Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

81results about How to "Recovery strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Durability traceless repair method for road and bridge concrete, color difference trimming putty and trimming material

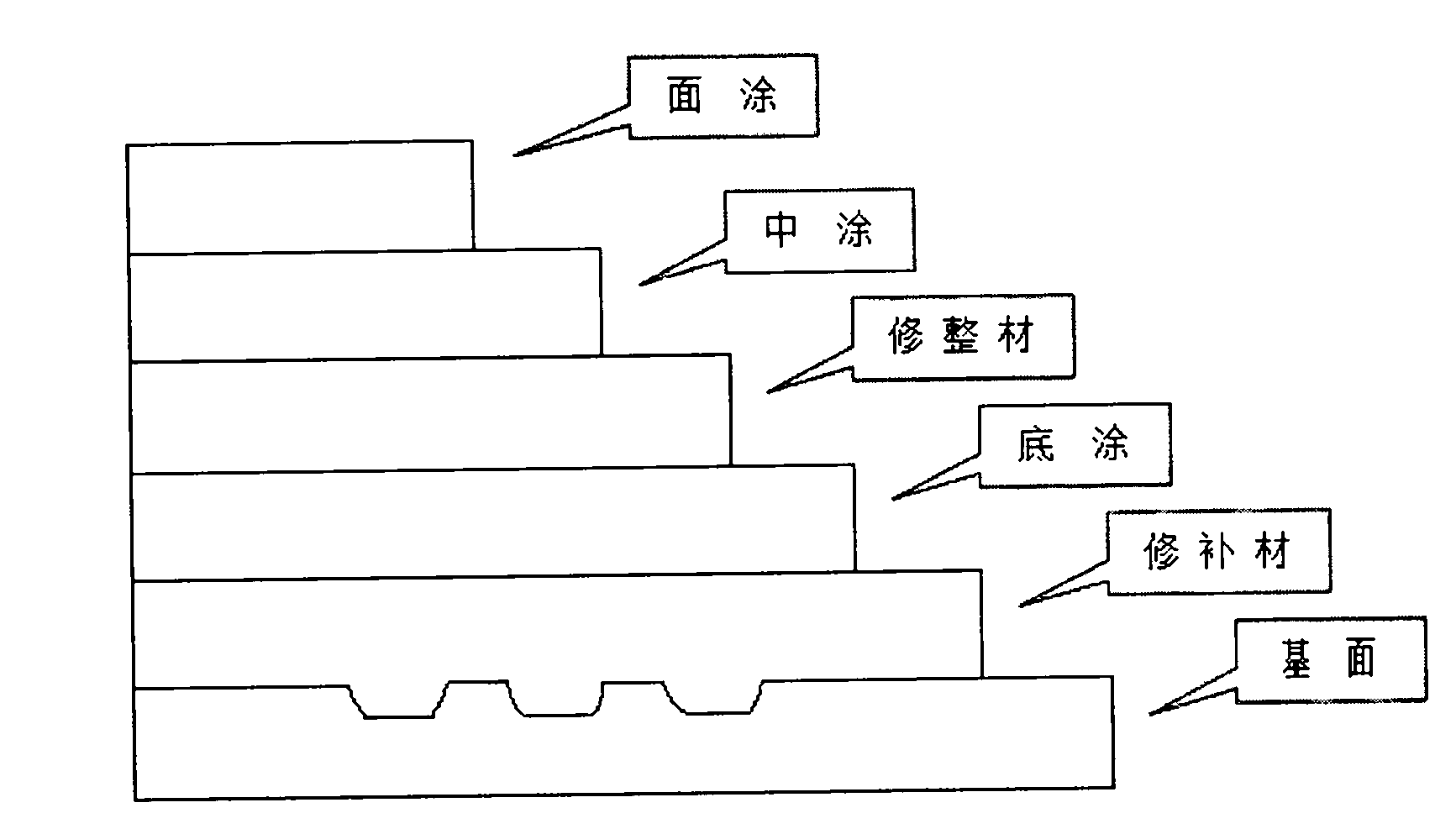

InactiveCN101876162AImprove performanceGood synergyIn situ pavingsFilling pastesAdditive ingredientRepair material

The invention relates to a durability traceless repair method for road and bridge concrete. The method comprises the following steps of: (1) repairing a base surface of the concrete with a surface defect by using a repairing material so as to trim and flatten the base surface, wherein the repairing material comprises polymer fine sand mortar and color difference trimming putty; (2) performing prime coat on the repairing material; (3) preparing a trimming material, wherein the structure and color of the trimming material are similar to those of the concrete, and the trimming material has a high adhesive property; (4) performing floating coat by adopting an organic silicon resin coating; and (5) performing top coat by adopting a coating prepared from a silicon resin accessory ingredient. The formulas of the color difference trimming putty and the trimming material are introduced. The method has the advantages of effectively repairing the surface defect of the concrete structure tracklessly, restoring the strength of the concrete structure and improving waterproof property and durability of the concrete structure.

Owner:上海惠邦特种涂料有限公司

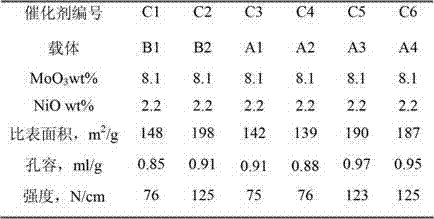

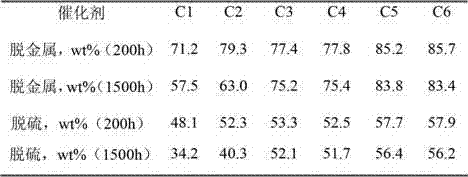

Coal tar hydrodemetalization catalyst and preparation method thereof

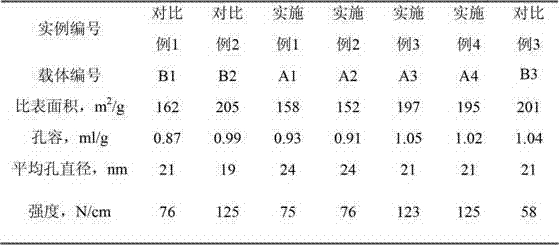

ActiveCN102847541AUnobstructed pore structureIncrease profitCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsOrganic acidPtru catalyst

The invention discloses a coal tar hydrodemetalization catalyst and a preparation method thereof. The method comprises the steps of: (1) taking or preparing an alumina carrier; (2) treating the alumina carrier from the step (1) with an organic acid solution with pH value lower than 3; then impregnating the alumina carrier subjected to acid treatment with an aluminium nitrate solution; and drying and roasting to obtain a modified alumina carrier; and (3) loading and hydrogenating an active component by an impregnation method to obtain the coal tar hydrodemetalation catalyst. Compared with the prior art, the coal tar hydrodemetalation catalyst provided by the invention has better activity and activity stability, and longer operation cycle.

Owner:上海竣铭化工工程设计有限公司

Vacuum brazing connection technology for tungsten copper composite block

ActiveCN103658904AImprove wettabilityImprove bindingWelding/cutting media/materialsWelding/soldering/cutting articlesButt jointTungsten

The invention belongs to the technical field of heterogeneous material welding, and particularly relates to a method for vacuum brazing connection of tungsten and copper. The method is applied to connection of a tungsten copper composite block of a high-heating-load component of a fusion device. The method comprises the following steps that (1) brazing connection materials and brazing filter metal are determined; (2) a welding surface is preprocessed, a tungsten block and a chromium-zirconium-copper alloy block are cleaned, impurities, oil contamination and an oxidation film of the welding surface are removed, and dewatering and drying are conducted; (3) the ribbon copper-based brazing filter metal is cleaned; (4) assembly is conducted, connection is conducted in a butt-joint mode, the copper-based brazing filter metal is placed between the preprocessed surface to be welded of the tungsten and the preprocessed surface to be welded of copper alloy, assembly is conducted through a clamp and the pressure of 0.01MPa-0.1MPa is perpendicularly exerted; (5) welding is conducted, the assembled tungsten block-ribbon copper-based brazing filter metal-chromium copper alloy welding piece is placed in a vacuum brazing device for welding. According to the technical scheme, the obtained pure tungsten and the chromium-zirconium-copper alloy are welded in a butt joint mode, welding-seam forming is good, deformation of the welding piece is avoided, and shortages of microscopic cracks, air holes and impurities and the like are avoided.

Owner:SOUTHWESTERN INST OF PHYSICS

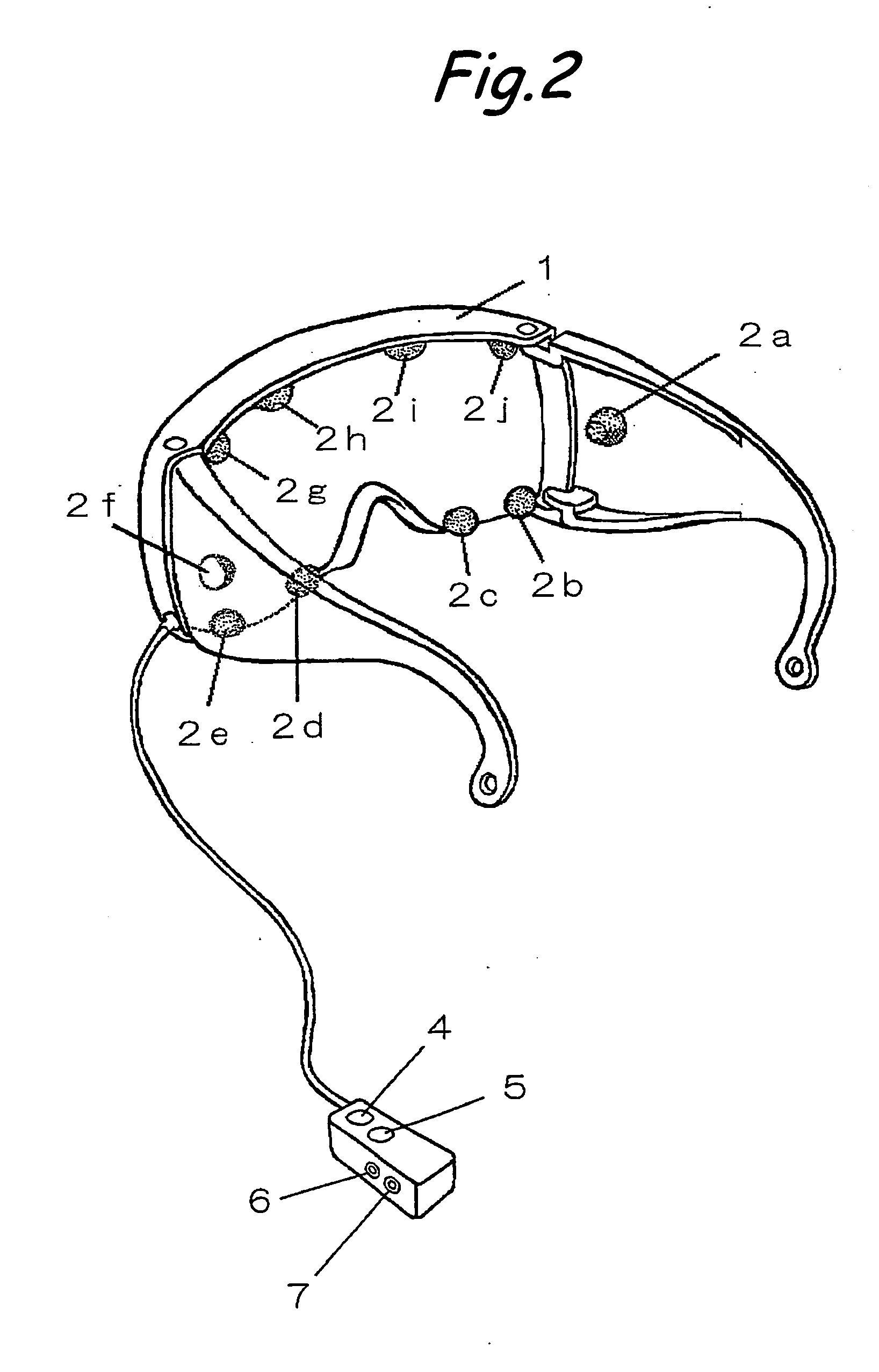

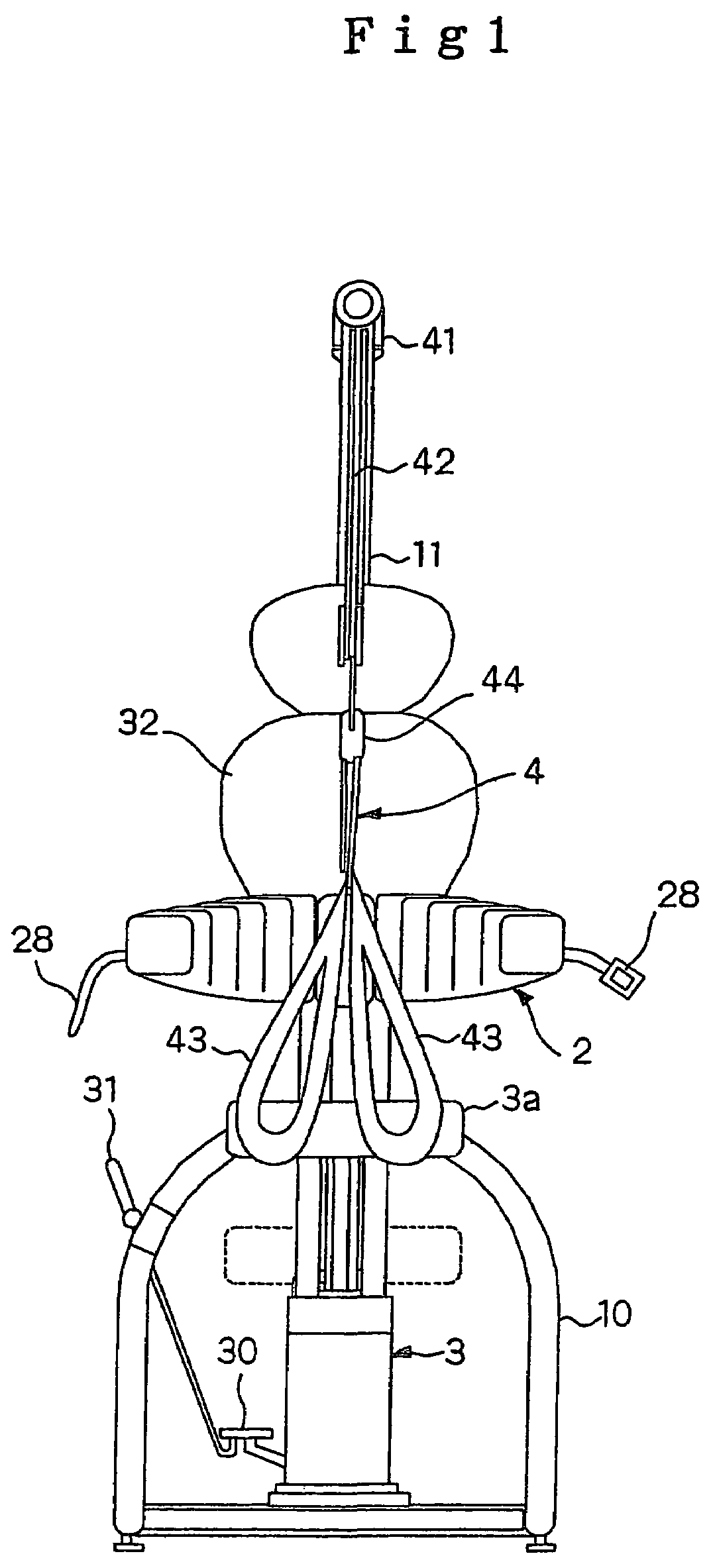

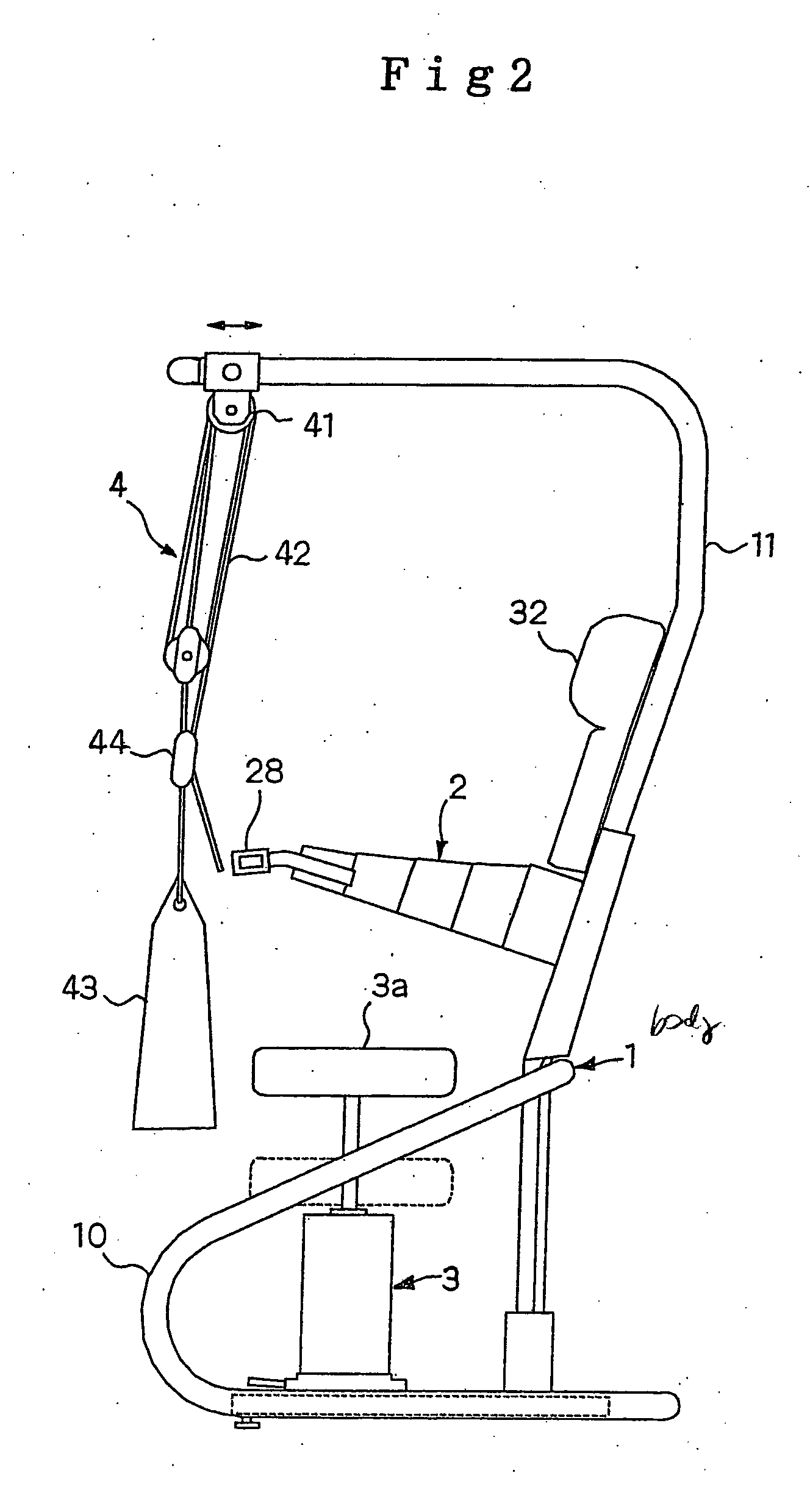

Eye training equipment

InactiveUS20050213034A1Regaining his eye-muscular strengthImproved kinetic visual fieldGogglesGymnastic exercisingOphthalmology departmentIrritation

Eye training equipment, wherein at least two irritation generating devices for perceiving irritating positions are disposed around an eye ball, and the disposed irritation generating devices are operated one by one to allow the line of sight of a user to follow up in the direction of the irritating position, whereby, since merely the line of sight of the user is allowed to follow up in the direction of the irritating position, the user of the training equipment can perform an eye muscle motion without requiring the need for specifically viewing an object by opening an eye.

