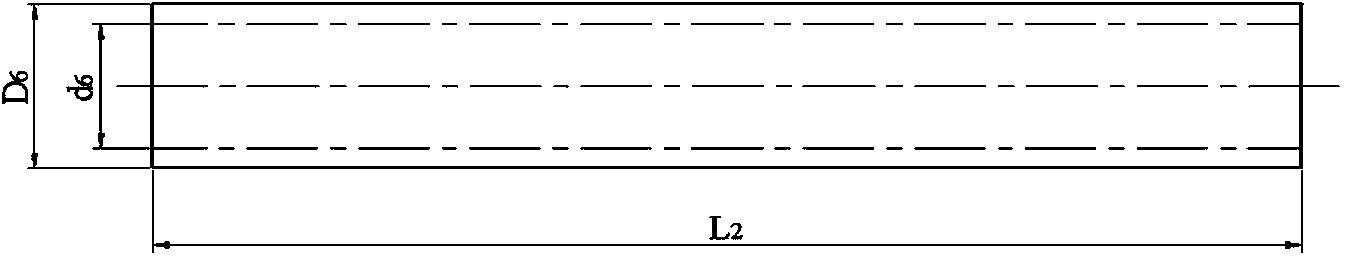

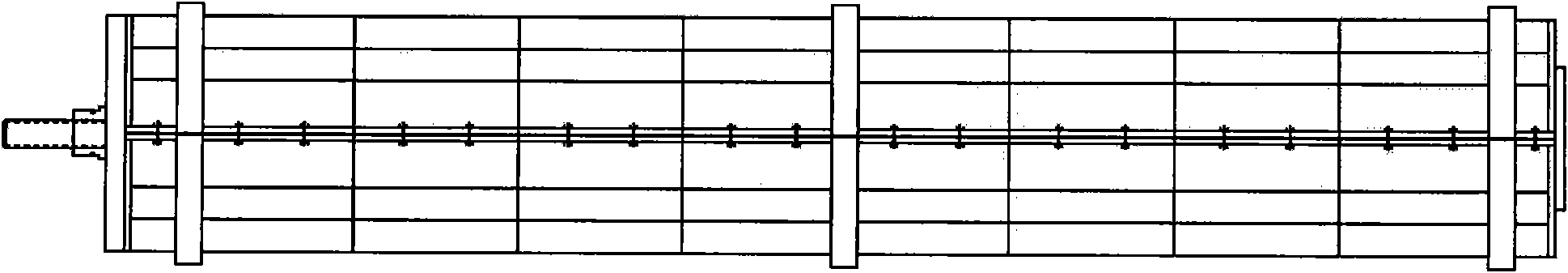

Prestressed tube tensioning mold

The invention discloses a prestressed tube tensioning mold, which comprises an upper mold and a lower mold. The upper mold and the lower mold are mutually fastened; and an inner mold is also arranged inside a mold formed by the upper mold and the lower mold. A tensioning mechanism is arranged at one end of the mold, and a tensioning fixed plate is arranged at the other end of the mold. The prestressed tube tensioning mold is characterized in that: the tensioning mechanism comprises a tensioning screw rod connected with a tensioning draw plate; the tensioning draw plate is connected with a tensioning connecting plate through a tensioning connecting piece; and the tensioning connecting plate is connected with concrete centrifugal products. The prestressed tube tensioning mold can effectively reduce the labor intensity, effectively suppress slurry leakage of a pile head, prolongs the service life of the screw rod and die assembly screws, guarantees the verticality of the screw rod and the section of the concrete centrifugal products, prevents the screw rod from inclining, reduces the die clamping probability and whole prestress non-uniformity of the pile, avoids steel mould damage and fittings damage during mold removal, avoids the damage of the concrete centrifugal products simultaneously, and improves the working efficiency.

Owner:SHANGHAI ZHONGJI PILE IND

Dyeing technique for polyester cotton or polyester viscose/chinlon/spandex multi-component fabric by one-bath two-step process

The invention relates to a dyeing technique for polyester cotton or polyester viscose / chinlon / spandex multi-component fabric by a one-bath two-step process and belongs to the technical field of textile dyeing process. The dyeing technical includes the following process steps: putting the to-be-dyed polyester cotton or polyester viscose / chinlon / spandex multi-component fabric into a dye vat, feeding water to the specified water quantity, increasing the temperature to 30+ / -5 DEG C, sequentially adding salt or anhydrous sodium sulphate and levelling agent prior to continuing operation for 5-10 minutes, then adding reactive dye, disperse dye, weak acid dye or neutral dye for operation for 5-10 minutes prior to increasing the temperature to 60+ / -2 DEG C at the rate of 0.5-1 DEG C / min, then adding sodium carbonate, keeping at the temperature for 30-50 minutes prior to neutralizing the sodium carbonate with dyeing acid, slowly regulating the pH value to 5.5-6.5, uniformly rotating prior to increasing the temperature to 130+ / -2 DEG C at the rate of 1-1.5 DEG C / min, keeping at the temperature for 40-60 minutes, and then cooling and discharging water prior to aftertreatment. By the technique, the process of the dyeing technique can be shortened effectively, time for dyeing is reduced, production efficiency is improved, steam and water consumption is reduced, pollution discharge is reduced, and dyeing cost is lowered.