Owner:YOSHITOMO +1

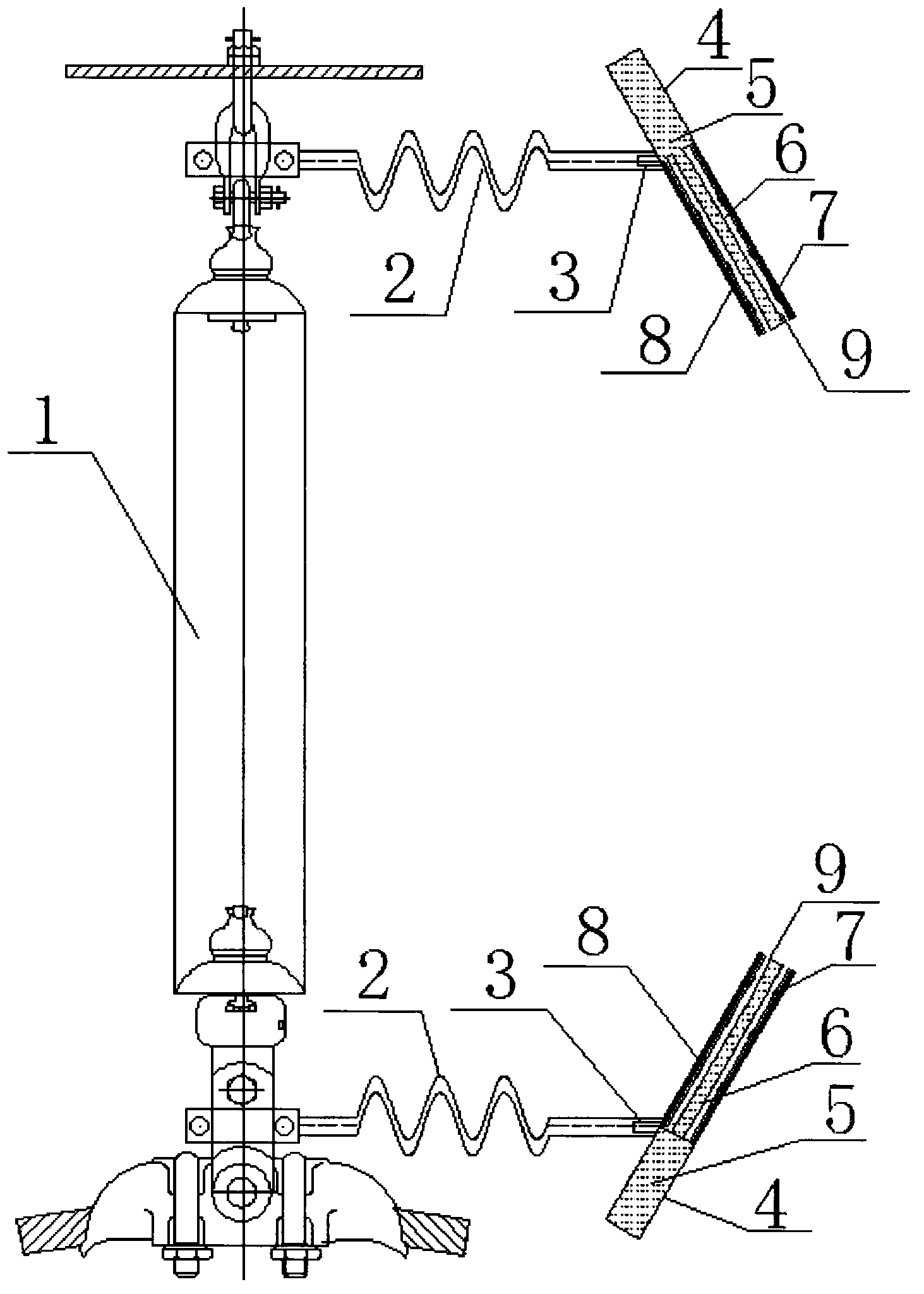

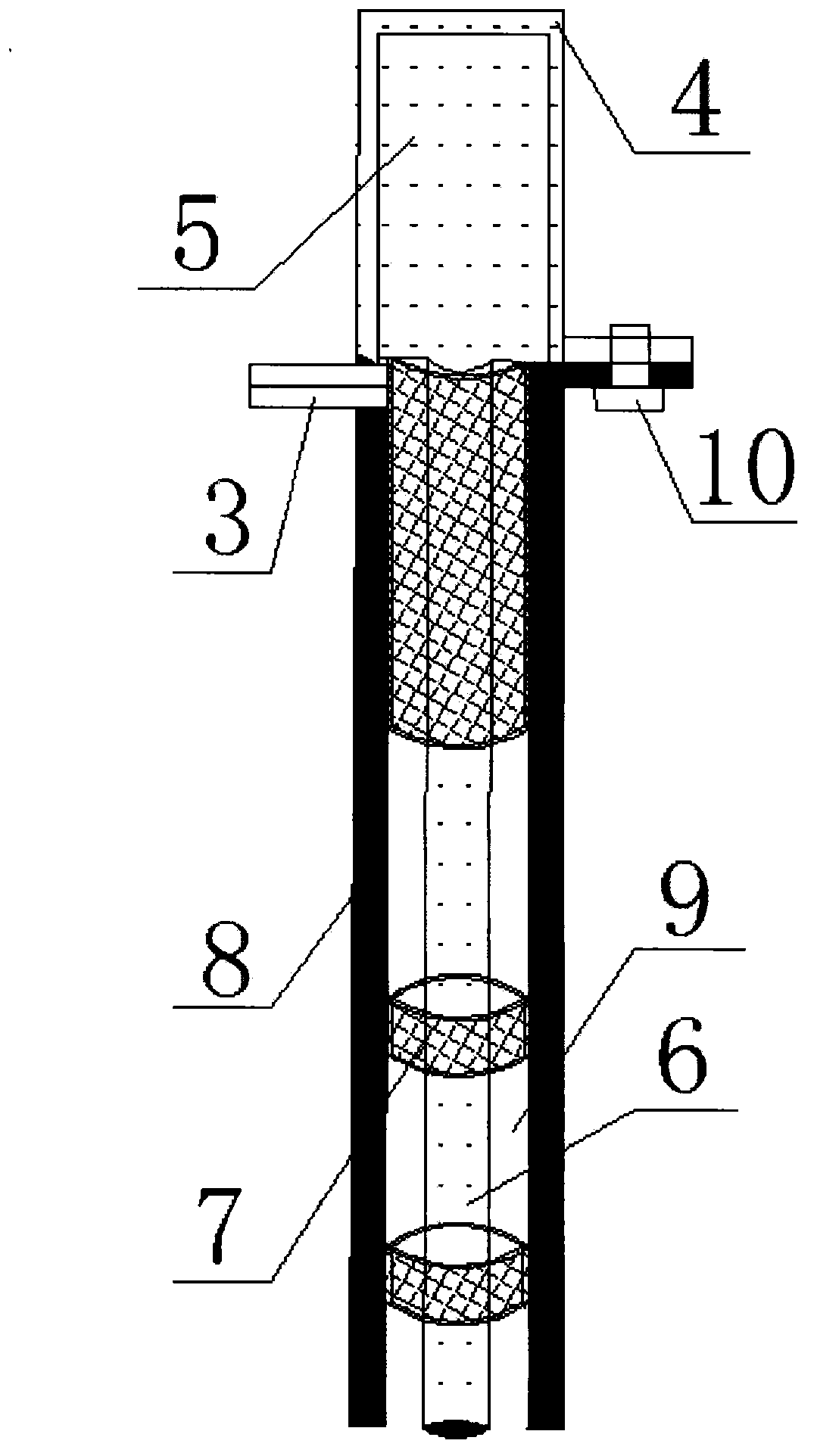

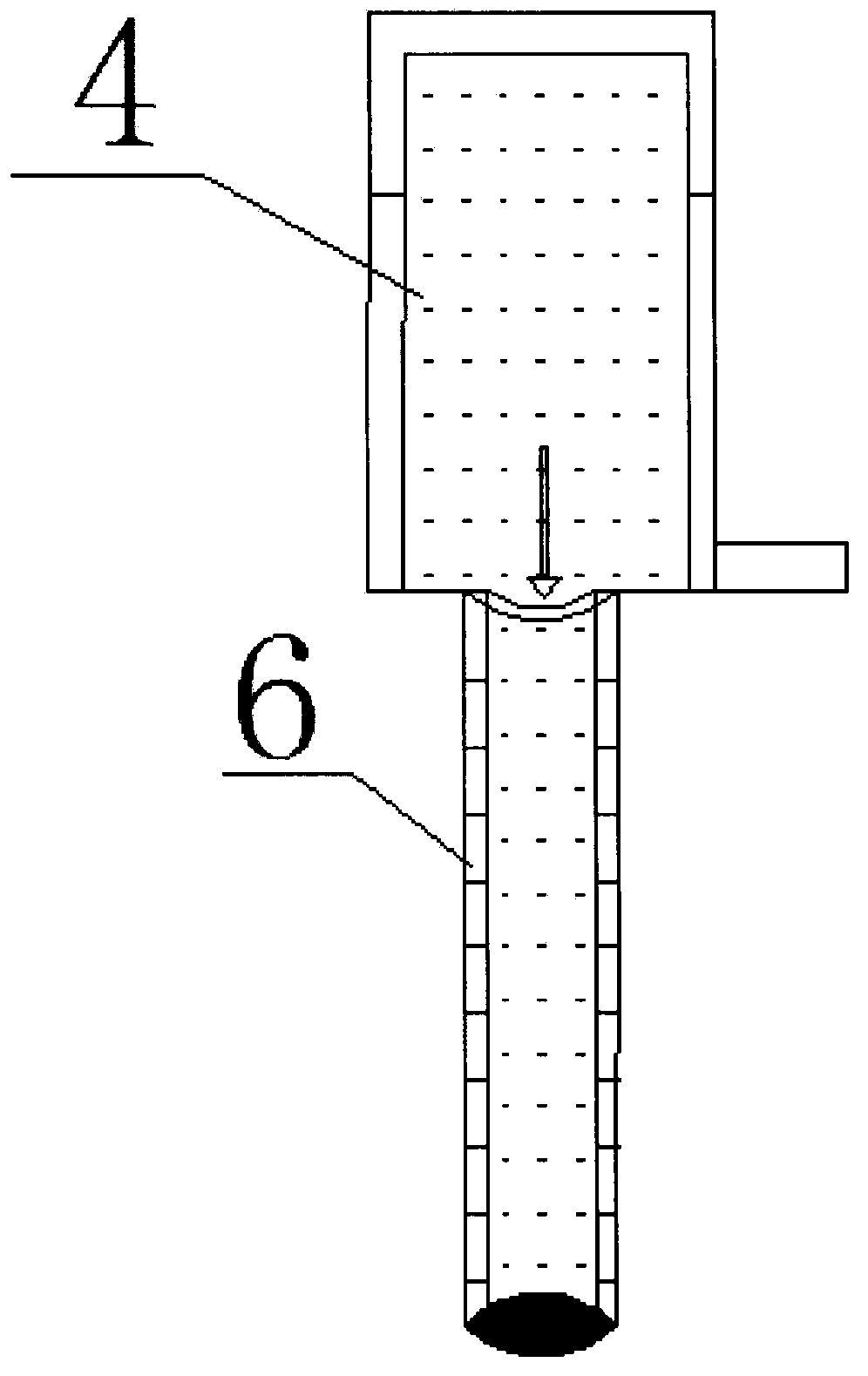

Gas injection type parallel gap device

InactiveCN103730834APrevent trippingEffective protectionSpark gap detailsInsulatorsTransformerElectric power system

The invention discloses a gas injection type parallel gap device. The protection device belongs to the field of lightening protection gap for power transmission lines of alternating-current and direct-current electric power systems. The device is connected with the two ends of a power transmission line insulator chain in parallel, under a lightening stroke, the device is broken down before the insulator chain can be broken down, and thus the insulator chain and the corresponding power transmission line can be protected; moreover, a high-speed high-voltage gas flow can be generated fast and acts on arcs to restrain formation and development of the arcs, the arcs are extinguished in a transient state, and thus the lightning trip-out rate and the lightening accident rate of an electric power system are reduced. The gas injection type parallel gap device comprises arc-control devices on the grounding side and the wire side, fixing devices and parallel spiral fittings installed at the two ends of the insulator train of the line. The arc-control device on the grounding side and the arc-control device on the wire side respectively comprise an arc extinguishing powder storage chamber, an arc air-termination ring, an insulating gas generation chamber, an arc spray channel and the like. With the device, the stability of the electric power system is improved, the on-load action frequency of a breaker is effectively reduced, the service life of electric power equipment such as a transformer is prolonged, and production, operation and maintenance cost is very low.

Owner:闫仁宝 +1

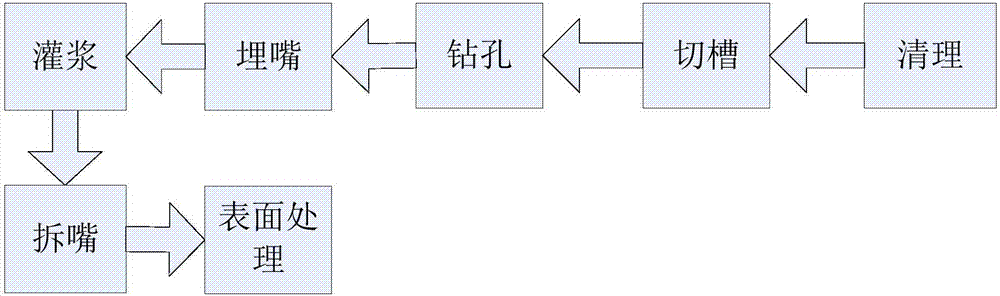

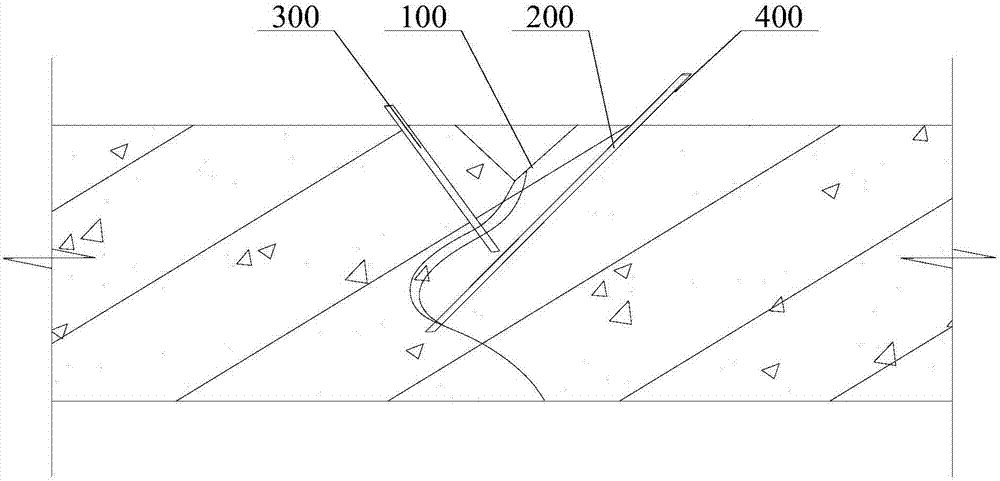

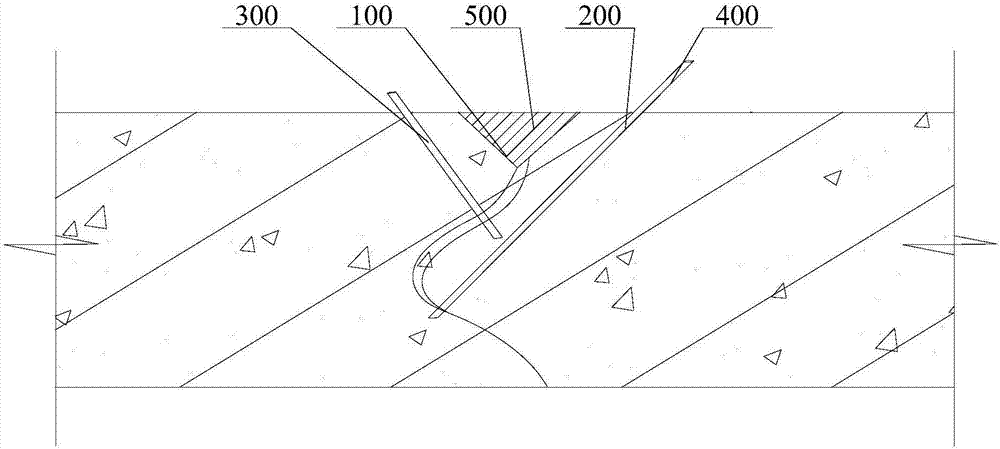

Leaking stoppage and reinforcement method for traffic tunnel cracks in vibration and disturbance environments

InactiveCN107201910ARecovery strengthPrevent leakageUnderground chambersTunnel liningWhole bodySlurry

The invention provides a traffic tunnel crack plugging and reinforcement method used in a vibration-disturbed environment, and relates to the technical field of crack repair in traffic tunnels. The grouting material is poured by using the method of minimal damage and adopting the pinhole oblique side drilling method. , Reinforcing while plugging. The specific method is to use a cutting machine to cut grooves along the seam first, clean them up and fill them with special cement for sealing, then make grouting holes along both sides of the seam to 1 / 3 to 1 / 2 of the seam. The grouting nozzle is installed in the hole, the grouting material is injected, and through the sealing effect of the cutting groove, and through the cross grouting, the grout is injected into the depth of the crack, so that the lining concrete at the crack is restored to form a whole, which solves the existing problems in the prior art. The technical problem that underground engineering cannot effectively plug leaks in the vibration-disturbed environment prevents leakage and cracking due to vibration-disturbed deformation and damage, and restores the compactness and structural integrity of the lining concrete.