Owner:ZHEJIANG QIAOERTINGTING FASHION +1

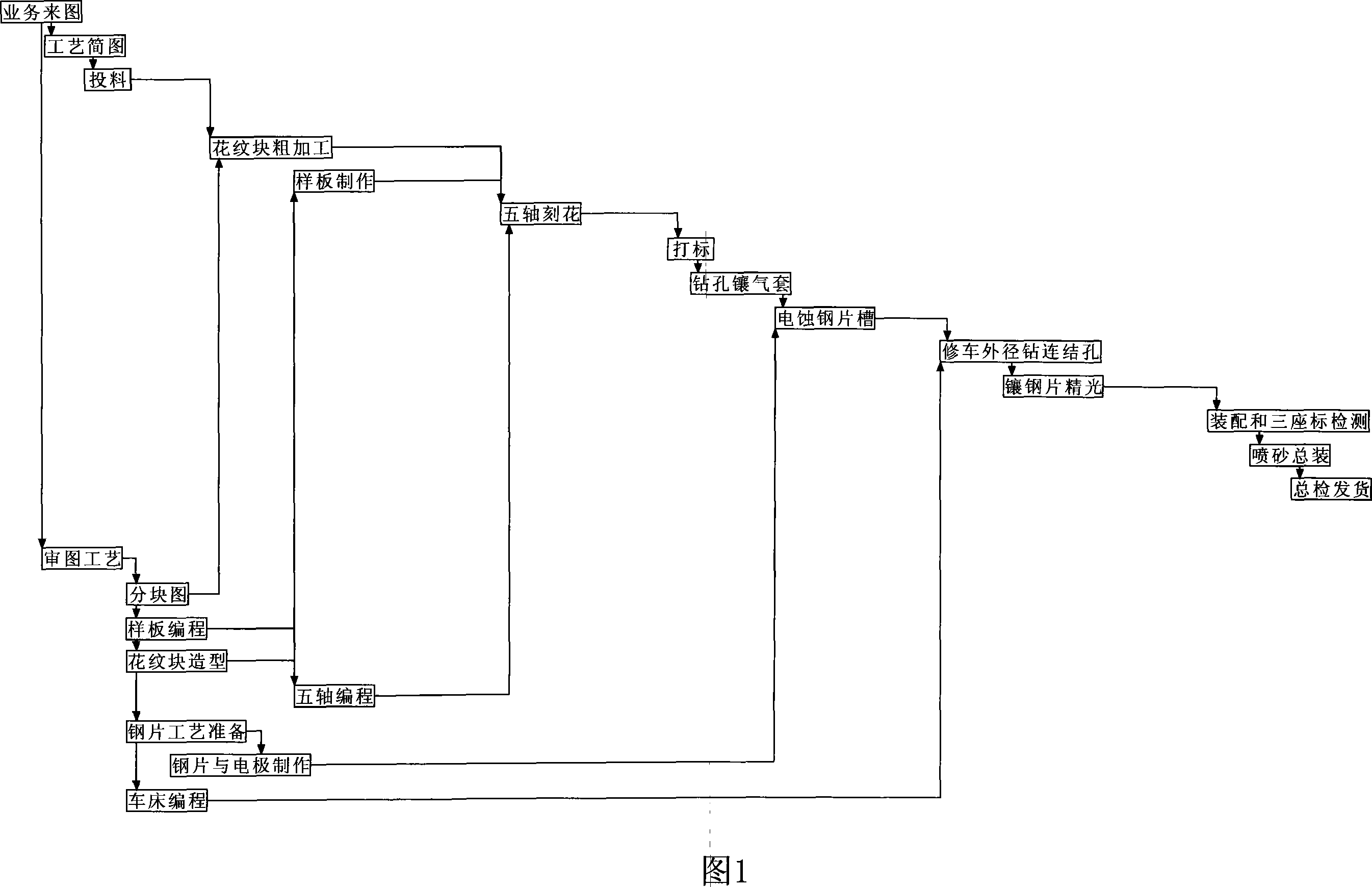

Tire mold high speed high precision parallel machining constitution method

InactiveCN101236416AShorten the design cycleReduce process preparation timeProgramme controlComputer controlNumerical controlEngineering

The invention relates to a high velocity and high precision constituting method for collaterally elaborating a tyre mould, comprising the following steps of a concurrence of designing and manufacture processing; a concurrence of designing and material purchasing; a concurrence of technology planning, rough machining and semifinishing; a concurrence of designing and numerical control process programming; and an elaboration for a single piece with high velocity and high precision. The high velocity and high precision constituting method for collaterally elaborating a tyre mould has the advantages of improving an elaborating precision of a product, shortening a delivery date for the mould and reducing the cost, and is suitable for collaterally elaborating the tyre mould with high velocity and high precision.

Owner:GREATOO INTELLIGENT EQUIP INC

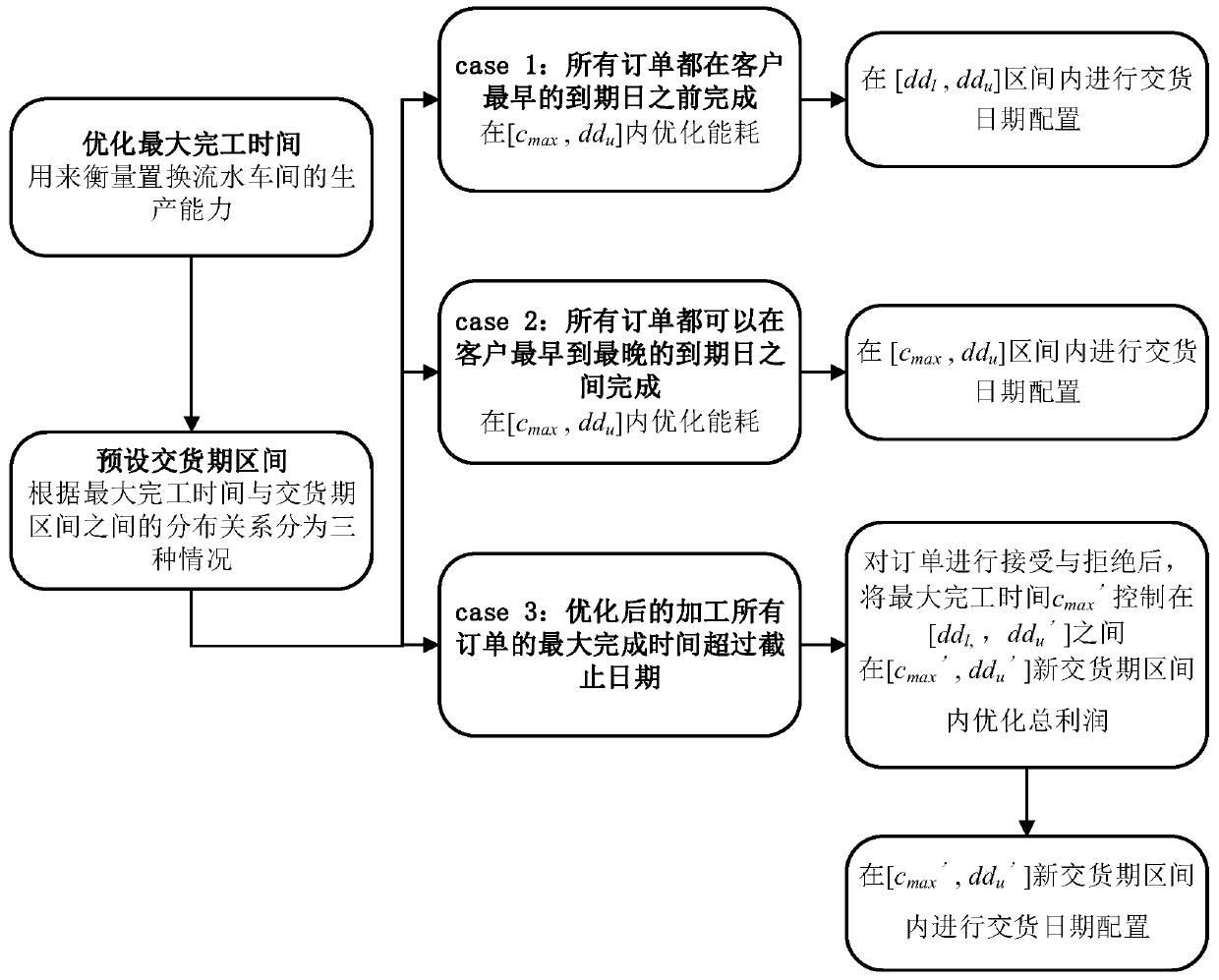

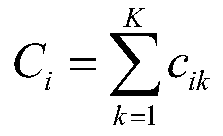

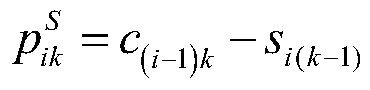

Replacement flow shop energy efficiency optimization scheduling method integrating delivery date configuration

ActiveCN111382942AImprove efficiencyQuality improvementEnergy industryArtificial lifeLocal optimumBusiness enterprise

The invention discloses a replacement flow shop energy efficiency optimization scheduling method integrating delivery date configuration. The method comprises the steps of collecting production data to generate three energy efficiency optimization and delivery date configuration frameworks; carrying out integrated encoding between the workpiece and the machine by two frameworks; wherein the code of the rejected order in the third framework is spliced after the code of the received order; generating an initial solution by adopting an NEH heuristic algorithm according to a coding mode, and initializing a tabu table; performing tabu search on the later generated initial solution, and updating a local optimal solution and a tabu table; decoding the obtained optimal solution to obtain a scheduling scheme; generating an initial population according to a coding mode; calculating a target fitness value of the generated population and carrying out fitness value distribution; and performing selection, crossover and mutation operations on the later generated population, updating a local optimal solution, performing decoding, and performing integration to obtain a scheduling scheme. Accordingto the method, a scheduling scheme satisfying enterprises and clients is obtained in a reasonable time, energy consumption is reduced, enterprise profits are improved, and production efficiency is improved.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

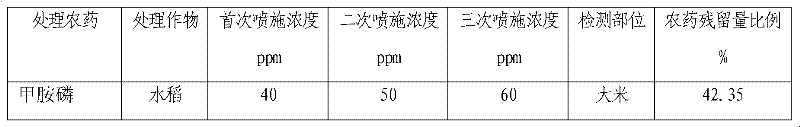

Chitosan oligosaccharide composition for reducing content of residual pesticides in crops

ActiveCN102365938AResidue reductionReduce total timeBiocideAnimal repellantsPesticide residuePhytotoxicity

The invention which relates to a chitosan oligosaccharide composition for reducing the content of residual pesticides in crops, a purpose thereof and a method thereof concretely provides a pesticide composition for reducing the content of the residual pesticides in the crops. The pesticide composition comprises 0.003-0.008 wt% of a chitosan oligosaccharide. The invention also provides a purpose of the chitosan oligosaccharide-contained pesticide composition in reducing the content of the residual pesticides in the crops and a method for applying the chitosan oligosaccharide-contained composition in reducing the content of the residual pesticides in the crops. According to the invention, an important problem of the reduction of the content of the residual pesticide in the crops is solved; and after the chitosan oligosaccharide-contained pesticide composition is adopted to process the pesticide applied crops, the content of the residual pesticides in the crops is reduced, the phytotoxicity to the crops is not generated, and no secondary pesticide residual problems appear.

Owner:HAINAN ZHENGYE ZHONGNONG HIGH TECH

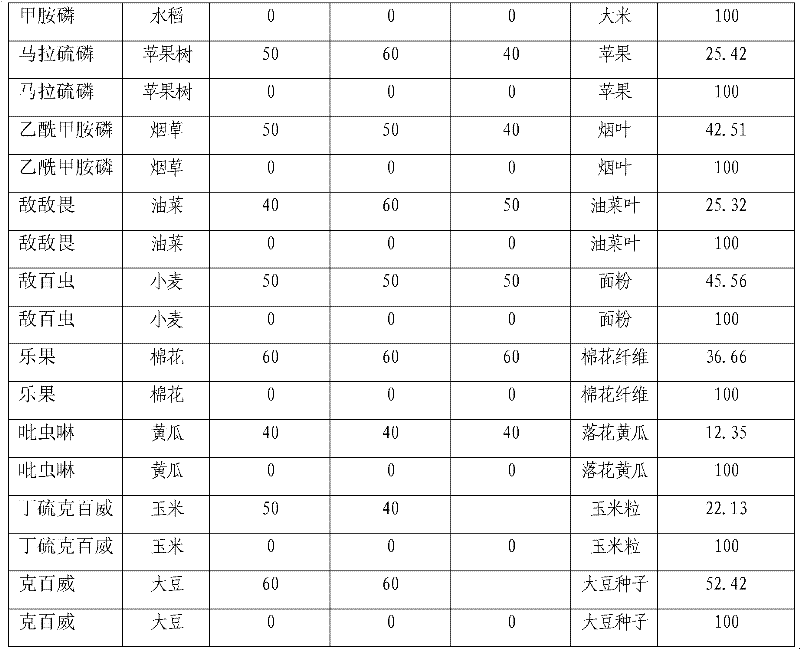

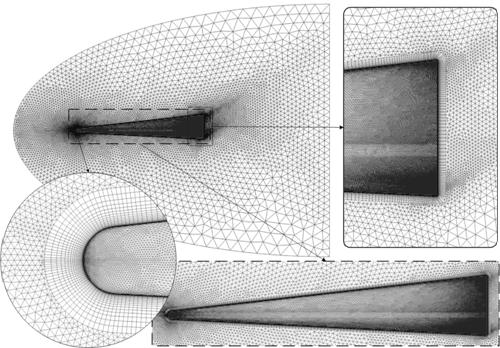

Aircraft aerodynamic configuration design method and system based on simulation and optimization coupling

ActiveCN112016167AAvoid performance degradationAvoid Sampling and Simulation CalculationsGeometric CADSustainable transportationFlight vehicleField simulation

The invention discloses an aircraft aerodynamic configuration design method and system based on simulation and optimization coupling, and the method comprises the steps: determining an aircraft configuration parameterization method according to a given aircraft configuration model, and obtaining a design variable; generating an initial sampling point by using a constraint domain experiment designmethod; carrying out flow field simulation calculation by using a high-precision pneumatic simulation model to obtain simulation flow field distribution, constructing a training set and generating a full flow field approximation model; predicting an optimal point in a design space for the full flow field approximation model, and taking the optimal point as a new sampling point; performing simulation calculation on the new sampling point by using a high-precision pneumatic simulation model to obtain a simulation flow field approximation model of the new sampling point; and outputting a new sampling point when a convergence judgment condition is met. Through deep coupling of the optimization algorithm and the simulation model, double acceleration of convergence of the simulation solution information acceleration optimization algorithm and acceleration of aerodynamic simulation solution by the optimization algorithm is realized, so that the total time consumption of the optimization process is greatly reduced, and the aerodynamic optimization efficiency is improved.