Owner:南京康泰建筑灌浆科技有限公司

Metal coordination self-healing polyurethane elastomer and preparation method thereof

ActiveCN111217985AExcellent self-healing performanceRecovery strengthPolyurethane elastomerPolymer science

The invention discloses a metal coordination self-healing polyurethane elastomer and a preparation method thereof, and belongs to the technical field of self-healing. The preparation method comprisesthe following steps: mixing a dihydric alcohol oligomer with isocyanate to prepare a polyurethane prepolymer; taking 2,4-dihydroxypyridine is used as a chain extender, adding a catalyst and a solvent,and carrying out a chain extension reaction on the polyurethane prepolymer; and after chain extension is finished, adding a metal ion solution, stirring at 70-90 DEG C for 1-2 h, and curing to obtainthe metal coordination self-healing polyurethane elastomer. Asymmetric 2,4-dihydroxypyridine is adopted as the chain extender, conventional cognition in the industry is broken through, and the prepared polyurethane elastomer has good self-repairing performance under the combined action of pyridine, a metal ion coordination bond and a double-dynamic network of intermolecular hydrogen bonds.

Owner:SHANDONG FANGDING SAFETY GLASS TECH CO LTD

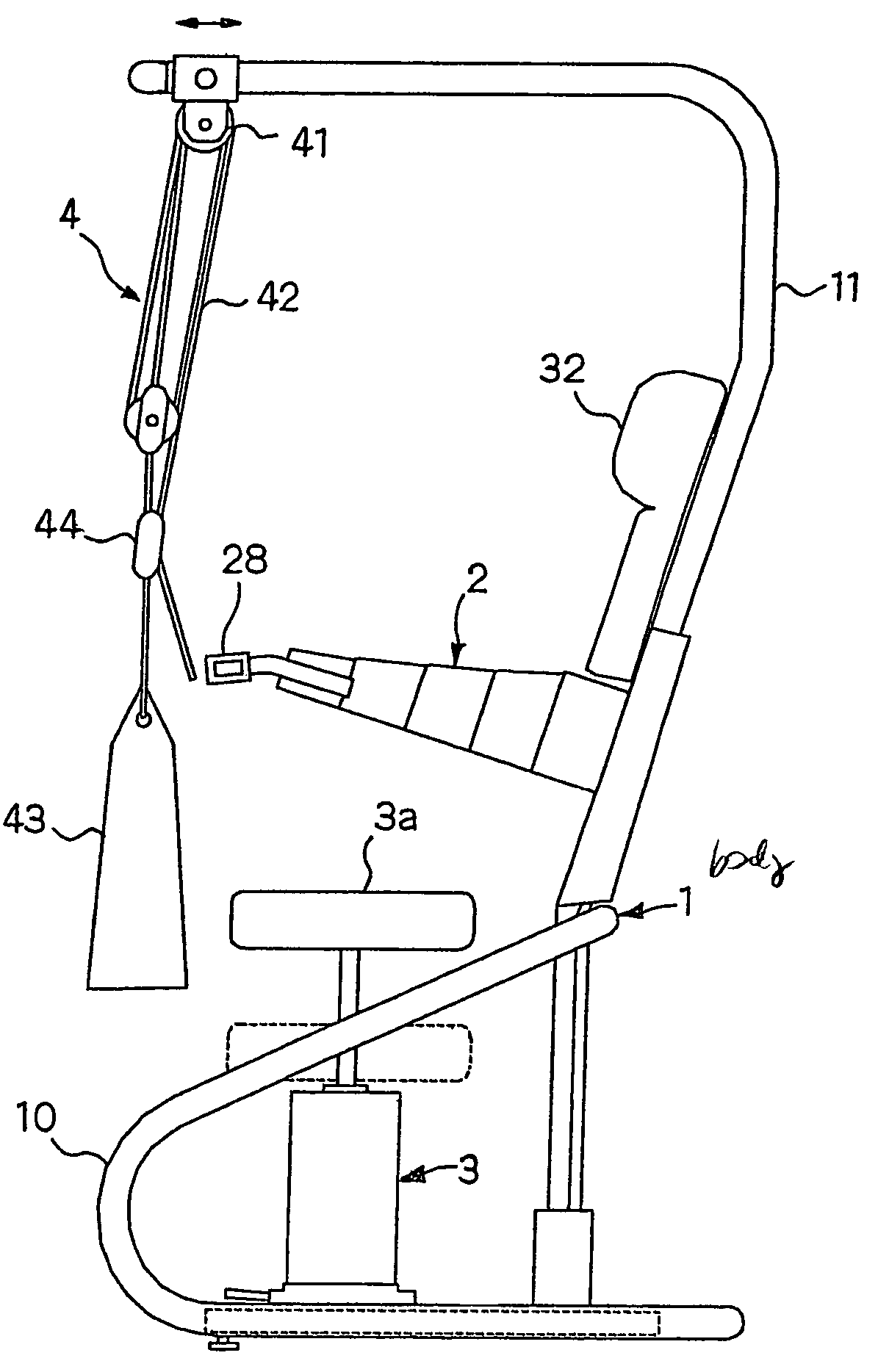

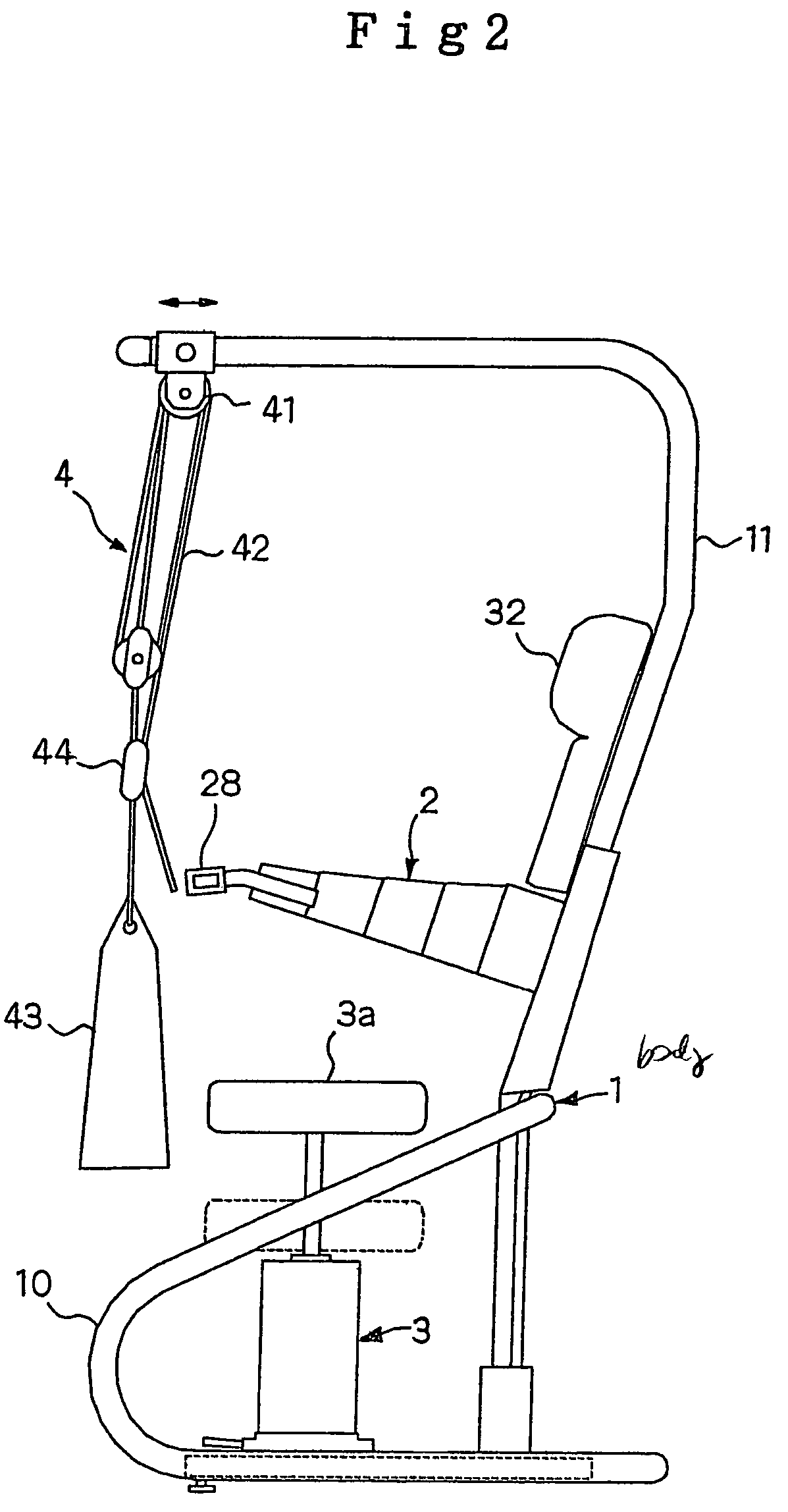

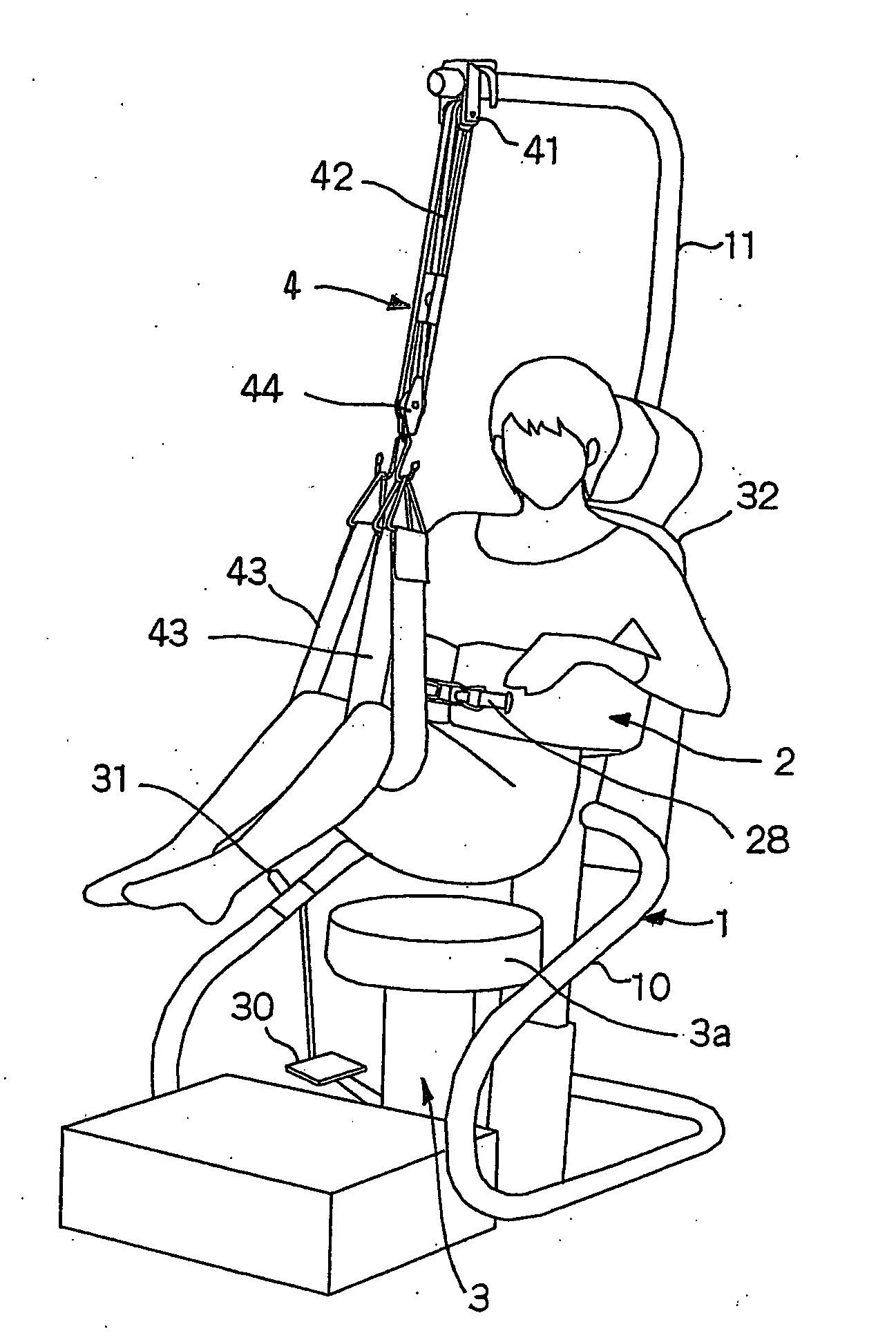

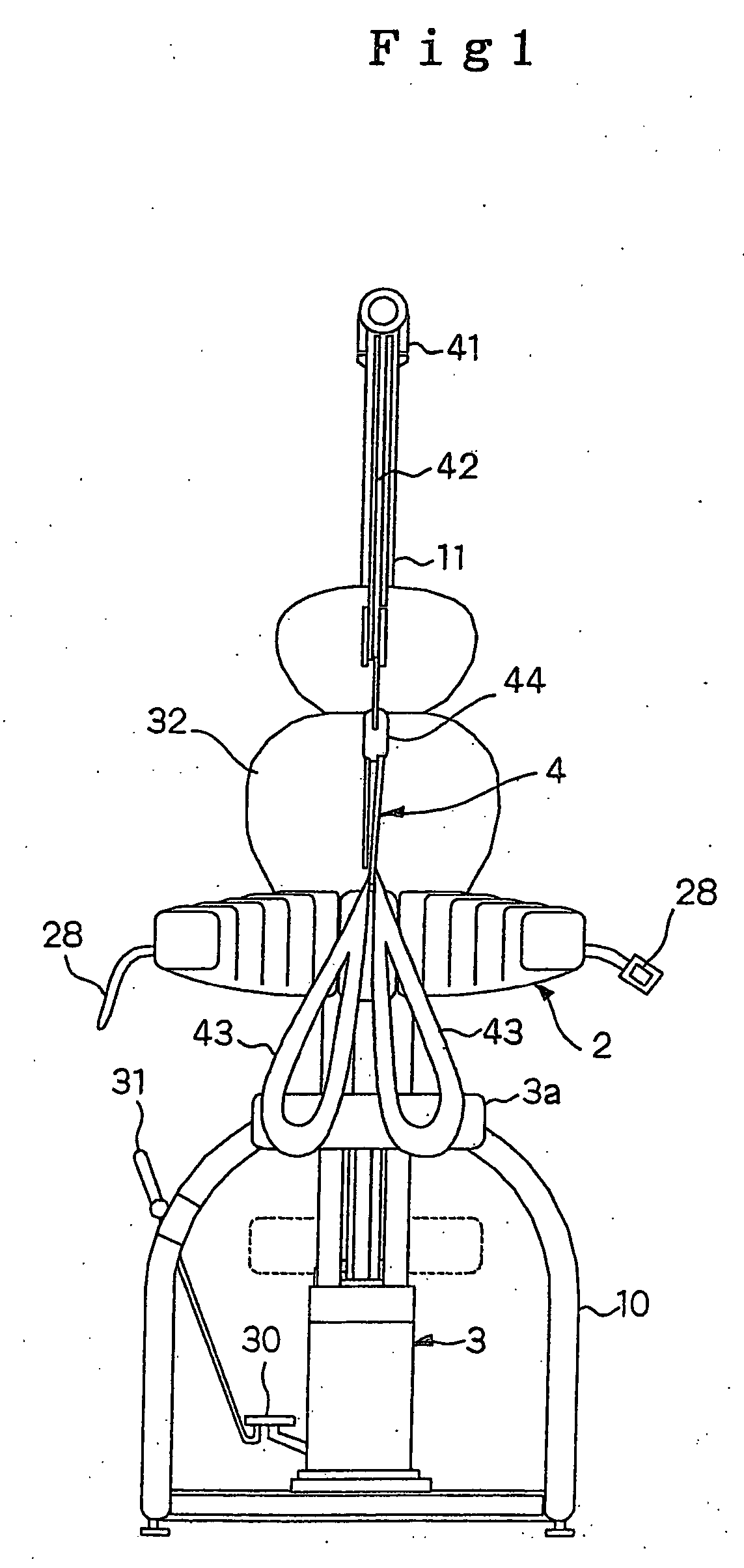

Health equipment

InactiveUS7510539B2Simple to executeFit tightlyChiropractic devicesNon-surgical orthopedic devicesHuman bodyPhysical medicine and rehabilitation

Health equipment for dragging the lumber with the trunk of the human body securely supported is provided. The trunk support 2 is bendable only inwardly, and holds and supports the trunk of the human body. Since the trunk support 2 is placed around the human body and enfolds from the area below the costae to above the pelvis, the human body is securely supported, whereby lumbago treatment can be carried out with the patient suspended in the air. Since the lumber is dragged with the weight of the lower part of the patient's body, there is no possibility that the lumber is dragged with the excessive weight. The leg hanging unit 4 is a device to hang the legs of the patient. By using this leg hanging unit 4, so called mobilization may be carried out with the lower back portion suspended in the air, thereby increasing effectiveness of lumbago treatment.