Owner:NAT UNIV OF DEFENSE TECH

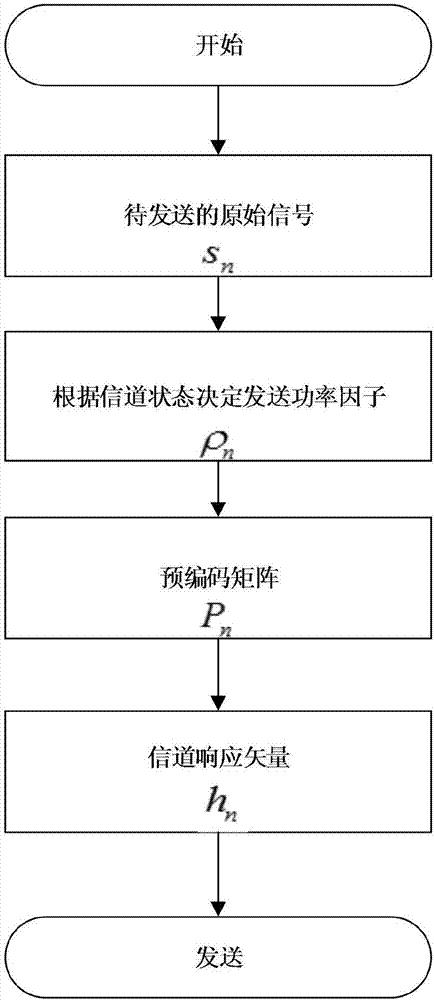

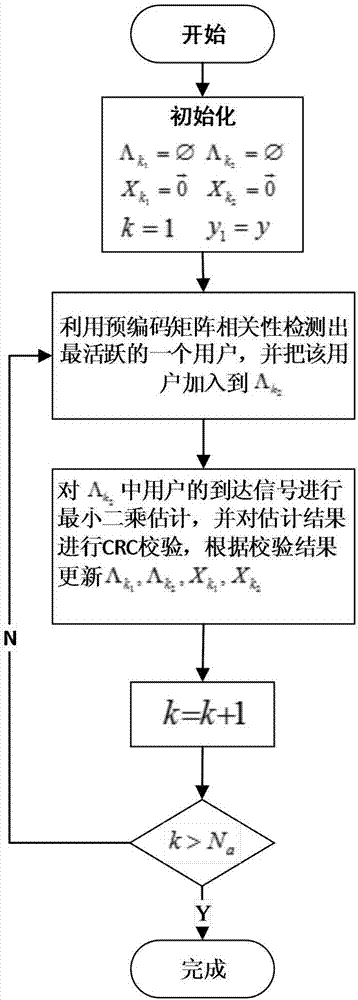

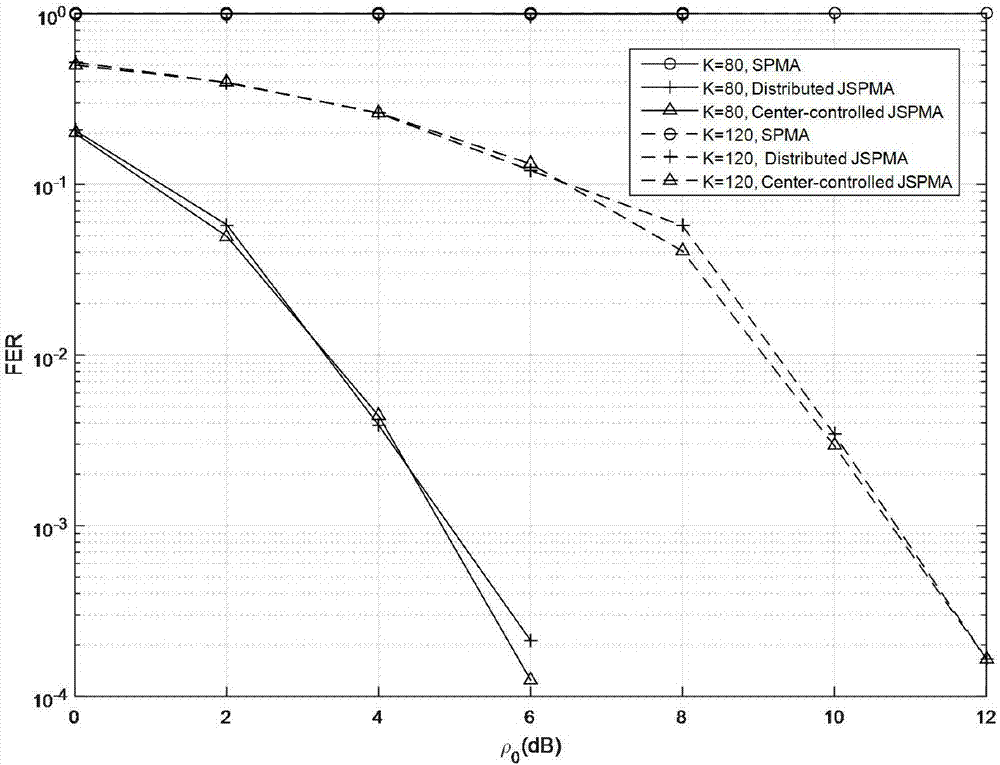

Uplink non-orthogonal multiple access method based on power and code word joint domain

ActiveCN107332599AIncrease the overload rateReduce access delayRadio transmissionChannel coding adaptationIteration processSignal recovery

The invention discloses an uplink non-orthogonal multiple access method based on a power and code word joint domain. The uplink non-orthogonal multiple access method is characterized by comprising the following steps: 1, allocating different pre-coding matrixes to users; 2, making the users determine transmission power according to amplitude information of own channel responses; and 3, performing user detection and signal recovery by using an iteration algorithm, and performing successive interference cancellation in an iteration process. Specific to the problem of sparse signal reconstruction of large-scale user access, the user overload rate can be increased extremely by the uplink non-orthogonal multiple access method without central scheduling of a base station.