Owner:PROTEK KO

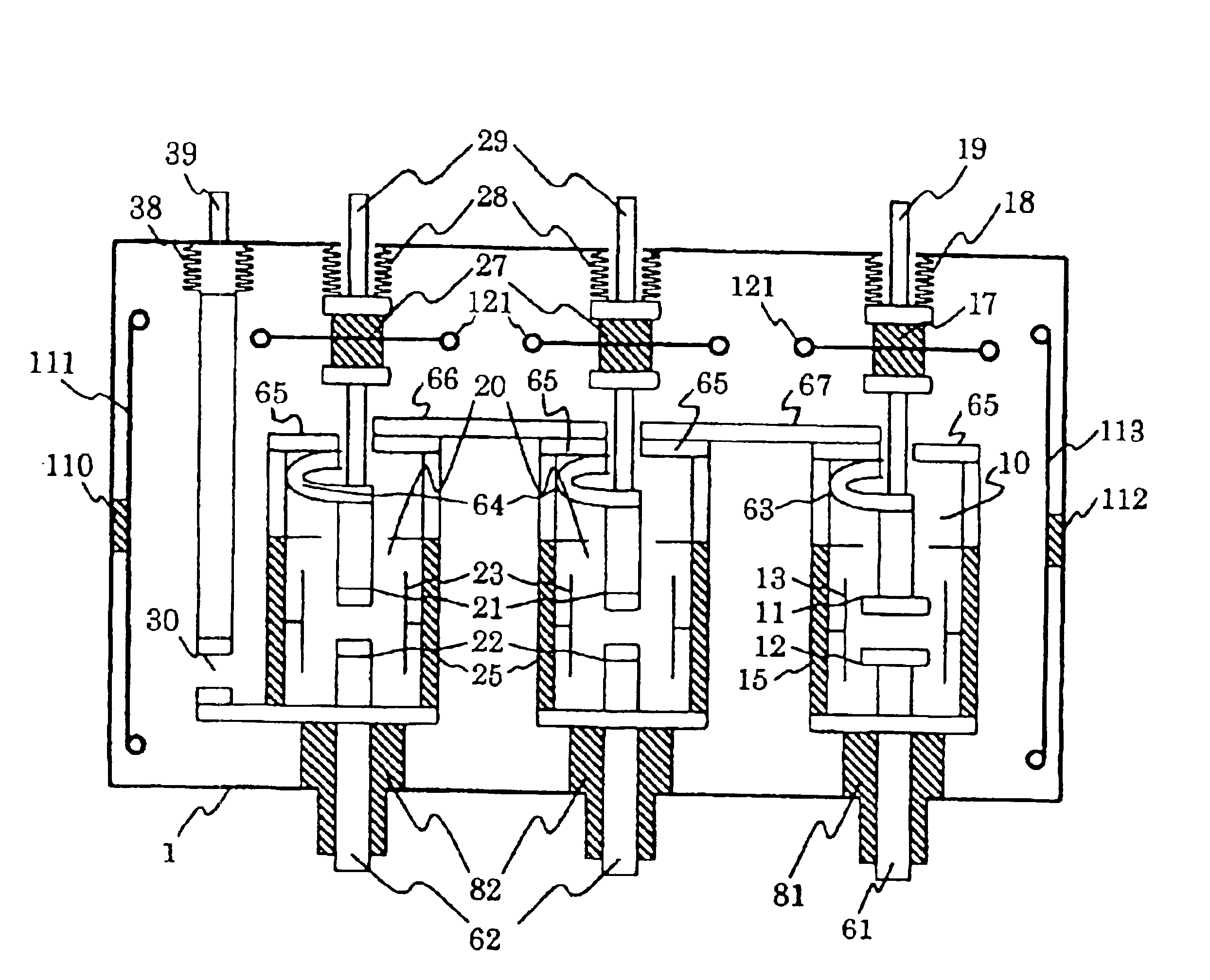

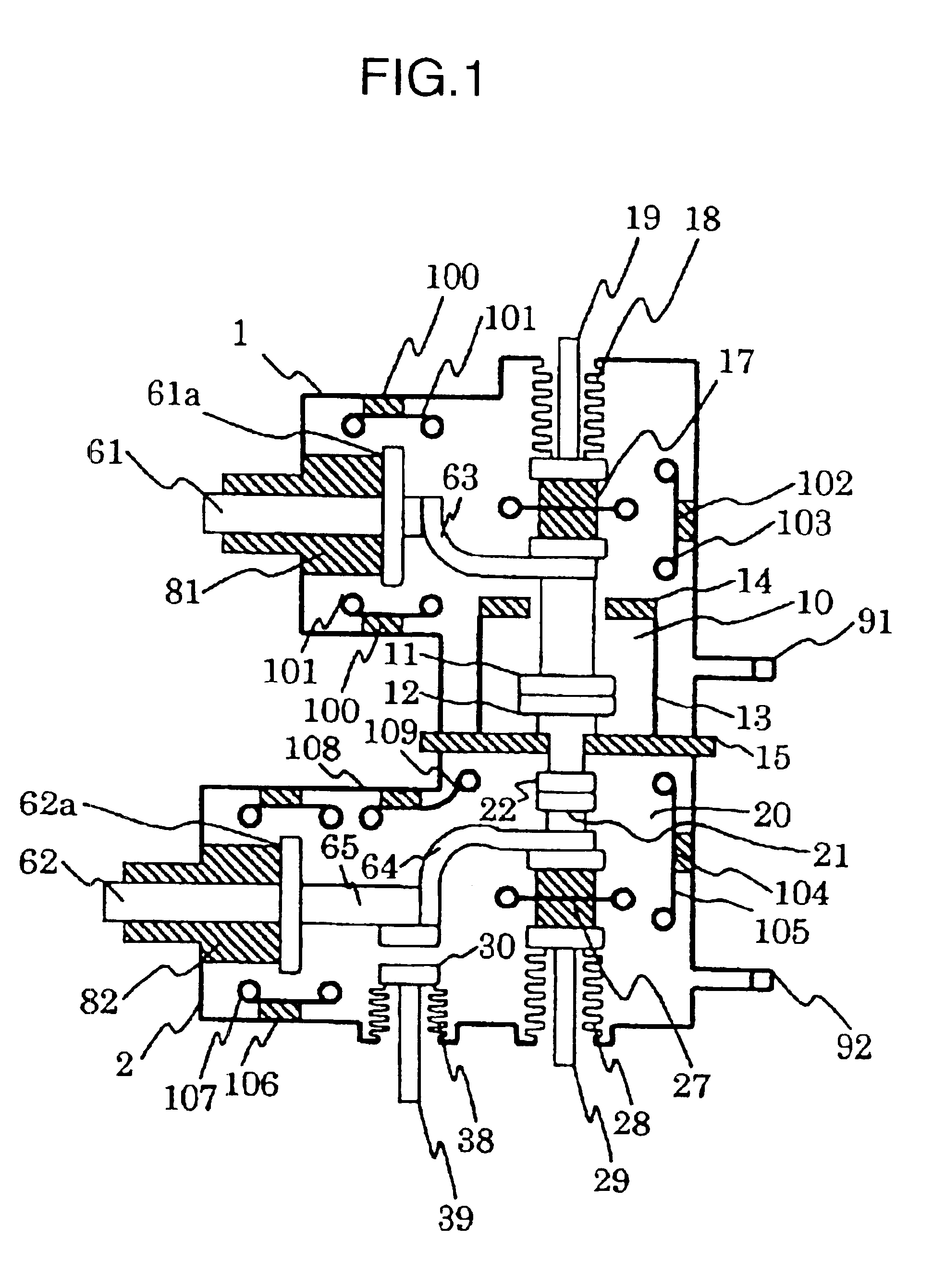

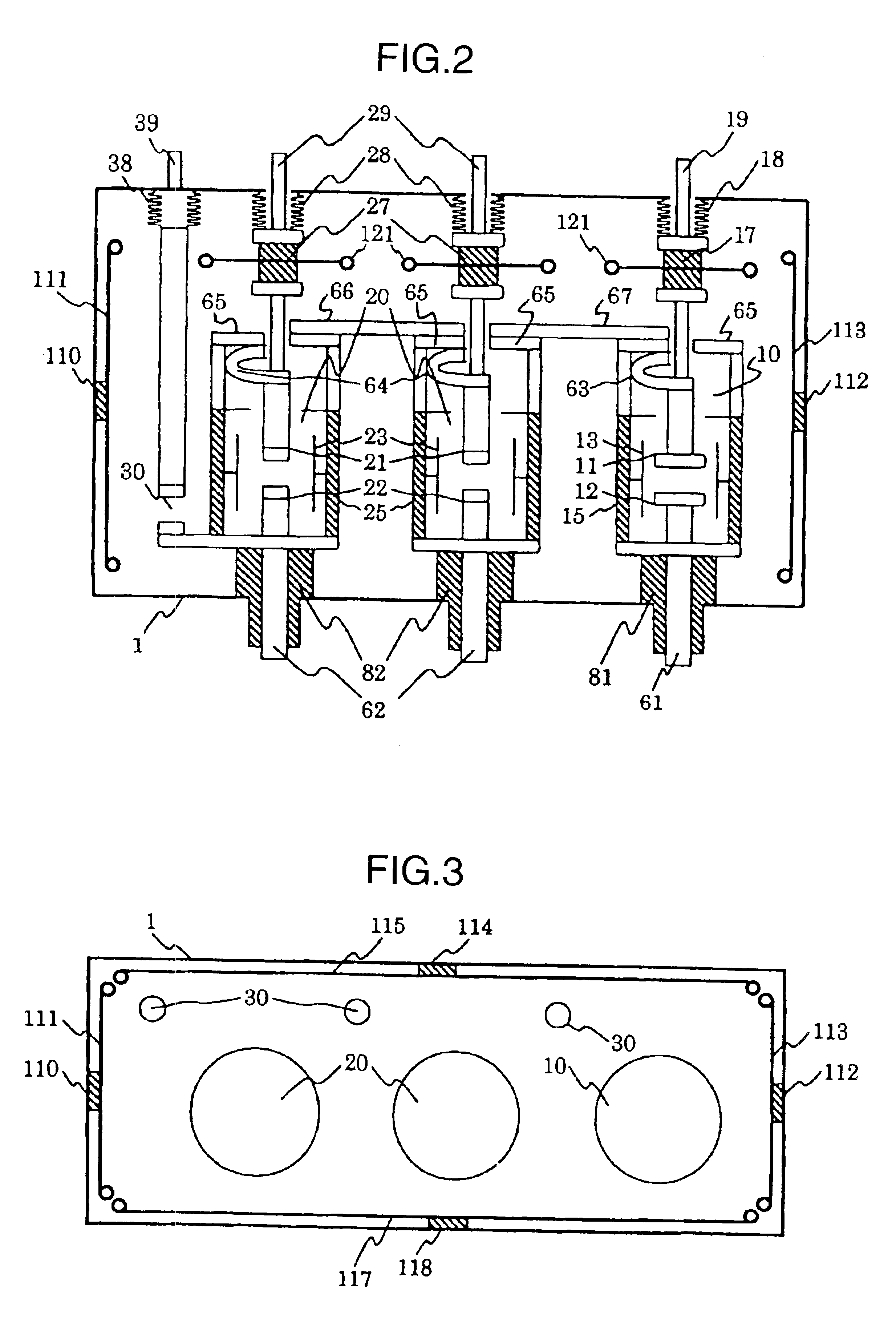

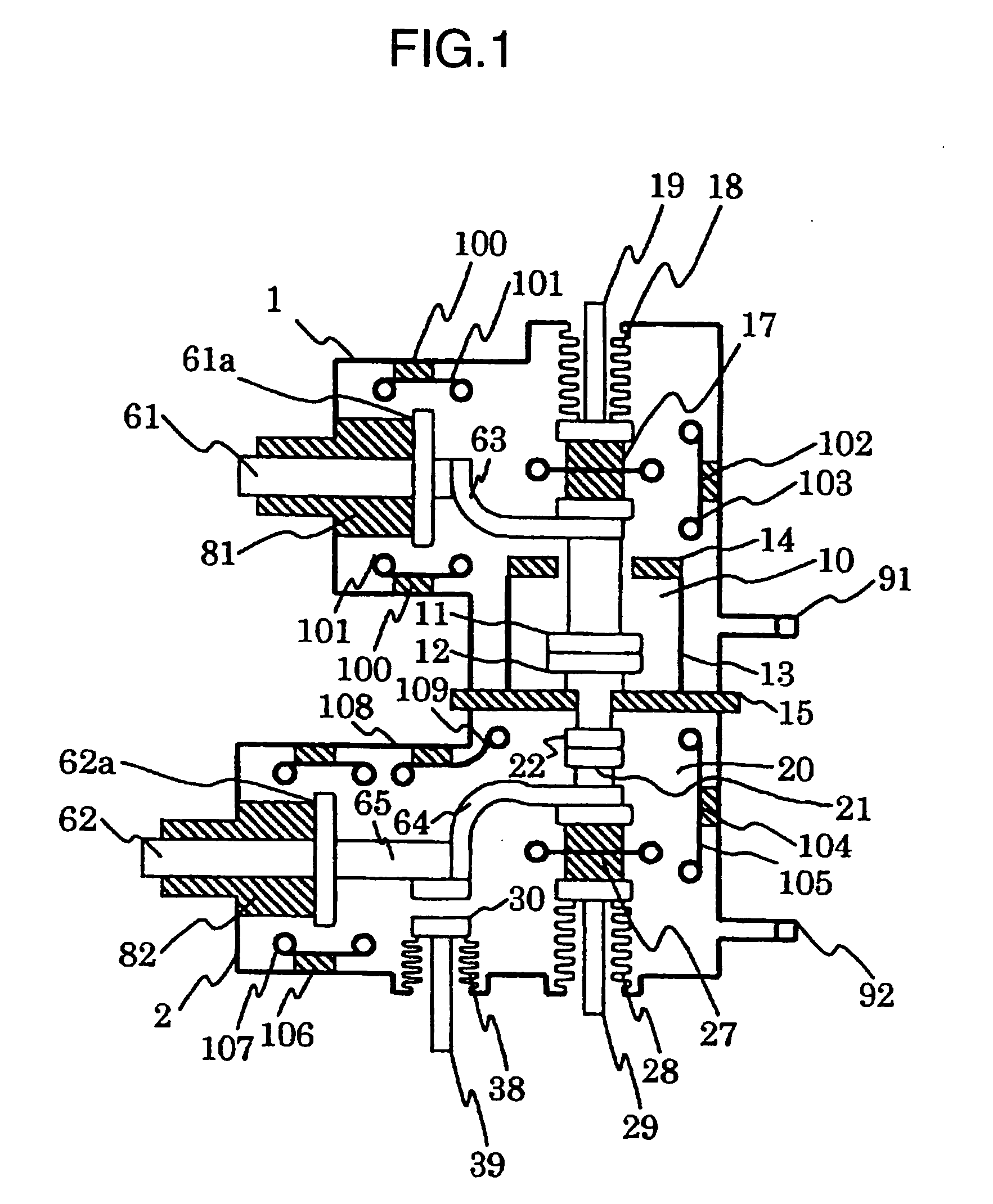

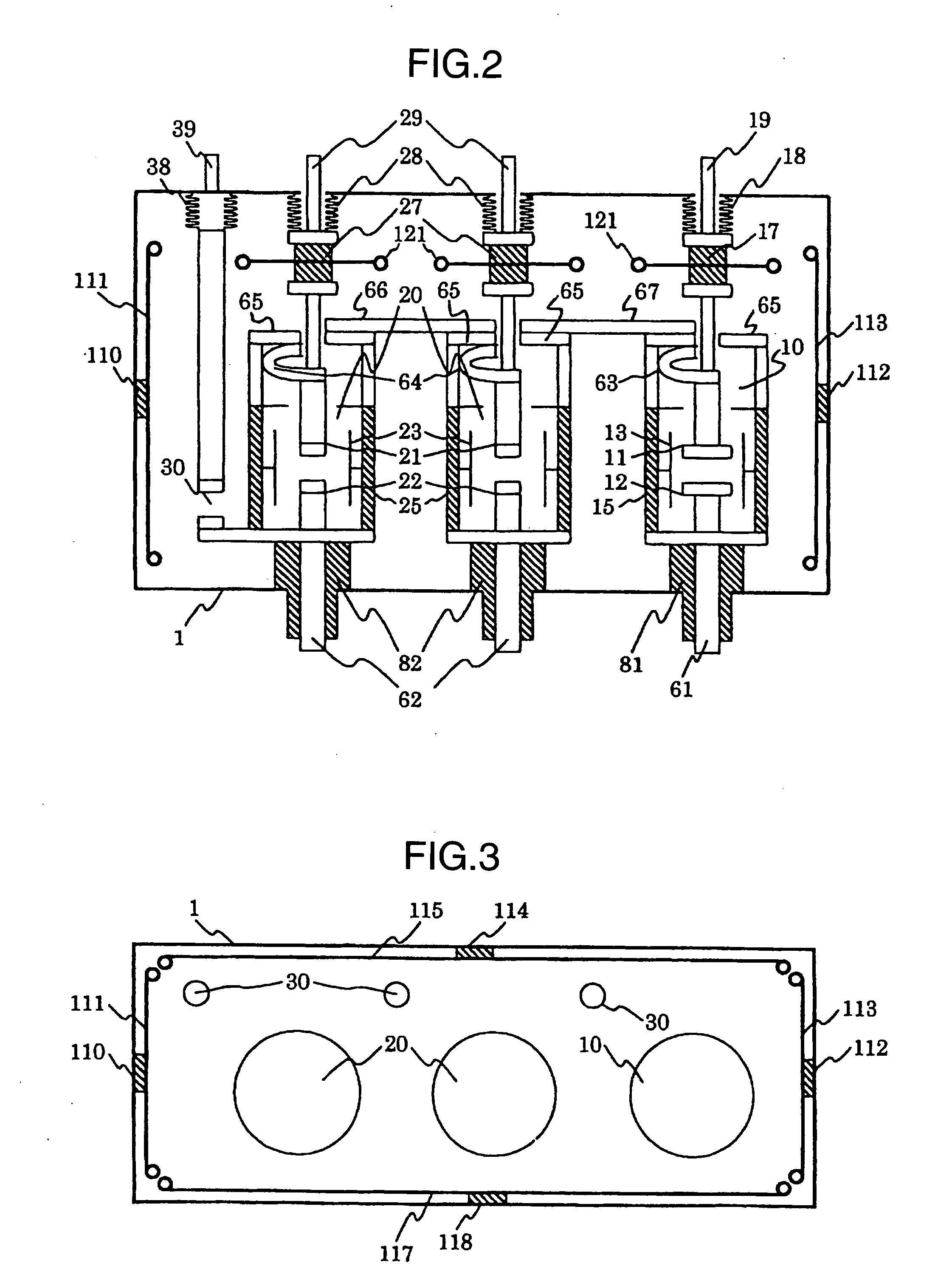

Vacuum switchgear

InactiveUS6884940B1Improve insulation reliabilityAvoid damageMagnetic/electric field screeningConductive materialForeign matterElectrical conductor

A main circuit switching unit and an isolator are accommodated in a vacuum container. A first conductor and a main circuit conductor are arranged to extend in and out of the vacuum container. A movable electrode of the main circuit switching unit is connected to the first conductor through a first flexible conductor, and a movable electrode of the isolator is connected to the main circuit conductor through a second flexible conductor. A shield is arranged around the first conductor and the main circuit conductor. Another shield is arranged around a connecting portion between the first flexible conductor and the movable electrode of the main circuit switching unit. A still another shield is arranged around the isolator. A further another shield is arranged around the second flexible conductor. These shields are secured to the vacuum container through insulating spacers. This arrangement instantly eliminates a dielectric breakdown phenomenon that occurs at electric field concentrated regions by the shields to prevent a dielectric breakdown caused by particulate foreign matters and thereby improve an insulation reliability of the devices.

Owner:HITACHI LTD

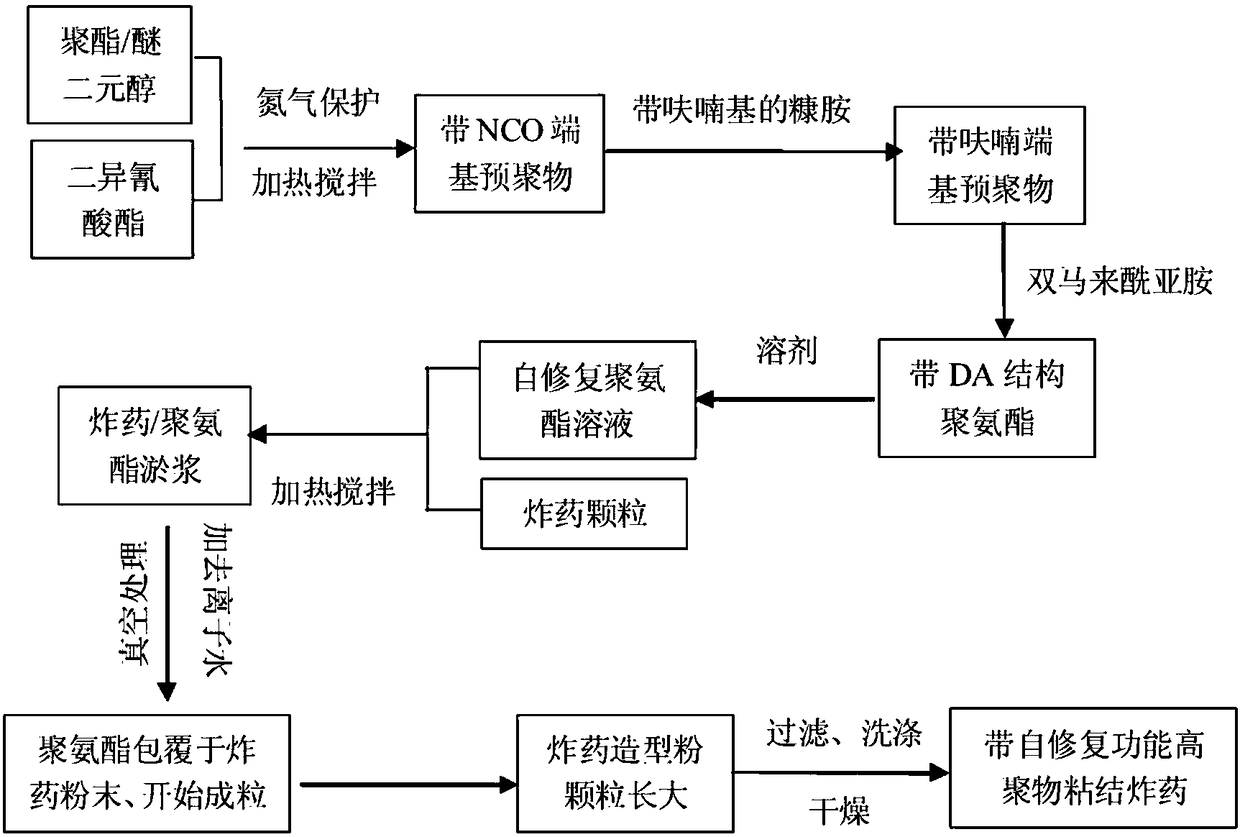

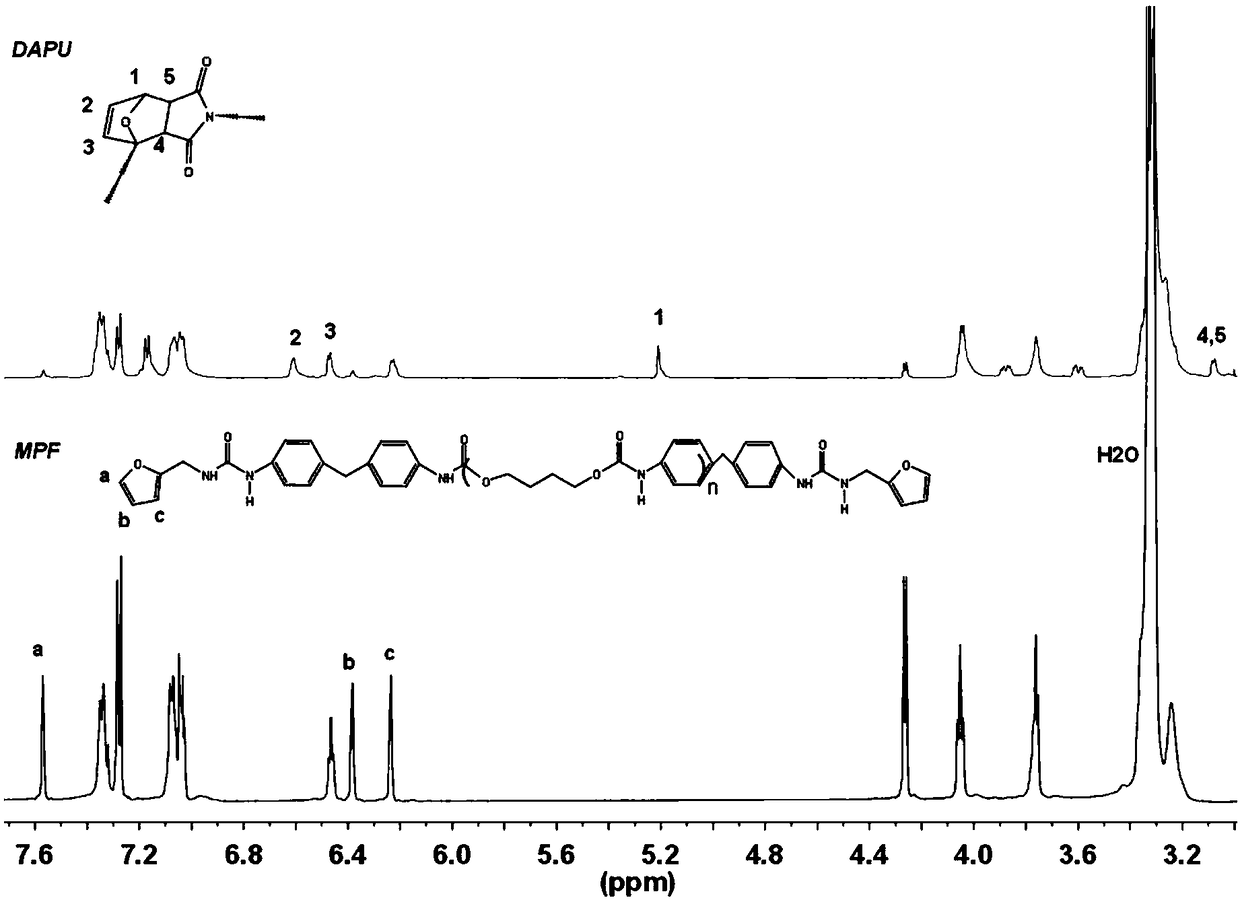

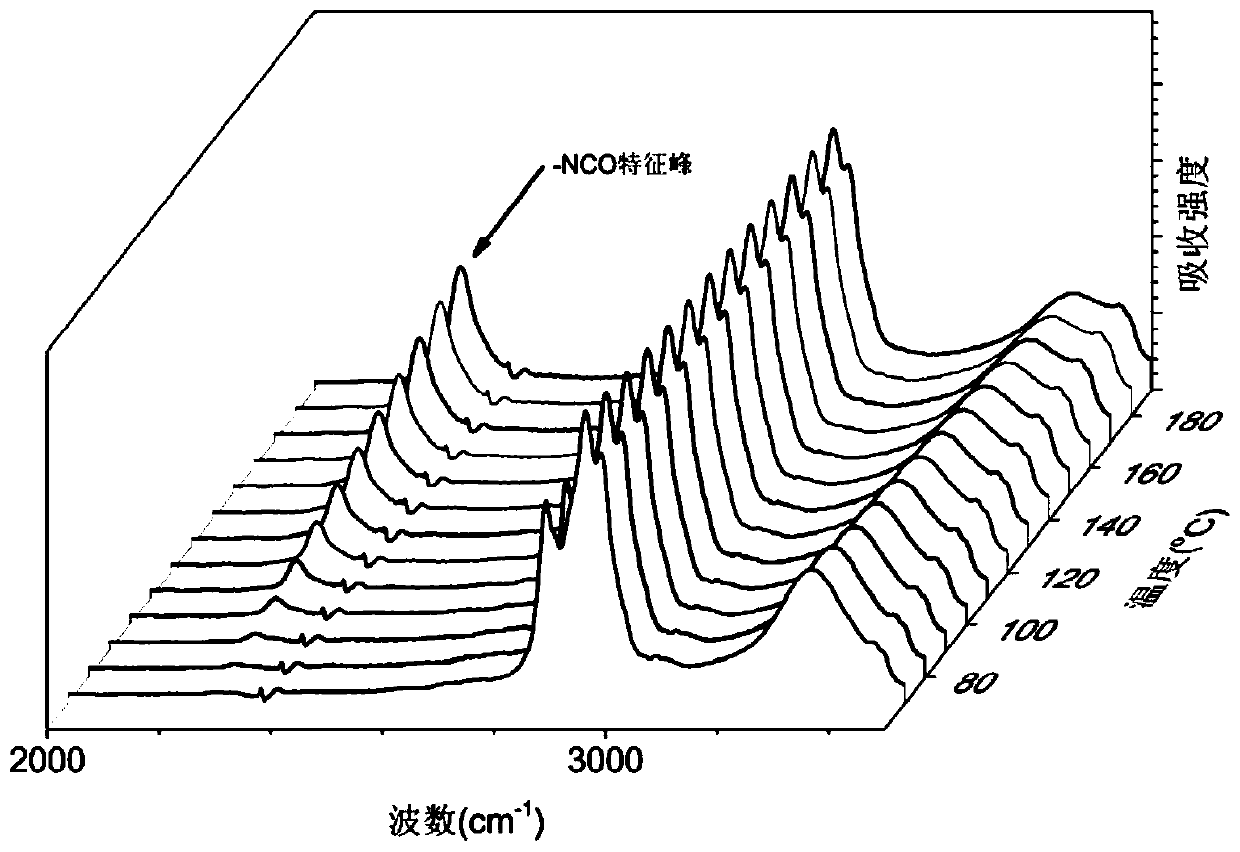

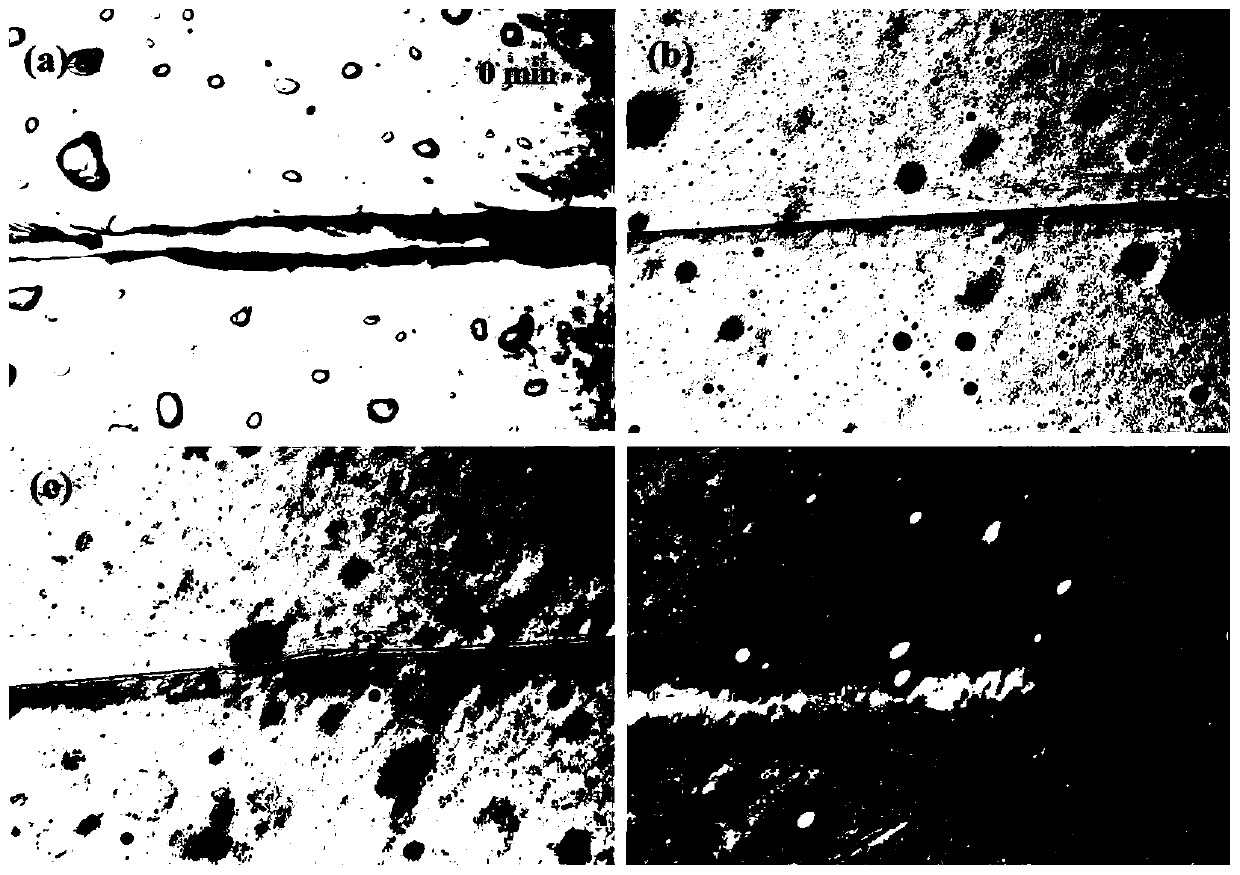

High polymer bonded explosive with self-repair function and preparation method thereof

ActiveCN108329184AReturn to normal structureRecovery strengthNitroparaffin explosive compositionsPolymer scienceEnd-group

The invention provides a preparation method of a high polymer bonded explosive with a self-repair function, wherein the preparation method includes the following steps: step 1, firstly, carrying out areaction of excess diisocyanate with polyether / ester diol to produce a prepolymer with -NCO groups at both ends; step two, then, carrying out a reaction of furfuryl amine with a furan group with theprepolymer, to generate polyurethane with a furan end group; step three, carrying out a reaction of bismaleimide with the polyurethane, to generate a thermoplastic polyurethane with a DA bond; and step four, preparing a dilute solution from the thermoplastic polyurethane, and adding an explosive with metered proportioning; and heating to make the solvent gradually evaporated, then adding a properamount of deionized water, wrapping the surface of the explosive after the polyurethane is precipitated, filtering and drying, and thus obtaining the high polymer bonded explosive with the self-repairfunction. The invention also provides the high polymer bonded explosive with the self-repair function. The preparation method has the advantages of simple preparation process, mild conditions and high universality.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

Bisphenol-containing self-healing thermally-reversible cross-linked polyurethane and production method thereof

The invention discloses bisphenol-containing self-healing thermally-reversible cross-linked polyurethane and a production method thereof. The method comprises the steps of mixing a bisphenol compound,a polyisocyanate compound, a polyhydric alcohol compound and a catalyst, and conducting curing to obtain the bisphenol-containing self-healing thermally-reversible cross-linked polyurethane. By adopting the method, the re-processing self-healing thermally-reversible cross-linked polyurethane can be produced, so that the polyurethane is advantageously used for the aspect of self-healing coatings,intelligent devices, thermoplastic polyurethane elastomers, plastic or the like, and the problem that in the prior art, chemical cross-linked polyurethane is hard to recycle is solved.

Owner:TSINGHUA UNIV

Method for improving softening of high strength aluminum alloy welded joint

ActiveCN104233124APromote softeningRecovery strengthArc welding apparatusFurnace typesRoom temperatureHeating furnace

The invention discloses a method for improving softening of high strength aluminum alloy welded joint. The method is as below: first heating a heating furnace to a solid solution temperature at a uniform speed; placing the welded workpiece into a furnace for heat preservation when the temperature is stable; after the heat preservation, taking out the workpiece; placing the workpiece into the cold water for quenching treatment; then placing the quenched workpiece into the heating furnace, and heating to aging temperature at a uniform speed for insulation; and after insulation, cooling the workpiece with the furnace to room temperature. Through solid solution treatment and artificial aging on the welded high strength aluminum alloy, the invention improves the problem of joint softening; and by means of hardness test and tensile test of the workpiece, the method can recover the strength of welded joint to more than 80% of the parent material.