Owner:UNIV OF SCI & TECH OF CHINA

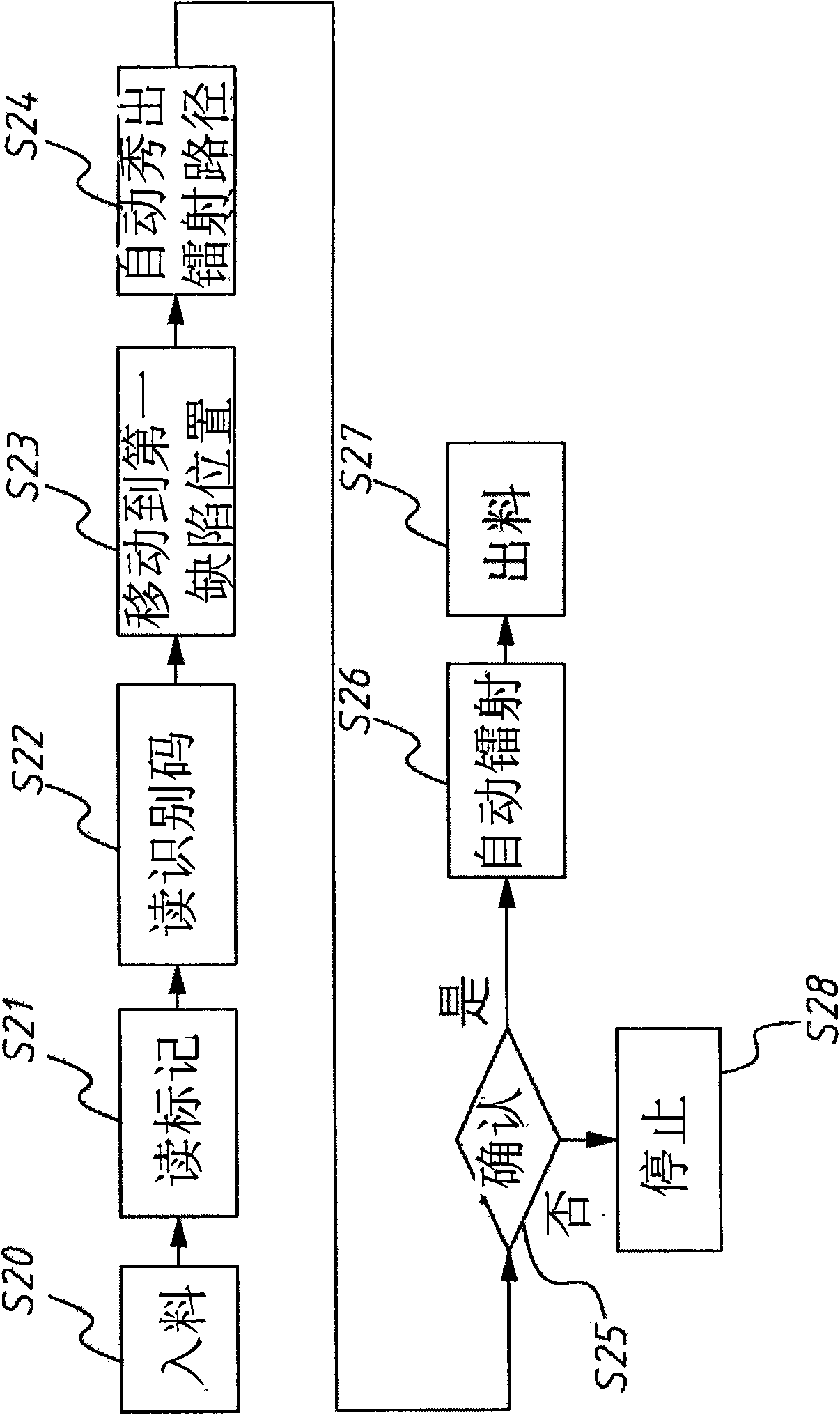

Automatic laser repair method

InactiveCN101571629AShorten the timeIncrease production capacityNon-linear opticsOptoelectronicsSurface plate

The invention mainly relates to a Laser repair method, in particular to an automatic laser repair method for repairing defects generated during manufacturing a display panel. The method comprises the following steps: at least one panel to be repaired is provided, and the panel to be repaired has at least one defect and is processed by classification of defects to have the defect of only one laser path; according to a defect position, a laser head automatically moves to the defect position and selects a corresponding laser prescription; and a laser path is automatically displayed according to the laser prescription, and the only one laser path is utilized to automatically laser the defect for repairing. The automatic laser repair technology can effectively shorten the Tact time required by a laser repair processing procedure so as to improve the productivity, reduce the opportunity of manual operation errors and improve the repair success ratio.

Owner:CENTURY DISPLAY (SHENZHEN) CO LTD

Manufacture method for differentiated tingible cotton yarn

ActiveCN103088498AStrong contrastDecrease stockSucessive textile treatmentsDyeing processYarnPulp and paper industry

The invention discloses a manufacture method for differentiated tingible cotton yarn. The method includes the following steps: cationic modified cotton and anionic modified cotton are prepared; the prepared cationic modified cotton and the prepared anionic modified cotton are blended into yarn; by weight, the blending proportion of the cationic modified cotton and the anionic modified cotton is 2%-98%: 98%-2%; and the spinning style is bunchy yarn or AB yarn or splash yarn or damask yarn. The differentiated tingible cotton yarn manufactured by using the method can have the effects of color-blend fancy yarn with strong contrast ratios, and needed hues are formed for one time; the differentiated tingible cotton yarn is excellent raw materials for processing top-grade underclothes, T-shirts, casual clothes and the like; and besides, the method is beneficial for reduction of factory inventory and shortening of product delivery time.