Owner:TIANJIN UNIV

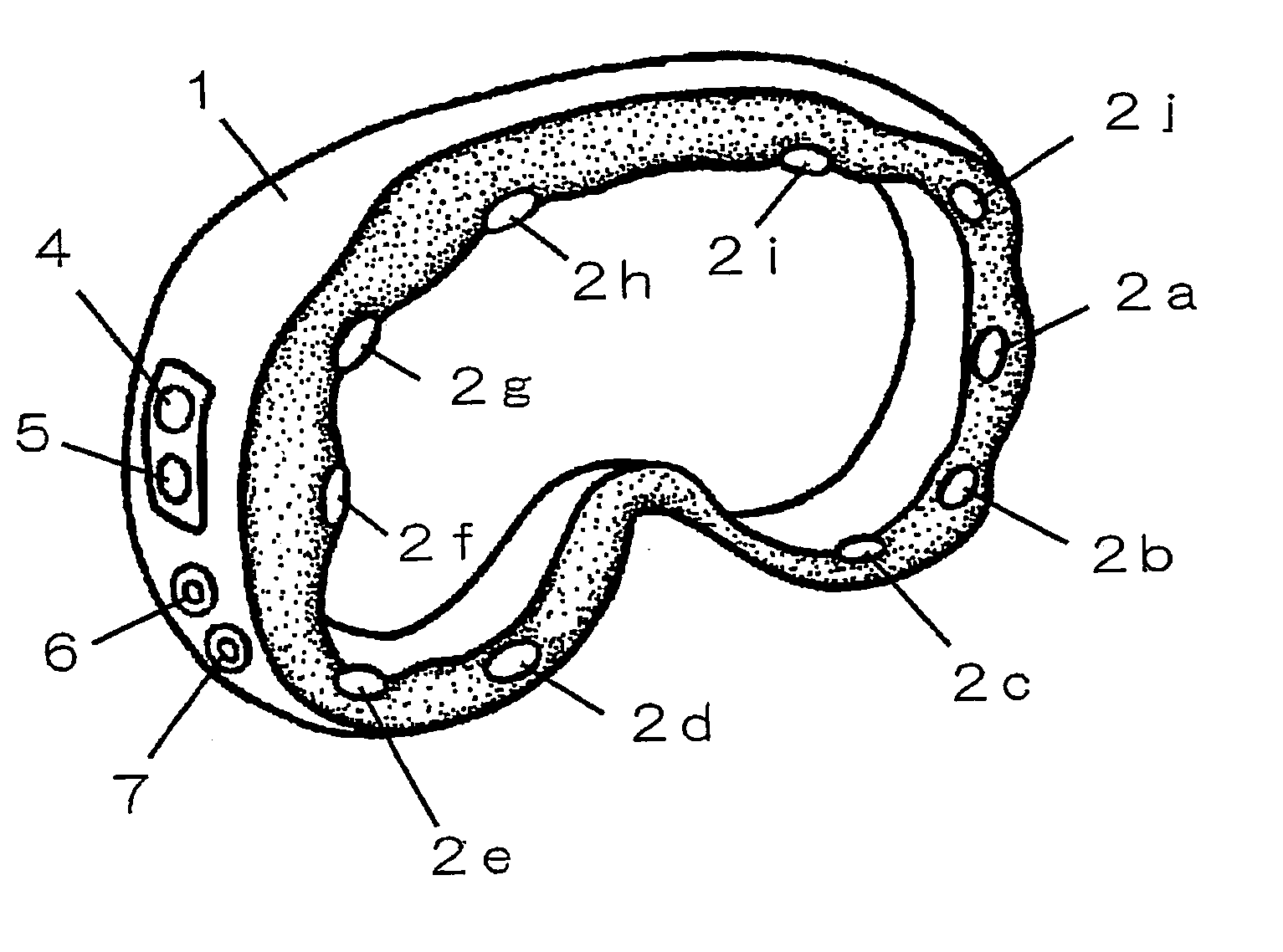

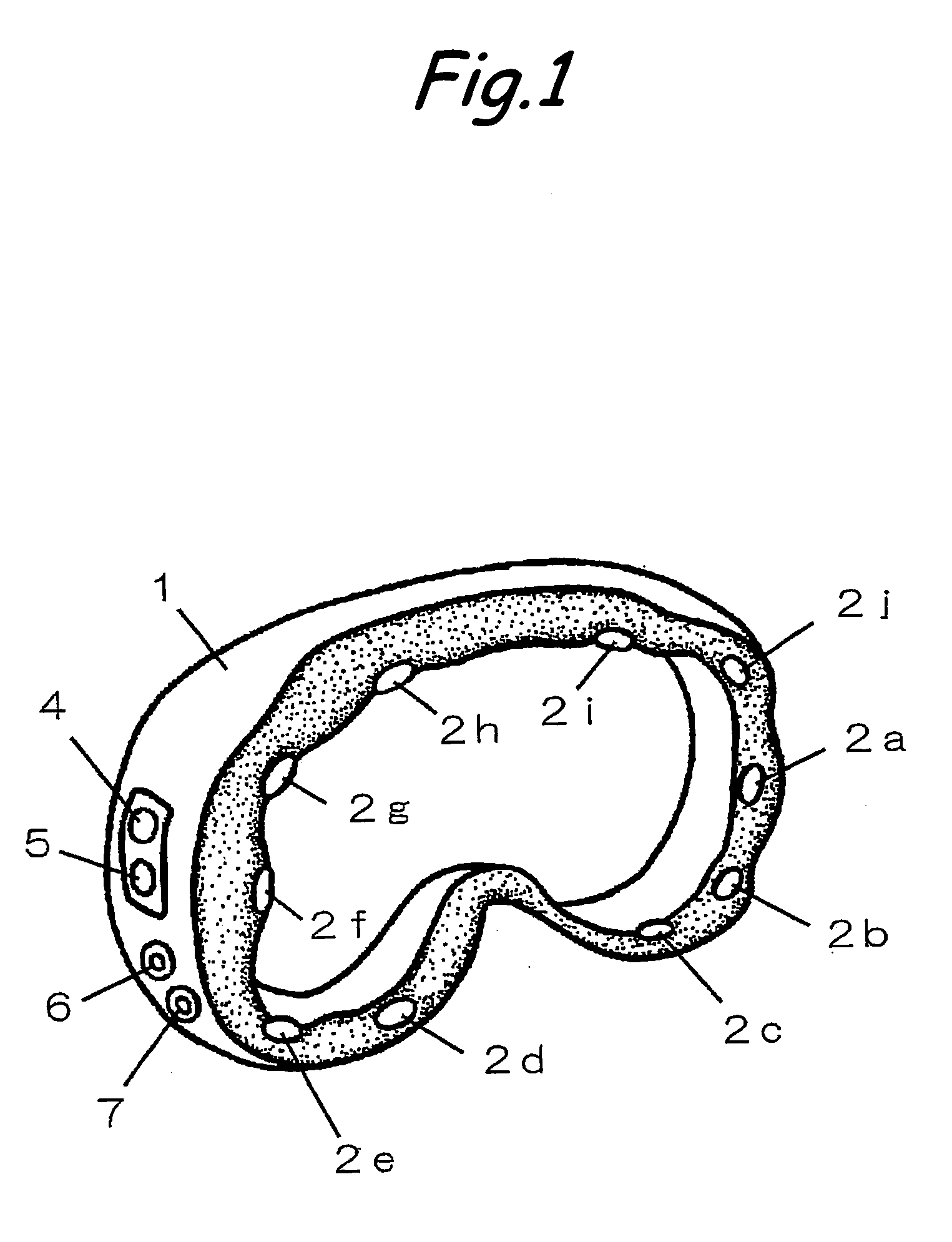

Health equipment

InactiveUS20050020954A1Recovery of muscular strengthSimple to executeChiropractic devicesTherapy exerciseHuman bodyPhysical therapy

Health equipment for dragging the lumber with the trunk of the human body securely supported is provided. The trunk support 2 is bendable only inwardly, and holds and supports the trunk of the human body. Since the trunk support 2 is placed around the human body and enfolds from the area below the costae to above the pelvis, the human body is securely supported, whereby lumbago treatment can be carried out with the patient suspended in the air. Since the lumber is dragged with the weight of the lower part of the patient's body, there is no possibility that the lumber is dragged with the excessive weight. The leg hanging unit 4 is a device to hang the legs of the patient. By using this leg hanging unit 4, so called mobilization may be carried out with the lower back portion suspended in the air, thereby increasing effectiveness of lumbago treatment.

Owner:PROTEK KO

Elastic woven or knitted fabric, and cushioning material and seat using the same

InactiveUS20030096547A1Ability to recoverRecovery strengthWarp knittingTextile/flexible product manufactureYarnRecovery factors

The present invention relates to an elastic woven or knitted fabric that has an elastic yarn comprising an organic synthetic macromolecule disposed in at least part thereof, and has the following physical properties: (1) a stress at 10% elongation in a range of 100 to 600N per 5 cm width in at least one of a warp direction and a weft direction, and an elongation recovery factor at 15% elongation of at least 75% in the same direction; (2) a ratio ST1 / ST2 of not more than 5, wherein ST1 is the stress at 10% elongation in one of the warp and weft directions, and ST2 is the stress at 10% elongation in the other one of the warp and weft directions, with the proviso that ST1>=ST2; and (3) a dry heat shrinkage factor at 180° C. in a range of 1.0% to 15% in each of the warp direction and the weft direction.

Owner:TOYO TOYOBO CO LTD

Maintaining method of dry fibers at roots of glass fiber reinforced plastic blades

The invention discloses a maintaining method of dry fibers at roots of glass fiber reinforced plastic blades. The dry fibers belong to a major quality defect easily generated when glass fiber reinforced plastic blades are formed, and can seriously impact the intensity of the glass fiber reinforced plastic blades. The maintaining method of the dry fibers at roots of the glass fiber reinforced plastic blades comprises the following ten steps: step 1, detecting the dry fibers at the roots of the blades; step 2, grinding the dry fibers at the roots; step 3, reinforcing and strengthening the annular inner parts of the blade roots; step 4, staggering and grinding the dry fibers at the blade roots; step 5, trimming the dry fibers at the blade roots and laying glass fiber cloth; step 6, trimming the dry fibers at the blade roots and carrying out vacuum laying by auxiliary materials; step 7, trimming the dry fibers at the blade roots and carrying out vacuum guide injection; step 8, trimming and precuring the dry fibers at the blade roots; step 9, trimming the dry fibers at the blade roots and uncovering a mold; and step 10, trimming the dry fibers at the blade roots and post curing. The maintaining method provided by the invention is suitable for maintaining the dry fibers at the roots of the glass fiber reinforced plastic blades.

Owner:HEILONGJIANG TIANHUA WIND POWER EQUIP MFG

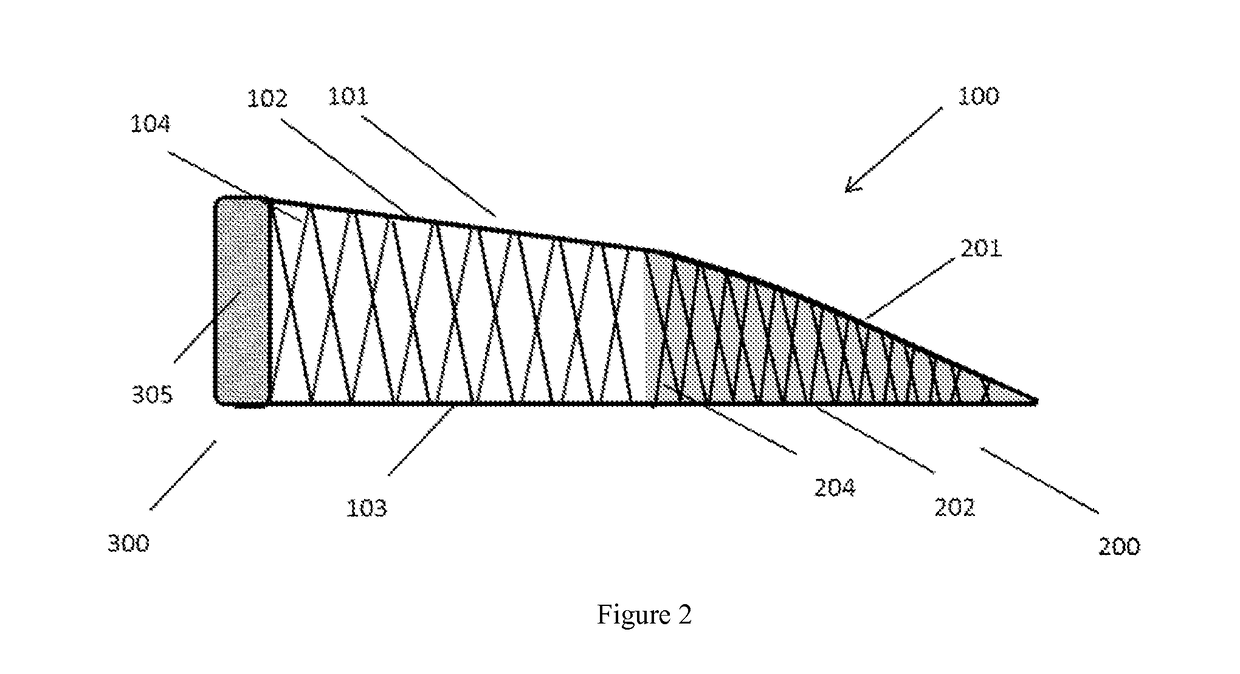

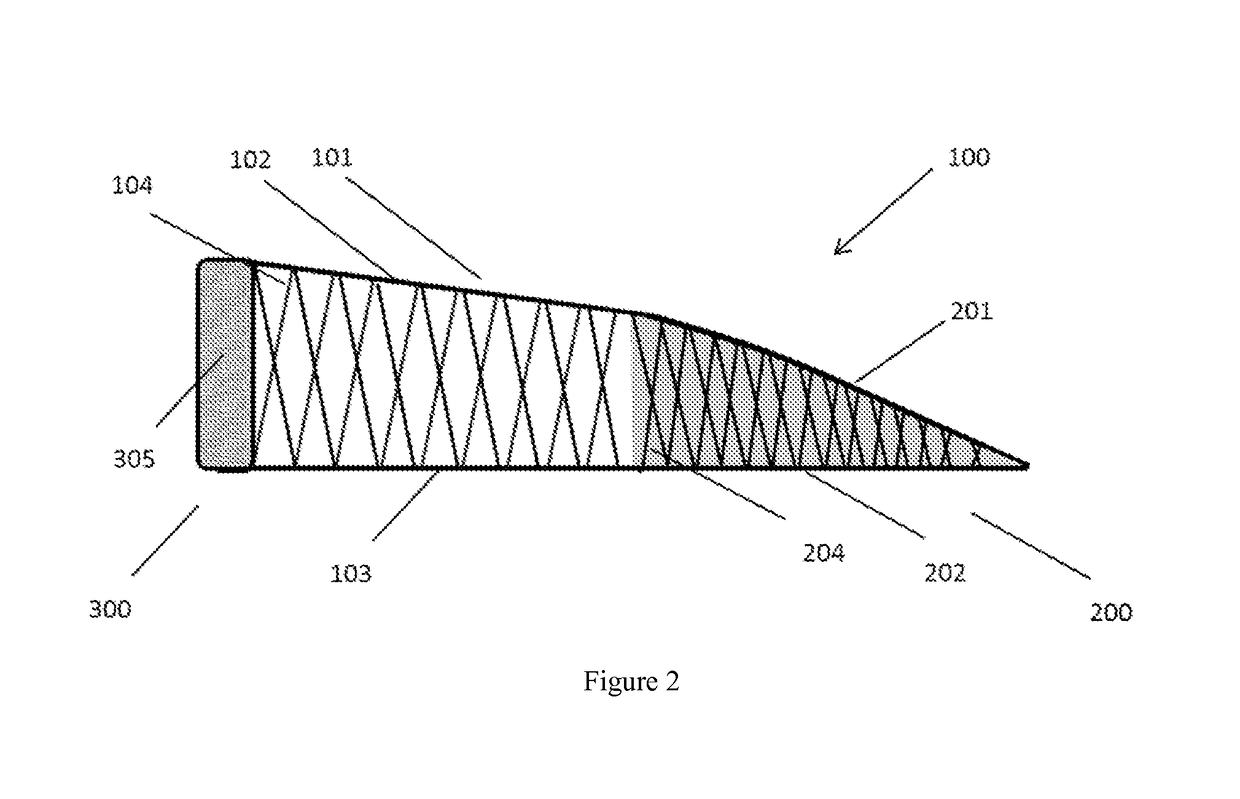

Anatomically Designed Meniscus Implantable Devices

ActiveUS20170224498A1Compressive strength and and compressive recoveryReduce thicknessJoint implantsKnee jointsKnee meniscusImplanted device

An implant device used to replace and restore the function of the knee meniscus in a human. The compliant, yet resilient device is comprised of a biocompatible, non-degradable three-dimensional body comprised of at least a central body, a second structure, a third structure, and a coating. The device is concentrically aligned wherein the second structure is adjoined to the central body wherein the third structure is adjoined on the central body opposite of the second structure. The third structure further features a first and a second pulling element which is coupled to the central body and forms the outer periphery and major circumference of the device. The device is comprised of multiple components which provide tensile strength, compressive resilience, and attachment mechanisms for replacing the meniscus. Each structure is comprised of multiple surfaces which are further reinforced, separated, and connected by an individual plurality of vertical elements. The implantable device further features a surface coating on the surface of the central body.

Owner:MCCULLEN SETH +1

Anatomically designed meniscus implantable devices

ActiveUS10034755B2Reduce thicknessRecovery strengthJoint implantsKnee jointsKnee meniscusImplanted device

An implant device used to replace and restore the function of the knee meniscus in a human. The compliant, yet resilient device is comprised of a biocompatible, non-degradable three-dimensional body comprised of at least a central body, a second structure, a third structure, and a coating. The device is concentrically aligned wherein the second structure is adjoined to the central body wherein the third structure is adjoined on the central body opposite of the second structure. The third structure further features a first and a second pulling element which is coupled to the central body and forms the outer periphery and major circumference of the device. The device is comprised of multiple components which provide tensile strength, compressive resilience, and attachment mechanisms for replacing the meniscus. Each structure is comprised of multiple surfaces which are further reinforced, separated, and connected by an individual plurality of vertical elements. The implantable device further features a surface coating on the surface of the central body.

Owner:ORTHONIKA LTD

Vacuum switchgear

InactiveUS20050103514A1Improve insulation reliabilityAvoid damageMagnetic/electric field screeningConductive materialForeign matterElectrical conductor

A main circuit switching unit and an isolator are accommodated in a vacuum container. A first conductor and a main circuit conductor are arranged to extend in and out of the vacuum container. A movable electrode of the main circuit switching unit is connected to the first conductor through a first flexible conductor, and a movable electrode of the isolator is connected to the main circuit conductor through a second flexible conductor. A shield is arranged around the first conductor and the main circuit conductor. Another shield is arranged around a connecting portion between the first flexible conductor and the movable electrode of the main circuit switching unit. A still another shield is arranged around the isolator. A further another shield is arranged around the second flexible conductor. These shields are secured to the vacuum container through insulating spacers. This arrangement instantly eliminates a dielectric breakdown phenomenon that occurs at electric field concentrated regions by the shields to prevent a dielectric breakdown caused by particulate foreign matters and thereby improve an insulation reliability of the devices.