Owner:BROS EASTERN +1

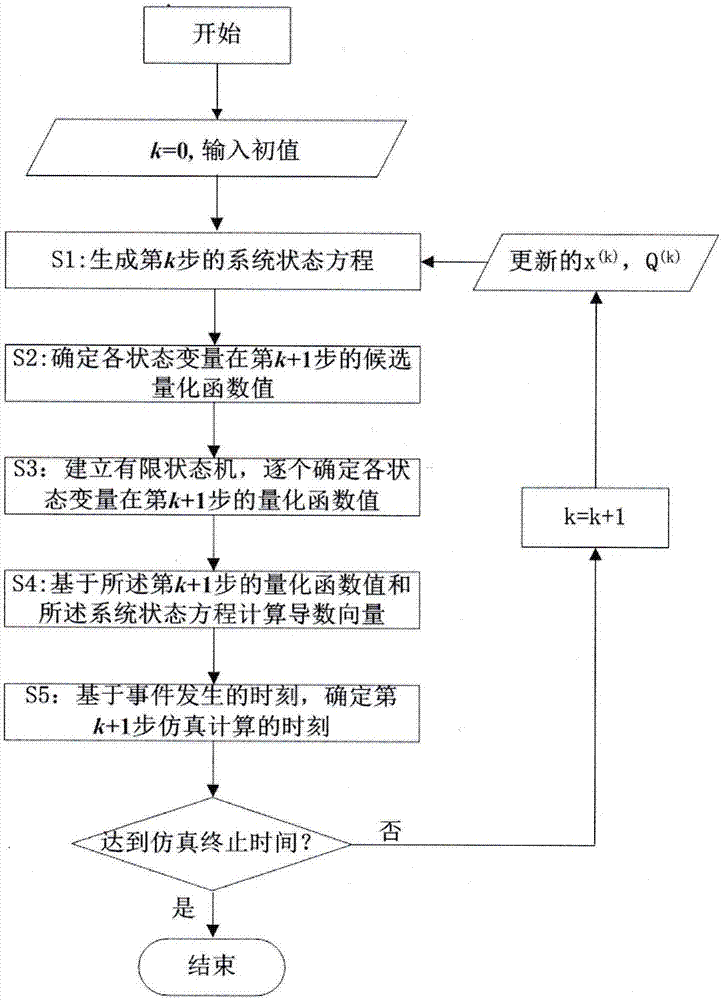

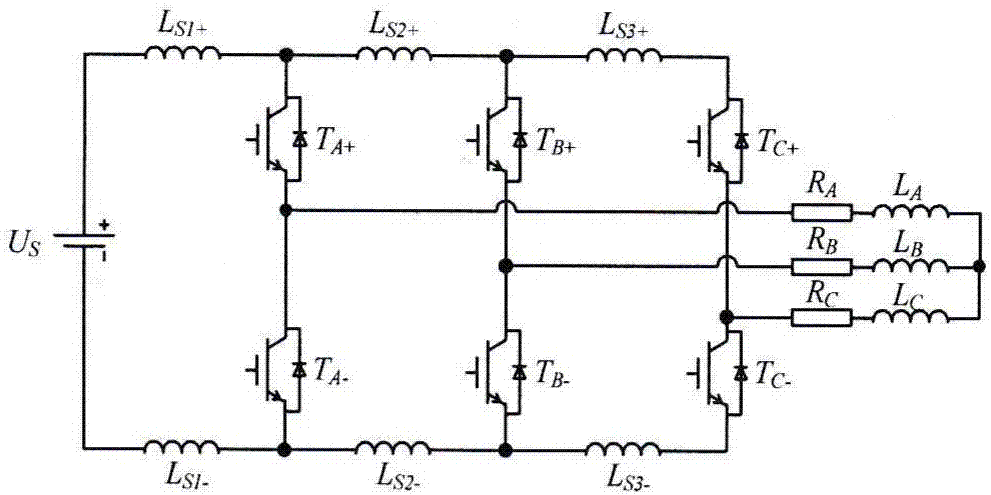

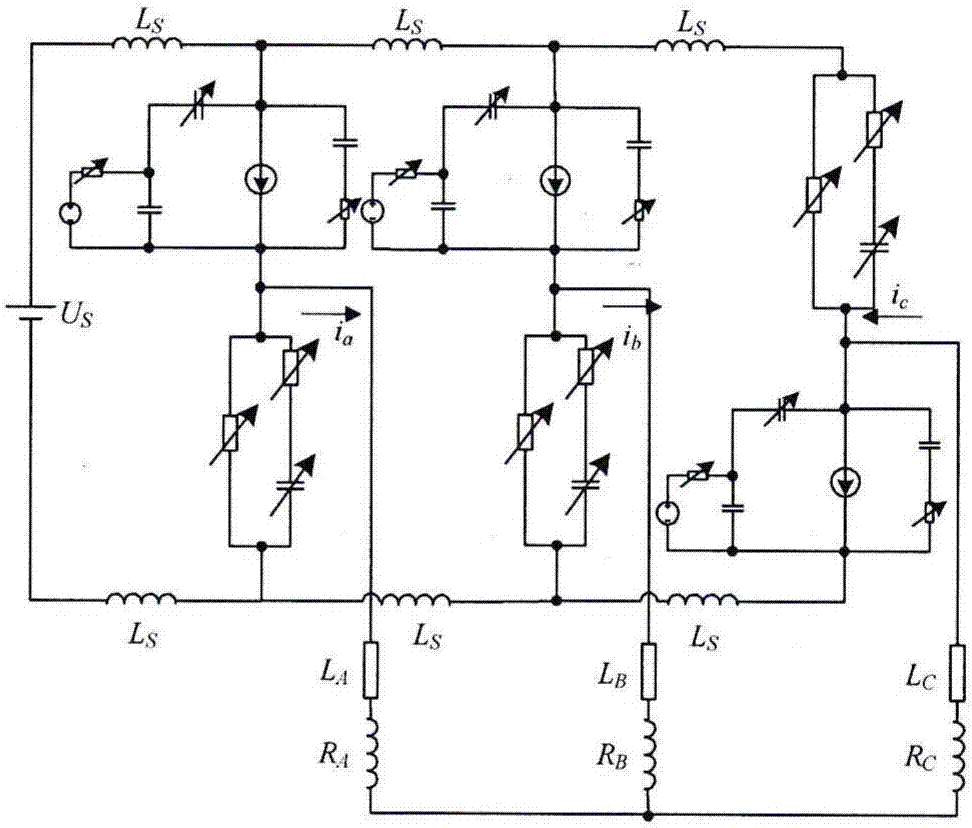

Backward discrete state event-driven power electronic simulation method, device and medium

ActiveCN107290977ASolve processing problemsAvoid enumerationSimulator controlDesign optimisation/simulationNumerical stabilityState variable

The invention discloses a backward discrete state event-driven power electronic simulation method, and the method comprises the steps: carrying out the simulation initialization and the simulation calculation at a k-th step, wherein K is not less than zero, and the simulation calculation at the k-th step comprises the following steps: S1, generating a system state equation at the k-th step; S2, determining the candidate quantification function value of each state variable at a (k+1)-th step; S3, building a finite-state machine, and determining the quantification function value of each state variable; S4, calculating a derivative vector based on the quantification function values at the (k+1)-th step and the system state equation; S5, determining the moment of simulation calculation at the (k+1)-th step based on the occurrence moment of an event. The invention also discloses a simulation calculation device and a computer readable storage medium storing a simulation program. According to the invention, the simulation method provided by the invention can achieve the high-efficiency selection of a Q function vector, and the simulation efficiency and numerical value stability of the method are apparently superior to the simulation efficiency and numerical value stability of a quantification state system (QSS) method and a conventional time discretization rigid solving method during the solving of a rigid system.