Owner:HITACHI LTD

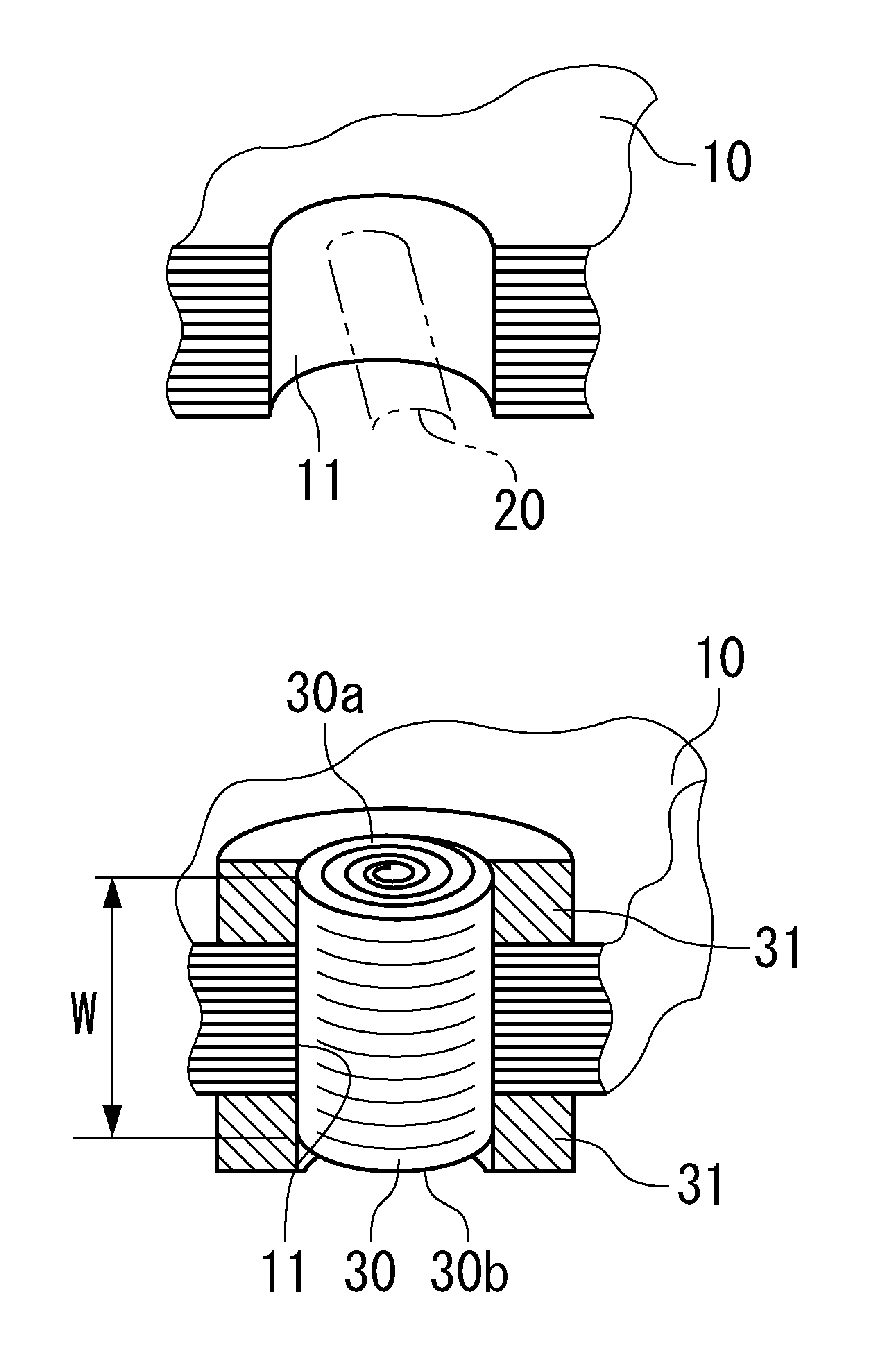

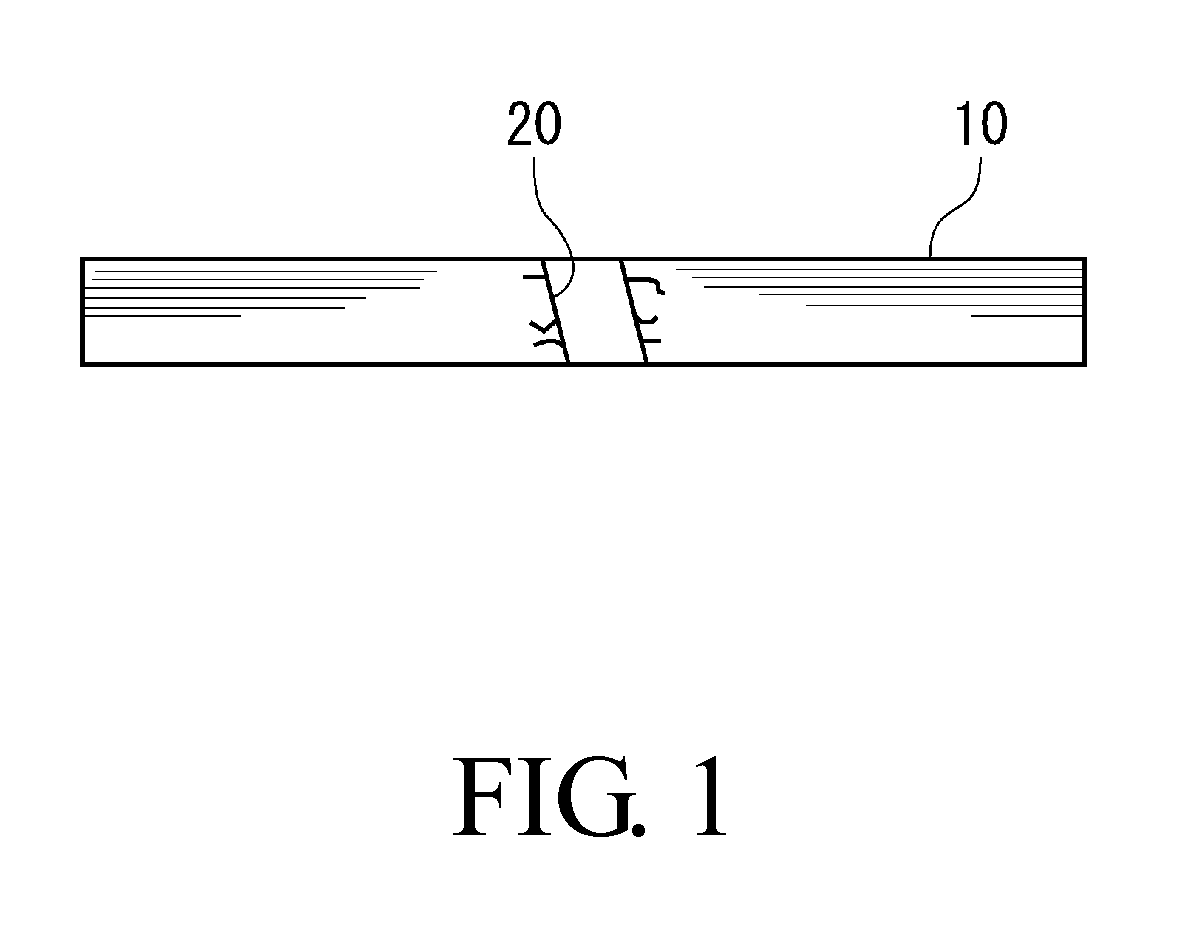

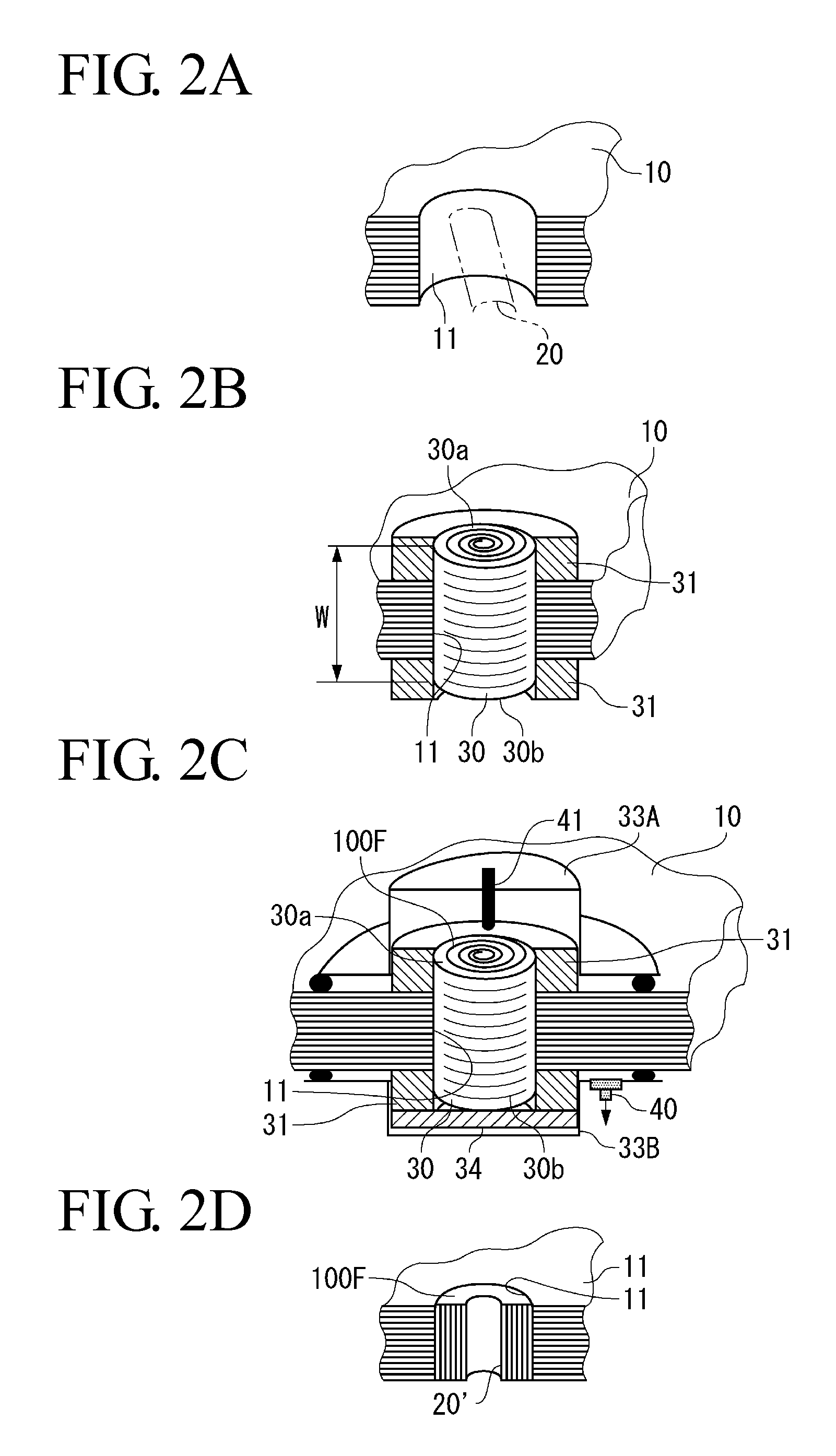

Method for repairing a member comprising a fiber-reinforced plastic

ActiveUS20130025770A1Recovering bearing strengthRecovering bypass strengthLayered productsLaminationEngineeringFiber reinforcement

There is provided a method for repairing a member comprising a fiber-reinforced plastic, which method can repair a through hole easily at a low cost. When a through hole 20 is repaired, a temporary hole 11 is formed, a fabric sheet 30 comprising reinforcing fibers is rolled into a cylindrical shape and inserted into the temporary hole 11, the fabric sheet 30 is impregnated with a resin, the resin is cured, and a new through hole 20′ is formed.

Owner:MITSUBISHI AIRCRAFT

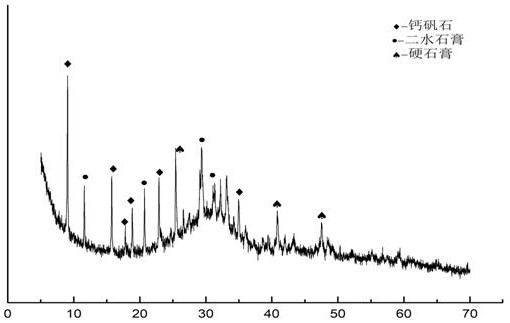

Titanium slag-based solid waste cementing material and preparation method thereof

The invention discloses a titanium slag-based solid waste cementing material and a preparation method thereof. The titanium slag-based solid waste cementing material comprises the following raw materials by weight: 70-80% of a titanium slag-based material, 15-25% of gypsum, and 2.5-7.5% of cement clinker. The preparation method is simple, and the used materials are subjected to separate or mixed grinding according to different types of grindability differences, and then are mixed and stirred. In the raw materials, the titanium-containing slag-based material is used as a main component and is matched with the cement clinker and the gypsum to form the gel material, so that effective comprehensive utilization of a large amount of high-titanium-containing slag and industrial byproduct gypsum resources produced by iron and steel enterprises in Panzhihua, Leshan sand bay and the like in the southwest region can be realized, most of conventional engineering applications can be met, and the material can also be used in a construction environment with rich tunnel terrestrial heat.

Owner:JIAHUA SPECIAL CEMENT

Preparation method of fluorine-silicon-oxygen superfine modified glass fiber filter material

ActiveCN107376509AReduced filament diameterHigh porositySucessive textile treatmentsDispersed particle filtrationSilicon oxygenDust emission

The invention is suitable for the technical field of dust-removal and filter materials, provides a preparation method of a fluorine-silicon-oxygen superfine modified glass fiber filter material and aims at solving the technical problems in the prior art that a glass fiber is relatively poor in toughness, temperature tolerance and wearing and folding resistance and has relatively poor anti-oxidative performance on sulfur dioxide and other harmful gases. The preparation method comprises the steps of acid steeping, washing, drying, potassium permanganate oxidation treatment, heat cleaning, chemical infiltrating agent steeping, and drying to prepare the finished product. The product produced by the preparation method is good in performance, good in chemical stability, high in strength and low in ductility, and has outstanding wear-resisting property, folding resistance, acid and alkali resistance and corrosion resistance, and the resistant temperature is improved to 600 DEG C or above from about 280 DEG C of an original glass fiber filter material; the glass fiber material can be widely applied to the industries, such as steel, smelting, cement, a coal-fired boiler, carbon black and electric power; the dust collection rate of the fluorine-silicon-oxygen superfine modified glass fiber filter material can reach 99.99%, and the dust emission is lower than 5-20mg / N.m; and therefore, the material has very broad development prospects at home and abroad and great market potential.

Owner:辽宁凯富环保科技集团有限公司

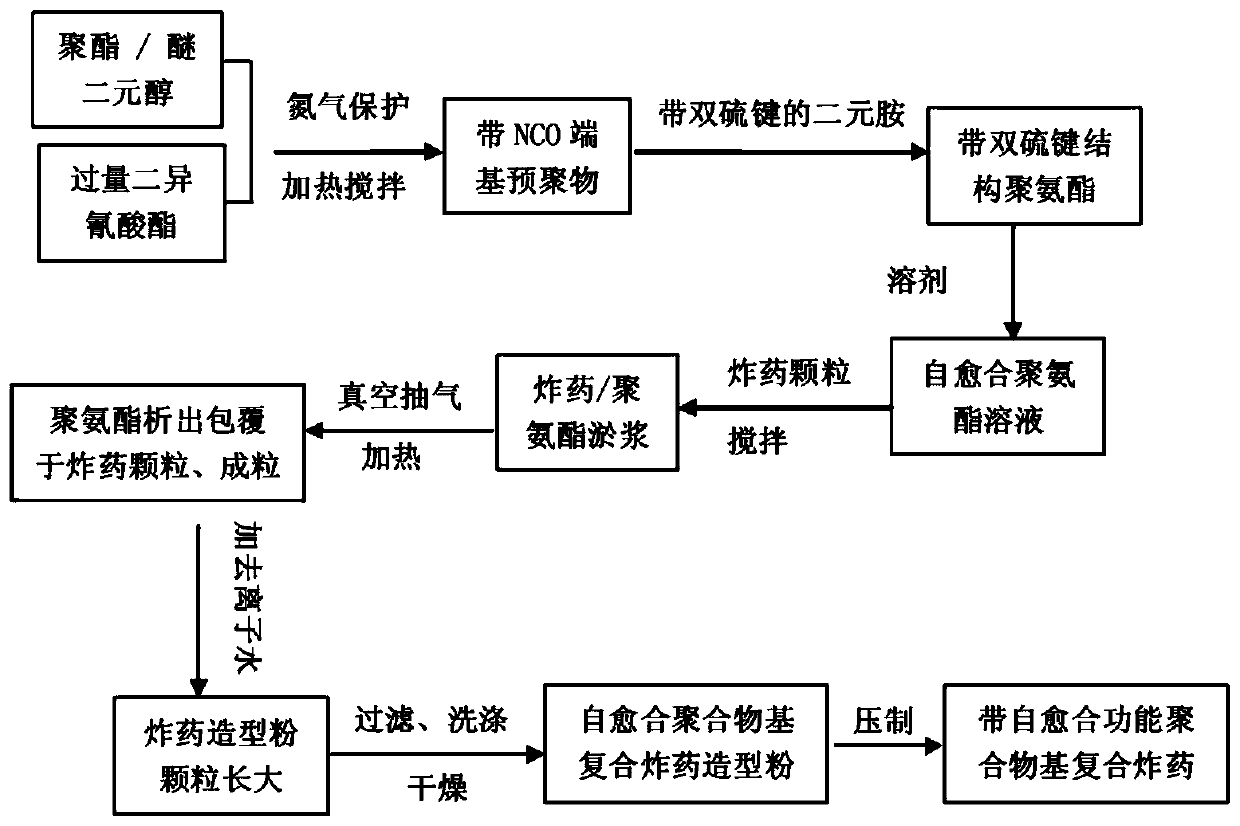

Damage self-healing polymer-based composite explosive and preparation method thereof

InactiveCN110172010AReturn to normal structureRecovery strengthNitrated aromatic explosive compositionsNitrated acyclic/alicyclic/heterocyclic amine explosive compositionsDiolSolvent

The invention discloses a preparation method of a damage self-healing polymer-based composite explosive. The preparation method comprises the following steps: step 1: firstly enabling excessive diisocyanate to react with polyether / ester diol to generate a prepolymer having -NCO groups at two ends; step 2: then enabling a diamine with a disulfide bond to react with the prepolymer having the -NCO groups at two ends to generate polyurethane having the disulfide bond; step 3: preparing the polyurethane having the disulfide bond into a diluted solution, adding an explosive in a metered proportion,heating the mixture to volatilize a solvent such that the polyurethane is precipitated and wraps the surface of the explosive, and filtering and drying to obtain the damage self-healing polymer-basedcomposite explosive. The high polymer product provided by the invention has a unique disulfide bond structure; after damage occurs inside the polymer-based composite explosive, dynamic exchange reaction of the disulfide bond occurs under a mild heating condition, so that the damaged part of the polymer-based composite explosive is re-bonded to recover the structure and the strength of the explosive.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

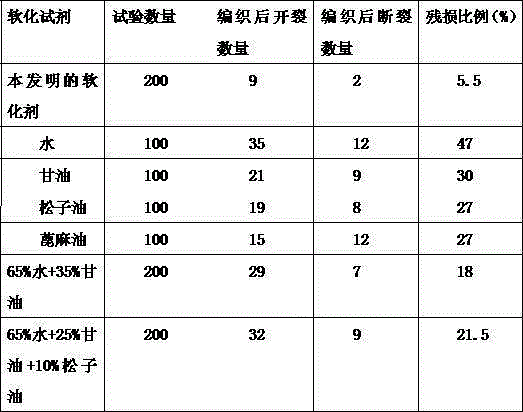

Regeneration method of waste leather

InactiveCN107723390ARestore flexibilityRecovery strengthTanning treatmentPre-tanning chemical treatmentProtein activityUltimate tensile strength

The invention mainly relates to the technical field of leather processing and discloses a regeneration method of waste leather. The regeneration method comprises cleaning, softening, retanning, strengthening, drying and packaging, the method is simple and convenient to operate, softness and strength of the waste leather can be restored, secondary use can be achieved, and the traditional preparation method of recycling the waste leather and regenerating leather is avoided. The novel waste leather treating method is provided, the method is green and environmentally friendly, waste residues of raw materials are not generated, the waste leather is fully recycled, after being cleaned, the waste leather is placed into softening liquid to be subjected to low-temperature rotary drum soaking, thus,the softening liquid permeates into the waste leather slowly, softening treatment is carried out fully, the softening liquid is safe and healthy, does not contain any poisonous agent, contains plentyof polypeptide, bio-enzyme and protein polysaccharide, and can activate protein activity in the waste leather, and softness and smoothness of the leather are improved.

Owner:安徽乐踏鞋业有限公司

Anti-cracking treatment method for rattan

InactiveCN106393369APrevent peelingAvoid breakingElectric wood treatmentWood treatment detailsWarm waterLow temperature plasma

The invention discloses an anti-cracking treatment method for a rattan. The method comprises the following steps: treating the rattan in a dark environment of which the humidity is 65% to 68% and the temperature is 8 to 10 DEG C, and irradiating twice; subsequently soaking the rattan in warm water and putting in cold storage; dissolving chitosan in a saturated carbon dioxide water solution to prepare a solution for soaking the rattan; and treating the rattan by utilizing low-temperature plasma generated by dielectric barrier discharge at atmospheric pressure. In comparison with an existing rattan treatment method, the method disclosed by the invention has the advantages that a knitted product made from the rattan treated by the method disclosed by the invention is not deformed, free of cracks and very comfortable to skin in use; the bearing capacity is increased; the dimensional stability is good; decrustation of the rattan can be effectively prevented; after the rattan is knitted, the strength of the rattan is gradually restored and is increased by 2% to 3% in comparison with the original strength; the treated rattan is quite good in corrosion prevention effect, good in rattan softening effect and harder to mildew and damage in use; the knitted product prepared by the rattan treated by the method disclosed by the invention is free of mildew and worm damages and can be kept in the original color within at least 8 years.

Owner:阜南县环宇柳木工艺制品有限公司

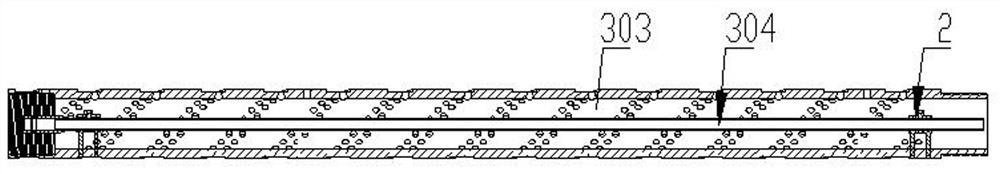

Outburst coal seam hole protection and pressure relief in-hole drilling tool and special out-hole sealing and deslagging system thereof

The invention discloses an outburst coal seam hole protection and pressure relief in-hole drilling tool and a special out-hole sealing and deslagging system thereof. The in-hole drilling tool comprises a double-channel sieve hole drill bit and a plurality of double-channel sieve hole drill rods. The out-hole sealing and deslagging system comprises an outer sealing assembly, a carved seam inner sealing pipe and a drill tail flow supply and deslagging assembly. The drilling tool is matched with the out-hole sealing and deslagging system for use; the outer diameter of each double-channel sieve hole drill rod is close to the diameter of the drill bit, and the double-channel sieve hole drill rods have the hole protection effect; spiral grooves and spiral convex ribs are arranged on the outer surfaces of the drill rods, pressure relief sieve holes are formed along the spiral grooves and the spiral convex ribs, and the pressure relief sieve holes can relieve pressure on the outer surfaces of the drill rods; out-hole exposed sieve holes of the double-channel sieve hole drill rods are sealed with the outer sealing assembly and the carved seam inner sealing pipe, so that the leakage and loss of slag discharge air flow or water flow are prevented; and the in-hole drilling tool has the functions of hole protection and pressure relief, and an inner slag discharge channel is of a steel sieve hole structure, so that the smoothness of the inner slag discharge channel can be ensured, the gas over-limit accident of a spray hole can be prevented, the excessive hole collapse of a drill hole wall is restrained, the hole forming quality is improved, and the drill hole skewness is reduced.

Owner:HENAN POLYTECHNIC UNIV

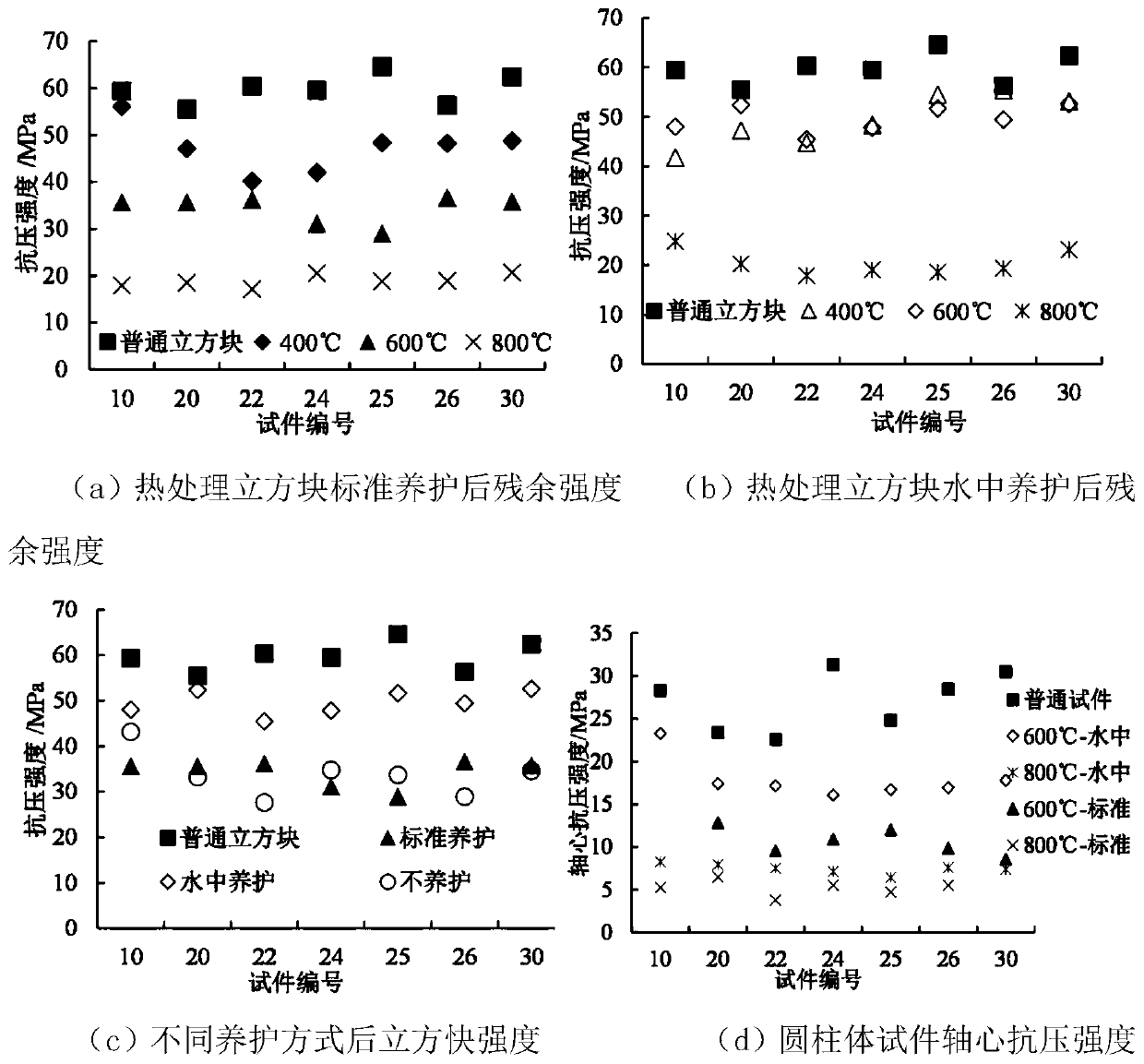

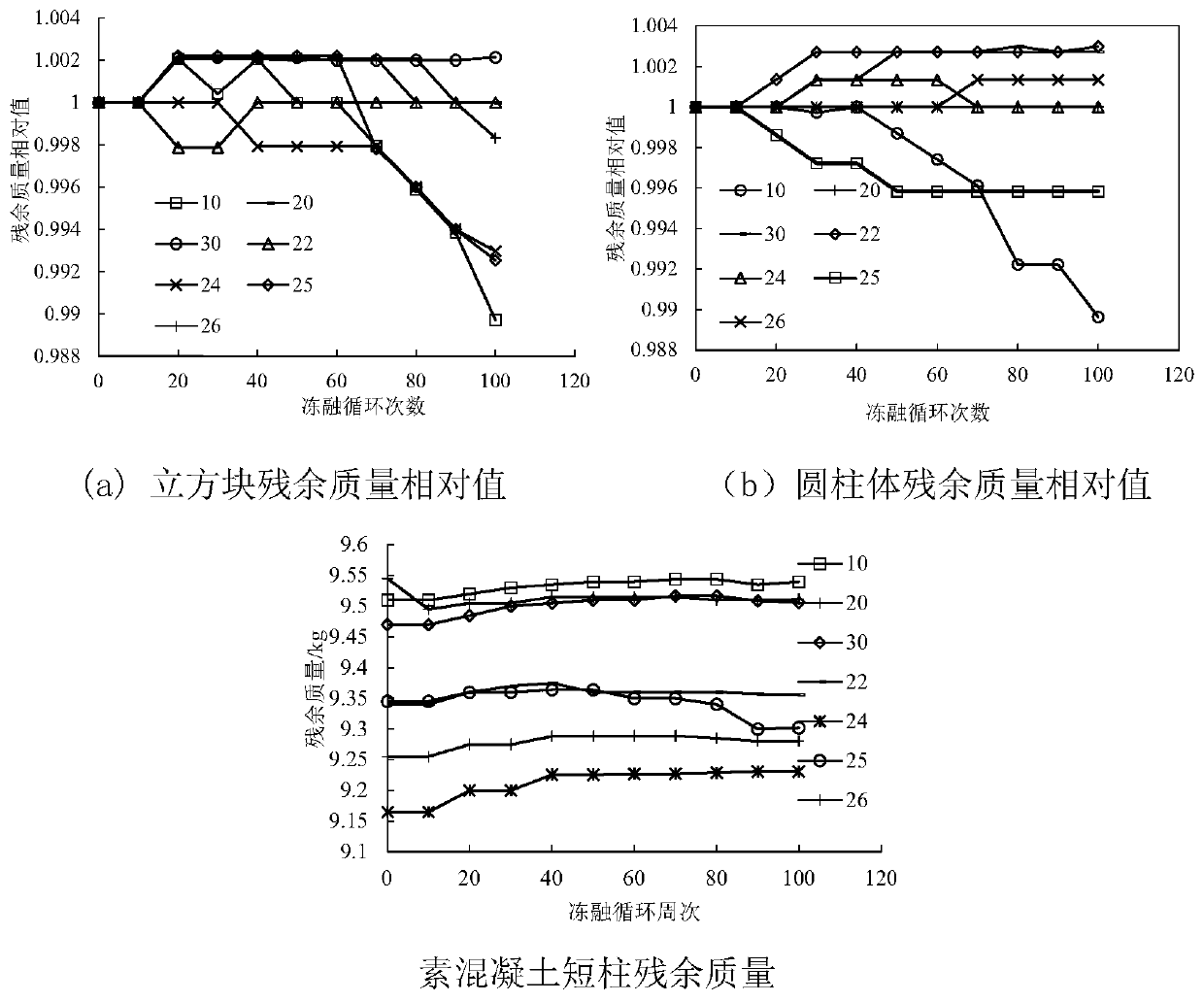

Method for improving high temperature resistance and freeze thawing resistance of high strength recycled concrete

ActiveCN110240440AFast and stable strength developmentRecovery strengthHigh resistanceFreeze thawing

The invention discloses a method for improving high temperature resistance and freeze thawing resistance of high strength recycled concrete. The method for improving durability of the high strength recycled concrete at high temperature (as high as 800 DEG C) and in an extreme freeze thawing environment (100 freezing and thawing cycles highest) is mainly realized by a method of the mixing of basalt fibres and later maintenance. The improvement of the freeze thawing resistance, permeability resistance and high temperature resistance of the concrete is facilitated by mixing the basalt fibres in the concrete, and environment damage and crack initiation and expansion under exogenic action of the concrete can be inhibited. When the mixing amount of the fibres is 4 kg / m<3>, the strength development of the recycled concrete is the fastest and stable, the strength is relatively high with 28 days of maintenance, the quality loss of the fiber recycled concrete is less than 1% after 100 times of freeze thawing, and the strength of plain concrete columns is relatively high after freeze thawing; 24 hours of underwater maintenance is beneficial to the strength recovery of the fiber recycled concrete after high temperature loss, and when the high temperature is less than 600 DEG C, the strength can recover to a same level.

Owner:SICHUAN UNIV

Magnetic control pulling single-crystal superconducting magnet for conduction cooling and cooling method thereof

PendingCN113436825ASpeed up coolingProblems affecting coolingSuperconducting magnets/coilsTest sampleSuperconducting Coils

A magnetic control pulling single-crystal superconducting magnet for conduction cooling comprises a coil framework, and an arc section of the coil framework is connected with a left and right coil cold conduction connecting device. The upper side of the left and right coil cold conduction connecting device is provided with a cold shield cold conduction device, and the lower side of the left and right coil cold conduction connecting device is provided with a coil cold conduction device; the first-stage cold head of a G-M refrigerator is connected with the second-stage cold head of the G-M refrigerator through a heat pipe; and the upper side of the cold shield cold conduction device is connected with the G-M refrigerator. The cooling method comprises the following steps: 1 setting the cooling magnetic control pulling single-crystal superconducting magnet; 2 filling the heat pipe with gas, and starting the G-M refrigerator to cool a test sample; and 3 achieving rapid cooling of the superconducting coil. The cooling method has the characteristic of high cooling efficiency.

Owner:XIAN JUNENG SUPERCONDUCTING MAGNET TECH

Rattan softener

The invention discloses a rattan softener which is composed of, by mass, 10-15 parts of propylene glycol, 10-12 parts of propylene glycol monomethyl ether acetate, 8-10 parts of propylene glycol ether acetate ester, 8-10 parts of polysiloxane polyethylene alkene ether, 6-8 parts of dodecyl sodium sulfate, 6-8 parts of fatty alcohol polyoxyethylene ether, 5-8 parts of nonylphenol polyoxyethylene ether, 8-10 parts of lauric acid monoglyceride and 50-80 parts of deionized water. The rattan softener can soften rattans, so that the rattans are convenient to process, the rattan softener is easy to prepare, convenient to use, free of toxic components and safe in use, the toughness of the rattans is improved through the rattan softener, the strength of the woven and processed rattans can be gradually recovered, and the strength is not decreased.

Owner:陈新棠

Anti-cracking processing method of osiers

InactiveCN106313237AImprove weaving effectReduce the probability of crackingWood treatment detailsPretreatment apparatusAmbient humidityWarm water

The invention discloses an anti-cracking processing method of osiers. The anti-cracking processing method of the osiers comprises the steps of processing the osiers in a dark environment with the ambient humidity being 70 to 75 percent and the temperature being 10 to 12 DEG C, and providing illumination for two times; then soaking in warm water and refrigerating; dissolving chitosan in a saturated carbon dioxide water solution to prepare into a solution for soaking the osiers; and utilizing a low-temperature plasma generated by atmospheric pressure dielectric barrier discharge to process the osiers. Compared with an existing osier processing method, the anti-cracking processing method of the osiers provided by the invention is simple, and the osiers can be effectively prevented from being cracked or deformed, so that the service time of an osier product can be further prolonged, the skin-friendly feeding is good, the bearing strength is increased, the size stability is good, the osiers can be effectively prevented from peeling, after the osiers are woven, the strength of the osiers is gradually recovered and is improved by 3 to 4 percent compared with the original strength, the processed osiers have a better preservative effect and an excellent osier softening effect, and the technological value and the economic value of the osier product are improved.

Owner:阜南县环宇柳木工艺制品有限公司

Rattan softening method

InactiveCN104924397ASoftening method is simpleImprove flexibilityWood treatment detailsReed/straw treatmentSodium bicarbonatePolyethylene glycol

The invention relates to a rattan softening method. The method comprises the following steps that (1), treating fluid is prepared; (2), rattan is soaked in the treating fluid for 15 hours to 20 hours at the temperature of 35 DEG C to 40 DEG C, and then, the rattan is fished out to be woven; (3), treating fluid B is used for treating, 75 parts of water is added into 3.8 parts of polyethylene glycol, mixed fluid is stirred at the temperature of 42 DEG C to 45 DEG C, and is fully dissolved, then, the woven rattan product is put into the mixed fluid to be soaked for 2 hours, 3.5 parts of sodium bicarbonate is added into the mixed fluid to be dissolved, the rattan continues to be soaked for 3 hours, and then is fished out, and clean water is used for washing out the rattan. The rattan softening method is simple, the fluid A and the fluid B are used for treating respectively, and after the fluid A treats the rattan, the flexibility of the rattan is increased, and the phenomenon that in the weaving process, the rattan is broken down or cracked, and the quality of a product is decreased is avoided; and after weaving is completed, the fluid B is used for carrying out soaking treatment, the strength of the rattan is restored, and the use performance is increased.

Owner:FUNAN TENGBO ARTS & CRAFTS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com