Owner:TSINGHUA UNIV

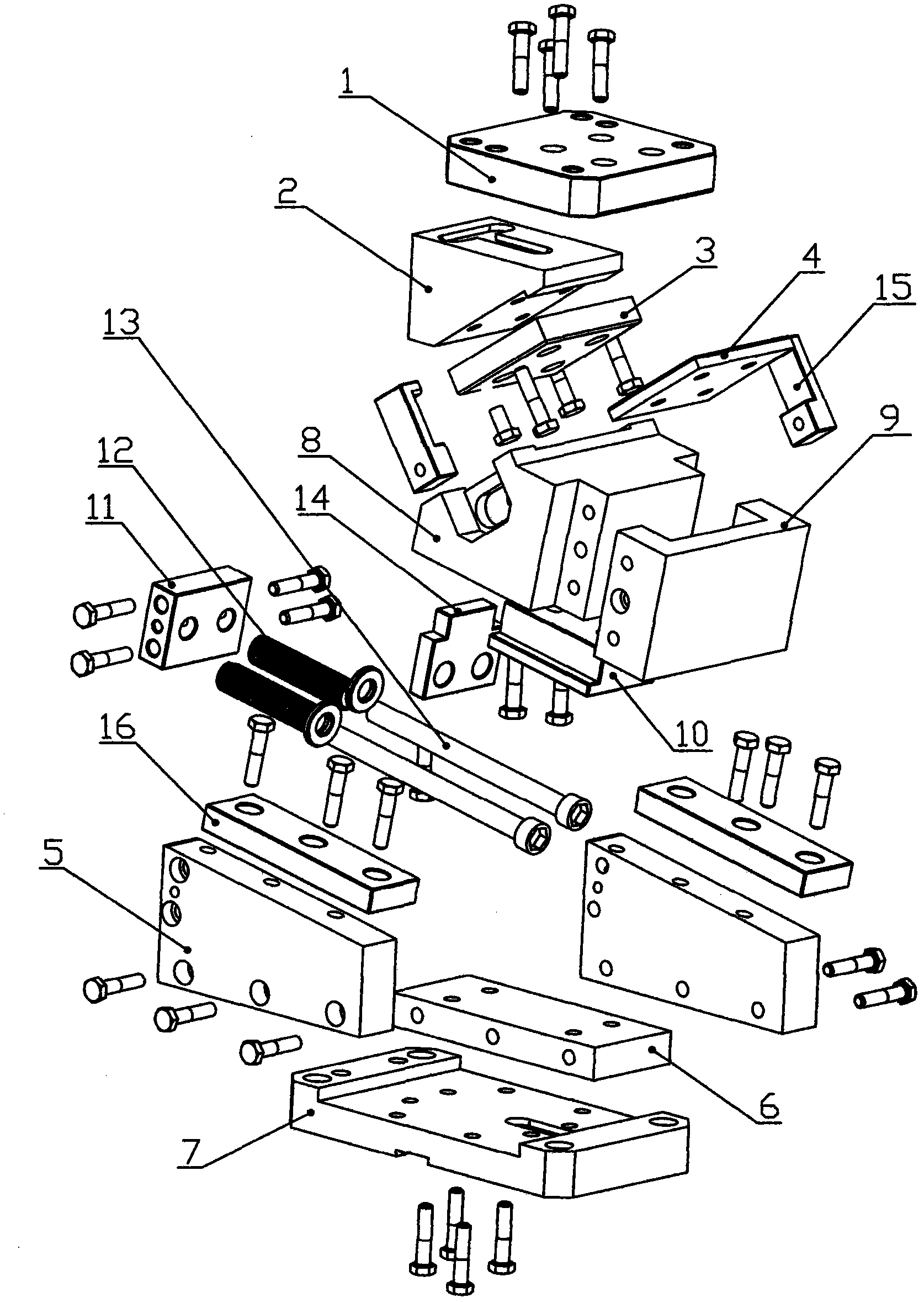

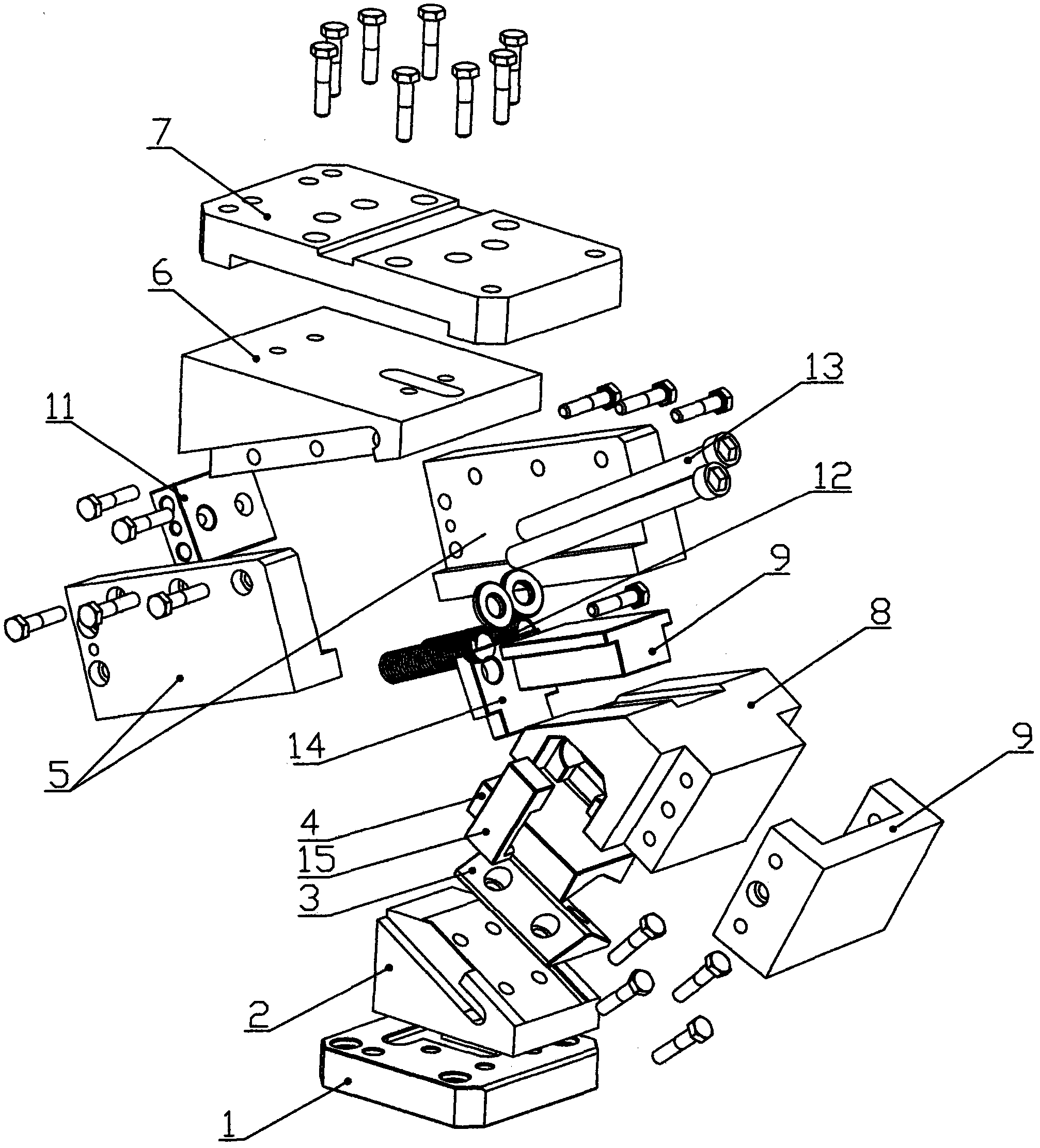

Multifunctional assembled inclined wedge

InactiveCN102000741AMeet the needs of alternate useAchieving low-carbon productionShaping toolsPress ramHigh volume manufacturingEngineering

The invention relates to a multifunctional assembled inclined wedge which comprises a driving block, a sliding block and a sliding block seat, wherein both the driving block and the sliding block seat are in a split structure; each of the driving block and the sliding block seat comprises a standard component and an adjusting component; the standard component is connected with a stamping mold; and the adjusting component is used for adjusting the working angle of the inclined wedge. In the invention, each component comprises the standard component and the adjusting component which can be detachably connected; a user only needs to replace the adjusting component for realizing any working angle according to the use requirement; in the use process, when one component is damaged, only the component needs to be replaced, and the use cost is saved; the angle of the adjusting component can be changed freely as required, thus meeting the requirement of users for alternately using different types of inclined wedge mechanisms; and simultaneously, in the production process of a manufacturer, because the standard components of different types of inclined wedge mechanisms are the same, the standard components of the different types of inclined wedge mechanisms can be produced in enormous quantities, while the adjusting components meeting the corresponding requirements can be respectively produced in bulk according to the requirements of the different types of inclined wedge mechanisms.

Owner:QINGDAO NUOYIXIN MOLD PARTS

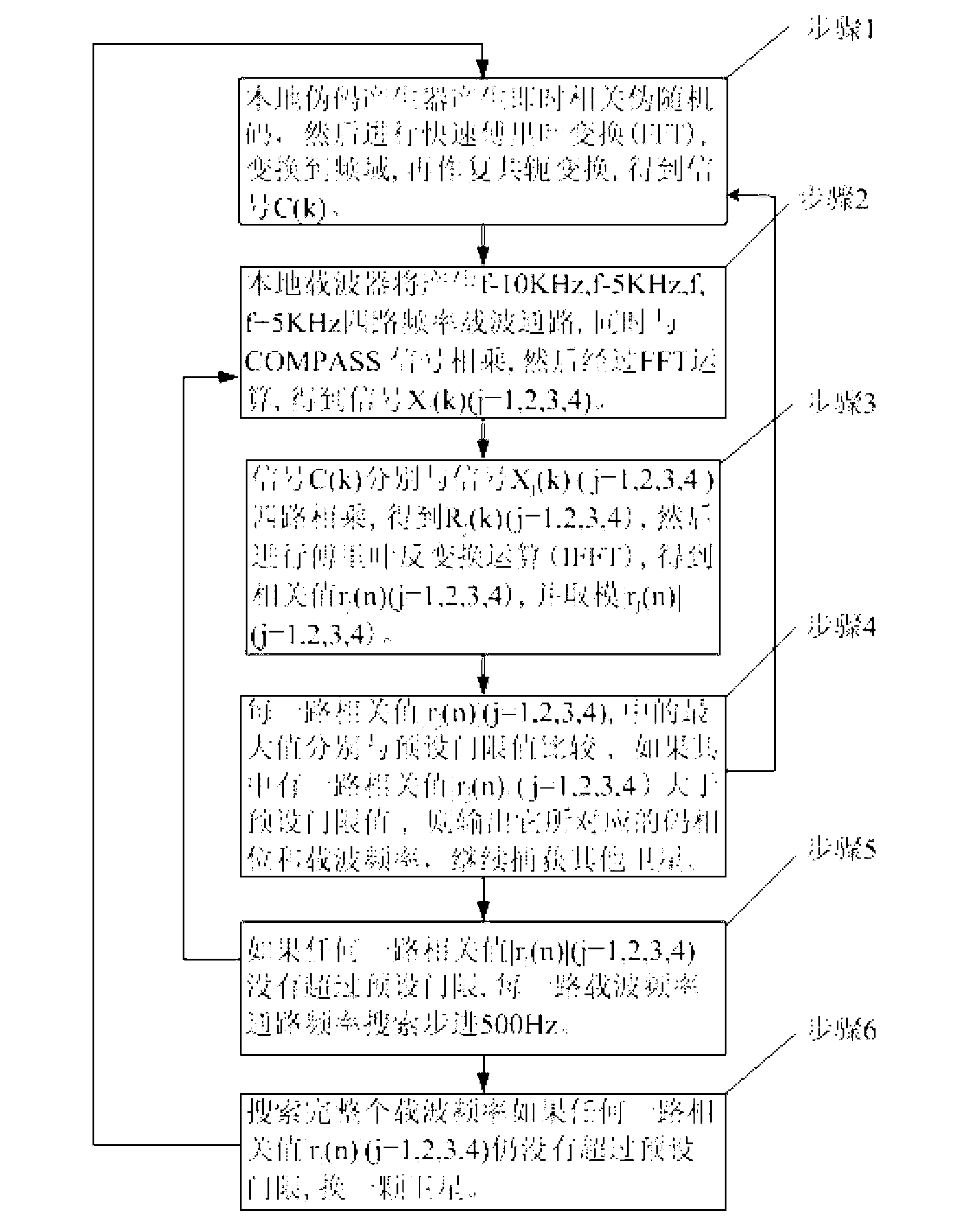

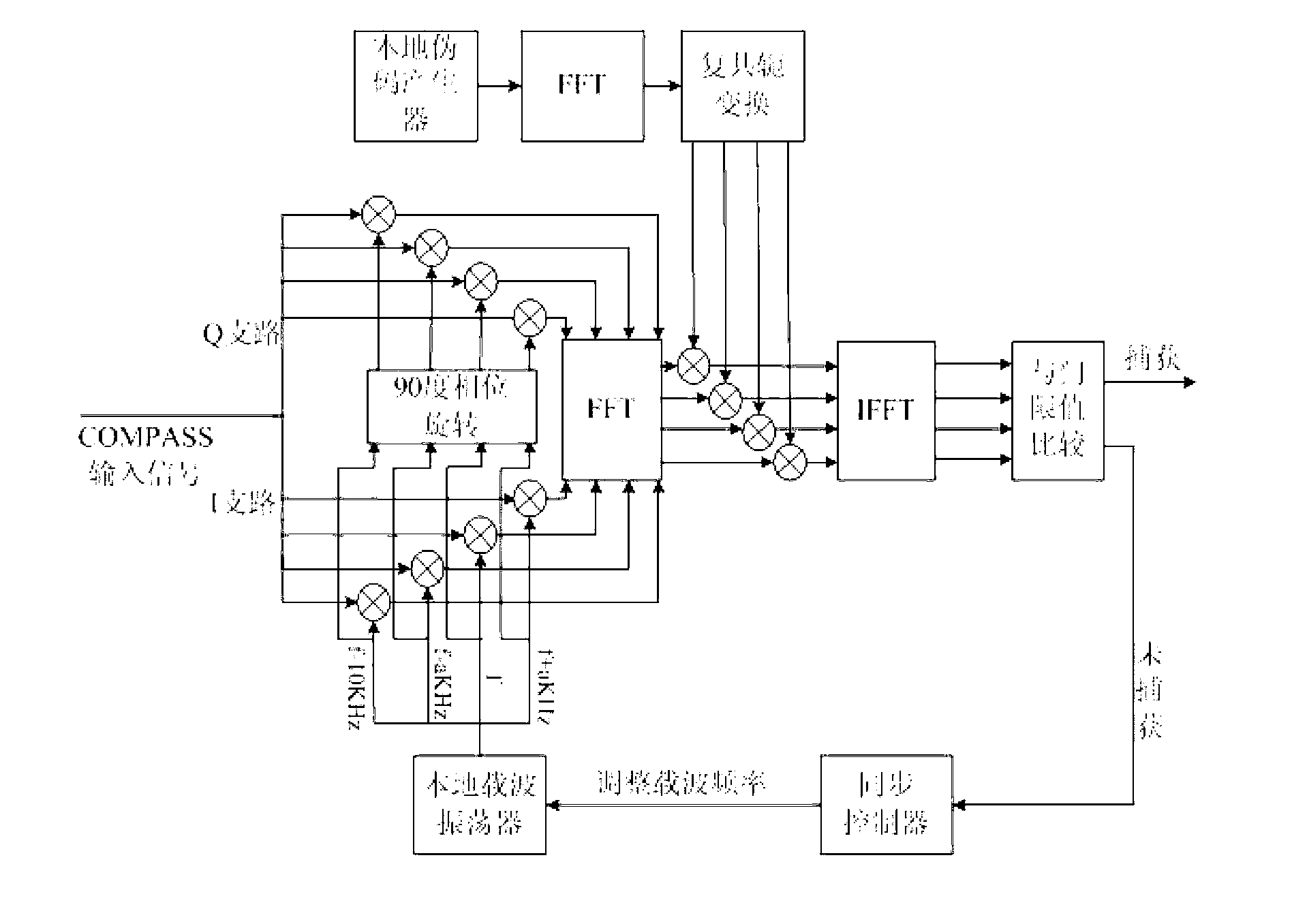

Method for fast capturing COMPASS signal

InactiveCN102707297AGuaranteed Capture AccuracyImprove capture speedSatellite radio beaconingFast Fourier transformCarrier signal

The invention discloses a method for capturing a satellite signal in the technical field of satellite navigation and particularly relates to a method for fast capturing a COMPASS signal. According to the method, a path of serial search of a carrier frequency is converted into four paths of parallel search. The method comprises the processes of: obtaining a signal C(k) from a local pseudo-random code by FFT (fast fourier transform) and complex conjugate transformation, locally generating four paths of carrier waves to multiply by the COMPASS signal, obtaining four paths of signals Xj(k) (j=1,2,3,4) via FFT, respectively multiplying C(k) by Xj(k) (j=1,2,3,4), and delivering and obtaining a signal absolute value of rj(n) (j=1,2,3,4) via IFFT (inverse fast fourier transform), wherein the maximal value of each path of obtained signal is compared with the preset threshold to determine whether the satellite signal is really captured. The capturing speed of the COMPASS signal is improved under the condition without affecting the capturing precision.

Owner:JIANGSU UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com